A Novel Packaging of the MEMS Gas Sensors Used for Harsh Outdoor and Human Exhale Sampling Applications

Abstract

1. Introduction

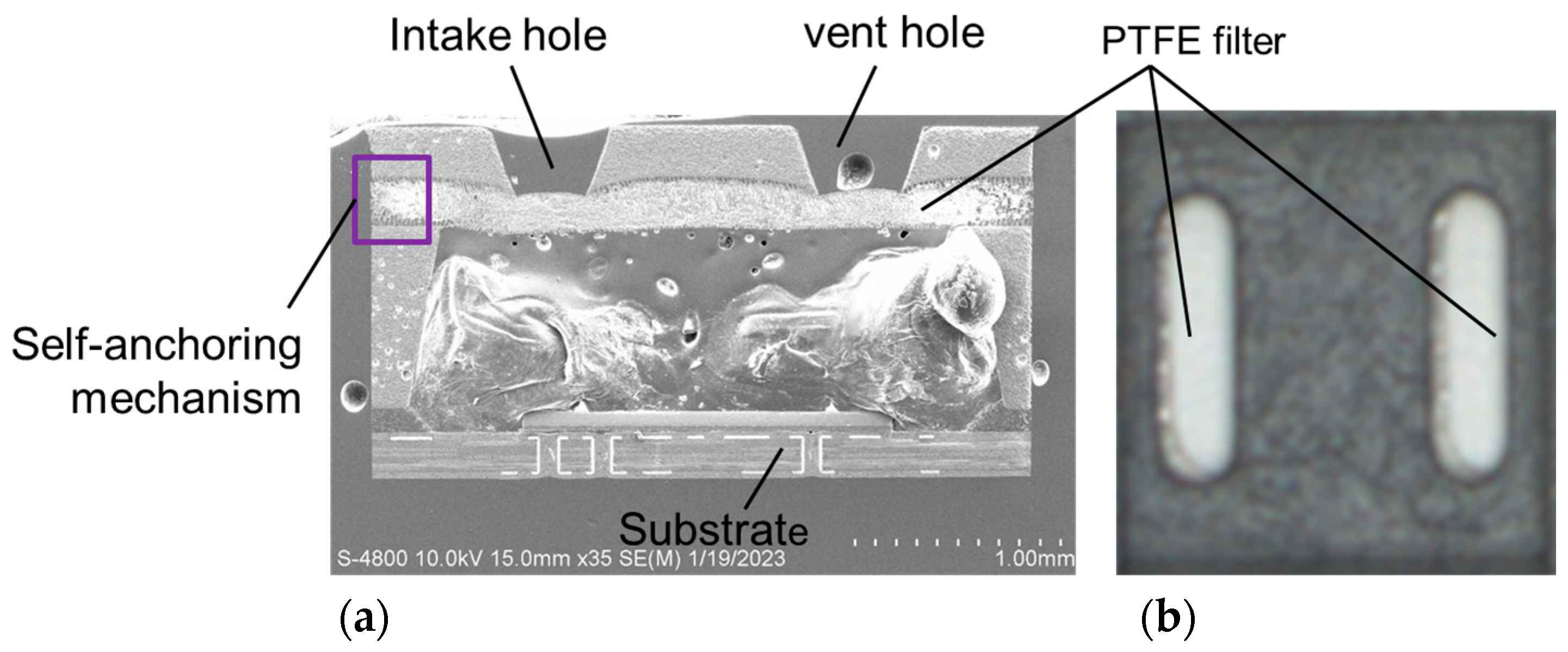

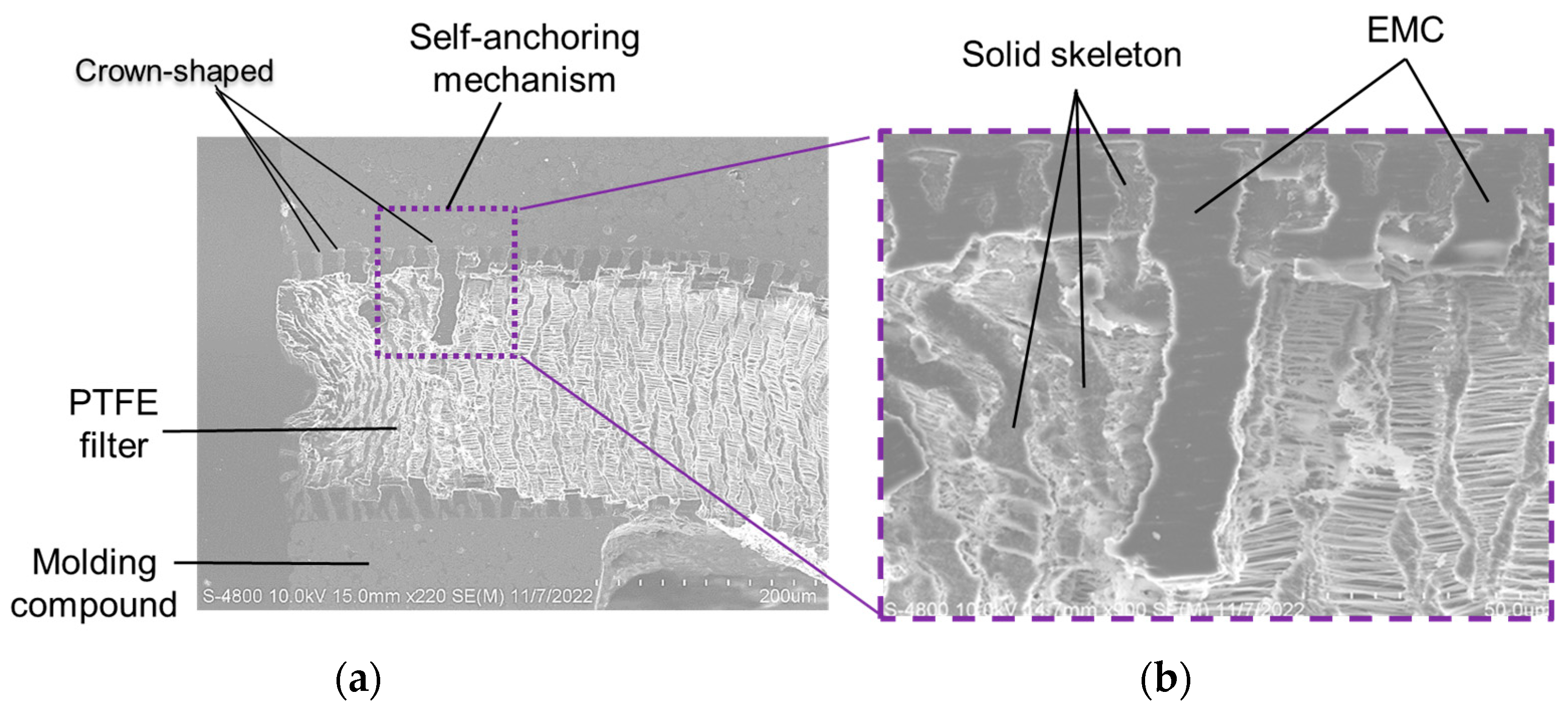

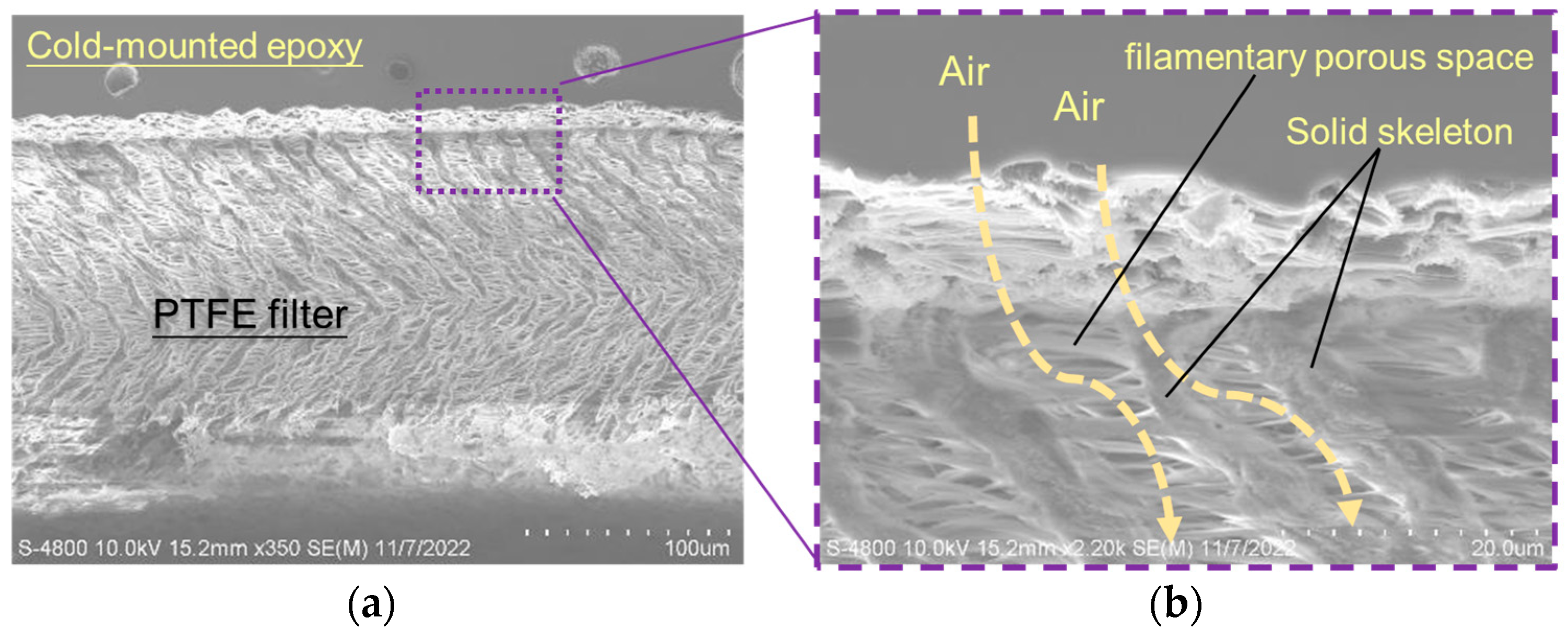

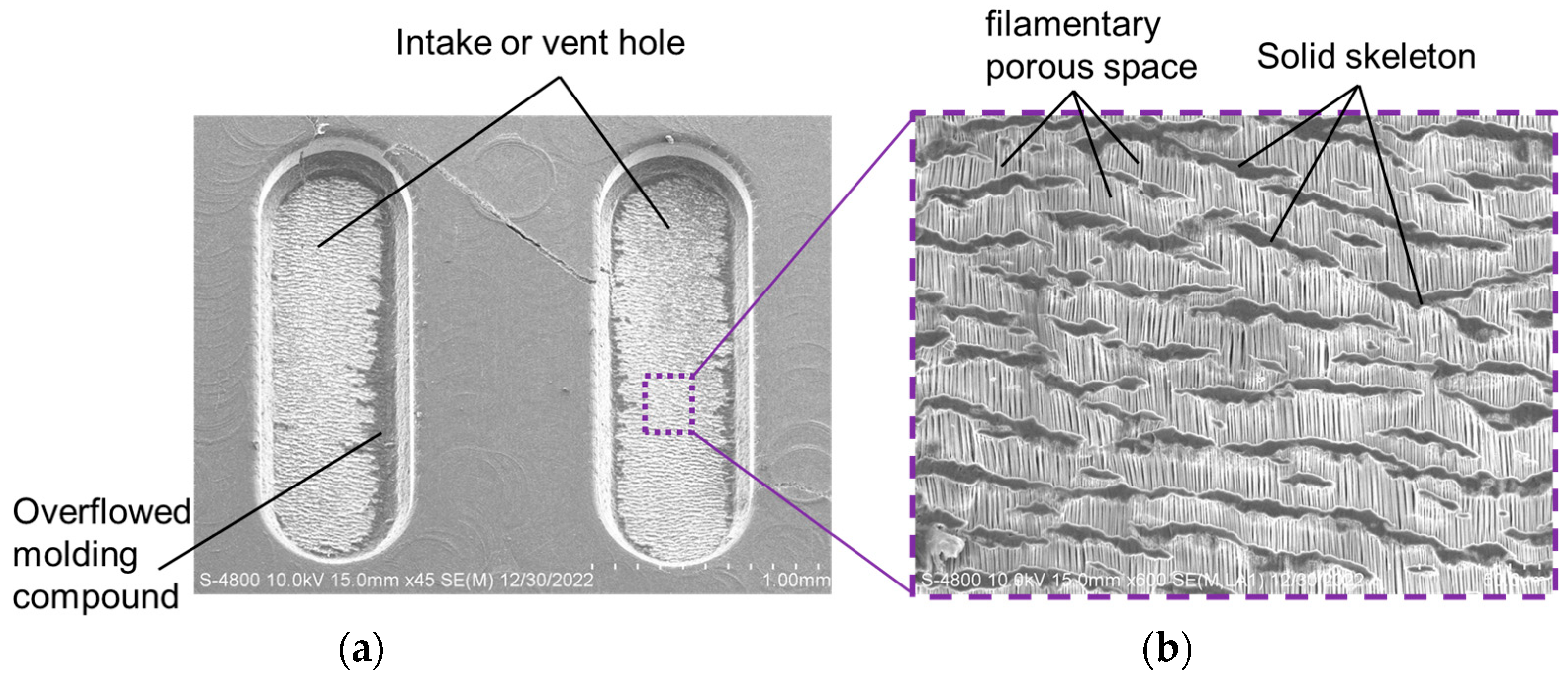

2. Design and Manufacturing

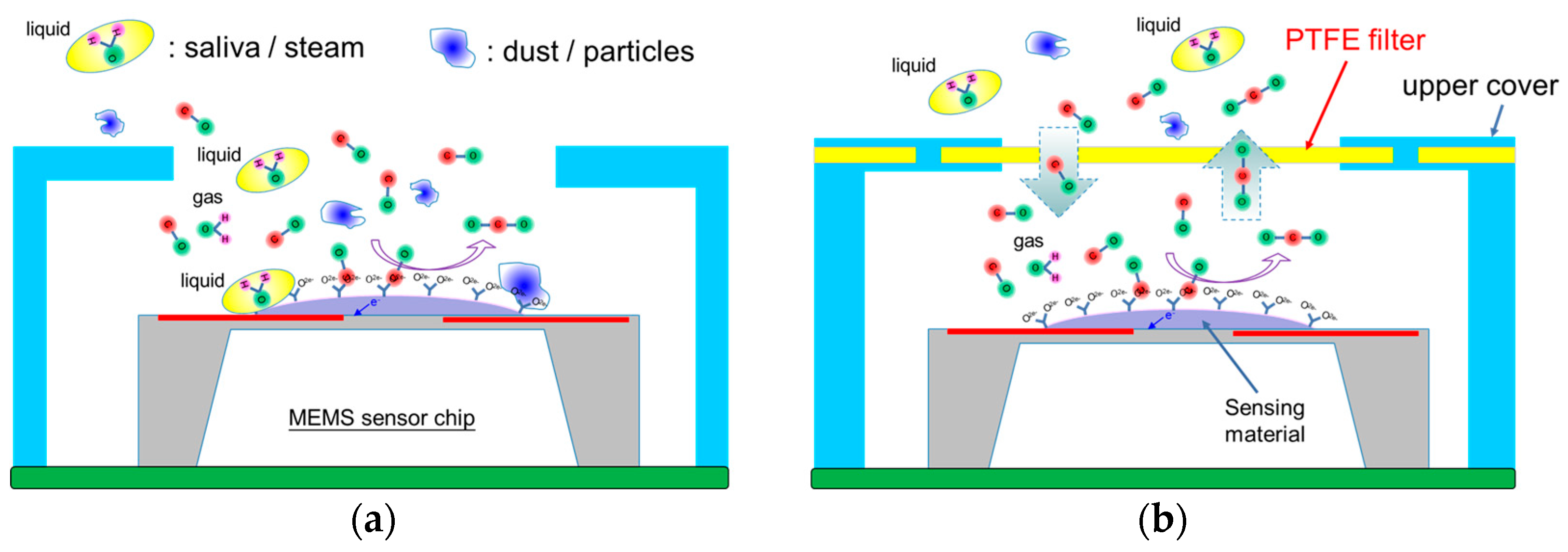

2.1. Packaging Design

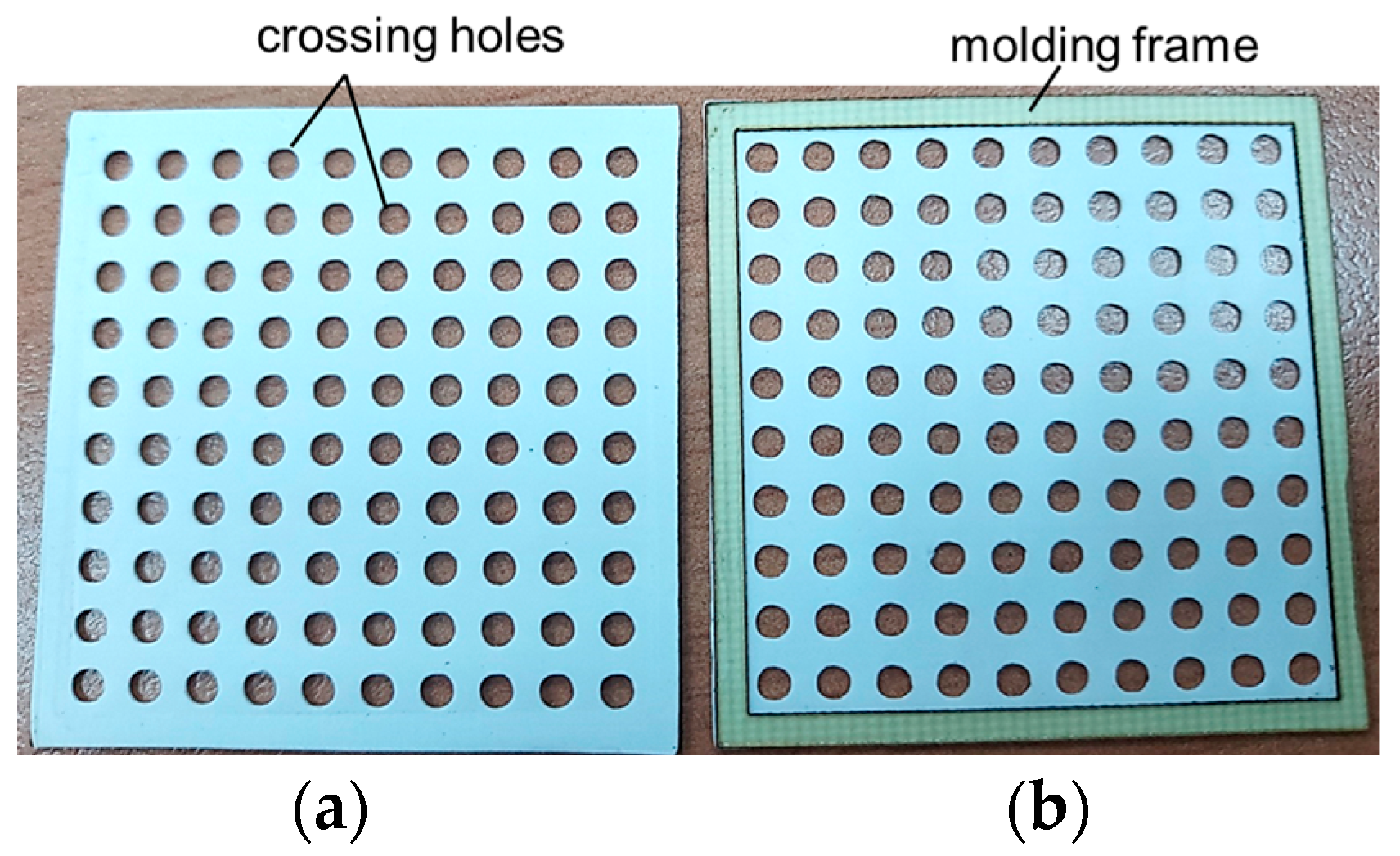

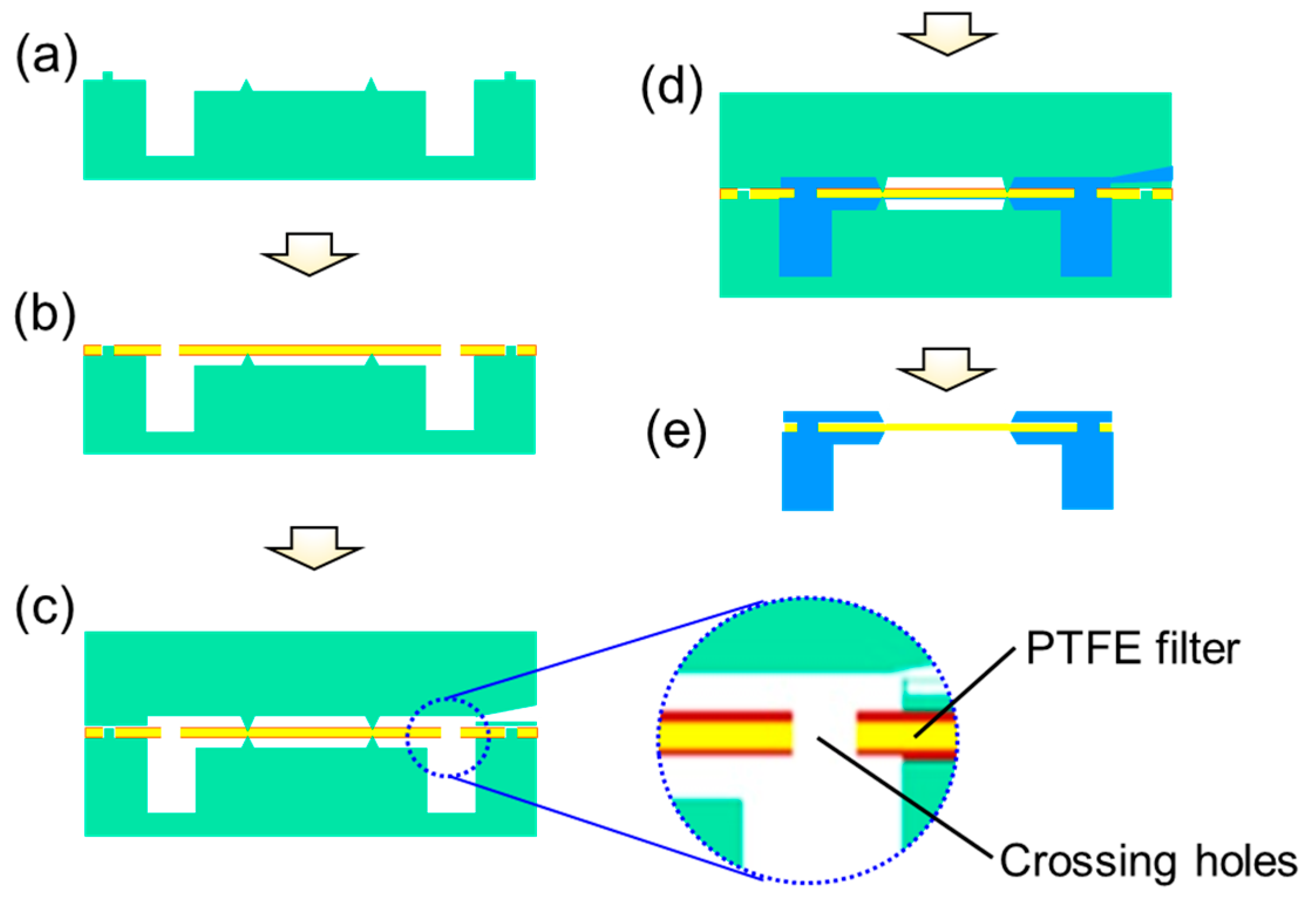

2.2. Manufacturing

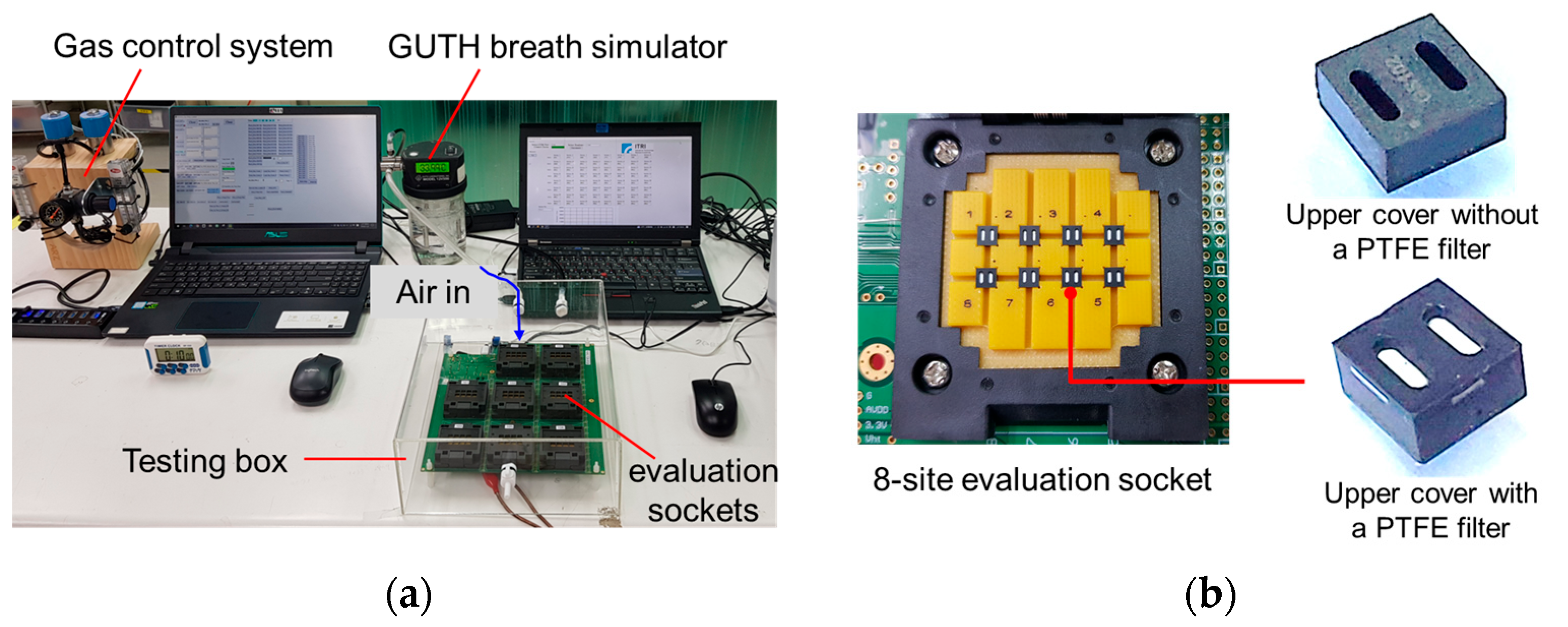

3. Tests

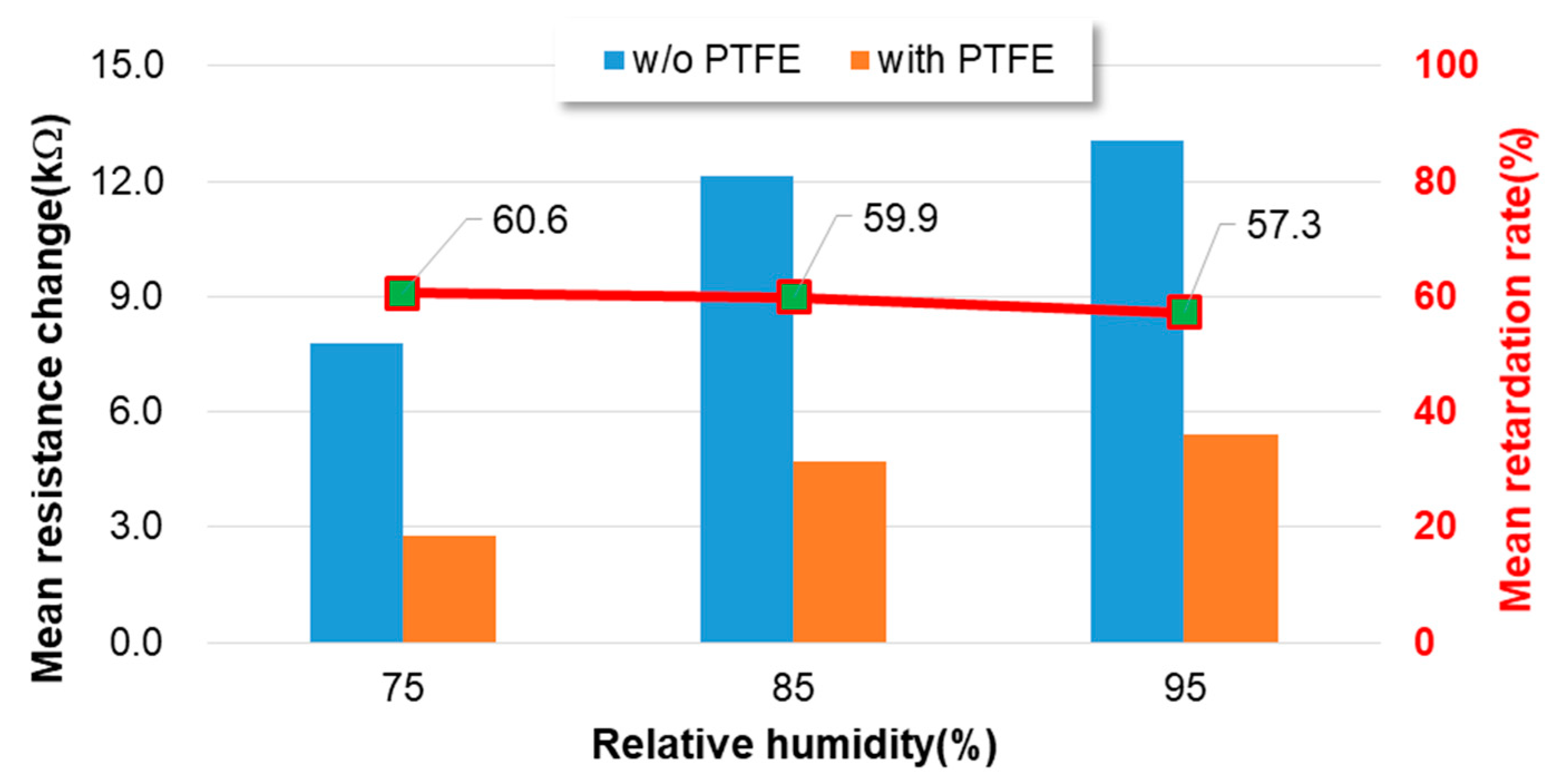

3.1. High-Moisture Response Test

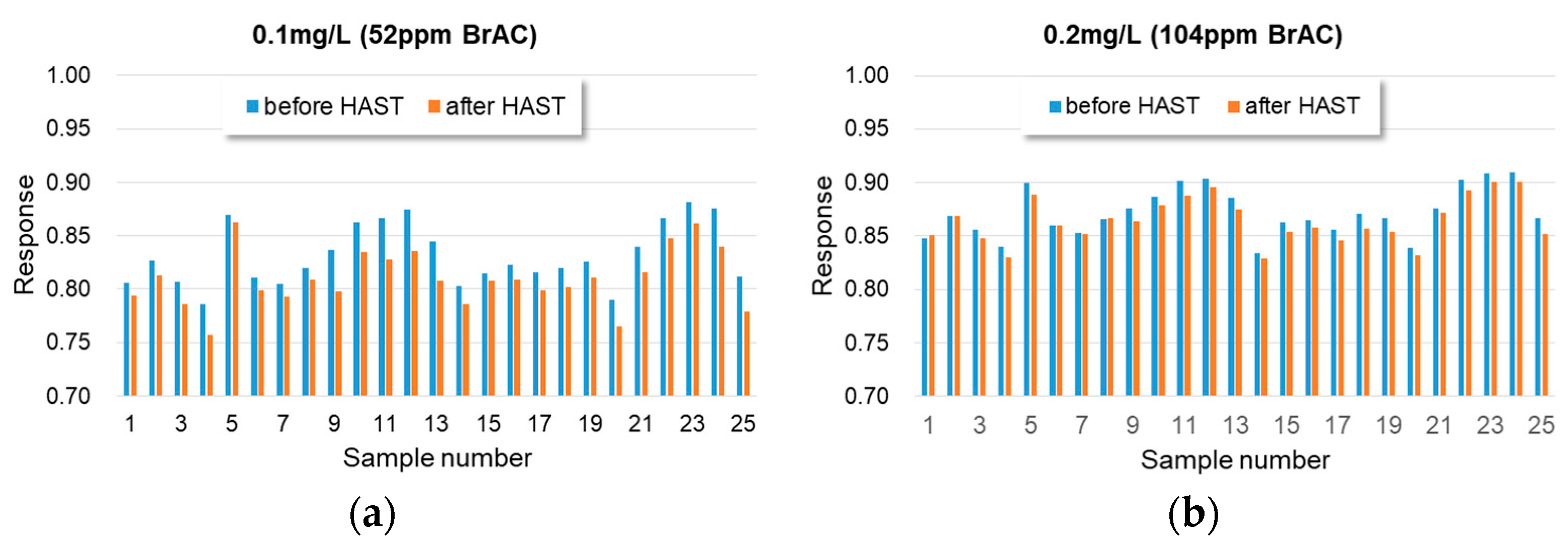

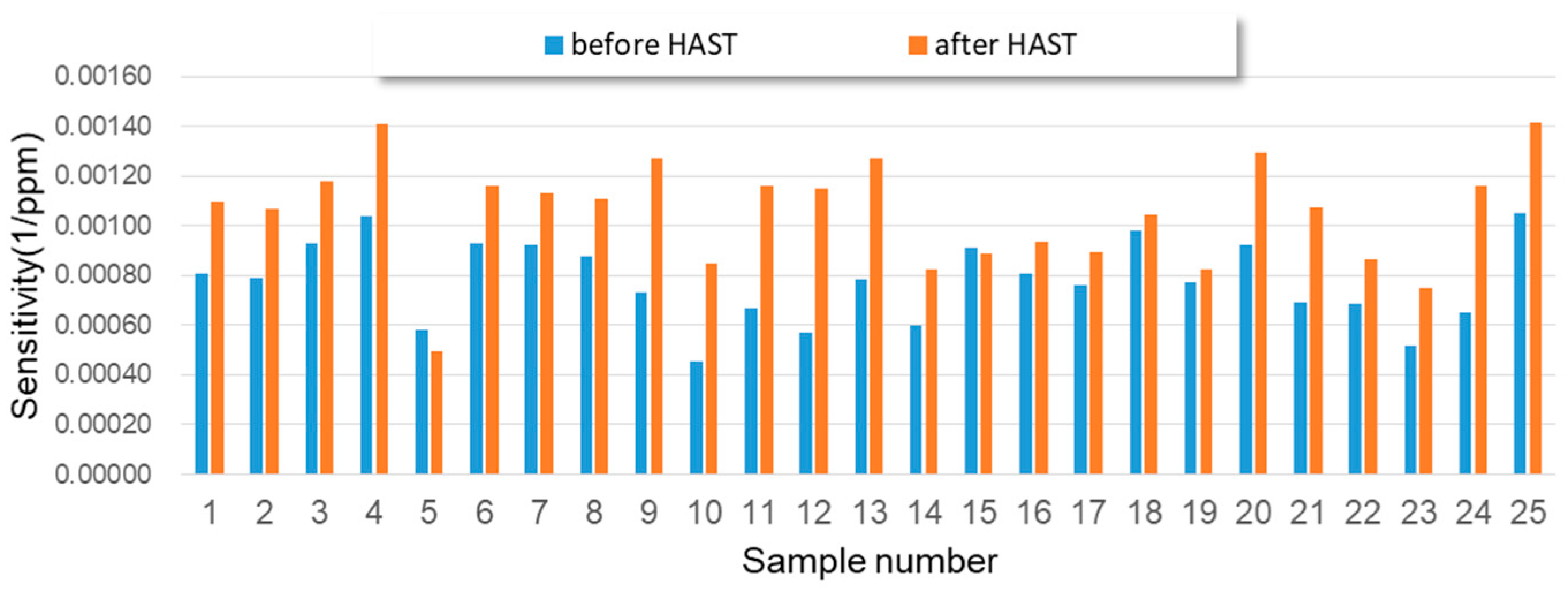

3.2. HAST Test

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, G.; Tan, Q.; Kou, H.; Zhang, L.; Wang, J.; Lv, W.; Dong, H.; Xiong, J. A Flexible Temperature Sensor Based on Reduced Graphene Oxide for Robot Skin Used in Internet of Things. Sensors 2018, 18, 1400. [Google Scholar] [CrossRef]

- Yadav, S.A.; Sharma, S.; Das, L.; Gupta, H.S.; Vashisht, S. An Effective IoT Empowered Real-time Gas Detection System for Wireless Sensor Networks. Int. Conf. Innov. Pract. Technol. Manag. (ICIPTM) 2021, 9, 44–49. [Google Scholar] [CrossRef]

- Abdullah, A.N.; Kamarudin, K.; Mamduh, S.M.; Adom, A.H. Development of MOX Gas Sensors Module for Indoor Air Contaminant Measurement. IOP Conf. Ser. Mater. Sci. Eng. 2019, 705, 012029. [Google Scholar] [CrossRef]

- Choi, S.; Park, K.; Lee, S.; Lim, Y.; Oh, B.; Chae, H.Y.; Park, C.S.; Shin, H.; Kim, J.J. A three-step resolution-reconfigurable hazardous multi-gas sensor interface for wireless air-quality monitoring applications. Sensors 2018, 18, 761. [Google Scholar] [CrossRef]

- Bilgera, C.; Yamamoto, A.; Sawano, M.; Matsukura, H.; Ishida, H. Application of Convolutional Long Short-Term Memory Neural Networks to Signals Collected from a Sensor Network for Autonomous Gas Source Localization in Outdoor Environments. Sensors 2018, 18, 4484. [Google Scholar] [CrossRef]

- Gunawan, T.; Munir, Y.M.S.; Kartiwi, M.; Mansor, H. Design and Implementation of Portable Outdoor Air Quality Measurement System using Arduino. Int. J. Elec. Comp. Eng. 2018, 8, 280–290. [Google Scholar] [CrossRef]

- Heru, S.; Ferbiyanto, E.D.; Harismah, K. Portable machine to machine system for monitoring temperature and flammable gas of outdoor environment. AIP Conf. Proc. 2019, 2114, 040014. [Google Scholar] [CrossRef]

- Tian, F.; Zhang, J.; Yang, S.X.; Zhao, Z.; Liang, Z.; Liu, Y.; Wang, D. Suppression of strong background interference on E-Nose sensors in an open country environment. Sensors 2016, 16, 233. [Google Scholar] [CrossRef]

- Cureau, R.J.; Pigliautile, I.; Pisello, A.L. A New Wearable System for Sensing Outdoor Environmental Conditions for Monitoring Hyper-Microclimate. Sensors 2022, 22, 502. [Google Scholar] [CrossRef]

- Alizadeh, N.; Jamalabad, H.; Tavoli, F. Breath acetone sensors as non-invasive health monitoring systems: A review. IEEE Sens. J. 2019, 20, 5–31. [Google Scholar] [CrossRef]

- Toma, K.; Iwasaki, K.; Zhang, G.; Iitani, K.; Arakawa, T.; Iwasaki, Y.; Mitsubayashi, K. Biochemical Methanol Gas Sensor (MeOH Bio-Sniffer) for Non-Invasive Assessment of Intestinal Flora from Breath Methanol. Sensors 2021, 21, 4897. [Google Scholar] [CrossRef] [PubMed]

- Kladsomboon, S.; Thippakorn, C.; Seesaard, T. Development of Organic-Inorganic Hybrid Optical Gas Sensors for the Non-Invasive Monitoring of Pathogenic Bacteria. Sensors 2018, 18, 3189. [Google Scholar] [CrossRef] [PubMed]

- Nazemi, H.; Joseph, A.; Park, J.; Emadi, A. Advanced Micro- and Nano-Gas Sensor Technology: A Review. Sensors 2019, 19, 1285. [Google Scholar] [CrossRef]

- Kakita, N.; Miyashita, H.; Kishida, S.; Lee, S.-S.; Lee, J.-O. MEMS based microstructure array design and its quantitative analysis of micropreconcentrator for cancer biomarker diagnosis. In Proceedings of the SENSORS, IEEE, Baltimore, MD, USA, 3–6 November 2013; pp. 1–4. [Google Scholar] [CrossRef]

- Putrino, G.; Keating, A.; Martyniuk, M.; Faraone, L.; Dell, J.M. An optically resonant position read-out system for MEMS gas sensors. In Micro-and Nanotechnology Sensors, Systems, and Applications VI; SPIE: Bellingham, WA, USA, 2014; pp. 598–604. [Google Scholar] [CrossRef]

- Cai, H.; Luo, N.; Hu, Q.; Xue, Z.; Wang, X.; Xu, J. Multishell SnO2 hollow microspheres loaded with bimetal PdPt nanoparticles for ultrasensitive and rapid formaldehyde MEMS sensors. ACS Sens. 2022, 7, 1484–1494. [Google Scholar] [CrossRef]

- Henderson, M.J.; Karge, B.A.; Wrenshall, G.A. Acetone in the Breath: A Study of Acetone Exhalation in Diabetic and Nondiabetic Human Subjects. Diabetes 1952, 1, 188–193. [Google Scholar] [CrossRef] [PubMed]

- Tang, L.; Chang, S.J.; Chen, C.J.; Liu, J.T. Non-Invasive Blood Glucose Monitoring Technology: A Review. Sensors 2020, 20, 6925. [Google Scholar] [CrossRef] [PubMed]

- Tassopoulos, C.N.; Barnett, D.; Fraser, T.R. Breath-aceton and blood-sugar measurements in diabetes. Lancet 1969, 293, 1282–1286. [Google Scholar] [CrossRef]

- Senthilmohan, S.T.; Milligan, D.B.; McEwan, M.J.; Freeman, C.G.; Wilson, P.F. Quantitative analysis of trace gases of breath during exercise using the new SIFT-MS technique. Redox Rep. 2000, 5, 151–153. [Google Scholar] [CrossRef]

- Takahashi, T.; Choi, Y.-J.; Sawada, K.; Takahashi, K. A ppm Ethanol Sensor Based on Fabry–Perot Interferometric Surface Stress Transducer at Room Temperature. Sensors 2020, 20, 6868. [Google Scholar] [CrossRef]

- Niu, G.; Wang, F.A. review of MEMS-based metal oxide semiconductors gas sensor in Mainland China. J. Micromech. Microeng. 2022, 32, 054003. [Google Scholar] [CrossRef]

- Li, M.; Luo, W.; Liu, X.; Niu, G.; Wang, F. Wafer-Level Patterning of SnO Nanosheets for MEMS Gas Sensors. IEEE Electron Device Lett. 2022, 43, 1981–1984. [Google Scholar] [CrossRef]

- Yang, M.Z.; Dai, C.L. Ethanol Microsensors with a Readout Circuit Manufactured Using the CMOS-MEMS Technique. Sensors 2015, 15, 1623–1634. [Google Scholar] [CrossRef]

- Török, Z.M.; Blaser, A.F.; Kavianynejad, K.; de Torrella, C.G.M.G.; Nsubuga, L.; Mishra, Y.K.; Rubahn, H.G.; Hansen, O.D.; Breath, R. Biomarkers as Disease Indicators: Sensing Techniques Approach for Detecting Breath Gas and COVID-19. Chemosensors 2022, 10, 167. [Google Scholar] [CrossRef]

- Velumani, M.; Prasanth, A.; Narasimman, S.; Chandrasekhar, A.; Sampson, A.; Meher, S.R.; Rajalingam, S.; Rufus, E.; Alex, Z.C. Nanomaterial-Based Sensors for Exhaled Breath Analysis: A Review. Coatings 2022, 12, 1989. [Google Scholar] [CrossRef]

- Wilson, A.D.; Forse, L.B. Potential for Early Noninvasive COVID-19 Detection Using Electronic-Nose Technologies and Disease-Specific VOC Metabolic Biomarkers. Sensors 2023, 23, 2887. [Google Scholar] [CrossRef]

- Zheng, Y.; Song, X.; Fredj, Z.; Bian, S.; Sawan, M. Challenges and perspectives of multi-virus biosensing techniques: A review. Anal. Chim. Acta 2023, 1244, 340860. [Google Scholar] [CrossRef]

- Wiryasaputra, R.; Huang, C.Y.; Kristiani, E.; Liu, P.Y.; Yeh, T.K.; Yang, C.T. Review of an intelligent indoor environment monitoring and management system for COVID-19 risk mitigation. Front. Public Health 2022, 10, 1022055. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, L.; Li, K.H.H.; Tan, O.K. Microhotplates for Metal Oxide Semiconductor Gas Sensor Applications-Towards the CMOS-MEMS Monolithic Approach. Micromachines 2018, 9, 557. [Google Scholar] [CrossRef]

- Blank, T.; Brouk, I.; Bar-Lev, S.; Amar, G.; Meimoun, E.; Bouscher, S.; Meltsin, M.; Vaiana, M.; Maierna, A.; Castagna, M.E.; et al. Non-imaging digital CMOS-SOI-MEMS uncooled passive infra-red sensing systems. IEEE Sens. J. 2020, 21, 3660–3669. [Google Scholar] [CrossRef]

- Burgués, J.; Marco, S. Low Power Operation of Temperature-Modulated Metal Oxide Semiconductor Gas Sensors. Sensors 2018, 18, 339. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, R.; Zhao, H.; Li, J.; Zhang, R.; Wang, Y.; Zhou, Y. Oxygen vacancy-rich ZnO nanorods-based MEMS sensors for swift trace ethanol recognition. J. Am. Ceram. Soc. 2023, 106, 1050–1061. [Google Scholar] [CrossRef]

- Liu, B.; Zhou, Y.; Fu, H.; Fu, P.; Feng, L. Lightweight Self-Detection and Self-Calibration Strategy for MEMS Gas Sensor Arrays. Sensors 2022, 22, 4315. [Google Scholar] [CrossRef]

- Arabi, M.; Alghamdi, M.; Kabel, K.; Labena, A.; Gado, W.S.; Mavani, B.; Scott, A.J.; Penlidis, A.; Yavuz, M.; Abdel-Rahman, E. Detection of Volatile Organic Compounds by Using MEMS Sensors. Sensors 2022, 22, 4102. [Google Scholar] [CrossRef] [PubMed]

- Viola, R.; Liberatore, N.; Mengali, S.; Elmi, I.; Tamarri, F.; Zampolli, S. Lightweight Gas Sensor Based on MEMS Pre-Concentration and Infrared Absorption Spectroscopy Inside a Hollow Fiber. Sensors 2023, 23, 2809. [Google Scholar] [CrossRef] [PubMed]

- Bouras, A.; Gutierrez-Galvez, A.; Burgués, J.; Bouzid, Y.; Pardo, A.; Guiatni, M.; Marco, S. Concentration map reconstruction for gas source location using nano quadcopters: Metal oxide semiconductor sensor implementation and indoor experiments validation. Measurement 2023, 213, 112638. [Google Scholar] [CrossRef]

- Thu, D.T.; Liu, Z.H.; Lee, Y.C.; Kuo, T.W.; Sung, W.L.; Chu, Y.C.; Chueh, Y.L.; Fang, W. A Miniaturized CMOS-MEMS Amperometric Gas Sensor for Rapid Ethanol Detection. IEEE Sens. J. 2023, 23, 8128–8137. [Google Scholar] [CrossRef]

- Lahlalia, A.; Le Neel, O.; Shankar, R.; Selberherr, S.; Filipovic, L. Improved Sensing Capability of Integrated Semiconducting Metal Oxide Gas Sensor Devices. Sensors 2019, 19, 374. [Google Scholar] [CrossRef]

- Lee, Y.C.; Chien, T.L.; Fang, C.T.; Huang, Y.; Sung, W.L.; Chu, Y.C.; Chen, R.; Fang, W. Implementation of a Monolithic SoC Environmental Sensing Hub Using CMOS-MEMS Technique. In Proceedings of the 2023 IEEE 36th International Conference on Micro Electro Mechanical Systems (MEMS), Munich, Germany, 15–19 January 2023; pp. 562–565. [Google Scholar] [CrossRef]

- Spannhake, J.; Schulz, O.; Helwig, A.; Miiller, G.; Doll, T. Design, development and operational concept of an advanced MEMS IR source for miniaturized gas sensor systems. In Proceedings of the SENSORS, 2005 IEEE, Irvine, CA, USA, 30 October–3 November 2005; pp. 762–765. [Google Scholar] [CrossRef]

- Das, I.; Bhattacharyya, R.; Saha, H.; Ghosh, S. Enhanced response of co-planar MEMS microheater-based methane gas sensor. IEEE Sens. J. 2020, 20, 14132–14140. [Google Scholar] [CrossRef]

- Gulshan, V.; Ankur, G. Sensing performance of room temperature operated MEMS gas sensor for ppb level detection of hydrogen sulfide: A review. J. Micromech. Microeng. 2022, 32, 094002. [Google Scholar] [CrossRef]

- Barandun, G.; Laura, G.M.; Lee, H.S.; Dincer, C.; Güder, F. Challenges and Opportunities for Printed Electrical Gas Sensors. ACS Sens. 2022, 7, 2804–2822. [Google Scholar] [CrossRef]

- Oshima, A.; Tabata, Y.; Kudoh, H.; Seguchii, T. Radiation induced crosslinking of polytetrafluoroethylene. Radiat. Phys. Chem. 1995, 45, 269–273. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.X.; Yue, T.T.; Xu, Y.; Zhao, M.L.; Yu, M.; Ramakrishna, S.; Long, Y.Z. Waterproof-breathable PTFE nano- and Microfiber Membrane as High Efficiency PM2.5 Filter. Polymers 2019, 11, 590. [Google Scholar] [CrossRef]

- Moon, I.Y.; Lee, H.W.; Oh, Y.S. Characterization of microfibril development on PTFE surface during hot imprinting process and its application for oil–water separation. Int. J. Adv. Manuf. Technol. 2019, 102, 1871–1883. [Google Scholar] [CrossRef]

- Feng, S.; Zhong, Z.; Wang, Y.; Xing, W.; Drioli, E. Progress and perspectives in PTFE membrane: Preparation, modification, and applications. J. Membr. Sci. 2018, 549, 332–349. [Google Scholar] [CrossRef]

- Xu, H.; Jin, W.; Wang, F.; Li, C.; Wang, J.; Zhu, H.; Guo, Y. Preparation and properties of PTFE hollow fiber membranes for the removal of ultrafine particles in PM2.5 with repetitive usage capability. RSC Adv. 2018, 8, 38245–38258. [Google Scholar] [CrossRef]

- Graunke, T.; Schmitt, K.; Raible, S.; Wöllenstein, J. Towards Enhanced Gas Sensor Performance with Fluoropolymer Membranes. Sensors 2016, 16, 1605. [Google Scholar] [CrossRef]

- Park, H.; Lee, S.; Jeong, S.H.; Jung, U.H.; Park, K.; Lee, M.G.; Kim, S.; Lee, J. Enhanced Moisture-Reactive Hydrophilic-PTFE-Based Flexible Humidity Sensor for Real-Time Monitoring. Sensors 2018, 18, 921. [Google Scholar] [CrossRef]

- Analog Humidity Sensor for Industrial Applications with Membrane. Available online: https://sensirion.com/products/catalog/SHT40I-HD1F (accessed on 12 March 2023).

- Product Catalog. Available online: https://sensirion.com/products/catalog/?category=VOC (accessed on 12 March 2023).

- FECS41-250 [Nitrogen Monoxide Sensor]. Available online: https://www.figarosensor.com/product/entry/fecs41-250.html (accessed on 6 March 2023).

- Usman, F.; Dennis, J.O.; Ahmed, A.Y.; Meriaudeau, F.; Ayodele, O.B.; Rabih, A.A.S. A Review of Biosensors for Non-Invasive Diabetes Monitoring and Screening in Human Exhaled Breath. IEEE Access 2019, 7, 5963–5974. [Google Scholar] [CrossRef]

- Zhang, Q.Q.; Zheng, T.; Fan, X.; Liu, H.; Wang, R.; Zeng, Y. Electrical response of Sm2O3-doped SnO2 to C2H2 and effect of humidity interference. Sens. Actuators B Chem. 2008, 134, 36–42. [Google Scholar] [CrossRef]

- Khan, M.A.; Debnath, H.R.; Motayed, A.; Rao, M.V. Accelerated Stress Tests and Statistical Reliability Analysis of Metal-Oxide/GaN Nanostructured Sensor Devices. IEEE Trans. Device Mater. Reliab. 2020, 20, 742–747. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Chang, C.; Chien, L.; Lee, B.; Shieh, W. A Novel Packaging of the MEMS Gas Sensors Used for Harsh Outdoor and Human Exhale Sampling Applications. Sensors 2023, 23, 5087. https://doi.org/10.3390/s23115087

Chen L, Chang C, Chien L, Lee B, Shieh W. A Novel Packaging of the MEMS Gas Sensors Used for Harsh Outdoor and Human Exhale Sampling Applications. Sensors. 2023; 23(11):5087. https://doi.org/10.3390/s23115087

Chicago/Turabian StyleChen, Lungtai, Chinsheng Chang, Liangju Chien, Borshiun Lee, and Wenlo Shieh. 2023. "A Novel Packaging of the MEMS Gas Sensors Used for Harsh Outdoor and Human Exhale Sampling Applications" Sensors 23, no. 11: 5087. https://doi.org/10.3390/s23115087

APA StyleChen, L., Chang, C., Chien, L., Lee, B., & Shieh, W. (2023). A Novel Packaging of the MEMS Gas Sensors Used for Harsh Outdoor and Human Exhale Sampling Applications. Sensors, 23(11), 5087. https://doi.org/10.3390/s23115087