Using Worker Position Data for Human-Driven Decision Support in Labour-Intensive Manufacturing

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

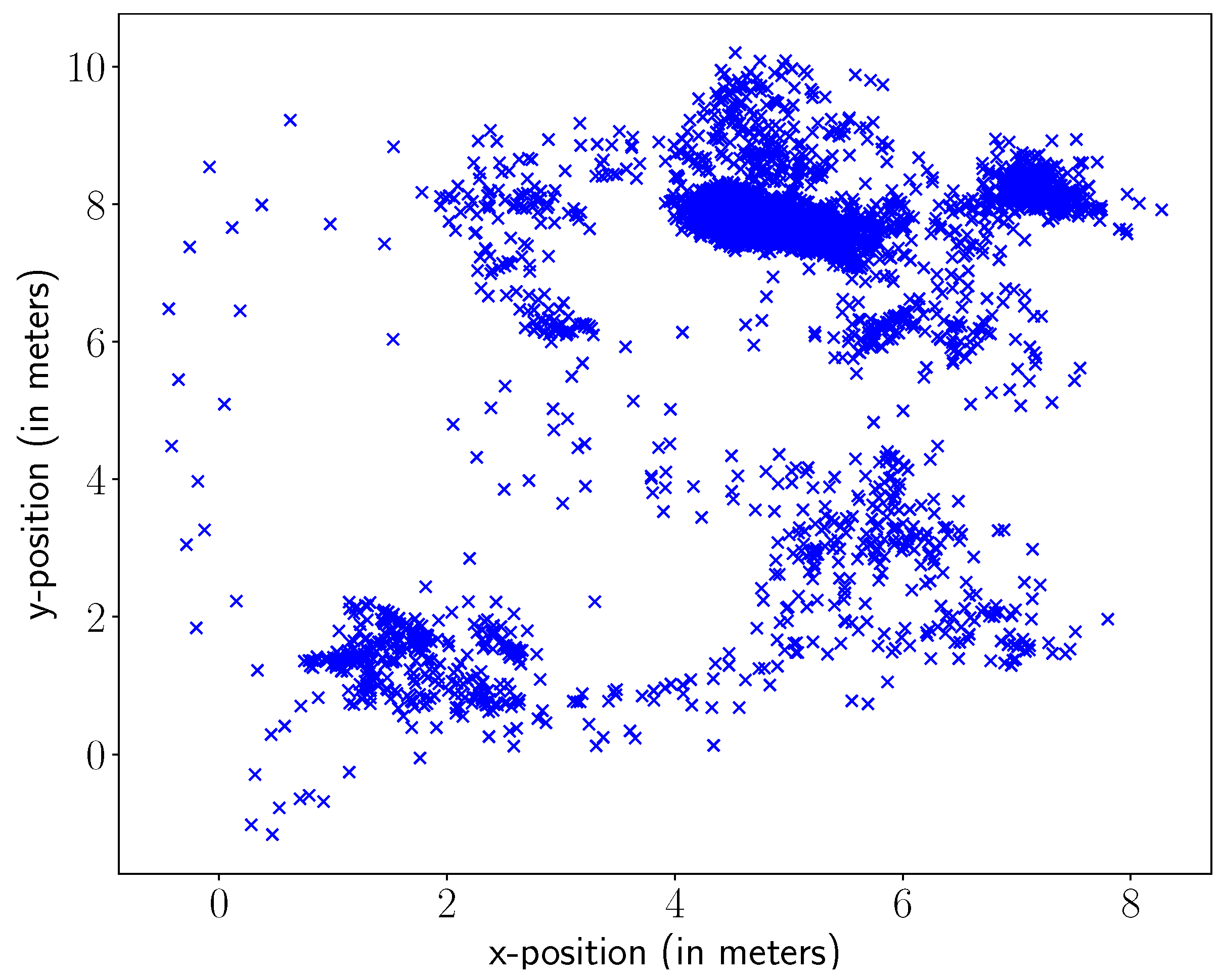

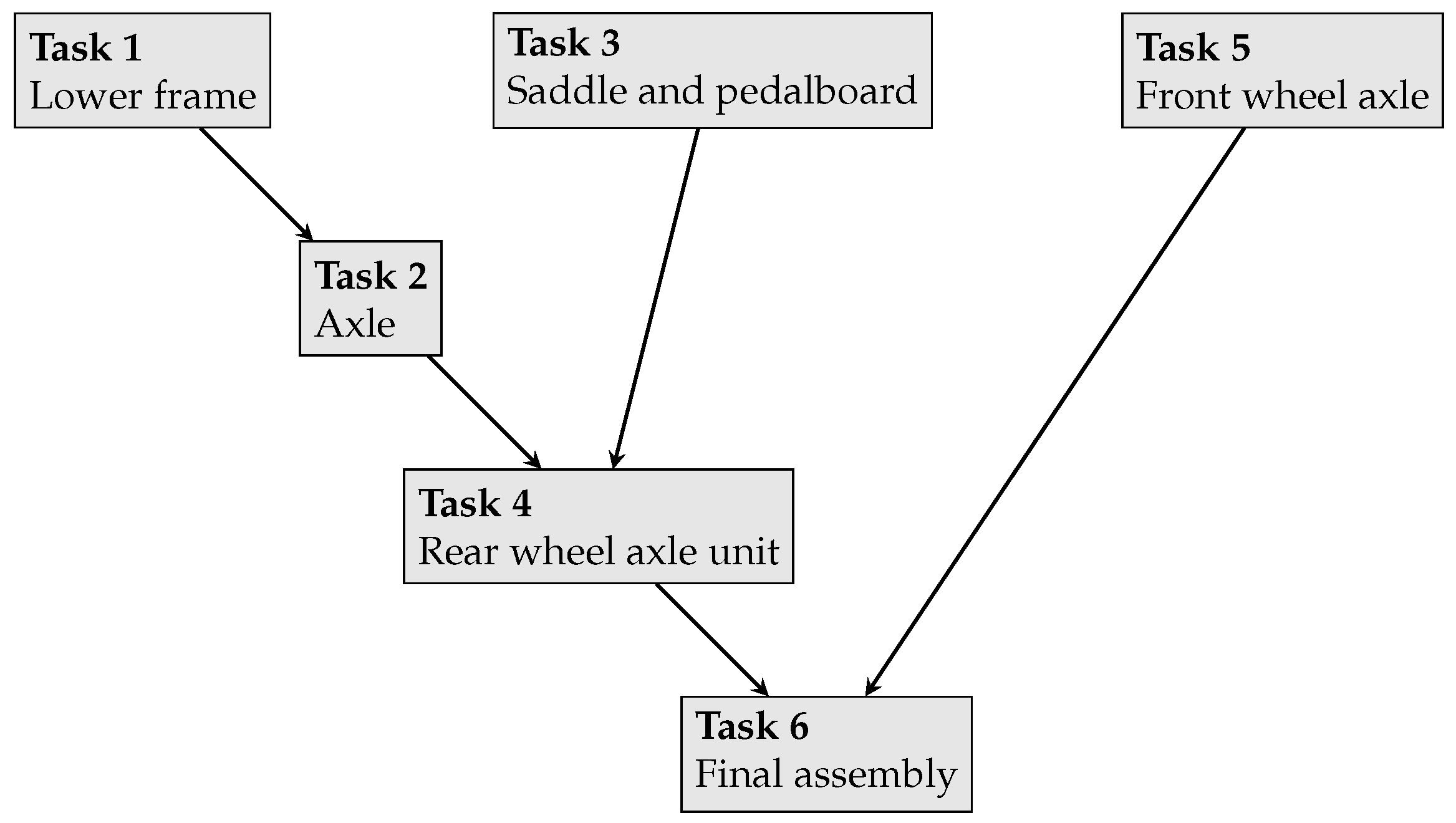

3.1. Data

3.2. Methodology

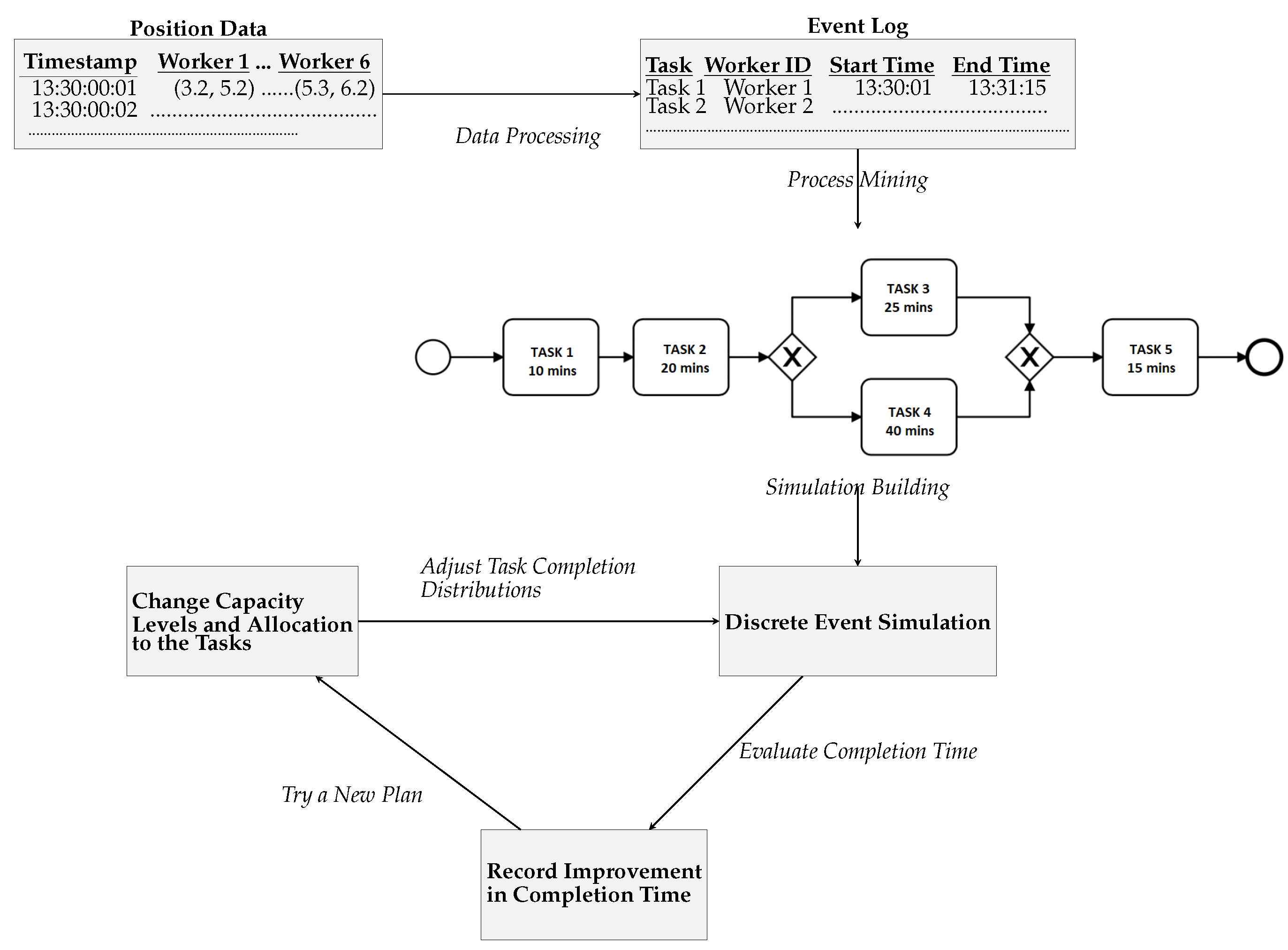

3.2.1. Data Processing and The Extraction of an Event Log

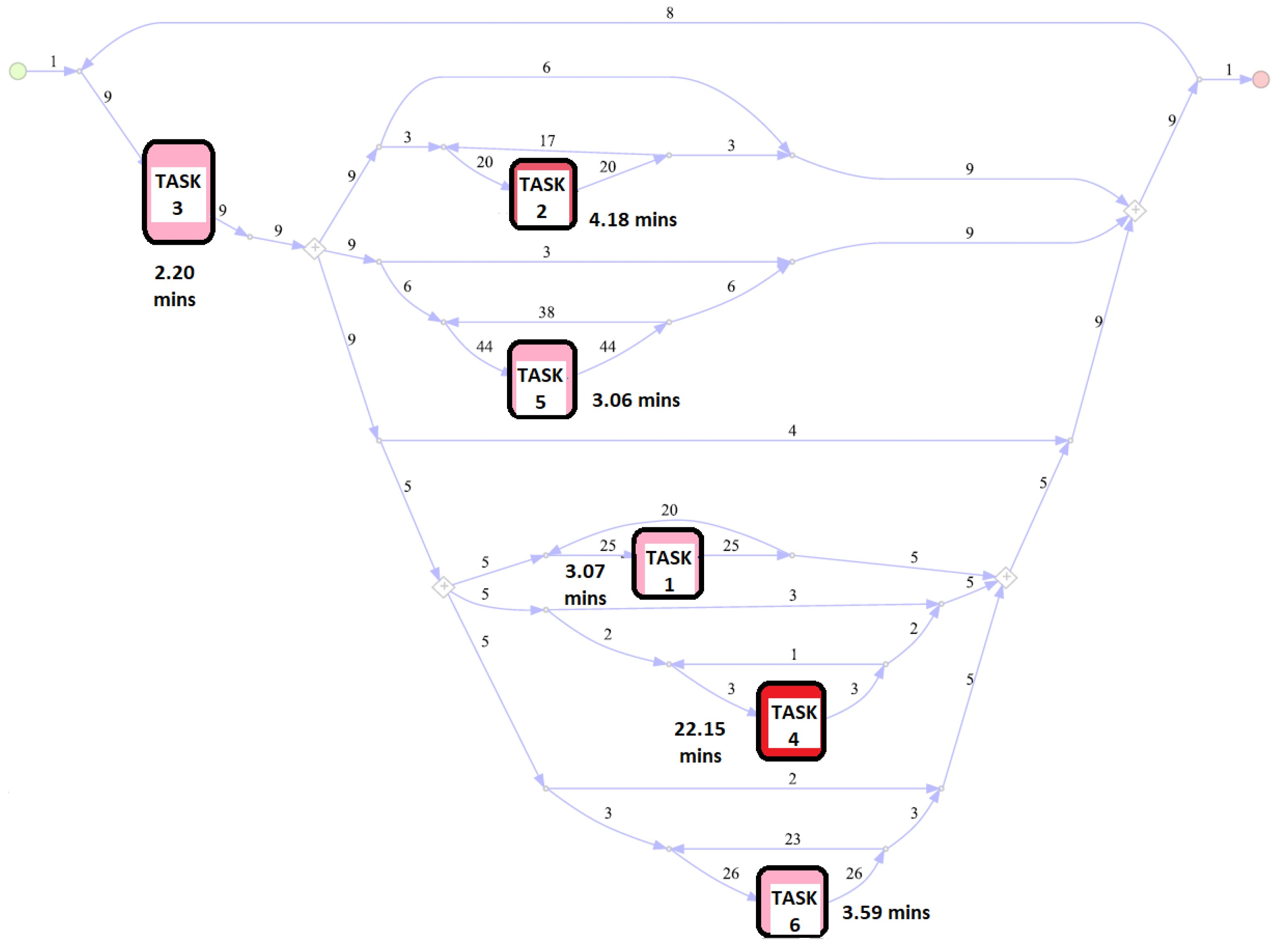

3.2.2. Process Mining to Derive Process Models

3.2.3. Building the Discrete Event Simulation

3.2.4. Using the Simulation for Decision Support on Capacity Allocation

4. Results

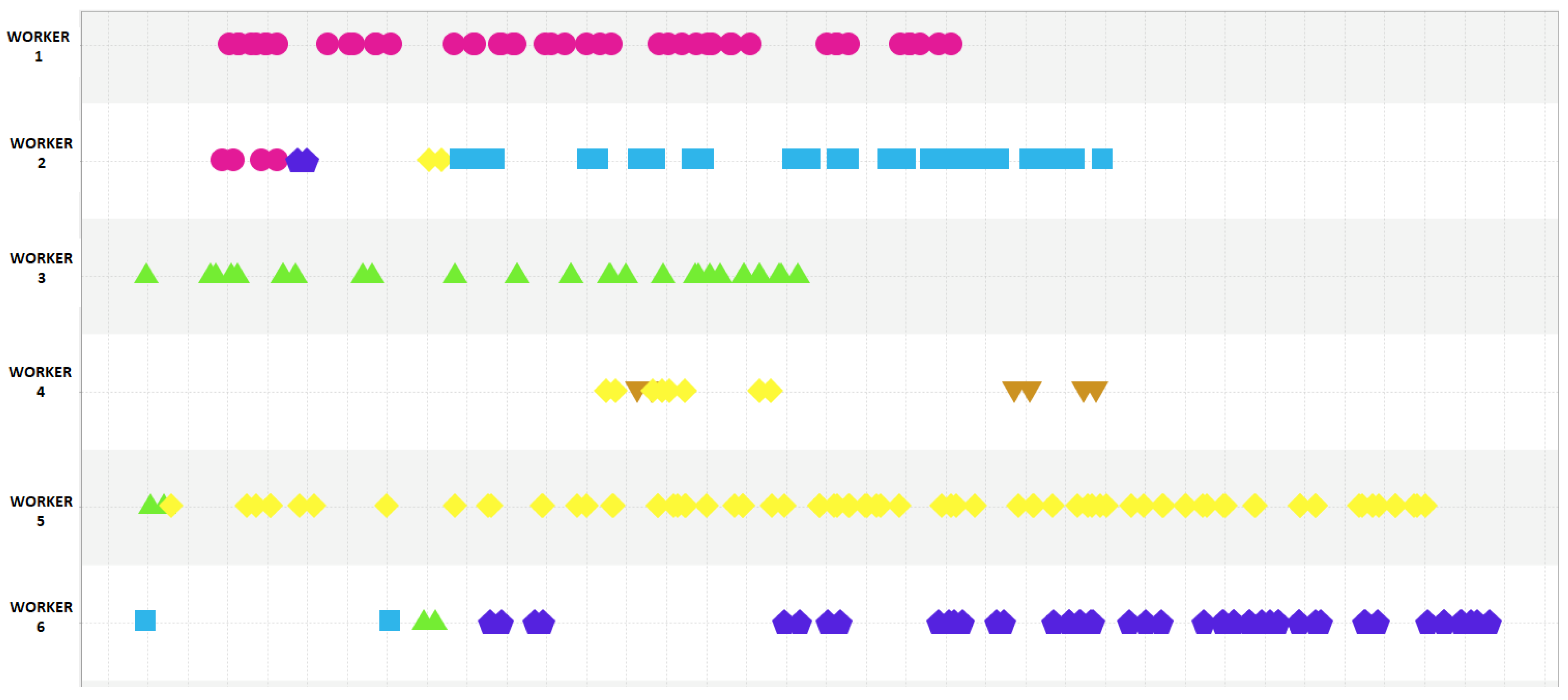

4.1. Observing Deviations from the Fixed Task Assignment and Finding the Assignment from the Data

4.2. Data-Driven Process Model

4.3. Decision Support on Capacity Allocation with Simulation

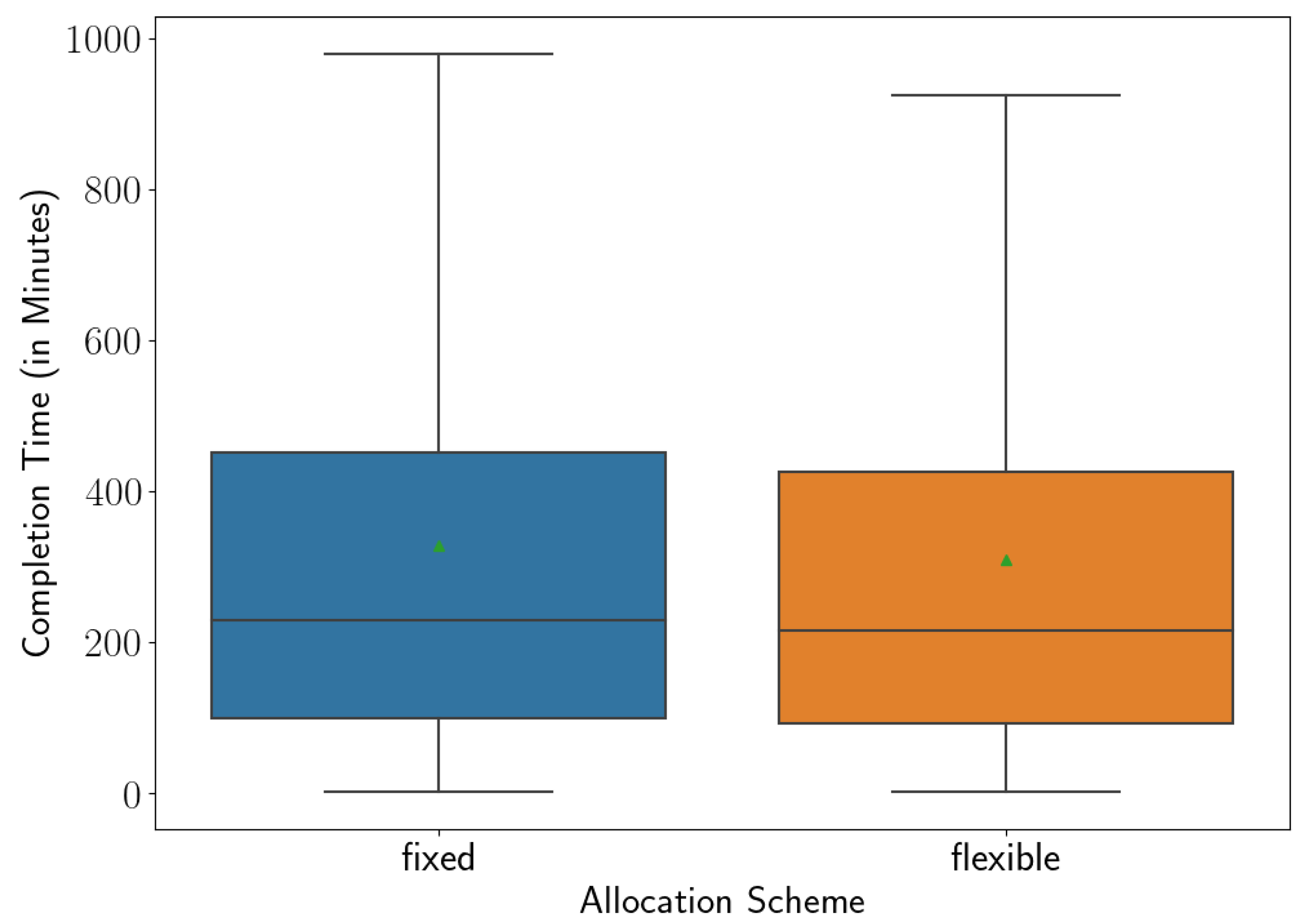

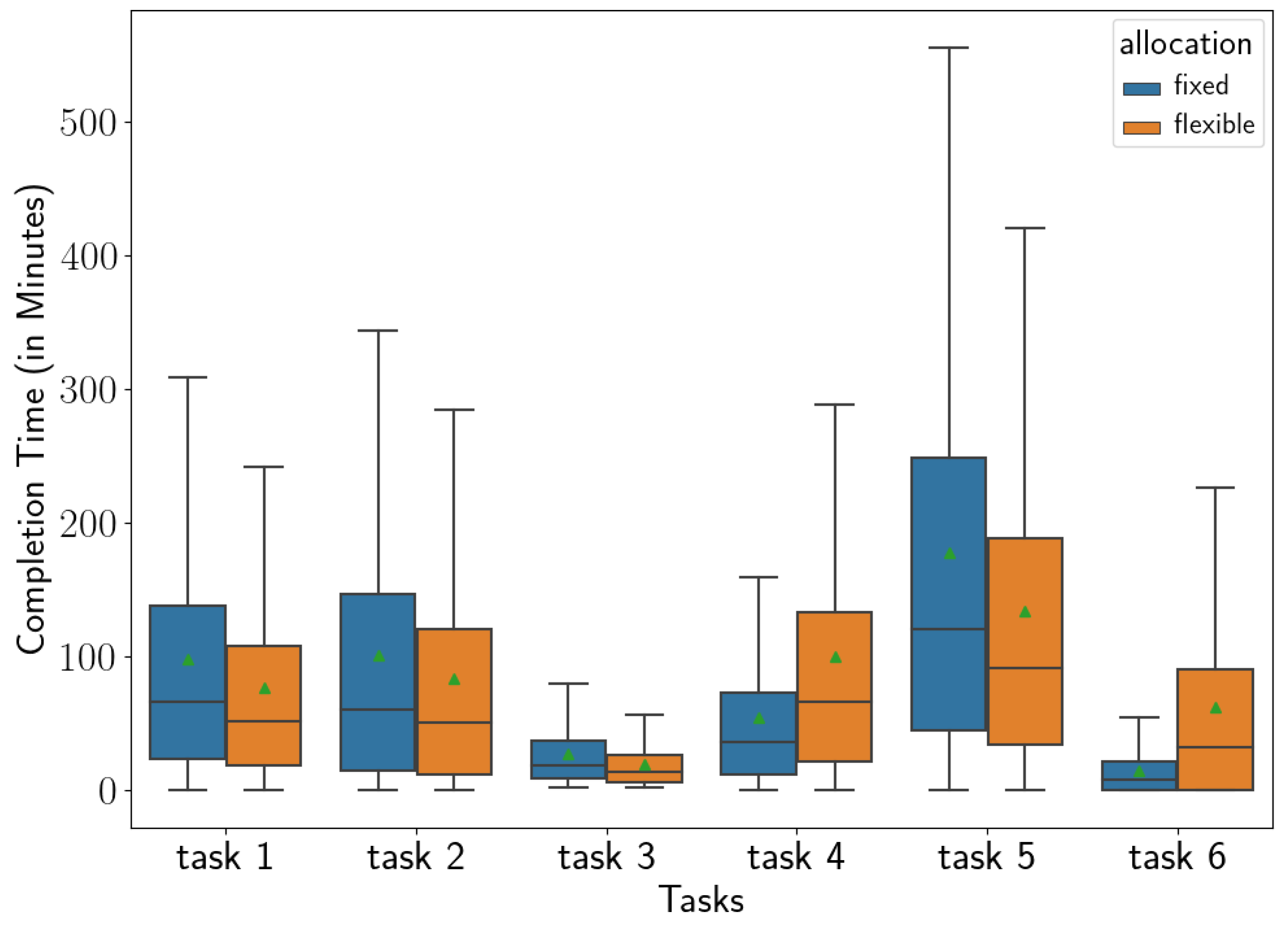

4.3.1. Comparing the Performance under the Worker-Driven Flexible Allocation to the Fixed Assignment

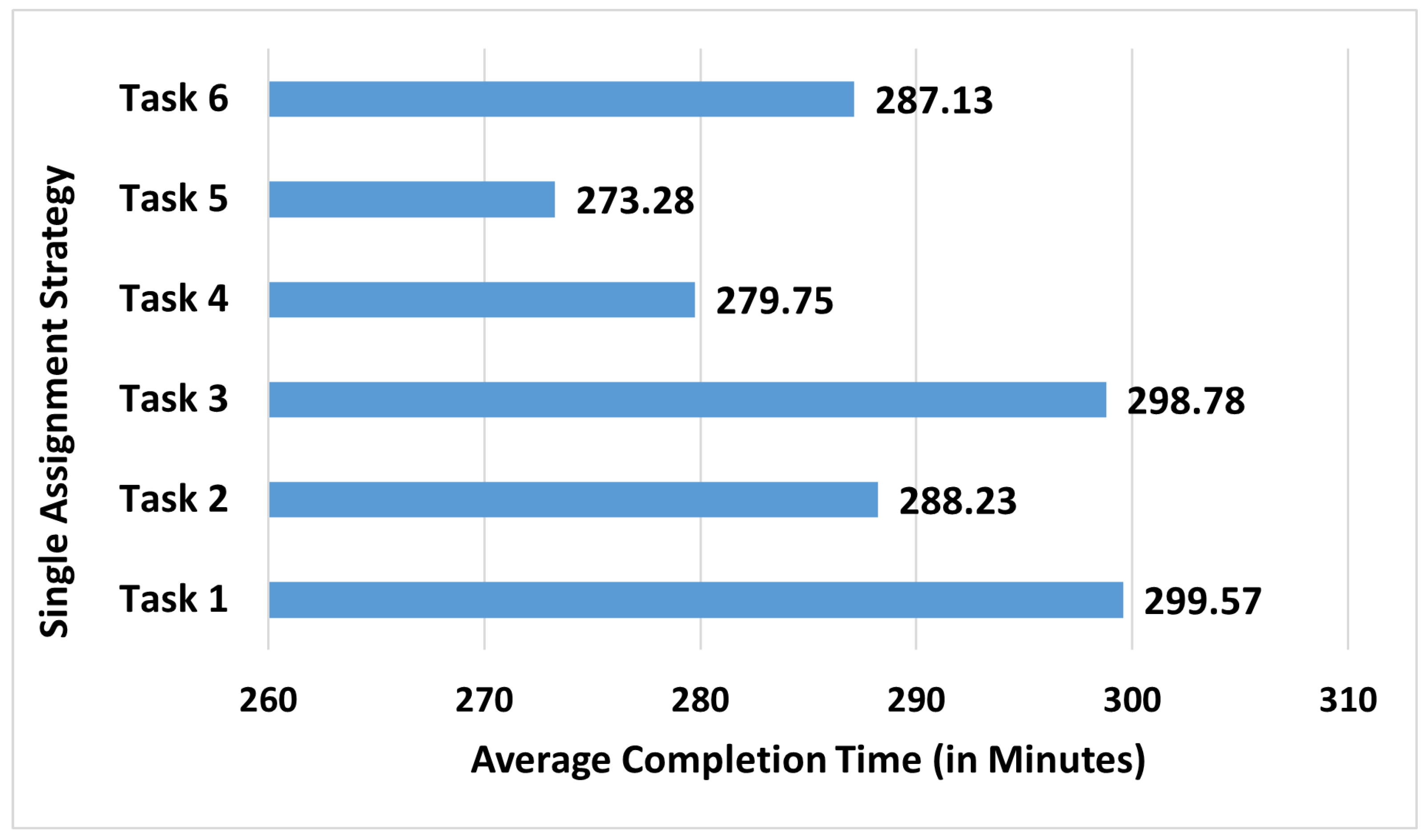

4.3.2. How to Reduce Completion Time through Small Adjustments Based on the Worker-Driven Flexible Allocation?

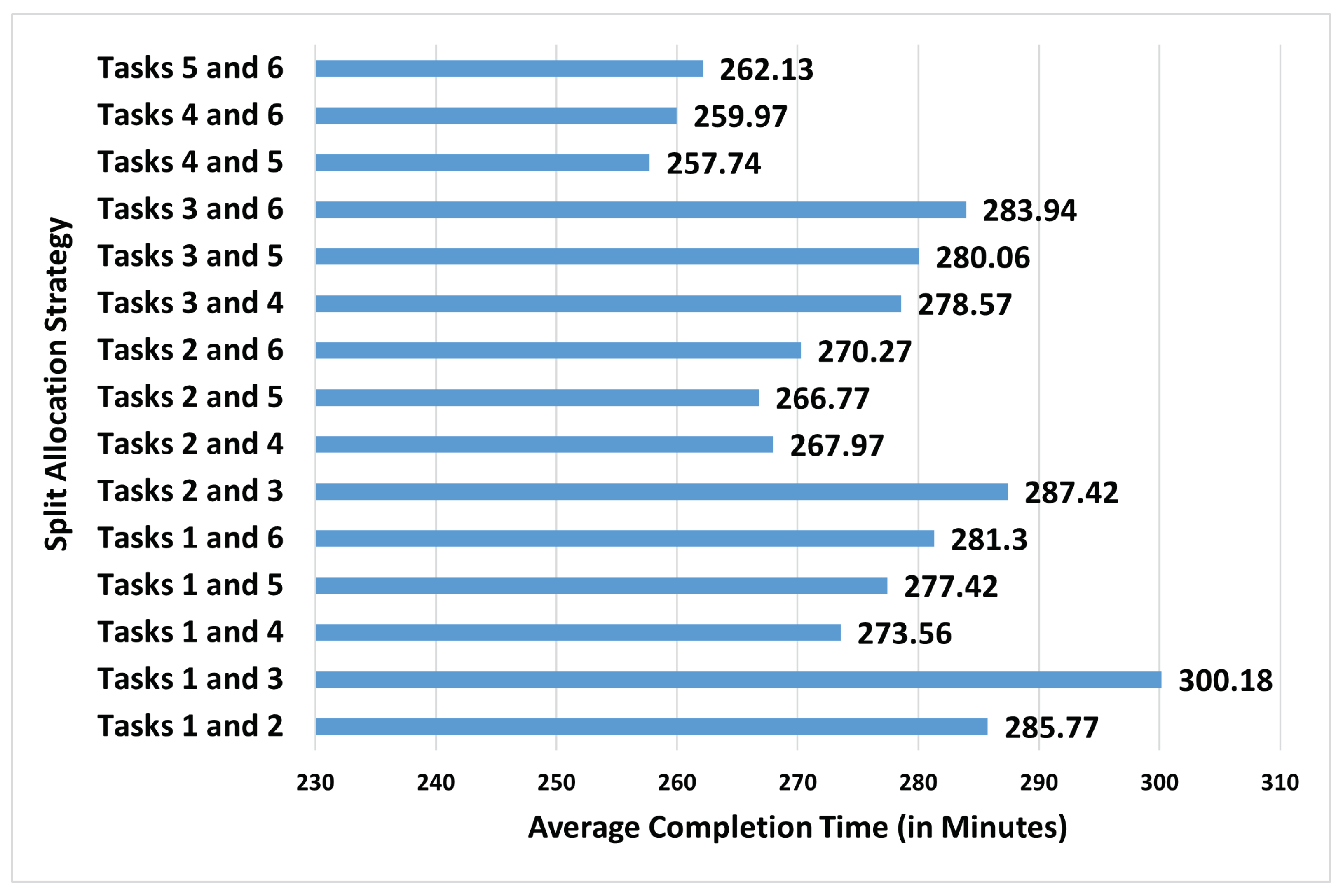

4.3.3. How to Use Additional Worker Capacity Based on the Worker-Driven Flexible Allocation?

5. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| RTLS | Real-time localisation system |

| IPS | Indoor positioning system |

| RFID | Radio frequency identification system |

| UWB | Ultra-wide Band |

| DES | Discrete event simulation |

| BPMN | Business process model and notation |

Appendix A

Appendix A.1. Details of the Discrete Event Simulation

References

- Süer, G.A. Optimal Operator Assignment and Cell Loading in Labor-intensive Manufacturing Cells. Comput. Ind. Eng. 1996, 31, 155–158. [Google Scholar] [CrossRef]

- Crețu-Sîrcu, A.L.; Schiøler, H.; Cederholm, J.P.; Sîrcu, I.; Schjørring, A.; Larrad, I.R.; Berardinelli, G.; Madsen, O. Evaluation and Comparison of Ultrasonic and UWB Technology for Indoor Localization in an Industrial Environment. Sensors 2022, 22, 2927. [Google Scholar] [CrossRef] [PubMed]

- Delamare, M.; Duval, F.; Boutteau, R. A New Dataset of People Flow in an Industrial Site with UWB and Motion Capture Systems. Sensors 2020, 20, 4511. [Google Scholar] [CrossRef] [PubMed]

- dos Santos Garcia, C.; Meincheim, A.; Faria Junior, E.R.; Dallagassa, M.R.; Sato, D.M.V.; Carvalho, D.R.; Santos, E.A.P.; Scalabrin, E.E. Process Mining Techniques and Applications—A Systematic Mapping Study. Expert Syst. Appl. 2019, 133, 260–295. [Google Scholar] [CrossRef]

- Süer, G.A.; Dagli, C. Intra-cell Manpower Transfers and Cell Loading in Labor-intensive Manufacturing Cells. Comput. Ind. Eng. 2005, 48, 643–655. [Google Scholar] [CrossRef]

- Song, B.L.; Wong, W.K.; Fan, J.T.; Chan, S.F. A Recursive Operator Allocation Approach for Assembly Line-balancing Optimization Problem with the Consideration of Operator Efficiency. Comput. Ind. Eng. 2006, 51, 585–608. [Google Scholar] [CrossRef]

- Chang, P.-C.; Lin, Y.-K.; Chan, S.F. Fuzzy-based System Reliability of a Labour-intensive Manufacturing Network with Repair. Int. J. Prod. Res. 2015, 53, 1980–1995. [Google Scholar] [CrossRef]

- Aslan, A.; El-Raoui, H.; Hanson, J.; Vasantha, G.; Quigley, J.; Corney, J. Data-driven Discovery of Manufacturing Processes and Performance from Worker Localisation Data. Flexible Automation and Intelligent Manufacturing FAIM 2023. Lecture Notes in Mechanical Engineering. 2023. Available online: https://napier-repository.worktribe.com/output/3055612 (accessed on 1 May 2023).

- Thiede, S.; Sullivan, B.; Damgrave, R.; Lutters, E. Real-time Locating Systems (RTLS) in Future Factories: Technology Review, Morphology and Application Potentials. Procedia CIRP 2021, 104, 671–676. [Google Scholar] [CrossRef]

- Barbieri, L.; Brambilla, M.; Trabattoni, A.; Mervic, S.; Nicoli, M. UWB Localization in a Smart Factory: Augmentation Methods and Experimental Assessment. IEEE Trans. Instrum. Meas. 2021, 70, 1–18. [Google Scholar] [CrossRef]

- Kunhoth, J.; Karkar, A.; Al-Maadeed, S.; Al-Ali, A. Indoor Positioning and Wayfinding Systems: A Survey. Hum. Cent. Comput. Inf. Sci. 2020, 10, 18. [Google Scholar] [CrossRef]

- Witrisal, K.; Hinteregger, S.; Kulmer, J.; Leitinger, E.; Meissner, P. High-accuracy Positioning for Indoor Applications: RFID, UWB, 5G, and Beyond. IEEE Int. Conf. RFID 2016, 1–7. [Google Scholar] [CrossRef]

- Rácz-Szabó, A.; Ruppert, T.; Bántay, L.; Löcklin, A.; Jakab, L.; Abonyi, J. Real-time Locating System in Production Management. Sensors 2020, 20, 6766. [Google Scholar] [CrossRef]

- Thiesse, F.; Fleisch, E. On the Value of Location Information to Lot Scheduling in Complex Manufacturing Processes. Int. J. Prod. Econ. 2008, 112, 532–547. [Google Scholar] [CrossRef]

- Arkan, I.; Van Landeghem, H. Evaluating the Performance of a Discrete Manufacturing Process using RFID: A Case Study. Robot. Comput.-Integr. Manuf. 2013, 29, 502–512. [Google Scholar] [CrossRef]

- Chongwatpol, J.; Sharda, R. RFID-enabled Track and Traceability in Job-shop Scheduling Environment. Eur. J. Oper. Res. 2013, 227, 453–463. [Google Scholar] [CrossRef]

- Guo, Z.X.; Ngai, E.W.T.; Yang, C.; Liang, X. An RFID-based Intelligent Decision Support System Architecture for Production Monitoring and Scheduling in a Distributed Manufacturing Environment. Int. J. Prod. Econ. 2015, 159, 16–28. [Google Scholar] [CrossRef]

- Ruppert, T.; Abonyi, J. Software Sensor for Activity-time Monitoring and Fault Detection in Production Lines. Sensors 2018, 18, 2346. [Google Scholar] [CrossRef]

- Mieth, C. Semantic Enrichment of Spatio-temporal Production Data to Determine Lead Times for Manufacturing Simulation. In Proceedings of the 2019 Winter Simulation Conference, National Harbor, MD, USA, 8–12 December 2019; Available online: https://www.informs-sim.org/wsc19papers/200.pdf (accessed on 10 April 2023).

- Nwakanma, C.I.; Islam, F.B.; Maharani, M.P.; Lee, J.-M.; Kim, D.-S. Detection and Classification of Human Activity for Emergency Response in Smart Factory Shop Floor. Appl. Sci. 2021, 11, 3662. [Google Scholar] [CrossRef]

- Tran, T.-A.; Ruppert, T.; Abonyi, J. Indoor Positioning Systems can Revolutionise Digital Lean. Appl. Sci. 2021, 11, 5291. [Google Scholar] [CrossRef]

- Islam, F.B.; Lee, J.-M.; Kim, D.-S. Smart Factory Floor Safety Monitoring Using UWB Sensor. IET Sci. Meas. 2022, 16, 412–425. [Google Scholar] [CrossRef]

- Sullivan, B.P.; Ghafoorpoor Yazdi, P.; Suresh, A.; Thiede, S. Digital Value Stream Mapping: Application of UWB Real Time Location Systems. Procedia CIRP 2022, 107, 1186–1191. [Google Scholar] [CrossRef]

- Lugaresi, G.; Ciappina, A.D.; Rossi, M.; Matta, A. Exploiting a Combined Process Mining Approach to Enhance the Discovery and Analysis of Support Processes in Manufacturing. Int. J. Comput. Integr. 2022, 133, 1–21. [Google Scholar] [CrossRef]

- Lorenz, R.; Senoner, J.; Sihn, W.; Netland, T. Using Process Mining to Improve Productivity in Make-to-stock Manufacturing. Int. J. Prod. Res. 2021, 59, 4869–4880. [Google Scholar] [CrossRef]

- Choueiri, A.C.; Sato, D.M.V.; Scalabrin, E.E.; Santos, E.A.P. An Extended Model for Remaining Time Prediction in Manufacturing Systems Using Process Mining. J. Manuf. Syst. 2020, 56, 188–201. [Google Scholar] [CrossRef]

- Mannhardt, F.; Bovo, R.; Oliveira, M.F.; Julier, S. A Taxonomy for Combining Activity Recognition and Process Discovery in Industrial Environments. In Intelligent Data Engineering and Automated Learning—IDEAL 2018. IDEAL 2018. Lecture Notes in Computer Science; Yin, H., Camacho, D., Novais, P., Tallón-Ballesteros, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; Volume 11315. [Google Scholar] [CrossRef]

- Knoch, S.; Ponpathirkoottam, S.; Schwartz, T. Video-to-model: Unsupervised Trace Extraction from Videos for Process Discovery and Conformance Checking in Manual Assembly. In Business Process Management. BPM 2020. Lecture Notes in Computer Science; Fahland, D., Ghidini, C., Becker, J., Dumas, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; Volume 12168. [Google Scholar] [CrossRef]

- Law, A.M.; Kelton, W.D. Simulation Modeling and Analysis. In Industrial Engineering Series; McGraw-Hill: New York, NY, USA, 1982. [Google Scholar]

- Friederich, F.; Francis, D.P.; Lazarova-Molnar, S.; Mohamed, N. A Framework for Data-driven Digital Twins of Smart Manufacturing Systems. Comput. Ind. 2022, 136, 103586. [Google Scholar] [CrossRef]

- Lazarova-Molnar, S.; Li, X. Deriving Simulation Models from Data: Steps of Simulation Studies Revisited. In Proceedings of the 2019 Winter Simulation Conference (WSC), National Harbor, MD, USA, 8–11 December 2019; pp. 2771–2782. [Google Scholar] [CrossRef]

- Rozinat, A.; Mans, R.S.; van der Aalst, W.M.P. Discovering Simulation Models. Inf. Syst. 2009, 34, 305–327. [Google Scholar] [CrossRef]

- Tamburis, O. Bridging the Gap Between Process Mining and DES Modeling in the Healthcare Domain. In Proceedings of the 2019 E-Health and Bioengineering Conference (EHB), Iasi, Romania, 21–23 November 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Tamburis, O.; Esposito, C. Process Mining as Support to Simulation Modeling: A Hospital-based Case Study. Simul. Model. Pract. 2020, 104, 102149. [Google Scholar] [CrossRef]

- Goel, P.; Mehta, S.; Kumar, R.; Castaño, F. Sustainable Green Human Resource Management Practices in Educational Institutions: An Interpretive Structural Modelling and Analytic Hierarchy Process Approach. Sustainability 2022, 14, 12853. [Google Scholar] [CrossRef]

- Wan, P.K.; Leirmo, T.L. Human-centric Zero-defect Manufacturing: State-of-the-art Review, Perspectives, and Challenges. Comput. Ind. 2023, 144, 103792. [Google Scholar] [CrossRef]

- Wang, L. A Futuristic Perspective on Human-centric Assembly. J. Manuf. Syst. 2022, 62, 199–201. [Google Scholar] [CrossRef]

- Pradana, M.I.A.; Kurniati, A.P.; Wisudiawan, G.A.A. Inductive Miner Implementation to Improve Healthcare Efficiency on Indonesia National Health Insurance Data. In Proceedings of the 2022 International Conference on Data Science and Its Applications (ICoDSA), Bandung, Indonesia, 6–7 July 2022; pp. 239–244. [Google Scholar] [CrossRef]

- Leemans, S.J.J.; Fahland, D.; van der Aalst, W.M.P. Discovering Block-Structured Process Models from Event Logs—A Constructive Approach. In Application and Theory of Petri Nets and Concurrency, PETRI NETS 2013. Lecture Notes in Computer Science; Colom, J.M., Desel, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 7927. [Google Scholar] [CrossRef]

- Sherry, K.J. Business Process Modelling with BPMN: Modelling and Designing Business Processes Course Book Using the Business Process Model and Notation Specification Version 2.0.; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2012. [Google Scholar]

| Study | Sensor Technology | Tracked Objects | Purpose | Technique of Analysis |

|---|---|---|---|---|

| [14] | RFID | products | job scheduling in machines | simulation |

| [15] | RFID | products | re-design of workflow | simulation |

| [16] | RFID | products | production scheduling | simulation |

| [17] | RFID | products | production scheduling | multi objective optimisation |

| [18] | Fixture | workstations | fault detection | quadratic programming |

| [19] | UWB | products | lead time prediction | semantic enriching |

| [20] | Lidar and UWB | workers | safety monitoring | supervised machine learning |

| [21] | UWB | products | bottleneck identification | process mining and value stream mapping |

| [22] | UWB | workers | safety monitoring | supervised machine learning |

| [23] | UWB | products | bottleneck identification | value stream mapping |

| Our paper | UWB | workers | worker capacity allocation | process mining and simulation |

| Adjustment | Shift 5% | Shift 10% | Shift 20% | Shift 50% |

|---|---|---|---|---|

| From Task 1 to 2 | 308.4 ± 1.4 | 307.6 ± 1.4 | 308.1 ± 1.4 | 332.7 ± 1.5 |

| From Task 1 to 3 | 313.4 ± 1.4 | 314.4 ± 1.4 | 317.8 ± 1.4 | 347.2 ± 1.5 |

| From Task 1 to 4 | 302.2 ± 1.3 | 299.5 ± 1.3 | 298.3 ± 1.3 | 326.7 ± 1.4 |

| From Task 1 to 5 | 307.0 ± 1.4 | 305.0 ± 1.3 | 303.3 ± 1.3 | 323.9 ± 1.4 |

| From Task 1 to 6 | 303.8 ± 1.3 | 301.1 ± 1.3 | 301.6 ± 1.3 | 333.2 ± 1.4 |

| From Task 2 to 1 | 311.2 ± 1.4 | 313.7 ± 1.4 | 320.8 ± 1.4 | 370.2 ± 1.7 |

| From Task 2 to 3 | 311.3 ± 1.4 | 314.1 ± 1.4 | 321.6 ± 1.4 | 370.4 ± 1.6 |

| From Task 2 to 4 | 307.3 ± 1.3 | 306.3 ± 1.3 | 309.0 ± 1.4 | 354.0 ± 1.6 |

| From Task 2 to 5 | 307.8 ± 1.4 | 307.8 ± 1.4 | 310.7 ± 1.4 | 352.0 ± 1.6 |

| From Task 2 to 6 | 303.5 ± 1.3 | 302.7 ± 1.3 | 307.0 ± 1.3 | 356.7 ± 1.6 |

| From Task 3 to 1 | 308.4 ± 1.4 | 308.3 ± 1.4 | 308.9 ± 1.4 | 320.0 ± 1.4 |

| From Task 3 to 2 | 308.8 ± 1.3 | 307.1 ± 1.3 | 305.1 ± 1.3 | 310.8 ± 1.4 |

| From Task 3 to 4 | 302.5 ± 1.3 | 298.6 ± 1.3 | 294.5 ± 1.3 | 300.6 ± 1.3 |

| From Task 3 to 5 | 306.2 ± 1.3 | 303.1 ± 1.3 | 298.7 ± 1.3 | 299.1 ± 1.3 |

| From Task 3 to 6 | 302.4 ± 1.3 | 298.7 ± 1.3 | 296.8 ± 1.3 | 308.1 ± 1.3 |

| From Task 4 to 1 | 313.3 ± 1.4 | 316.6 ± 1.4 | 325.4 ± 1.4 | 384.4 ± 1.7 |

| From Task 4 to 2 | 311.0 ± 1.4 | 313.6 ± 1.4 | 321.1 ± 1.4 | 376.9 ± 1.7 |

| From Task 4 to 3 | 312.2 ± 1.4 | 315.7 ± 1.4 | 324.7 ± 1.4 | 383.2 ± 1.7 |

| From Task 4 to 5 | 309.8 ± 1.4 | 311.9 ± 1.4 | 318.3 ± 1.4 | 371.1 ± 1.6 |

| From Task 4 to 6 | 307.7 ± 1.4 | 308.5 ± 1.4 | 314.2 ± 1.4 | 371.6 ± 1.6 |

| From Task 5 to 1 | 314.8 ± 1.4 | 319.3 ± 1.4 | 331.5 ± 1.5 | 411.7 ± 1.8 |

| From Task 5 to 2 | 309.5 ± 1.3 | 312.5 ± 1.4 | 322.1 ± 1.4 | 397.4 ± 1.7 |

| From Task 5 to 3 | 313.2 ± 1.4 | 318.1 ± 1.4 | 330.6 ± 1.4 | 409.6 ± 1.8 |

| From Task 5 to 4 | 307.9 ± 1.3 | 308.8 ± 1.4 | 316.7 ± 1.4 | 394.0 ± 1.7 |

| From Task 5 to 6 | 305.1 ± 1.3 | 306.2 ± 1.3 | 315.9 ± 1.4 | 396.7 ± 1.7 |

| From Task 1 to 4 and From Task 3 to 6 | 287 ± 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aslan, A.; El-Raoui, H.; Hanson, J.; Vasantha, G.; Quigley, J.; Corney, J.; Sherlock, A. Using Worker Position Data for Human-Driven Decision Support in Labour-Intensive Manufacturing. Sensors 2023, 23, 4928. https://doi.org/10.3390/s23104928

Aslan A, El-Raoui H, Hanson J, Vasantha G, Quigley J, Corney J, Sherlock A. Using Worker Position Data for Human-Driven Decision Support in Labour-Intensive Manufacturing. Sensors. 2023; 23(10):4928. https://doi.org/10.3390/s23104928

Chicago/Turabian StyleAslan, Ayse, Hanane El-Raoui, Jack Hanson, Gokula Vasantha, John Quigley, Jonathan Corney, and Andrew Sherlock. 2023. "Using Worker Position Data for Human-Driven Decision Support in Labour-Intensive Manufacturing" Sensors 23, no. 10: 4928. https://doi.org/10.3390/s23104928

APA StyleAslan, A., El-Raoui, H., Hanson, J., Vasantha, G., Quigley, J., Corney, J., & Sherlock, A. (2023). Using Worker Position Data for Human-Driven Decision Support in Labour-Intensive Manufacturing. Sensors, 23(10), 4928. https://doi.org/10.3390/s23104928