Industry 5 and the Human in Human-Centric Manufacturing

Abstract

1. Introduction

“Although manufacturing companies are currently situated at a transition point in what has been called Industry 4.0, a new revolutionary wave—Industry 5.0—is emerging as an “Age of Augmentation” when the human and machine reconcile and work in perfect symbiosis with one another.”[17]

“Human-centric manufacturing is a prerequisite for future factories seeking to increase flexibility, agility and competitiveness in the face of new social challenges. The basic principle of human-centricity is that “humans should never be subservient to machines and automation, but machines and automation should be subservient to humans”

1.1. Disciplinary Conceptualisations of the Human

1.2. Research Aims

- This paper sheds light on the disciplinary axiomatic and epistemic culture of engineering. Engineering is an extremely wide-ranging field of practice, and notions of the human within this may vary widely. The interest is in aspects of technology deployed in the workplace aimed at being implemented in digital (smart) manufacturing processes. Specifically, the focus is on the stage of often incremental innovation that fuels the engineering pipeline with new models or concepts that are discussed within the scientific community.

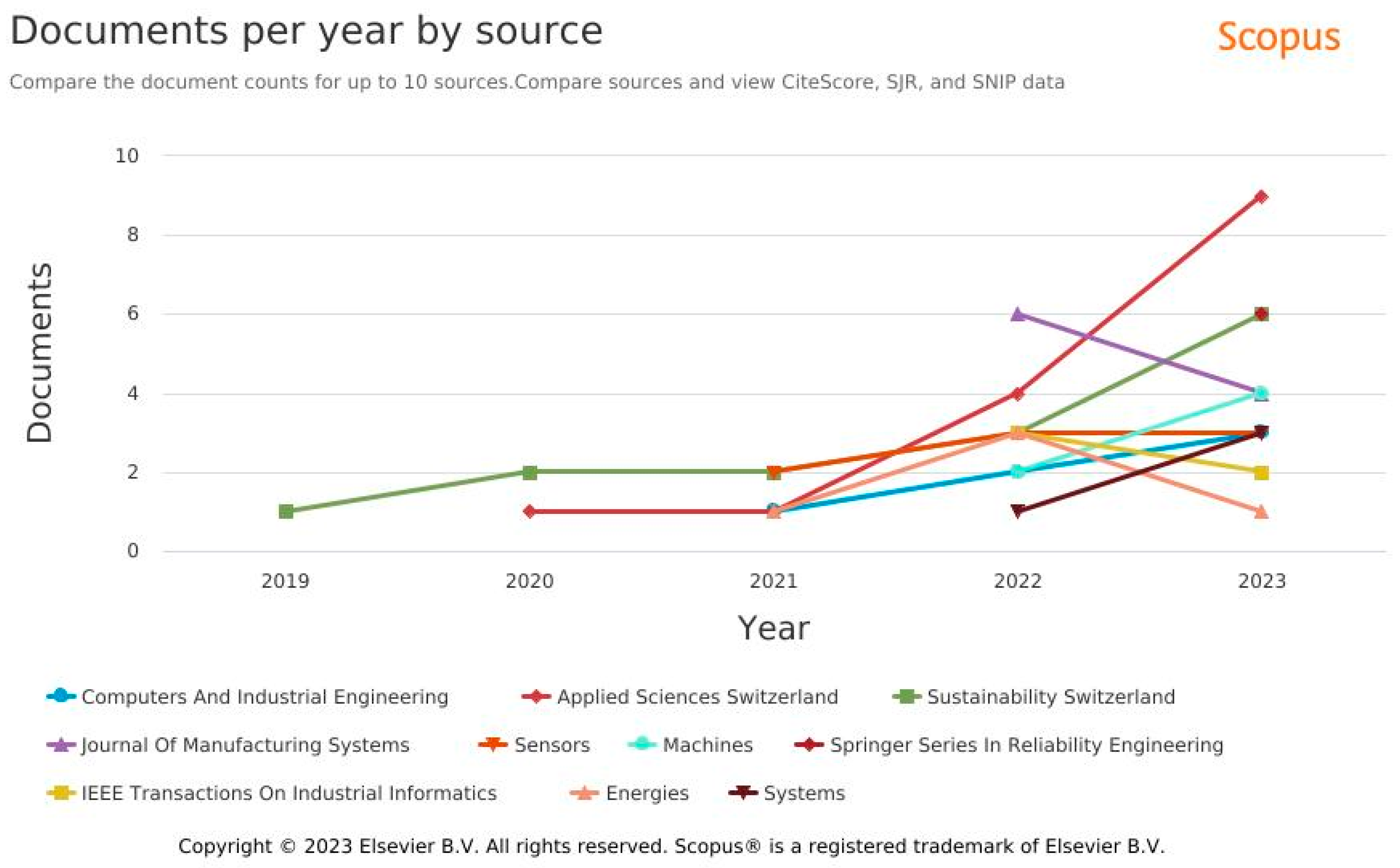

- The project started with exploratory interviews [31] in the engineering discipline to understand what informs research activities, what publications are relevant to keep up to date with latest developments and what success in this field looks like. The interviews partially informed key words for a systematic literature review of academic papers. The review focuses on papers within the industrial context of warehousing, where system technologies such as digital twins (DTs), cyber-physical systems (CPSs) and point technologies such as robotics and sensors are considered [13,24,32]. There is ample reflection on warehousing as a context for I4, with publications still being offered in 2023, but less has been done to review this newer area of contribution comprehensively [3,33]. As well as being a test bed for implementing technologies deemed relevant for I5 in manufacturing, engineering and social science research interest has overlapped in the context of warehousing [34,35,36,37]. The papers were assessed through interpretive coding based on intercoder reliability assessments, and focussing on the underlying perception of the role for the human worker in human–technology relations.

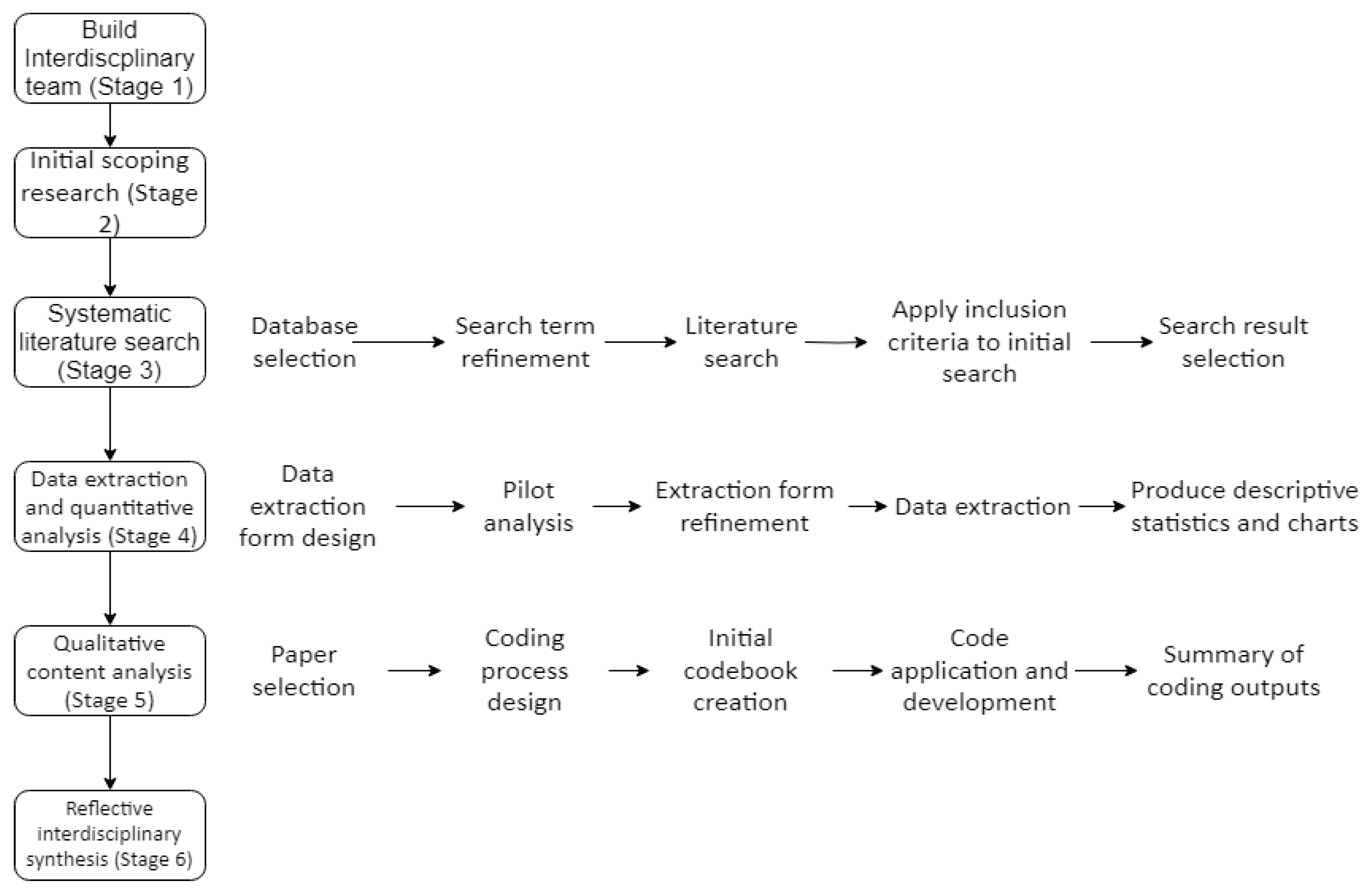

2. Materials and Methods

2.1. Overview of Method

2.2. Building Interdiscplinarity (Stage 1)

2.3. Initial Scoping Research (Stage 2)

2.4. Systematic Literature Review

2.5. Search Strategy

2.6. Inclusion Criteria

2.7. Quality Assessment

2.8. Data Extraction and Synthesis

2.9. Interpretive Coding

- Framing for the problem to be solved in this paper: in this section, coding was initiated against rationales and justifications driving the applied research outcome;

- Attributes, indicating the roles associated with either technologies or humans and allowing for assessment of the quality of the interaction and collaboration;

- Values, which reflect evaluations, beliefs and attitudes around humans, machines and the relationship between the two.

3. Results

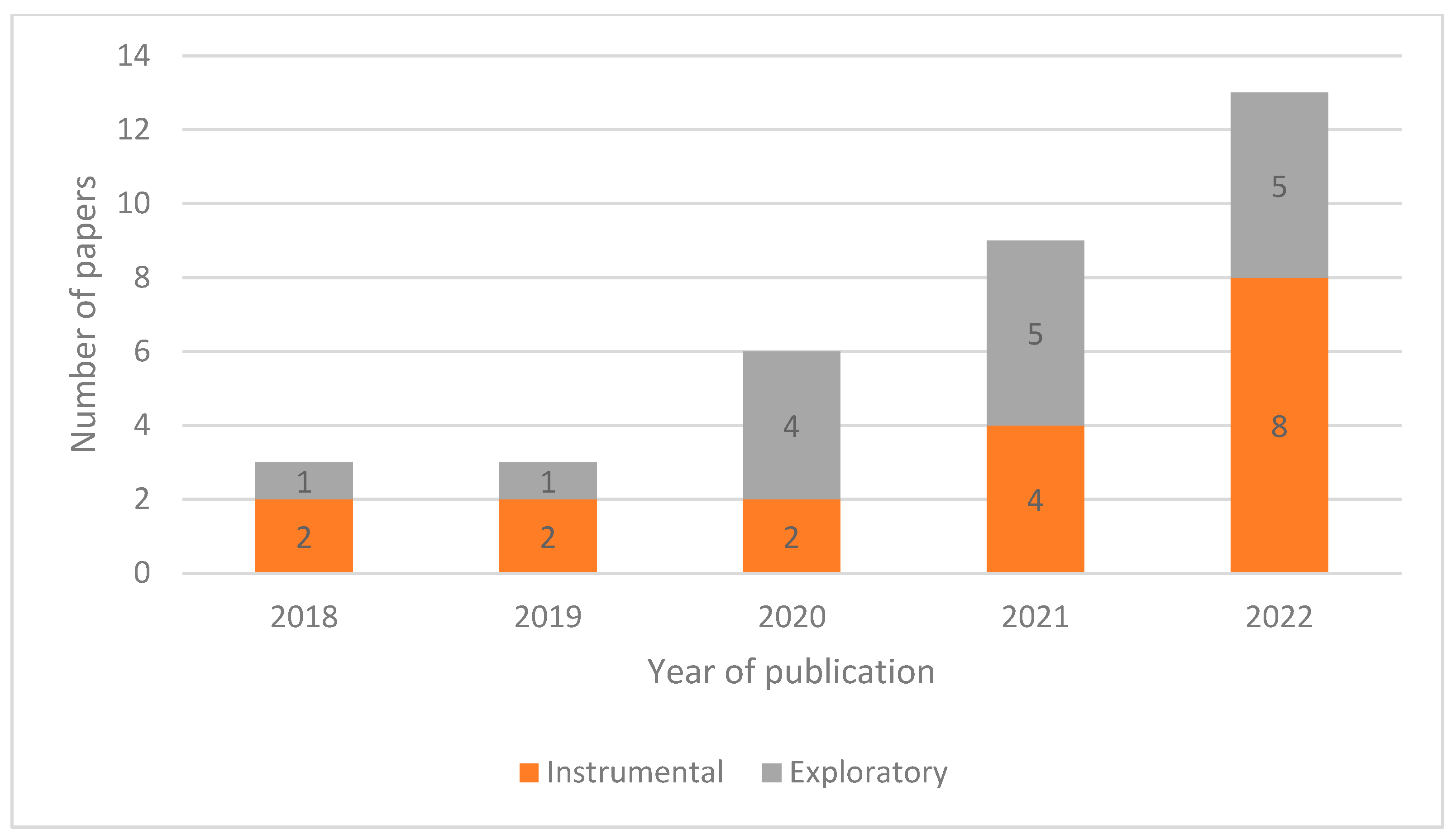

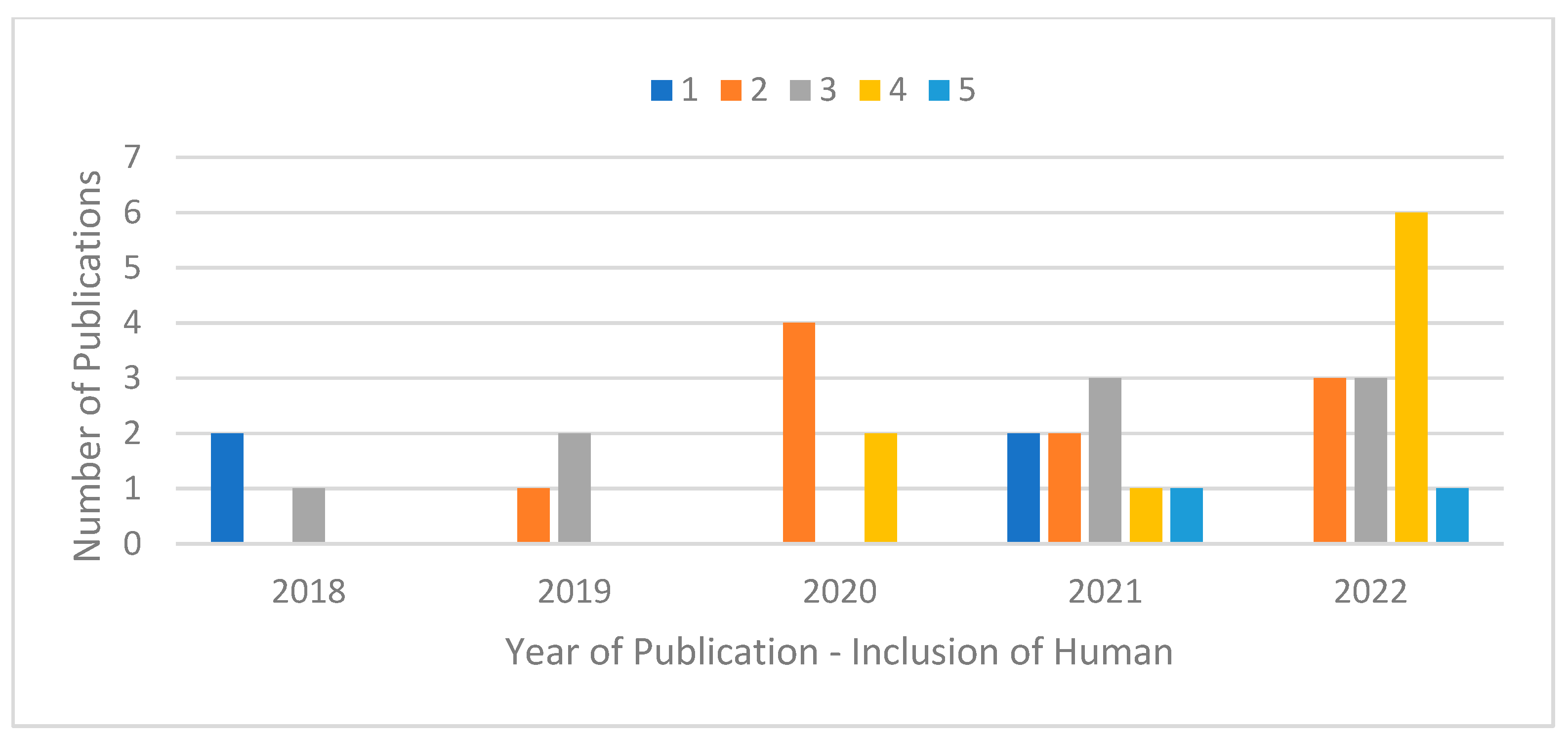

3.1. Data Extraction Findings

3.2. Interpretive Coding Results

- Framing: The interpretive coding focussing on the framing, or, rationale, highlighted the relevance for efficiency gains in engineering projects. Either papers addressed the costs in general or they claimed to help reduce these by improving the speed and accuracy of the throughflow of commodities. Often, technology is seen as reducing dangerous tasks, hence helping to decrease costs due to accidents at work. Papers generally focussed on the reduction in new tech-induced risks rather than any inherent risks for humans induced by the technology (e.g., work intensification, lack of ergonomic support).Example code:“They use movable racks that can be lifted by small, autonomous robots. By bringing the product to the worker, productivity is increased by a factor of two or more, while simultaneously improving accountability and flexibility.” (HRI2018)

- Attributes: During the intersubjective coding process, a distinction between human and technology-supported attributes was established. The role for the human is framed around either “collaborator” or as a “service”. None of the coding related to human attributes represented the human as having a voice in relation to decision making, although they were addressed as workers. The notion of the human as operator was absent in this subset of warehouse-focussed papers. In one paper, a smiling face emoji is used to capture the worker in the simulation. The paper does not acknowledge evidence about poor job quality in real world warehouse environments. Instead, the worker seems to be happy, and ends up in a simulation represented as a 1980s computer game character (HIE2019). The attributes, or role for technology is that of an assistant, or, in most cases, of a caretaker. Throughout all papers, the technology was framed as a 24/7 working robot without any need for maintenance. Example code: “It has to be ensured that the worker is assisted and not impeded during work.” (HIE2018)

- Values (evaluation): A core code emerged in terms of the potential for either the technology or the human as an asset to the process. Technology clearly dominates in this respect, as it was seen as an asset to the process, to the human, and to the firm. The human is mentioned as an asset less frequently, and simply in relation to maintenance work for technology. A second set of values—fallibility, vulnerability and obstacle—appeared far more often when describing a human worker. Consistent with this, technology was framed as supportive in fixing errors occurring in the system and stemming from human action (control and surveillance), while the human was framed by exposing their irrational intentions and unpredictability.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

| Method | Category | Codes |

|---|---|---|

| Descriptive | Framing | Costly |

| Dangerous | ||

| Dull | ||

| Dirty | ||

| Attributes | Human Attributes | Colleague |

| Controller | ||

| Customer | ||

| Operator | ||

| Remote | ||

| Subordinate | ||

| Tech Attributes | Tech as fallible | |

| Tech as organic | ||

| Tech as replacement | ||

| Tech as Sapient | ||

| Tech as Specialised | ||

| Values | Beliefs/Evaluations | Asset |

| Error | ||

| External | ||

| Fragile | ||

| Incidental | ||

| Obstacle | ||

| Support | ||

| Variable |

| Method | Category | Codes | Sub-Codes |

|---|---|---|---|

| Descriptive | Framing | Costly | |

| Dangerous | |||

| Attributes | Human Attributes | Colleague | |

| Operator | |||

| Remote | |||

| Service | |||

| Worker | |||

| Tech Attributes | Tech as fallible | ||

| Tech as assistant | |||

| Tech as robota | |||

| Tech as Specialised | |||

| Values | Beliefs/Evaluations | Asset | Tech as asset to firm |

| Tech as asset to human | |||

| Error | Tech fixing human | ||

| Fragile | Human as fragile | ||

| Obstacle | |||

| Variable | Unpredictable variable |

Appendix C

| No. | Year | Key Tech. | Includes Human? | Theoretical vs. Empirical | Rig. | Relev. | Cred. | Rigour (of Research) | Reporting & Relevance (of Study) | Credibility (of Findings) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2022 | Management Algorithms | 4 | Theoretical | HR, T | T, I | FR, S, Np | HR—High rigour | P—practical | FR—Findings reliable |

| 2 | 2022 | Cyber-physical System (CPS) | 5 | Theoretical | HR, T | T, I/E | FR, S, Nr | MR—Med. Rigour | T—theoretical | FU—Findings unreliable |

| 3 | 2021 | Management Algorithms | 1 | Empirical | HR, T | P, I | FU, S, Nr | LR—Low rigour | I—instrumental | S—Scope provided |

| 4 | 2019 | Management Algorithms, CPS | 3 | Theoretical | HR, T | P, I | FR, S, Np | T—Transparent | E—explorative | NS—No scope given |

| 5 | 2022 | Management Algorithms | 4 | Theoretical | MR, T | P, I | FR, S, Np | MT—Minimal transparency | Re—Researcher ‘present’ | |

| 6 | 2019 | Modelling, Sensors | 3 | Theoretical | MR, T | P, I | FR, S, Nr | Nr—No relationship established | ||

| 7 | 2022 | CPS, Sensors | 3 | Theoretical | HR, T | P, E | FR, S, Np | |||

| 8 | 2021 | Management Algorithms | 2 | Theoretical | MR, T | P, E | FR, S, Np | Np—No participants | ||

| 9 | 2021 | Management Algorithms | 2 | Theoretical | MR, T | P, E | FR, S, Np | Human Inclusion | ||

| 10 | 2022 | Modelling | 2 | Empirical | HR, T | P, E | FR, S, Re | 1—No inclusion, 2—Initial framing, 3—Full component, 4—co-focus, 5—primary focus | ||

| 11 | 2020 | Modelling | 4 | Theoretical | MR, T | T, E | FR, S, Np | |||

| 12 | 2021 | Cyber-physical System (CPS) | 3 | Theoretical | MR, T | T, E | FR, S, Np | |||

| 13 | 2021 | Modelling, Management Algorithms, CPS | 3 | Theoretical | HR, T | P, E | FR, S, Np | |||

| 14 | 2020 | Management Algorithms | 2 | Theoretical | MR, T | T, E | FR, S, Np | |||

| 15 | 2022 | Modelling, Management Algorithms | 3 | Theoretical | MR, T | T, E/I | FR, S, Np | |||

| 16 | 2022 | Modelling, Management Algorithms, CPS | 2 | Empirical | HR, T | P, E | FR, S, Re | |||

| 17 | 2021 | Modelling | 5 | Theoretical | MR, T | T, E | FR, S, Np | |||

| No. | Year | Key Tech. | Includes Human? | Theoretical vs. Empirical | Rig. | Relev. | Cred. | |||

| 18 | 2022 | Modelling, Management Algorithms | 2 | Theoretical | HR, T | T, E | FR, S, Np | |||

| 19 | 2022 | Modelling | 4 | Theoretical | MR, T | T, E | FR, S, Np | |||

| 20 | 2022 | Modelling, Management Algorithms, CPS | 4 | Theoretical | MR, T | T, E/I | FR, S, Np | |||

| 21 | 2022 | Modelling, Management Algorithms, CPS | 4 | Theoretical | MR, T | T, E/I | FR, S, Np | |||

| 22 | 2022 | Modelling, Management Algorithms, CPS | 4 | Theoretical | HR, T | T, E/I | FR, S, Np | |||

| 23 | 2022 | Modelling, Sensors | 3 | Theoretical | HR, T | T, E/I | FR, S, Np | |||

| 24 | 2018 | Modelling, Management Algorithms, CPS | 3 | Empirical | HR, T | T, E, P, I | FR, S, Nr | |||

| 25 | 2018 | Modelling, Management Algorithms | 1 | Theoretical | HR, T | T, E/I | FR, S, Np | |||

| 26 | 2018 | Modelling, Management Algorithms | 1 | Theoretical | HR, T | T, E | FR, S, Np | |||

| 27 | 2019 | Modelling, Management Algorithms, CPS | 2 | Theoretical | LR, MT | T, P, E | FR, S, Np | |||

| 28 | 2020 | Modelling, Sensors | 2 | Empirical | LR, MT | P, I | S, Nr | |||

| 29 | 2020 | Modelling, Management Algorithms | 2 | Theoretical | MR, T | T, E | FR, S, Np | |||

| 30 | 2020 | Modelling, Management Algorithms | 2 | Theoretical | HR, T | T, P, E | FR, Np | |||

| 31 | 2020 | Cyber-physical System (CPS) | 4 | Empirical | MR, T | T, E/I | FR, S, Re | |||

| 32 | 2021 | Modelling | 1 | Theoretical | LR, MT | T, E/I | S, Np | |||

| 33 | 2021 | Cyber-physical System (CPS) | 4 | Empirical | MR, T | P, I | FR, S | |||

| 34 | 2021 | Cyber-physical System (CPS) | 3 | Empirical | HR, T | T, I | FR, Nr | |||

| No. | Title & Reference No. | Authors | Year |

|---|---|---|---|

| 1 | A Case Study on Optimization of Warehouses [79] | Lesch, Veronika; Müller, Patrick; Krämer, Moritz; Kounev, Samuel; Krupitzer, Christian; | 2021 |

| 2 | A Conceptual Reference Model for Human as a Service Provider in Cyber Physical Systems [64] | Ignatius, Hargyo TN; Bahsoon, Rami; | 2021 |

| 3 | A proposed method using GPU based SDO to optimize retail warehouses [65] | Bengtsson, Magnus; Waidringer, Jonas; | 2021 |

| 4 | Adaptive task planning for large-scale robotized warehouses [80] | Shi, Dingyuan; Tong, Yongxin; Zhou, Zimu; Xu, Ke; Tan, Wenzhe; Li, Hongbo; | 2022 |

| 5 | An exact analysis and comparison of manual picker routing heuristics [81] | Engels, Tim; Adan, Ivo; Boxma, Onno; Resing, Jacques; | 2022 |

| 6 | An integrated light management system with real-time light measurement and human perception [82] | Tsesmelis, Theodore; Hasan, Irtiza; Cristani, Marco; Bue, A Del; Galasso, Fabio; | 2021 |

| 7 | Analysis of safe ultrawideband human-robot communication in automated collaborative warehouse [66] | Ivšić, Branimir; Šipuš, Zvonimir; Bartolić, Juraj; Babić, Josip; | 2020 |

| 8 | Autonomous Intruder Detection Using a ROS-Based Multi-Robot System Equipped with 2D-LiDAR Sensors [83] | Islam, Mashnoon; Ahmed, Touhid; Nuruddin, Abu Tammam Bin; Islam, Mashuda; Siddique, Shahnewaz; | 2020 |

| 9 | Autonomous Warehouse Robot using Deep Q-Learning [84] | Peyas, Ismot Sadik; Hasan, Zahid; Tushar, Md Rafat Rahman; Musabbir, Al; Azni, Raisa Mehjabin; Siddique, Shahnewaz; | 2021 |

| 10 | Bimanual shelf picking planner based on collapse prediction [85] | Motoda, Tomohiro; Petit, Damien; Wan, Weiwei; Harada, Kensuke; | 2021 |

| 11 | Computing Policies That Account For The Effects Of Human Agent Uncertainty During Execution In Markov Decision Processes [86] | Gopalakrishnan, Sriram; Verma, Mudit; Kambhampati, Subbarao; | 2021 |

| 12 | Designing environments conducive to interpretable robot behavior [87] | Kulkarni, Anagha; Sreedharan, Sarath; Keren, Sarah; Chakraborti, Tathagata; Smith, David E; Kambhampati, Subbarao; | 2020 |

| 13 | E-commerce warehousing: learning a storage policy [88] | Rimélé, Adrien; Grangier, Philippe; Gamache, Michel; Gendreau, Michel; Rousseau, Louis-Martin; | 2021 |

| 14 | Efficient task allocation in smart warehouses with multi-delivery stations and heterogeneous robots [89] | Oliveira, George S; Röoning, Juha; Carvalho, Jônata T; Plentz, Patricia DM; | 2022 |

| 15 | Formulating and solving integrated order batching and routing in multi-depot AGV-assisted mixed-shelves warehouses [90] | Xie, Lin; Li, Hanyi; Luttmann, Laurin; | 2022 |

| 16 | From simulation to real-world robotic mobile fulfillment systems [91] | Xie, Lin; Li, Hanyi; Thieme, Nils; | 2018 |

| 17 | Generative modeling of multimodal multi-human behavior [92] | Ivanovic, Boris; Schmerling, Edward; Leung, Karen; Pavone, Marco; | 2018 |

| 18 | Hierarchically Structured Scheduling and Execution of Tasks in a Multi-agent Environment [93] | Carvalho, Diogo; Sengupta, Biswa; | 2022 |

| 19 | Human Activity Recognition using Attribute-Based Neural Networks and Context Information [94] | Lüdtke, Stefan; Rueda, Fernando Moya; Ahmed, Waqas; Fink, Gernot A; Kirste, Thomas; | 2021 |

| 20 | Human intention estimation based on hidden Markov model motion validation for safe flexible robotized warehouses [95] | Petković, Tomislav; Puljiz, David; Marković, Ivan; Hein, Björn; | 2019 |

| 21 | Human intention recognition for human aware planning in integrated warehouse systems [96] | Petković, Tomislav; Hvězda, Jakub; Rybecký, Tomáš; Marković, Ivan; Kulich, Miroslav; Přeučil, Libor; Petrović, Ivan; | 2020 |

| 22 | Human intention recognition in flexible robotized warehouses based on markov decision processes [97] | Petković, Tomislav; Marković, Ivan; Petrović, Ivan; | 2018 |

| 23 | Implementation of augmented reality in autonomous warehouses: challenges and opportunities [98] | Puljiz, David; Gorbachev, Gleb; Hein, Björn; | 2018 |

| 24 | Intuitive and Efficient Human-robot Collaboration via Real-time Approximate Bayesian Inference [99] | Leon, Javier Felip; Gonzalez-Aguirre, David; Nachman, Lama; | 2022 |

| 25 | Layout design for intelligent warehouse by evolution with fitness approximation [100] | Zhang, Haifeng; Guo, Zilong; Zhang, Weinan; Cai, Han; Wang, Chris; Yu, Yong; Li, Wenxin; Wang, Jun; | 2019 |

| 26 | Learning General Inventory Management Policy for Large Supply Chain Network [101] | Kumabe, Soh; Shiroshita, Shinya; Hayashi, Takanori; Maruyama, Shirou; | 2022 |

| 27 | Modelling of Ultrawideband Propagation Scenarios for Safe Human-Robot Interaction in Warehouse Environment [102] | Ivšić, Branimir; Šipuš, Zvonimir; Bartolić, Juraj; Babić, Josip; | 2019 |

| 28 | Projecting robot navigation paths: Hardware and software for projected AR [103] | Han, Zhao; Parrillo, Jenna; Wilkinson, Alexander; Yanco, Holly A; Williams, Tom; | 2022 |

| 29 | Real-Time Visual Localisation in a Tagged Environment [104] | Taquet, Jérémy; Ecorchard, Gaël; Přeučil, Libor; | 2017 |

| 30 | Reinforcement Learning Based User-Guided Motion Planning for Human-Robot Collaboration [105] | Yu, Tian; Chang, Qing; | 2022 |

| 31 | Seeing thru walls: Visualizing mobile robots in augmented reality [106] | Gu, Morris; Cosgun, Akansel; Chan, Wesley P; Drummond, Tom; Croft, Elizabeth; | 2021 |

| 32 | Uwb propagation characteristics of human-to-robot communication in automated collaborative warehouse [107] | Ivsic, Branimir; Bartolic, Juraj; Sipus, Zvonimir; Babic, Josip; | 2020 |

| 33 | Warevr: Virtual reality interface for supervision of autonomous robotic system aimed at warehouse stocktaking [75] | Kalinov, Ivan; Trinitatova, Daria; Tsetserukou, Dzmitry; | 2021 |

| 34 | Wearable camera-based human absolute localization in large warehouses [108] | Écorchard, Gaël; Košnar, Karel; Přeučil, Libor | 2020 |

References

- Castano, F.; Cruz, Y.J.; Villalonga, A.; Haber, R.E. Data-driven insights on time-to-failure of electromechanical manufacturing devices: A procedure and case study. IEEE Trans. Ind. Inform. 2022, 19, 7190–7200. [Google Scholar] [CrossRef]

- Misra, A.; Mittal, A.; Misra, V.; Pandey, D. Improving non-deterministic uncertainty modelling in Industry 4.0 scheduling. arXiv 2021, arXiv:2101.05677. [Google Scholar]

- Tubis, A.A.; Rohman, J. Intelligent Warehouse in Industry 4.0—Systematic Literature Review. Sensors 2023, 23, 4105. [Google Scholar] [CrossRef] [PubMed]

- Baena, F.; Guarin, A.; Mora, J.; Sauza, J.; Retat, S. Learning factory: The path to industry 4.0. Procedia Manuf. 2017, 9, 73–80. [Google Scholar] [CrossRef]

- Arinez, J.F.; Chang, Q.; Gao, R.X.; Xu, C.; Zhang, J. Artificial Intelligence in Advanced Manufacturing: Current Status and Future Outlook. J. Manuf. Sci. Eng. 2020, 142, 110804. [Google Scholar] [CrossRef]

- Vrontis, D.; Christofi, M.; Pereira, V.; Tarba, S.; Makrides, A.; Trichina, E. Artificial intelligence, robotics, advanced technologies and human resource management: A systematic review. Int. J. Hum. Resour. Manag. 2021, 33, 1237–1266. [Google Scholar] [CrossRef]

- Cruz, Y.J.; Rivas, M.; Quiza, R.; Haber, R.E.; Castaño, F.; Villalonga, A. A two-step machine learning approach for dynamic model selection: A case study on a micro milling process. Comput. Ind. 2022, 143, 103764. [Google Scholar] [CrossRef]

- Butollo, F.; Jürgens, U.; Krzywdzinski, M. Von Lean Production zur Industrie 4.0: Mehr Autonomie für die Beschäftigten? AIS-Studien 2018, 11, 75–90. [Google Scholar]

- Briken, K. Welcome in the machine: Human–machine relations and knowledge capture. Cap. Cl. 2020, 44, 159–171. [Google Scholar] [CrossRef]

- Kinzel, H. Industry 4.0—Where Does This Leave the Human Factor? J. Urban Cult. Res. 2017, 15, 70–83. [Google Scholar]

- Sætren, G.B.; Hogenboom, S.; Laumann, K. A study of a technological development process: Human factors—The forgotten factors? Cogn. Technol. Work 2016, 18, 595–611. [Google Scholar] [CrossRef]

- Kurz, C.; Metall, I. Arbeit in der Industrie 4.0. Inf. Manag. Consult. 2012, 3, 56–59. [Google Scholar]

- Müller, J. Enabling Technologies for Industry 5.0: Results of a Workshop with Europe’s Technology Leaders; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; European Commission, Directorate-General for Research and Innovation: Luxembourg, 2021. [Google Scholar]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Lu, Y.; Zheng, H.; Chand, S.; Xia, W.; Liu, Z.; Xu, X.; Wang, L.; Qin, Z.; Bao, J. Outlook on human-centric manufacturing towards Industry 5.0. J. Manuf. Syst. 2022, 62, 612–627. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-Oriented and Ethical Technology Engineering in Industry 5.0: A Human-Centric Perspective for the Design of the Factory of the Future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Howaldt, J.; Kopp, R.; Schultze, J. Why Industrie 4.0 Needs Workplace Innovation—A Critical Essay About the German Debate on Advanced Manufacturing. In Workplace Innovation: Theory, Research and Practice; Oeij, P., Rus, D., Pot, F.D., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 45–60. [Google Scholar]

- Prinz, C.; Kreggenfeld, N.; Kuhlenkötter, B. Lean meets Industrie 4.0—A practical approach to interlink the method world and cyber-physical world. Procedia Manuf. 2018, 23, 21–26. [Google Scholar] [CrossRef]

- Collier, I.; Shakspeare, P. Manufacturing the Future Workforce; High Value Manufacturing Catapult: Solihul, UK, 2020. [Google Scholar]

- Wan, P.K.; Leirmo, T.L. Human-centric zero-defect manufacturing: State-of-the-art review, perspectives, and challenges. Comput. Ind. 2023, 144, 103792. [Google Scholar] [CrossRef]

- Rosenbrock, H.H. Machines with a Purpose; Oxford University Press: New York, NY, USA, 1990. [Google Scholar]

- Kaasinen, E.; Anttila, A.-H.; Heikkilä, P.; Laarni, J.; Koskinen, H.; Väätänen, A. Smooth and resilient human-machine teamwork as an industry 5.0 design challenge. Sustainability 2022, 14, 2773. [Google Scholar] [CrossRef]

- John, K.K.; Adarsh, S.N.; Pattali, V. Workers to super workers: A brief discussion on important technologies for industry 5.0 manufacturing systems. AIP Conf. Proc. 2020, 2311, 070025. [Google Scholar]

- Wood, S.; De Menezes, L.M. High involvement management, high-performance work systems and well-being. Int. J. Hum. Resour. Manag. 2011, 22, 1586–1610. [Google Scholar] [CrossRef]

- Elliott, C.S.; Long, G. Manufacturing rate busters: Computer control and social relations in the labour process. Work Employ. Soc. 2016, 30, 135–151. [Google Scholar] [CrossRef]

- Appelbaum, E.; Bailey, T.; Berg, P.; Kalleberg, A.L. Manufacturing Advantage: Why High-Performance Work Systems Pay Off; Cornell University Press: New York, NY, USA, 2000. [Google Scholar]

- Ramsay, H.; Scholarios, D.; Harley, B. Employees and High-Performance Work Systems: Testing inside the Black Box. Br. J. Ind. Relat. 2000, 38, 501–531. [Google Scholar] [CrossRef]

- Findlay, P.; Kalleberg, A.L.; Warhurst, C. The challenge of job quality. Hum. Relat. 2013, 66, 441–451. [Google Scholar] [CrossRef]

- Krzywdzinski, M.; Pfeiffer, S.; Evers, M.; Gerber, C. Measuring Work and Workers: Wearables and Digital Assistance Systems in Manufacturing and Logistics; Wissenschaftszentrum Berlin für Sozialforschung (WZB): Berlin, Germany, 2022. [Google Scholar]

- Flick, U. The Sage Handbook of Qualitative Data Collection; Sage Publications Ltd.: London, UK, 2017. [Google Scholar]

- Emma-Ikata, D.; Doyle-Kent, M. Industry 5.0 Readiness—“Optimization of the Relationship between Humans and Robots in Manufacturing Companies in Southeast of Ireland”. IFAC-PapersOnLine 2022, 55, 419–424. [Google Scholar] [CrossRef]

- Jafari, N.; Azarian, M.; Yu, H. Moving from Industry 4.0 to Industry 5.0: What are the implications for smart logistics? Logistics 2022, 6, 26. [Google Scholar] [CrossRef]

- Delfanti, A. The Warehouse: Workers and Robots at Amazon; Pluto Books: London, UK, 2021. [Google Scholar]

- Fazal, N.; Haleem, A.; Bahl, S.; Javaid, M.; Nandan, D. Digital management systems in manufacturing using industry 5.0 technologies. In Advancement in Materials, Manufacturing and Energy Engineering, Vol. II: Select Proceedings of ICAMME 2021; Springer: Berlin/Heidelberg, Germany, 2022; pp. 221–234. [Google Scholar]

- Mocan, A.; Gaureanu, A.; Szabó, G.; Mrugalska, B. Arguments for emerging technologies applications to improve manufacturing warehouse ergonomics. In Sustainability and Innovation in Manufacturing Enterprises: Indicators, Models and Assessment for Industry 5.0; Springer: Berlin/Heidelberg, Germany, 2022; pp. 115–164. [Google Scholar]

- Briken, K.; Taylor, P. Fulfilling the ‘British way’: Beyond constrained choice—Amazon workers’ lived experiences of workfare. Ind. Relat. J. 2018, 49, 438–458. [Google Scholar] [CrossRef]

- Montfort, D.; Brown, S.; Shinew, D. The Personal Epistemologies of Civil Engineering Faculty. J. Eng. Educ. 2014, 103, 388–416. [Google Scholar] [CrossRef]

- Dur, R.; Van Lent, M. Socially useless jobs. Ind. Relat. A J. Econ. Soc. 2019, 58, 3–16. [Google Scholar] [CrossRef]

- Soffia, M.; Wood, A.J.; Burchell, B. Alienation Is Not ‘Bullshit’: An Empirical Critique of Graeber’s Theory of BS Jobs. Work Employ. Soc. 2022, 36, 816–840. [Google Scholar] [CrossRef]

- Downey, G.L.; Lucena, J.C. Knowledge and professional identity in engineering: Code-switching and the metrics of progress. Hist. Technol. 2004, 20, 393–420. [Google Scholar] [CrossRef]

- Motyl, B.; Filippi, S. Trends in engineering education for additive manufacturing in the industry 4.0 era: A systematic literature review. Int. J. Interact. Des. Manuf. 2021, 15, 103–106. [Google Scholar] [CrossRef]

- Borrego, M.; Foster, M.J.; Froyd, J.E. Systematic literature reviews in engineering education and other developing interdisciplinary fields. J. Eng. Educ. 2014, 103, 45–76. [Google Scholar] [CrossRef]

- Borrego, M.; Foster, M.J.; Froyd, J.E. What is the state of the Art of systematic review in engineering education? J. Eng. Educ. 2015, 104, 212–242. [Google Scholar] [CrossRef]

- Khan, M.A.-M.; Khan, M.R.J.; Tooshil, A.; Sikder, N.; Mahmud, M.P.; Kouzani, A.Z.; Nahid, A.-A. A systematic review on reinforcement learning-based robotics within the last decade. IEEE Access 2020, 8, 176598–176623. [Google Scholar] [CrossRef]

- Nagaraju, M.; Chawla, P. Systematic review of deep learning techniques in plant disease detection. Int. J. Syst. Assur. Eng. Manag. 2020, 11, 547–560. [Google Scholar] [CrossRef]

- Flah, M.; Nunez, I.; Ben Chaabene, W.; Nehdi, M.L. Machine learning algorithms in civil structural health monitoring: A systematic review. Arch. Comput. Methods Eng. 2021, 28, 2621–2643. [Google Scholar] [CrossRef]

- Nassif, A.B.; Talib, M.A.; Nasir, Q.; Dakalbab, F.M. Machine learning for anomaly detection: A systematic review. IEEE Access 2021, 9, 78658–78700. [Google Scholar] [CrossRef]

- Hwang, S. A Systematic Review of Female Engineering Students Related Studies. J. Eng. Educ. Res. 2020, 23, 31–42. [Google Scholar]

- Espino, M.L.; Rodriguez, S.L.; Le, B.D. A systematic review of literature: Engineering identity and students with financial need in community colleges. Community Coll. J. Res. Pract. 2020, 46, 352–363. [Google Scholar] [CrossRef]

- Morelock, J.R. A systematic literature review of engineering identity: Definitions, factors, and interventions affecting development, and means of measurement. Eur. J. Eng. Educ. 2017, 42, 1240–1262. [Google Scholar] [CrossRef]

- Khan, M.A.; Shaikh, S.A.; Marri, S. Systematic review of lean manufacturing practices in pharmaceutical industry. In Proceedings of the 5th NA International Conference on Industrial Engineering and Operations Management, Detroit, MI, USA, 10–14 August 2020. [Google Scholar]

- Alam, M.Z.; Nasir, N.; Rehman, C.A. Intrapreneurship concepts for engineers: A systematic review of the literature on its theoretical foundations and agenda for future research. J. Innov. Entrep. 2020, 9, 8. [Google Scholar] [CrossRef]

- Kolus, A.; Wells, R.; Neumann, P. Production quality and human factors engineering: A systematic review and theoretical framework. Appl. Ergon. 2018, 73, 55–89. [Google Scholar] [CrossRef] [PubMed]

- Acosta Castellanos, P.M.; Queiruga-Dios, A.; Álvarez, L.G. Inclusion of Education for Sustainable Development in Environmental Engineering. A Systematic Review. Sustainability 2021, 13, 10180. [Google Scholar] [CrossRef]

- Janahi, N.A.; Durugbo, C.M.; Al-Jayyousi, O.R. Eco-innovation strategy in manufacturing: A systematic review. Clean. Eng. Technol. 2021, 5, 100343. [Google Scholar] [CrossRef]

- Brennan, R. A systematic review of Canadian engineering education research 2004–2017. In Proceedings of the Canadian Engineering Education Association (CEEA), Vancouver, BC, Canada, 3–6 June 2018. [Google Scholar]

- Denton, M.; Borrego, M.; Boklage, A. Community cultural wealth in science, technology, engineering, and mathematics education: A systematic review. J. Eng. Educ. 2020, 109, 556–580. [Google Scholar] [CrossRef]

- Karabulut-Ilgu, A.; Jaramillo Cherrez, N.; Jahren, C.T. A systematic review of research on the flipped learning method in engineering education. Br. J. Educ. Technol. 2018, 49, 398–411. [Google Scholar] [CrossRef]

- Hess, J.L.; Fore, G. A systematic literature review of US engineering ethics interventions. Sci. Eng. Ethics 2018, 24, 551–583. [Google Scholar] [CrossRef]

- Kitchenham, B.; Charters, S. Guidelines for Performing Systematic Literature Reviews in Software Engineering; EBSE Technical Report; Keele University: Staffs, UK; University of Durham: Durham, UK, 2007; pp. 1–65. [Google Scholar]

- Soldatos, J.; Kyriazis, D. (Eds.) Trusted Artificial Intelligence in Manufacturing: A Review of the Emerging Wave of Ethical and Human Centric AI Technologies for Smart Production; Now Publishers: Boston, MA, USA; Delft, The Netherlands, 2021. [Google Scholar]

- Fidel, R.; Green, M. The many faces of accessibility: Engineers’ perception of information sources. Inf. Process. Manag. 2004, 40, 563–581. [Google Scholar] [CrossRef]

- Nugroho Ignatius, H.T.; Bahsoon, R. A Conceptual Reference Model for Human as a Service Provider in Cyber Physical Systems. arXiv 2021, arXiv:2103.12563. [Google Scholar]

- Bengtsson, M.; Waidringer, J. A proposed method using GPU based SDO to optimize retail warehouses. arXiv 2021, arXiv:2110.13693. [Google Scholar]

- Ivšić, B.; Šipuš, Z.; Bartolić, J.; Babić, J. Analysis of safe ultrawideband human-robot communication in automated collaborative warehouse. In Proceedings of the 2020 14th European Conference on Antennas and Propagation (EuCAP), Copenhagen, Denmark, 15–20 March 2020. [Google Scholar]

- Dybå, T.; Dingsøyr, T.; Hanssen, G.K. Applying systematic reviews to diverse study types: An experience report. In Proceedings of the First International Symposium on Empirical Software Engineering and Measurement, Madrid, Spain, 20–21 September 2007; pp. 225–234. [Google Scholar]

- Boon, M.; Knuuttila, T. Models as epistemic tools in engineering sciences. In Philosophy of Technology and Engineering Sciences; Elsevier: Amsterdam, The Netherlands, 2009; pp. 693–726. [Google Scholar]

- Saldaña, J. The Coding Manual for Qualitative Researchers; Sage: London, UK, 2021. [Google Scholar]

- Benaquisto, L. Codes and Coding. In The SAGE Encyclopedia of Qualitative Research Methods; Given, L.M., Ed.; Sage: London, UK, 2008; pp. 85–88. [Google Scholar]

- Morgan, G.; Smircich, L. The Case for Qualitative Research. Acad. Manag. Rev. 1980, 5, 491–500. [Google Scholar] [CrossRef]

- Wodak, R. Complex texts: Analysing, understanding, explaining and interpreting meanings. Discourse Stud. 2011, 13, 623–633. [Google Scholar] [CrossRef]

- van den Hoonaard, W.C. Sensitizing Concepts. In The SAGE Encyclopedia of Qualitative Research Methods; Given, L.M., Ed.; Sage: London, UK, 2008; pp. 812–814. [Google Scholar]

- Bazeley, P.; Jackson, K. Qualitative Data Analysis with NVivo; Sage: London, UK, 2013. [Google Scholar]

- Kalinov, I.; Trinitatova, D.; Tsetserukou, D. Warevr: Virtual reality interface for supervision of autonomous robotic system aimed at warehouse stocktaking. In Proceedings of the 2021 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Melbourne, Australia, 17–20 October 2021. [Google Scholar]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Operator 5.0: A survey on enabling technologies and a framework for digital manufacturing based on extended reality. J. Mach. Eng. 2022, 22, 43–69. [Google Scholar] [CrossRef]

- Romero, D.; Stahre, J. Towards the resilient operator 5.0: The future of work in smart resilient manufacturing systems. Procedia CIRP 2021, 104, 1089–1094. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Lesch, V.; Müller, P.; Krämer, M.; Kounev, S.; Krupitzer, C. A Case Study on Optimization of Warehouses. arXiv 2021, arXiv:2112.12058. [Google Scholar]

- Shi, D.; Tong, Y.; Zhou, Z.; Xu, K.; Tan, W.; Li, H. Adaptive task planning for large-scale robotized warehouses. In Proceedings of the 2022 IEEE 38th International Conference on Data Engineering (ICDE), Kuala Lumpur, Malaysia, 9–12 May 2022. [Google Scholar]

- Engels, T.; Adan, I.; Boxma, O.; Resing, J. An exact analysis and comparison of manual picker routing heuristics. arXiv 2022, arXiv:2201.05025. [Google Scholar]

- Tsesmelis, T.; Hasan, I.; Cristani, M.; Bue, A.D.; Galasso, F. An integrated light management system with real-time light measurement and human perception. Light. Res. Technol. 2021, 53, 74–88. [Google Scholar] [CrossRef]

- Islam, M.; Ahmed, T.; Nuruddin, A.T.B.; Islam, M.; Siddique, S. Autonomous Intruder Detection Using a ROS-Based Multi-Robot System Equipped with 2D-LiDAR Sensors. In Proceedings of the 2020 IEEE International Symposium on Safety, Security, and Rescue Robotics (SSRR), Abu Dhabi, United Arab Emirates, 4–6 November 2020. [Google Scholar]

- Peyas, I.S.; Hasan, Z.; Tushar, M.R.R.; Musabbir, A.; Azni, R.M.; Siddique, S. Autonomous Warehouse Robot using Deep Q-Learning. In Proceedings of the TENCON 2021–2021 IEEE Region 10 Conference (TENCON), Auckland, New Zealand, 7–10 December 2021. [Google Scholar]

- Motoda, T.; Petit, D.; Wan, W.; Harada, K. Bimanual shelf picking planner based on collapse prediction. In Proceedings of the 2021 IEEE 17th International Conference on Automation Science and Engineering (CASE), Lyon, France, 23–27 August 2021. [Google Scholar]

- Gopalakrishnan, S.; Verma, M.; Kambhampati, S. Computing Policies That Account For The Effects Of Human Agent Uncertainty During Execution In Markov Decision Processes. arXiv 2021, arXiv:2109.07436. [Google Scholar]

- Kulkarni, A.; Sreedharan, S.; Keren, S.; Chakraborti, T.; Smith, D.E.; Kambhampati, S. Designing environments conducive to interpretable robot behavior. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 24 October 2020–24 January 2021. [Google Scholar]

- Rimélé, A.; Grangier, P.; Gamache, M.; Gendreau, M.; Rousseau, L.-M. E-commerce warehousing: Learning a storage policy. arXiv 2021, arXiv:2101.08828. [Google Scholar]

- Oliveira, G.S.; Röoning, J.; Carvalho, J.T.; Plentz, P.D. Efficient task allocation in smart warehouses with multi-delivery stations and heterogeneous robots. In Proceedings of the 2022 25th International Conference on Information Fusion (FUSION), Linköping, Sweden, 4–7 July 2022. [Google Scholar]

- Xie, L.; Li, H.; Luttmann, L. Formulating and solving integrated order batching and routing in multi-depot AGV-assisted mixed-shelves warehouses. Eur. J. Oper. Res. 2023, 307, 713–730. [Google Scholar] [CrossRef]

- Xie, L.; Li, H.; Thieme, N. From simulation to real-world robotic mobile fulfillment systems. arXiv 2018, arXiv:1810.03643. [Google Scholar]

- Ivanovic, B.; Schmerling, E.; Leung, K.; Pavone, M. Generative modeling of multimodal multi-human behavior. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018. [Google Scholar]

- Carvalho, D.; Sengupta, B. Hierarchically Structured Scheduling and Execution of Tasks in a Multi-agent Environment. In Proceedings of the Progress in Artificial Intelligence: 21st EPIA Conference on Artificial Intelligence, EPIA 2022, Lisbon, Portugal, 31 August–2 September 2022. [Google Scholar]

- Lüdtke, S.; Rueda, F.M.; Ahmed, W.; Fink, G.A.; Kirste, T. Human Activity Recognition using Attribute-Based Neural Networks and Context Information. arXiv 2021, arXiv:2111.04564. [Google Scholar]

- Petković, T.; Puljiz, D.; Marković, I.; Hein, B. Human intention estimation based on hidden Markov model motion validation for safe flexible robotized warehouses. Robot. Comput.-Integr. Manuf. 2019, 57, 182–196. [Google Scholar] [CrossRef]

- Petković, T.; Hvězda, J.; Rybecký, T.; Marković, I.; Kulich, M.; Přeučil, L.; Petrović, I. Human intention recognition for human aware planning in integrated warehouse systems. In Proceedings of the 2020 28th Mediterranean Conference on Control and Automation (MED), Saint-Raphaël, France, 15–18 September 2020. [Google Scholar]

- Petković, T.; Marković, I.; Petrović, I. Human intention recognition in flexible robotized warehouses based on markov decision processes. In Proceedings of the ROBOT 2017: Third Iberian Robotics Conference, Sevilla, Spain, 22–24 November 2018; Volume 2. [Google Scholar]

- Puljiz, D.; Gorbachev, G.; Hein, B. Implementation of augmented reality in autonomous warehouses: Challenges and opportunities. arXiv 2018, arXiv:1806.00324. [Google Scholar]

- Leon, J.F.; Gonzalez-Aguirre, D.; Nachman, L. Intuitive and Efficient Human-robot Collaboration via Real-time Approximate Bayesian Inference. arXiv 2022, arXiv:2205.08657. [Google Scholar]

- Zhang, H.; Guo, Z.; Zhang, W.; Cai, H.; Wang, C.; Yu, Y.; Li, W.; Wang, J. Layout design for intelligent warehouse by evolution with fitness approximation. IEEE Access 2019, 7, 166310–166317. [Google Scholar] [CrossRef]

- Kumabe, S.; Shiroshita, S.; Hayashi, T.; Maruyama, S. Learning General Inventory Management Policy for Large Supply Chain Network. arXiv 2022, arXiv:2204.13378. [Google Scholar]

- Ivšić, B.; Šipuš, Z.; Bartolić, J.; Babić, J. Modelling of Ultrawideband Propagation Scenarios for Safe Human-Robot Interaction in Warehouse Environment. arXiv 2019, arXiv:2001.03160. [Google Scholar]

- Han, Z.; Parrillo, J.; Wilkinson, A.; Yanco, H.A.; Williams, T. Projecting robot navigation paths: Hardware and software for projected AR. In Proceedings of the 2022 17th ACM/IEEE International Conference on Human-Robot Interaction (HRI), Sapporo, Japan, 7–10 March 2022. [Google Scholar]

- Taquet, J.; Ecorchard, G.; Přeučil, L. Real-Time Visual Localisation in a Tagged Environment. arXiv 2017, arXiv:1708.02283. [Google Scholar]

- Yu, T.; Chang, Q. Reinforcement Learning Based User-Guided Motion Planning for Human-Robot Collaboration. arXiv 2022, arXiv:2207.00492. [Google Scholar] [CrossRef]

- Gu, M.; Cosgun, A.; Chan, W.P.; Drummond, T.; Croft, E. Seeing thru walls: Visualizing mobile robots in augmented reality. In Proceedings of the 2021 30th IEEE International Conference on Robot & Human Interactive Communication (RO-MAN), Vancouver, BC, Canada, 8–12 August 2021. [Google Scholar]

- Ivsic, B.; Bartolic, J.; Sipus, Z.; Babic, J. UWB propagation characteristics of human-to-robot communication in automated collaborative warehouse. In Proceedings of the 2020 IEEE International Symposium on Antennas and Propagation and North American Radio Science Meeting, Montreal, QC, Canada, 5–10 July 2020. [Google Scholar]

- Écorchard, G.; Košnar, K.; Přeučil, L. Wearable camera-based human absolute localization in large warehouses. In Proceedings of the Twelfth International Conference on Machine Vision (ICMV 2019), Amsterdam, The Netherlands, 16–18 November 2020. [Google Scholar]

| Score | Scope of Inclusion |

|---|---|

| 1 | No inclusion |

| 2 | Human included in initial framing/as minor variable |

| 3 | Human included throughout/as full component in consideration |

| 4 | Human included as co-focus of paper or system design |

| 5 | Human included as primary focus of paper or system design |

| Stage | No. | % |

|---|---|---|

| Initial search (articles retrieved though arXiv) | 1130 | 100 |

| Screening of title (excluded if not around human/warehouse) | 211 | 18.7 |

| Screening of abstract (excluded if focussed on technical system only) | 94 | 8.3 |

| Articles eligible after duplicates removed | 92 | 8.1 |

| Articles included in systematic study | 34 | 3 |

| Articles included in the final “coding” analysis | 11 | 1 |

| Key Technologies Discussed | No. |

|---|---|

| Modelling, Management Algorithms, CPS | 7 |

| Modelling, Management Algorithms | 6 |

| Management Algorithms | 6 |

| Cyber-physical System (CPS) | 5 |

| Modelling | 5 |

| Modelling, Sensors | 3 |

| CPS, Sensors | 1 |

| Management Algorithms, CPS | 1 |

| Scale of Human Inclusion (Paper Count) | |||||

|---|---|---|---|---|---|

| Key Technology | 1 | 2 | 3 | 4 | 5 |

| CPS | 1 | ||||

| CPS, Sensors | 1 | ||||

| Cyber-physical System (CPS) | 1 | 2 | 1 | ||

| Management Algorithms | 1 | 3 | 2 | ||

| Management Algorithms, CPS | 1 | ||||

| Modelling | 1 | 1 | 2 | 1 | |

| Modelling, Management Algorithms | 2 | 3 | 1 | ||

| Modelling, Management Algorithms, CPS | 2 | 2 | 3 | ||

| Modelling, Sensors | 1 | 2 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Briken, K.; Moore, J.; Scholarios, D.; Rose, E.; Sherlock, A. Industry 5 and the Human in Human-Centric Manufacturing. Sensors 2023, 23, 6416. https://doi.org/10.3390/s23146416

Briken K, Moore J, Scholarios D, Rose E, Sherlock A. Industry 5 and the Human in Human-Centric Manufacturing. Sensors. 2023; 23(14):6416. https://doi.org/10.3390/s23146416

Chicago/Turabian StyleBriken, Kendra, Jed Moore, Dora Scholarios, Emily Rose, and Andrew Sherlock. 2023. "Industry 5 and the Human in Human-Centric Manufacturing" Sensors 23, no. 14: 6416. https://doi.org/10.3390/s23146416

APA StyleBriken, K., Moore, J., Scholarios, D., Rose, E., & Sherlock, A. (2023). Industry 5 and the Human in Human-Centric Manufacturing. Sensors, 23(14), 6416. https://doi.org/10.3390/s23146416