Cyber-Enabled Optimization of HVAC System Control in Open Space of Office Building

Abstract

1. Introduction

- Develop a co-simulation platform based on a cyber-physical system (CPS) that can simulate building physics through specialized building simulation software while externally implementing advanced control algorithms.

- Establish a quantitative method of generating simulated building occupants using heat balance models and adaptive factors and determine the impact of occupant variability on HVAC control outcomes.

- Create a data-driven thermal comfort model and evaluate the accuracy of various machine-learning algorithms.

- Optimize the overall thermal comfort of multiple occupants in open-space office buildings using the proposed thermal comfort prediction model and assess its effectiveness.

2. Materials and Methods

2.1. Overview of Methods

2.1.1. Co-Simulation

2.1.2. Control System

2.1.3. Control Strategies

2.2. Experiment Setups

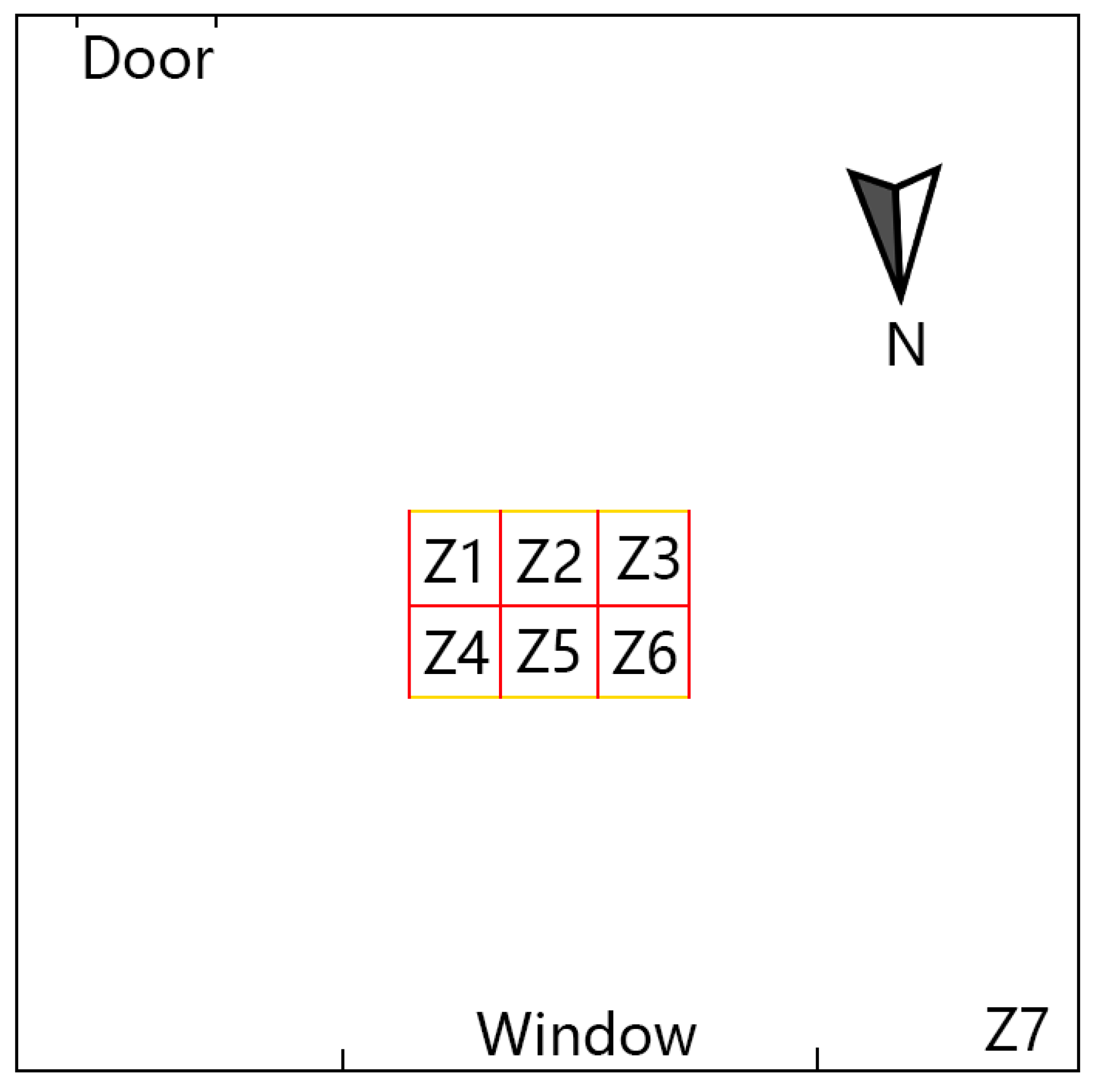

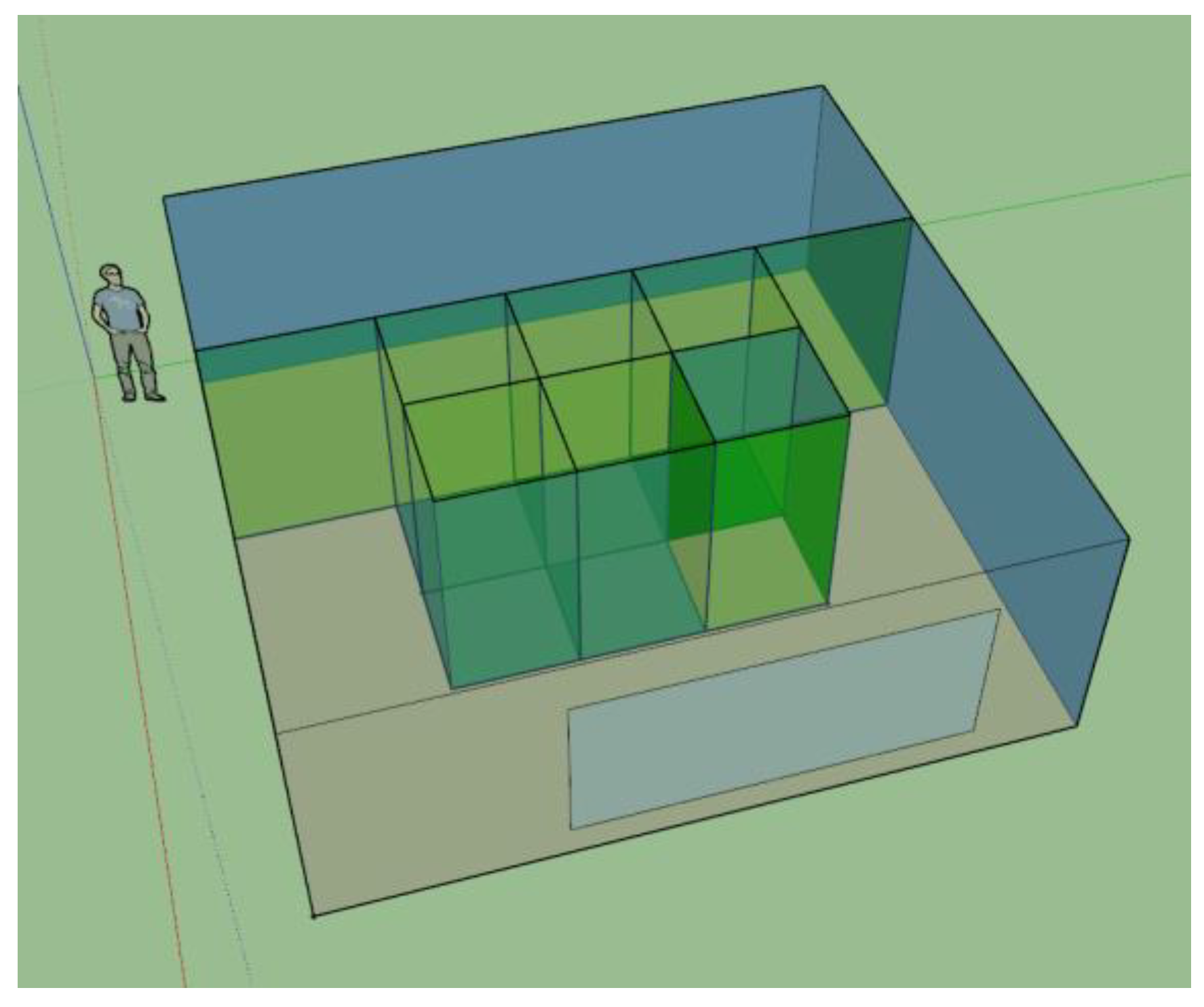

2.2.1. Building Simulation

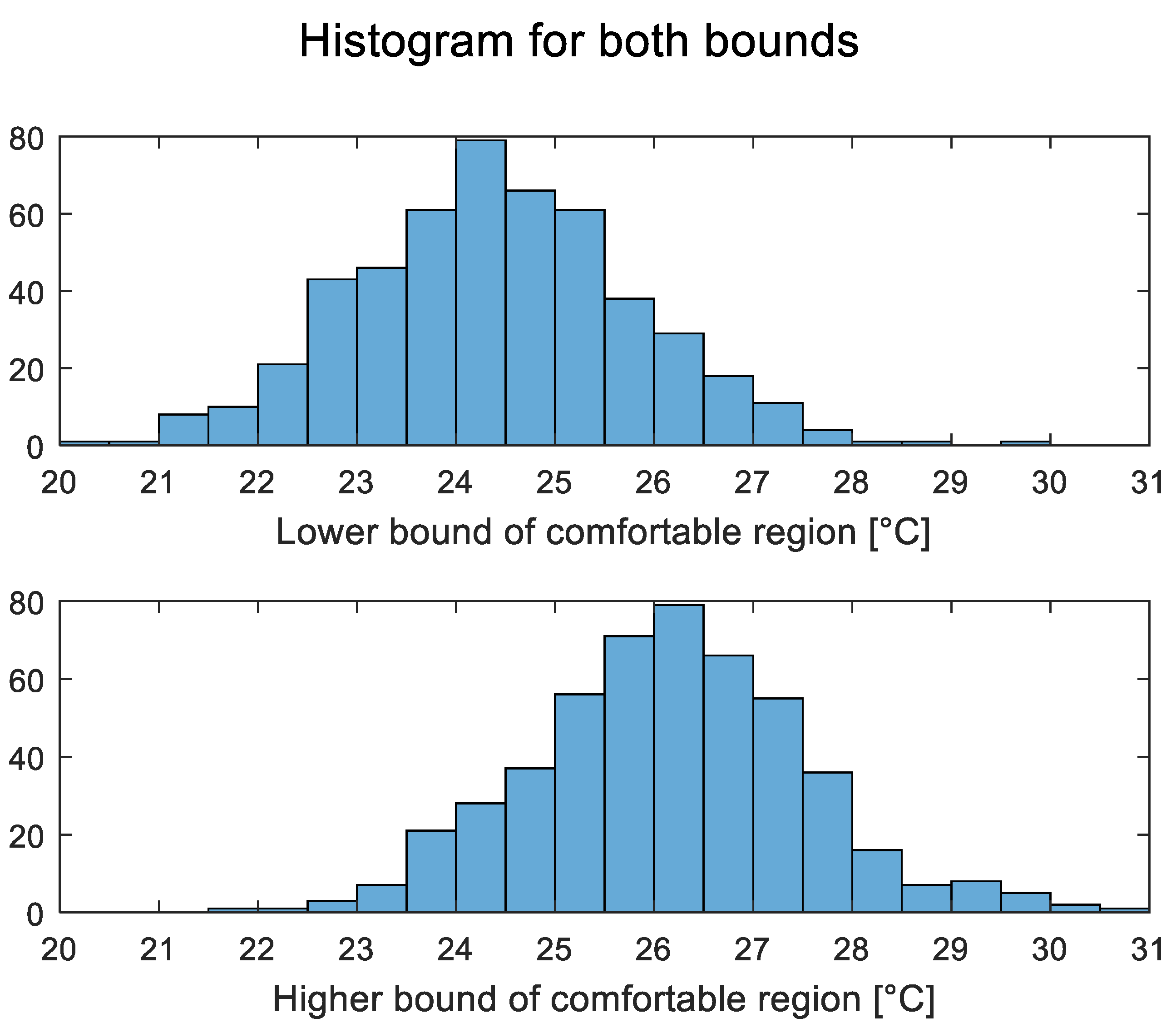

2.2.2. Occupant Simulation

2.3. Procedures

- Randomly generate six subjects to use, following the rules above. The features (gender, age, and fitness level) are uniformly chosen.

- Assign each subject to a cubicle in the simulated building.

- The building physical model is simulated in EnergyPlus, with the environmental data pipelined to MATLAB.

- The simulation period spans 6 months, from 1 May to 31 October. The corresponding weather data are provided by the EnergyPlus database, which is the average historical data for each location.

- For the probability model and machine learning model, the first few days are used as training phases. The thermal comfort level of each subject represents their “votes.”

- After the model is trained, the predicted level from the thermal comfort model is used as an input to the control algorithm. The values of the control variables at the conclusion of each cycle are pipelined back to EnergyPlus as settings for the actuators (set point, volume flow rate of each vent in each cube) for the next cycle.

- For the machine-learning-based modeling methods, the trial is repeated 500 times for each city with different random seeds.

3. Results

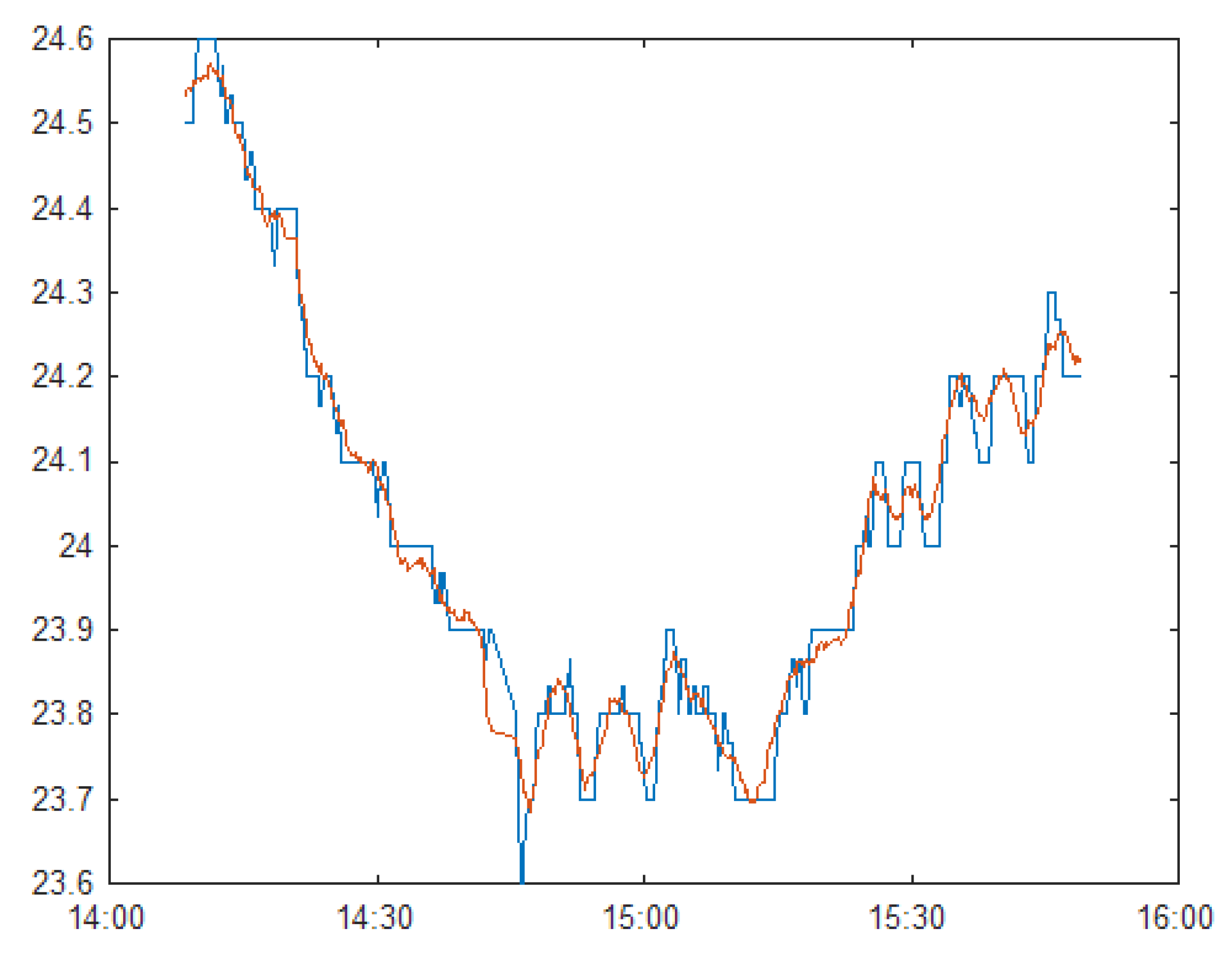

3.1. Experimental Calibration of the Simulation Model

3.2. Thermal Comfort Level

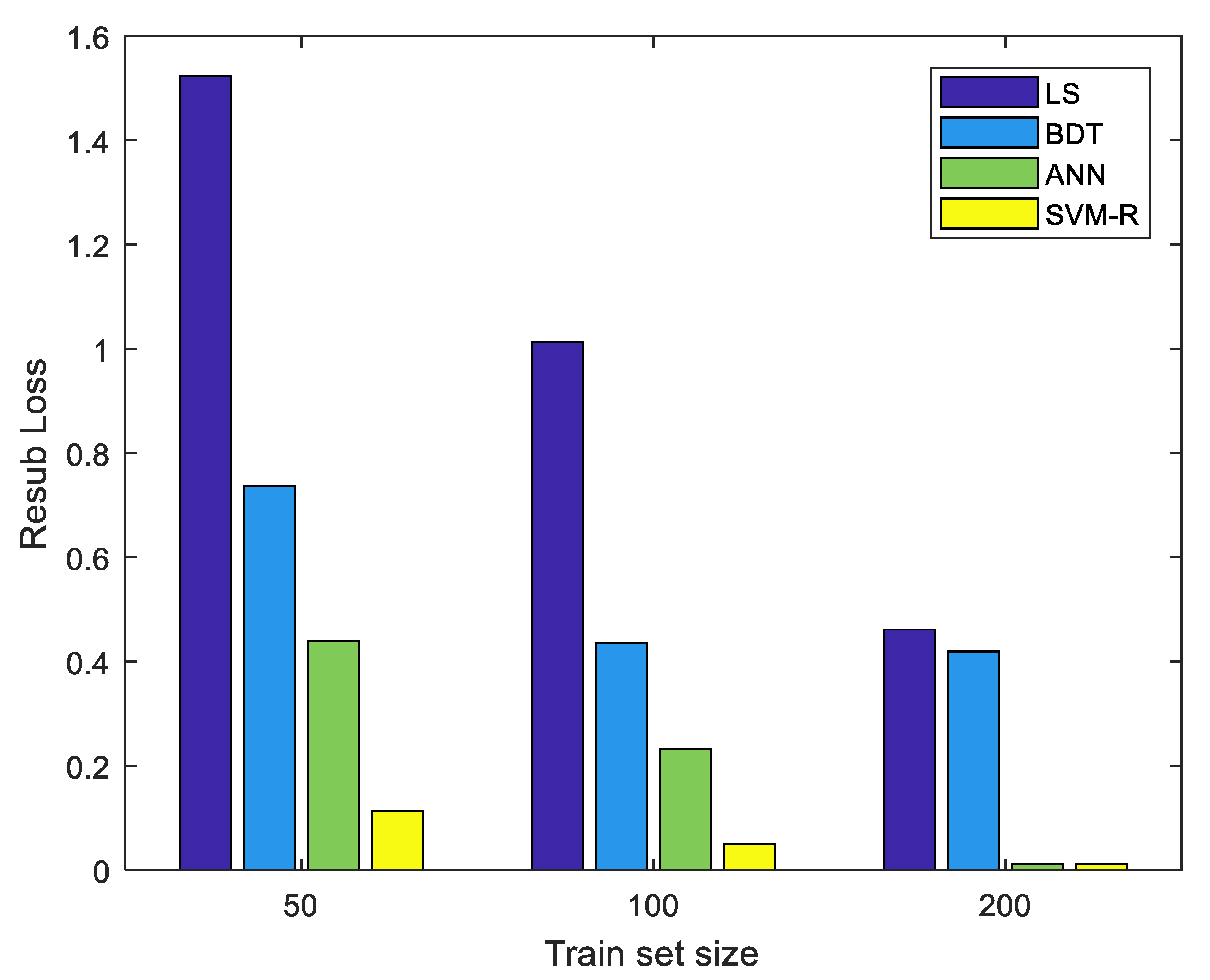

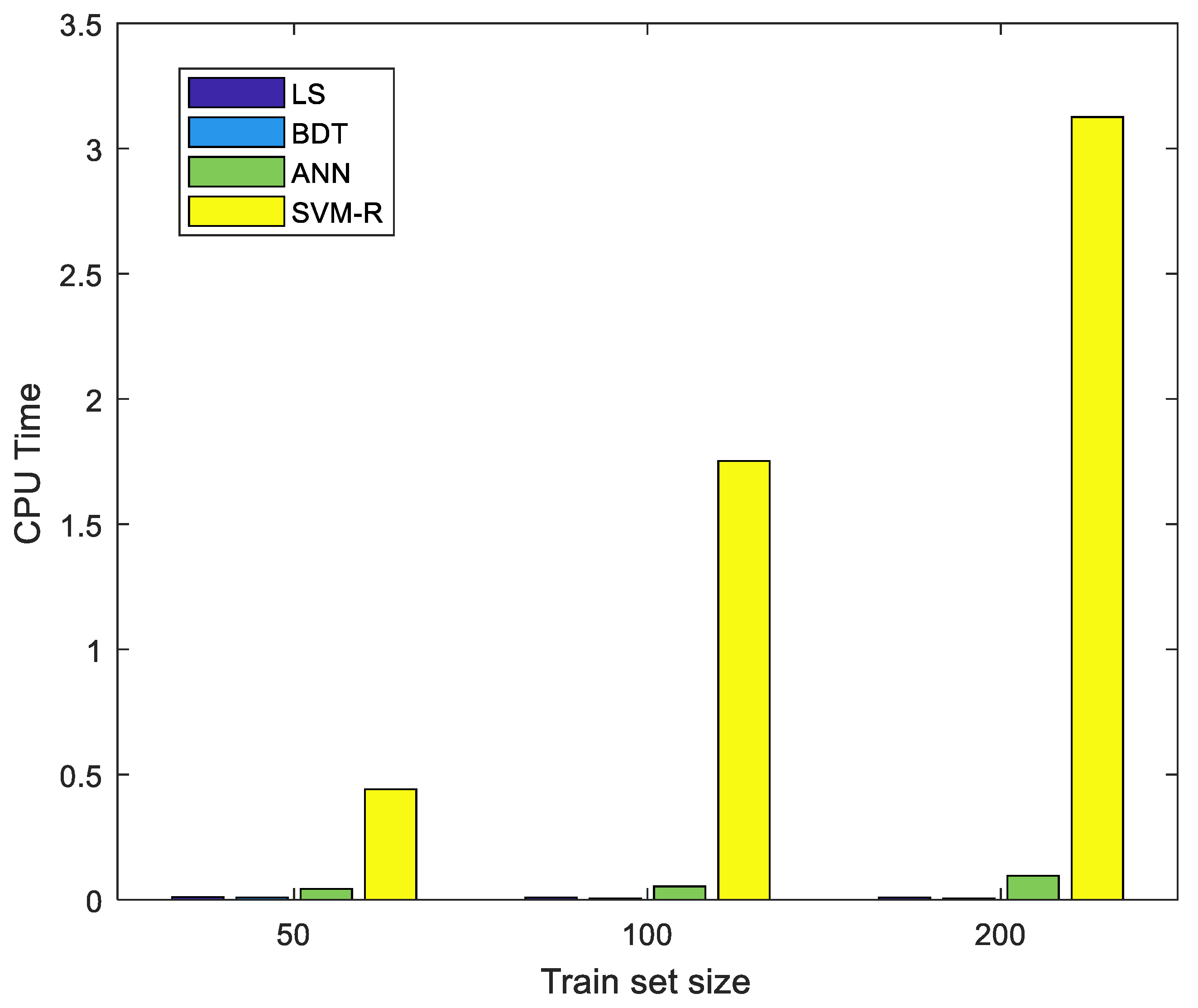

3.2.1. Training and Validation

3.2.2. Prediction Test Performance

3.2.3. Hybrid Thermal Comfort Model

3.2.4. The Influence of Noise and Delay in Data Sensing

- Distortion up to a certain percentage X is added to the temperature and humidity values before they are fed into the thermal comfort prediction model. The probability model of the distortion is a two-sided truncated normal distribution with mean equal to 0 and sigma set to X/2 (Figure 12).

- A time delay between the moment the sensing data is measured and the moment the data is used to build the thermal comfort model.

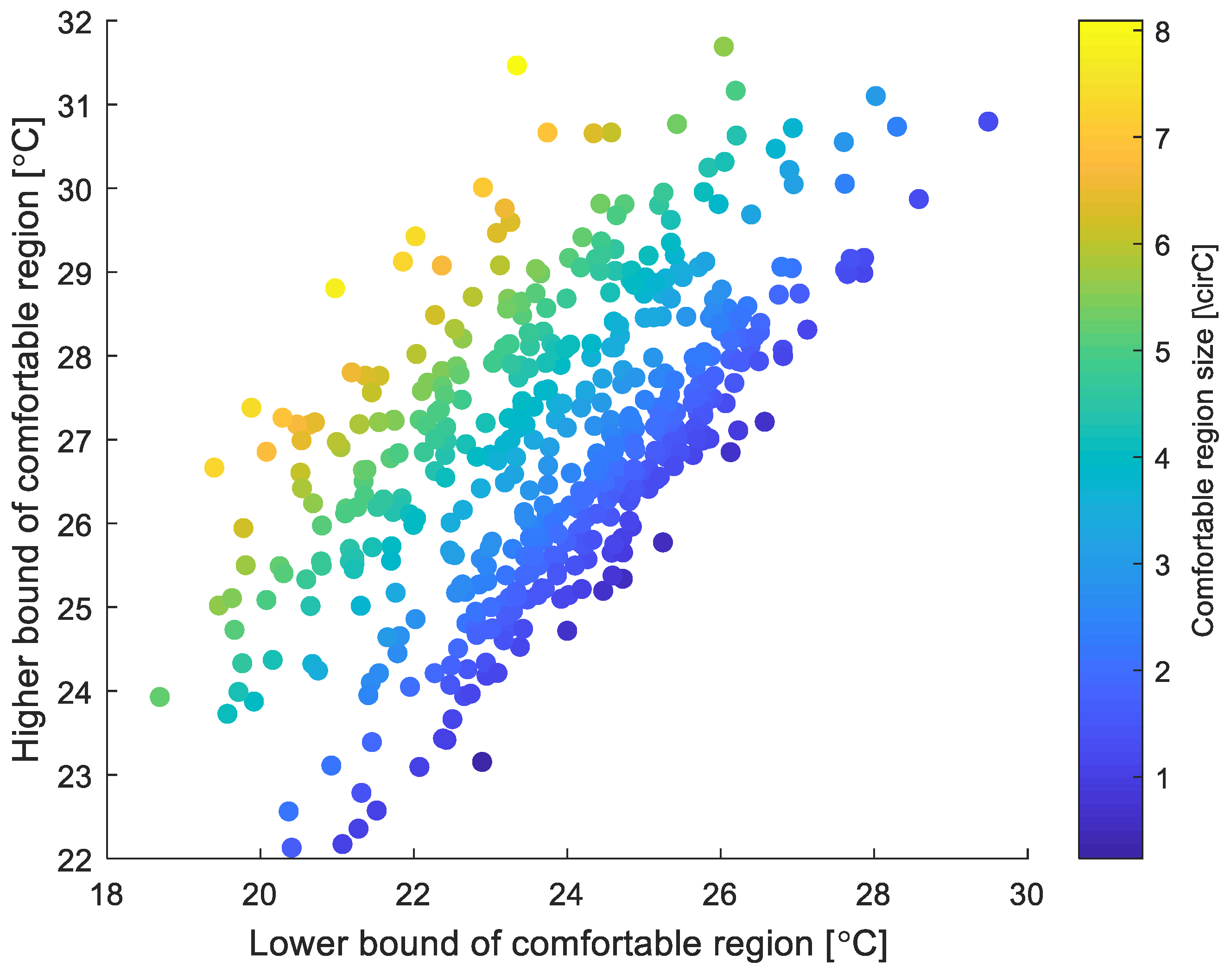

3.3. Control Performance

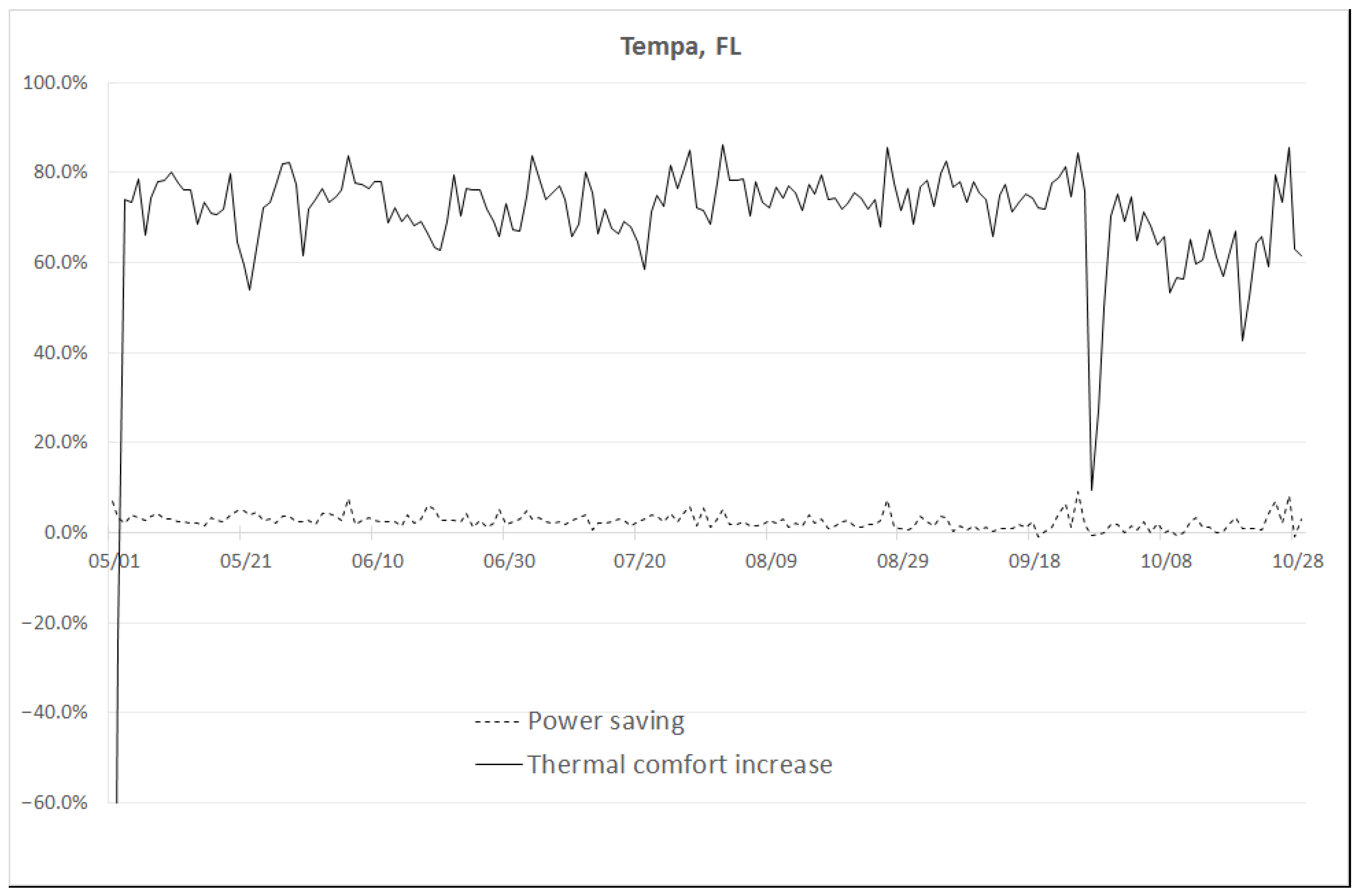

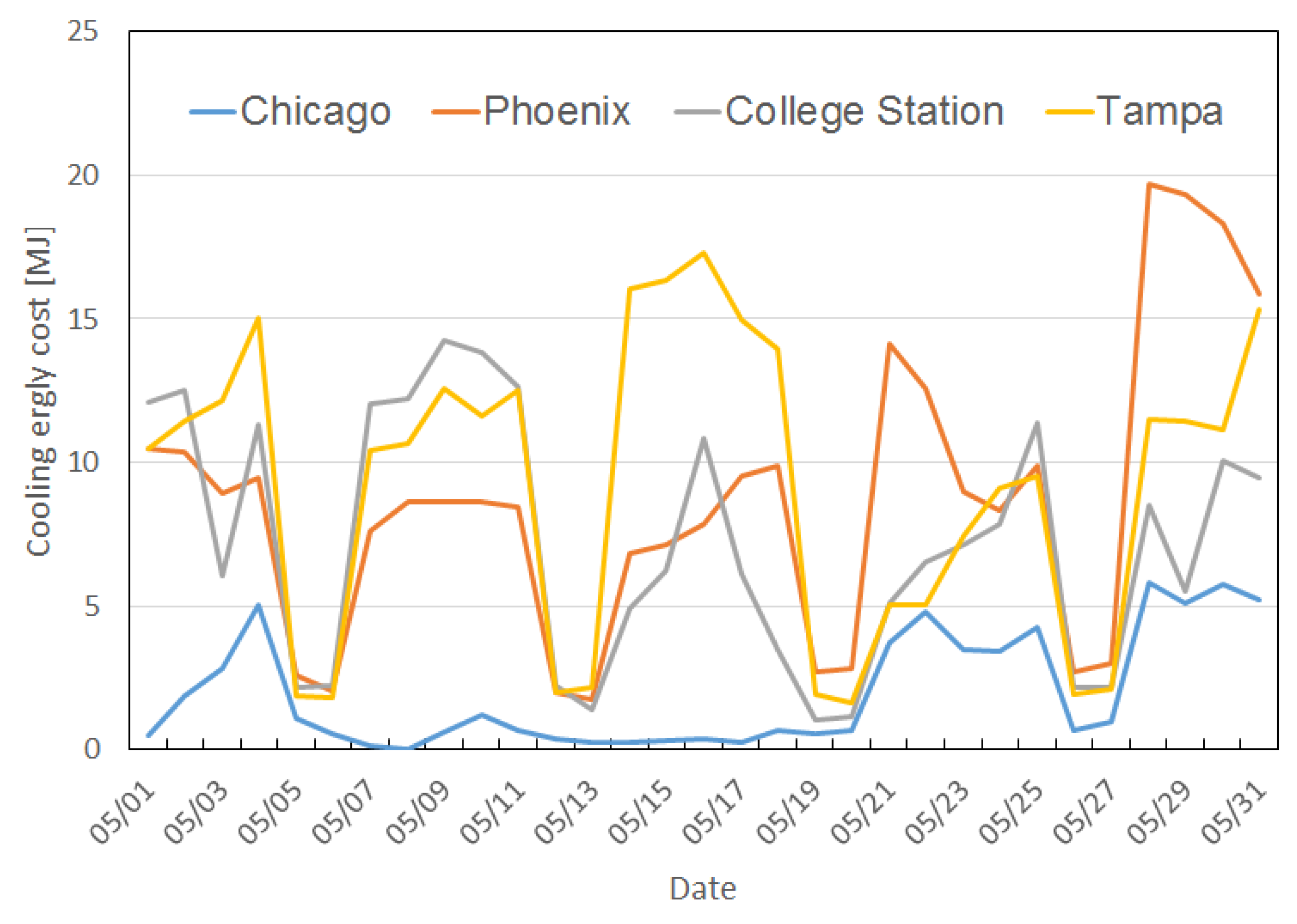

3.3.1. Overall Thermal Comfort Level and Energy Cost

3.3.2. Effect of Thermal Comfort Models

3.3.3. Variances in Zones and Subjects

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Siddharth, V.; Ramakrishna, P.; Geetha, T.; Sivasubramaniam, A. Automatic generation of energy conservation measures in buildings using genetic algorithms. Energy Build. 2011, 43, 2718–2726. [Google Scholar] [CrossRef]

- Crawley, D.B.; Lawrie, L.K.; Winkelmann, F.C.; Buhl, W.; Huang, Y.; Pedersen, C.O.; Strand, R.K.; Liesen, R.J.; Fisher, D.E.; Witte, M.J.; et al. EnergyPlus: Creating a new-generation building energy simulation program. Energy Build. 2001, 33, 319–331. [Google Scholar] [CrossRef]

- Klein, S.A. TRNSYS, a Transient System Simulation Program; Solar Energy Laboratory, University of Wisconsin-Madison: Madison, WI, USA, 1979. [Google Scholar]

- Fanger, P.O. Thermal Comfort. Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970. [Google Scholar]

- Boregowda, S.; Tiwari, S. Numerical investigation of thermal comfort using a finite element human thermal model. In Proceedings of the 8th AIAA/ASME Joint Thermophysics and Heat Transfer Conference, St. Louis, MO, USA, 24–26 June 2002; p. 2877. [Google Scholar]

- Al-Mutawa, N.; Chakroun, W.; Hosni, M.H. Evaluation of Human Thermal Comfort in Offices in Kuwait and Assessment of the Applicability of the Standard PMV Model. In Proceedings of the HT-FED04 2004 ASME Heat Transfer Summer Conference, Charlotte, NC, USA, 11–15 July 2004; Volume 46903, pp. 999–1009. [Google Scholar]

- Sobia Farooq, F.B. Evaluation of Thermal Comfort and Energy Demands in University Classrooms. In Proceedings of the ASME 2009 Heat Transfer Summer Conference HT2009, San Francisco, CA, USA, 19–23 July 2009; pp. 1–7. [Google Scholar]

- Katramiz, E.; Ghaddar, N.; Ghali, K. Effective Mixed-Mode Ventilation System with Intermittent Personalized Ventilation for Improving Thermal Comfort in an Office Space. In Proceedings of the Heat Transfer Summer Conference, Online, 13–15 July 2020; American Society of Mechanical Engineers: New York, NY, USA, 2020; Volume 83709, p. V001T04A002. [Google Scholar]

- Mishra, A.K.; Kramer, R.P.; Loomans, M.G.L.C.; Schellen, H.L. Development of thermal discernment among visitors: Results from a field study in the Hermitage Amsterdam. Build. Environ. 2016, 105, 40–49. [Google Scholar] [CrossRef]

- Chung, T.; Tong, W. Thermal comfort study of young Chinese people in Hong Kong. Build. Environ. 1990, 25, 317–328. [Google Scholar] [CrossRef]

- Tanabe, S. Thermal comfort requirement during the summer season in Japan. ASHRAE Trans. 1987, 93, 564–577. [Google Scholar]

- Fanger, P.O. Assessment of man’s thermal comfort in practice. Br. J. Ind. Med. 1973, 30, 313–324. [Google Scholar] [CrossRef] [PubMed]

- Karyono, T.H. Report on thermal comfort and building energy studies in Jakarta—Indonesia. Build. Environ. 2000, 35, 77–90. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, Z.; Lin, B.; Mumovic, D. Development of a health data-driven model for a thermal comfort study. Build. Environ. 2020, 177, 106874. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhao, Y.; Wang, F.; Wang, J.; Jiang, Y.; Zhang, F. A data-driven method to describe the personalized dynamic thermal comfort in ordinary office environment: From model to application. Build. Environ. 2014, 72, 309–318. [Google Scholar] [CrossRef]

- Bermejo, P.; Redondo, L.; de la Ossa, L.; Rodríguez, D.; Flores, J.; Urea, C.; Gámez, J.A.; Puerta, J.M. Design and simulation of a thermal comfort adaptive system based on fuzzy logic and on-line learning. Build. Environ. 2012, 49, 367–379. [Google Scholar] [CrossRef]

- Ferreira, P.; Ruano, A.; Silva, S.; Conceição, E. Neural networks based predictive control for thermal comfort and energy savings in public buildings. Build. Environ. 2012, 55, 238–251. [Google Scholar] [CrossRef]

- Shin, S.; Baek, K.; So, H. Rapid monitoring of indoor air quality for efficient HVAC systems using fully convolutional network deep learning model. Build. Environ. 2023, 234, 110191. [Google Scholar] [CrossRef]

- Navares, R.; Aznarte, J.L. Predicting air quality with deep learning LSTM: Towards comprehensive models. Ecol. Inform. 2020, 55, 101019. [Google Scholar] [CrossRef]

- Li, Q.; Meng, Q.; Cai, J.; Yoshino, H.; Mochida, A. Applying support vector machine to predict hourly cooling load in the building. Appl. Energy 2009, 86, 2249–2256. [Google Scholar] [CrossRef]

- Liang, J.; Du, R. Model-based fault detection and diagnosis of HVAC systems using support vector machine method. Int. J. Refrig. 2007, 30, 1104–1114. [Google Scholar] [CrossRef]

- Kumar, M.; Kar, I.N. Non-linear HVAC computations using least square support vector machines. Energy Convers. Manag. 2009, 50, 1411–1418. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, L.; Zhang, J.; Niu, B.; Luo, M.; Zhou, G.; Zhang, X. Data-driven thermal comfort model via support vector machine algorithms: Insights from ASHRAE RP-884 database. Build. Environ. 2020, 211, 109795. [Google Scholar] [CrossRef]

- Wetter, M. Building Control Virtual Testbed—Bcvtb; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2009. [Google Scholar]

- Bernal, W.; Behl, M.; Nghiem, T.X.; Mangharam, R. MLE+: A tool for integrated design and deployment of energy efficient building controls. In Proceedings of the Fourth ACM Workshop on Embedded Sensing Systems for Energy-Efficiency in Buildings; ACM: New York, NY, USA, 2012. [Google Scholar]

- Wilcox, S.; Marion, W. Users Manual for TMY3 Data Sets; National Renewable Energy Laboratory Golden: Golden, CO, USA, 2008. [Google Scholar]

- Nevins, R.G. Temperature-humidity chart for thermal comfort of seated persons. Ashrae Trans. 1966, 72, 282–291. [Google Scholar]

- Collins, K.J.; Exton-Smith, A.N.; Doré, C. Urban hypothermia: Preferred temperature and thermal perception in old age. Br. Med. J. (Clin. Res. Ed.) 1981, 282, 175–177. [Google Scholar] [CrossRef] [PubMed]

| Thermal Comfort Model | Inputs | Available Control Algorithms |

|---|---|---|

| Traditional | T, RH | On/Off |

| Probability-based | T, RH | On/Off, PID, Fuzzy |

| Machine-learning-based | T, RH, Tmrt, Tcool air, vair | On/Off, PID, Predictive |

| Construction | Material | Major Thermal Properties |

|---|---|---|

| Wall | R13 Layer | Thermal resistance: 2.291 m2⋅K/W |

| Roof | R31 Layer | Thermal resistance: 5.456 m2⋅K/W |

| Floor | HW Concrete | Conductivity: 1.729577 W/(m⋅K) Specific heat: 836.8 J/(kg⋅K) |

| Window | Glass (6 mm) | Conductivity: 0.9 W/(m⋅K) Transmittance: 0.81 |

| City Name | Location | Elevation (m) | Data Sources |

|---|---|---|---|

| Phoenix, AZ | N33°25′, W112°1′ | +339 | WMO Station 722780 |

| Chicago, IL | N41°58′, W 87°55′ | +201 | WMO Station 725300 |

| College Station, TX | N30°34′, W 96°22′ | +96 | WMO Station 722445 |

| Tampa, FL | N27°58′, W 82°31′ | +6 | WMO Station 722110 |

| Gender | |

|---|---|

| Female | −0.5 ± 1.3 |

| Male | 0.4 ± 1.4 |

| Fitness (BMI) | |

|---|---|

| Thin (<20) | 0.3 |

| Normal (20–24) | 0 |

| Fat (>24) | −0.5 |

| Parameter | Unit | Lower Limit | Upper Limit |

|---|---|---|---|

| Room temperature | °C | 20 | 28 |

| Mean radiant temperature | °C | 20 | 28 |

| Relative humidity | (n/a) | 10% | 90% |

| Air speed | m/s | 0 | 0.3 |

| Wall Resistance (m2⋅K/W) | Correlation R2 | ||

|---|---|---|---|

| Average | Zone 4 | Zone 6 | |

| 0.01 | 0.67 | 0.57 | 0.62 |

| 0.043 (best) | 0.87 | 0.86 | 0.90 |

| 0.1 | 0.74 | 0.79 | 0.69 |

| Method | Abbreviation | Parameters |

|---|---|---|

| Linear (least squares) | LS | L2 regularization applied Regularization: ridge |

| Binary decision tree | BDT | Min leaf size: 2 Max number splits: 30 |

| Artificial neural network | ANN | Backpropagation algorithm: Levenberg–Marquardt Hidden layer size: 10 Validation dataset ratio: 20% |

| Support vector machine regression | SVM | Kernel function: Gaussian Kernel scale: 6.68 Box constraint: Inf Epsilon: 0.008 Standardized Outlier fraction: 20% |

| Train Set Size | Least Squares | Binary Decision Tree | Artificial Neural Network | Support Vector Machine |

|---|---|---|---|---|

| 50 | 0.7947 | 0.9092 | 0.9715 | 0.9897 |

| 100 | 0.8924 | 0.9366 | 0.9913 | 0.9970 |

| 200 | 0.9309 | 0.9499 | 0.9983 | 0.9987 |

| Training Dataset Size | Least Squares | Binary Decision Tree | ANN | SVM | ||||

|---|---|---|---|---|---|---|---|---|

| MSE | R2 | MSE | R2 | MSE | R2 | MSE | R2 | |

| 50 | 1.7189 | 0.7700 | 4.1075 | 0.6330 | 0.8143 | 0.9117 | 0.4321 | 0.9643 |

| 100 | 1.1663 | 0.8852 | 1.7640 | 0.7233 | 0.4622 | 0.9773 | 0.2574 | 0.9815 |

| 200 | 0.4868 | 0.9267 | 1.3835 | 0.7896 | 0.0289 | 0.9962 | 0.0592 | 0.9935 |

| Period | Static PMV Model | SVM Only | ANN Only | Hybrid (Proposed) |

|---|---|---|---|---|

| First day | 0.482 | 0.928 | 1.708 | 0.484 |

| Second day | 0.466 | 0.332 | 0.606 | 0.336 |

| Day 3–5 | 0.462 | 0.200 | 0.366 | 0.202 |

| First work week average | 0.47 | 0.278 | 0.468 | 0.244 |

| Maximum Noise Percentage | Accuracy Drop in R2 | Accuracy Drop in MSE | Significant? (p < 0.01) |

|---|---|---|---|

| 5% | 1.22% | 1.01% | No |

| 10% | 2.02% | 2.49% | Yes |

| 15% | 4.88% | 4.10% | Yes |

| 20% | 15.50% | 19.00% | Yes |

| Time Delay (Min) | Reduction in Training R2 | Reduction in Training MSE | Significant? (p < 0.05) | Accuracy Drop in Temperature Reading | Accuracy Drop in Humidity Reading |

|---|---|---|---|---|---|

| 6 | 3.03% | 3.65% | Yes | 2.88% | 3.14% |

| 12 | 4.03% | 3.80% | Yes | 3.20% | 3.56% |

| 18 | 4.11% | 3.99% | Yes | 3.70% | 3.88% |

| Batch | Thermal Comfort Model | Control Strategy | City | Trial (Total) | Note |

|---|---|---|---|---|---|

| 1–4 | (T and RH) | Rule-based | 4 cities | 4 | Conventional |

| 5–8 | (T and RH) | Fuzzy-PID | 4 cities | 4 | Probability-based |

| 9–12 | SVM-only | Fuzzy-PID | 4 cities | 2000 | |

| 13–16 | Hybrid | Fuzzy-PID | 4 cities | 2000 | Proposed |

| City | Month | Monthly Mean Absolute Thermal Comfort Level | Monthly Cooling Energy Cost (MJ) | ||||

|---|---|---|---|---|---|---|---|

| Baseline | Proposed | Reduction | Baseline | Proposed | Reduction | ||

| Chicago, IL | May | 0.235 | 0.203 | 13.84% | 64.628 | 61.624 | 4.65% |

| June | 0.236 | 0.081 | 65.79% | 155.881 | 149.508 | 4.09% | |

| July | 0.194 | 0.066 | 65.74% | 266.506 | 259.994 | 2.44% | |

| Aug. | 0.230 | 0.073 | 68.40% | 164.487 | 158.317 | 3.75% | |

| Sept. | 0.301 | 0.140 | 53.70% | 88.348 | 85.282 | 3.47% | |

| Oct. | 0.460 | 0.375 | 18.46% | 19.718 | 17.217 | 12.69% | |

| Ave/Sum | 0.276 | 0.156 | 43.41% | 760.568 | 732.942 | 3.63% | |

| Phoenix, AZ | May | 0.181 | 0.102 | 43.63% | 276.985 | 269.030 | 2.87% |

| June | 0.158 | 0.069 | 56.12% | 487.225 | 480.375 | 1.41% | |

| July | 0.154 | 0.074 | 51.66% | 525.389 | 523.556 | 0.35% | |

| Aug. | 0.169 | 0.080 | 52.44% | 484.505 | 481.204 | 0.68% | |

| Sept. | 0.224 | 0.105 | 52.98% | 315.150 | 314.920 | 0.07% | |

| Oct. | 0.272 | 0.132 | 51.64% | 173.904 | 171.283 | 1.51% | |

| Ave/Sum | 0.193 | 0.094 | 51.37% | 2264.158 | 2241.368 | 1.01% | |

| College Station, TX | May | 0.199 | 0.073 | 63.21% | 232.391 | 224.570 | 3.37% |

| June | 0.221 | 0.050 | 77.56% | 296.316 | 284.955 | 3.83% | |

| July | 0.149 | 0.043 | 70.85% | 425.060 | 416.939 | 1.91% | |

| Aug. | 0.199 | 0.051 | 74.56% | 394.577 | 387.364 | 1.83% | |

| Sept. | 0.238 | 0.071 | 70.13% | 197.880 | 190.579 | 3.69% | |

| Oct. | 0.368 | 0.129 | 64.92% | 136.967 | 129.460 | 5.48% | |

| Ave/Sum | 0.229 | 0.069 | 69.65% | 1684.191 | 1634.867 | 2.93% | |

| Tampa, FL | May | 0.180 | 0.069 | 61.56% | 295.717 | 286.487 | 3.12% |

| June | 0.173 | 0.047 | 72.94% | 328.932 | 318.950 | 3.03% | |

| July | 0.173 | 0.046 | 73.62% | 401.569 | 390.060 | 2.87% | |

| Aug. | 0.177 | 0.043 | 75.86% | 382.716 | 374.504 | 2.15% | |

| Sept. | 0.200 | 0.057 | 71.57% | 305.316 | 301.425 | 1.27% | |

| Oct. | 0.230 | 0.082 | 64.47% | 199.123 | 195.800 | 1.67% | |

| Ave/Sum | 0.189 | 0.057 | 69.73% | 1914.373 | 1868.226 | 2.41% | |

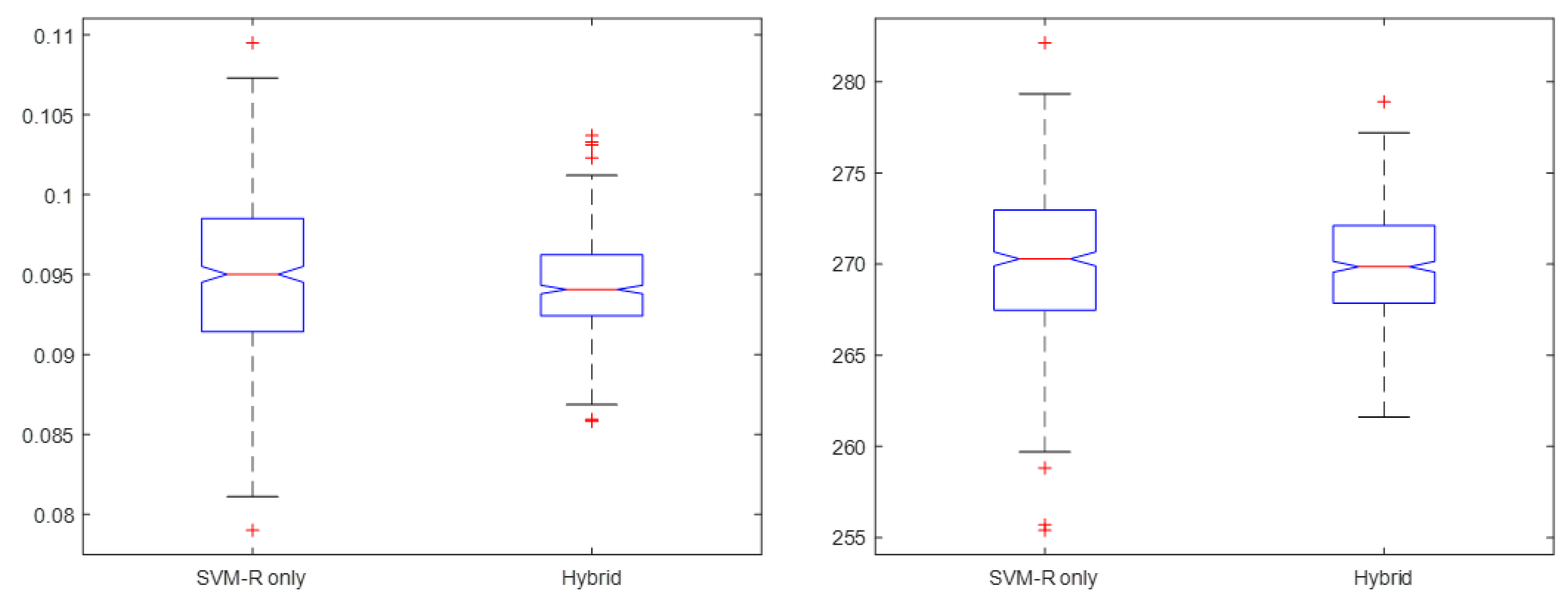

| Metric | Item | Baseline (Conventional Control) | Probability-Based | ML: SVM-R Only | ML: Hybrid |

|---|---|---|---|---|---|

| Comfort level | Mean | 0.2217 | 0.1451 | 0.0949 | 0.0943 |

| SD | (N/A) | (N/A) | 0.0053 | 0.0030 | |

| Monthly cooling energy cost (MJ) | Mean | 275.970 | 268.035 | 270.178 | 269.987 |

| SD | (N/A) | (N/A) | 4.001 | 3.086 |

| Metric (between Groups) | Df | F-Value | p-Value | Significant? |

|---|---|---|---|---|

| Average comfort level | 1 | 5.84 | 0.0159 | Yes |

| Energy cost | 1 | 0.69 | 0.4054 | No |

| No. | Zone | Gender | BMI | Region | Age |

|---|---|---|---|---|---|

| 1 | 1 | Male | High | United States | Young |

| 2 | 2 | Male | Low | Elder | |

| 3 | 3 | Male | Low | Young | |

| 4 | 4 | Female | High | Elder | |

| 5 | 5 | Female | High | Young | |

| 6 | 6 | Female | Low | Elder |

| No. | Mean No. of Manual Actions Taken during Training Period | Thermal Comfort Level in Training | Thermal Comfort Level after Training | Reduction |

|---|---|---|---|---|

| 1 | 5.9 | 0.102 | 0.060 | 41.6% |

| 2 | 10.3 | 0.130 | 0.086 | 33.8% |

| 3 | 8.1 | 0.120 | 0.071 | 40.8% |

| 4 | 10.1 | 0.150 | 0.104 | 30.7% |

| 5 | 13.5 | 0.193 | 0.084 | 56.5% |

| 6 | 20.3 | 0.258 | 0.161 | 37.6% |

| Average | 11.4 | 0.159 | 0.094 | 40.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, B.; Hsieh, S.-J. Cyber-Enabled Optimization of HVAC System Control in Open Space of Office Building. Sensors 2023, 23, 4857. https://doi.org/10.3390/s23104857

Peng B, Hsieh S-J. Cyber-Enabled Optimization of HVAC System Control in Open Space of Office Building. Sensors. 2023; 23(10):4857. https://doi.org/10.3390/s23104857

Chicago/Turabian StylePeng, Bo, and Sheng-Jen Hsieh. 2023. "Cyber-Enabled Optimization of HVAC System Control in Open Space of Office Building" Sensors 23, no. 10: 4857. https://doi.org/10.3390/s23104857

APA StylePeng, B., & Hsieh, S.-J. (2023). Cyber-Enabled Optimization of HVAC System Control in Open Space of Office Building. Sensors, 23(10), 4857. https://doi.org/10.3390/s23104857