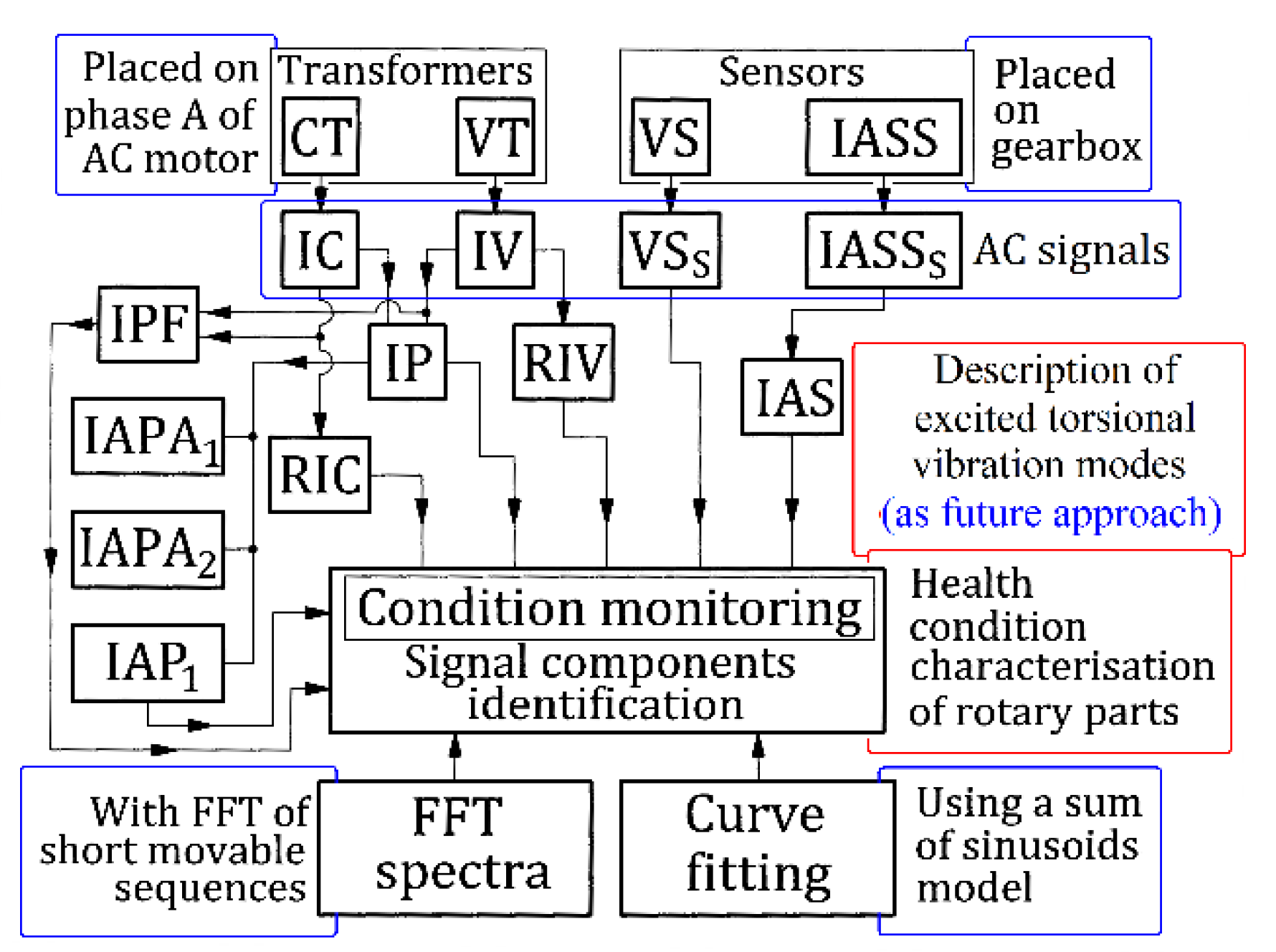

4.1. Some Resources of Signals Processing in Frequency Domain Revealed by Fast Fourier Transform

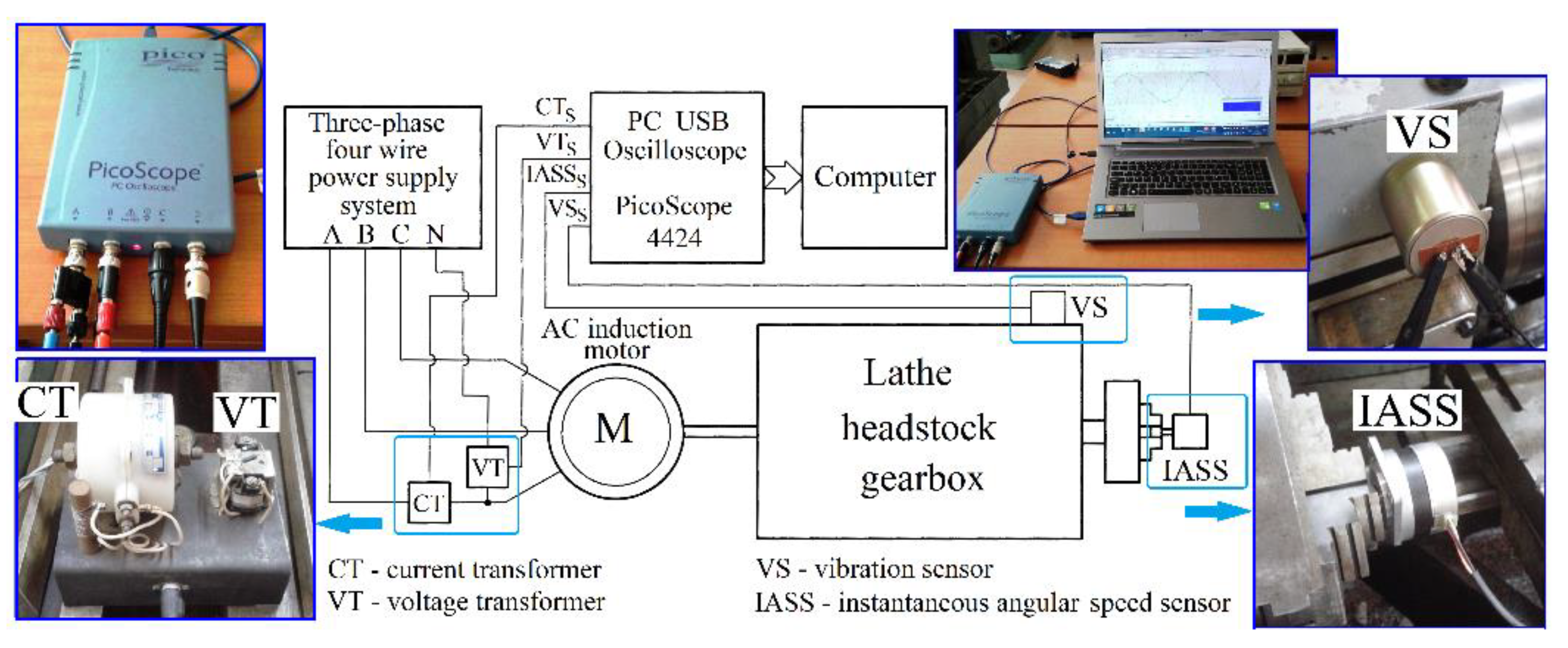

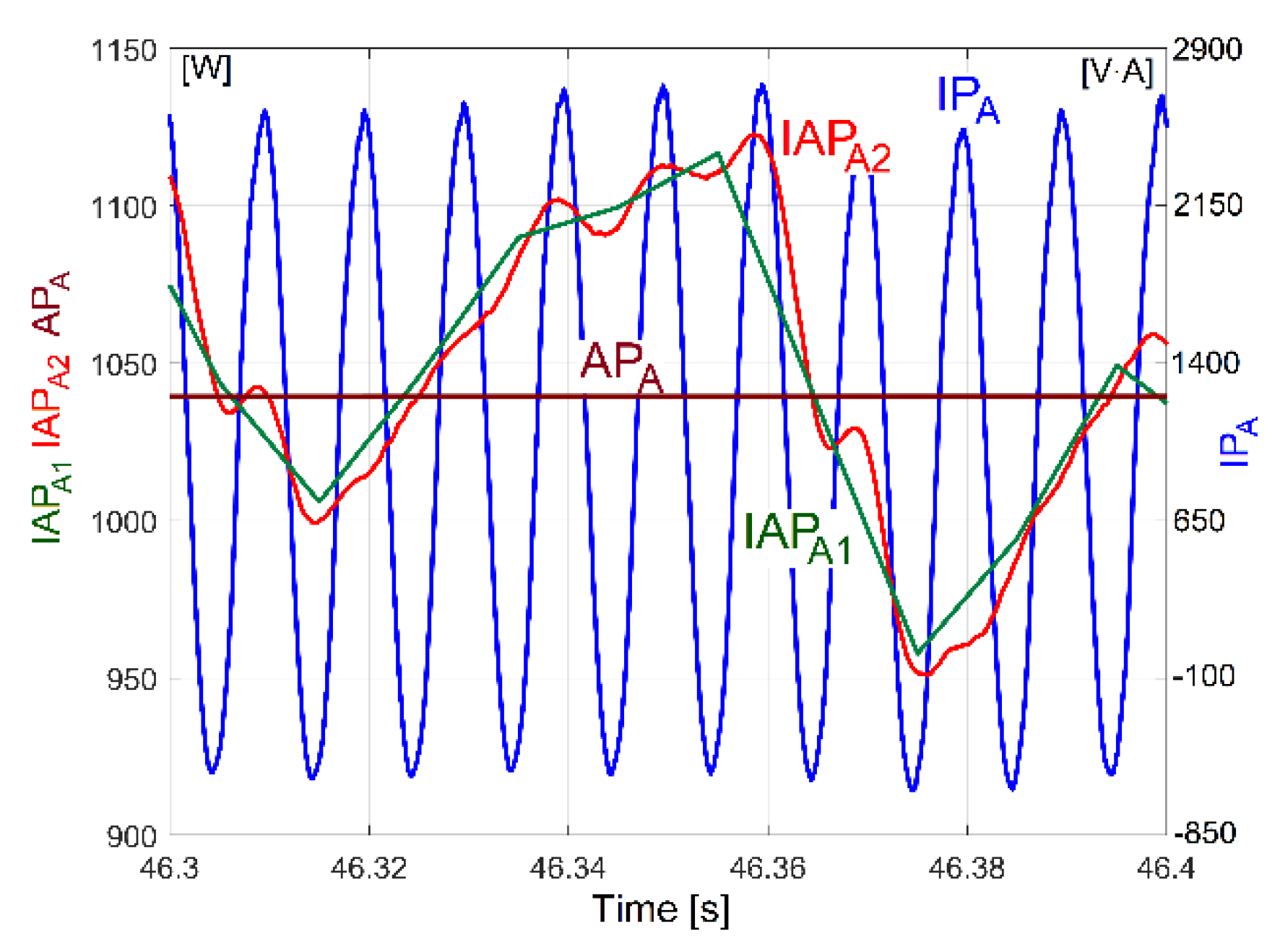

For gearbox condition monitoring purposes, it is appropriate to use the evolution of the variable parts of IP

A, IAP

A1 or IAP

A2, which are supposed to contain periodical components. The easiest way to explore these variable parts is to use the evolutions in the frequency domain obtained by the fast Fourier transform (FFT) with Matlab.

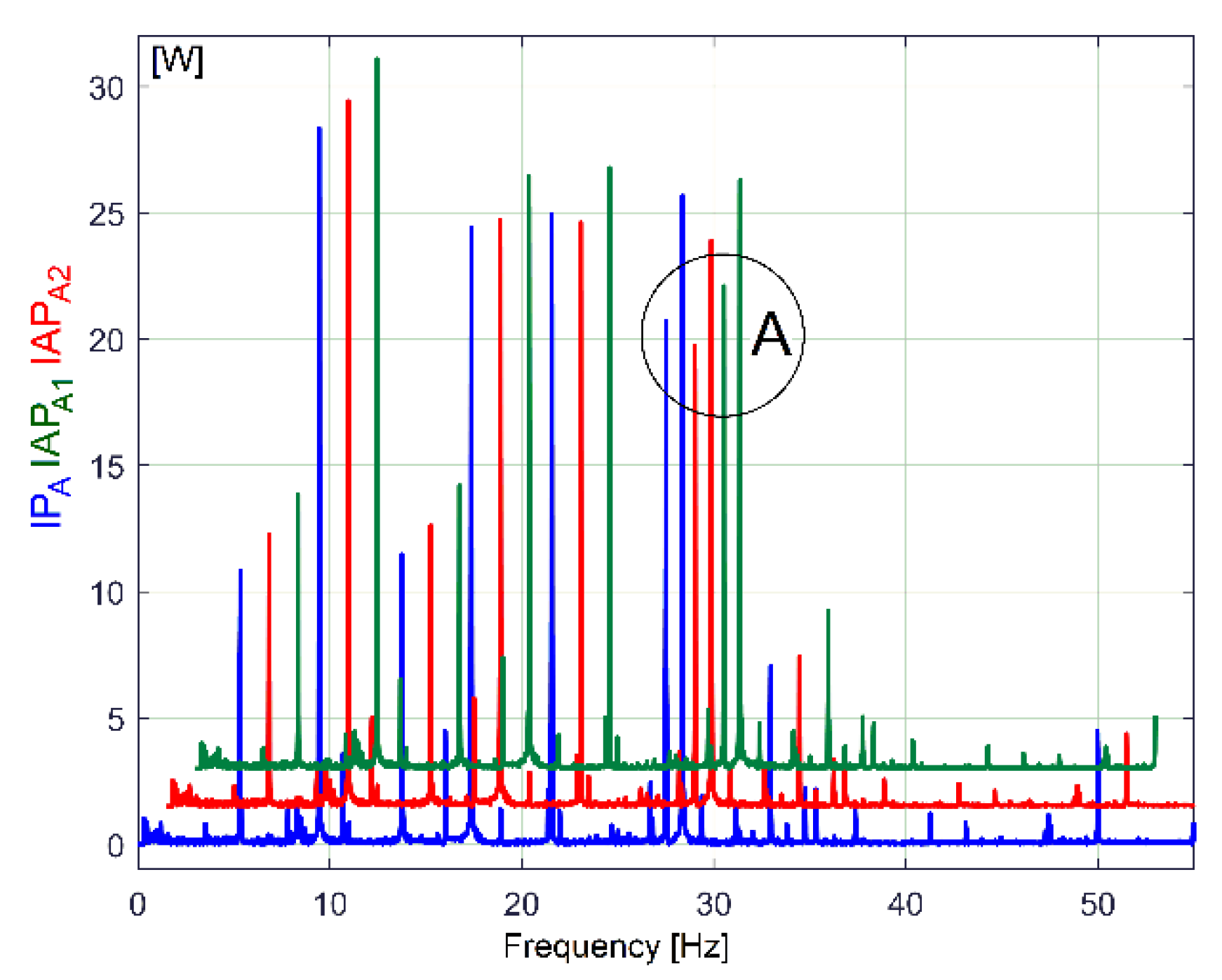

Figure 5 describes a part of the FFT spectrum evolution (0 ÷ 55 Hz) of IP

A, IAP

A1 and IAP

A2 during the same experiment as before (the lathe headstock gearbox running idle), with IAP

A2 (IAP

A1) being shifted vertically by 1.5 W (3 W) and horizontally by 1.5 Hz (3 Hz), respectively, in comparison with IP

A (in order to avoid the graphical overlap).

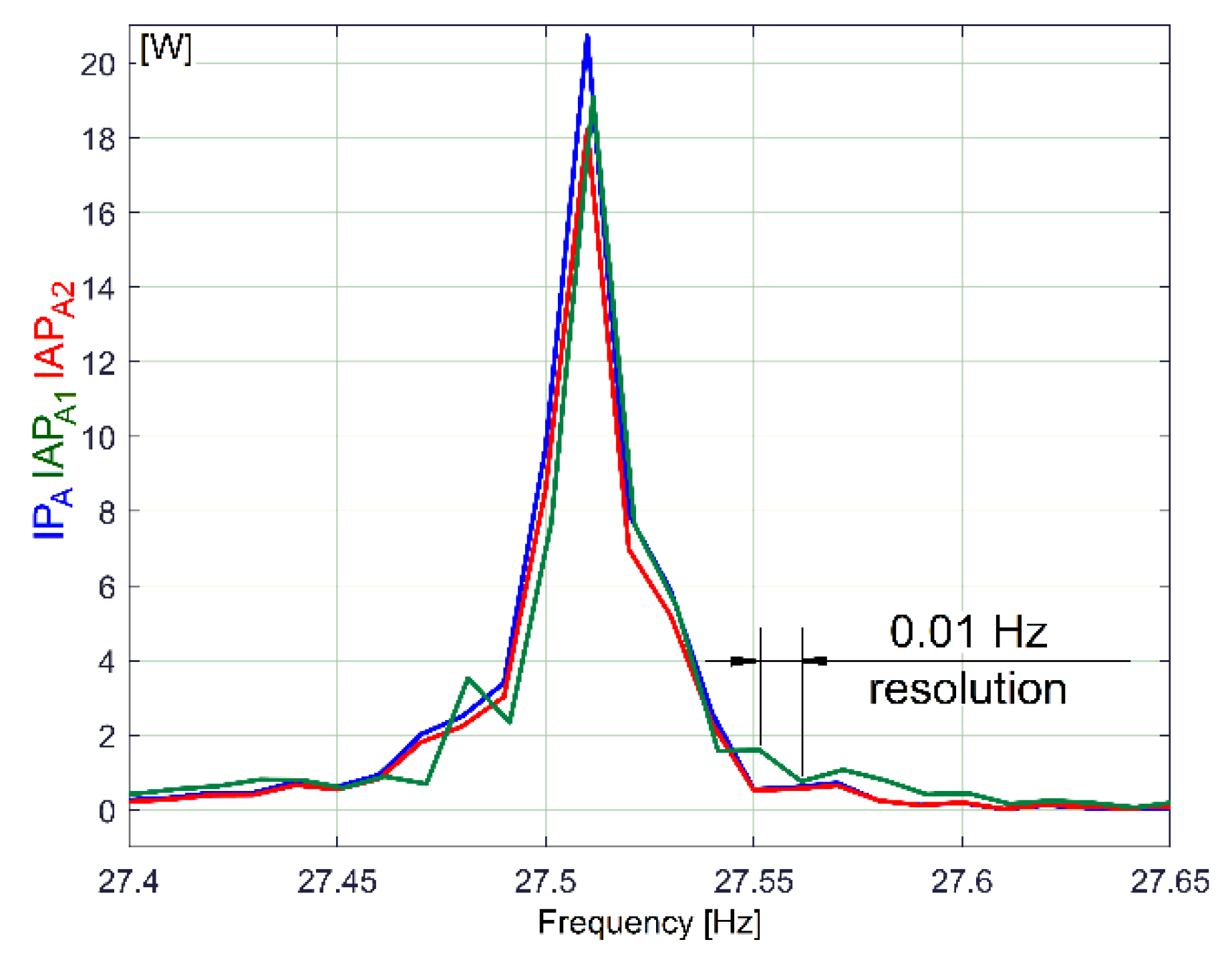

It is obvious that these three evolutions involved in the description of electric power are deterministic signals (each peak is related to a sinusoidal component of the electric power); these three FFT spectra are very similar. All of the spectra have (the same) high resolution in frequency (Fs/Ns = 0.01 Hz) with the same sampling rate (Fs = 25,000 s−1) for IP and IAPA2 (with Ns = 2.5 Ms), while the IAPA1 spectrum has the sampling rate Fs/n =100 s−1 and Ns/n = 10,000 samples. Because of a low Nyquist limit, the spectrum of IAPA1 ends at 50 Hz (Fs/(2n) = 50 Hz), while, for IPA and IAPA2, the spectra end at Fs/(2) = 12,500 Hz.

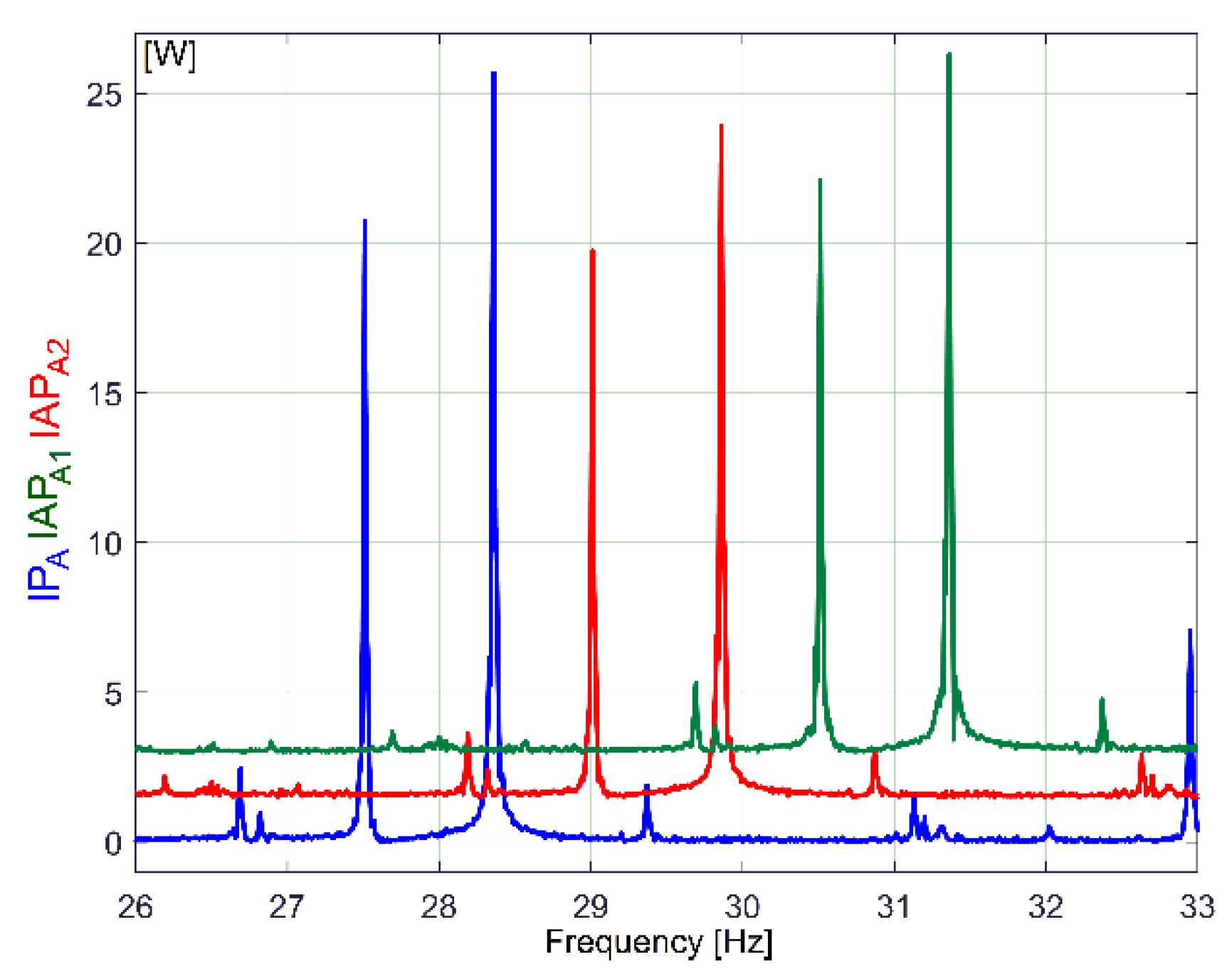

A zoomed-in detail in the area marked with A in

Figure 5 is described in

Figure 6.

Figure 7 describes the first major peak from

Figure 6 (approx. 27.5 Hz frequency) on all three types of powers (not shifted). It is obviously that—related to amplitudes—the best description of these sinusoidal components is given by the FFT of IP

A evolution (compared with IAP

A1 and IAP

A2).

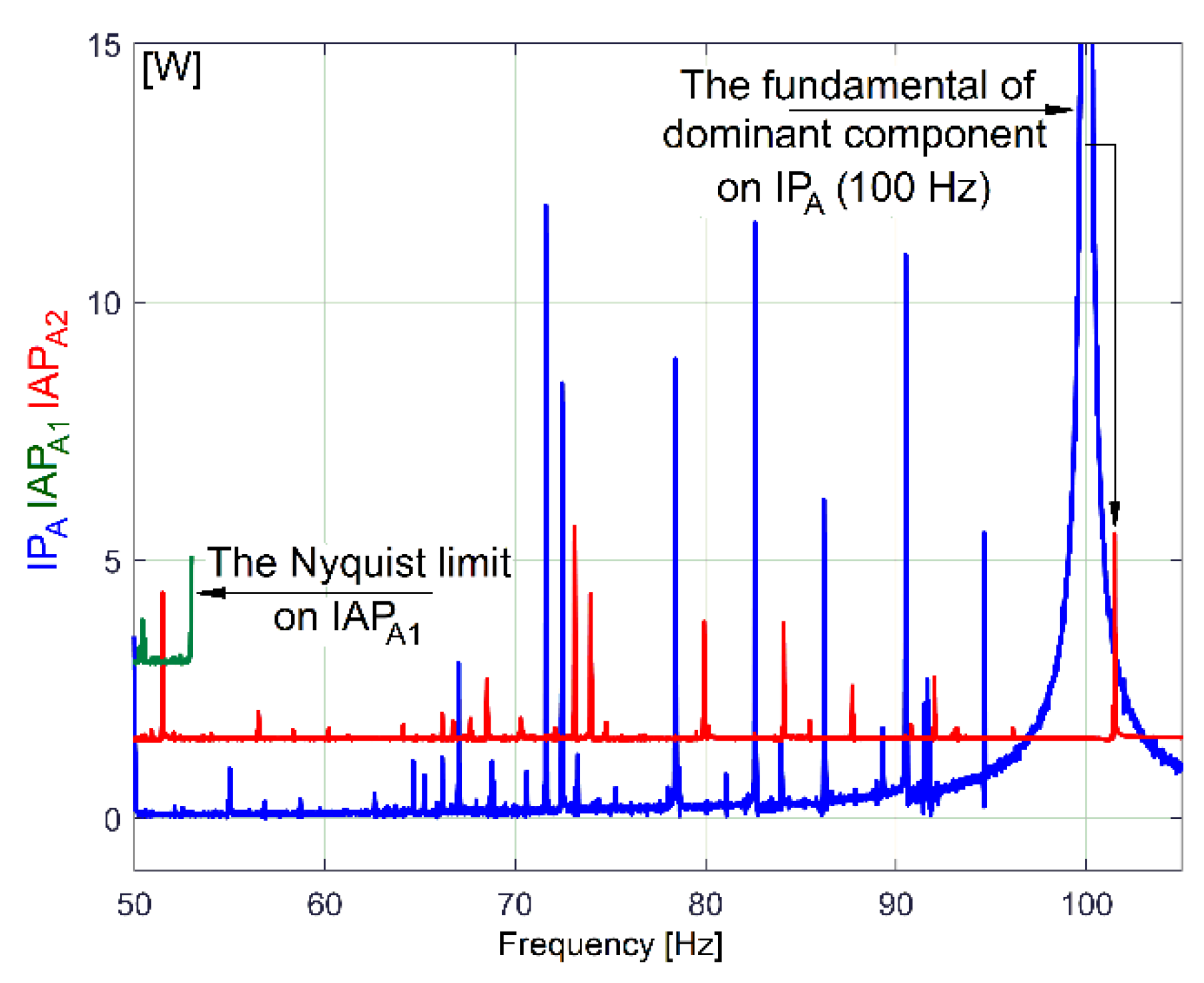

As major disadvantages, the evolution of IAP

A1 has a low sampling rate and a low Nyquist limit because of its definition as an average (Equation (1)), while the amplitudes of the FFT peaks on the IAP

A2 spectrum strongly decrease with frequency because of filtering (Equation (2)), as is clearly indicated in

Figure 8 (a sequence of spectra between 50 ÷ 105 Hz).

Contrary to expectations, here the fundamental of the dominant component from IP

A (100 Hz theoretical frequency and 99.97 Hz real frequency and 923.2 W in amplitude) is not completely eliminated by the moving average filter on IAP

A2 (there is still a peak of 4.012 W in amplitude). This happens because the spectrum is calculated by averaging a long sequence (100 s). During this sequence, the frequency of the supply of instantaneous voltage (and current as well) varies slightly around 50 Hz, as we will experimentally prove later on, in

Section 5. This also implies a variation in the frequency of the dominant component in IP

A, leading to a slight decrease in the filtering efficiency.

There are two reasons to prefer IPA evolution for condition monitoring: firstly, it is easy to obtain the description of its evolution in time; secondly, it provides the best description of the sinusoidal components in the FFT spectrum.

In the FFT spectrum of IPA, the measurement unit for the variable components involved in condition monitoring can be considered to be the watt (due to the similarities of the FFT amplitudes with IAPA1 and IAPA2 already revealed). For a complete description of the periodical phenomena inside the lathe headstock gearbox as mirrored in the electric power evolution, it is suitable to use the total instantaneous power p(t) absorbed by the AC motor (or IP, as being three times bigger than IPA, with p(t) = 3·pA(t)).

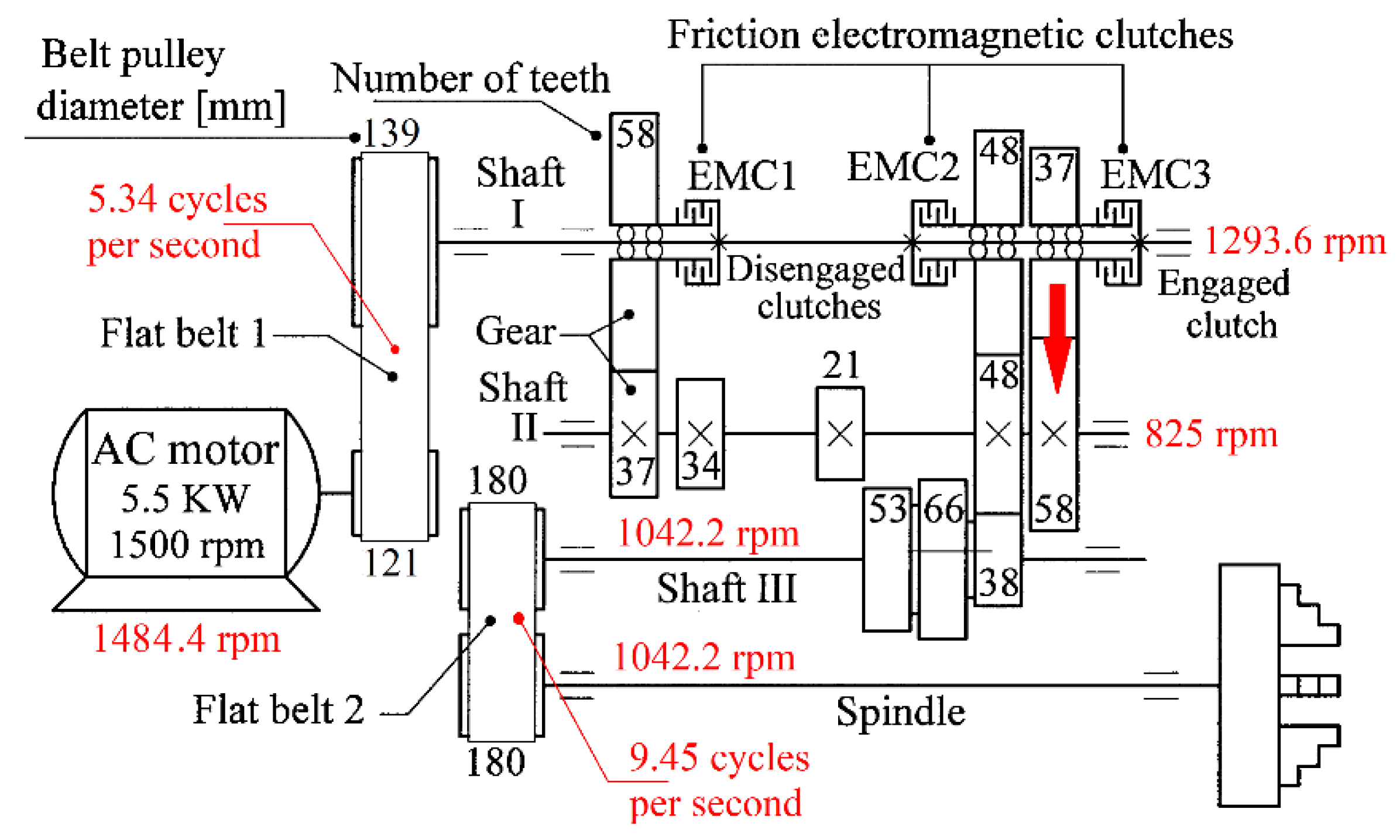

These periodical phenomena revealed before (as sums of sinusoids) can be associated with the normal behaviour (or malfunction) of gearbox mechanical parts (shafts, belts, bearings, etc.) using the relationship between the peak frequencies of fundamentals in the FFT spectrum and the rotation frequency of these parts inside the gearbox (running idle with constant rotation speed).

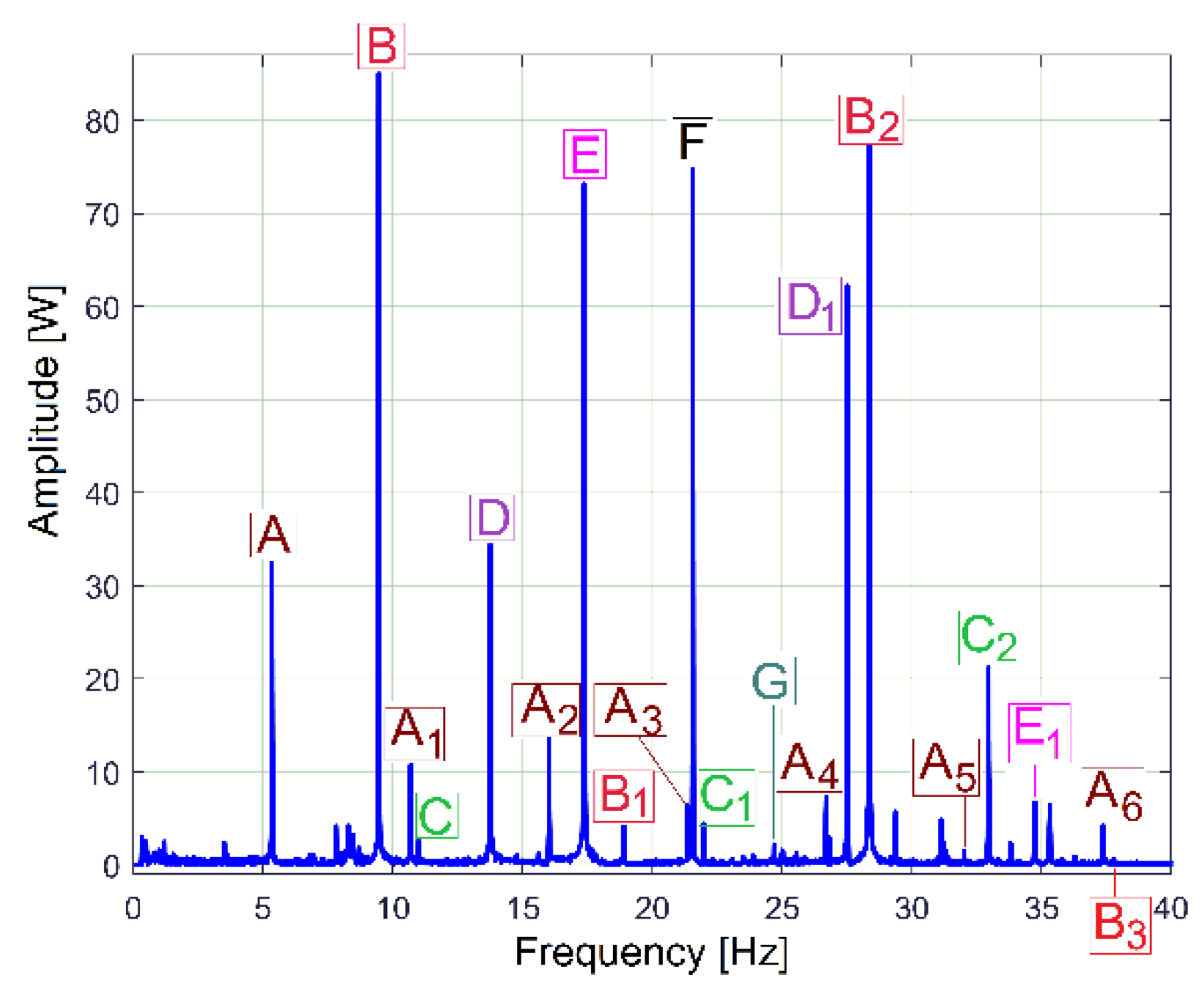

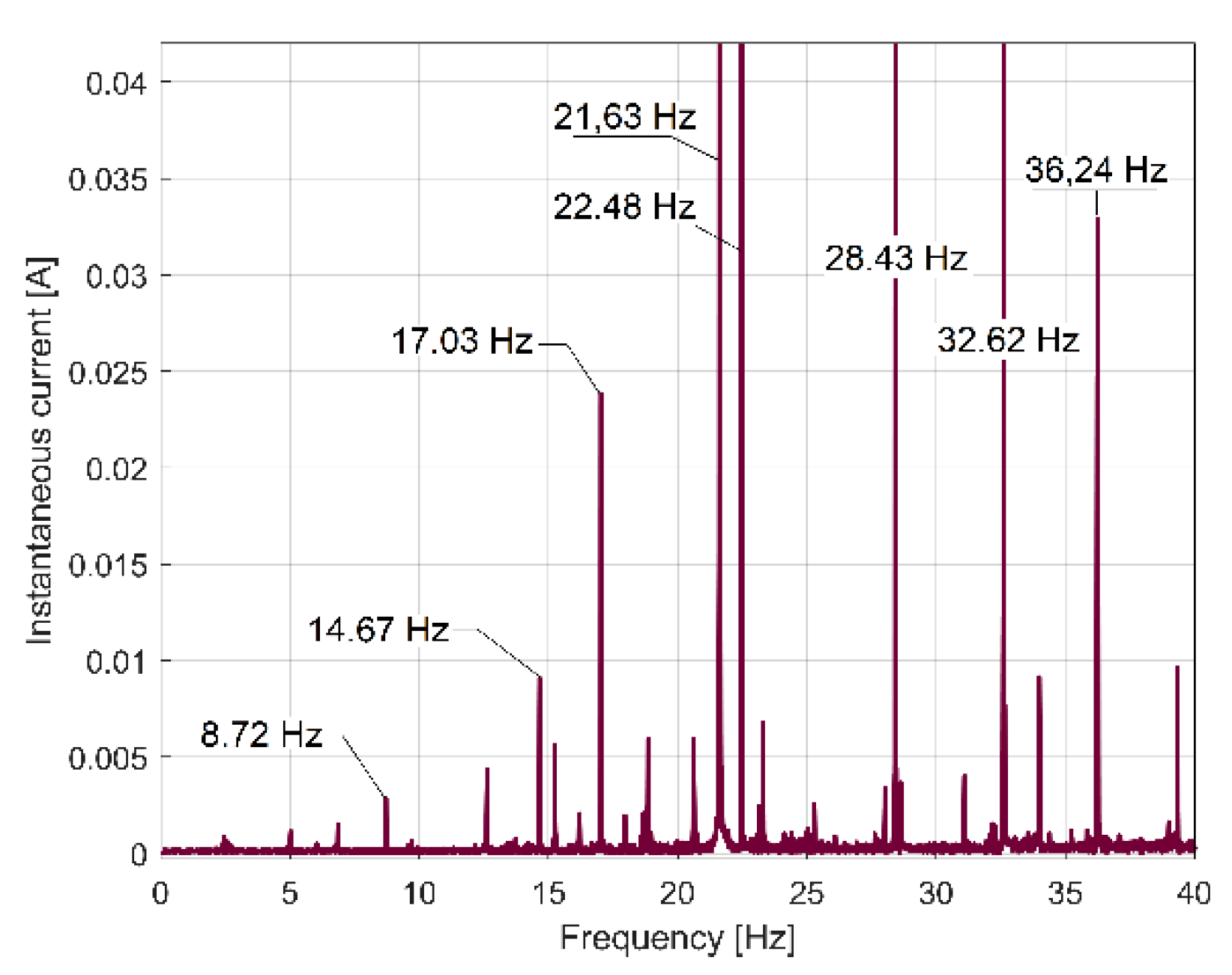

Figure 9 and

Table 1 describe the FFT spectrum of IP as having sinusoidal components (the fundamentals and some harmonics, in a frequency range of 0 ÷ 40 Hz) generated by the mechanical parts of the gearbox running idle, for the gearing diagram described in

Figure 2. This spectrum, with the origins of its main peaks described in

Table 1, is the first argument that IP is a predominantly deterministic signal, well distinguished from the noise.

The average value of the rotation frequency of shaft III and the spindle (17.37 s

−1, or 1042.2 r.p.m., measured using the IASS sensor [

46]) is exactly the value

fE of the peak E. This means that these two mechanical parts (having theoretically the same frequency of rotation) produce together, for certain reasons, a mechanical loading (with the variable part revealed in

Figure 9 and

Table 1 by the spectrum component E as the fundamental and E

1 as the first harmonic) on each rotation. This issue will be discussed later. As expected, because of the gears (and gear ratios), there are kinematic relationships between the frequencies of fundamentals

fD,

fE and

fF (

fD being the rotation frequency of the shaft II,

fF the rotation frequency of the shaft I) as follows:

fD =

fE·38/48 and

fF =

fD·58/37. The ratio of flat belt 1 transmission ((139 + 2)/(121 + 2)) implies a well accomplished demonstration of the relationship

fG =

fF·(139 + 2)/(121 + 2). Here the thickness of the flat belt is 2 mm.

It is interesting to know why and how flat belt 1 (

Figure 10) introduces a periodical instantaneous power (described in

Table 1 by the components with frequencies

fA, fA1 ÷

fA6). It is probably a matter of the stiffness variation of the belt along its entire length (

lfb1). Flat belt 1 continuously moves with

fA cycles per second.

When a portion with low stiffness (due to belt manufacturing errors or due to wear, such as a crevice or a tear) is placed on the tight side of the belt transmission, the transferred mechanical power decreases. In contrast, when this portion is not placed on the tight side, the transferred mechanical power increases.

This means that a torsional vibration is generated in the power transmission (having fA as its fundamental frequency, and fA1 ÷ fA6 as harmonics). If Dd1 is the diameter of the driven pulley, then the frequency fA of the fundamental component introduced by the first belt in the IP evolution is simply calculated as fA = fF·lfb1/(π·Dd1).

Similar comments are available for flat belt 2 (here the frequencies

fB, fB1 ÷

fB3 are involved). In contrast with the first belt, flat belt 2 is 35 years older; it has bigger amplitudes for the fundamental and 2nd harmonic (on the

fB and

fB2 frequencies). Certainly, using the FFT of IP, structural damage to the belts can be detected and described (condition monitoring) long before they break by a severe increase in the amplitude of the fundamentals and/or some harmonics. This issue is supplementarily addressed in

Section 4.2.

The amplitude of all other components (peaks) from FFT spectrum of IP revealed in

Figure 9 and

Table 1 are useful for condition monitoring of the shafts and the output spindle.

The behaviour of the gearbox parts can also be described by IPF spectrum, according to

Figure 11, also, an FFT spectrum sequence between 0 ÷ 40 Hz. Almost all components already revealed in the FFT spectrum of the IP evolution (

Figure 9) are also well described in the FFT spectrum of IPF (except B

3). This means that the resources of the IPF spectrum are also useful in experimental research on condition monitoring. However, as a major disadvantage, the Nyquist limit for IPF evolution is very low: only 50 Hz.

Apparently, increasing the number of samples

Ns of the IP sequence (e.g., from

Ns = 2.5 Ms to

Ns = 5 Ms, with the same sampling rate

Fs = 25,000 s

−1) decreases the frequency resolution of the FFT spectrum (from 0.01 to 0.005 Hz) while yielding better descriptions of the components in the frequency domain. Unfortunately, because of a slow fluctuation in the rotational speed of the AC induction motor rotor (mainly because of motor slip with the fluctuation of mechanical loading), an undesirable phenomenon occurs: spectral smearing [

47]. As result, the FFT components are poorly described, as

Figure 12 indicates (a zoomed-in detail, in the area of peaks D

1 and B

2 as revealed in

Figure 9).

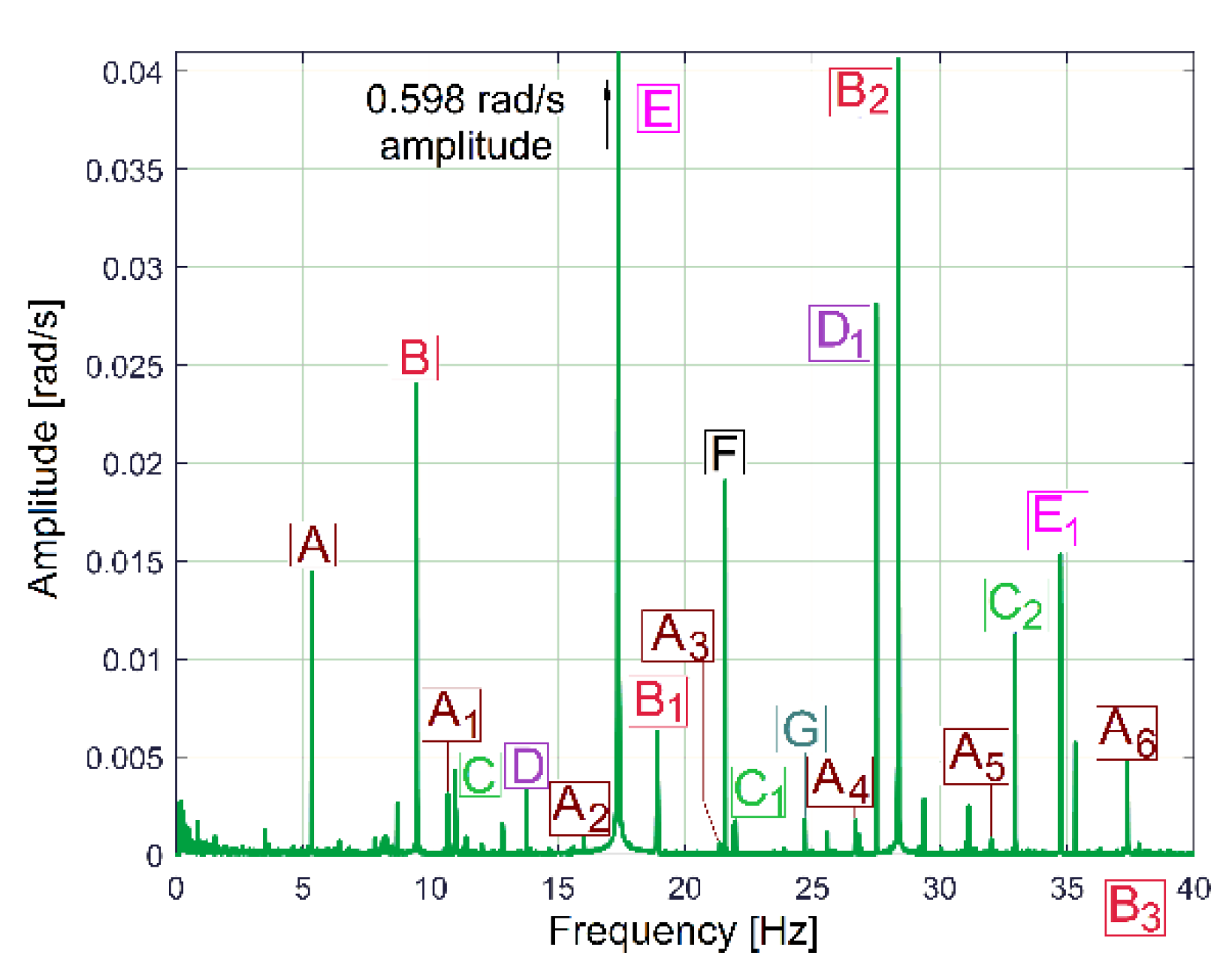

It is interesting for condition monitoring that the periodical phenomena earlier revealed in

Figure 9 and

Figure 10 are also mirrored in the FFT spectrum of the IAS measured at the spindle, as

Figure 13 indicates. The IAS evolution also depends on mechanical loading, which shows another use for the AC induction motor as a sensor, as already revealed in a previous work [

46]. The average value of the IAS of the spindle is 109.14 rad·s

−1 (with 17.37 Hz average rotational frequency), the sampling frequency is 1737 s

−1 and the number of samples is 173,700.

For condition monitoring purposes (and better results), it would be much better if the IAS sensor (IASS) were placed on the rotor of the AC induction motor (because normally the jaw chuck of the spindle should be permanently available to the work piece during the working process).

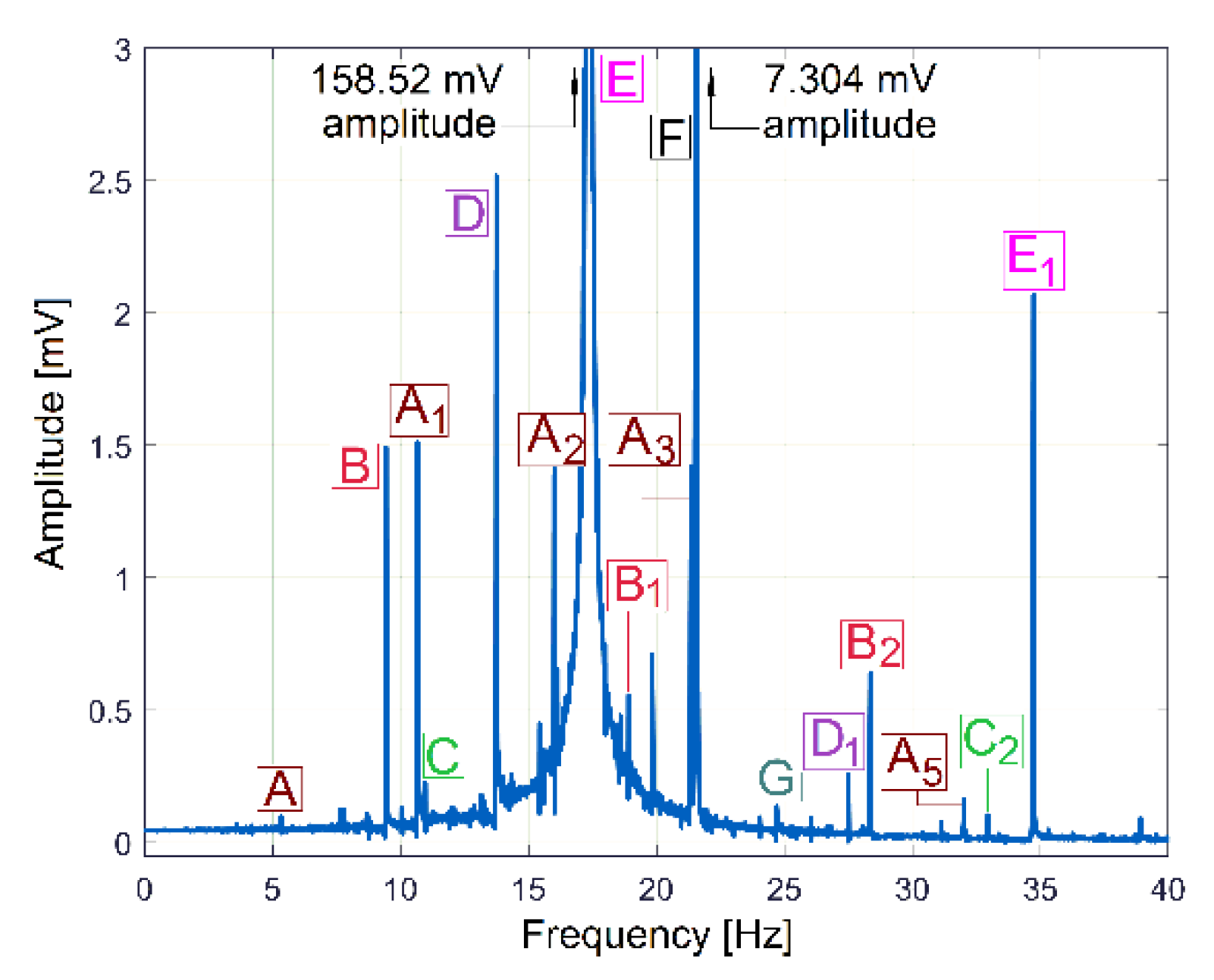

The FFT spectrum of the vibration signal VS

S (from

Figure 14, proportional with vibration velocity) delivered by the vibration sensor VS placed on the gearbox (

Figure 1) describes the same periodical components already found before in the IP, IPF and IAS evolutions in frequency domains (

Figure 9,

Figure 10 and

Figure 13).

In

Figure 14, the component E is dominant (as already was stated in

Figure 3); it has the highest amplitude in the spectrum (158.52 mV, on the spindle rotational frequency of 17.37 Hz). In brief, this vibration component E is generated by shaft III and the output spindle rotation having unbalanced masses. It is strongly amplified by a mechanical resonance due to a low damped vibration mode of the entire lathe placed on its foundation (18.79 Hz frequency, 5.899 s

−1 damping constant [

48]). This issue will be supplementarily discussed later on. Apart from the comparison of the similarities between

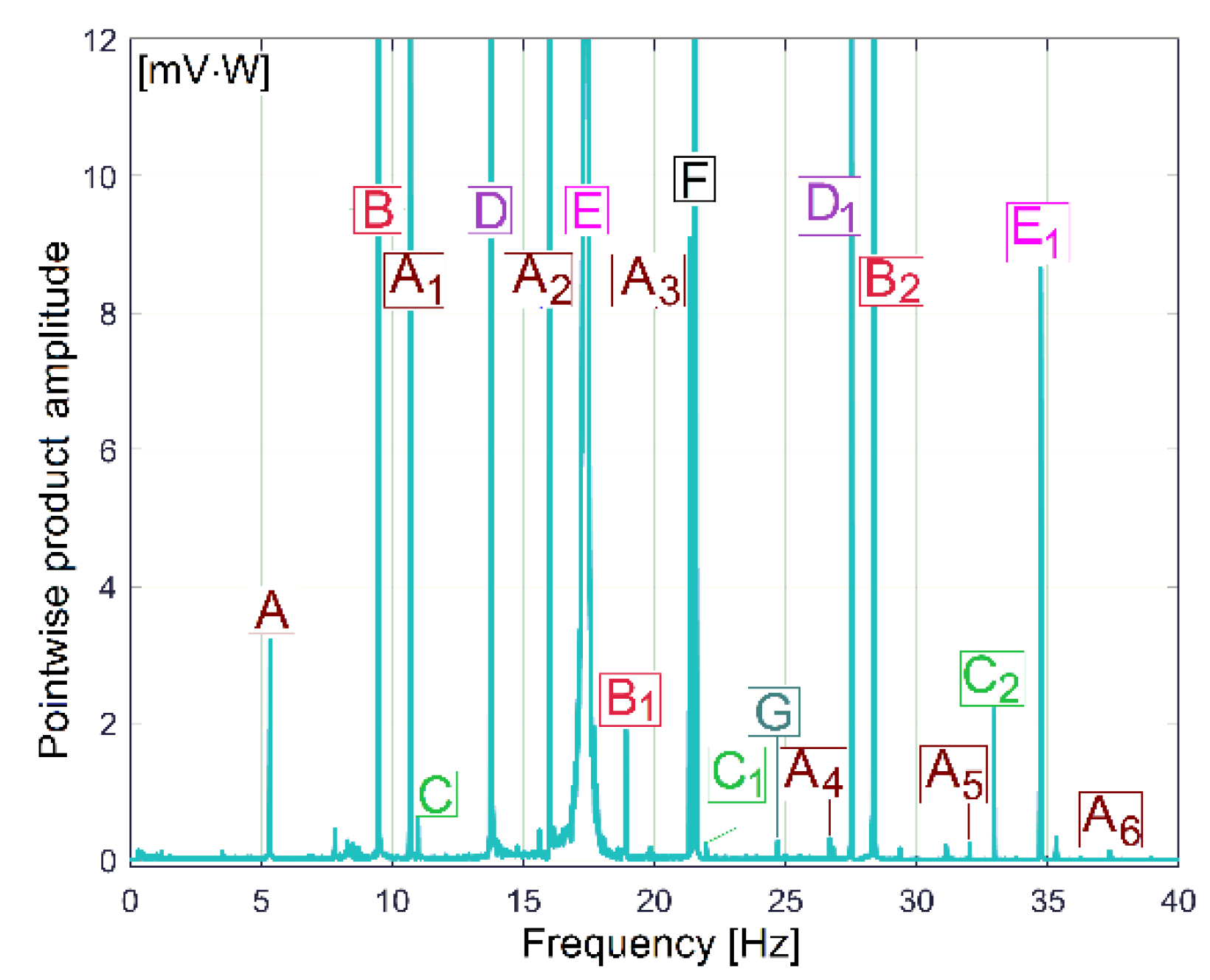

Figure 9 and

Figure 14, giving two different ways to describe the behaviour of the same gearbox parts (with IP and VS

S spectra), it is more appropriate to check these similarities using the pointwise product of FFT spectra for IP and VS

S, as

Figure 15 indicates. This is possible because the evolutions of IP and VS

S are numerically described with the same sampling rate (

Fs = 25,000 s

−1) and the same number of samples (

Ns = 2.5 Ms).

It astonishes us that, contrary to any expectations, there is not any similarity between the FFT spectra of IC (depicted in

Figure 16) and IP (from

Figure 9). It seems that the IC evolution is not suitable for condition monitoring, at least when using our method to obtain the FFT spectra.

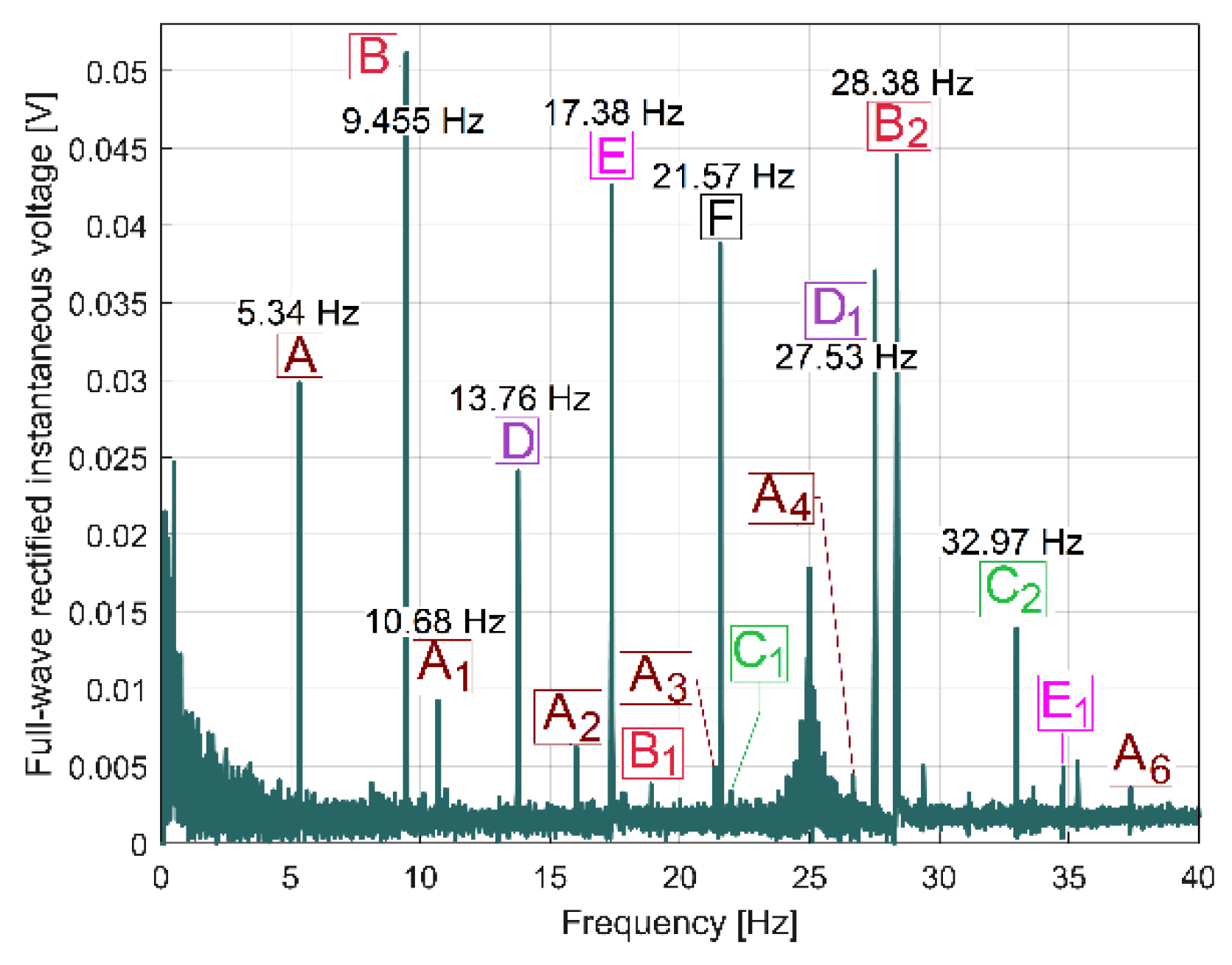

However, we discovered that if, instead of IC spectrum, the full-wave rectified instantaneous current (as RIC) spectrum is used, the result is totally changed, as

Figure 17 indicates (the same magnitude was used for

Figure 16 and

Figure 17). Now, there are strong similarities between the FFT spectra of RIC and IP (

Figure 9 and

Figure 17 have almost the same components, which are placed at the same frequencies in spectra). We should mention that, while IC is described with

iA[

tk] samples, RIC is described with |

iA[

tk]| samples (as a modulus function applied to

iA[

tk] sample). It is obvious that RIC also provides useful information for condition monitoring, but probably no better than IP, mainly because IP (and its derivatives IAP

A1 and IAP

A2, as well) is more strongly related to mechanical loading than IC and RIC. It is known that IC and RIC are not able to describe a negative mechanical power flow delivered by a motor during a transient regime [

1], when the AC motor works as a braking system.

A similar study was performed on IV, the second constituent of IP. Theoretically, IV should be permanently constant (as amplitude and frequency), indifferent to the IP absorbed by the AC induction motor. However, because each of the three wires used to supply the AC motor has a non-zero electrical resistivity, the variation of IC generates a variation of the voltage drop in these wires (due to the Ohm’s law), which implies the variation of IV measured at the input of the AC induction motor.

As expected (and similarly to the IC spectrum), the IV spectrum (depicted in

Figure 18) does not have any similarities with the IP spectrum from

Figure 9. However, if the IV evolution (described with

uA[

tk] samples) is replaced by the full-wave rectified instantaneous voltage (as RIV, described with |

uA[

tk]| samples), the spectrum of RIV (depicted in

Figure 19) has strong similarities with the IP spectrum (and the RIC spectrum as well), as a comparison between

Figure 9 and

Figure 19 proves. This means that RIV also provides useful information for condition monitoring, but certainly no better than IP or RIC (due to an important noise in the spectrum).

For the time being, we do not have a feasible explanation for why the IC and IV spectra (generated by FFT in Matlab) are not relevant in condition monitoring, in comparison with the RIC and RIV spectra. However, we should mention that there are strong similarities between the IC and IV spectra, related to the frequency of some relevant components, as a comparison between

Figure 16 and

Figure 18 proves.

It is not surprising that the behaviour of many of the gearbox’s rotating parts is mirrored simultaneously, particularly in FFT spectra of the IP and VSS signals. As an example, any unbalanced rotating shaft inside the gearbox acts as a sinusoidal vibration exciter that moves the lathe periodically on its foundation (acting as an excited spring-mass-damper system). A fundamental on-shaft rotation frequency on the FFT spectrum of VSS occurs.

When we talk about the amplitudes of the vibratory motions generated by the unbalancing of shaft III and the output spindle, these amplitudes depend on the mass unbalanced, the almost identical rotation frequency (17.37 Hz) and the proximity to the mechanical resonance frequency of the lathe on its foundation (a 18.79 Hz frequency, with a damping constant of 5.899 s

−1 [

48]).

Obviously, the mechanical power necessary to supply this sinusoidal motion (as vibration excitation power, maximal at mechanical resonance) is delivered by the AC induction motor. This excitation power is a constituent of IP absorbed by the motor from the electrical supply system and is described as a peak in the IP FFT spectrum. As an example of gearbox failure, a bent shaft regularly needs a mechanical power to rotate it, such as drive power. Corresponding to the variable (periodical) part of this drive power, a fundamental on its rotation frequency and some harmonics on the IP FFT spectrum are generated. The rotation of this bent shaft generates a deformation of the gearbox housing, sometimes perceived as vibration by the vibration sensor (a fundamental on its rotation frequency and some harmonics on FFT spectrum of VSS are generated). A similar approach is available for many other anomalies involving the rotating parts inside the gearbox (e.g., bearing misalignment, gear run out, damaged belts, etc.).

Sometimes, the mechanical variable power necessary to rotate a bent shaft with a mechanical imbalance (e.g., shaft III or/and the output spindle, with the variable power depicted by peak E in

Figure 9) has two cumulated constituents with the same (rotation) frequency, often with a phase shift between: one constituent is the periodical part of the drive power used to rotate the shaft if the imbalance is ignored; the other constituent is the vibration excitation power, used to supply only the vibration motion of the lathe on its foundation, excited by the mechanical imbalance of this rotary shaft.

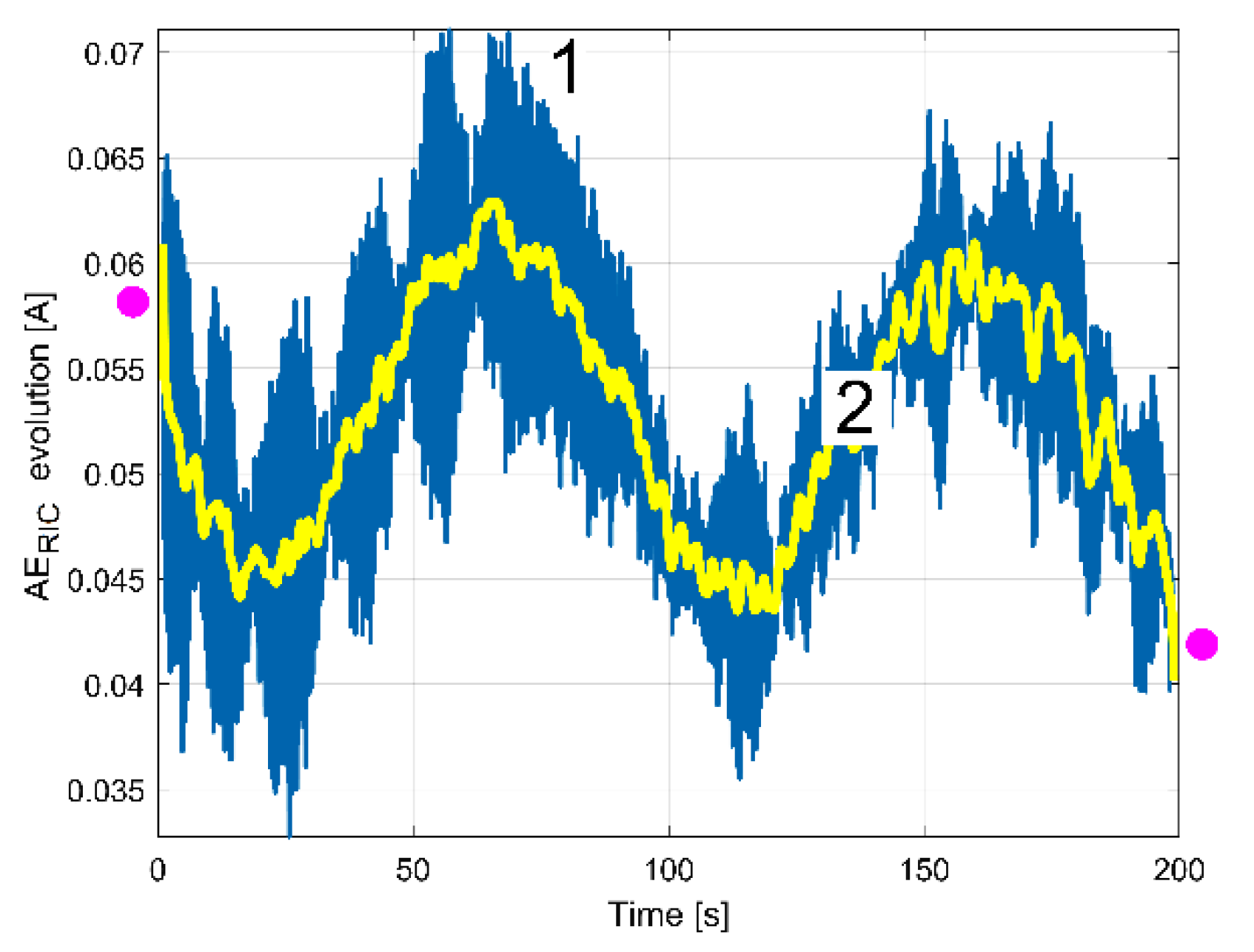

A particular rotational property of shaft III and the output spindle, revealed in a previous work [

48], is useful to highlight the existence of these two constituents in the evolution of IP (drive power and vibration excitation power): a beating phenomenon in the vibrations of the gearbox (together with the lathe on its foundation) with nodes and antinodes, as is experimentally described by the evolution of the VS

S signal (curve 1 in

Figure 20) with

Ns = 5 Ms and

Fs = 25,000 Hz during 200 s, with the gearbox running idle as previously.

This beating phenomenon (generated by vibration superposition with constructive and destructive interferences) occurs because there is a very small difference (less than 0.01 Hz) between the rotation frequencies (or IAS) of the output spindle and shaft III (due to a slight sliding of flat belt 2 on its pulleys) and due to a mechanical imbalance of shaft III and the output spindle. The amplitude of beating vibrations increases a lot because of a resonant amplification of the lathe suspension on its foundation, previously highlighted in [

48]. Normally, we should observe two very close peaks on the FFT spectrum of VS

S: a peak generated by shaft III and another peak generated by the output spindle. Nevertheless, because there is not a small enough frequency resolution in the FFT of VS

S, and because there is a very small difference in the rotation frequency of the output spindle compared with that of shaft III, a single peak occurs in the VS

S spectrum (as dominant peak E in

Figure 14, having the frequency

fE = 17.37 Hz).

The variation in time of the amplitude of the dominant peak E (and the relationship with the amplitude of the beating vibration phenomenon) should be experimentally revealed. This paper proposes an appropriate method, as described below.

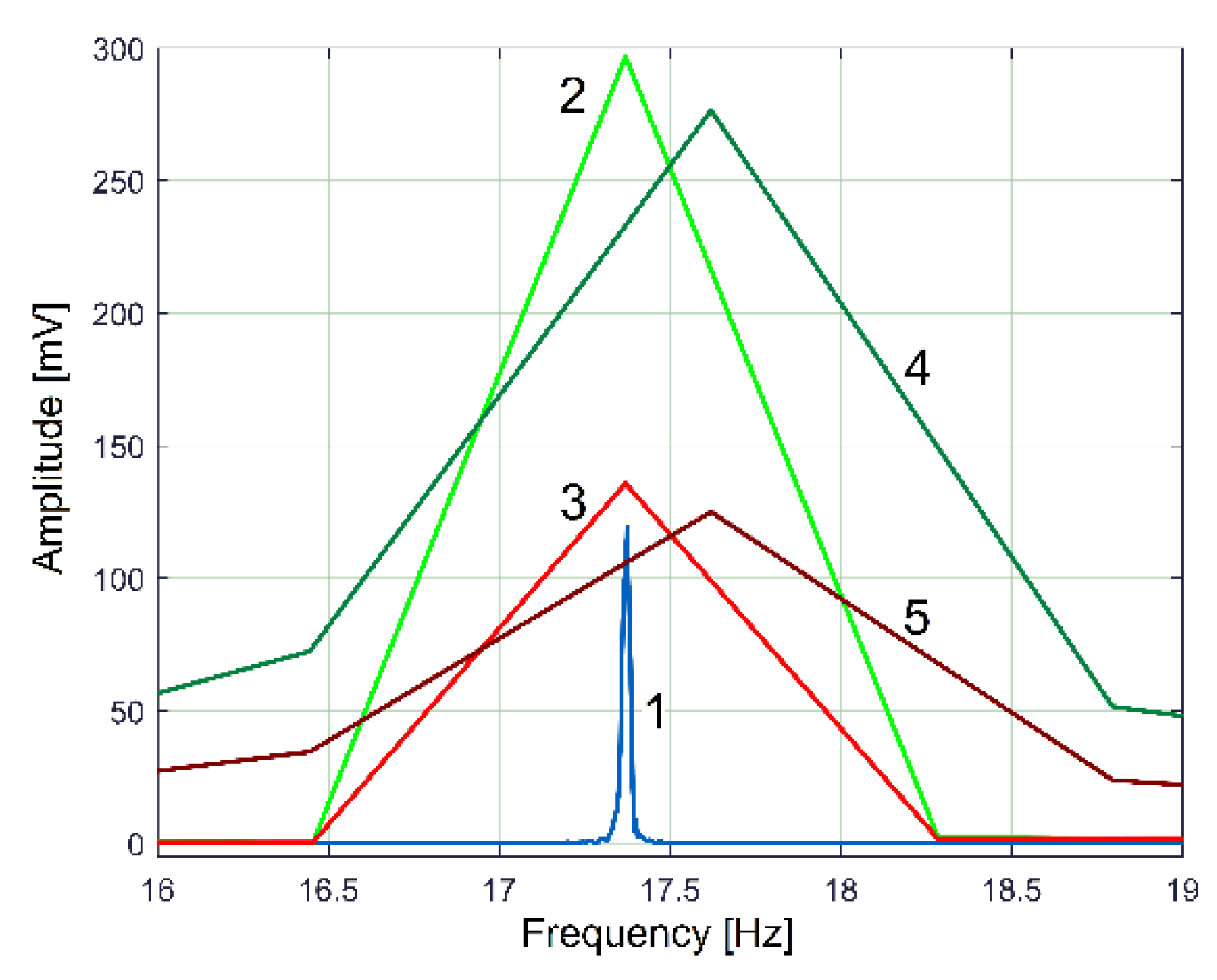

It is expected that the FFT spectrum of a short movable sequence of VSS (as SMSVs, with Nss samples, and Nss << Ns) will reveal that the amplitude of peak E (the dominant component in VSS) is variable in time, with an evolution close to that of the amplitude of the beating vibration. On the FFT spectrum of each SMSVs having the average time tAEj, a value for the amplitude of peak E (as AEVs) is available. Any two successive SMSVs (eventually with an overlap between them) produce two successive samples, AEVs(tAEj) and AEVs(tAEj + 1).

There is a major difficulty to this approach: the FFT frequency resolution of SMSVs is very small (Fs/Nss >> Fs/Ns). In order to detect exactly the (average) value of the amplitude of the peak E inside a SMSVs, it is mandatory to accomplish exactly the condition k·Fs/Nss = fE. In other words, the frequency k·Fs/Nss of the kth sample on the FFT spectrum of each SMSVs should have exactly the value fE, or should at least have the closest value possible of k·Fs/Nss relative to fE, taking into account the fact that k and Nss are positive integers. For fE = 17.37 Hz and Fs = 25,000 s−1, a computer-assisted trial algorithm produces the appropriate value of Nss = 27,346 (for k = 19), with k·Fs/Nss = 17.369999 Hz ≈ fE = 17.37 Hz.

In

Figure 21, the advantages of this method of using the FFT spectrum of SMSVs are revealed.

Curve 1 depicts the peak E on the entire FFT spectrum of VS

S, with

Ns = 5 Ms. It describes the frequency very well but gives a bad description of amplitude (expected to be close to the average value of the amplitudes on curve 1,

Figure 20). Curve 2 in

Figure 21 depicts the peak E on the FFT spectrum of a single SMSVs placed in the area of the first antinode in

Figure 20, while curve 3 in

Figure 21 depicts the peak E on the FFT of a single SMSVs in the area of the second node in

Figure 20 (both SMSVs with

Nss = 27,346 samples for the best fulfilment of the previously defined condition

k·Fs/

Nss =

fE). Despite a very small frequency resolution, as expected, there is a good description of the frequency and, very importantly, a good description of the amplitudes (compared with the amplitudes of the nodes and antinodes in

Figure 20, curve 1). Using this SMSVs movably on the entire VS

S signal (

Ns = 5 MS, with 1000 samples of overlap between two successive SMSVs), the complete AE

Vs evolution is obtained and described with curve 2 in

Figure 20, which uses 4946 samples. A computer program was developed in order to find the description of each

AEVs(

tAEj) sample on the AE

Vs evolution.

Two arguments explain why the AE

Vs evolution from curve 2 in

Figure 20 is slightly different from the amplitude of VS

S (of curve 1): firstly, each sample on AE

Vs is the average of an SMSVs; secondly, the VS

S signal contains many other vibration components (some of them already revealed in

Figure 14). A wrong value for

Nss in SMSVs (e.g.,

Nss = 21,282) inaccurately describes the peak E in the FFT of SMSVs (in frequency and amplitude), as

Figure 21 proves, with curve 4 for the amplitude in the first antinode and curve 5 for the amplitude in the second node. Consequently, the evolution of AE

Vs found using this wrong value of

Nss (curve 3 in

Figure 20) is not correctly described.

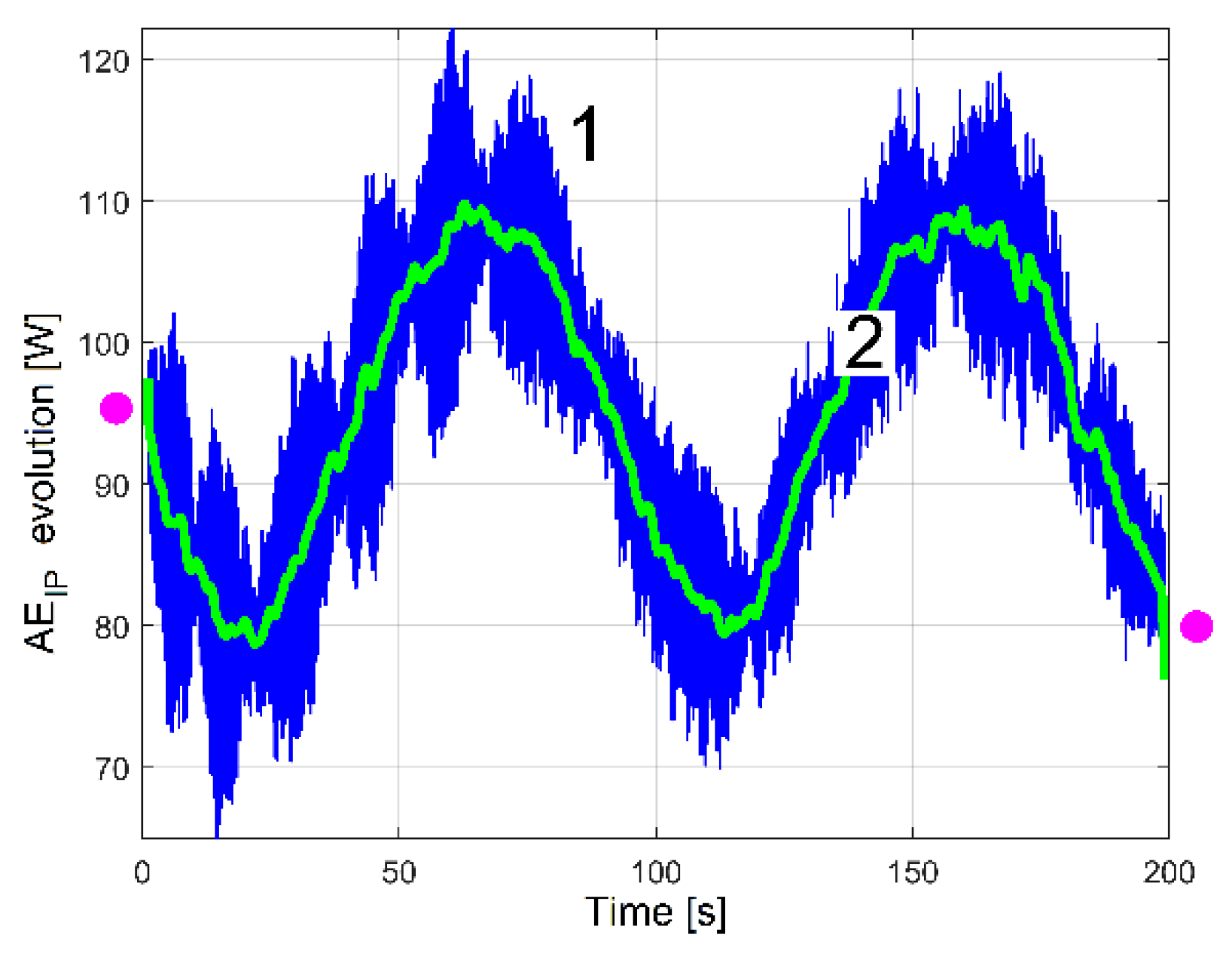

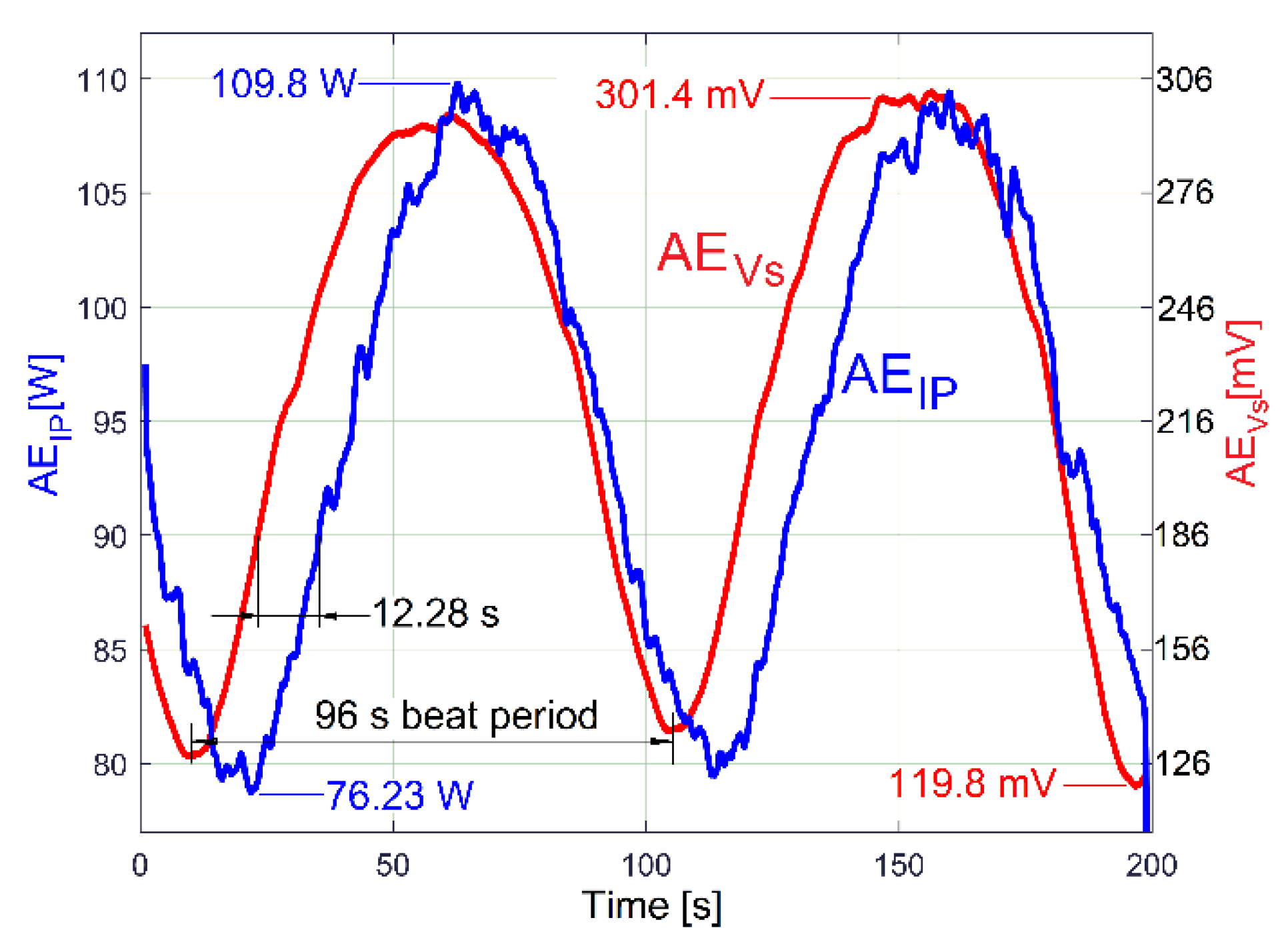

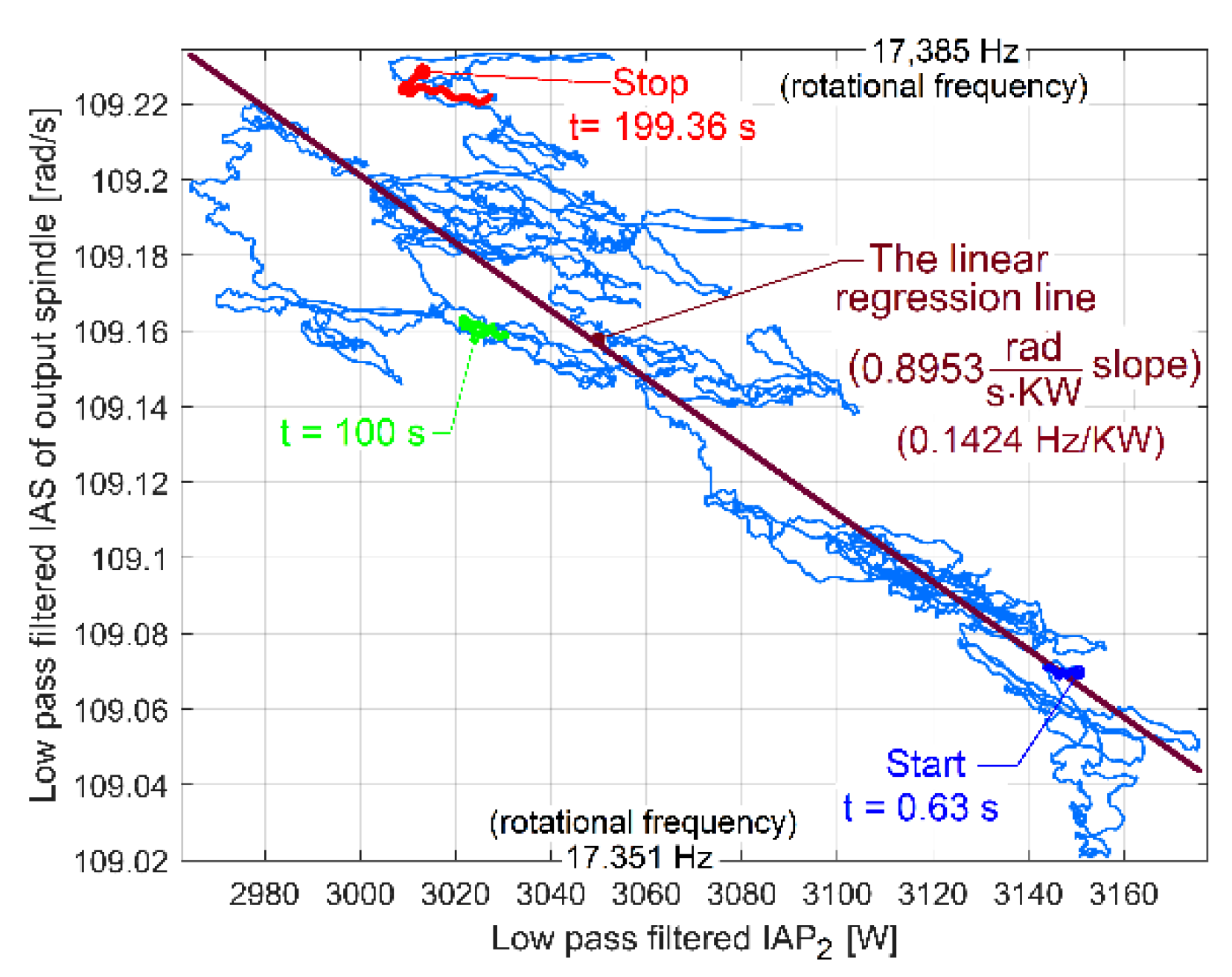

A hypothesis can be formulated: the beating phenomenon in the vibration should be mandatorily mechanically powered by the electrical power absorbed by the AC motor. A beating phenomenon generated by the superposition of two sinusoidal components of the IP having very close frequencies should take place (one component—having the frequency

fEIII—related to shaft III’s imbalance and its rotational frequency, the other—having the frequency

fES—related to the output spindle’s imbalance and its rotational frequency), both as mechanical power components used to excite these vibrations. The same type of evolution for amplitude of peak E (already revealed in the VS

S evolution, curve 2 in

Figure 20) should be observed in the IP evolution (as AE

IP) during the same experiment previously conducted for VS

S (

Ns = 5 Ms and

Fs = 25,000 Hz). Here, the same FFT analysis with short movable sequences of IP (as SMSIP, also with

Nss = 27,346 samples and 1000 samples of overlap) was performed. The previously formulated hypothesis is fully confirmed in

Figure 22.

It is obvious that AEIP (curve 1) has a noisy evolution. It is experimentally proved now that AEIP has relatively important variations of amplitude. In order to reduce the noise, this evolution from curve 1 can be low pass numerically filtered through the medium of three consecutive moving average filters (with 20, 10 and 5 samples in average), with the result depicted with curve 2 (as averaged AEIP, also having 4946 samples). A strong reduction of the noise can be obtained also (before filtering) if the number of samples from SMSIP is doubled, tripled, etc., keeping the same overlap.

The FFT analysis of the IP evolution was repeated in exactly the same manner for the RIC evolution, in order to find out the evolution of the peak E amplitude in RIC (with a short movable sequence of RIC as SMSRIC, also with

Nss = 27,346 samples and 1000 samples overlap). The results (as AE

RIC evolutions) are depicted in

Figure 23. All the considerations and comments made in

Figure 22 (e.g., the filtering of curve 1) are also applicable here. The similarities between curves 2 in

Figure 22 and

Figure 23 are obvious, despite the fact that curve 2 from

Figure 23 (as averaged AE

RIC evolution) is more poorly defined.

In the start and in the end areas of

Figure 22 and

Figure 23 (marked with pink dots), a couple of distorted values generated by filtering (edge effect) should be ignored.

A better comparison between the averaged AE

IP and AE

RIC evolutions is provided in

Figure 24. Here, the averaged AE

RIC evolution was graphically fitted (related only by magnitude) against the averaged AE

IP evolution in such a way as to highlighted that there is no time delay (or phase shift, either) between these evolutions. As expected, there is no shift of phase between the beating phenomena described with the AE

IP or AE

RIC averaged evolutions (both describing the variable part of the mechanical loading).

It is obvious also that the averaged AE

IP (curve 2 in

Figure 22) and AE

Vs (curve 2 in

Figure 20) have similar evolutions. The beating phenomenon in vibration is supplied by a beating phenomenon in IP (the AC motor supplies with mechanical power the forced vibrations). A better comparison between the averaged AE

IP and AE

Vs evolutions is provided in

Figure 25.

Here, similarly to the averaged AE

RIC from

Figure 24, the AE

Vs evolution was graphically fitted (related only by magnitude) against the averaged AE

IP evolution in such a way that only the time delay between them (and the phase shift, as well) is highlighted.

This phase shift proves that there are two variable IP components used by shaft III (having the same frequency fEIII): the fundamental of the variable part of the drive power (pvdpIII, used to rotate the shaft if the imbalance is ignored) and the excitation power (pepIII, used only to excite the gearbox due to shaft III imbalance during the rotary motion). Similarly, there are two IP components generated by the output spindle (having the same frequency fES): the fundamental of the variable part of drive power (pvdpS, used to rotate the output spindle if the imbalance is ignored) and the excitation power (pepS, used only to excite the gearbox due to spindle imbalance during the rotary motion). Generally, there is a shift of phase (unknown for the time being) between the pvdpIII and pepIII evolutions; also, there is a shift of phase (unknown) between the pvdpS and pepS evolutions. A first IP beating phenomenon (as IPvdp) takes place through the addition of the powers pvdpIII + pvdpS = pvdp (with pvdp having a variable amplitude and the frequency fE). A second IP beating phenomenon (as IPep) takes place through the addition of the powers pepIII + pepS = pep (with pep having a variable amplitude and the frequency fE). Generally, is expected that, for a certain IAS spindle, there is a constant shift of phase between pvdp and pep.

The IP

ep beating phenomenon supplies the vibration beating phenomenon, with no phase shift in between. The IP

vdp and IP

ep beating phenomena defines (by interference) a third IP beating phenomenon (as IP

E) by the addition of the powers

pvdp +

pep =

pE, with the amplitude evolution already described in

Figure 22 (curve 1). It has the averaged AE

IP as its average amplitude evolution (curve 2 in

Figure 22) and the frequency

fE. Since the amplitude of

pvdp is not zero, then

pE ≠

pep. As a consequence, there is a time delay (shift of phase) between the averaged AE

IP and AE

Vs, as

Figure 25 clearly indicates. The time delay (shift of phase) between the averaged AE

IP and AE

Vs evolutions can be changed if the amplitude of

pvdp or

pep (or both) is changed, because IP

E depends on IP

vdp and IP

ep (their sizes and shapes and the phase shift between them).

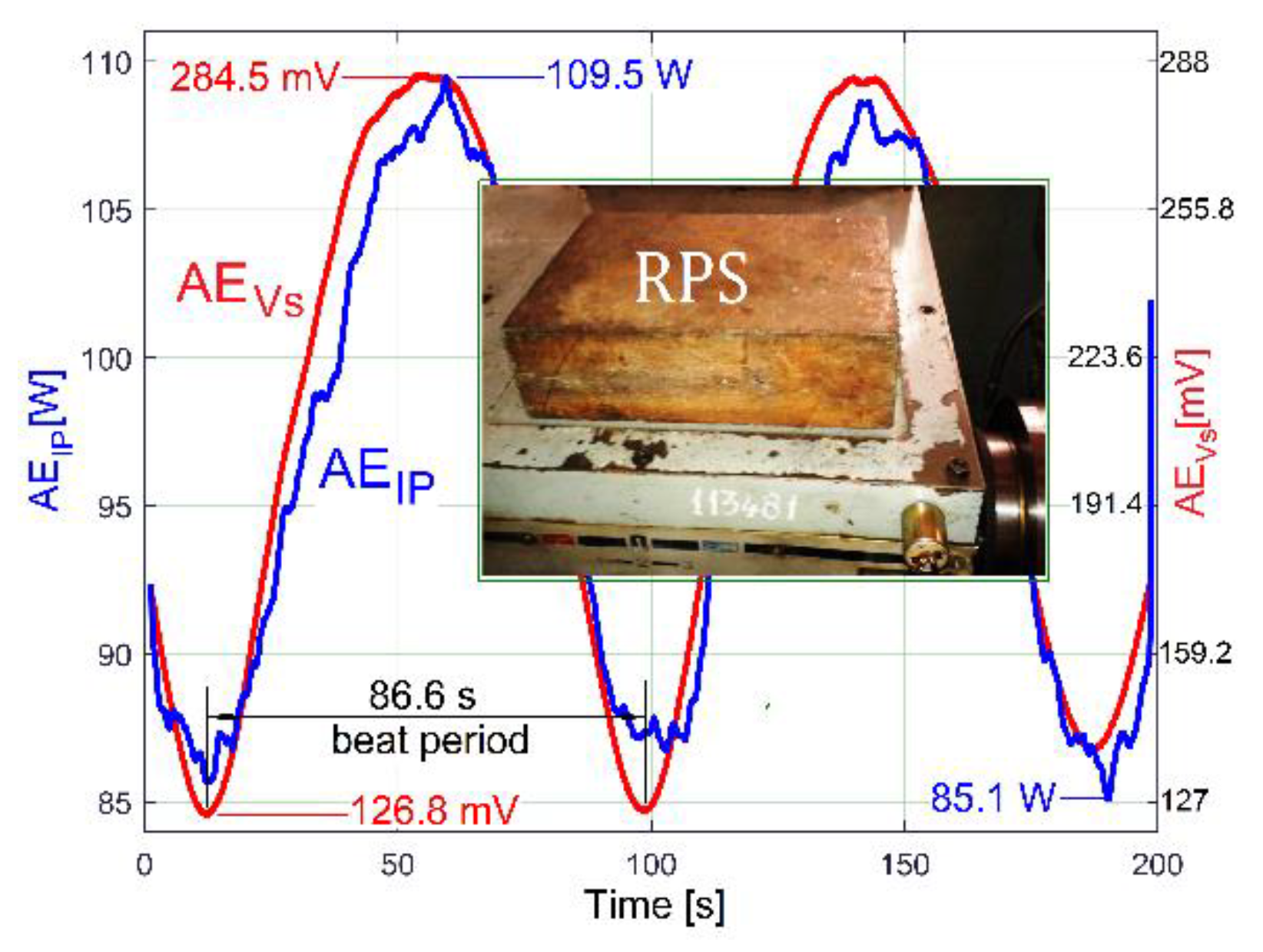

As a first example, the influence of

pep on

pE is indirectly proved by a new experiment in almost identical conditions (

fE = 17.39 Hz and

Nss = 29,471), with a 36.8 Kg additional mass (a rectangular parallelepiped made of steel, RPS) placed on the lathe gearbox (

Figure 26).

The circumstances of the excited vibrations (of the lathe on its foundation) are changed: because of the additional mass, the resonant amplification diminishes, and the resonance frequency moves away from the excitation frequency. As

Figure 26 proves, there are two major consequences: firstly, the time delay (shift of phase) between the averaged AE

IP and AE

Vs evolutions decreases significantly; secondly, the peak-to-peak amplitude of

pE decreases from 33.57 W in

Figure 25 to 24.4 W here. During this new experiment, the ambient temperature is higher (approximately with 5 degrees Celsius), the sliding of flat belt 2 increases, the difference between the rotational frequencies of shaft III and the output spindle increases, and, consequently, the beat period decreases from 96 s (in

Figure 25) to 86.6 s here in

Figure 26.

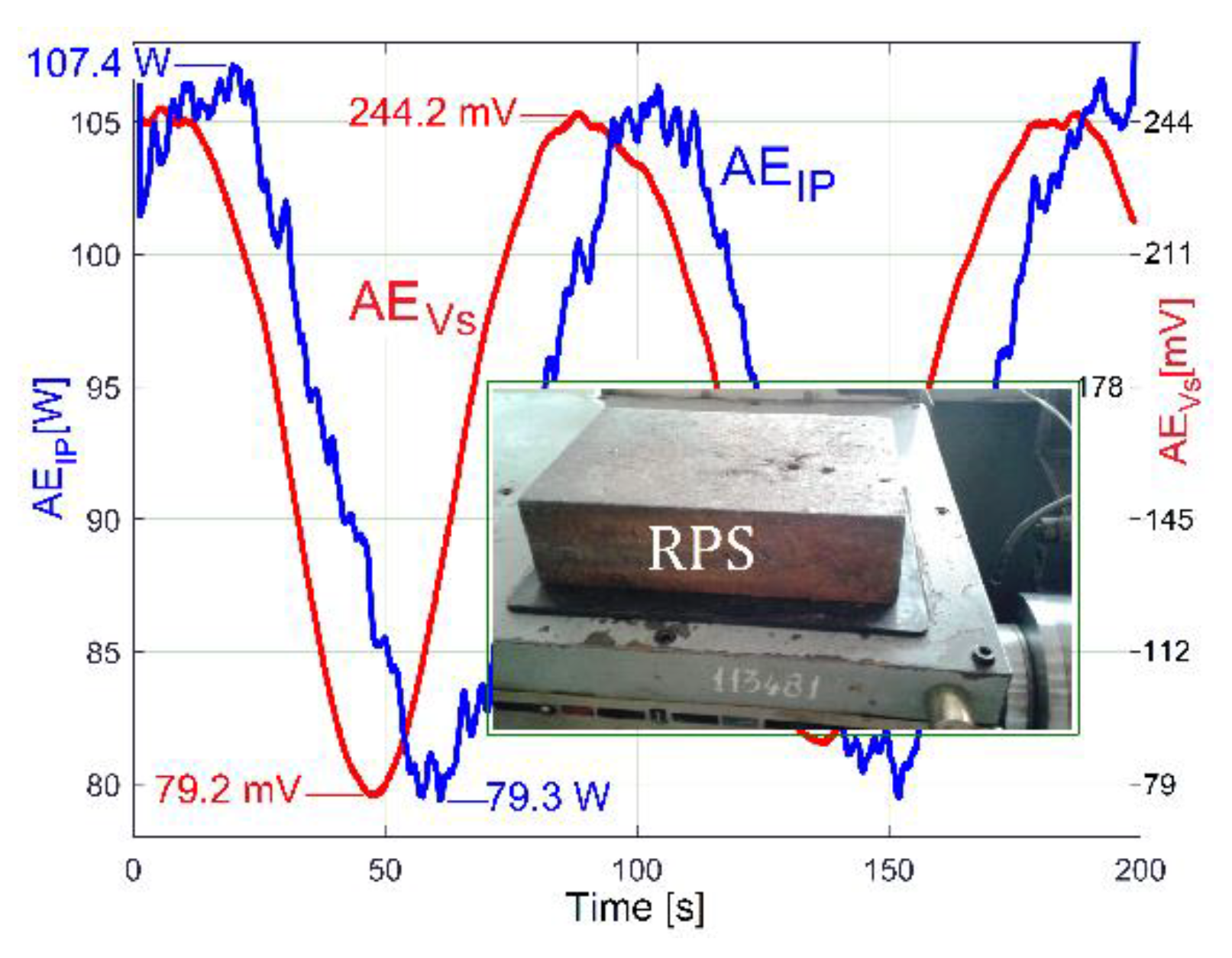

The experiment from

Figure 26 was repeated in new conditions. This time, a sheet of rubber 6 mm in thickness was placed between the additional mass and the gearbox. As

Figure 27 proves, there is a big change in the time delay between the averaged AE

IP and AE

Vs evolutions and a noticeable change in the AE

Vs average values (from 205.65 mV in

Figure 26 to 161.7 mV in

Figure 27). The additional mass RPS and the sheet of rubber work together as a passive dynamic vibration damper (PDVD). The amplitude of the average vibration decreases because a part of the instantaneous power

pep absorbed by the AC induction motor and converted in mechanical power (previously used to supply the gearbox vibration) is now absorbed by the PDVD and converted irreversibly into heat inside the rubber sheet (which also works as a damper).

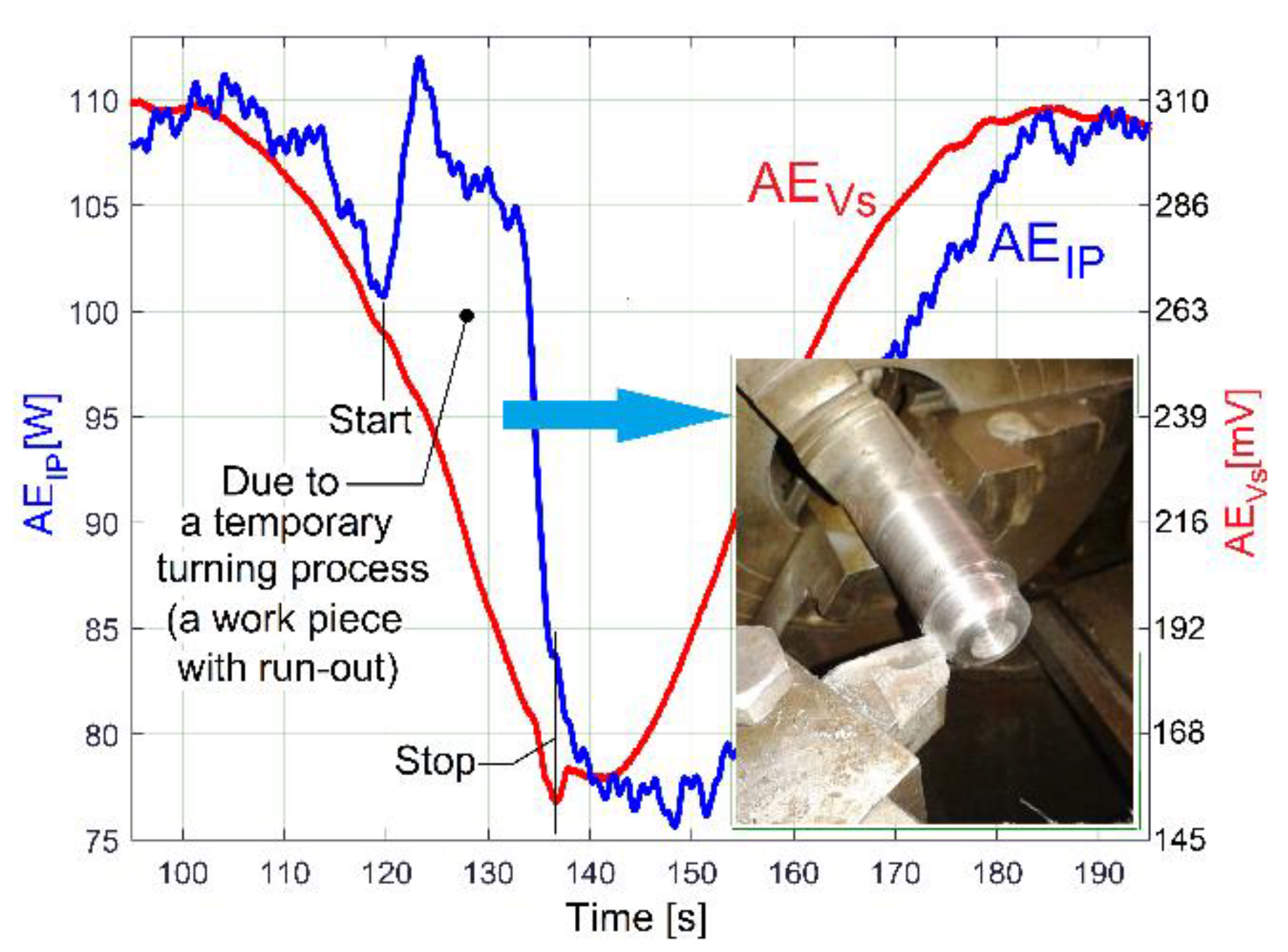

Under the same experimental conditions as in

Figure 25, a short sequence (approximately 17 s in duration) of a longitudinal interrupted turning process with manual feed, on a steel work piece (30 mm diameter) with radial run out (3 mm, bigger than the depth of cut—1.5 mm), acts temporary as a periodical mechanical power consumption phenomenon at the output spindle (as an additional part of the variable drive power

pvdpS). The influence of this sequence on

pE and on the evolution of the averaged AE

IP is clearly described in

Figure 28, with a local increasing of the averaged AE

IP and a shift of phase in comparison with the AE

Vs. The influence of this cutting process on the gearbox vibrations (more exactly on the AE

Vs) is null, as the action–reaction periodical cutting forces (against the work piece, respectively, against the cutting tool) cancel each other out. However, the AE

Vs decreases temporary when the cutting process ceases (because of the manual removal of the cutting tool from the process, some temporary damping is introduced).

The results and comments about

Figure 25 and especially

Figure 28 prove that some important phenomena involved in condition monitoring (e.g., related to a periodical mechanical loading) are not perceptible by a vibration sensor (however it may be useful for other phenomena). Also, it is highlighted here that there are two ways to describe a forced periodical vibration: directly, by using an appropriate vibration sensor, or indirectly, by measuring the mechanical power at vibration excitation source (here through the medium of the IP absorbed by the AC induction motor).

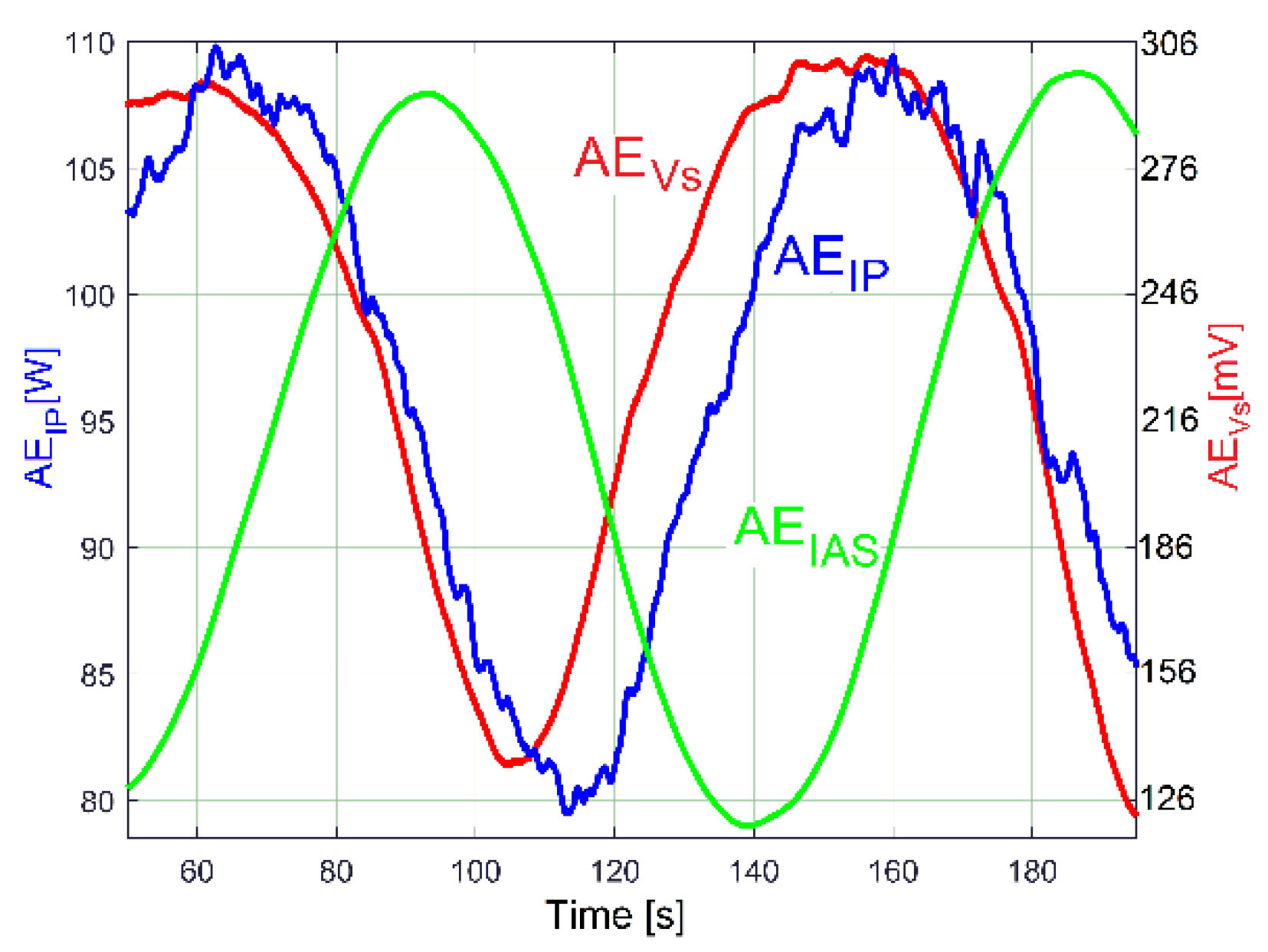

It is interesting that the beating phenomenon generated by shaft III and the spindle (previously illustrated in averaged AE

IP and AE

Vs evolutions) is also mirrored in the evolution of the amplitude of the peak E on the FFT spectrum of the IAS (as AE

IAS) evolution (

Ns = 347,406 samples,

Fs = 1737 s

−1). This evolution was obtained by the same procedure of analysis on the FFT with short movable sequences of IAS signal (as SMSIAS with

Nss = 2150).

Figure 29 presents the AE

IAS evolution (AE

IP and AE

Vs, too) during the experiment already described in

Figure 25.

Here, the AE

IAS evolution has a peak-to-peak variation of 0.0393 rad/s and an average value of 0.601 rad/s. It would be assumed that there is not a significant phase shift between AE

IAS and averaged AE

IP, but this hypothesis is not confirmed by

Figure 29. There is a shift of phase generated by the IAS sensor (a stepper motor working as a two-phase 50 pole AC generator [

46]). A false periodical IAS component is generated by IASS due to the constructive inaccuracy (as measurement error, with the fundamental component having the frequency

fES). An IAS beating phenomenon occurs, caused by the addition of three sinusoidal components: a sinusoidal component generated by shaft III with the frequency

fEIII (a consequence of variable power

pvdpIII +

pepIII), a sinusoidal component generated by the output spindle with the frequency

fES (a consequence of variable power

pvdpS +

pepS), and the fundamental of the IAS measurement error (also sinusoidal), with the frequency

fES. If the angular position of the IASS rotor related to angular position of spindle is changed, then the phase shift between AE

IAS and the averaged AE

IP evolution must also change. This is proved by the evolutions from

Figure 30 achieved in a new experiment, in similar conditions to those in

Figure 29. Here, there is a 0.0326 rad/s peak-to-peak variation and a 1.148 rad/s average value of AE

IAS, significantly bigger than before.

If the IASS rotor is attached to another shaft (e.g., shaft II, shaft I or the AC motor’s rotor), the measurement error induced by IASS (related to the negative influence on peak E’s amplitude on the FFT spectrum of IAS, in

Figure 13) disappears, and the AE

IAS and averaged AE

IP evolutions should then be in phase.

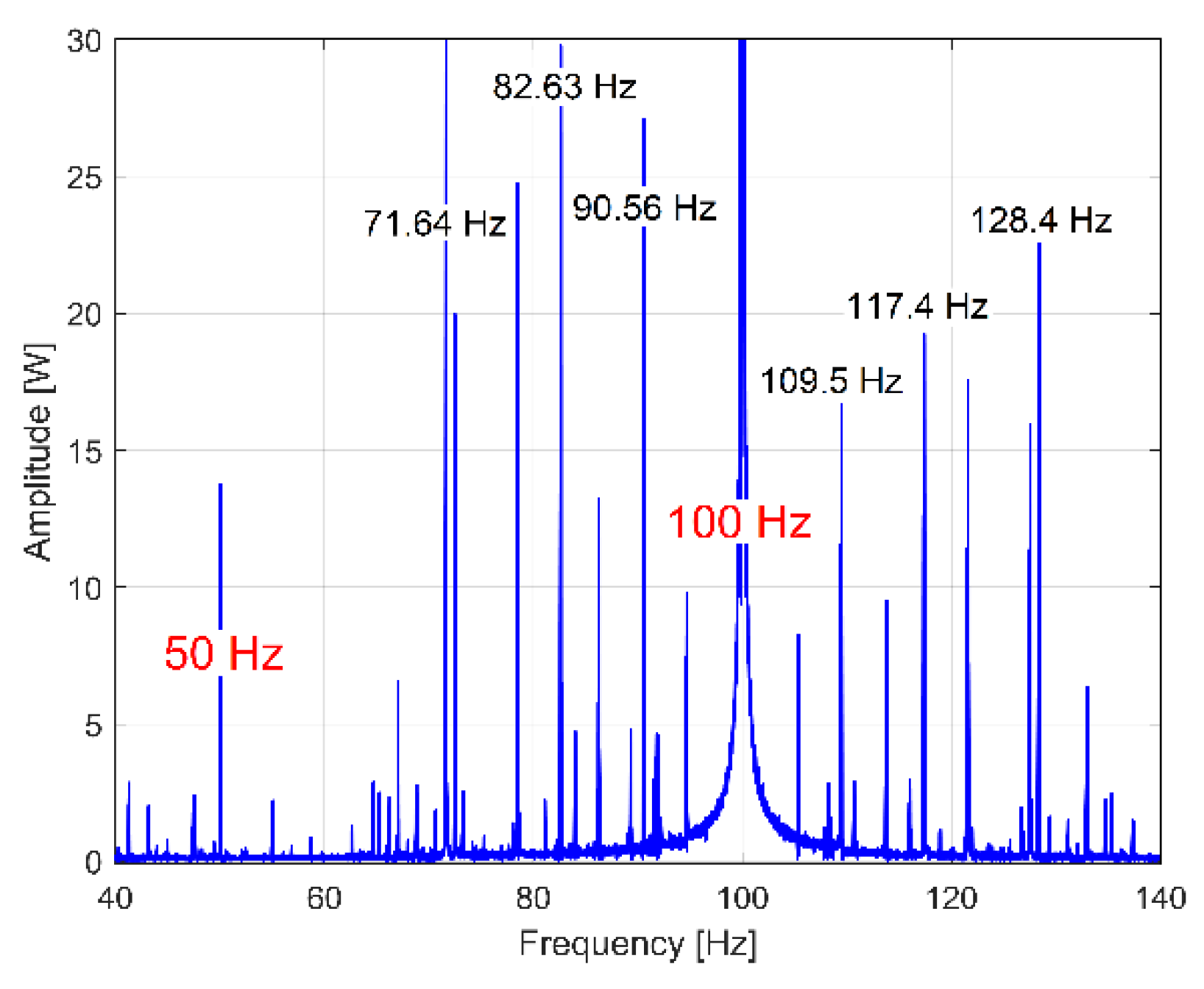

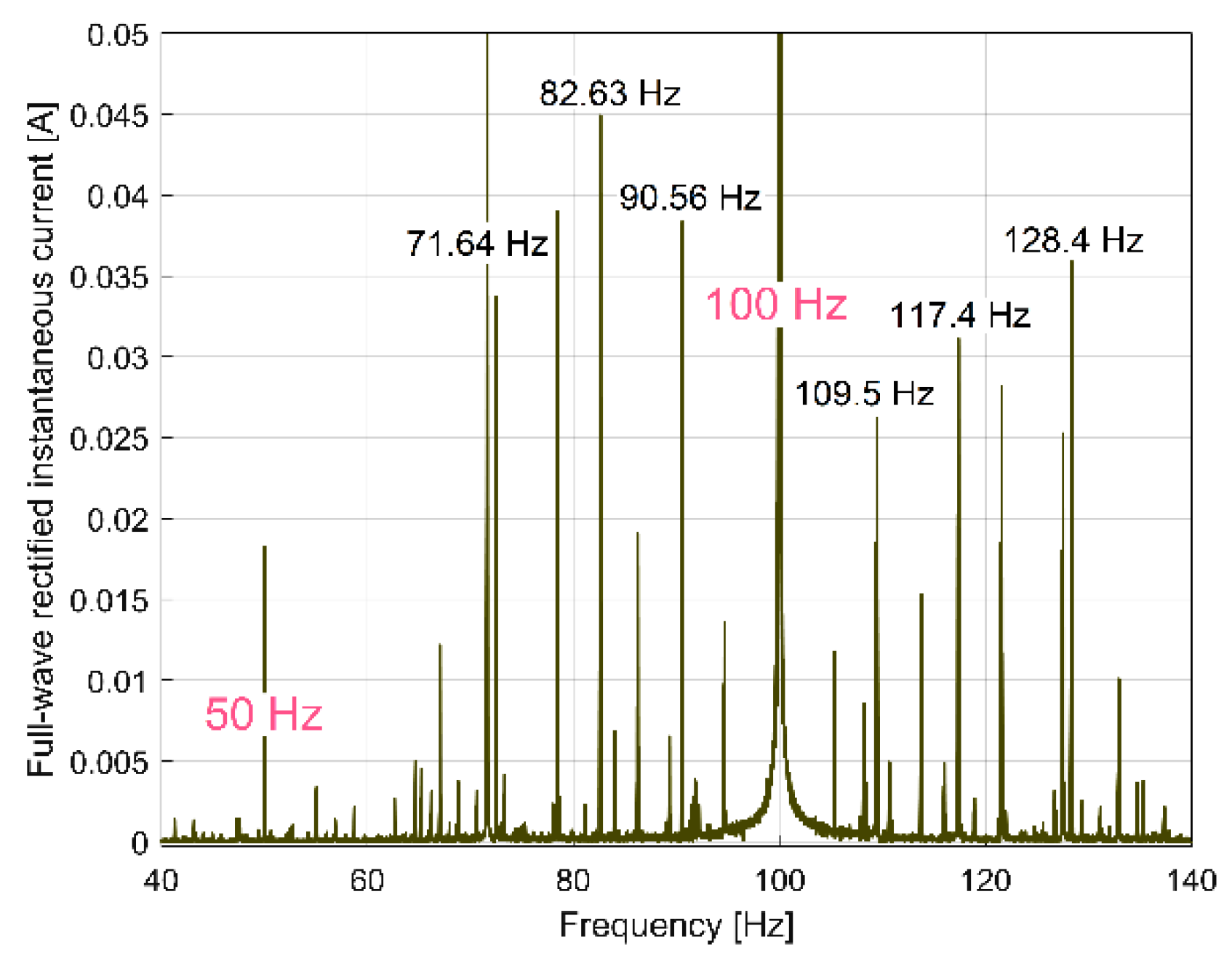

For condition monitoring purposes concerning other parts of the gearbox (e.g., gears, bearings, etc.), the best approach is to use the entire FFT spectrum of IP (or RIC and eventually RIV as well), mainly in order to check the values and the evolutions of the amplitudes of high order harmonics of the fundamentals generated by the shafts where the gears and the bearings are placed.

All of the harmonics of the fundamentals on 50 Hz and 100 Hz (electrically generated in the IP or RIC spectra) should be ignored. The availability of the FFT spectrum for this purpose is proved in

Figure 31, which depicts a short sequence of the IP spectrum, and in

Figure 32, which depicts a short sequence of the RIC spectrum. The same range of frequencies (40 ÷ 140 Hz, as example) is used for both spectra.

It is obvious that there are strong similarities between these IP and RIC spectra (at least related to the frequency of the spectral peaks). It is important to mention that some peaks in the IP and RIC spectra are related to the excited torsional vibration modes of the shafts and spindle, this being a challenge for a future study.

In contrast with IAP

1, the IP (or RIC, RIV) spectrum does not (invariably) have an upper limit at 50 Hz. The value of the Nyquist frequency for the IP (or RIC, RIV) spectrum (12,500 Hz in

Figure 31 and

Figure 32) depends only on the value of the sampling frequency (25,000 s

−1 here).

It is expected that many other gearbox condition monitoring techniques presently used in vibrations or instantaneous current analysis in the frequency domain are applicable to the IP (or RIC) evolutions.

For non-stationary processes (e.g., starting, stopping and the changing of spindle speed by changing the gearing diagram), or, eventually, for a catastrophic failure, the FFT analysis is useless (except probably the analysis with the FFT of short movable sequences). Nevertheless, these processes can be very well characterized using the evolution of the low pass filtered instantaneous average electrical power IAP

1, as was proved in [

1].

4.2. An Approach on IAP1 Signal Components Identification by Curve Fitting

The FFT spectrum of IP describes the frequency of each component well and the amplitude fairly well. A better approach to the study of the behaviour of the gearbox parts mirrored in the IP evolution is possible if a complete description of each variable IP component (as a sinusoidal evolution, with amplitude, frequency and phase at origin of time) is achieved by curve fitting (with the sum of sinusoids model) as a signal components identification procedure. For curve fitting, two options were explored, both having similar results: a method proposed by us (slower), and a method based on Curve Fitting Tool (faster), both conducted in Matlab.

However, at first glance, it is relatively difficult to identify the IP components, because the IP has a high Nyquist frequency and too many sinusoidal components (including the electrically generated dominant on 100 Hz and its harmonics). If we are interested only in the description of low frequency IP sinusoidal components (e.g., between 0 and 40 Hz, as previously), then it is better to use the curve fitting of the IAP

1 evolution (the instantaneous active power absorbed by the AC motor, defined as being three times IAP

A1), which has a Nyquist frequency of 50 Hz and a sampling frequency of

Fs = 100 s

−1. Of course, in the range of 0 ÷ 50 Hz, the IP and IAP

1 have the same sinusoidal components. For an IAP

1 sequence with a duration of 5 s (

Ns = 500 samples), the curve fitting procedures allow the determination of at least 38 of the most significant sinusoidal components (some of them described in

Table 2). At each step in the curve fitting method, a single sinusoidal component is identified (usually that with the highest amplitude) and mathematically removed from the IAP

1 evolution.

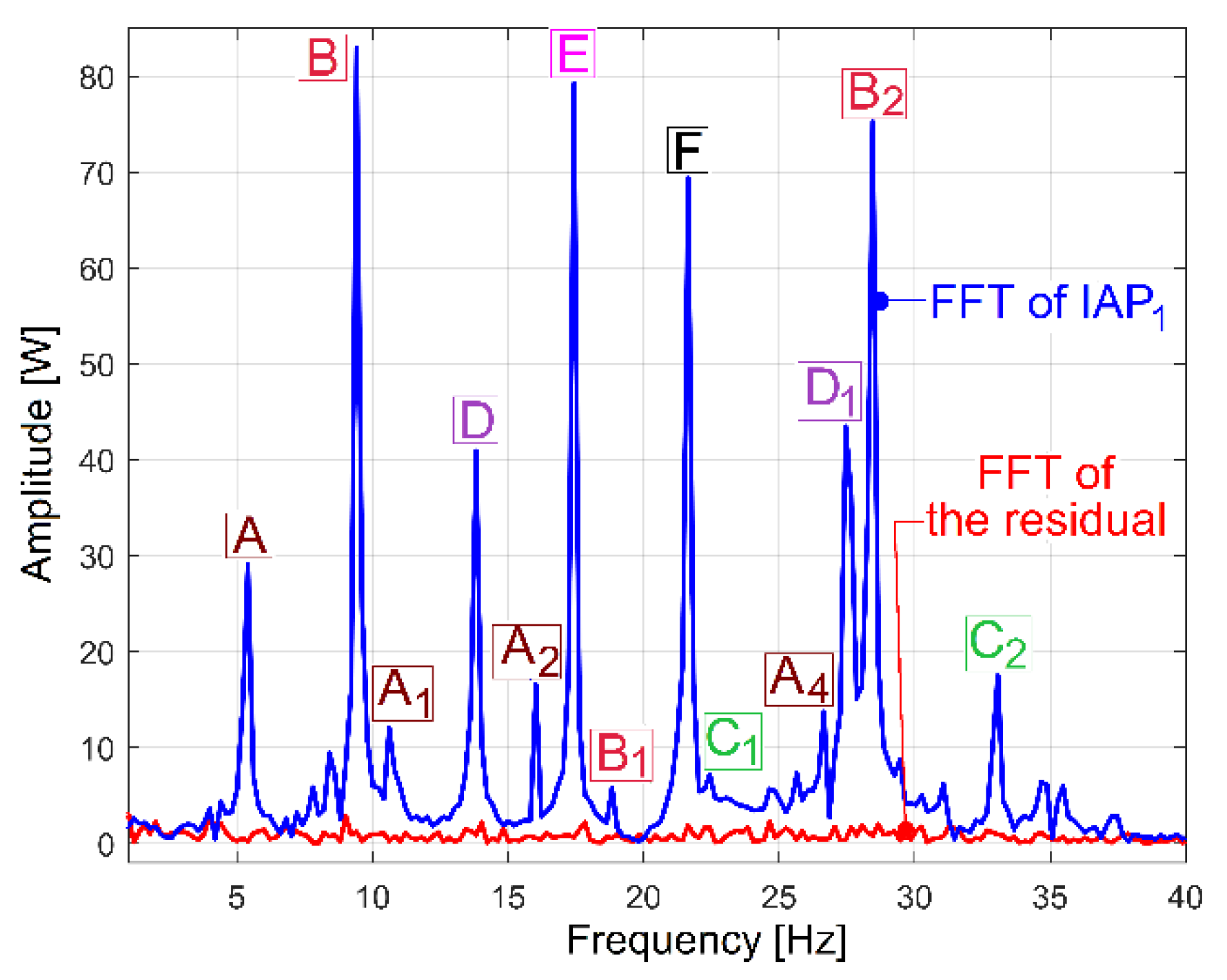

The first confirmation of the correctness of this identification is provided in

Figure 33. Here, the blue evolution is the FFT spectrum of IAP

1, while the red evolution is the FFT of the residual evolution after these identified 38 sinusoidal components were removed (mathematically subtracted) from IAP

1. It is obvious that the FFT of the residual does not contain significant peaks anymore.

Because of a small resolution of the FFT for the IAP

1 spectrum (only 0.2 Hz in

Figure 33, by comparison with the resolution of 0.01 Hz for IP in

Figure 9), some variable components in the IAP

1 spectrum are hidden (e.g., C

1, A

3, A

5, A

6, E

1). However, they are well revealed by curve fitting.

Table 2 presents the values of the amplitude and frequency of the 20 most significant sinusoidal components from IP (already revealed before in

Table 1) and the values of amplitude, frequency and phase at origin of time for the same sinusoidal components, but as determined by curve fitting of IAP

1.

The second confirmation of the correctness of the identification and description of low frequency IAP1 sinusoidal components by curve fitting is provided in

Figure 34. Here, the experimental evolution in the time domain for the variable part of IAP

1 is depicted (as a blue curve, a short sequence with duration of 1.5 s, with 150 samples, at the beginning of the sequence analysed by curve fitting), along with the evolution of the variable part of the power theoretically built by the mathematical addition of these 38 sine-identified components (the evolution depicted with a red curve). It is obvious that these two evolutions fit fairly well each other. The difference between these evolutions is described by quite a small residual (the experimental evolution minus the theoretical one) in

Figure 34. The results from

Figure 33 and

Figure 34 (and

Table 2 as well) are another argument that IP (IAP

1) is a predominantly deterministic signal, well distinguished from the noise by a relatively small residual.

By mathematical addition of the sine components A (as fundamental) and A

1 ÷ A

6 (as harmonics) identified by curve fitting, it is possible to find the evolution of the variable part of IAP

1 (or IP as well) generated by flat belt 1. Because, in

Table 2, the frequencies

fAi of the harmonics A

i (depicted in the 4th row, identified by curve fitting) are not perfectly related to the frequency

fA of the fundamental (with the relationship

fAi = (

I + 1)

·fA), mainly because of errors in curve fitting, it is more appropriate to approximate the value

fA with an average value

fAa calculated as described in Equation (4).

In this way, the frequencies of the harmonics are now approximated as fAai = (i + 1)fAa (e.g., fA = 5.336 Hz becomes fAa = 5.3336 Hz, fA1 = 10.664 Hz becomes fAa1 = 10.6672 Hz, … fA6 = 37.330 Hz becomes fAa6 = 37.3352 Hz).

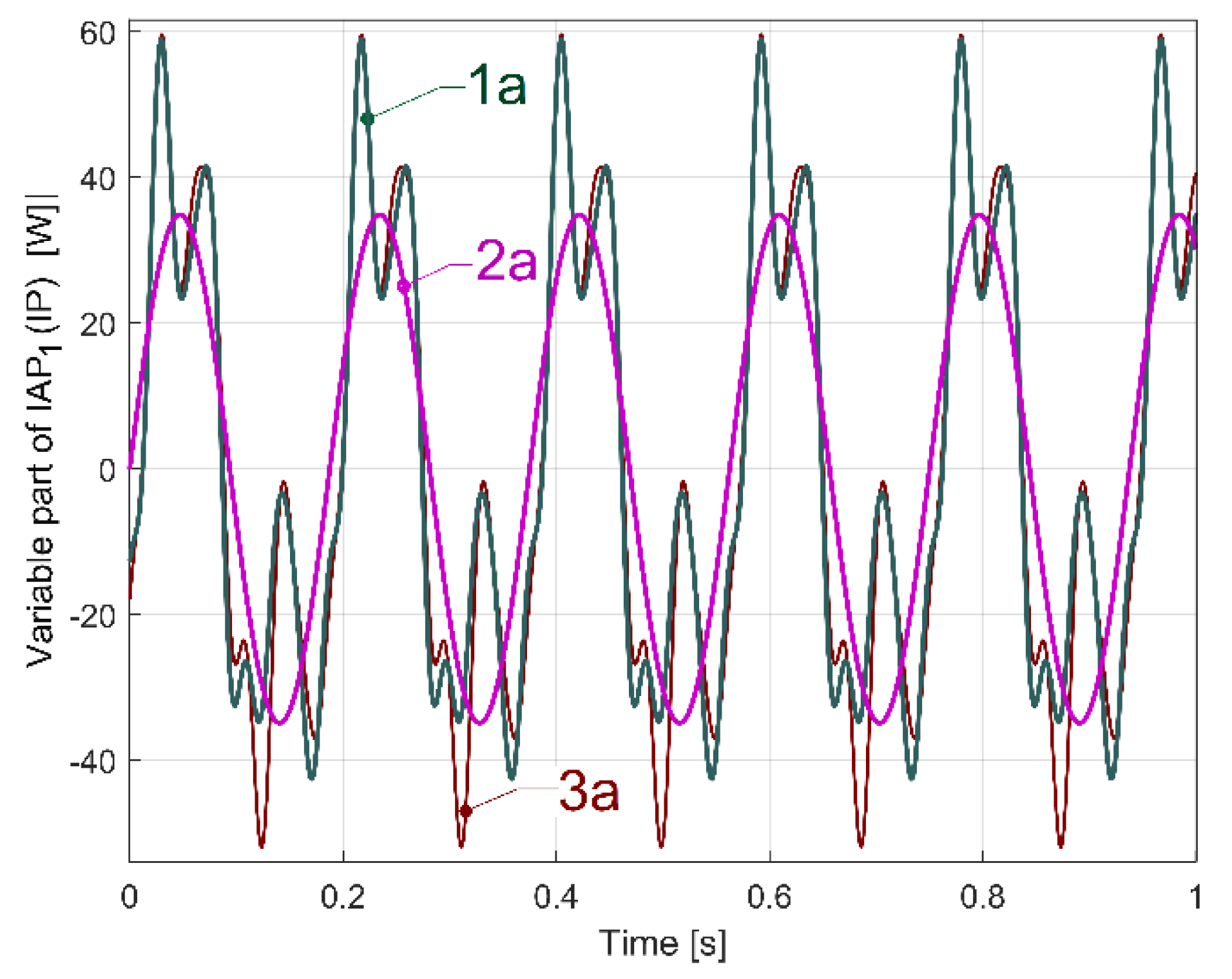

In such a way, a more accurate description of the evolution of the variable part of IAP

1 (or IP as well) generated by flat belt 1 is possible, as curve 1a in

Figure 35 indicates.

Here, curve 1a results from a mathematical addition of the sinusoidal components A, A

1 ÷ A

6 (having the frequencies

fAa,

fAai and the amplitudes indicated in

Table 2) with a sampling frequency of 25,000 s

−1, in a simulation during 1 s. Curve 2a in

Figure 35 depicts the evolution of the fundamental A. The new origin of time for the curves 1a and 2a is considered to be at a zero-crossing moment (from negative to positive values) of the fundamental A. Before the addition of the sinusoidal components, all the phases at origin of time for components A, A

1 ÷ A

6 from

Table 2 are recalculated relative to this new origin of time. Curve 3a describes in the same way the evolution of the variable part of IAP

1 (IP) generated by the same flat belt 1 after 100 s of supplementary running in idle of the gearbox. It is obvious that there is quite a good similarity between the curves 1a and 3a, with some relatively minor changes, probably due to the rising temperature of the belt and pulleys.

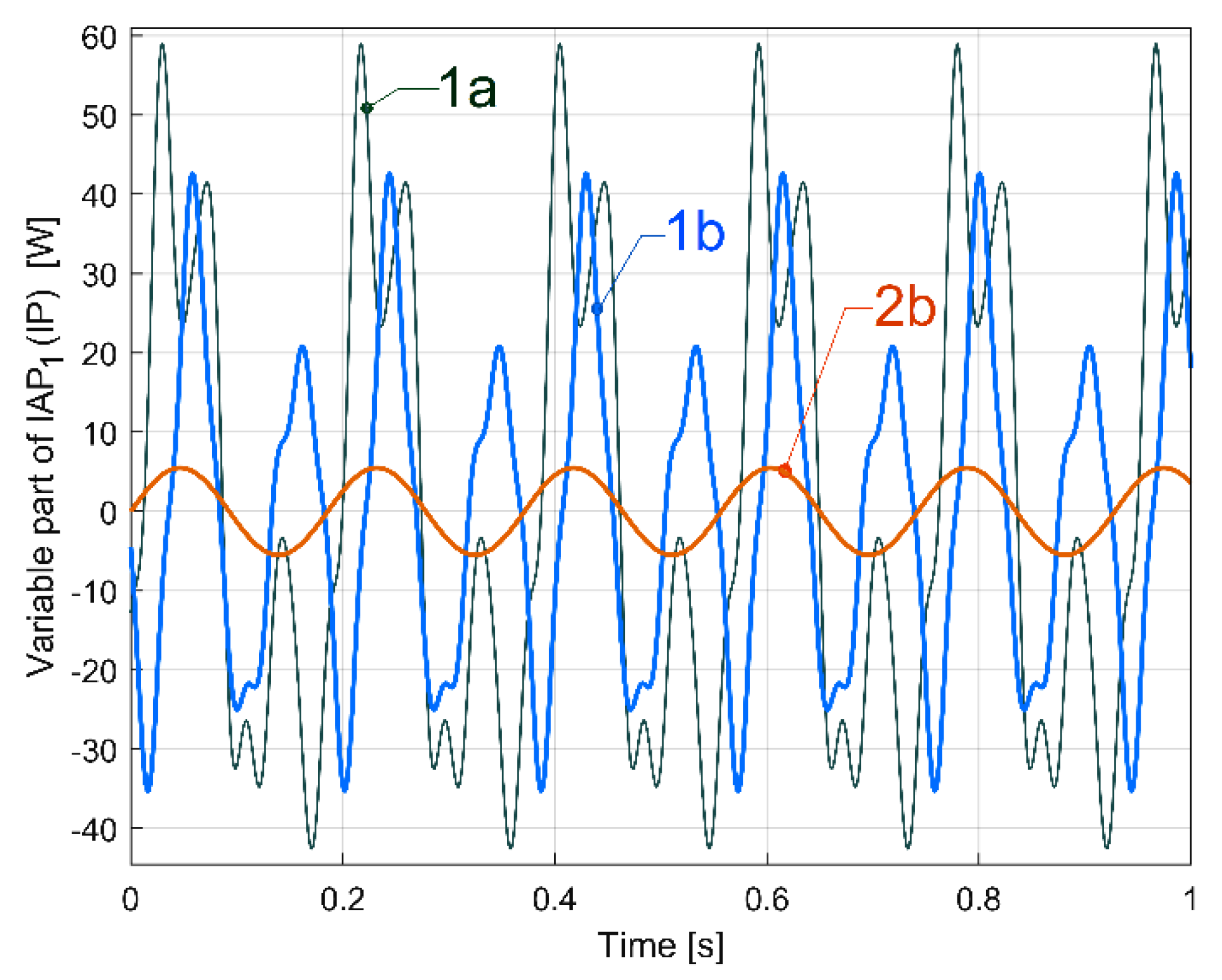

By comparison with the evolution depicted by curve 1a (from

Figure 35), curve 1b in

Figure 36 presents the description of flat belt 1’s influence on the variable part of IAP

1 (or IP as well) if, in the gearing diagram (

Figure 2), the electromagnetic clutch EMC3 is disengaged. Now, the rotation of shafts II and III and the output spindle are stopped, the AC motor drives only flat belt 1 and shaft I, and the average value of the IAP1 decreases from 3067 W (related to

Figure 35) to 1021 W (related to

Figure 36). Apart from changing the aspect of evolution (1b versus 1a), the amplitude of the fundamental (37.99 W on curve 2a) strongly decreases (only 5.5 W on curve 2b).

Here

fA = 5.390 Hz and

fAa = 5.388 Hz. In

Figure 36, there is a small progressively decreasing time delay between the curves 1a and 1b because the value

fAa is slightly different (5.336 Hz for curve 1a compared to 5.388 Hz for curve 1b). The decrease in the mechanical loading of the AC induction motor (due to the fact that the electromagnetic clutch EMC3 is disengaged) produces a slight increase in rotation speed, and the increase in the frequency

fA (and

fAa as well) is due to the decreasing motor slip.

We should mention that (with the electromagnetic clutch EMC3 disengaged) the dynamic model of the AC motor’s rotor, which is rotated by a rotary magnetic field, now has a torsional vibration mode of 10.785 Hz in frequency (with an 0.308 damping ratio). With

fA1 = 10.77 Hz, there is a resonant amplification for the first harmonic A

1 (having a 26.95 W amplitude). Because of structural damping, this resonant amplification strongly decreases when the entire gearing diagram is used (in

Figure 35, on curve 1a, and in

Table 2, the same first harmonic A

1 has its amplitude diminished at 15.48 W).

Similarly, by the mathematical addition of sine components B, B

1, B

2 and B

3 (having their description revealed by curve fitting, but with the frequency of harmonics

fBai = (

I + 1)

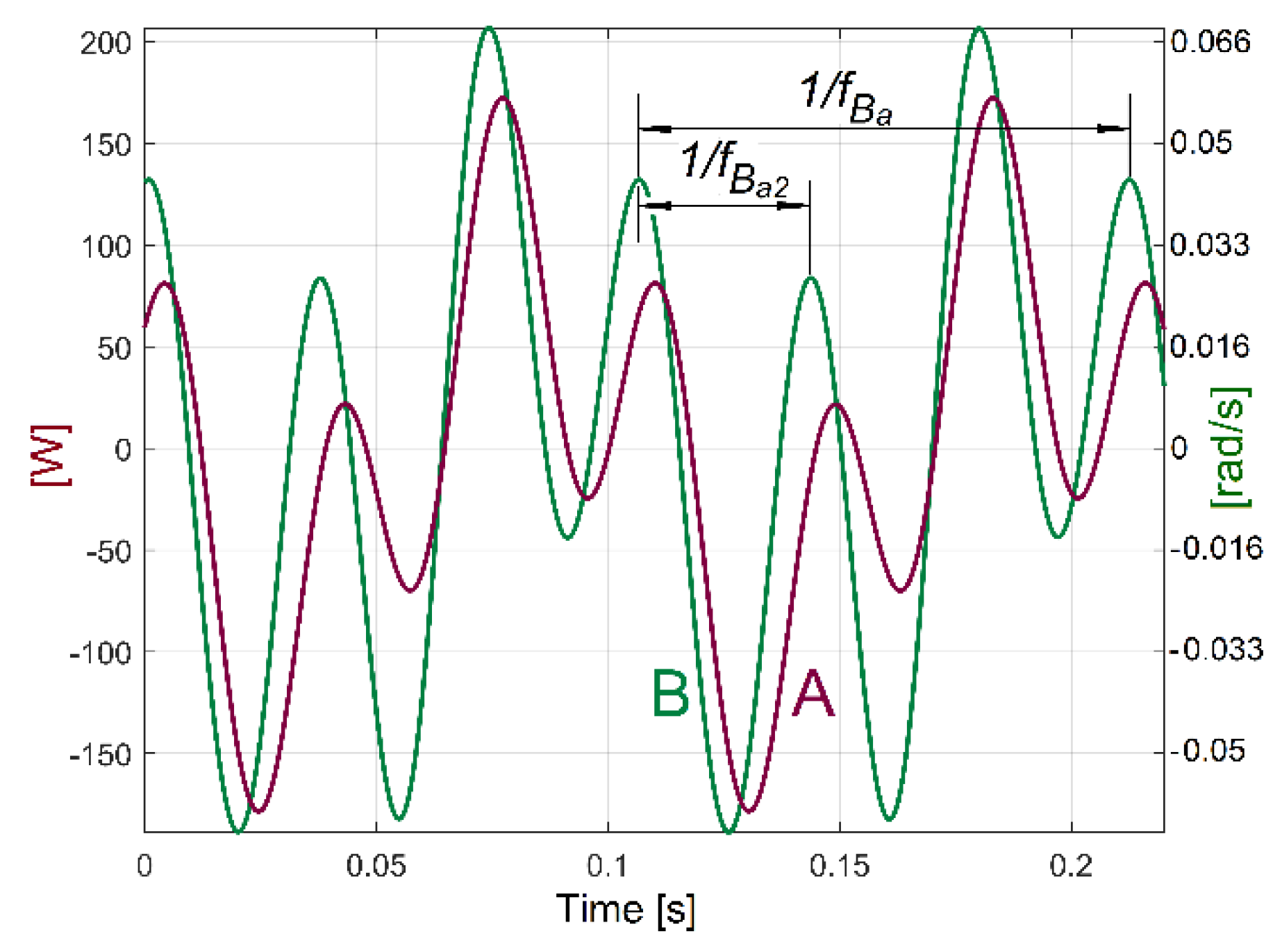

·fBa and

fBa = 9.4423 Hz calculated in the same way as in Equation (4)), it is possible to find the evolution of the variable part of IAP

1 (or IP as well) generated by flat belt 2, as

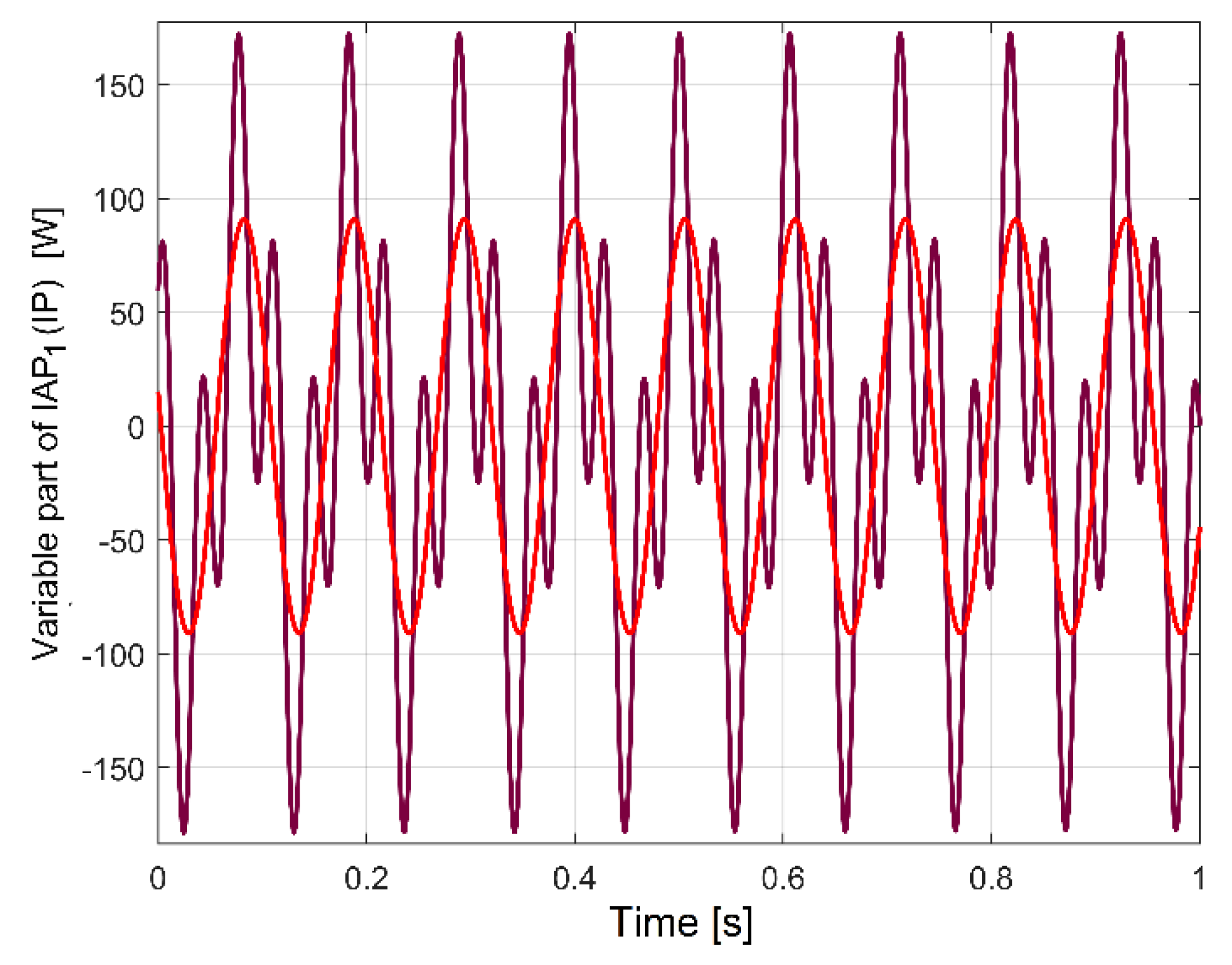

Figure 37 indicates (with the fundamental in red).

The analysis by curve fitting allows a comparative study of the variation produced by flat belt 2 on IAP

1 (curve A in

Figure 38, as a short sequence from

Figure 37) and on IAS (curve B in

Figure 38) during the same experiment. There is a difference of shapes and a shift of phase between the curves because IAP

1 is measured on the AC motor (at the gearbox input), and IAS is measured at the output spindle (at the gearbox output). The gearbox introduces different attenuations (and different phase shifts) for the influence of flat belt 2 (on IAP

1 and IAS) towards the AC motor and towards the output spindle.

The evolutions from

Figure 35,

Figure 36 and

Figure 37 are useful in the condition monitoring of the flat belt transmissions (available for many other types of belts). There is a simple possible approach: if the peak-to-peak value of the IAP

1 (IP) variable part generated by a belt (or the amplitude of the fundamental or some harmonics) exceeds an imposed limit, then the end of its proper working life has been reached. This is clearly proved by a new experiment. The headstock gearbox runs in idle in the configuration already depicted in

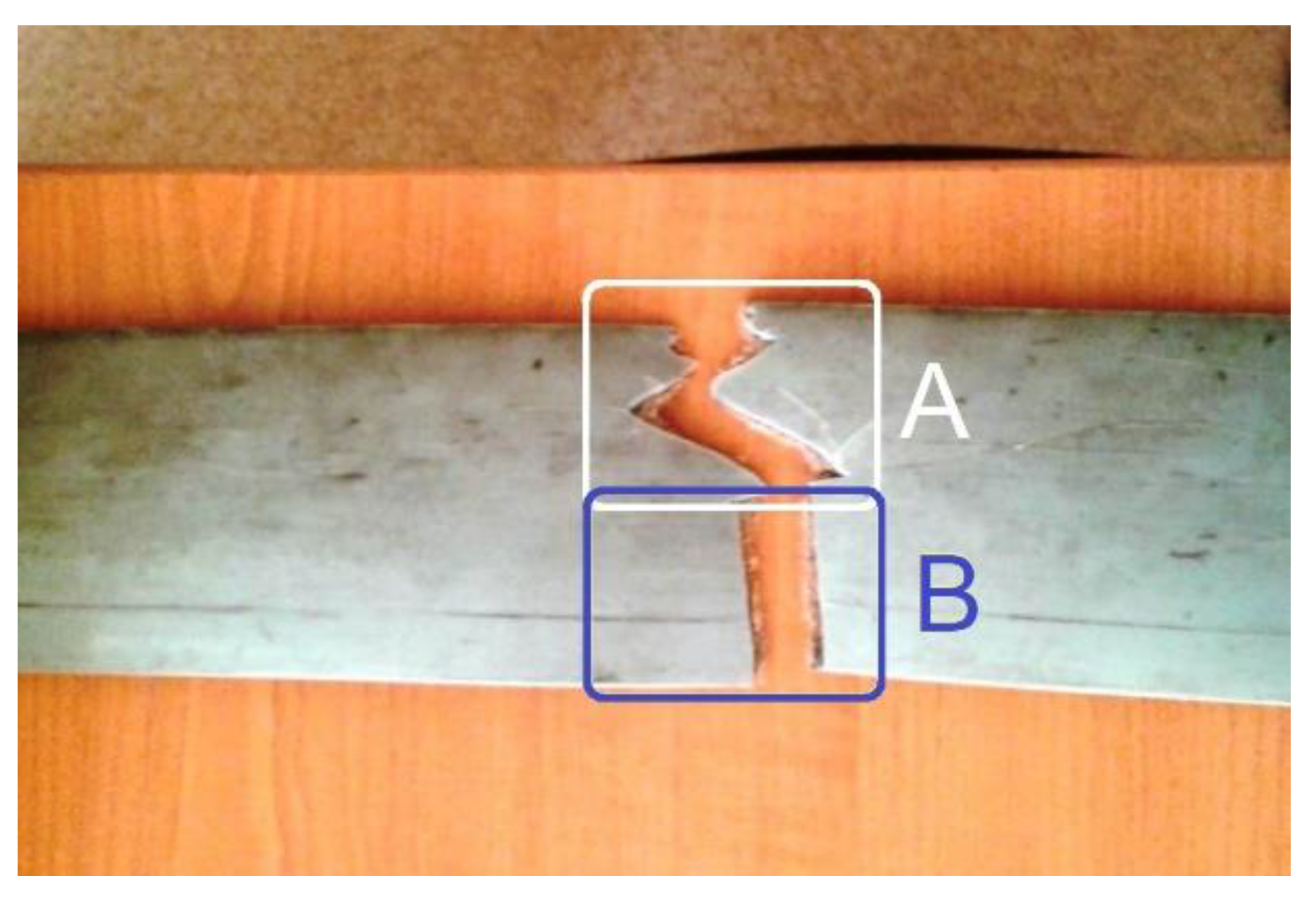

Figure 2 and used in the previous experiments. This time, a damaged flat belt 1 (more than 40 years old) was used.

Figure 39 presents a partial view of this flat belt, finally broken during the experiments.

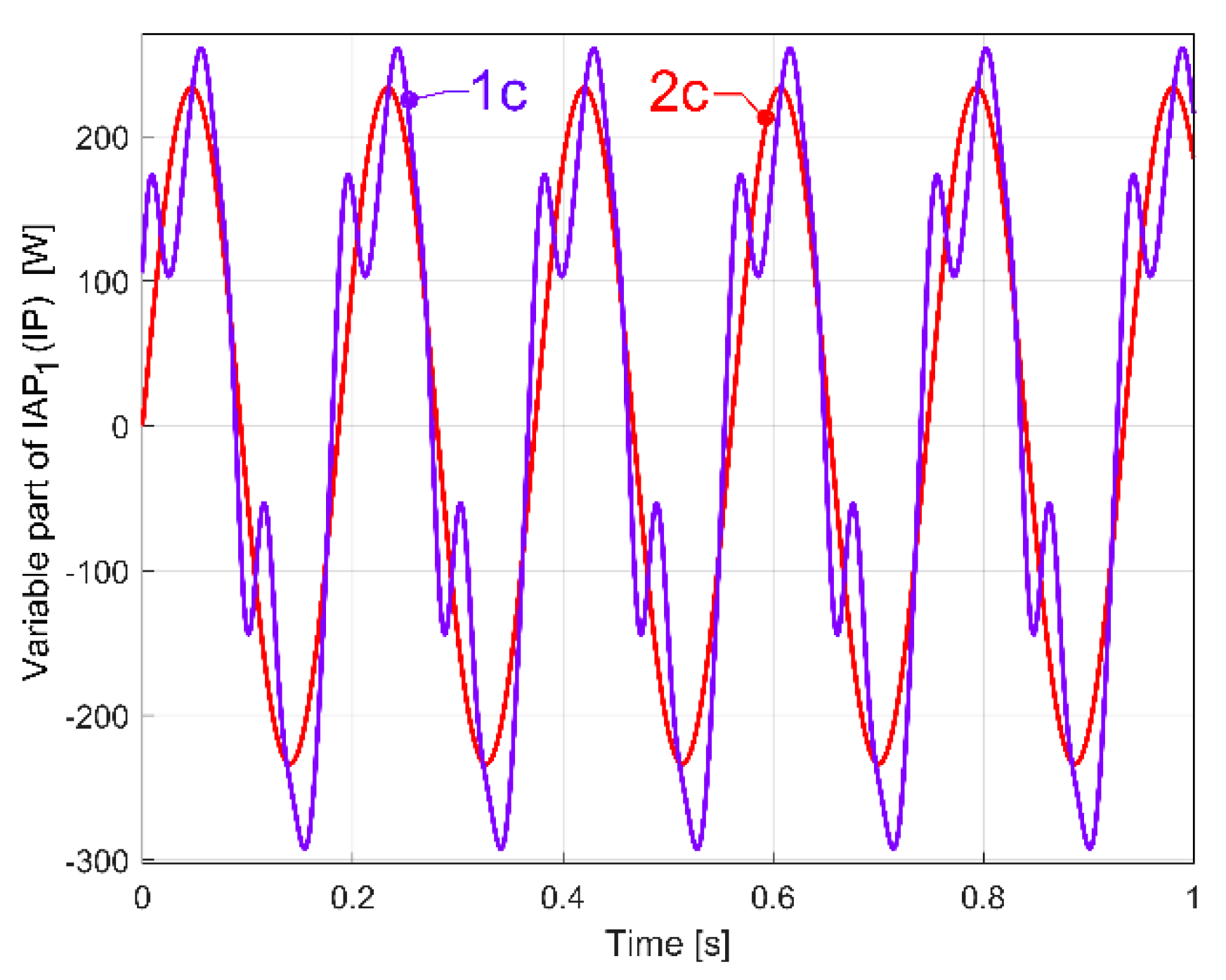

Firstly, the belt was partially broken only in area A, due to a mistake made when it was reinstalled on the pulleys. A severe decrease in the belt’s stiffness is produced in that area. For the time being, the belt is not yet broken in area B. The description of the variable part of IAP

1 (IP) generated by this damaged flat belt was determined in a similar way to those depicted in

Figure 35 (for curve 1a) and described with curve 1c in

Figure 40.

Here, curve 2c describes the evolution of the fundamental. A comparison between

Figure 35 and

Figure 40 reveals a big increase in the peak-to-peak evolution of the variable part of IAP

1 (IP) generated by the damaged belt compared with a regular one, and a big increasing in the amplitude of the fundamental (233.704 W here, in contrast with 37.99 W in

Figure 35).

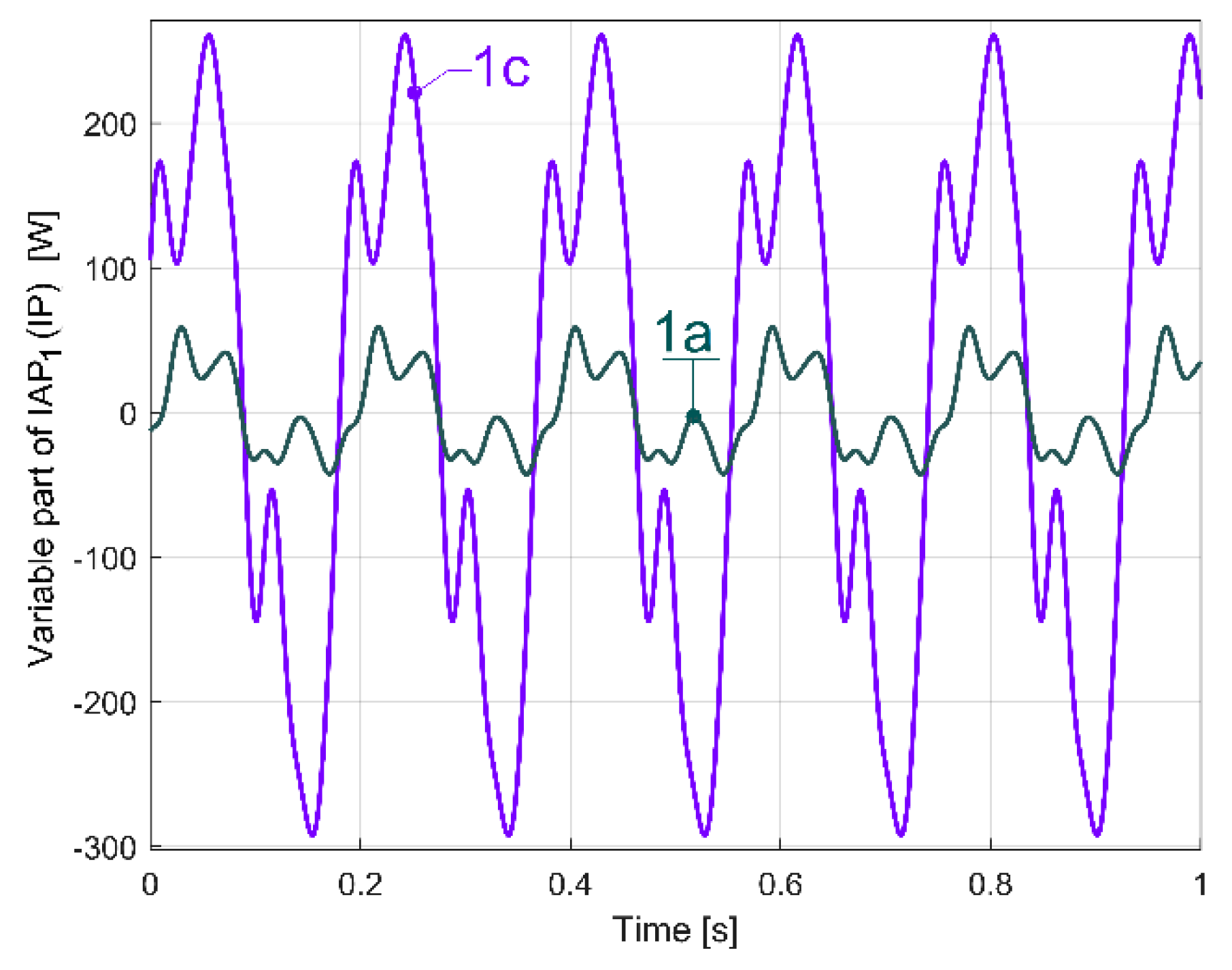

A better comparison between curve 1a (from

Figure 35, which describes the behaviour of a regular flat belt) and curve 1c (from

Figure 40, which describes the behaviour of a damaged flat belt) is allowed by

Figure 41. The same magnitude was used for both curves.

It is obvious that damage to a flat belt can be detected a long time before a catastrophic failure. We should mention that this flat belt was completely broken much later in area B (

Figure 39) during an experiment with an abnormally severe transient regime of gearbox acceleration.

We should highlight an important matter: the comparison between curves 1a and 3a in

Figure 35, or between curves 1a and 1b in

Figure 36, or between curves 1a and 1c in

Figure 41 (each curve being the result of a different experiment) was possible (related to the phase relationships between the curves) firstly because each one has its origin on time strictly (recalculated) at a zero-crossing moment of its fundamental (curve 2a, 2b and 2c respectively) and secondly because the fundamentals have, with a good approximation, the same frequency.

This type of condition monitoring can be also applied for other types of drive belts (e.g., v-belts, in some preliminary experiments).

In the same way, it is possible to produce good descriptions of the behaviour of some other parts of the gearbox (especially the shafts) and to detect abnormal operating situations using mainly the variable parts of IAP1 (IP).

As a first example, the ordinates of some samples of the AE

IP evolution from

Figure 22 were recalculated by curve fitting (as AE

PCF samples). Each AE

PCF sample (described as a red rectangle in

Figure 42, a completion of

Figure 22) describes an average of the amplitude of peak E during 5 s of the evolution of IAP

1, determined by curve fitting (the spectra of IP and IAP

1 being identical). The fact that there is no perfect fit between the AE

IAP1 samples and the average AE

IP indicates once more that the IP

E (or IAP

1E as the variable part of IAP

1 related to peak E) has a noisy evolution, partially because the frequency

fE of the peak E on IAP

1 (IP) is not strictly constant (another issue involved in condition monitoring). The average values of this frequency for each AE

IAP1 sample (also a result of curve fitting process) are written in

Figure 42.

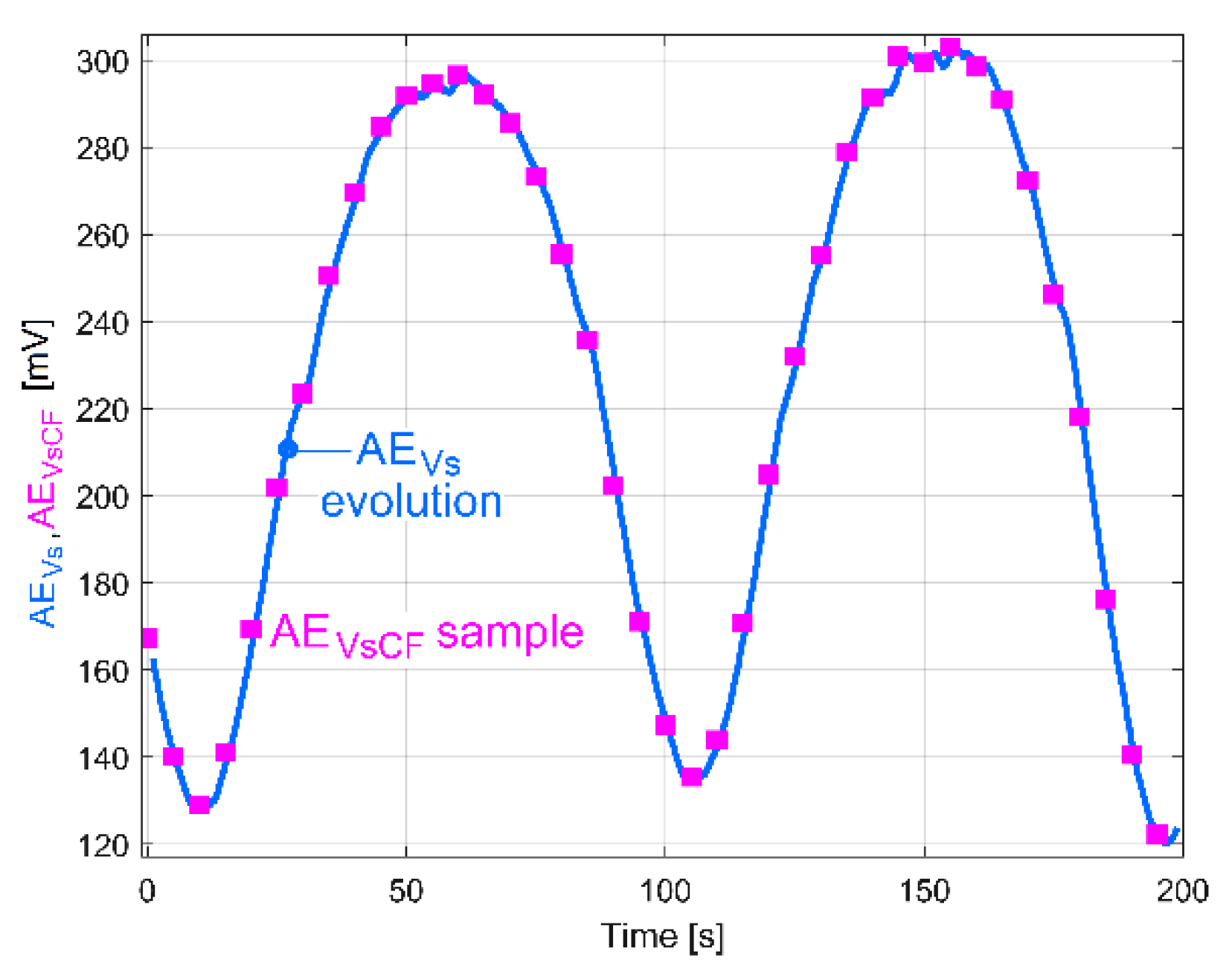

As a second example, the ordinates of some samples of the AE

Vs evolution (curve 2 from

Figure 20, depicted in bright blue in

Figure 43) were recalculated by curve fitting from the VS

S signal (as AE

VsCF samples).

Each of the 40 timewise equidistant AE

VsCF samples (depicted as pink rectangles in

Figure 43) describes an average of the local amplitude of peak E during 1 s of evolution of VS

S, determined by curve fitting. This time, there is an almost perfect fit between the AE

Vs evolution and the AE

VsCF samples (due to the fact that the component E is dominant in vibration). This means, first, that both methods for finding the amplitude of the peak E on VS

S (the FFT spectra on short movable sequences SMSVs and the curve fit) work quite well. Secondly, this means that, in contrast to the AE

IP (or AE

PCF) evolution, the AE

Vs (and AE

VsCF as well) evolution does not have a noisy evolution. In the amount of power used to rotate shaft III and the spindle (

pE =

pvdp +

pep) the AE

IP (noisy) evolution is strictly related to the power

pE, while the AE

Vs (noiseless) evolution is strictly related to the power

pep. It follows that the power

pvdp also has a noisy evolution.

The determination of the mathematical description of the main signals components (sum of sinusoids model) by curve fitting can be successfully applied for condition monitoring purposes based on the gearbox vibration [

49,

50] (partially proved in

Figure 43) or instantaneous angular speed evolutions (partially proved in

Figure 38).