Recent Advances in Sensors for Fire Detection

Abstract

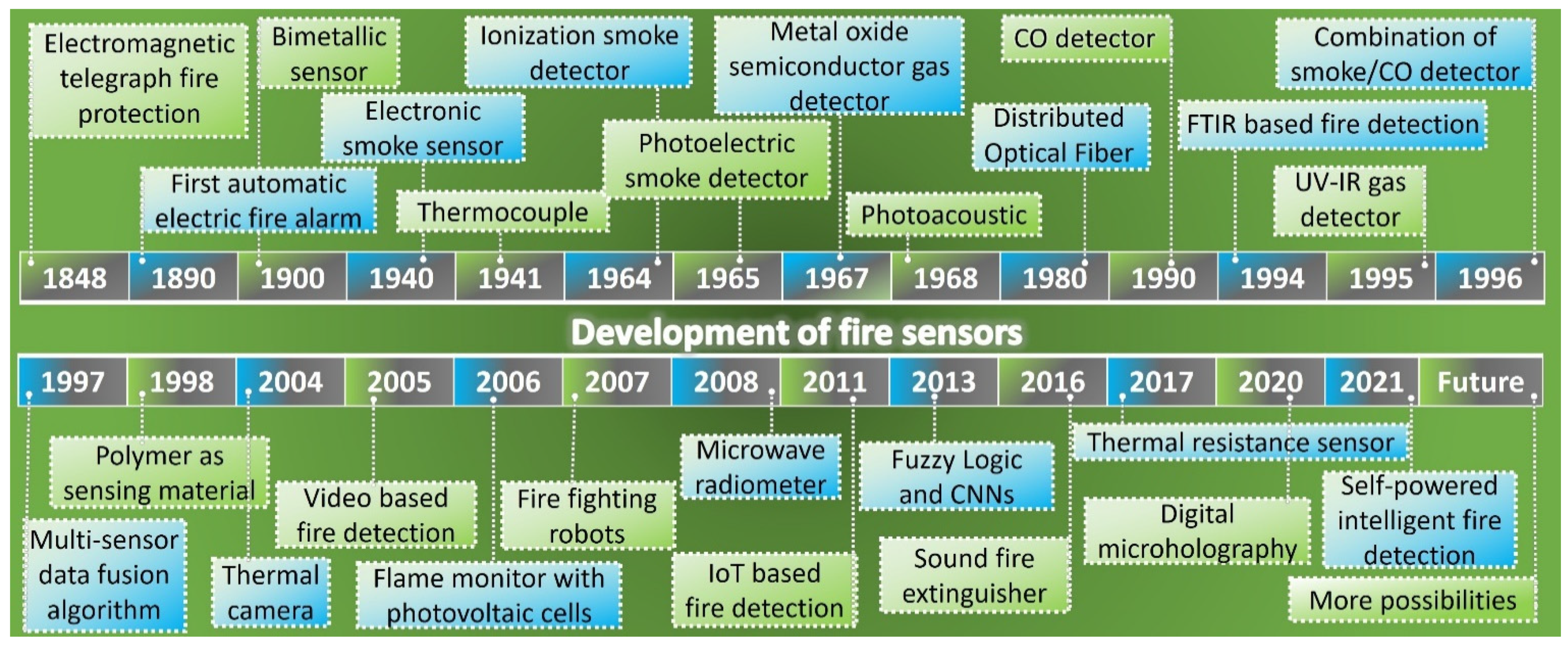

1. Introduction

2. Stages of Fire and Structural Designs for Fire Risk Mitigation

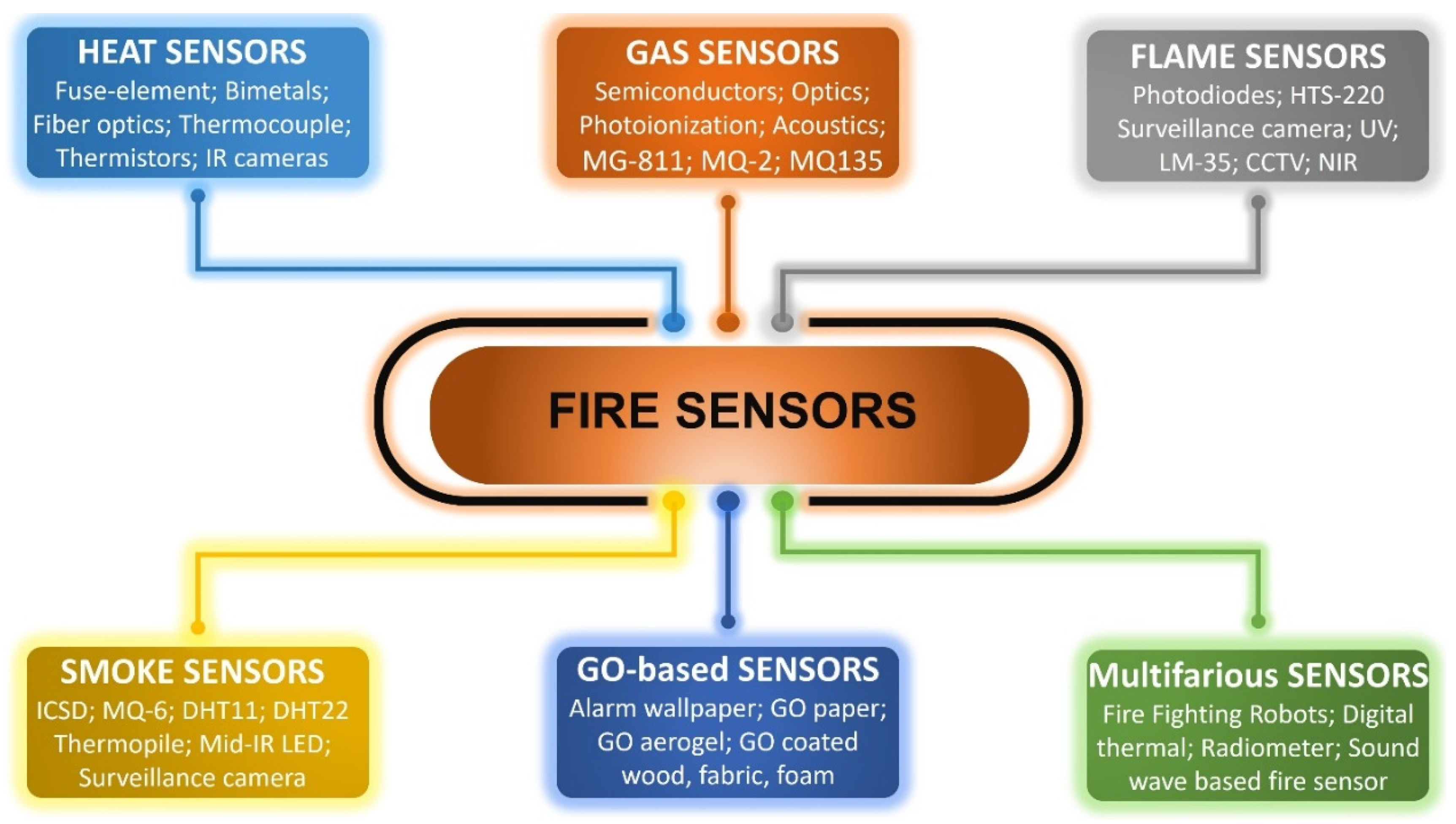

3. Fire Sensors

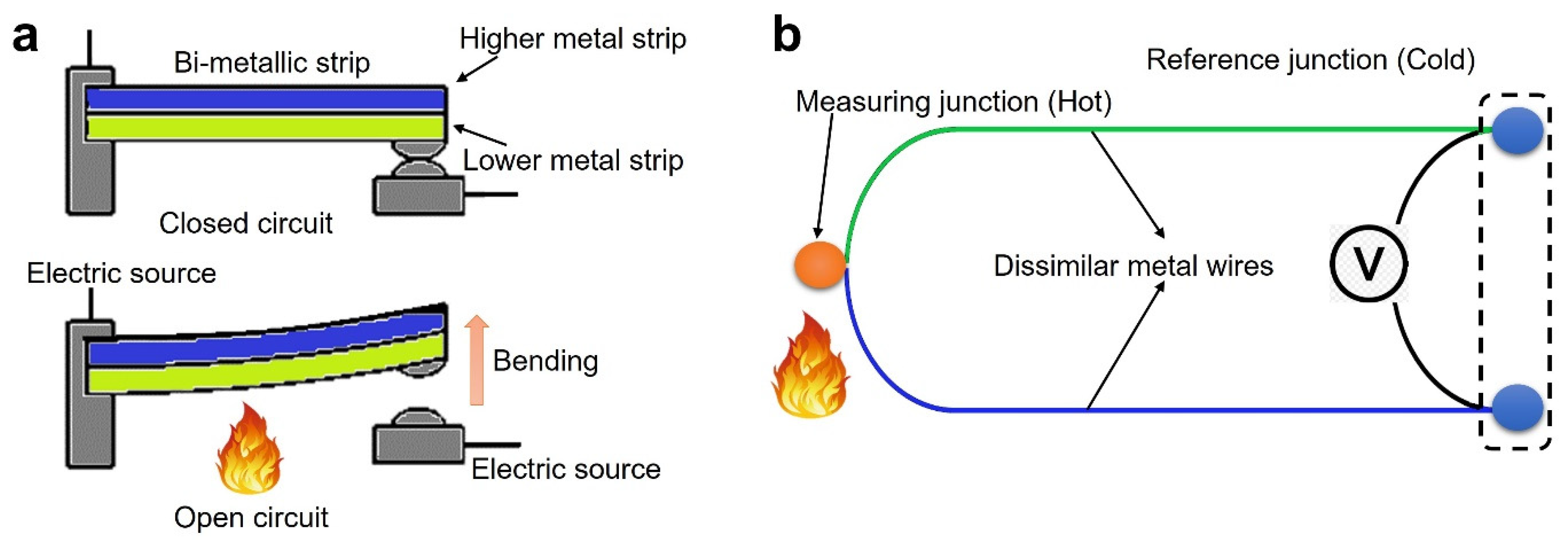

3.1. Heat Sensors

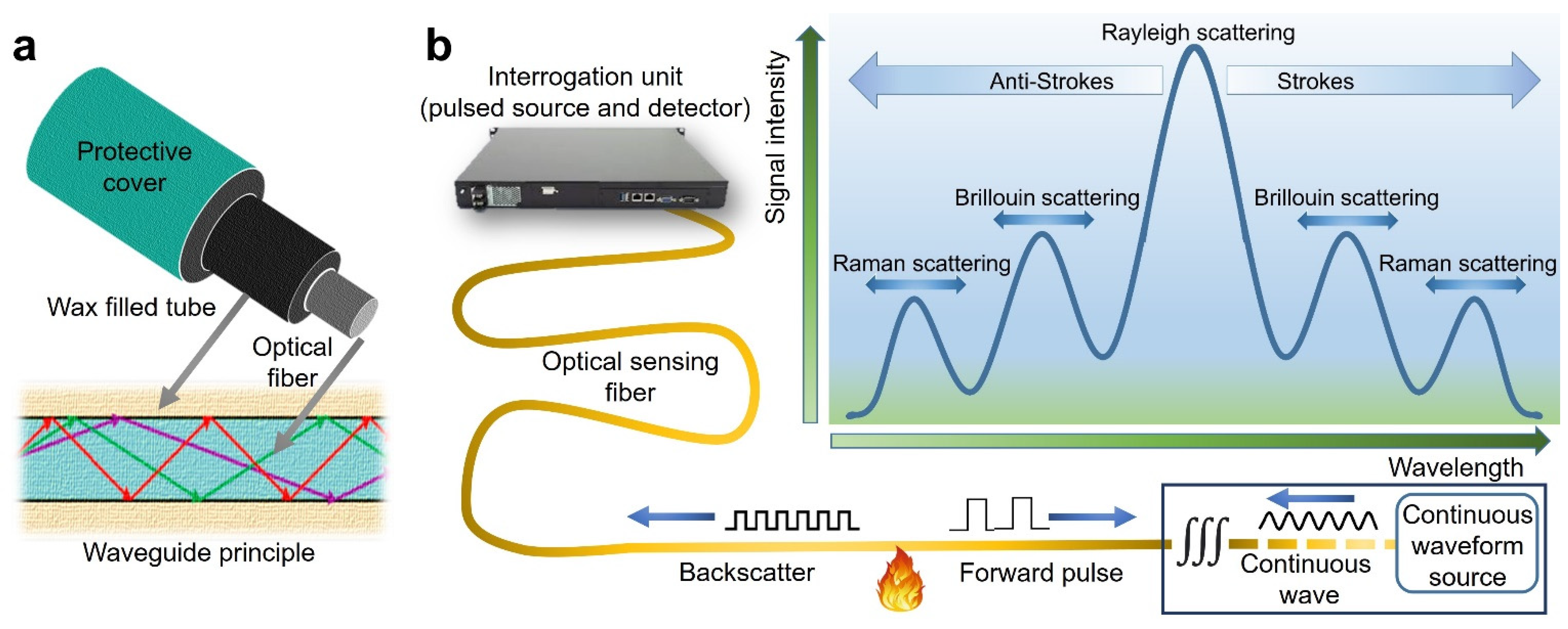

3.1.1. Distributed Optical Fiber Heat Detectors

3.1.2. Thermal Resistance Sensors

3.1.3. Miscellaneous Heat Detectors

3.2. Gas Sensors

3.2.1. Metal Oxide Semiconductor Gas Sensors

3.2.2. Optical Gas Sensors

3.2.3. Acoustic Gas Sensors

3.2.4. Miscellaneous Gas Sensors

3.3. Flame Sensors

3.3.1. Non-Visual Flame Detection

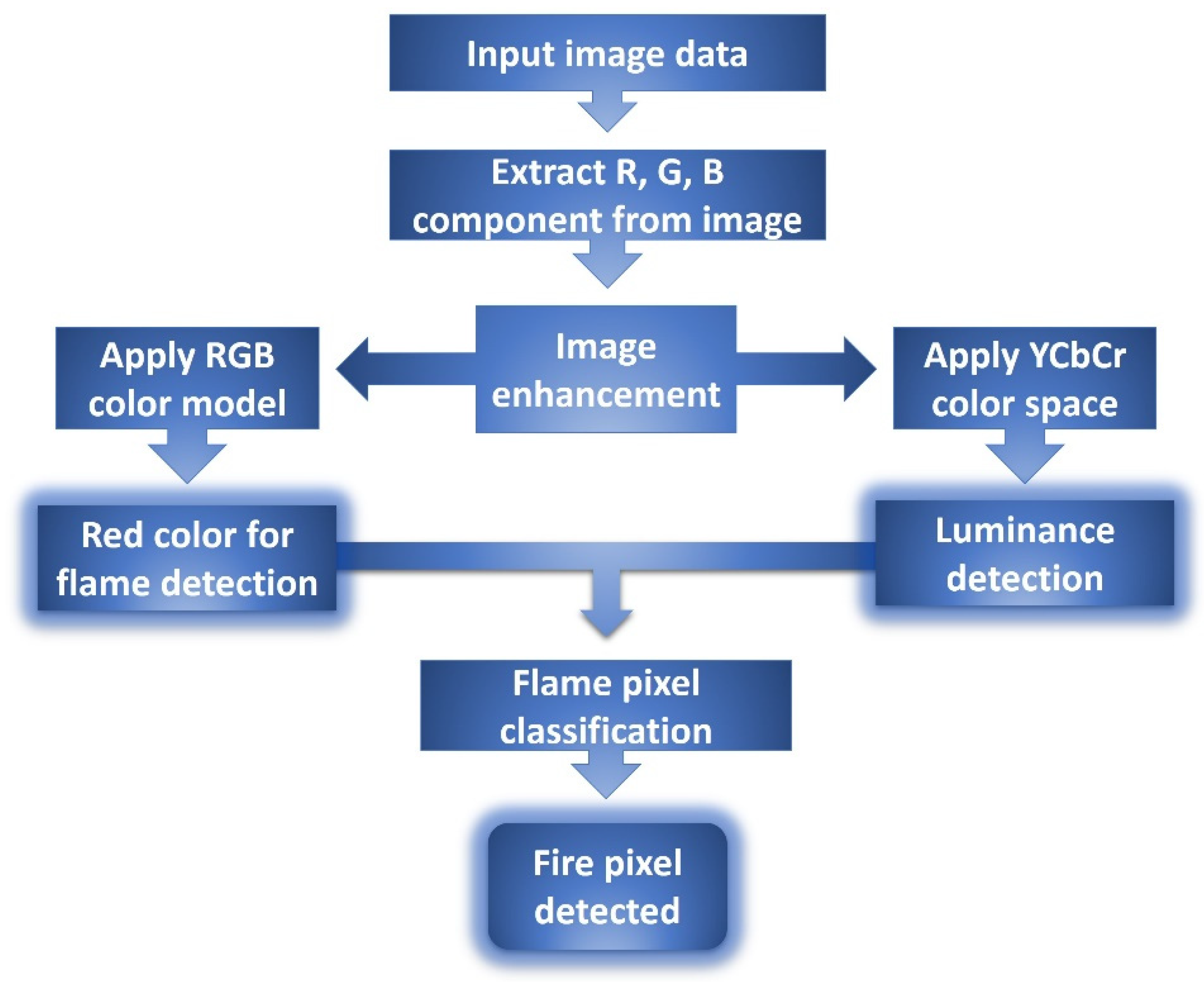

3.3.2. Visual Flame Detection

3.4. Smoke Sensors

3.4.1. Non-Visual Smoke Detection

3.4.2. Visual Smoke Detection

3.5. Multifarious Sensors

3.5.1. Microwave Radiometers for Fire Detection

3.5.2. Acoustic Wave Fire Detection

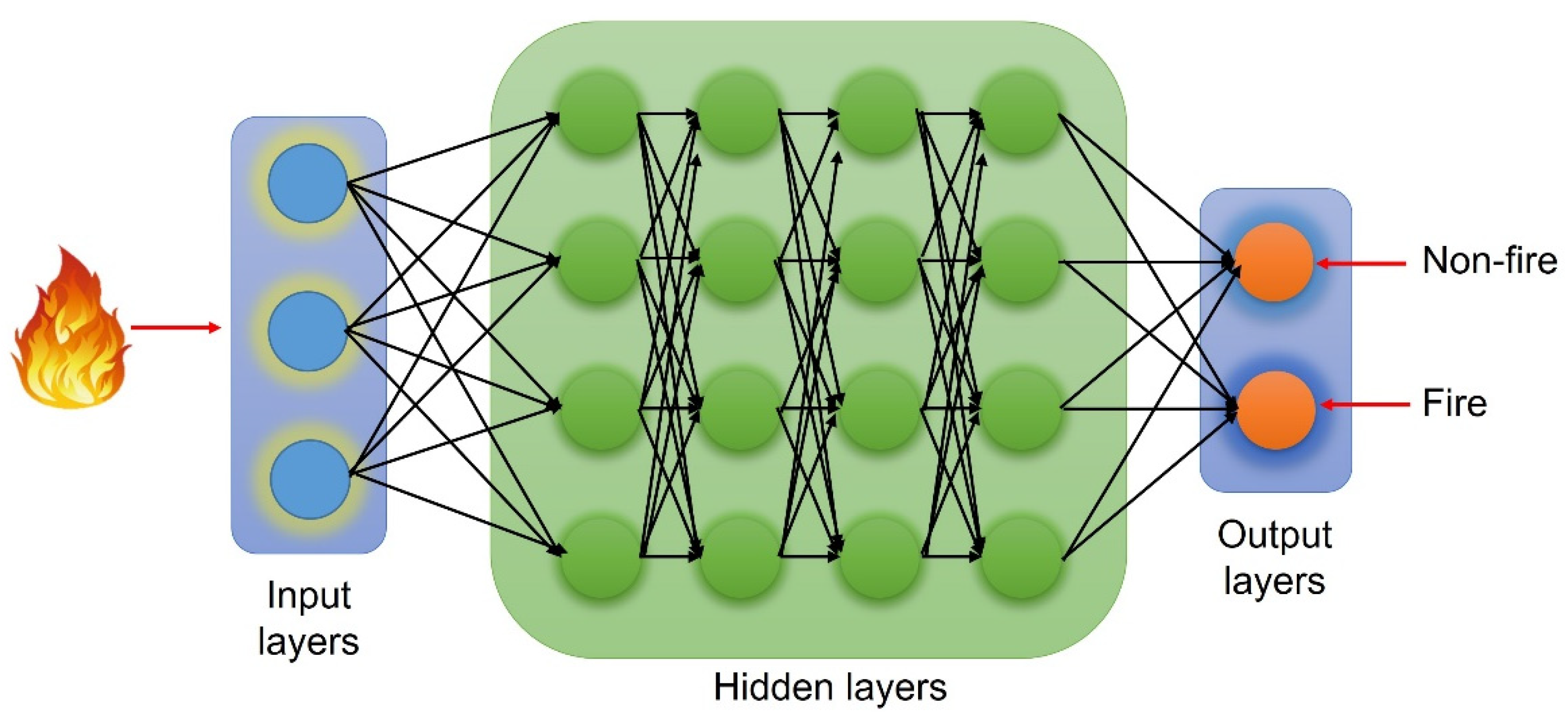

3.5.3. Deep Learning for Fire Detection

3.5.4. Fire Fighting Robot System

4. Conclusions and Perspective

Author Contributions

Funding

Conflicts of Interest

References

- Brushlinsky, P.W.N.; Ahrens, M.; Sokolov, S. World Fire Statistics. 2019. Available online: https://www.ctif.org/ (accessed on 15 May 2021).

- Joo, J.-Y.; Ilić, M.D. An information exchange framework utilizing smart buildings for efficient microgrid operation. Proc. IEEE 2016, 104, 858–864. [Google Scholar] [CrossRef]

- Morgan, A. New Fire Detection Concepts. Fire Saf. Eng. 2000, 7, 35–37. [Google Scholar]

- Liu, Z.; Makar, J.; Kim, A.K. Development of fire detection systems in the intelligent building. NIST Spec. Publ. SP 2001, 2001, 561–573. [Google Scholar]

- Crapo, W.R. Smoke Detectors and Life Safety. Fire Eng. 2002, 153, 61–69. [Google Scholar]

- Purser, D.A. Toxicity Assessment of Combustion Products. In The SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2016; pp. 83–171. [Google Scholar]

- Fonollosa, J.; Solórzano, A.; Marco, S. Chemical sensor systems and associated algorithms for fire detection: A review. Sensors 2018, 18, 553. [Google Scholar] [CrossRef]

- Gaur, A.; Singh, A.; Kumar, A.; Kumar, A.; Kapoor, K. Video flame and smoke based fire detection algorithms: A literature review. Fire Technol. 2020, 56, 1943–1980. [Google Scholar] [CrossRef]

- Çetin, A.E.; Dimitropoulos, K.; Gouverneur, B.; Grammalidis, N.; Günay, O.; Habiboǧlu, Y.H.; Töreyin, B.U.; Verstockt, S. Video fire detection–Review. Digit. Signal Process. 2013, 23, 1827–1843. [Google Scholar] [CrossRef]

- Kaabi, R.; Frizzi, S.; Bouchouicha, M.; Fnaiech, F.; Moreau, E.; R Kaabi, S.F.; Moreau, E. Video Smoke Detection Review: State of the Art of Smoke Detection in Visible and IR Range. In Proceedings of the 2017 International Conference on Smart, Monitored and Controlled Cities (SM2C), Sfax, Tunisia, 17–19 February 2017; pp. 81–86. [Google Scholar]

- Bogue, R. Sensors for fire detection. Sens. Rev. 2013, 33, 99–103. [Google Scholar] [CrossRef]

- Ghali, R.; Jmal, M.; Mseddi, W.S.; Attia, R. Recent Advances in Fire Detection and Monitoring Systems: A Review. In Proceedings of the International conference on the Sciences of Electronics, Technologies of Information and Telecommunications, Genoa, Italy, 18–20 December 2018; pp. 332–340. [Google Scholar]

- Barmpoutis, P.; Papaioannou, P.; Dimitropoulos, K.; Grammalidis, N. A review on early forest fire detection systems using optical remote sensing. Sensors 2020, 20, 6442. [Google Scholar] [CrossRef]

- Ukil, A.; Braendle, H.; Krippner, P. Distributed temperature sensing: Review of technology and applications. IEEE Sens. J. 2011, 12, 885–892. [Google Scholar] [CrossRef]

- Garlock, M.; Paya-Zaforteza, I.; Kodur, V.; Gu, L. Fire hazard in bridges: Review, assessment and repair strategies. Eng. Struct. 2012, 35, 89–98. [Google Scholar] [CrossRef]

- Debliquy, M.; Lahem, D.; Bueno-Martinez, A.; Ravet, G.; Renoirt, J.-M.; Caucheteur, C. Review of the Use of the Optical Fibers for Safety Applications in Tunnels and Car Parks: Pollution Monitoring, Fire and Explosive Gas Detection. In Sensing Technology: Current Status and Future Trends III; Springer: Cham, Switzerland, 2015; pp. 1–24. [Google Scholar]

- Kennedy, P.M.; Kennedy, K.C.; Kennedy, J.A. Flashover and Fire Analysis—A Discussion of the Practical Use of Flashover Analysis in Fire Investiga-tions; CiteSeer: University Park, PA, USA, 2003; pp. 1–20. [Google Scholar]

- Harmathy, T.Z.; Mehaffey, J.R. Post-Flashover compartment fires. Fire Mater. 1983, 7, 49–61. [Google Scholar] [CrossRef]

- Wickström, U. Temperature Calculation in Fire Safety Engineering; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Notarianni, K.A.; Cyganski, D.; Duckworth, R.J. Development of a Portable Flashover Predictor (Fire-Ground Environment Sensor System). In Proceedings of the International Conference on Safety (ICS2012), Gandhinagar, India, 12–13 October 2012. [Google Scholar]

- Fang, H.; Lo, S.M.; Zhang, Y.; Shen, Y. Development of a machine-learning approach for identifying the stages of fire development in residential room fires. Fire Saf. J. 2021, 126, 103469. [Google Scholar] [CrossRef]

- He, Y.; Wang, J.; Wu, Z.; Hu, L.; Xiong, Y.; Fan, W. Smoke venting and fire safety in an industrial warehouse. Fire Saf. J. 2002, 37, 191–215. [Google Scholar] [CrossRef]

- Feasey, R.; Buchanan, A. Post-flashover fires for structural design. Fire Saf. J. 2002, 37, 83–105. [Google Scholar] [CrossRef]

- Behnam, B. Post-Earthquake Fire Analysis in Urban Structures: Risk Management Strategies; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Khorasani, N.E.; Garlock, M.E.M. Overview of fire following earthquake: Historical events and community responses. Int. J. Disaster Resil. Built Environ. 2017, 8, 158–174. [Google Scholar] [CrossRef]

- Wang, S.-H.; Wang, W.-C.; Wang, K.-C.; Shih, S.-Y. Applying building information modeling to support fire safety management. Autom. Constr. 2015, 59, 158–167. [Google Scholar] [CrossRef]

- Lu, X.; Yang, Z.; Xu, Z.; Xiong, C. Scenario simulation of indoor post-earthquake fire rescue based on building information model and virtual reality. Adv. Eng. Softw. 2020, 143, 102792. [Google Scholar] [CrossRef]

- Lotfi, N.; Behnam, B.; Peyman, F. A BIM-based framework for evacuation assessment of high-rise buildings under post-earthquake fires. J. Build. Eng. 2021, 43, 102559. [Google Scholar] [CrossRef]

- Luan, N.; Ding, C.; Yao, J. A refractive index and temperature sensor based on surface plasmon resonance in an exposed-core microstructured optical fiber. IEEE Photonics J. 2016, 8, 1–8. [Google Scholar] [CrossRef]

- Jevtić, R.B.; Blagojević, M.Đ. On a linear fire detection using coaxial cables. Therm. Sci. 2014, 18, 603–614. [Google Scholar] [CrossRef]

- Wu, J.; Wu, Z.; Ding, H.; Wei, Y.; Yang, X.; Li, Z.; Yang, B.-R.; Liu, C.; Qiu, L.; Wang, X. Multifunctional and high-sensitive sensor capable of detecting humidity, temperature, and flow stimuli using an integrated microheater. ACS Appl. Mater. Interfaces 2019, 11, 43383–43392. [Google Scholar] [CrossRef] [PubMed]

- Hoff, H. Using Distributed Fibre Optic Sensors for Detecting Fires and Hot Rollers on Conveyor Belts. In Proceedings of the 2017 2nd International Conference for Fibre-Optic and Photonic Sensors for Industrial and Safety Applications (OFSIS), Brisbane, Australia, 8–10 January 2017; pp. 70–76. [Google Scholar]

- Barrias, A.; Casas, J.R.; Villalba, S. A review of distributed optical fiber sensors for civil engineering applications. Sensors 2016, 16, 748. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.; Liu, W.; Li, X.; Yue, C.; Wang, Y.; Wang, Q.; Cai, X. Distributed optical fiber temperature detecting and alarm system. In Proceedings of the 12th International Conference on Automatic Fire Detection, Gaithersburg, MD, USA, 25–28 March 2001. [Google Scholar]

- Yilmaz, G.; Karlik, S.E. A distributed optical fiber sensor for temperature detection in power cables. Sens. Actuators A Phys. 2006, 125, 148–155. [Google Scholar] [CrossRef]

- Laarossi, I.; Quintela-Incera, M.Á.; López-Higuera, J.M. Comparative experimental study of a high-temperature raman-based distributed optical fiber sensor with different special fibers. Sensors 2019, 19, 574. [Google Scholar] [CrossRef]

- Meacham, B.J. International developments in fire sensor technology. J. Fire Prot. Eng. 1994, 6, 89–98. [Google Scholar] [CrossRef]

- Bao, X.; Brown, A.; DeMerchant, M.; Smith, J. Characterization of the Brillouin-loss spectrum of single-mode fibers by use of very short (<10-ns) pulses. Opt. Lett. 1999, 24, 510–512. [Google Scholar]

- Liu, Z.; Ferrier, G.; Bao, X.; Zeng, X.; Yu, Q.; Kim, A.K. Brillouin scattering based distributed fiber optic temperature sensing for fire detection. Fire Saf. Sci. 2003, 7, 221–232. [Google Scholar] [CrossRef][Green Version]

- Junwei, D.; Weiping, L.; Cui, T.; Xida, Y. Fire detector based on serial FBG temperature sensors optical cabling. J. Phys. Conf. Ser. 2020, 1550, 042054. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Fu, X.; Wang, H.; Jiang, D. Distributed temperature sensing system based on a densely spaced FBG array for small fire recognition. Measurement 2021, 179, 109406. [Google Scholar] [CrossRef]

- Zhu, Y.; Klegseth, M.; Bao, Y.; Hoehler, M.S.; Choe, L.; Chen, G. Distributed fiber optic measurements of strain and temperature in long-span composite floor beams with simple shear connections subject to compartment fires. Fire Saf. J. 2021, 121, 103275. [Google Scholar] [CrossRef] [PubMed]

- Ju, H.-M.; Huh, S.H.; Choi, S.-H.; Lee, H.-L. Structures of thermally and chemically reduced graphene. Mater. Lett. 2010, 64, 357–360. [Google Scholar] [CrossRef]

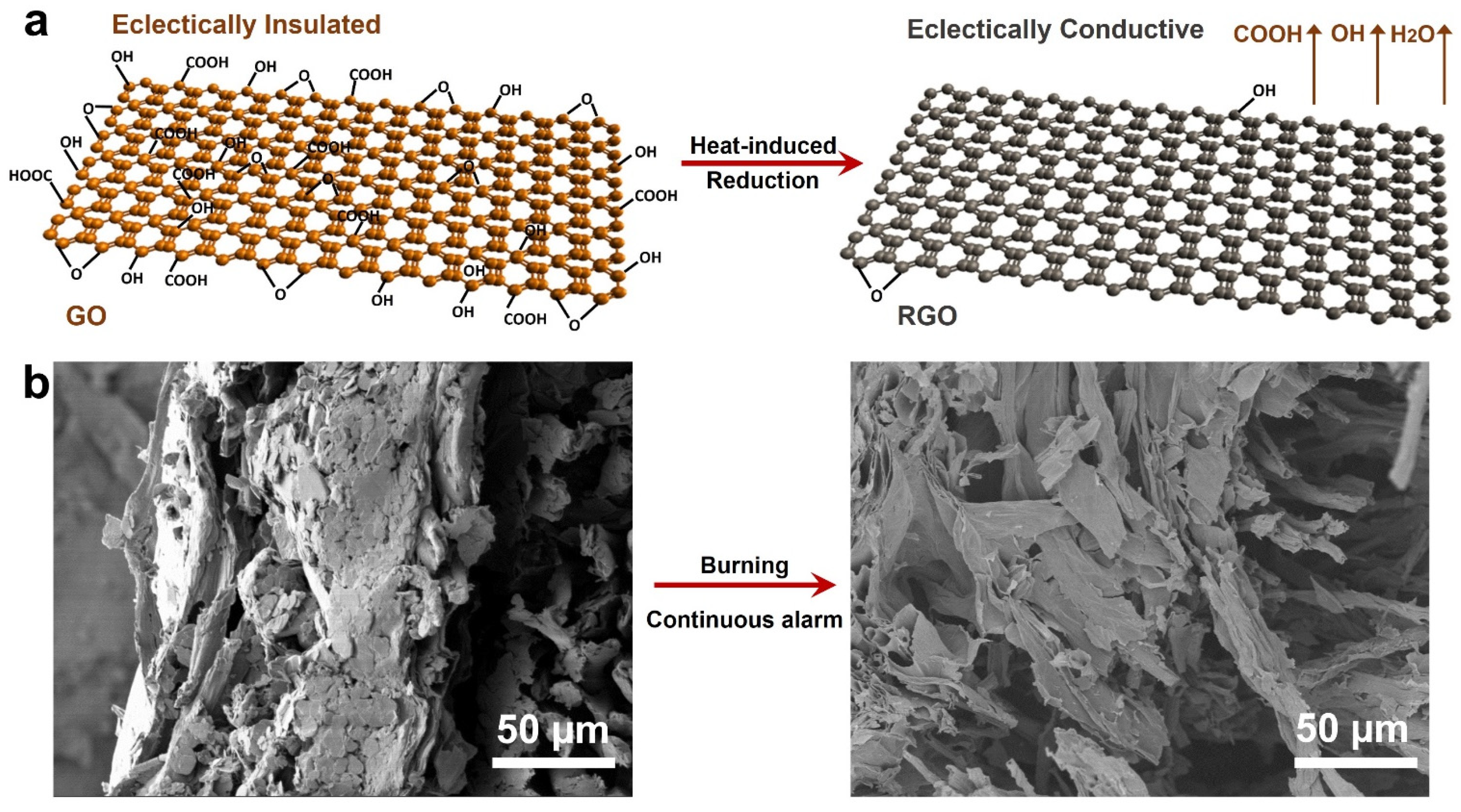

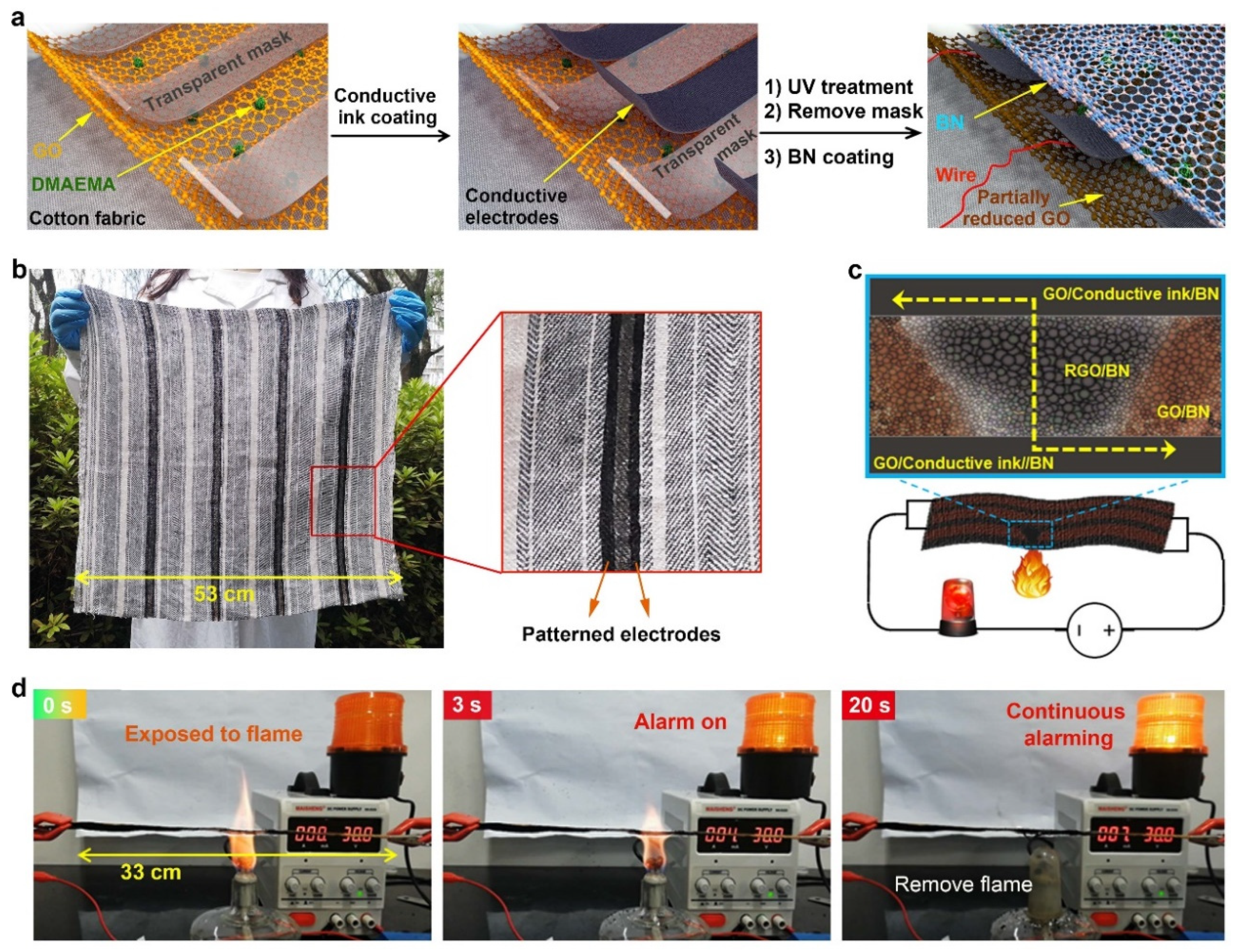

- Khan, F.; Wang, S.; Ma, Z.; Ahmed, A.; Song, P.; Xu, Z.; Liu, R.; Chi, H.; Gu, J.; Tang, L.C.; et al. A Durable, Flexible, Large-Area, Flame-Retardant, Early Fire Warning Sensor with Built-In Patterned Electrodes. Small Methods 2021, 5, 2001040. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Gong, L.-X.; Li, Y.; Cao, C.-F.; Tang, L.-C.; Wu, L.; Zhao, L.; Zhang, G.-D.; Li, S.-N.; Gao, J.; et al. Efficient flame detection and early warning sensors on combustible materials using hierarchical graphene oxide/silicone coatings. ACS Nano 2017, 12, 416–424. [Google Scholar] [CrossRef]

- Xie, H.; Lai, X.; Li, H.; Gao, J.; Zeng, X.; Huang, X.; Lin, X. A highly efficient flame retardant nacre-inspired nanocoating with ultrasensitive fire-warning and self-healing capabilities. Chem. Eng. J. 2019, 369, 8–17. [Google Scholar] [CrossRef]

- Xie, H.; Lai, X.; Li, H.; Gao, J.; Zeng, X.; Huang, X.; Zhang, S. A sandwich-like flame retardant nanocoating for supersensitive fire-warning. Chem. Eng. J. 2019, 382, 122929. [Google Scholar] [CrossRef]

- Xu, H.; Li, Y.; Huang, N.-J.; Yu, Z.-R.; Wang, P.-H.; Zhang, Z.-H.; Xia, Q.-Q.; Gong, L.-X.; Li, S.-N.; Zhao, L.; et al. Temperature-triggered sensitive resistance transition of graphene oxide wide-ribbons wrapped sponge for fire ultrafast detecting and early warning. J. Hazard. Mater. 2019, 363, 286–294. [Google Scholar] [CrossRef]

- Huang, N.-J.; Cao, C.-F.; Li, Y.; Zhao, L.; Zhang, G.-D.; Gao, J.-F.; Guan, L.-Z.; Jiang, J.-X.; Tang, L.-C. Silane grafted graphene oxide papers for improved flame resistance and fast fire alarm response. Compos. Part B Eng. 2019, 168, 413–420. [Google Scholar] [CrossRef]

- Qu, Z.; Xu, C.A.; Li, X.; Wu, Y.; Wang, K.; Zheng, X.; Cui, X.; Wu, X.; Shi, J.; Wu, K. Facile Preparation of BP-MoS2/GO Composite Films with Excellent Flame Retardancy and Ultrasensitive Response for Smart Fire Alarm. Chem. Eng. J. 2021, 426, 130717. [Google Scholar] [CrossRef]

- Qu, Z.; Wu, K.; Xu, C.-A.; Li, Y.; Jiao, E.; Chen, B.; Meng, H.; Cui, X.; Wang, K.; Shi, J. Facile Construction of a Flexible Film with Ultrahigh Thermal Conductivity and Excellent Flame Retardancy for a Smart Fire Alarm. Chem. Mater. 2021, 33, 3228–3240. [Google Scholar] [CrossRef]

- Chiang, C.-T.; Chang, F.-W. Design of a calibrated temperature difference sensor transducer for monitoring environmental temperature difference applications. IEEE Sens. J. 2015, 16, 1038–1043. [Google Scholar] [CrossRef]

- Jevtić, R.B.; Blagojević, M.Đ. Linear fire detection with distance determination using coaxial cables. In Proceedings of the 2011 19th Telecommunications Forum (TELFOR) Proceedings of Papers, Belgrade, Serbia, 22–24 November 2011; pp. 856–859. [Google Scholar]

- Wang, S.; Berentsen, M.; Kaiser, T. Signal processing algorithms for fire localization using temperature sensor arrays. Fire Saf. J. 2005, 40, 689–697. [Google Scholar] [CrossRef]

- Bosch, I.; Gomez, S.; Molina, R.; Miralles, R. Object discrimination by infrared image processing. In Proceedings of the International Work-Conference on the Interplay between Natural and Artificial Computation, Santiago de Compostela, Spain, 22–26 June 2009; pp. 30–40. [Google Scholar]

- Sun, M.; Tang, Y.; Yang, S.; Li, J.; Sigrist, M.W.; Dong, F. Fire source localization based on distributed temperature sensing by a dual-line optical fiber system. Sensors 2016, 16, 829. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Han, B.; Du, J.; Cao, S.; Gao, H.; An, N.; Li, Y.; An, S.; Ran, Z.; Lin, Y.; et al. Kilometers Long Graphene-Coated Optical Fibers for Fast Thermal Sensing. Research 2021, 2021, 5612850. [Google Scholar] [CrossRef]

- Du, H.; Wu, H.; Zhang, Z.; Zhao, C.; Zhao, Z.; Tang, M. Single-ended self-calibration high-accuracy Raman distributed temperature sensing based on multi-core fiber. Opt. Express 2021, 29, 34762–34769. [Google Scholar] [CrossRef]

- Cao, C.; Yuan, B. Thermally induced fire early warning aerogel with efficient thermal isolation and flame-retardant properties. Polym. Adv. Technol. 2021, 32, 2159–2168. [Google Scholar] [CrossRef]

- Chen, W.; Liu, P.; Liu, Y.; Wang, Q.; Duan, W. A temperature-induced conductive coating via layer-by-layer assembly of functionalized graphene oxide and carbon nanotubes for a flexible, adjustable response time flame sensor. Chem. Eng. J. 2018, 353, 115–125. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Zhang, J.-W.; Cao, C.-F.; Guo, K.-Y.; Zhao, L.; Zhang, G.-D.; Gao, J.-F.; Tang, L.-C. Temperature-responsive resistance sensitivity controlled by L-ascorbic acid and silane co-functionalization in flame-retardant GO network for efficient fire early-warning response. Chem. Eng. J. 2020, 386, 123894. [Google Scholar] [CrossRef]

- Chen, G.; Yuan, B.; Zhan, Y.; Dai, H.; He, S.; Chen, X. Functionalized graphene paper with the function of fuse and its flame-triggered self-cutting performance for fire-alarm sensor application. Mater. Chem. Phys. 2020, 252, 123292. [Google Scholar] [CrossRef]

- Yuan, B.; Wang, Y.; Chen, G.; Yang, F.; Zhang, H.; Cao, C.; Zuo, B. Nacre-like graphene oxide paper bonded with boric acid for fire early-warning sensor. J. Hazard. Mater. 2021, 403, 123645. [Google Scholar] [CrossRef]

- Guo, K.-Y.; Wu, Q.; Maoa, M.; Chenb, H.; Zhanga, G.D.; Zhaoa, L.; Gaoc, J.F.; Songd, P.; Tang, L.-C. Water-based hybrid coatings toward mechanically flexible, super-hydrophobic and flame-retardant polyurethane foam nanocomposites with high-efficiency and reliable fire alarm response. Compos. Part B Eng. 2020, 193, 108017. [Google Scholar] [CrossRef]

- Huang, N.-J.; Xia, Q.-Q.; Zhang, Z.-H.; Zhao, L.; Zhang, G.-D.; Gao, J.-F.; Tang, L.-C. Simultaneous improvements in fire resistance and alarm response of GO paper via one-step 3-mercaptopropyltrimethoxysilane functionalization for efficient fire safety and prevention. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105797. [Google Scholar] [CrossRef]

- Chen, J.; Xie, H.; Lai, X.; Li, H.; Gao, J.; Zeng, X. An ultrasensitive fire-warning chitosan/montmorillonite/carbon nanotube composite aerogel with high fire-resistance. Chem. Eng. J. 2020, 399, 125729. [Google Scholar] [CrossRef]

- Qualey, J.R.; Desmarais, L.; Pratt, J. Response-time comparisons of ionization and photoelectric/heat detectors. NIST Spec. Publ. SP 2001, 25, 283–299. [Google Scholar]

- Ma, Y.; Feng, X.; Jiao, J.; Peng, Z.; Qian, S.; Xue, H.; Li, H. Smart Fire Alarm System with Person Detection and Thermal Camera. In International Conference on Computational Science; Springer: Cham, Switzerland, 2020; pp. 353–366. [Google Scholar]

- Kushnir, A.; Kopchak, B.; Gavryliuk, A. Operational Algorithm for a Heat Detector Used in Motor Vehicles. East.-Eur. J. Enterp. Technol. 2021, 3, 111. [Google Scholar]

- Wu, X.; Zhang, X.; Huang, X.; Xiao, F.; Usmani, A. A Real-Time Forecast of Tunnel Fire Based on Numerical Database and Artificial Intelligence. Build. Simul. 2021, 15, 511–524. [Google Scholar] [CrossRef]

- Schmoetzer, K. Aircraft Fire Detection: Requirements, Qualification, and Certification Aspects. In 12th International Conference on Automatic Fire Detection; NIST: Gaithersburg, MD, USA, 2001; pp. 151–162. [Google Scholar]

- Jackson, M.A.; Robins, I. Gas sensing for fire detection: Measurements of CO, CO2, H2, O2, and smoke density in European standard fire tests. Fire Saf. J. 1994, 22, 181–205. [Google Scholar] [CrossRef]

- Barrett, R. CO Fire Detection: A Useful Technique? Report on a Test Programme and Discusses the Issues Involved in the Use of CO Fire Detectors. Fire Saf. Eng. 2000, 7, 20–25. [Google Scholar]

- Liu, X.; Cheng, S.; Liu, H.; Hu, S.; Zhang, D.; Ning, H. A survey on gas sensing technology. Sensors 2012, 12, 9635–9665. [Google Scholar] [CrossRef]

- Wiedinmyer, C.; Neff, J.C. Estimates of CO2 from fires in the United States: Implications for carbon management. Carbon Balance Manag. 2007, 2, 10. [Google Scholar] [CrossRef]

- Stec, A.A. Fire toxicity–The elephant in the room? Fire Saf. J. 2017, 91, 79–90. [Google Scholar] [CrossRef]

- Reddy, A.P.K.; Reddy, E.S.; Bhaskar, T.; Yadav, B.P.; Singh, A.K. Design of Fire and Gas Detection System for a Process Plant: A Review. In Advances in Industrial Safety; Springer: Singapore, 2020; pp. 271–280. [Google Scholar]

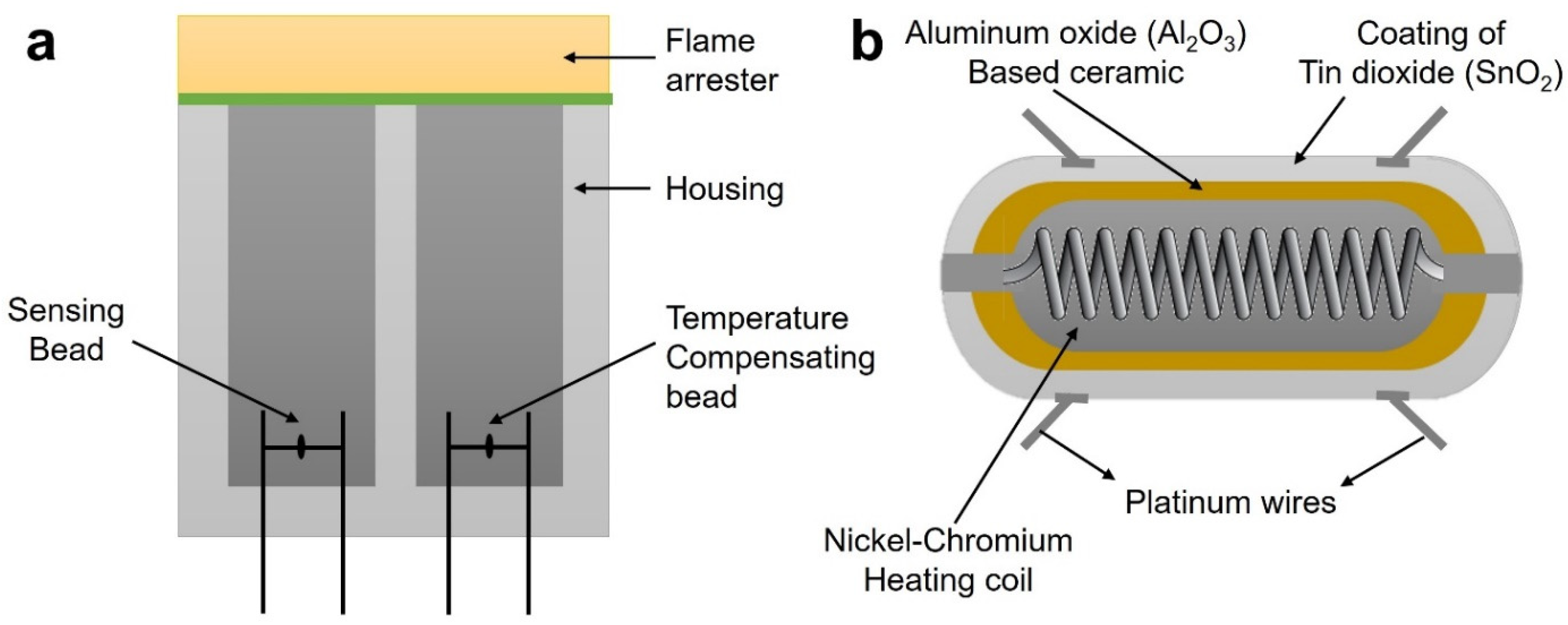

- Jabłoński, K.; Grychowski, T. The Method for Easy Identifying Zero Temperature Drift of Catalytic Bead Sensor. In Proceedings of the 2018 XV International Scientific Conference on Optoelectronic and Electronic Sensors (COE), Warsaw, Poland, 17–20 June 2018; pp. 1–4. [Google Scholar]

- Mann, D.P.; Pratt, K.F.E.; Paraskeva, T.; Parkin, I.P.; Williams, D.E. Transition metal exchanged zeolite layers for selectivity enhancement of metal-oxide semiconductor gas sensors. IEEE Sens. J. 2007, 7, 551–556. [Google Scholar] [CrossRef]

- Naik, A.; Parkin, I.; Binions, R. Gas sensing studies of an NN hetero-junction array based on SnO2 and ZnO composites. Chemosensors 2016, 4, 3. [Google Scholar] [CrossRef]

- Prajapati, C.S.; Soman, R.; Rudraswamy, S.B.; Nayak, M.; Bhat, N. Single chip gas sensor array for air quality monitoring. J. Microelectromech. Syst. 2017, 26, 433–439. [Google Scholar] [CrossRef]

- Zhang, L.; Rahimabady, M.; Tan, S.Y.; Tan, C.Y.; Chen, S.; Chen, Y.F.; Yao, K.; Humbert, A.; Soccol, D.; Zang, K.; et al. P (VDF-HFP) polymer as sensing material for capacitive carbon dioxide sensors. IEEE Sens. J. 2017, 17, 4349–4356. [Google Scholar] [CrossRef]

- Riches, J.; Chapman, A.; Beardon, J. The Detection of Fire Precursors Using Chemical Sensors. In Proceedings of the 8th International Fire Science and Engineering Conference, Edinburgh, Scotland, 28 June–1 July 1999. [Google Scholar]

- Mandayo, G.G.; Castano, E.; Gracia, F.J. Carbon monoxide detector fabricated on the basis of a tin oxide novel doping method. IEEE Sens. J. 2002, 2, 322–328. [Google Scholar] [CrossRef]

- Juang, F.-R.; Fang, Y.-K.; Chiang, Y.-T.; Chou, T.-H.; Lin, C.-I.; Lin, C.-W.; Liou, Y.-W. Comparative study of carbon monoxide gas sensing mechanism for the LTPS MOS Schottky diodes with various metal oxides. IEEE Sens. J. 2010, 11, 1227–1232. [Google Scholar] [CrossRef]

- Adib, M.; Eckstein, R.; Hernandez-Sosa, G.; Sommer, M.; Lemmer, U. SnO2 nanowire-based aerosol jet printed electronic nose as fire detector. IEEE Sens. J. 2017, 18, 494–500. [Google Scholar] [CrossRef]

- Mirzaei, A.; Lee, J.-H.; Majhi, S.M.; Weber, M.; Bechelany, M.; Kim, H.W.; Kim, S.S. Resistive gas sensors based on metal-oxide nanowires. J. Appl. Phys. 2019, 126, 241102. [Google Scholar] [CrossRef]

- Ebnali-Heidari, M.; Koohi-Kamali, F.; Ebnali-Heidari, A.; Moravvej-Farshi, M.K.; Kuhlmey, B.T. Designing tunable microstructure spectroscopic gas sensor using optofluidic hollow-core photonic crystal fiber. IEEE J. Quantum Electron. 2014, 50, 1–8. [Google Scholar] [CrossRef]

- Dankner, Y.; Jacobson, E.; Goldenberg, E.; Pashin, S. Optical-Based UV-IR Gas Detector for Environmental Monitoring of Flammable Hydrocarbons and Toxic Gases. Environ. Monit. Hazard. Waste Site Remediat. 1995, 2504, 35–38. [Google Scholar]

- Leis, J.; Buttsworth, D. A robust method for tuning photoacoustic gas detectors. IEEE Trans. Ind. Electron. 2017, 65, 4338–4346. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, Y.; Tan, Y.; Ho, H.L.; Jin, W. All-optical fiber photoacoustic gas sensor with double resonant enhancement. IEEE Photonics Technol. Lett. 2018, 30, 1752–1755. [Google Scholar] [CrossRef]

- Gatsa, O.; Combette, P.; Rosenkrantz, E.; Fourmentel, D.; Destouches, C.; Ferrandis, J.-Y. High-temperature ultrasonic sensor for fission gas characterization in MTR harsh environment. IEEE Trans. Nucl. Sci. 2018, 65, 2448–2455. [Google Scholar] [CrossRef]

- Shi, M.; Bermak, A.; Chandrasekaran, S.; Amira, A.; Brahim-Belhouari, S. A committee machine gas identification system based on dynamically reconfigurable FPGA. IEEE Sens. J. 2008, 8, 403–414. [Google Scholar] [CrossRef]

- Kumar, A.; Hancke, G.P. An energy-efficient smart comfort sensing system based on the IEEE 1451 standard for green buildings. IEEE Sens. J. 2014, 14, 4245–4252. [Google Scholar] [CrossRef]

- Serio, M.A.; Bonanno, A.S.; Newman, J.S. FT-IR Based System for Fire Detection. In Proceedings of the NIST Annual Conference on Fire Research, Gaithersburg, MD, USA, 17–20 October 1994. [Google Scholar]

- Serio, M.A.; Bonamno, A.S.; Knight, K.S.; Newman, J.S. Fourier Transform Infrared Diagnostics for Improved Fire Detection Systems. In Proceedings of the NIST Annual Conference on Fire Research, Gaithersburg, MD, USA, 28–31 October 1996. [Google Scholar]

- Cleary, T.; Ono, T. Enhanced Residential Fire Detection by Combining Smoke and CO Sensors (SP 965), Special Publication (NIST SP); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2001. [CrossRef]

- Qiu, X.; Wei, Y.; Li, N.; Guo, A.; Zhang, E.; Li, C.; Peng, Y.; Wei, J.; Zalng, Z. Development of an early warning fire detection system based on a laser spectroscopic carbon monoxide sensor using a 32-bit system-on-chip. Infrared Phys. Technol. 2019, 96, 44–51. [Google Scholar] [CrossRef]

- Parent, G.; Acem, Z.; Lechêne, S.; Boulet, P. Measurement of infrared radiation emitted by the flame of a vegetation fire. Int. J. Therm. Sci. 2010, 49, 555–562. [Google Scholar] [CrossRef]

- Sidey, J.; Mastorakos, E.; Gordon, R.L. Simulations of autoignition and laminar premixed flames in methane/air mixtures diluted with hot products. Combust. Sci. Technol. 2014, 186, 453–465. [Google Scholar] [CrossRef][Green Version]

- Xu, L.; Yan, Y. A new flame monitor with triple photovoltaic cells. IEEE Trans. Instrum. Meas. 2006, 55, 1416–1421. [Google Scholar] [CrossRef]

- Pauchard, A.R.; Manic, D.; Flanagan, A.; Besse, P.A.; Popovic, R.S. A method for spark rejection in ultraviolet flame detectors. IEEE Trans. Ind. Electron. 2000, 47, 168–174. [Google Scholar] [CrossRef]

- de Iacovo, A.; Venettacci, C.; Colace, L.; Scopa, L.; Foglia, S. PbS colloidal quantum dot visible-blind photodetector for early indoor fire detection. IEEE Sens. J. 2017, 17, 4454–4459. [Google Scholar] [CrossRef]

- Prema, C.E.; Vinsley, S.S.; Suresh, S. Efficient flame detection based on static and dynamic texture analysis in forest fire detection. Fire Technol. 2018, 54, 255–288. [Google Scholar] [CrossRef]

- Töreyin, B.U.; Cinbis, R.G.; Dedeoglu, Y.; Cetin, A.E. Fire detection in infrared video using wavelet analysis. Opt. Eng. 2007, 46, 67204. [Google Scholar] [CrossRef]

- Celik, T.; Demirel, H. Fire detection in video sequences using a generic color model. Fire Saf. J. 2009, 44, 147–158. [Google Scholar] [CrossRef]

- Kozeki, D. Smoldering Fire Detection by Image-Processing. In Proceedings of the 12th International Conference on Automatic Detection, Gaithersburg, MD, USA, 25–28 March 2001; pp. 71–78. [Google Scholar]

- Khalil, A.; Rahman, S.U.; Alam, F.; Ahmad, I.; Khalil, I. Fire Detection Using Multi Color Space and Background Modeling. Fire Technol. 2021, 57, 1221–1239. [Google Scholar] [CrossRef]

- Chen, J.; He, Y.; Wang, J. Multi-feature fusion based fast video flame detection. Build. Environ. 2010, 45, 1113–1122. [Google Scholar] [CrossRef]

- Celik, T. Fast and efficient method for fire detection using image processing. ETRI J. 2010, 32, 881–890. [Google Scholar] [CrossRef]

- Kong, S.G.; Jin, D.; Li, S.; Kim, H. Fast fire flame detection in surveillance video using logistic regression and temporal smoothing. Fire Saf. J. 2016, 79, 37–43. [Google Scholar] [CrossRef]

- Muhammad, K.; Ahmad, J.; Mehmood, I.; Rho, S.; Baik, S.W. Convolutional neural networks based fire detection in surveillance videos. IEEE Access 2018, 6, 18174–18183. [Google Scholar] [CrossRef]

- Torabian, M.; Pourghassem, H.; Mahdavi-Nasab, H. Fire Detection Based on Fractal Analysis and Spatio-Temporal Features. Fire Technol. 2021, 57, 2583–2614. [Google Scholar] [CrossRef]

- Mueller, M.; Karasev, P.; Kolesov, I.; Tannenbaum, A. Optical flow estimation for flame detection in videos. IEEE Trans. Image Processing 2013, 22, 2786–2797. [Google Scholar] [CrossRef] [PubMed]

- Marbach, G.; Loepfe, M.; Brupbacher, T. An image processing technique for fire detection in video images. Fire Saf. J. 2006, 41, 285–289. [Google Scholar] [CrossRef]

- Günay, O.; Taşdemir, K.; Töreyin, B.U.; Çetin, A.E. Fire detection in video using LMS based active learning. Fire Technol. 2010, 46, 551–577. [Google Scholar] [CrossRef]

- Töreyin, B.U.; Dedeoğlu, Y.; Güdükbay, U.; Cetin, A.E. Computer vision based method for real-time fire and flame detection. Pattern Recognit. Lett. 2006, 27, 49–58. [Google Scholar] [CrossRef]

- Habiboğlu, Y.H.; Günay, O.; Çetin, A.E. Covariance matrix-based fire and flame detection method in video. Mach. Vis. Appl. 2012, 23, 1103–1113. [Google Scholar] [CrossRef]

- Ko, B.C.; Ham, S.J.; Nam, J.Y. Modeling and formalization of fuzzy finite automata for detection of irregular fire flames. IEEE Trans. Circuits Syst. Video Technol. 2011, 21, 1903–1912. [Google Scholar] [CrossRef]

- Wang, D.; Cui, X.; Park, E.; Jin, C.; Kim, H. Adaptive flame detection using randomness testing and robust features. Fire Saf. J. 2013, 55, 116–125. [Google Scholar] [CrossRef]

- Zhang, Z.; Shen, T.; Zou, J. An improved probabilistic approach for fire detection in videos. Fire Technol. 2014, 50, 745–752. [Google Scholar] [CrossRef]

- Foggia, P.; Saggese, A.; Vento, M. Real-time fire detection for video-surveillance applications using a combination of experts based on color, shape, and motion. IEEE Trans. Circuits Syst. Video Technol. 2015, 25, 1545–1556. [Google Scholar] [CrossRef]

- Borges, P.V.K.; Izquierdo, E. A probabilistic approach for vision-based fire detection in videos. IEEE Trans. Circuits Syst. Video Technol. 2010, 20, 721–731. [Google Scholar] [CrossRef]

- Dimitropoulos, K.; Barmpoutis, P.; Grammalidis, N. Spatio-temporal flame modeling and dynamic texture analysis for automatic video-based fire detection. IEEE Trans. Circuits Syst. Video Technol. 2014, 25, 339–351. [Google Scholar] [CrossRef]

- Qiu, T.; Yan, Y.; Lu, G. An autoadaptive edge-detection algorithm for flame and fire image processing. IEEE Trans. Instrum. Meas. 2011, 61, 1486–1493. [Google Scholar] [CrossRef]

- Chi, R.; Lu, Z.; Ji, Q. Real-Time Multi-Feature Based Fire Flame Detection in Video. IET Image Process. 2017, 11, 31–37. [Google Scholar] [CrossRef]

- Shen, D.; Chen, X.; Nguyen, M.; Yan, W.Q. Flame Detection Using Deep Learning. In Proceedings of the 2018 4th International Conference on Control, Automation and Robotics (ICCAR), Auckland, New Zealand, 20–23 April 2018; pp. 416–420. [Google Scholar]

- Perera, I.E.; Litton, C.D. A detailed study of the properties of smoke particles produced from both flaming and non-flaming combustion of common mine combustibles. Fire Saf. Sci. 2011, 10, 213–226. [Google Scholar] [CrossRef]

- Drysdale, D.D. Thermochemistry. In SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2016; pp. 138–150. [Google Scholar]

- Vojtisek-Lom, M. Total diesel exhaust particulate length measurements using a modified household smoke alarm ionization chamber. J. Air Waste Manag. Assoc. 2011, 61, 126–134. [Google Scholar] [CrossRef]

- Brunner, C.; Peynot, T.; Vidal-Calleja, T. Combining Multiple Sensor Modalities for a Localisation Robust to Smoke. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; pp. 2489–2496. [Google Scholar]

- Morgan, A. Left Luggage’-Automatic Fire Detection and the New Century. Fire Eng. J. 2000, 60, 37–39. [Google Scholar]

- Milke, J.A.; Hulcher, M.E.; Worrell, C.L.; Gottuk, D.T.; Williams, F.W. Investigation of multi-sensor algorithms for fire detection. Fire Technol. 2003, 39, 363–382. [Google Scholar] [CrossRef]

- Qualey, J.R. Fire test comparisons of smoke detector response times. Fire Technol. 2000, 36, 89–108. [Google Scholar] [CrossRef]

- Conforti, F. Multi-sensor, multi-criteria detectors are better. Proc. AUBE 1999, 99, 247–249. [Google Scholar]

- Gottuk, D.T.; Peatross, M.J.; Roby, R.J.; Beyler, C.L. Advanced fire detection using multi-signature alarm algorithms. Fire Saf. J. 2002, 37, 381–394. [Google Scholar] [CrossRef]

- Jeong, J.-Y.; Ryou, H.-S. A study on smoke movement in room fires with various pool fire location. KSME Int. J. 2002, 16, 1485–1496. [Google Scholar] [CrossRef]

- Liu, B.; Alvarez-Ossa, D.; Kherani, N.P.; Zukotynski, S.; Chen, K.P. Gamma-free smoke and particle detector using tritiated foils. IEEE Sens. J. 2007, 7, 917–918. [Google Scholar] [CrossRef]

- Bakhoum, E.G. High-sensitivity miniature smoke detector. IEEE Sens. J. 2012, 12, 3031–3035. [Google Scholar] [CrossRef]

- Aspey, R.A.; Brazier, K.J.; Spencer, J.W. Multiwavelength sensing of smoke using a polychromatic LED: Mie extinction characterization using HLS analysis. IEEE Sens. J. 2005, 5, 1050–1056. [Google Scholar] [CrossRef]

- Li, M.; Xu, W.; Xu, K.; Fan, J.; Hou, D. Review of fire detection technologies based on video image. J. Theor. Appl. Inf. Technol. 2013, 49, 700–707. [Google Scholar]

- Çelik, T.; Özkaramanlı, H.; Demirel, H. Fire and Smoke Detection without Sensors: Image Processing Based Approach. In Proceedings of the 2007 15th European Signal Processing Conference, Poznan, Poland, 3–7 September 2007; pp. 1794–1798. [Google Scholar]

- Gubbi, J.; Marusic, S.; Palaniswami, M. Smoke detection in video using wavelets and support vector machines. Fire Saf. J. 2009, 44, 1110–1115. [Google Scholar] [CrossRef]

- Ko, B.C.; Cheong, K.-H.; Nam, J.-Y. Fire detection based on vision sensor and support vector machines. Fire Saf. J. 2009, 44, 322–329. [Google Scholar] [CrossRef]

- Ko, B.; Cheong, K.-H.; Nam, J.-Y. Early fire detection algorithm based on irregular patterns of flames and hierarchical Bayesian Networks. Fire Saf. J. 2010, 45, 262–270. [Google Scholar] [CrossRef]

- Yuan, F. Video-based smoke detection with histogram sequence of LBP and LBPV pyramids. Fire Saf. J. 2011, 46, 132–139. [Google Scholar] [CrossRef]

- Qureshi, W.S.; Ekpanyapong, M.; Dailey, M.N.; Rinsurongkawong, S.; Malenichev, A.; Krasotkina, O. QuickBlaze: Early fire detection using a combined video processing approach. Fire Technol. 2016, 52, 1293–1317. [Google Scholar] [CrossRef]

- Yuan, F.; Fang, Z.; Wu, S.; Yang, Y.; Fang, Y. Real-time image smoke detection using staircase searching-based dual threshold AdaBoost and dynamic analysis. IET Image Process. 2015, 9, 849–856. [Google Scholar] [CrossRef]

- Li, P.; Zhao, W. Image fire detection algorithms based on convolutional neural networks. Case Stud. Therm. Eng. 2020, 19, 100625. [Google Scholar] [CrossRef]

- Ryu, J.; Kwak, D. Flame Detection Using Appearance-Based Pre-Processing and Convolutional Neural Network. Appl. Sci. 2021, 11, 5138. [Google Scholar] [CrossRef]

- Saponara, S.; Elhanashi, A.; Gagliardi, A. Real-time video fire/smoke detection based on CNN in antifire surveillance systems. J. Real-Time Image Process. 2021, 18, 889–900. [Google Scholar] [CrossRef]

- Muhammad, K.; Ahmad, J.; Baik, S.W. Early fire detection using convolutional neural networks during surveillance for effective disaster management. Neurocomputing 2018, 288, 30–42. [Google Scholar] [CrossRef]

- Khan, S.; Muhammad, K.; Hussain, T.; Del Ser, J.; Cuzzolin, F.; Bhattacharyya, S.; Akhtar, Z.; de Albuquerque, V.H.C. Deepsmoke: Deep learning model for smoke detection and segmentation in outdoor environments. Expert Syst. Appl. 2021, 182, 115125. [Google Scholar] [CrossRef]

- Valikhujaev, Y.; Abdusalomov, A.; Cho, Y.I. Automatic fire and smoke detection method for surveillance systems based on dilated cnns. Atmosphere 2020, 11, 1241. [Google Scholar] [CrossRef]

- Ruser, H.; Magori, V. Fire Detection with a Combined Ultrasonic-Microwave Doppler Sensor. In Proceedings of the 1998 IEEE Ultrasonics Symposium. Proceedings (Cat. No. 98CH36102), Sendai, Japan, 5–8 October 1998; pp. 489–492. [Google Scholar]

- Schmitz, H.; Soltner, H.; Bousack, H. Biomimetic infrared sensors based on photomechanic infrared receptors in pyrophilous (‘fire-loving’) insects. IEEE Sens. J. 2010, 12, 281–288. [Google Scholar] [CrossRef]

- L’vov, A.A.; Komarov, V.V.; Kuzin, S.A.; L’vov, P.A. Fire Detection and Alarm Sensor for Avionics Based on Current Loop Circuit. In Proceedings of the 2018 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), Moscow and St. Petersburg, Russia, 29 January–1 February 2018; pp. 1109–1112. [Google Scholar]

- Ishigaki, T.; Higuchi, T.; Watanabe, K. An information fusion-based multiobjective security system with a multiple-input/single-output sensor. IEEE Sens. J. 2007, 7, 734–742. [Google Scholar] [CrossRef]

- Hu, H.B.; Duan, J.J.; Lu, W.J. Design of Fire Detection System Based on Digital Microholography. In Proceedings of the Second Target Recognition and Artificial Intelligence Summit Forum, Changchun, China, 20–22 August 2019. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, J.; Yang, Q.; Yang, H.; Yang, H.; Li, Q.; Li, X.; Hu, C.; Xi, Y.; Wang, Z.L. Harvesting Multidirectional Breeze Energy and Self-Powered Intelligent Fire Detection Systems Based on Triboelectric Nanogenerator and Fluid-Dynamic Modeling. Adv. Funct. Mater. 2021, 31, 2106527. [Google Scholar] [CrossRef]

- Bianchi, G. Radiometer aids: Fire detection. Microw. RF 2014, 66–71. [Google Scholar]

- Dvorak, P.; Mazanek, M.; Zvanovec, S. Fire emissivity detection by a microwave radiometer. IEEE Geosci. Remote Sens. Lett. 2015, 12, 2306–2310. [Google Scholar] [CrossRef]

- Liu, B.; Han, T.; Zhang, C. Error correction method for passive and wireless resonant SAW temperature sensor. IEEE Sens. J. 2015, 15, 3608–3614. [Google Scholar] [CrossRef]

- Beisner, E.; Wiggins, N.D.; Yue, K.-B.; Rosales, M.; Penny, J.; Lockridge, J.; Page, R.; Smith, A.; Guerrero, L. Acoustic flame suppression mechanics in a microgravity environment. Microgravity Sci. Technol. 2015, 27, 141–144. [Google Scholar] [CrossRef]

- Salauddin, S.; Nalajala, P.; Godavarth, B. Sound Fire Extinguishers in Space Stations. In Proceedings of the 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT), Chennai, India, 3–5 March 2016; pp. 3454–3457. [Google Scholar]

- Park, J.H.; Lee, S.; Yun, S.; Kim, H.; Kim, W.-T. Dependable fire detection system with multifunctional artificial intelligence framework. Sensors 2019, 19, 2025. [Google Scholar] [CrossRef]

- Qin, Y.-Y.; Cao, J.-T.; Ji, X.-F. Fire detection method based on depthwise separable convolution and yolov3. Int. J. Autom. Comput. 2021, 18, 300–310. [Google Scholar] [CrossRef]

- Avazov, K.; Mukhiddinov, M.; Makhmudov, F.; Cho, Y.I. Fire Detection Method in Smart City Environments Using a Deep-Learning-Based Approach. Electronics 2021, 11, 73. [Google Scholar] [CrossRef]

- Ren, X.; Li, C.; Ma, X.; Chen, F.; Wang, H.; Sharma, A.; Gaba, G.; Masud, M. Design of multi-information fusion based intelligent electrical fire detection system for green buildings. Sustainability 2021, 13, 3405. [Google Scholar] [CrossRef]

- Park, M.; Ko, B.C. Two-step real-time night-time fire detection in an urban environment using Static ELASTIC-YOLOv3 and Temporal Fire-Tube. Sensors 2020, 20, 2202. [Google Scholar] [CrossRef]

- Liu, P.; Yu, H.; Cang, S.; Vladareanu, L. Robot-Assisted Smart Firefighting and Interdisciplinary Perspectives. In Proceedings of the 2016 22nd International Conference on Automation and Computing (ICAC), Colchester, UK, 7–8 September 2016; pp. 395–401. [Google Scholar]

- Ando, H.; Ambe, Y.; Ishii, A.; Konyo, M.; Tadakuma, K.; Maruyama, S.; Tadokoro, S. Aerial hose type robot by water jet for fire fighting. IEEE Robot. Autom. Lett. 2018, 3, 1128–1135. [Google Scholar] [CrossRef]

- Liljeback, P.; Stavdahl, O.; Beitnes, A. SnakeFighter-Development of a Water Hydraulic Fire Fighting Snake Robot. In Proceedings of the 2006 9th International Conference on Control, Automation, Robotics and Vision, Singapore, 5–8 December 2006; pp. 1–6. [Google Scholar]

- Ackerman, E.G.E. New WALK-MAN Robot Is Slimmer, Quicker, Better at Quenching Your Flames—IEEE Spectrum. IEEE Spectrum. Available online: https://spectrum.ieee.org/automaton/robotics/humanoids/new-version-of-walkman-is-slimmer-quicker-better-at-quenching-your-flames (accessed on 18 June 2021).

- L. 60TM. LUF 60—LUF GmbH. 2019. Available online: https://www.luf60.at/en/extinguishing-support/fire-fighting-robot-luf-60/ (accessed on 18 June 2021).

- Fire Fighting UGV|Parosha Cheatah GOSAFER. Available online: http://www.parosha-cheatah-gosafer.com/tasks/fire-fighting-ugv/ (accessed on 18 June 2021).

- TAF20 Robot: Firefighting Robot. Available online: https://robot.cfp.co.ir/en/newsdetail/106 (accessed on 18 June 2021).

- ThermiteTM|Howe & Howe Technologies. Available online: https://www.howeandhowe.com/civil/thermite (accessed on 18 June 2021).

- DRB Fatec. Available online: http://www.drbfatec.com/html/01_business/business_0501.php (accessed on 18 June 2021).

- Products Archive—Brokk Global. Available online: https://www.brokk.com/product/ (accessed on 18 June 2021).

| Sensor | Detection Element | Construction and Working Principle | Response Time | Detection Area | Features and Advantages | Ref. |

|---|---|---|---|---|---|---|

| Distributed Optical Fiber Heat Detectors | Two parallel optical fibers | By measuring the temperature of hot air flows | 40 s | Wide ranges | Simple and efficient | [56] |

| Graphene-coated optical fiber | Fiber Bragg grating | 18-fold faster than conventional fiber heat detectors | 1 km | Long-distance and fast optical transmission | [57] | |

| Multi-core fiber | Raman scattering | Real-time | 10 km | Self-calibration | [58] | |

| Thermal Resistance Sensors | Ammonium polyphosphate and GO | Freeze-drying | ~2.6 s | Small | Compressible | [59] |

| FGO/CNTs | Layer-by-layer | 5 s | Small | Twisted and bended | [60] | |

| AgNW/FPVB and GO/FC | Spray coating | 0.83 s | Large (>30 cm) | Hydrophobic and self-cleaning | [47] | |

| MPMS and LLA | EISA | ∼1 s | Small | Twisted, folded and Structure stability | [61] | |

| RGOP-NaCl | Evaporation-induced self-assembly | 5.3 s | Small | Twisted, can fuse function and can cut off in fire | [62] | |

| GO-BA | Evaporation-induced self-assembly | ∼0.8 s | Small | Twisted and bended | [63] | |

| APP/GO/TFTS | Water-based coating | 2 s | Small | Flexible and Super-hydrophobic | [64] | |

| MPTS-GO | TEISA | 1 s | Small | Twisted and bended | [65] | |

| CCS/MMT/A-CNT | Freeze-drying | ~0.25 s | Small | Light weight and Compressible | [66] | |

| Miscellaneous Heat Detectors | Thermistor | Steinhart-Hart equation | 260 s | Small | Suitable for sprinklers | [67] |

| Bi-spectrum camera | YOLOv3 and TNNI | 0.6 s | Limited to camera vision | Low cost, and automatic disposal of devices | [68] | |

| Thermocouple anddigital multimeter | Operational algorithm | 2.3 times faster | Small | Useful where temperaturevaries | [69] | |

| Artificial intelligence | LSTM and TCNN | 1 s | 5 m | Predict fire danger before 60 s | [70] | |

| Rate of temperature rise | Operational algorithm | 120–180 s | Small | Useful where temperature varies | [71] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, F.; Xu, Z.; Sun, J.; Khan, F.M.; Ahmed, A.; Zhao, Y. Recent Advances in Sensors for Fire Detection. Sensors 2022, 22, 3310. https://doi.org/10.3390/s22093310

Khan F, Xu Z, Sun J, Khan FM, Ahmed A, Zhao Y. Recent Advances in Sensors for Fire Detection. Sensors. 2022; 22(9):3310. https://doi.org/10.3390/s22093310

Chicago/Turabian StyleKhan, Fawad, Zhiguang Xu, Junling Sun, Fazal Maula Khan, Adnan Ahmed, and Yan Zhao. 2022. "Recent Advances in Sensors for Fire Detection" Sensors 22, no. 9: 3310. https://doi.org/10.3390/s22093310

APA StyleKhan, F., Xu, Z., Sun, J., Khan, F. M., Ahmed, A., & Zhao, Y. (2022). Recent Advances in Sensors for Fire Detection. Sensors, 22(9), 3310. https://doi.org/10.3390/s22093310