Whey Protein Isolate Film and Laser-Ablated Textured PDMS-Based Single-Electrode Triboelectric Nanogenerator for Pressure-Sensor Application

Abstract

:1. Introduction

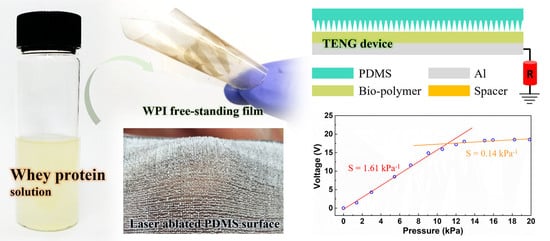

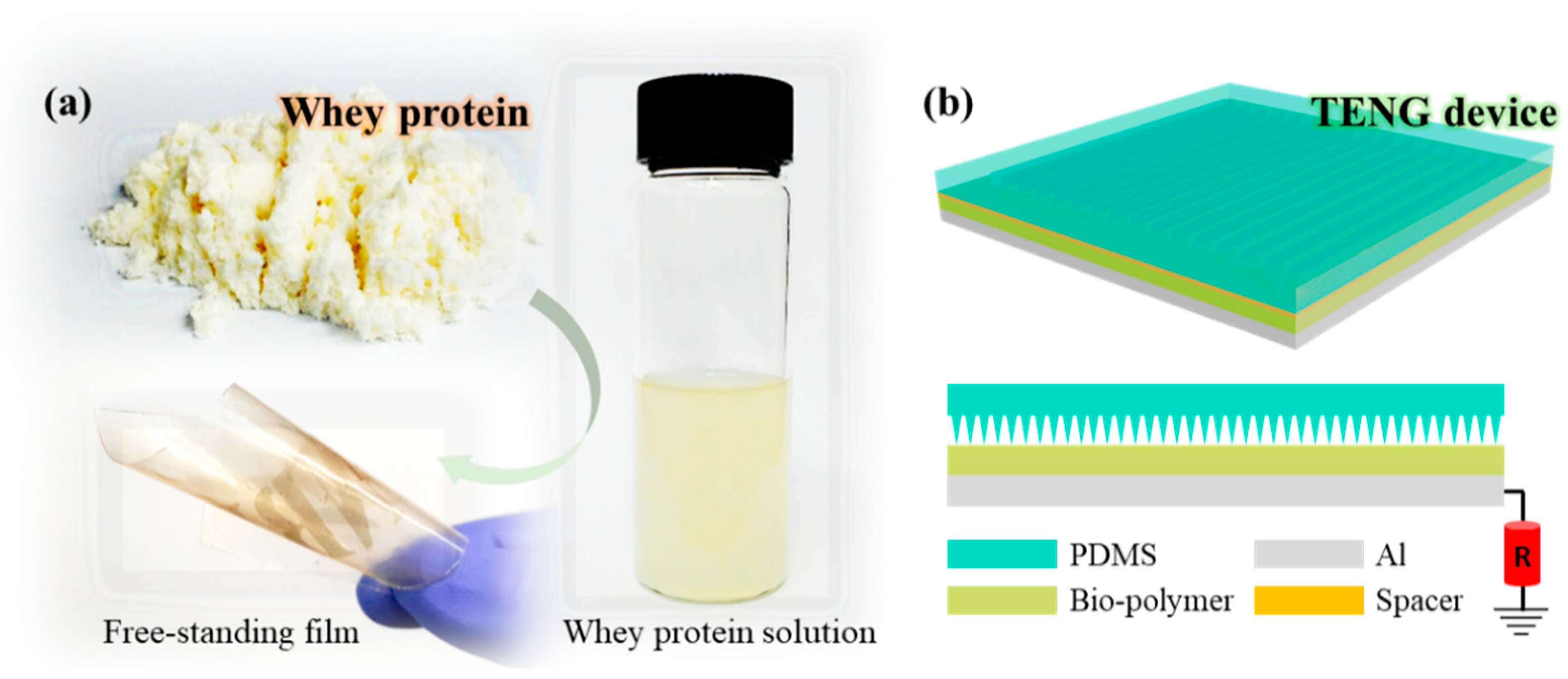

2. Materials and Methods

2.1. Materials

2.2. Materials Characterization

2.3. Film Preparation

2.4. TENG Device Preparation

2.5. Electrical Characterization

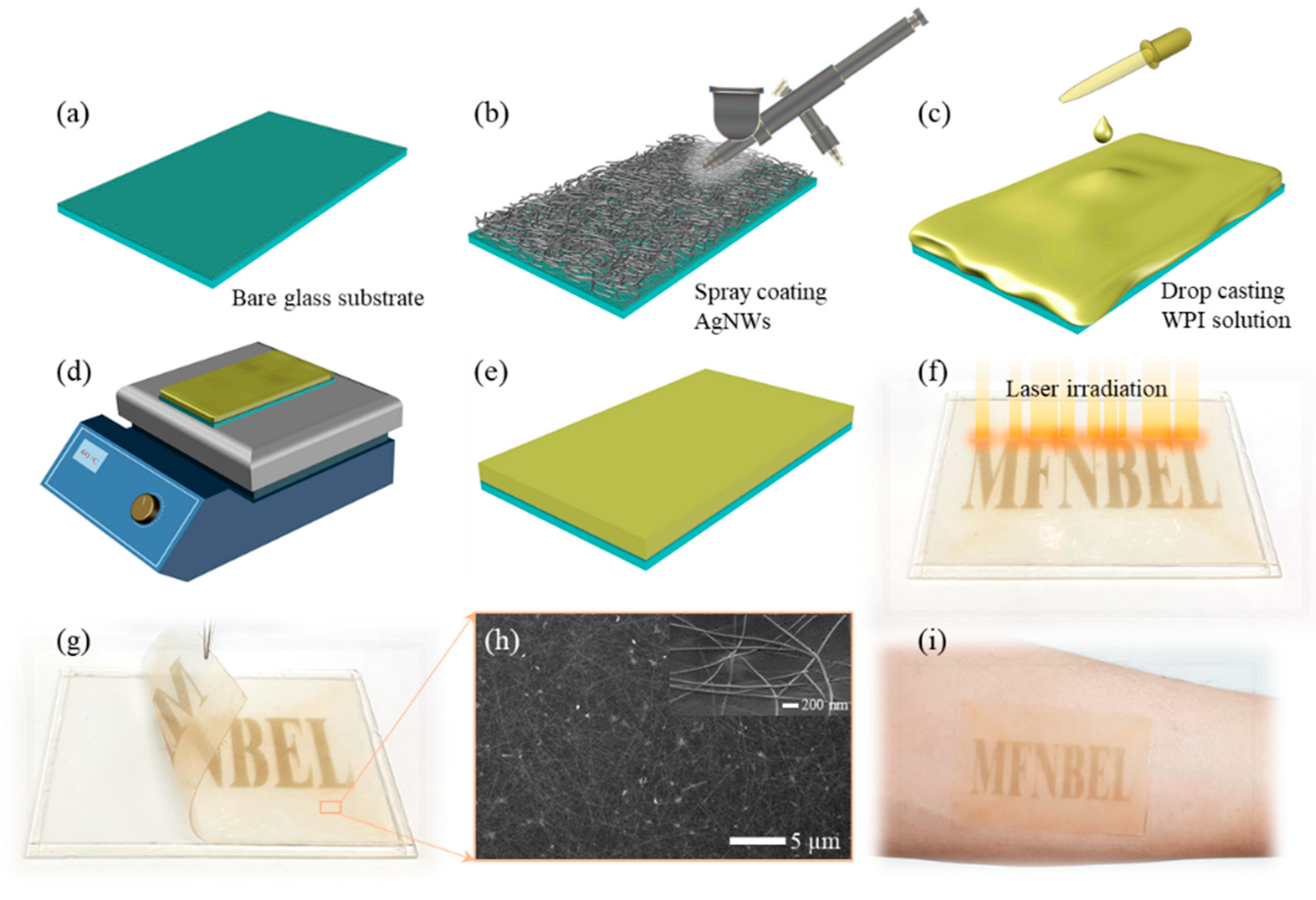

3. Results

4. Discussion

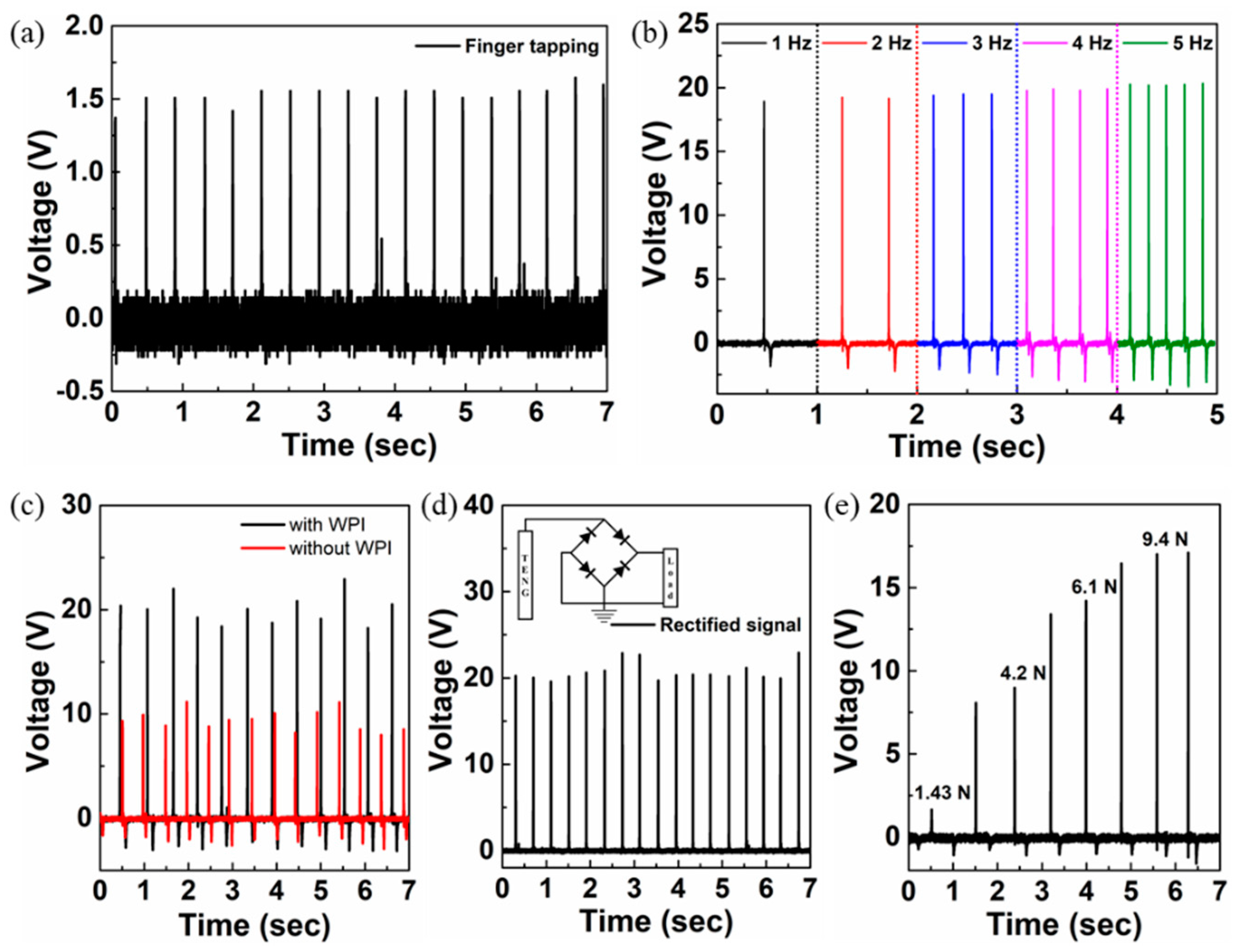

TENG Pressure Sensor

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ganesh, R.S.; Yoon, H.; Kim, S. Recent trends of biocompatible triboelectric nanogenerators toward self-powered e-skin. EcoMat 2020, 2, e12065. [Google Scholar] [CrossRef]

- Slabov, V.; Kopyl, S.; Soares dos Santos, M.P.; Kholkin, A.L. Natural and Eco-Friendly Materials for Triboelectric Energy Harvesting. Nano-Micro Lett. 2020, 12, 42. [Google Scholar] [CrossRef] [Green Version]

- Gogurla, N.; Roy, B.; Park, J.-Y.; Kim, S. Skin-contact actuated single-electrode protein triboelectric nanogenerator and strain sensor for biomechanical energy harvesting and motion sensing. Nano Energy 2019, 62, 674–681. [Google Scholar] [CrossRef]

- Peng, X.; Dong, K.; Ye, C.; Jiang, Y.; Zhai, S.; Cheng, R.; Liu, D.; Gao, X.; Wang, J.; Wang, Z.L. A breathable, biodegradable, antibacterial, and self-powered electronic skin based on all-nanofiber triboelectric nanogenerators. Sci. Adv. 2020, 6, eaba9624. [Google Scholar] [CrossRef]

- Bok, M.; Lee, Y.; Park, D.; Shin, S.; Zhao, Z.-J.; Hwang, B.; Hwang, S.H.; Jeon, S.H.; Jung, J.-Y.; Park, S.H.; et al. Microneedles integrated with a triboelectric nanogenerator: An electrically active drug delivery system. Nanoscale 2018, 10, 13502–13510. [Google Scholar] [CrossRef]

- Kim, H.-J.; Yim, E.-C.; Kim, J.-H.; Kim, S.-J.; Park, J.-Y.; Oh, I.-K. Bacterial Nano-Cellulose Triboelectric Nanogenerator. Nano Energy 2017, 33, 130–137. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kim, J.; Kim, T.Y.; Al Hossain, M.S.; Kim, S.-W.; Kim, J.H. All-in-one energy harvesting and storage devices. J. Mater. Chem. A 2016, 4, 7983–7999. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.; Zou, Y.; Xu, J.; Chen, G.; Zhou, Y.; Deng, W.; Zhao, X.; Roustaei, M.; Hsiai, T.K.; Chen, J. Ambulatory Cardiovascular Monitoring Via a Machine-Learning-Assisted Textile Triboelectric Sensor. Adv. Mater. 2021, 33, 2104178. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, Z.; Chen, Z.; Liu, M.; Zhao, B.; Liu, Y.; Cheng, Z.; Wang, S.; Yang, W.; Yu, T. Recent Advances in Self-Powered Piezoelectric and Triboelectric Sensors: From Material and Structure Design to Frontier Applications of Artificial Intelligence. Sensors 2021, 21, 842. [Google Scholar] [CrossRef]

- Rahman, M.T.; Rana, S.S.; Zahed, M.A.; Lee, S.; Yoon, E.-S.; Park, J.Y. Metal-organic framework-derived nanoporous carbon incorporated nanofibers for high-performance triboelectric nanogenerators and self-powered sensors. Nano Energy 2022, 94, 106921. [Google Scholar] [CrossRef]

- Yao, G.; Xu, L.; Cheng, X.; Li, Y.; Huang, X.; Guo, W.; Liu, S.; Wang, Z.L.; Wu, H. Bioinspired Triboelectric Nanogenerators as Self-Powered Electronic Skin for Robotic Tactile Sensing. Adv. Funct. Mater. 2020, 30, 1907312. [Google Scholar] [CrossRef]

- Du, S.; Suo, H.; Xie, G.; Lyu, Q.; Mo, M.; Xie, Z.; Zhou, N.; Zhang, L.; Tao, J.; Zhu, J. Self-powered and photothermal electronic skin patches for accelerating wound healing. Nano Energy 2022, 93, 106906. [Google Scholar] [CrossRef]

- Bao, Y.; Wang, R.; Lu, Y.; Wu, W. Lignin biopolymer based triboelectric nanogenerators. APL Mater. 2017, 5, 074109. [Google Scholar] [CrossRef] [Green Version]

- Jakmuangpak, S.; Prada, T.; Mongkolthanaruk, W.; Harnchana, V.; Pinitsoontorn, S. Engineering Bacterial Cellulose Films by Nanocomposite Approach and Surface Modification for Biocompatible Triboelectric Nanogenerator. ACS Appl. Electron. Mater. 2020, 2, 2498–2506. [Google Scholar] [CrossRef]

- Ccorahua, R.; Huaroto, J.; Luyo, C.; Quintana, M.; Vela, E.A. Enhanced-performance bio-triboelectric nanogenerator based on starch polymer electrolyte obtained by a cleanroom-free processing method. Nano Energy 2019, 59, 610–618. [Google Scholar] [CrossRef]

- Ma, C.; Gao, S.; Gao, X.; Wu, M.; Wang, R.; Wang, Y.; Tang, Z.; Fan, F.; Wu, W.; Wan, H.; et al. Chitosan biopolymer-derived self-powered triboelectric sensor with optimized performance through molecular surface engineering and data-driven learning. InfoMat 2019, 1, 116–125. [Google Scholar] [CrossRef] [Green Version]

- Chao, S.; Ouyang, H.; Jiang, D.; Fan, Y.; Li, Z. Triboelectric nanogenerator based on degradable materials. EcoMat 2021, 3, e12072. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Mandal, D. Sustainable Energy Generation from Piezoelectric Biomaterial for Noninvasive Physiological Signal Monitoring. ACS Sustain. Chem. Eng. 2017, 5, 8836–8843. [Google Scholar] [CrossRef]

- Gogurla, N.; Roy, B.; Kim, S. Self-powered artificial skin made of engineered silk protein hydrogel. Nano Energy 2020, 77, 105242. [Google Scholar] [CrossRef]

- Peng, X.; Dong, K.; Zhang, Y.; Wang, L.; Wei, C.; Lv, T.; Wang, Z.L.; Wu, Z. Sweat-Permeable, Biodegradable, Transparent and Self-powered Chitosan-Based Electronic Skin with Ultrathin Elastic Gold Nanofibers. Adv. Funct. Mater. 2022, 2112241. [Google Scholar] [CrossRef]

- Chang, T.-H.; Peng, Y.-W.; Chen, C.-H.; Chang, T.-W.; Wu, J.-M.; Hwang, J.-C.; Gan, J.-Y.; Lin, Z.-H. Protein-based contact electrification and its uses for mechanical energy harvesting and humidity detecting. Nano Energy 2016, 21, 238–246. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, Q.; He, C.; Zhang, C.; Feng, X.; Li, X.; Zhao, Q.; Ying, Y.; Ping, J. Plant-protein-enabled biodegradable triboelectric nanogenerator for sustainable agriculture. Fundam. Res. 2021, 9, 10. [Google Scholar] [CrossRef]

- Li, T.; Wang, C.; Li, T.; Ma, L.; Sun, D.; Hou, J.; Jiang, Z. Surface Hydrophobicity and Functional Properties of Citric Acid Cross-Linked Whey Protein Isolate: The Impact of pH and Concentration of Citric Acid. Molecules 2018, 23, 2383. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lakkis, J.; Villota, R. Effect of acylation on substructural properties of proteins: A study using fluorescence and circular dichroism. J. Agric. Food Chem. 1992, 40, 553–560. [Google Scholar] [CrossRef]

- Guckian, S.; Dwyer, C.; O’Sullivan, M.; O’Riordan, E.D.; Monahan, F.J. Properties of and mechanisms of protein interactions in films formed from different proportions of heated and unheated whey protein solutions. Eur. Food Res. Technol. 2006, 223, 91–95. [Google Scholar] [CrossRef]

- Andrade, J.; Pereira, C.G.; Ranquine, T.; Azarias, C.A.; Bell, M.J.V.; de Carvalho dos Anjos, V. Long-Term Ripening Evaluation of Ewes’ Cheeses by Fourier-Transformed Infrared Spectroscopy under Real Industrial Conditions. J. Spectrosc. 2018, 2018, 1381864. [Google Scholar] [CrossRef]

- Wang, X.; Esquerre, C.; Downey, G.; Henihan, L.; O’Callaghan, D.; O’Donnell, C. Feasibility of Discriminating Dried Dairy Ingredients and Preheat Treatments Using Mid-Infrared and Raman Spectroscopy. Food Anal. Methods 2018, 11, 1380–1389. [Google Scholar] [CrossRef]

- Andrade, J.; Pereira, C.G.; de Almeida Junior, J.C.; Viana CC, R.; de Oliveira Neves, L.N.; da Silva PH, F.; Bell, M.J.V.; dos Anjos, V.D.C. FTIR-ATR determination of protein content to evaluate whey protein concentrate adulteration. LWT 2019, 99, 166–172. [Google Scholar] [CrossRef]

- Azevedo, V.M.; Dias, M.V.; Borges, S.V.; Fernandes, R.V.d.B.; Silva, E.K.; Medeiros, É.A.; Ferreira Soares, N.d.F. Optical and structural properties of biodegradable whey protein isolate nanocomposite films for active packaging. Int. J. Food Prop. 2017, 20, 1869–1878. [Google Scholar] [CrossRef]

- Feldman, M.Y. Reactions of Nucleic Acids and NucleoDroteins with Formaldehyde. Prog. Nucleic Acid Res. Mol. Biol. 1973, 13, 1–49. [Google Scholar]

- Hoffman, E.A.; Frey, B.L.; Smith, L.M.; Auble, D.T. Formaldehyde Crosslinking: A Tool for the Study of Chromatin Complexes. J. Biol. Chem. 2015, 290, 26404–26411. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, D.W.; Lee, J.H.; Kim, J.K.; Jeong, U. Material aspects of triboelectric energy generation and sensors. NPG Asia Mater. 2020, 12, 6. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, Z.; Zeng, X.; Fu, X.; Hu, Y. Expandable microsphere-based triboelectric nanogenerators as ultrasensitive pressure sensors for respiratory and pulse monitoring. Nano Energy 2019, 59, 295–301. [Google Scholar] [CrossRef]

- Xu, W.; Huang, L.-B.; Wong, M.-C.; Chen, L.; Bai, G.; Hao, J. Environmentally Friendly Hydrogel-Based Triboelectric Nanogenerators for Versatile Energy Harvesting and Self-Powered Sensors. Adv. Energy Mater. 2017, 7, 1601529. [Google Scholar] [CrossRef]

- Yang, J.; Chen, J.; Su, Y.; Jing, Q.; Li, Z.; Yi, F.; Wen, X.; Wang, Z.; Wang, Z.L. Eardrum-Inspired Active Sensors for Self-Powered Cardiovascular System Characterization and Throat-Attached Anti-Interference Voice Recognition. Adv. Mater. 2015, 27, 1316–1326. [Google Scholar] [CrossRef]

- Lin, L.; Xie, Y.; Wang, S.; Wu, W.; Niu, S.; Wen, X.; Wang, Z.L. Triboelectric Active Sensor Array for Self-Powered Static and Dynamic Pressure Detection and Tactile Imaging. ACS Nano 2013, 7, 8266–8274. [Google Scholar] [CrossRef]

- Huang, J.; Fu, X.; Liu, G.; Xu, S.; Li, X.; Zhang, C.; Jiang, L. Micro/nano-structures-enhanced triboelectric nanogenerators by femtosecond laser direct writing. Nano Energy 2019, 62, 638–644. [Google Scholar] [CrossRef]

- Huang, Y.; Fan, X.; Chen, S.; Zhao, N. Emerging Technologies of Flexible Pressure Sensors: Materials, Modeling, Devices, and Manufacturing. Adv. Funct. Mater. 2019, 29, 1808509. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Ha, M.; Cho, S.; Ko, H. Micro/nanostructured surfaces for self-powered and multifunctional electronic skins. J. Mater. Chem. B 2016, 4, 2999–3018. [Google Scholar] [CrossRef]

- Yang, J.; Luo, S.; Zhou, X.; Li, J.; Fu, J.; Yang, W.; Wei, D. Flexible, Tunable, and Ultrasensitive Capacitive Pressure Sensor with Microconformal Graphene Electrodes. ACS Appl. Mater. Interfaces 2019, 11, 14997–15006. [Google Scholar] [CrossRef]

- Yang, W.; Ding, W.; Liu, M.; Yang, J.; Li, M. A theoretical model of a flexible capacitive pressure sensor with microstructured electrodes for highly sensitive electronic skin. J. Phys. D Appl. Phys. 2021, 55, 094001. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, M.; Shin, J.; Kim, S.; Gandla, S. Whey Protein Isolate Film and Laser-Ablated Textured PDMS-Based Single-Electrode Triboelectric Nanogenerator for Pressure-Sensor Application. Sensors 2022, 22, 2154. https://doi.org/10.3390/s22062154

Lee M, Shin J, Kim S, Gandla S. Whey Protein Isolate Film and Laser-Ablated Textured PDMS-Based Single-Electrode Triboelectric Nanogenerator for Pressure-Sensor Application. Sensors. 2022; 22(6):2154. https://doi.org/10.3390/s22062154

Chicago/Turabian StyleLee, Minwoo, Jonghwan Shin, Sunkook Kim, and Srinivas Gandla. 2022. "Whey Protein Isolate Film and Laser-Ablated Textured PDMS-Based Single-Electrode Triboelectric Nanogenerator for Pressure-Sensor Application" Sensors 22, no. 6: 2154. https://doi.org/10.3390/s22062154

APA StyleLee, M., Shin, J., Kim, S., & Gandla, S. (2022). Whey Protein Isolate Film and Laser-Ablated Textured PDMS-Based Single-Electrode Triboelectric Nanogenerator for Pressure-Sensor Application. Sensors, 22(6), 2154. https://doi.org/10.3390/s22062154