Theoretical Demonstration of the Interest of Using Porous Germanium to Fabricate Multilayer Vertical Optical Structures for the Detection of SF6 Gas in the Mid-Infrared

Abstract

:1. Introduction

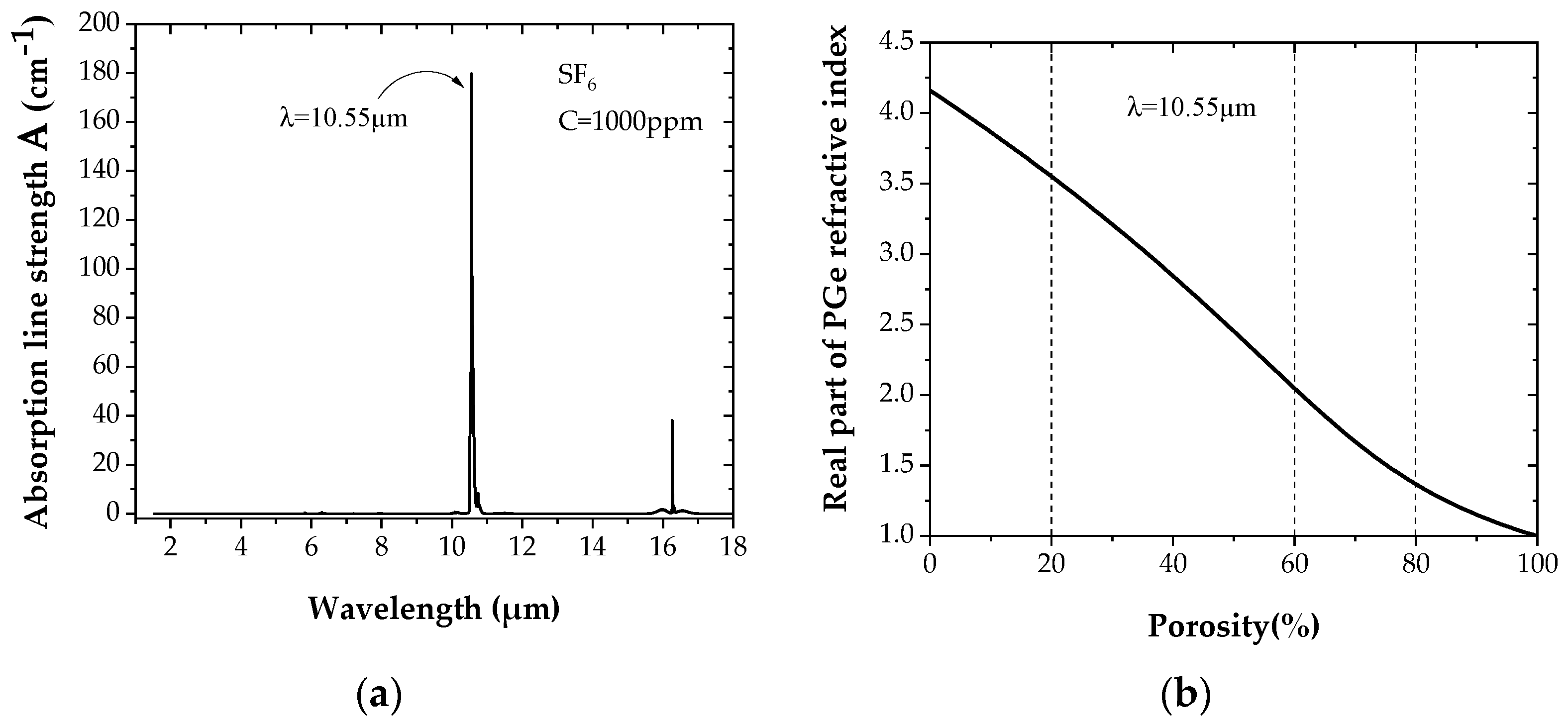

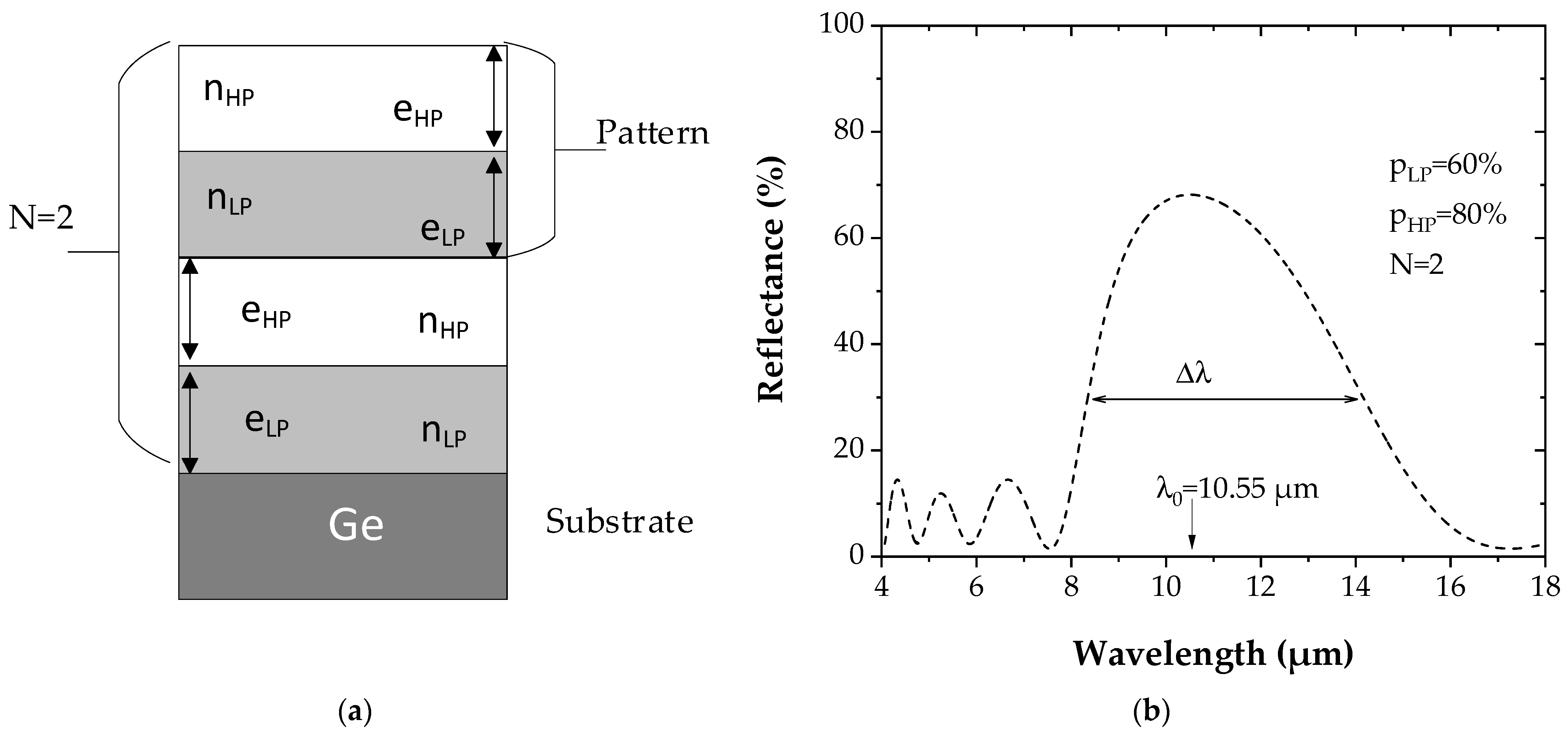

2. Modeling

2.1. Bragg Reflector Theory

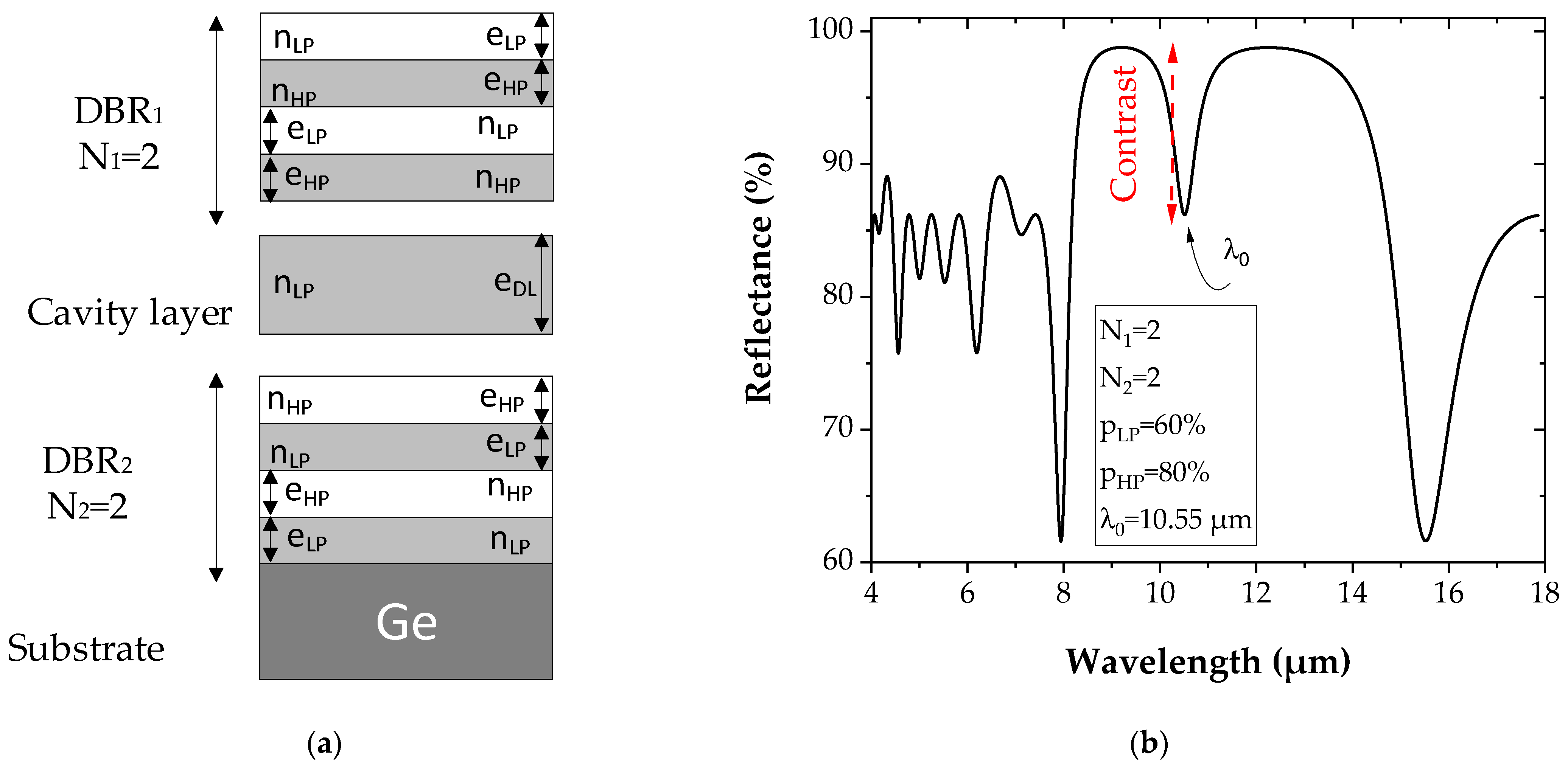

2.2. Microcavity Theory

3. Results and Discussion

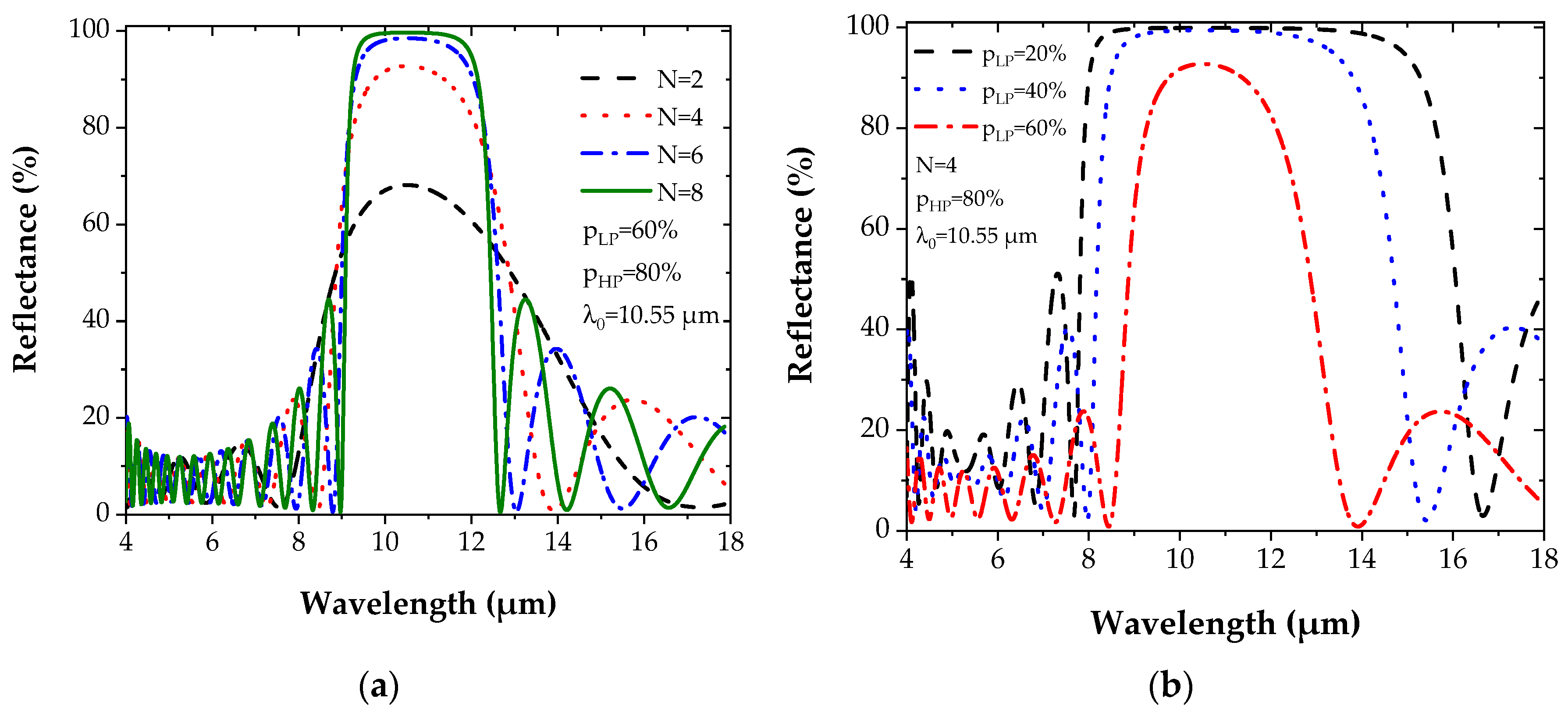

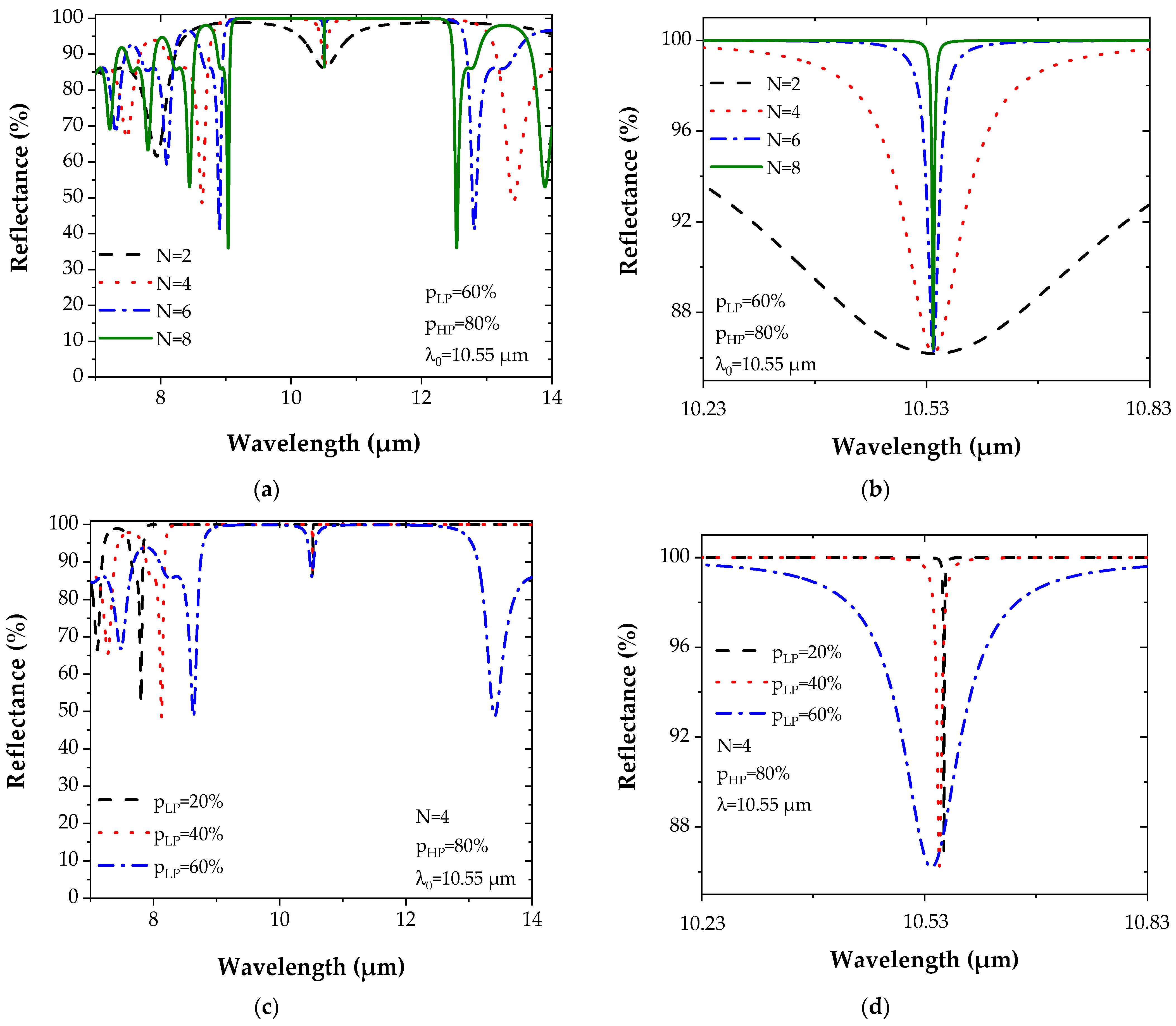

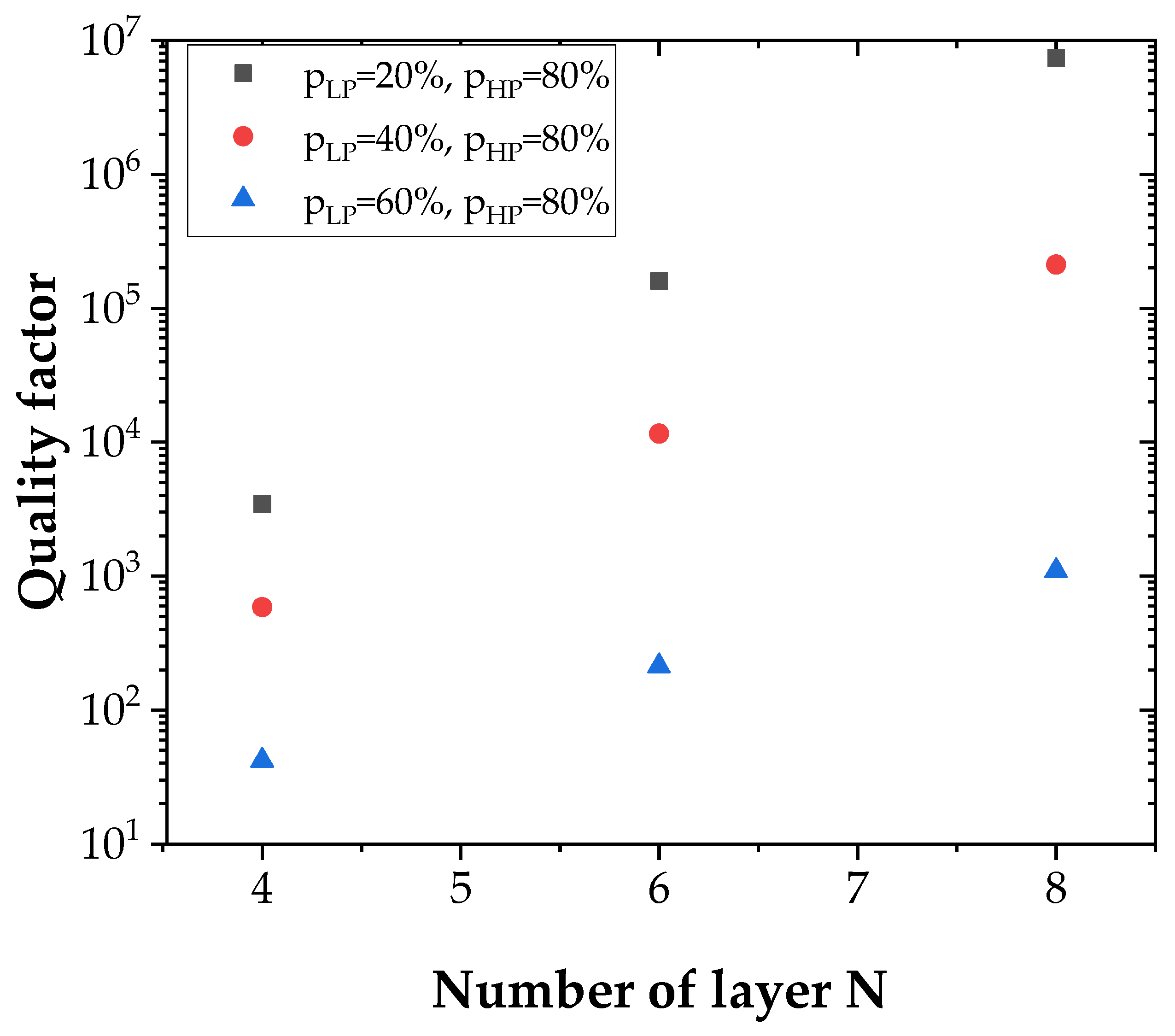

3.1. Bragg Reflector

3.2. Microcavity

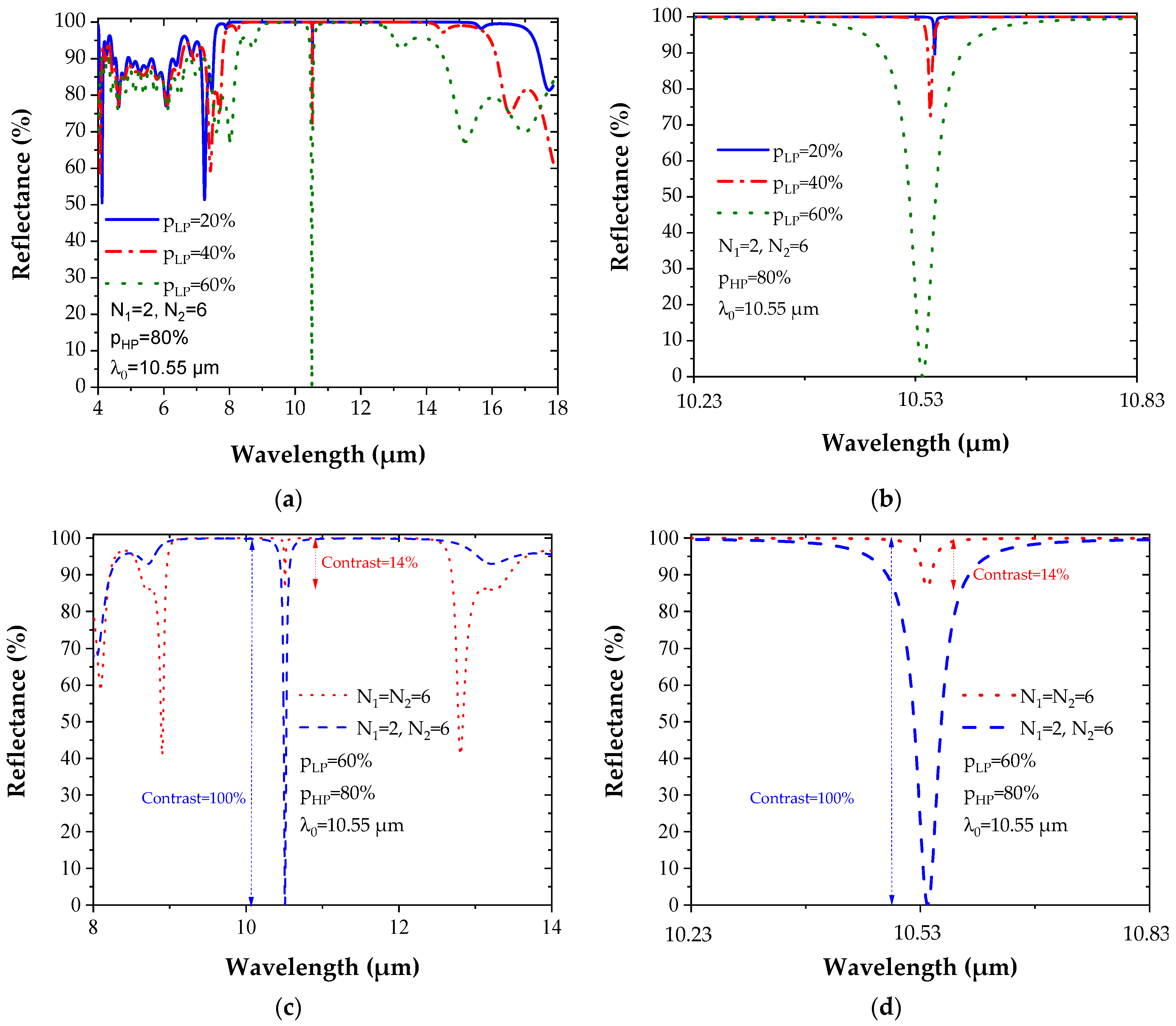

3.2.1. Optimization of the Structure

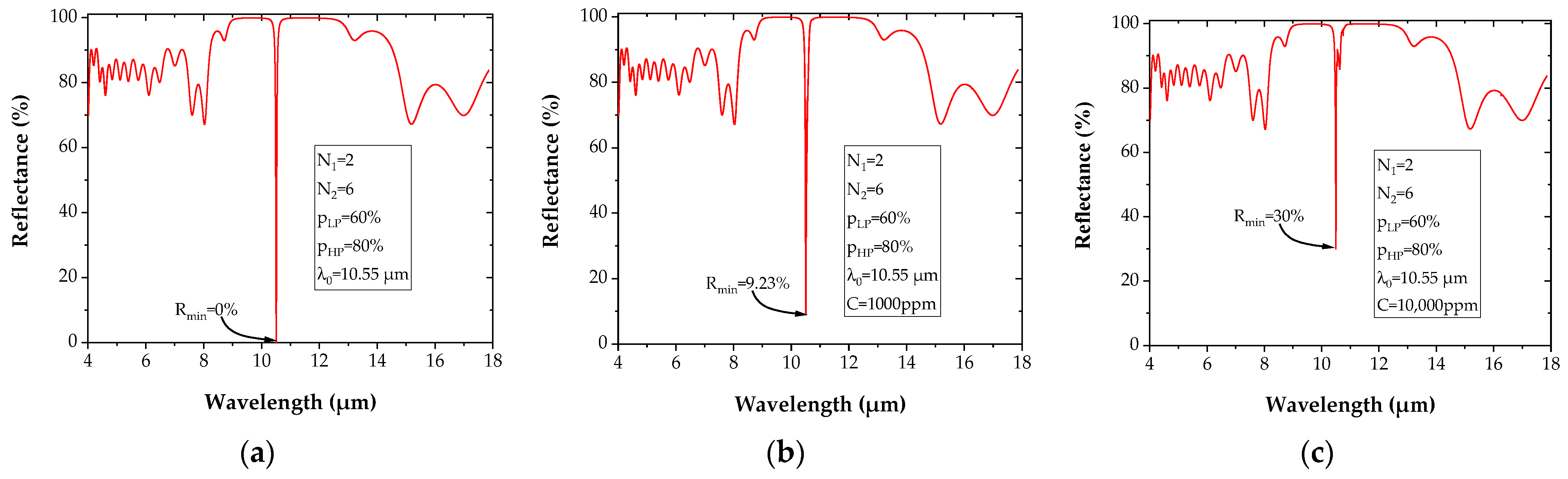

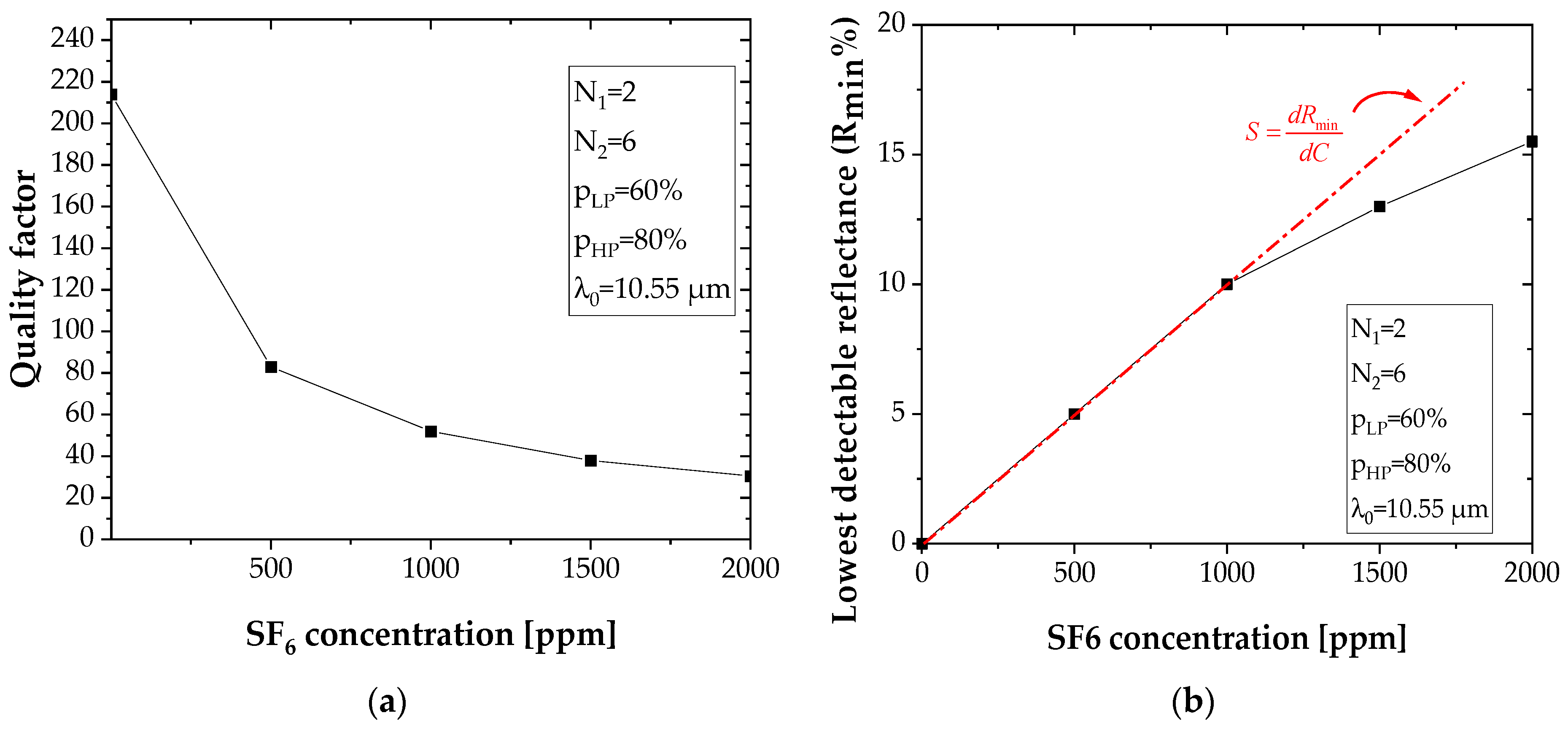

3.2.2. Theoretical SF6 Gas Detection

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hasan, D.; Lee, C. Hybrid Metamaterial Absorber Platform for Sensing of CO2 Gas at Mid-IR. Adv. Sci. 2018, 5, 1700581. [Google Scholar] [CrossRef]

- Chen, C.; Mohr, D.A.; Choi, H.-K.; Yoo, D.; Li, M.; Oh, S.-H. Waveguide-Integrated Compact Plasmonic Resonators for On-Chip Mid-Infrared Laser Spectroscopy. Nano Lett. 2018, 18, 7601–7608. [Google Scholar] [CrossRef]

- Mashanovich, G.Z.; Nedeljkovic, M.; Soler-Penades, J.; Qu, Z.; Cao, W.; Osman, A.; Wu, Y.; Stirling, C.J.; Qi, Y.; Cheng, Y.X.; et al. Group IV Mid-Infrared Photonics [Invited]. Opt. Mater. Express 2018, 8, 2276–2286. [Google Scholar] [CrossRef]

- Della Torre, A.; Sinobad, M.; Armand, R.; Luther-Davies, B.; Ma, P.; Madden, S.; Mitchell, A.; Moss, D.J.; Hartmann, J.-M.; Reboud, V.; et al. Mid-Infrared Supercontinuum Generation in a Low-Loss Germanium-on-Silicon Waveguide. APL Photonics 2021, 6, 016102. [Google Scholar] [CrossRef]

- Kang, J.; Takenaka, M.; Takagi, S. Novel Ge Waveguide Platform on Ge-on-Insulator Wafer for Mid-Infrared Photonic Integrated Circuits. Opt. Express 2016, 24, 11855–11864. [Google Scholar] [CrossRef]

- Lai, J.; Yuan, J.; Cheng, Y.; Mei, C.; Zhou, X.; Wu, Q.; Wu, Q.; Wu, Q.; Sang, X. Dispersion-Engineered T-Type Germanium Waveguide for Mid-Infrared Supercontinuum and Frequency Comb Generations in All-Normal Dispersion Region. OSA Contin. 2020, 3, 2320–2331. [Google Scholar] [CrossRef]

- Lin, Y.; Lee, K.H.; Bao, S.; Guo, X.; Wang, H.; Michel, J.; Tan, C.S. High-Efficiency Normal-Incidence Vertical p-i-n Photodetectors on a Germanium-on-Insulator Platform. Photonics Res. 2017, 5, 702–709. [Google Scholar] [CrossRef]

- Liu, S.; Pan, M.; Feng, Z.; Qin, Y.; Wang, Y.; Tan, L.; Sun, T. Ultra-High Adsorption of Tetracycline Antibiotics on Garlic Skin-Derived Porous Biomass Carbon with High Surface Area. New J. Chem. 2020, 44, 1097–1106. [Google Scholar] [CrossRef]

- Minhas, R.S.; Antunez, E.E.; Guinan, T.M.; Gengenbach, T.R.; Rudd, D.A.; Voelcker, N.H. Fluorocarbon Plasma Gas Passivation Enhances Performance of Porous Silicon for Desorption/Ionization Mass Spectrometry. ACS Sens. 2020, 5, 3226–3236. [Google Scholar] [CrossRef] [PubMed]

- Altaf, H.; Vorhauer, N.; Tsotsas, E.; Vidaković-Koch, T. Steady-State Water Drainage by Oxygen in Anodic Porous Transport Layer of Electrolyzers: A 2D Pore Network Study. Processes 2020, 8, 362. [Google Scholar] [CrossRef] [Green Version]

- Ocier, C.R.; Richards, C.A.; Bacon-Brown, D.A.; Krueger, N.A.; Clawson, M.K.; Soares, J.A.N.T.; Braun, P.V. Optically Anisotropic Porous Silicon Microlenses with Tunable Refractive Indexes and Birefringence Profiles. Opt. Mater. Express 2020, 10, 868–883. [Google Scholar] [CrossRef]

- Palavicini, A.; Wang, C. Ab-Initio Determination of Porous Silicon Refractive Index Confirmed by Infrared Transmittance Measurements of an Omnidirectional Multilayer Reflector. Appl. Phys. B 2018, 124, 65. [Google Scholar] [CrossRef]

- Shubair, T.; Eljamal, O.; Khalil, A.M.E.; Matsunaga, N. Multilayer System of Nanoscale Zero Valent Iron and Nano-Fe/Cu Particles for Nitrate Removal in Porous Media. Sep. Purif. Technol. 2018, 193, 242–254. [Google Scholar] [CrossRef]

- Robbiano, V.; Paternò, G.M.; La Mattina, A.A.; Motti, S.G.; Lanzani, G.; Scotognella, F.; Barillaro, G. Room-Temperature Low-Threshold Lasing from Monolithically Integrated Nanostructured Porous Silicon Hybrid Microcavities. ACS Nano 2018, 12, 4536–4544. [Google Scholar] [CrossRef] [PubMed]

- Zegadi, R.; Lorrain, N.; Bodiou, L.; Guendouz, M.; Ziet, L.; Charrier, J. Enhanced Mid-Infrared Gas Absorption Spectroscopic Detection Using Chalcogenide or Porous Germanium Waveguides. J. Opt. 2021, 23, 035102. [Google Scholar] [CrossRef]

- Porous Silicon-Based Photonic Biosensors: Current Status and Emerging Applications/Analytical Chemistry. Available online: https://pubs.acs.org/doi/full/10.1021/acs.analchem.8b05028?casa_token=Se1TDJUjhlsAAAAA:qvQshbSJOtIC5jB9AR5gsABJWndCCCnb5nEGZNaFDfDbPtTmH1KQ4prL0zyWLb_mXoRZpp9BQJA5PCE (accessed on 5 January 2021).

- Hirschman, K.D.; Tsybeskov, L.; Duttagupta, S.P.; Fauchet, P.M. Silicon-Based Visible Light-Emitting Devices Integrated into Microelectronic Circuits. Nature 1996, 384, 338–341. [Google Scholar] [CrossRef]

- Figueiredo, J.L. Nanostructured Porous Carbons for Electrochemical Energy Conversion and Storage. Surf. Coat. Technol. 2018, 350, 307–312. [Google Scholar] [CrossRef]

- Zhang, B.; Cheng, M.; Liu, G.; Gao, Y.; Zhao, L.; Li, S.; Wang, Y.; Liu, F.; Liang, X.; Zhang, T.; et al. Room Temperature NO2 Gas Sensor Based on Porous Co3O4 Slices/Reduced Graphene Oxide Hybrid. Sens. Actuators B Chem. 2018, 263, 387–399. [Google Scholar] [CrossRef]

- Zhang, M.; Zhao, C.; Gong, H.; Niu, G.; Wang, F. Porous GaN Submicron Rods for Gas Sensor with High Sensitivity and Excellent Stability at High Temperature. ACS Appl. Mater. Interfaces 2019, 11, 33124–33131. [Google Scholar] [CrossRef]

- Yang, X.; Li, H.; Li, T.; Li, Z.; Wu, W.; Zhou, C.; Sun, P.; Liu, F.; Yan, X.; Gao, Y.; et al. Highly Efficient Ethanol Gas Sensor Based on Hierarchical SnO2/Zn2SnO4 Porous Spheres. Sens. Actuators B Chem. 2019, 282, 339–346. [Google Scholar] [CrossRef]

- Azuelos, P.; Girault, P.; Lorrain, N.; Dumeige, Y.; Bodiou, L.; Poffo, L.; Guendouz, M.; Thual, M.; Charrier, J. Optimization of Porous Silicon Waveguide Design for Micro-Ring Resonator Sensing Applications. J. Opt. 2018, 20, 085301. [Google Scholar] [CrossRef] [Green Version]

- Girault, P.; Azuelos, P.; Lorrain, N.; Poffo, L.; Lemaitre, J.; Pirasteh, P.; Hardy, I.; Thual, M.; Guendouz, M.; Charrier, J. Porous Silicon Micro-Resonator Implemented by Standard Photolithography Process for Sensing Application. Opt. Mater. 2017, 72, 596–601. [Google Scholar] [CrossRef]

- Bioud, Y.A.; Boucherif, A.; Belarouci, A.; Paradis, E.; Fafard, S.; Aimez, V.; Drouin, D.; Arès, R. Fast Growth Synthesis of Mesoporous Germanium Films by High Frequency Bipolar Electrochemical Etching. Electrochim. Acta 2017, 232, 422–430. [Google Scholar] [CrossRef]

- Quantification of the SF6 Lifetime Based on Mesospheric Loss Measured in the Stratospheric Polar Vortex-Ray-2017—Journal of Geophysical Research: Atmospheres—Wiley Online Library. Available online: https://agupubs.onlinelibrary.wiley.com/doi/full/10.1002/2016JD026198 (accessed on 18 June 2021).

- Occhipinti, Z.; Verona, R. Kyoto Protocol (KP). In Climate Action; Leal Filho, W., Azul, A.M., Brandli, L., Özuyar, P.G., Wall, T., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 605–617. ISBN 978-3-319-95885-9. [Google Scholar]

- Lu, Q.; Li, Q.; Hu, L.; Huang, L. An Effective Low-Contrast SF6 Gas Leakage Detection Method for Infrared Imaging. IEEE Trans. Instrum. Meas. 2021, 70, 1–9. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, Z.; Zhang, X. Theoretical Screening into Ru-Doped MoS2 Monolayer as a Promising Gas Sensor upon SO2 and SOF2 in SF6 Insulation Devices. Mol. Phys. 2021, e2018517. [Google Scholar] [CrossRef]

- Cui, H.; Liu, T.; Zhang, Y.; Zhang, X. Ru-InN Monolayer as a Gas Scavenger to Guard the Operation Status of SF6 Insulation Devices: A First-Principles Theory. IEEE Sens. J. 2019, 19, 5249–5255. [Google Scholar] [CrossRef]

- Cui, H.; Yan, C.; Jia, P.; Cao, W. Adsorption and Sensing Behaviors of SF6 Decomposed Species on Ni-Doped C3N Monolayer: A First-Principles Study. Appl. Surf. Sci. 2020, 512, 145759. [Google Scholar] [CrossRef]

- Gui, Y.; Zhang, X.; Lv, P.; Wang, S.; Tang, C.; Zhou, Q. Ni-CNT Chemical Sensor for SF6 Decomposition Components Detection: A Combined Experimental and Theoretical Study. Sensors 2018, 18, 3493. [Google Scholar] [CrossRef] [Green Version]

- Katsidis, C.C.; Siapkas, D.I. General Transfer-Matrix Method for Optical Multilayer Systems with Coherent, Partially Coherent, and Incoherent Interference. Appl. Opt. 2002, 41, 3978–3987. [Google Scholar] [CrossRef]

- Gordon, I.E.; Rothman, L.S.; Hill, C.; Kochanov, R.V.; Tan, Y.; Bernath, P.F.; Birk, M.; Boudon, V.; Campargue, A.; Chance, K.V.; et al. The HITRAN2016 Molecular Spectroscopic Database. J. Quant. Spectrosc. Radiat. Transf. 2017, 203, 3–69. [Google Scholar] [CrossRef]

- Duris, M.; Guendouz, M.; Lorrain, N.; Pirasteh, P.; Bodiou, L.; Raiah, W.; Raiah, W.; Coffinier, Y.; Thomy, V.; Charrier, J. Vertical Multilayer Structures Based on Porous Silicon Layers for Mid-Infrared Applications. Opt. Mater. Express 2020, 10, 1921–1930. [Google Scholar] [CrossRef]

- Refractive Index of Ge (Germanium)—Amotchkina. Available online: https://refractiveindex.info/?shelf=main&book=Ge&page=Amotchkina (accessed on 14 November 2021).

- Astrova, E.V.; Voronkov, V.B.; Remenyuk, A.D.; Shuman, V.B.; Tolmachev, V.A. Variation of the Parameters and Composition of Thin Films of Porous Silicon as a Result of Oxidation: Ellipsometric Studies. Semiconductors 1999, 33, 1149–1155. [Google Scholar] [CrossRef]

- Tsai, W.-T. The Decomposition Products of Sulfur Hexafluoride (SF6): Reviews of Environmental and Health Risk Analysis. J. Fluor. Chem. 2007, 128, 1345–1352. [Google Scholar] [CrossRef]

- Zhang, W.; Xiong, B.; Shao, B.; Lei, X.; Chen, W. A Demodulation Model of Dynamic Low-Finesse Fabry-Perot Cavity Based on the Instantaneous Frequency. IEEE Access 2020, 8, 71074–71082. [Google Scholar] [CrossRef]

- Zhang, H.; Lv, J.; Jia, Z. Detection of Ammonia-Oxidizing Bacteria (AOB) Using a Porous Silicon Optical Biosensor Based on a Multilayered Double Bragg Mirror Structure. Sensors 2018, 18, 105. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Toanen, V.; Symonds, C.; Benoit, J.-M.; Gassenq, A.; Lemaıtre, A.; Bellessa, J. Room-Temperature Lasing in a Low-Loss Tamm Plasmon Cavity. ACS Photonics 2020, 7, 2952–2957. [Google Scholar] [CrossRef]

- Khoshmanesh, A.; Dixon, M.W.A.; Kenny, S.; Tilley, L.; McNaughton, D.; Wood, B.R. Detection and Quantification of Early-Stage Malaria Parasites in Laboratory Infected Erythrocytes by Attenuated Total Reflectance Infrared Spectroscopy and Multivariate Analysis. Anal. Chem. 2014, 86, 4379–4386. [Google Scholar] [CrossRef]

| p (%) | 20 | 40 | 60 | 80 |

| n | 3.549 | 2.844 | 2.048 | 1.367 |

| e (nm) | 743 | 927 | 1288 | 1929 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zegadi, R.; Lorrain, N.; Meziani, S.; Dumeige, Y.; Bodiou, L.; Guendouz, M.; Zegadi, A.; Charrier, J. Theoretical Demonstration of the Interest of Using Porous Germanium to Fabricate Multilayer Vertical Optical Structures for the Detection of SF6 Gas in the Mid-Infrared. Sensors 2022, 22, 844. https://doi.org/10.3390/s22030844

Zegadi R, Lorrain N, Meziani S, Dumeige Y, Bodiou L, Guendouz M, Zegadi A, Charrier J. Theoretical Demonstration of the Interest of Using Porous Germanium to Fabricate Multilayer Vertical Optical Structures for the Detection of SF6 Gas in the Mid-Infrared. Sensors. 2022; 22(3):844. https://doi.org/10.3390/s22030844

Chicago/Turabian StyleZegadi, Rami, Nathalie Lorrain, Sofiane Meziani, Yannick Dumeige, Loїc Bodiou, Mohammed Guendouz, Abdelouahab Zegadi, and Joël Charrier. 2022. "Theoretical Demonstration of the Interest of Using Porous Germanium to Fabricate Multilayer Vertical Optical Structures for the Detection of SF6 Gas in the Mid-Infrared" Sensors 22, no. 3: 844. https://doi.org/10.3390/s22030844

APA StyleZegadi, R., Lorrain, N., Meziani, S., Dumeige, Y., Bodiou, L., Guendouz, M., Zegadi, A., & Charrier, J. (2022). Theoretical Demonstration of the Interest of Using Porous Germanium to Fabricate Multilayer Vertical Optical Structures for the Detection of SF6 Gas in the Mid-Infrared. Sensors, 22(3), 844. https://doi.org/10.3390/s22030844