Development of a Robot Arm Link System Embedded with a Three-Axis Sensor with a Simple Structure Capable of Excellent External Collision Detection

Abstract

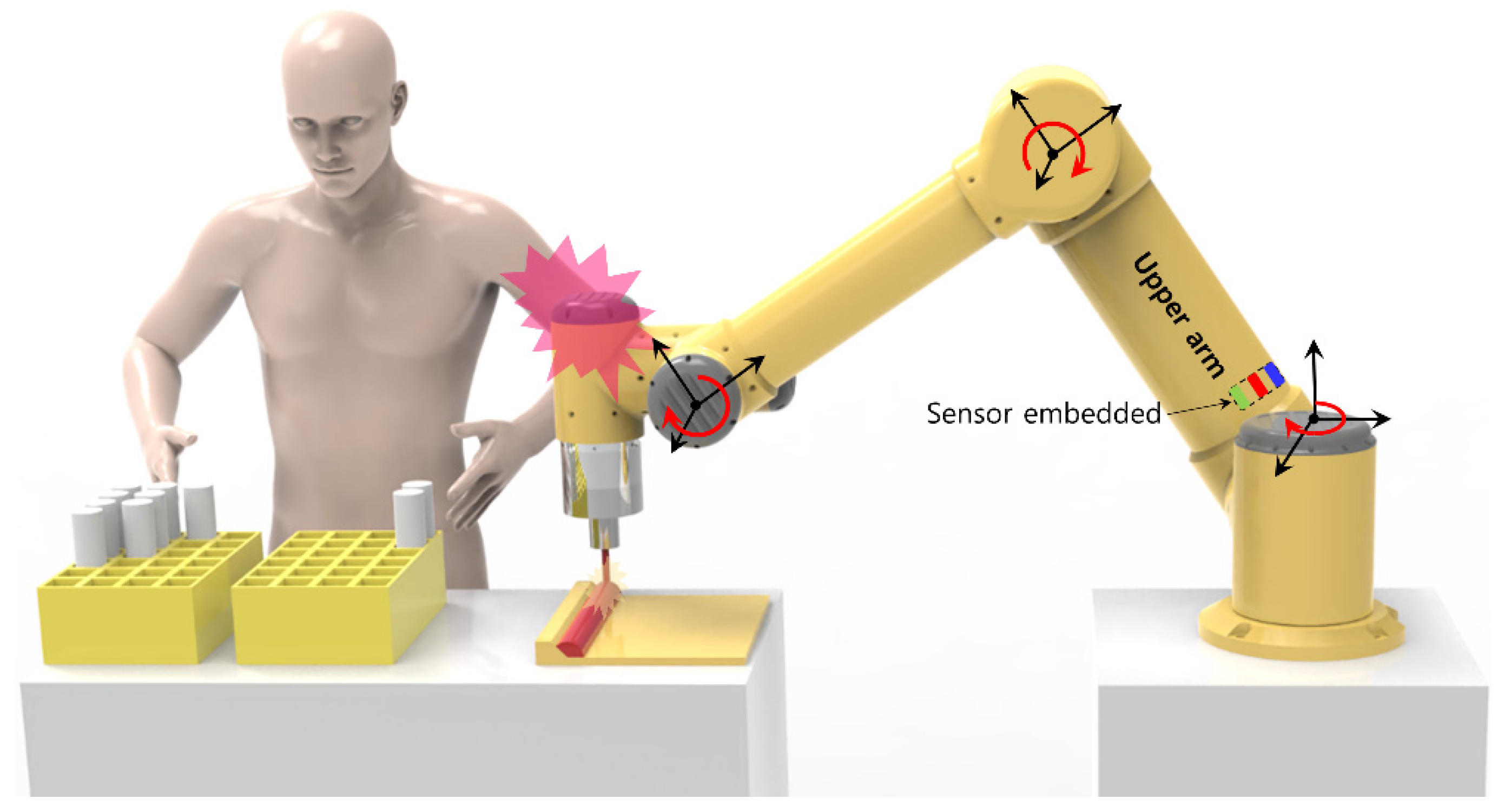

:1. Introduction

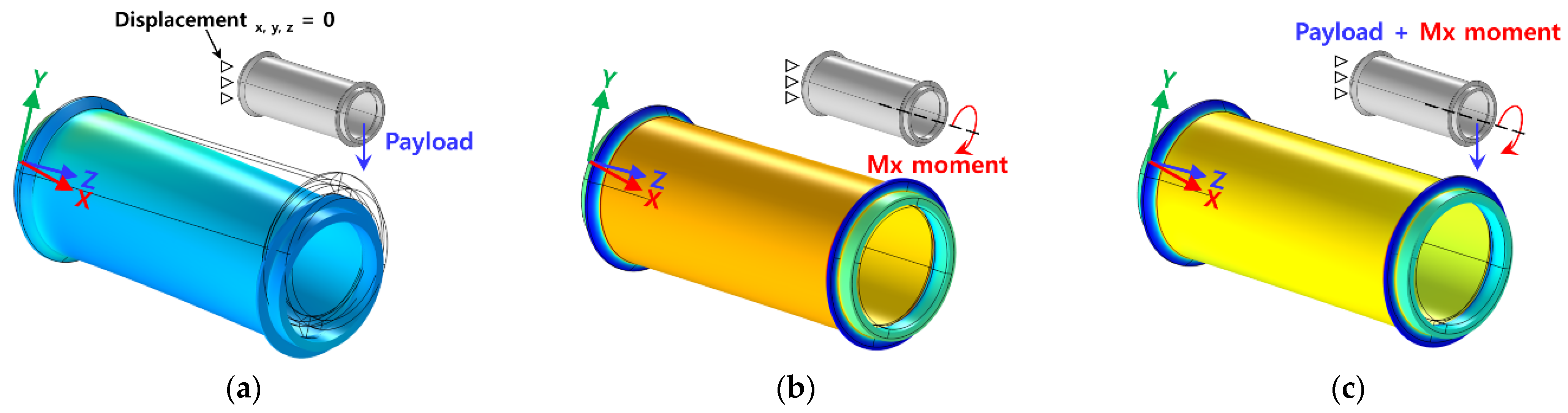

2. Development of the Three-Axis Sensor Embedded in the Link

2.1. External Force Estimation Principle

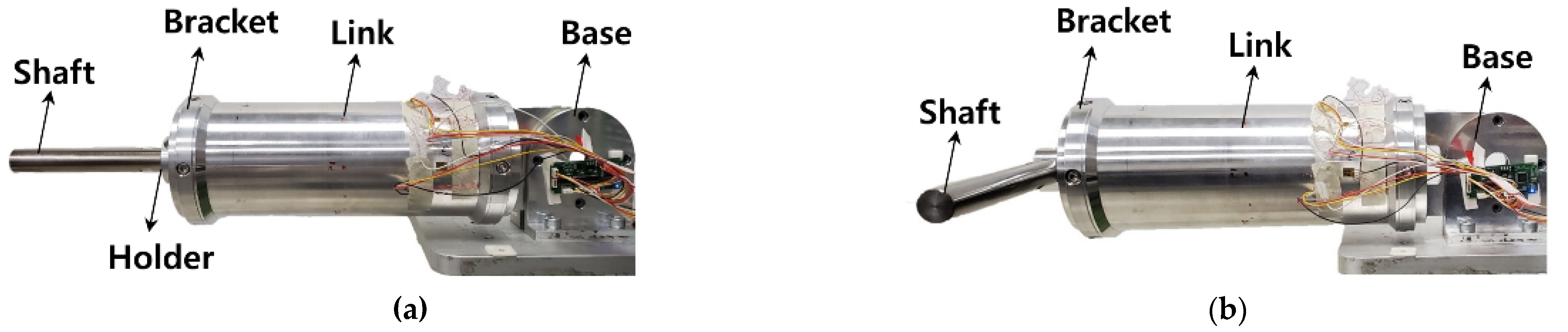

2.2. Manufacture of the Three-Axis Sensor and Setup of the Measurement System

3. Calibration of the Three-Axis Sensor

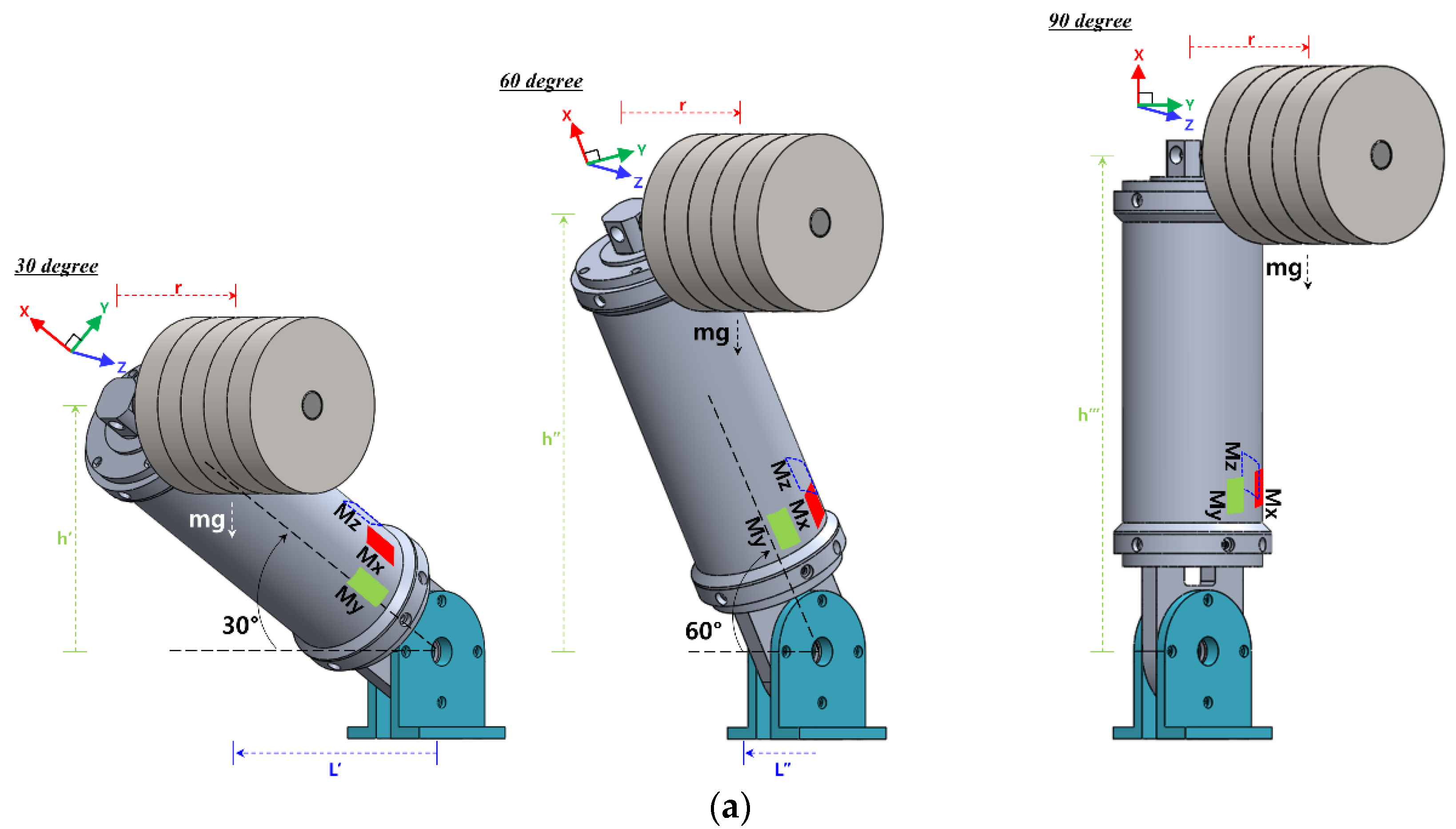

3.1. Fabrication of Static Load Evaluation Equipment

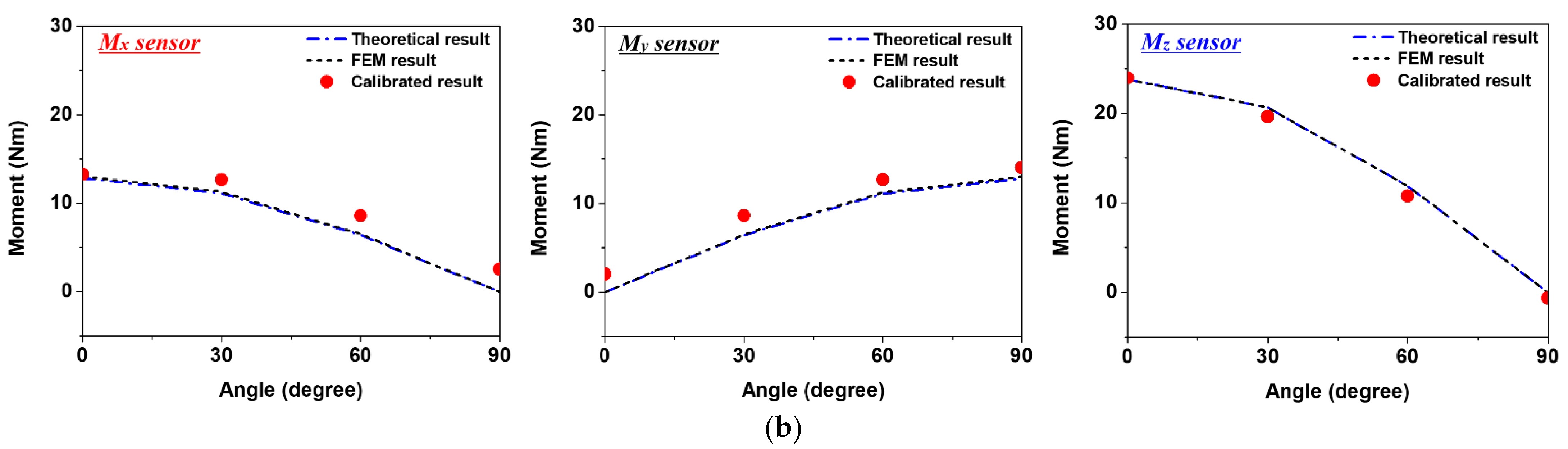

3.2. Sensor Calibration

3.3. Evaluation of Sensor Characteristics

4. Evaluation of Detection Performance

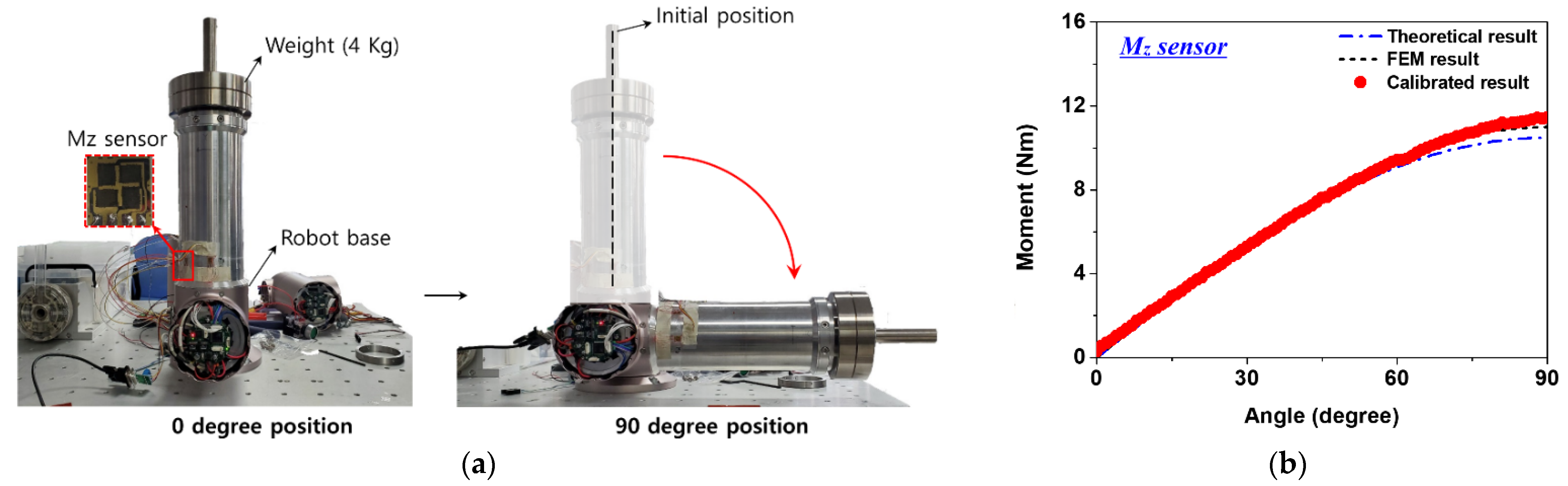

4.1. Evaluation of the Sensor’s Micro Force Detection Performance through Weight Test

4.2. Evaluation of the Sensor Tilt Detection Performance Using the Robot Base Axis

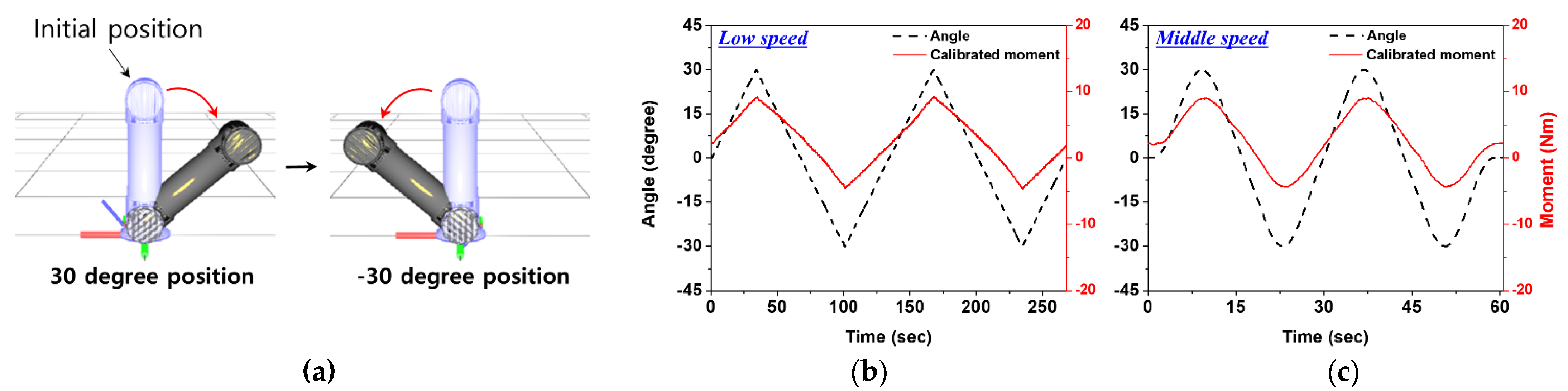

4.3. Evaluation of the Sensor’s Dynamic State Detection Performance, According to the Link Slope Speed Change

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Krüger, J.; Lien, T.K.; Verl, A. Cooperation of Human and Machines in Assembly Lines. CIRP Ann. 2009, 58, 628–646. [Google Scholar] [CrossRef]

- Cherubini, A.; Passama, R.; Crozier, A.; Lasnier, A.; Fraisse, P. Collaborative Manufacturing with Physical Human–Robot Interaction. Robot. Comput.-Integr. Manuf. 2016, 40, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Dimeas, F.; Moulianitis, V.C.; Aspragathos, N. Manipulator Performance Constraints in Human-Robot Cooperation. Robot. Comput.-Integr. Manuf. 2018, 50, 222–233. [Google Scholar] [CrossRef]

- Haddadin, S.; De Luca, A.; Albu-Schäffer, A. Robot Collisions: A Survey on Detection, Isolation, and Identification. IEEE Trans. Robot. 2017, 33, 1292–1312. [Google Scholar] [CrossRef] [Green Version]

- Tsetserukou, D.; Tachi, S. Torque Sensors for Robot Joint Control. Sens. Focus Tactile Force Stress Sens. 2008, 15–36. [Google Scholar] [CrossRef] [Green Version]

- Palli, G.; Pirozzi, S. An Optical Torque Sensor for Robotic Applications. Int. J. Optomechatronics 2013, 7, 263–282. [Google Scholar] [CrossRef] [Green Version]

- Al-Mai, O.; Ahmadi, M.; Albert, J. Design, Development and Calibration of a Lightweight, Compliant Six-Axis Optical Force/Torque Sensor. IEEE Sens. J. 2018, 18, 7005–7014. [Google Scholar] [CrossRef]

- Shams, S.; Lee, J.Y.; Han, C. Compact and Lightweight Optical Torque Sensor for Robots with Increased Range. Sens. Actuators A Phys. 2012, 173, 81–89. [Google Scholar] [CrossRef]

- Lee, D.-H.; Kim, U.; Jung, H.; Choi, H.R. A Capacitive-Type Novel Six-Axis Force/Torque Sensor for Robotic Applications. IEEE Sens. J. 2015, 16, 2290–2299. [Google Scholar] [CrossRef]

- Kim, U.; Lee, D.-H.; Kim, Y.B.; Seok, D.-Y.; Choi, H.R. A Novel Six-Axis Force/Torque Sensor for Robotic Applications. IEEE/ASME Trans. Mechatron. 2016, 22, 1381–1391. [Google Scholar] [CrossRef]

- Kim, D.; Lee, C.H.; Kim, B.C.; Lee, D.H.; Lee, H.S.; Nguyen, C.T.; Kim, U.K.; Nguyen, T.D.; Moon, H.; Koo, J.C. Six-Axis Capacitive Force/Torque Sensor Based on Dielectric Elastomer. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD) 2013, San Diego, CA, USA, 10–14 March 2013; International Society for Optics and Photonics: Bellingham, WA, USA, 2013; Volume 8687, pp. 86872J. [Google Scholar] [CrossRef]

- Alveringh, D.; Brookhuis, R.A.; Wiegerink, R.J.; Krijnen, G.J. A Large Range Multi-Axis Capacitive Force/Torque Sensor Realized in a Single SOI Wafer. In Proceedings of the 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014; pp. 680–683. [Google Scholar] [CrossRef]

- Kim, J.-I.; Jeon, H.-S.; Jeong, Y.-J.; Kim, Y.-J. High Stiffness Capacitive Type Torque Sensor with Flexure Structure for Cooperative Industrial Robots. In Proceedings of the 2017 14th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Jeju, Korea, 28 June–1 July 2017; pp. 433–437. [Google Scholar] [CrossRef]

- Kim, Y.B.; Kim, U.; Seok, D.-Y.; So, J.; Lee, Y.H.; Choi, H.R. Torque Sensor Embedded Actuator Module for Robotic Applications. IEEE/ASME Trans. Mechatron. 2018, 23, 1662–1672. [Google Scholar] [CrossRef]

- Seok, D.-Y.; Kim, Y.B.; Lee, S.Y.; Kim, J.; Choi, H.R. Ultra–Thin Joint Torque Sensor with Enhanced Sensitivity for Robotic Application. IEEE Robot. Autom. Lett. 2020, 5, 5873–5880. [Google Scholar] [CrossRef]

- Je, H.-W.; Baek, J.-Y.; Lee, M.-C. A Study of the Collision Detection of Robot Manipulator without Torque Sensor. In Proceedings of the 2009 ICCAS-SICE, Fukuoka, Japan, 18–21 August 2009; pp. 4468–4471. [Google Scholar]

- Lee, S.-D.; Kim, M.-C.; Song, J.-B. Sensorless Collision Detection for Safe Human-Robot Collaboration. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 2392–2397. [Google Scholar] [CrossRef]

- Chen, S.; Luo, M.; He, F. A Universal Algorithm for Sensorless Collision Detection of Robot Actuator Faults. Adv. Mech. Eng. 2018, 10, 1687814017740710. [Google Scholar] [CrossRef] [Green Version]

- Indri, M.; Trapani, S.; Lazzero, I. Development of a Virtual Collision Sensor for Industrial Robots. Sensors 2017, 17, 1148. [Google Scholar] [CrossRef] [Green Version]

- Aghili, F.; Buehler, M.; Hollerbach, J.M. Design of a Hollow Hexaform Torque Sensor for Robot Joints. Int. J. Robot. Res. 2001, 20, 967–976. [Google Scholar] [CrossRef]

- Muftah, M.H.; Haris, S.M.; Petroczki, K.; Khidir, E.A. An Improved Strain Gauge-Based Dynamic Torque Measurement Method. Int. J. Circuits Syst. Signal Processing 2013, 7, 66–73. [Google Scholar]

- Sun, Y.; Liu, Y.; Jin, M.; Liu, H. Design of a Novel Six-Axis Force/Torque Sensor Based on Strain Gauges by Finite Element Method. In Proceeding of the 11th World Congress on Intelligent Control and Automation, Shenyang, China, 29 June–4 July 2014; pp. 3387–3392. [Google Scholar] [CrossRef]

- Kim, S.Y.; Park, S.H.; Choi, B.G.; Kang, I.H.; Park, S.W.; Shin, J.W.; Kim, J.H.; Baek, W.K.; Lim, K.T.; Kim, Y.-J. Development of a Spoke Type Torque Sensor Using Painting Carbon Nanotube Strain Sensors. J. Nanosci. Nanotechnol. 2018, 18, 1782–1786. [Google Scholar] [CrossRef]

- Jung, B.; Kim, B.; Koo, J.C.; Choi, H.R.; Moon, H. Joint Torque Sensor Embedded in Harmonic Drive Using Order Tracking Method for Robotic Application. IEEE/ASME Trans. Mechatron. 2017, 22, 1594–1599. [Google Scholar] [CrossRef]

- Ubeda, R.P.; Gutiérrez Rubert, S.C.; Zotovic Stanisic, R.; Perles Ivars, A. Design and Manufacturing of an Ultra-Low-Cost Custom Torque Sensor for Robotics. Sensors 2018, 18, 1786. [Google Scholar] [CrossRef] [Green Version]

- Min, J.-K.; Ahn, K.-H.; Park, H.-C.; Song, J.-B. A Novel Reactive-Type Joint Torque Sensor with High Torsional Stiffness for Robot Applications. Mechatronics 2019, 63, 102265. [Google Scholar] [CrossRef]

- Lou, Y.; Wei, J.; Song, S. Design and Optimization of a Joint Torque Sensor for Robot Collision Detection. IEEE Sens. J. 2019, 19, 6618–6627. [Google Scholar] [CrossRef]

- Kim, J.H.; Kang, D.I.; Shin, H.H.; Park, Y.K. Design and Analysis of a Column Type Multi-Component Force/Moment Sensor. Measurement 2003, 33, 213–219. [Google Scholar] [CrossRef]

- Kim, G.-S. Design of a Six-Axis Wrist Force/Moment Sensor Using FEM and Its Fabrication for an Intelligent Robot. Sens. Actuators A Phys. 2007, 133, 27–34. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yun, A.; Lee, W.; Kim, S.; Kim, J.-H.; Yoon, H. Development of a Robot Arm Link System Embedded with a Three-Axis Sensor with a Simple Structure Capable of Excellent External Collision Detection. Sensors 2022, 22, 1222. https://doi.org/10.3390/s22031222

Yun A, Lee W, Kim S, Kim J-H, Yoon H. Development of a Robot Arm Link System Embedded with a Three-Axis Sensor with a Simple Structure Capable of Excellent External Collision Detection. Sensors. 2022; 22(3):1222. https://doi.org/10.3390/s22031222

Chicago/Turabian StyleYun, Alchan, Woosub Lee, Soonkyum Kim, Jong-Ho Kim, and Hyungseok Yoon. 2022. "Development of a Robot Arm Link System Embedded with a Three-Axis Sensor with a Simple Structure Capable of Excellent External Collision Detection" Sensors 22, no. 3: 1222. https://doi.org/10.3390/s22031222

APA StyleYun, A., Lee, W., Kim, S., Kim, J.-H., & Yoon, H. (2022). Development of a Robot Arm Link System Embedded with a Three-Axis Sensor with a Simple Structure Capable of Excellent External Collision Detection. Sensors, 22(3), 1222. https://doi.org/10.3390/s22031222