Research on Variable Parameter Drilling Method of Ti-CFRP-Ti Laminated Stacks Based on Real-Time Sensing of Drilling Axial Force

Abstract

:1. Introduction

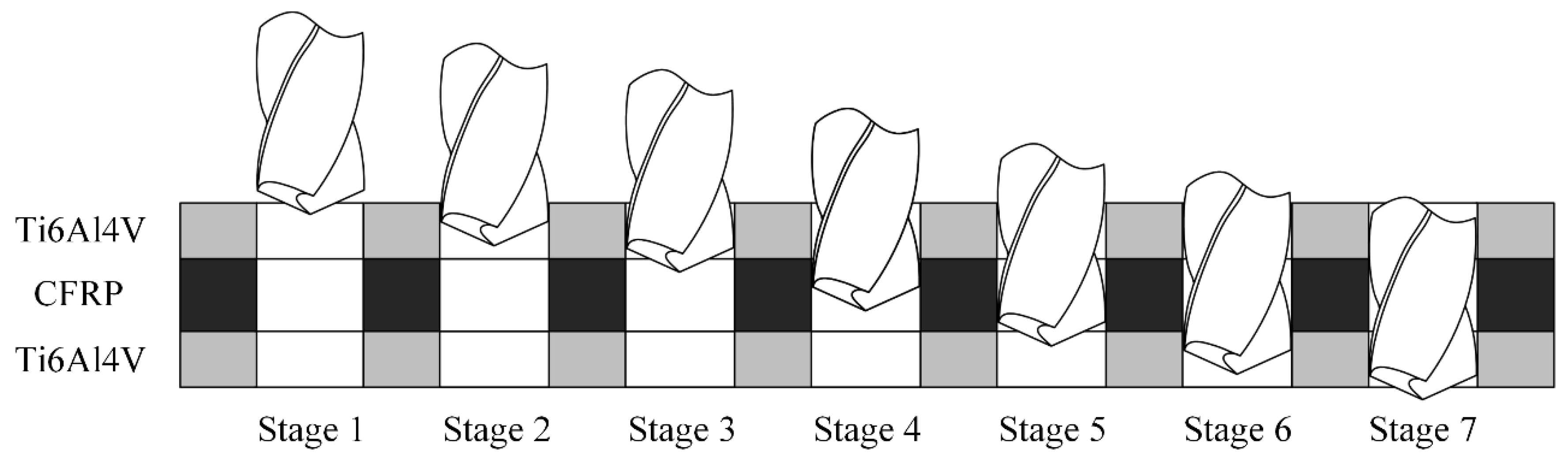

2. Analysis of Drilling Process for Ti-CFRP-Ti Laminated Stacks

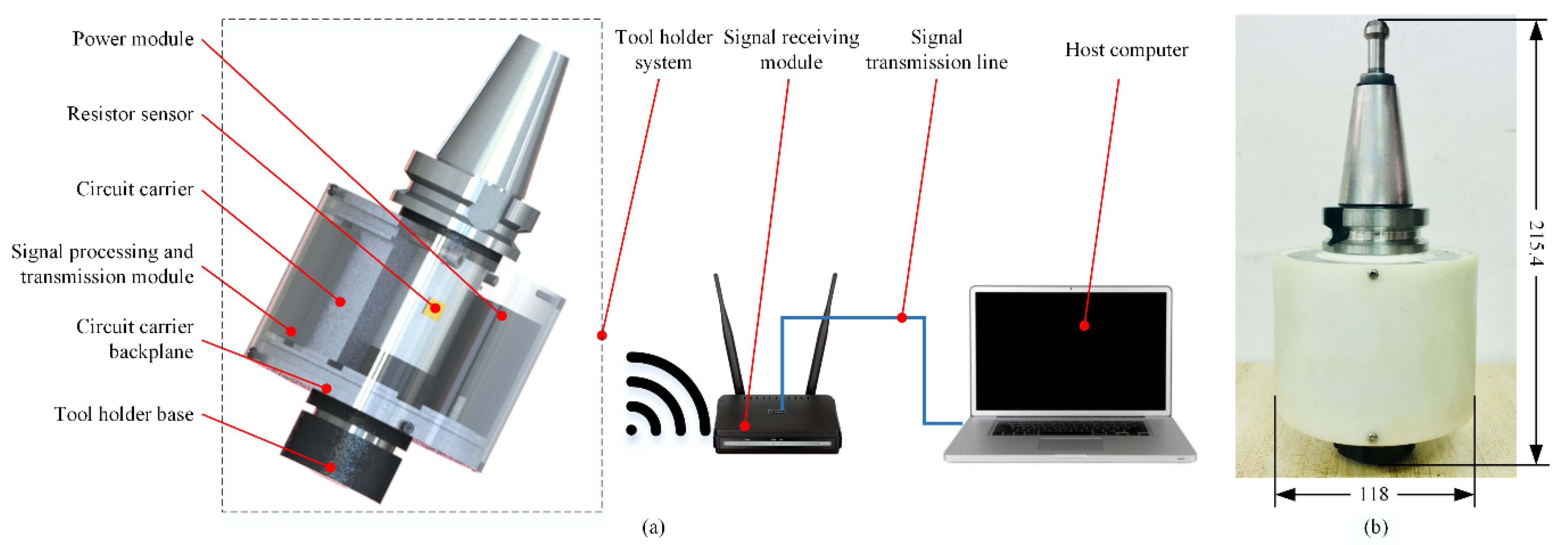

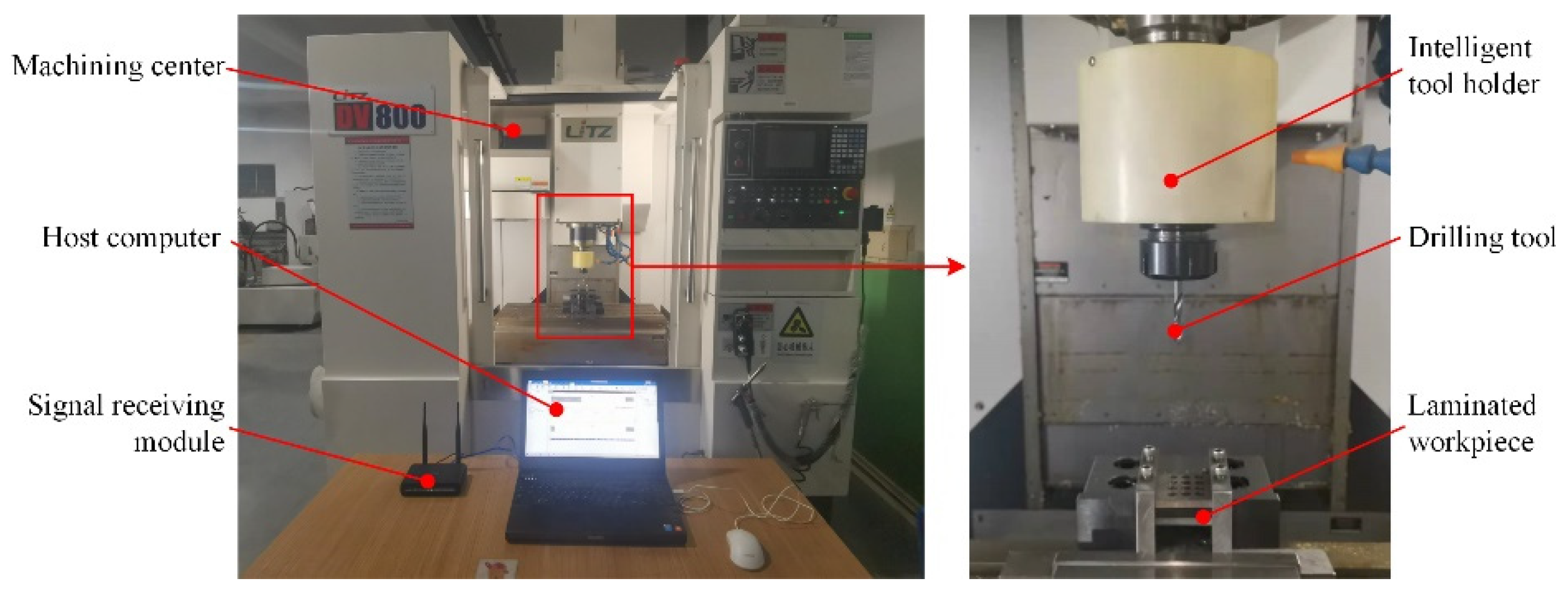

3. Design of Intelligent Tool Holder System

3.1. Overall System Composition

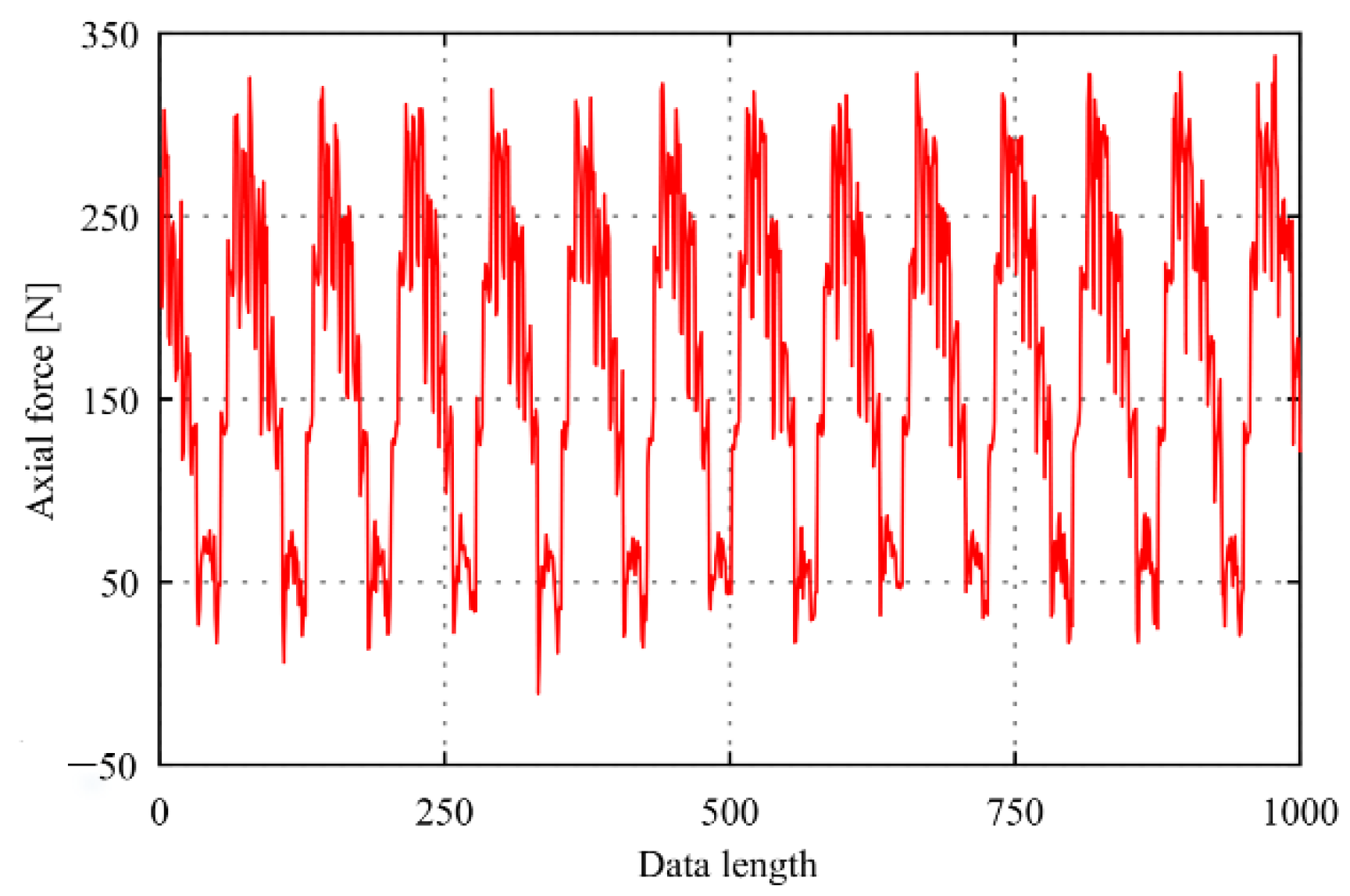

3.2. Cutting Force Signal Processing

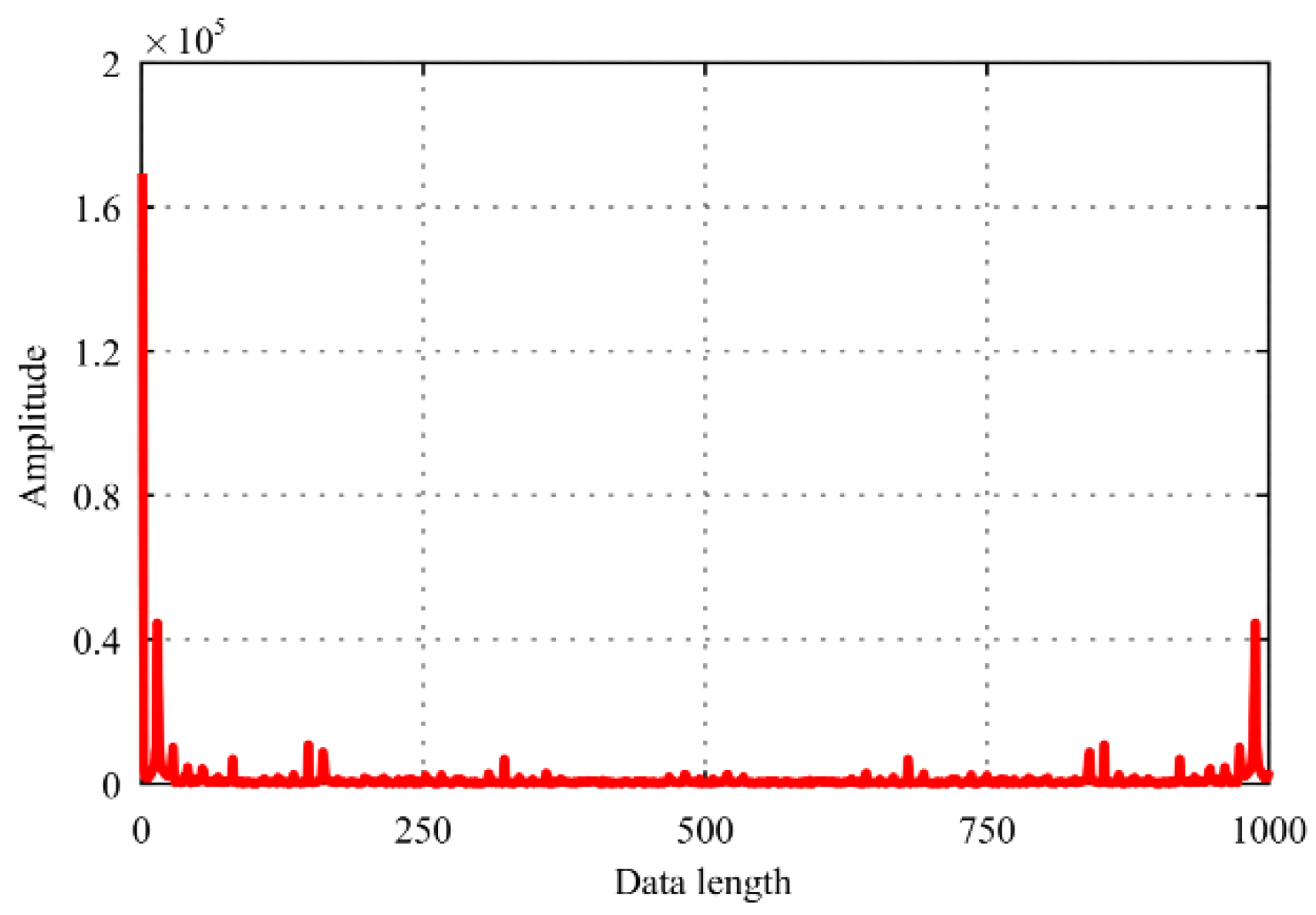

3.2.1. Sparse Representation Model Construction

3.2.2. Construction of Sampling Signals

3.2.3. Recovery of Sampling Signals

4. Scheme of Variable Parameter Peck Drilling Experiments

4.1. Scheme of Cutting Experiments for Intelligent Tool Holder System

4.2. Scheme of Drilling Experiments for Ti-CFRP-Ti Laminated Stacks

5. Experimental Results and Analysis

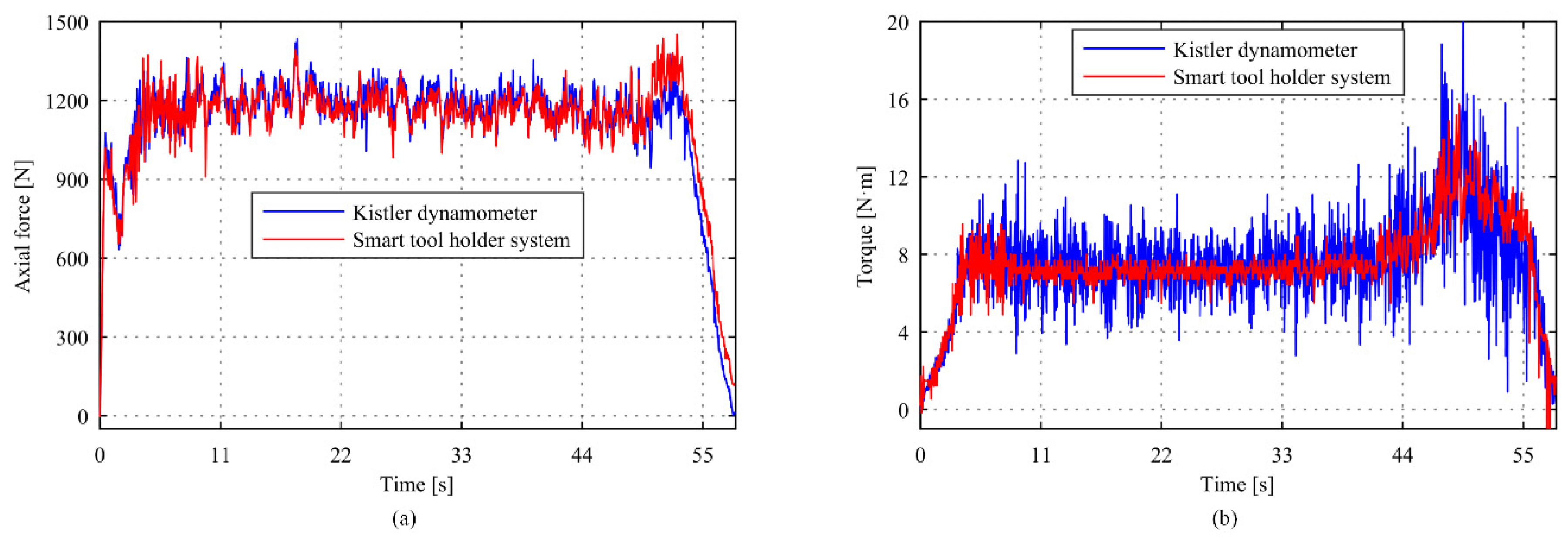

5.1. Cutting Experimental Results of Intelligent Tool Holder System

5.2. Drilling Experimental Results of Ti-CFRP-Ti Laminated Stacks

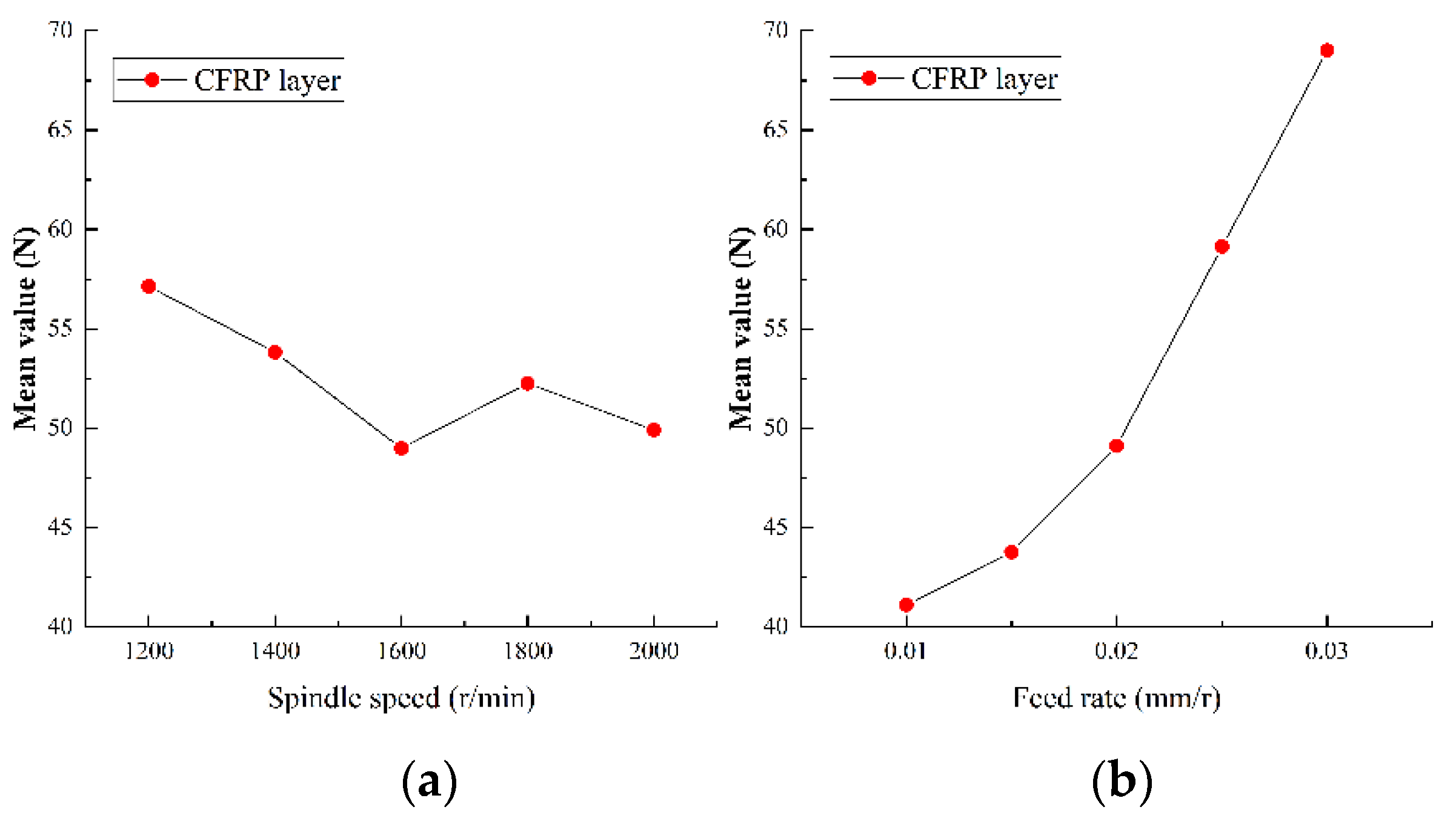

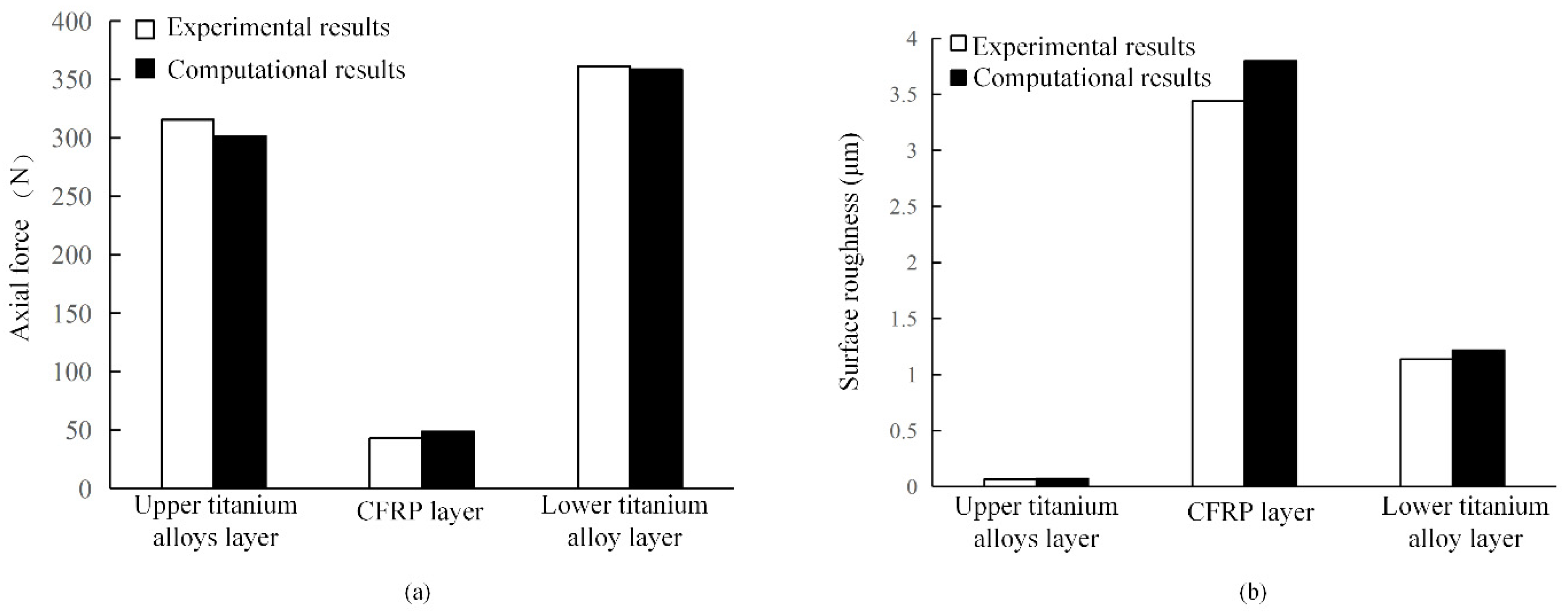

5.2.1. Analysis of Axial Force

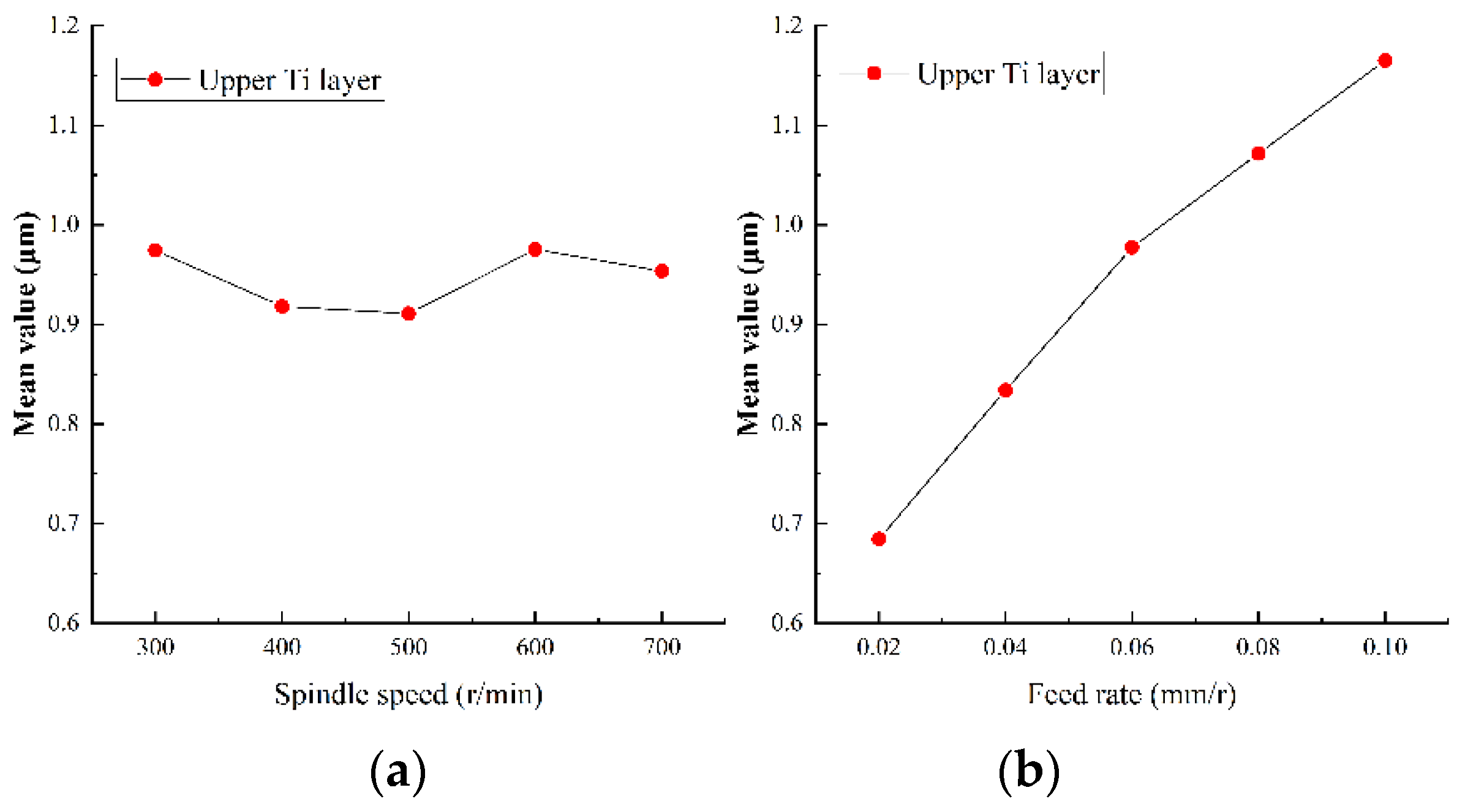

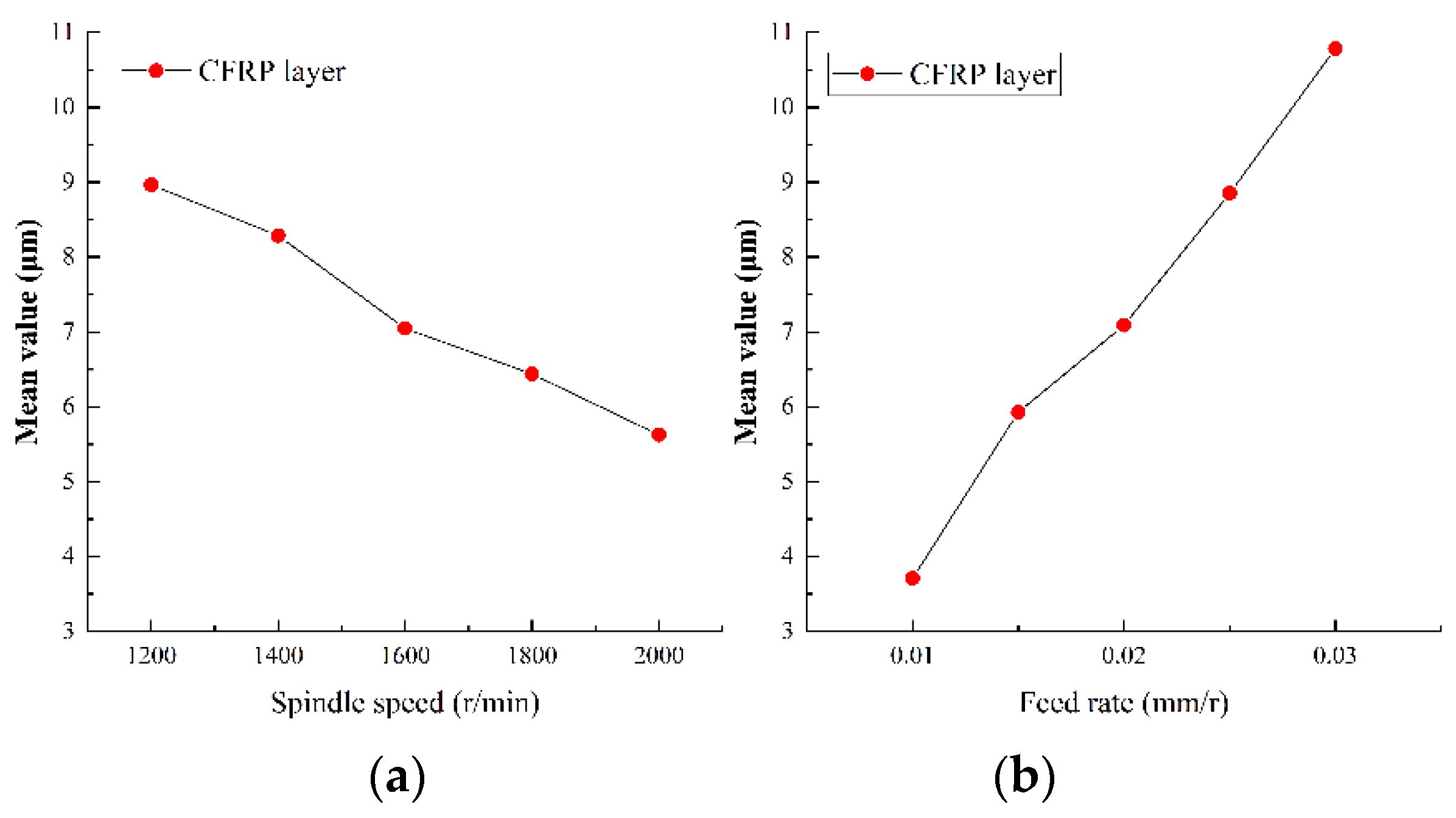

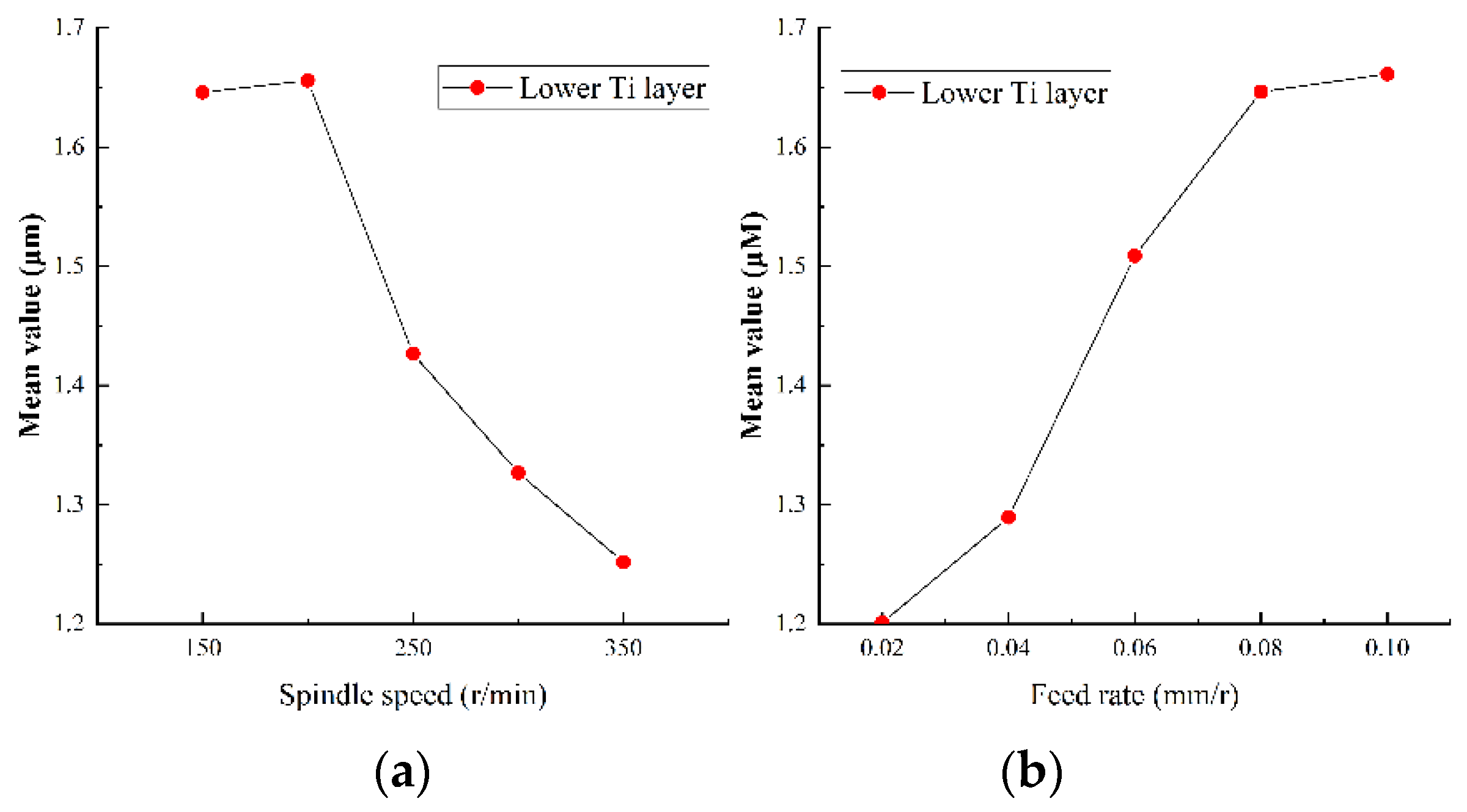

5.2.2. Analysis of Surface Roughness of Hole Wall

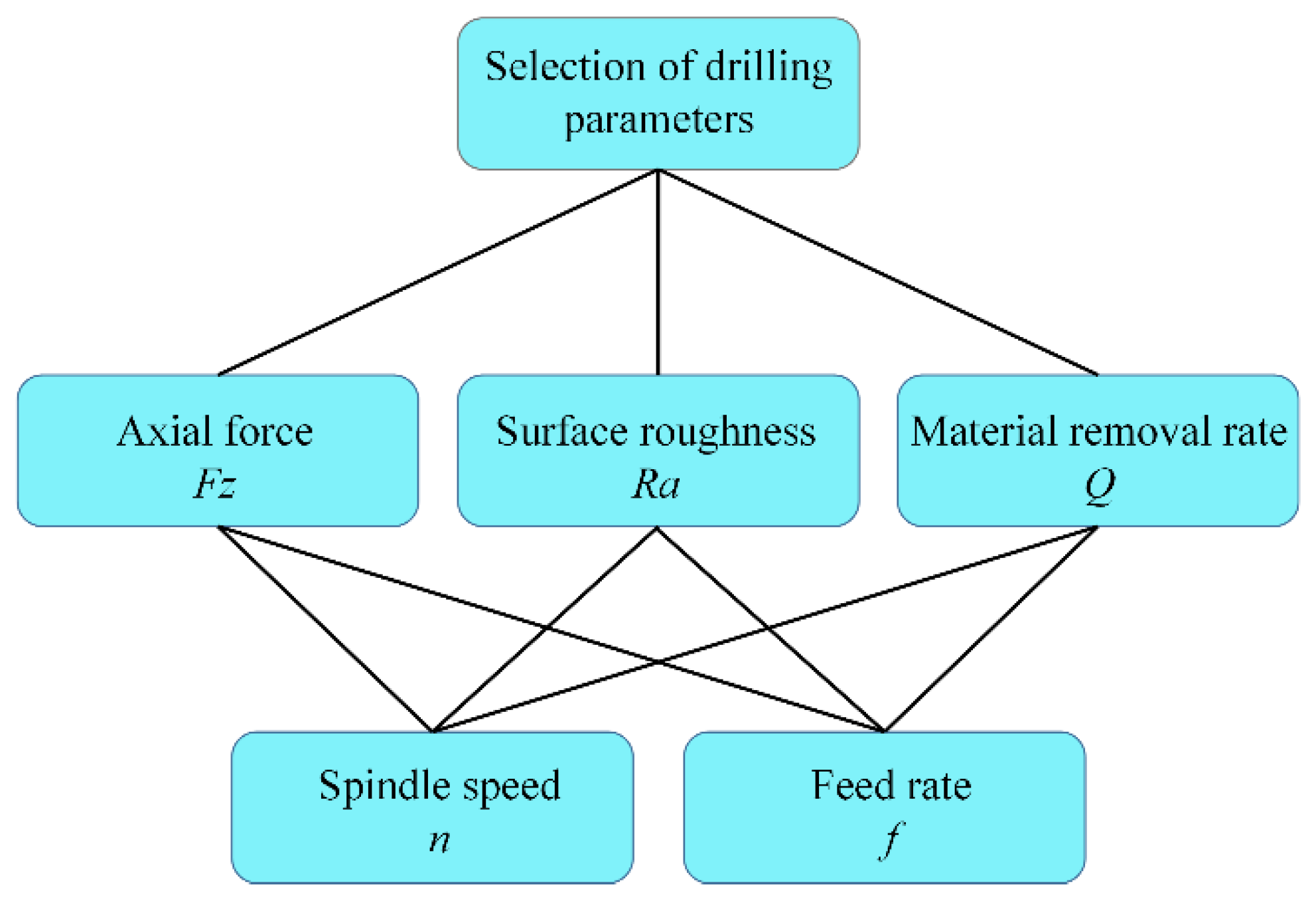

5.3. Multi-Objective Optimization of Drilling Parameters Based on Analytic Hierarchy Process (AHP)

5.3.1. Establishment of Multi-Objective Optimization Model

5.3.2. Solution Based on Genetic Algorithms

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, B.; Zhang, K.; Li, Y.; Cheng, H.; Liu, S. Modelling of thrust force for worn drill bits characterised by cutting edge radius in drilling carbon fibre–reinforced plastic/Ti-6Al-4V alloy stacks. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1960–1972. [Google Scholar] [CrossRef]

- Liu, D.; Tang, Y.; Cong, W.L. A review of mechanical drilling for composite laminates. Compos. Struct. 2012, 94, 1265–1279. [Google Scholar] [CrossRef]

- Xu, J.; El Mansori, M. Experimental study on drilling mechanisms and strategies of hybrid CFRP/Ti stacks. Compos. Struct. 2016, 157, 461–482. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Zhang, D.; Jiang, X.; Qin, W.; Geng, D. Study on rotary ultrasonic-assisted drilling of titanium alloys (Ti6Al4V) using 8-facet drill under no cooling condition. Int. J. Adv. Manuf. Technol. 2016, 90, 3249–3264. [Google Scholar] [CrossRef]

- Park, K.; Beal, A.; Kim, D.D.; Kwon, P.; Lantrip, J. Tool wear in drilling of composite/titanium stacks using carbide and polycrystalline diamond tools. Wear 2011, 271, 2826–2835. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Axinte, D.; Soo, S.L.; Nobel, C.; Attia, H.; Kappmeyer, G.; Engin, S.; Sim, W. High performance cutting of advanced aerospace alloys and composite materials. CIRP Ann. 2015, 64, 557–580. [Google Scholar] [CrossRef]

- Pramanik, A.; Basak, A.K.; Dong, Y.; Sarker, P.K.; Uddin, M.S.; Littlefair, G.; Dixit, A.R.; Chattopadhyaya, S. Joining of carbon fibre reinforced polymer (CFRP) composites and aluminium alloys–A review. Compos. Part A Appl. Sci. Manuf. 2017, 101, 1–29. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Li, C.; Chen, M.; El Mansori, M.; Ren, F. An investigation of drilling high-strength CFRP composites using specialized drills. Int. J. Adv. Manuf. Technol. 2019, 103, 3425–3442. [Google Scholar] [CrossRef]

- Chen, X.; Xie, L.; Nan, X.; Tian, J.; Zhao, W. Experimental Study on Small-hole Drilling Characteristics of SiCp/Al Composites. Procedia CIRP 2016, 46, 319–322. [Google Scholar] [CrossRef] [Green Version]

- Xi, W.; Wang, C.; Shi, R.; Song, Y.; Hu, Y. Research on the Effect of Low Temperature on the Performance of Drilling Carbon Fibre Reinforced Polymer and Ti Stack Materials. Mater. Sci. Forum 2012, 723, 30–34. [Google Scholar]

- Eneyew, E.D.; Ramulu, M. Experimental study of surface quality and damage when drilling unidirectional CFRP composites. J. Mater. Res. Technol. 2014, 3, 354–362. [Google Scholar] [CrossRef] [Green Version]

- Tsao, C.C. Investigation into the effects of drilling parameters on delamination by various step-core drills. J. Mater. Process. Technol. 2008, 206, 405–411. [Google Scholar] [CrossRef]

- Krishnaraj, V.; Prabukarthi, A.; Ramanathan, A.; Elanghovan, N.; Senthil Kumar, M.; Zitoune, R.; Davim, J.P. Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos. Part B Eng. 2012, 43, 1791–1799. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Y.; An, Q.; Cai, X.; Ming, W.; Chen, M. Drilling temperature and hole quality in drilling of CFRP/aluminum stacks using diamond coated drill. Int. J. Precis. Eng. Manuf. 2015, 16, 1689–1697. [Google Scholar] [CrossRef]

- Hu, L.; Tang, R.; Cai, W.; Feng, Y.; Ma, X. Optimisation of cutting parameters for improving energy efficiency in machining process. Robot. Int. Manuf. 2019, 59, 406–416. [Google Scholar] [CrossRef]

- Feito, N.; Muñoz-Sánchez, A.; Díaz-Álvarez, A.; Miguelez, M.H. Multi-objective optimization analysis of cutting parameters when drilling composite materials with special geometry drills. Compos. Struct. 2019, 225, 111187. [Google Scholar] [CrossRef]

- Feito, N.; Munoz-Sanchez, A.; Diaz-Alvarez, A.; Loya, J.A. Analysis of the Machinability of Carbon Fiber Composite Materials in Function of Tool Wear and Cutting Parameters Using the Artificial Neural Network Approach. Materials 2019, 12, 2747. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Zhao, Y.; Fei, J.; Qin, Y.; Zhao, Y.; Cai, A.; Gao, S. Design and Development of a Three-Component Force Sensor for Milling Process Monitoring. Sensors 2017, 17, 949. [Google Scholar] [CrossRef] [Green Version]

- Wu, F.; Li, Y.; Guo, B.; Zhang, P. The Design of Force Measuring Tool Holder System Based on Wireless Transmission. IEEE Access 2018, 6, 38556–38566. [Google Scholar] [CrossRef]

- Candes, E.J. The restricted isometry property and its implications for compressed sensing. Comptes Rendus Math. 2008, 346, 589–592. [Google Scholar] [CrossRef]

- Yang, A.; Zhang, J.; Hou, Z. Optimized Sensing Matrix Design Based on Parseval Tight Frame and Matrix Decomposition. J. Commun. 2013, 8, 456–462. [Google Scholar] [CrossRef]

- Elad, M. Optimized Projections for Compressed Sensing. IEEE Trans. Signal Process. 2007, 55, 5695–5702. [Google Scholar] [CrossRef]

- Rezaiifar, Y.C.P.R.; Krishnaprasad, P.S. Orthogonal Matching Pursuit: Recursive Function Approximation with Applications to Wavelet Decomposition. In Proceedings of the 27th Asilomar Conference on Signals, Systems and Computers, Pacific Grove, CA, USA, 1–3 November 1993. [Google Scholar]

- Needell, D.; Tropp, J.A. CoSaMP: Iterative signal recovery from incomplete and inaccurate samples-ScienceDirect. Appl. Comput. Harmon. A 2009, 26, 301–321. [Google Scholar] [CrossRef] [Green Version]

- Ramulu, M.; Branson, T.; Kim, D. A study on the drilling of composite and titanium stacks. Compos. Struct. 2001, 54, 67–77. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Ameyaw, E.E.; Owusu, E.K.; Pärn, E.; Edwards, D.J. Review of application of analytic hierarchy process (AHP) in construction. Int. J. Constr. Manag. 2019, 19, 436–452. [Google Scholar] [CrossRef]

| Material | Strength | Hardness | Density | Thermal Conductivity | Modulus of Elasticity | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| TC4 | 1020 MPa | 40–43 HRC | 4.51 g/cm3 | 7.9 W/(m·k) | 115 GPa | 0.34 |

| T300 | 3760 MPa | 53–60 HRC | 1.76 g/cm3 | 0.43 W/(m·k) | 135 GPa | 0.3 |

| Factors | Lever 1 | Lever 2 | Lever 3 | Lever 4 | Lever 5 |

|---|---|---|---|---|---|

| n1 (r/min) | 300 | 400 | 500 | 600 | 700 |

| f1 (mm/r) | 0.02 | 0.04 | 0.06 | 0.08 | 0.10 |

| n2 (r/min) | 1200 | 1400 | 1600 | 1800 | 2000 |

| f2 (mm/r) | 0.01 | 0.015 | 0.02 | 0.025 | 0.03 |

| n3 (r/min) | 150 | 200 | 250 | 300 | 350 |

| f3 (mm/r) | 0.02 | 0.04 | 0.06 | 0.08 | 0.10 |

| Material | Spindle Speed (r/min) | Feed Rate (mm/r) |

|---|---|---|

| Upper titanium alloy layer | 686.249 | 0.024 |

| CFRP layer | 1925.554 | 0.011 |

| Lower titanium alloy layer | 347.577 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Zhang, N.; Wu, F.; Teng, W.; Sun, Y.; Guo, B. Research on Variable Parameter Drilling Method of Ti-CFRP-Ti Laminated Stacks Based on Real-Time Sensing of Drilling Axial Force. Sensors 2022, 22, 1188. https://doi.org/10.3390/s22031188

Zhang Z, Zhang N, Wu F, Teng W, Sun Y, Guo B. Research on Variable Parameter Drilling Method of Ti-CFRP-Ti Laminated Stacks Based on Real-Time Sensing of Drilling Axial Force. Sensors. 2022; 22(3):1188. https://doi.org/10.3390/s22031188

Chicago/Turabian StyleZhang, Zhengzhu, Ning Zhang, Fenghe Wu, Weixiang Teng, Yingbing Sun, and Baosu Guo. 2022. "Research on Variable Parameter Drilling Method of Ti-CFRP-Ti Laminated Stacks Based on Real-Time Sensing of Drilling Axial Force" Sensors 22, no. 3: 1188. https://doi.org/10.3390/s22031188

APA StyleZhang, Z., Zhang, N., Wu, F., Teng, W., Sun, Y., & Guo, B. (2022). Research on Variable Parameter Drilling Method of Ti-CFRP-Ti Laminated Stacks Based on Real-Time Sensing of Drilling Axial Force. Sensors, 22(3), 1188. https://doi.org/10.3390/s22031188