Proposal of a Real-Time Test Platform for Tactile Internet Systems

Abstract

1. Introduction

- present a real-time test platform development for tactile internet applications;

- allow tactile interaction between a human operator, using a tactile glove, with different textures regions simulated on the Matlab-Simulink;

- simulate tactile sensations through vibratory feedback;

- enable the test of various algorithms and techniques associated with tactile internet;

- contribute to the development of new strategies used to minimize problems associated with tactile internet.

2. Related Works

3. Proposal Architecture

3.1. Overall Architecture

- operator;

- master device (MD);

- master device’s hardware (MDH);

- channel;

- simulation environment;

- slave device’s hardware (SDH);

- slave device (SD);

- environment.

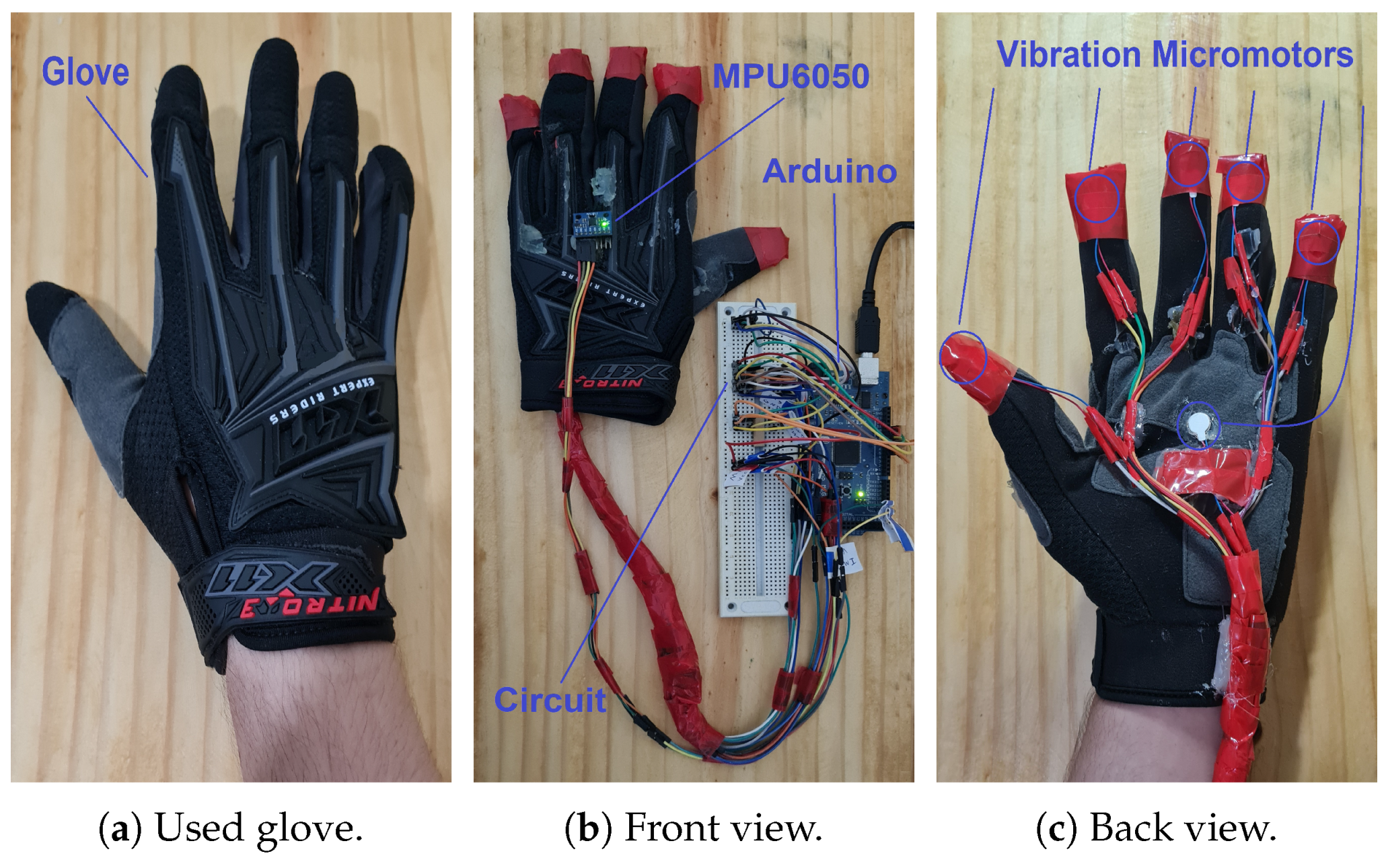

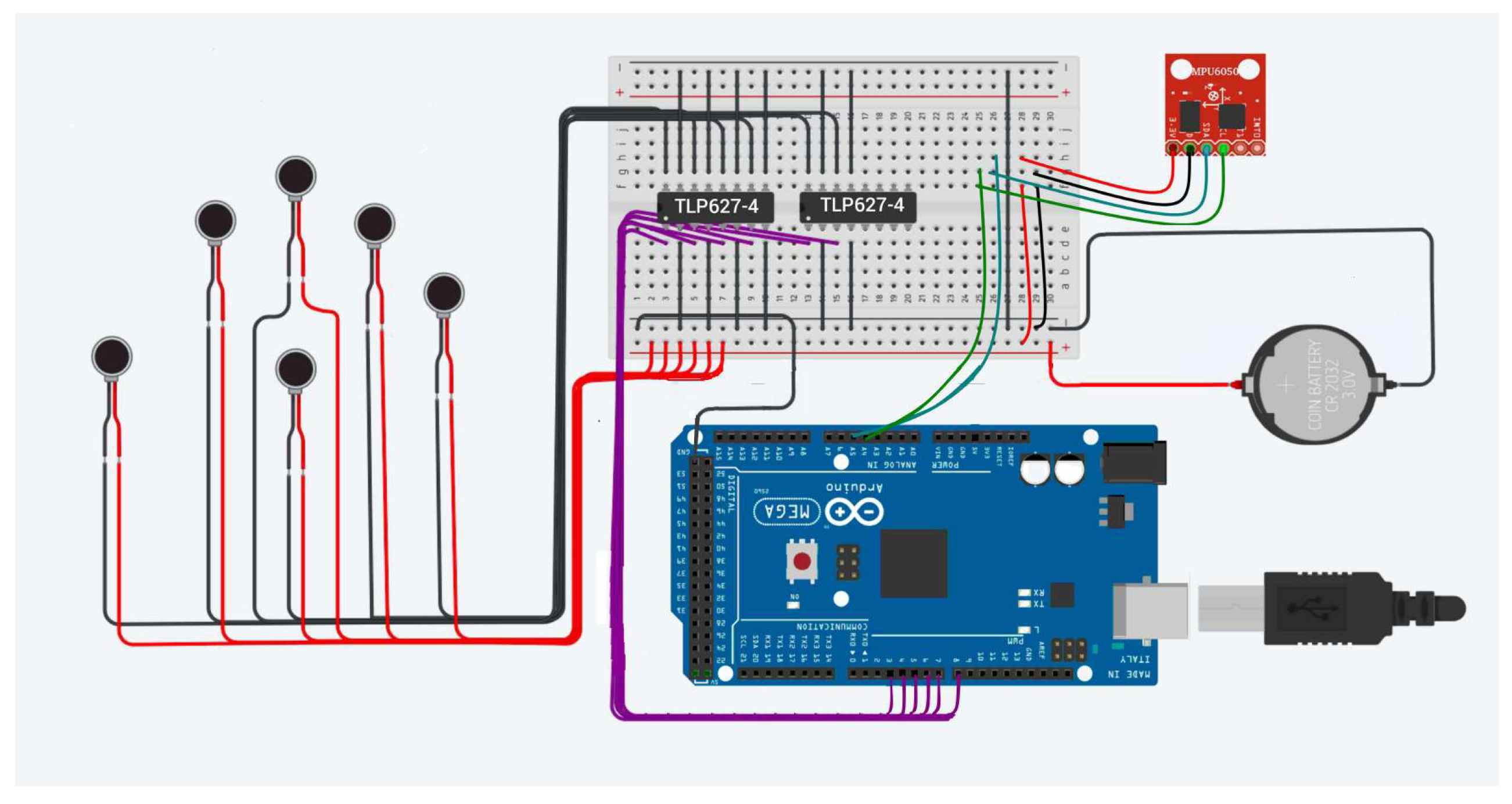

3.2. Master Device (MD) and Master Device’S Hardware (MDH)

3.3. Communication Channel

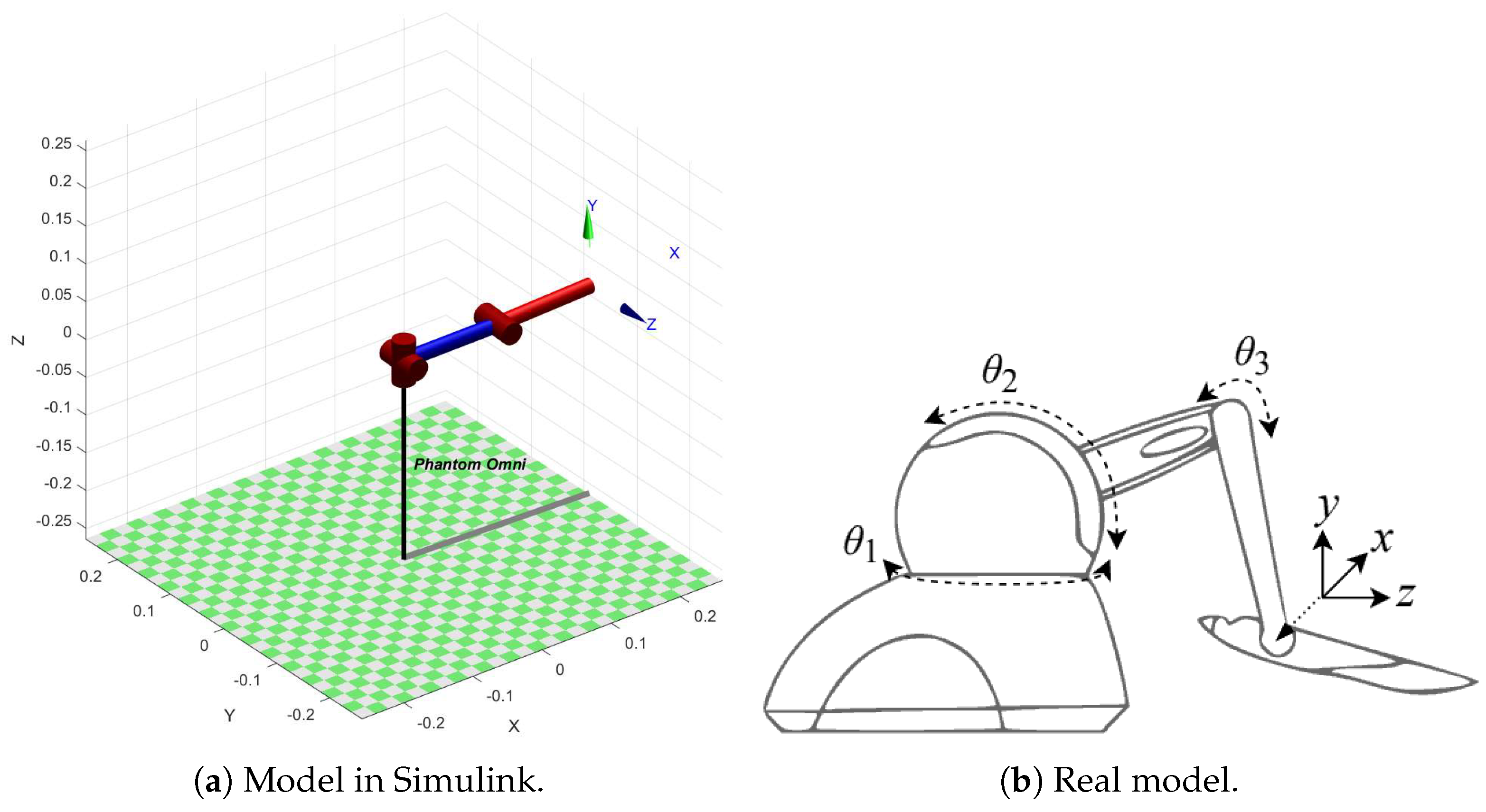

3.4. Simulation Environment

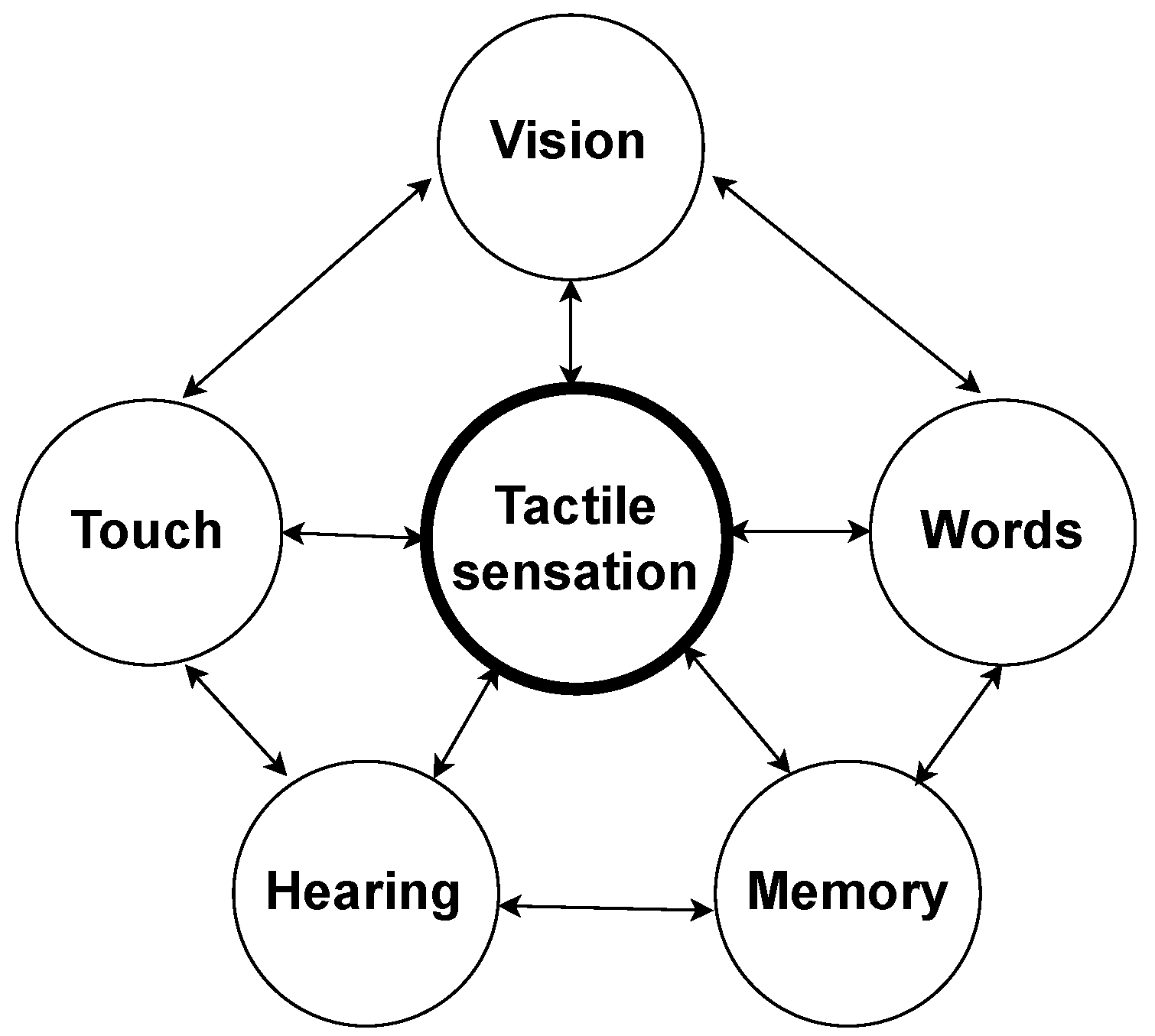

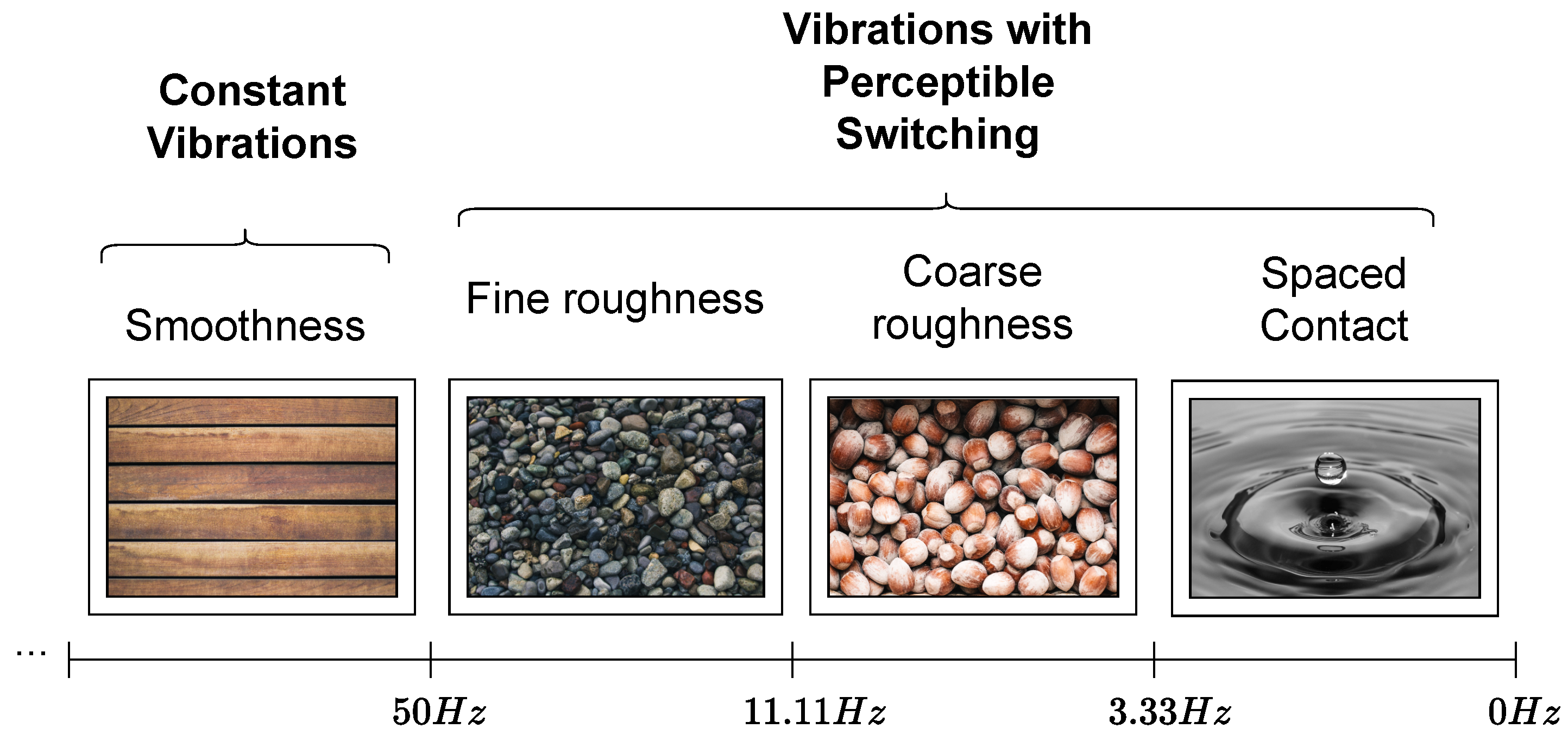

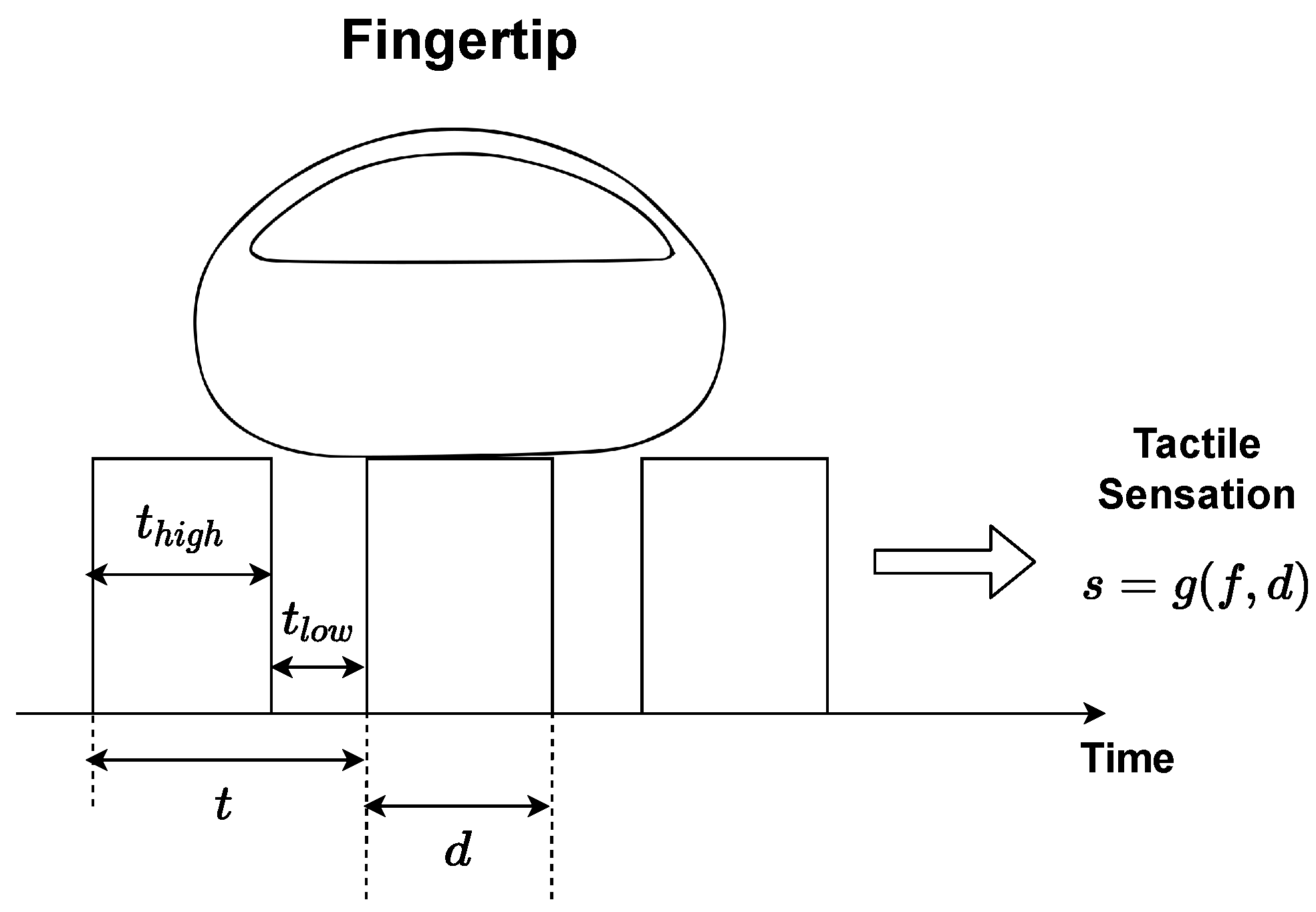

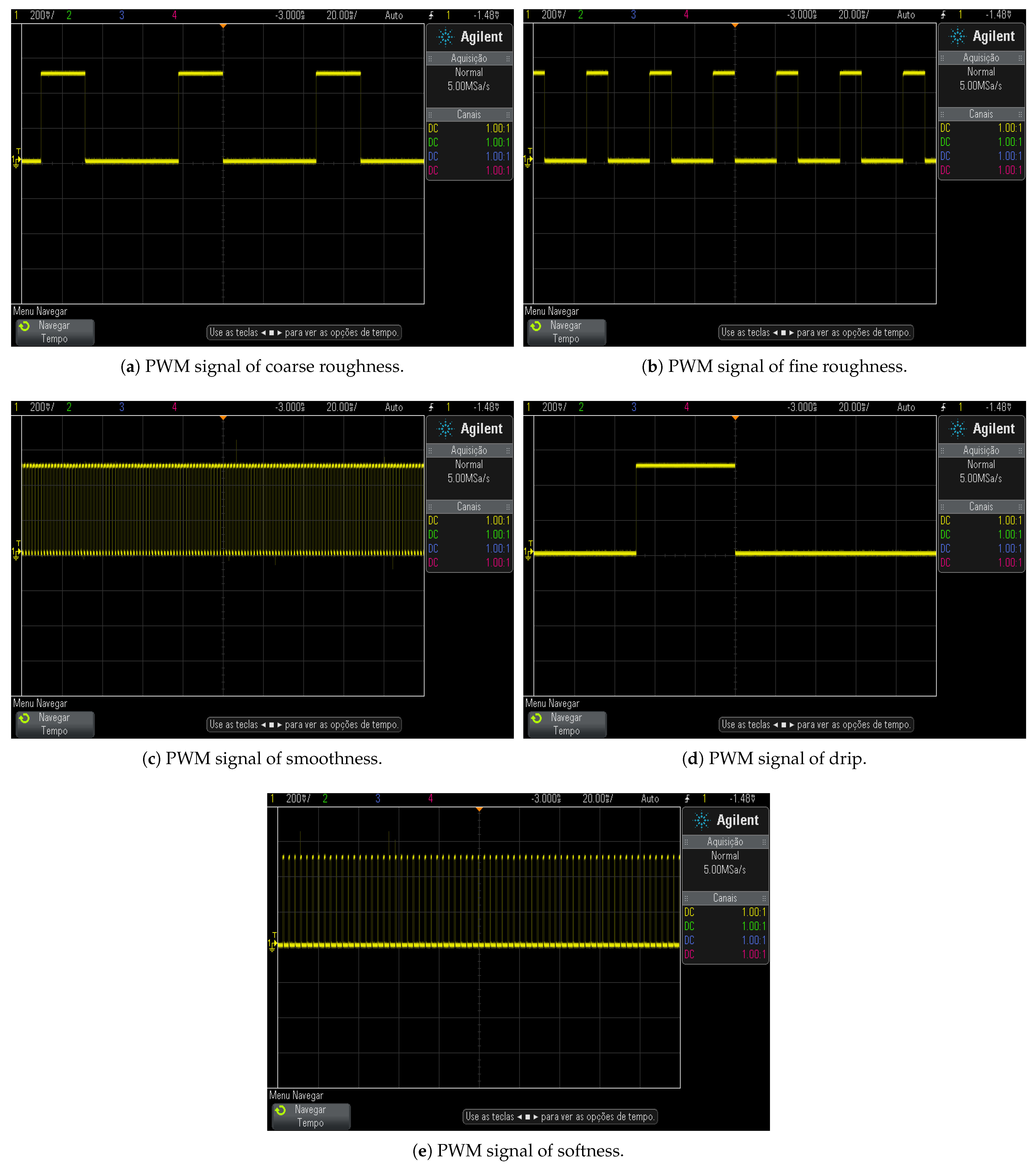

3.5. Tactile Sensations

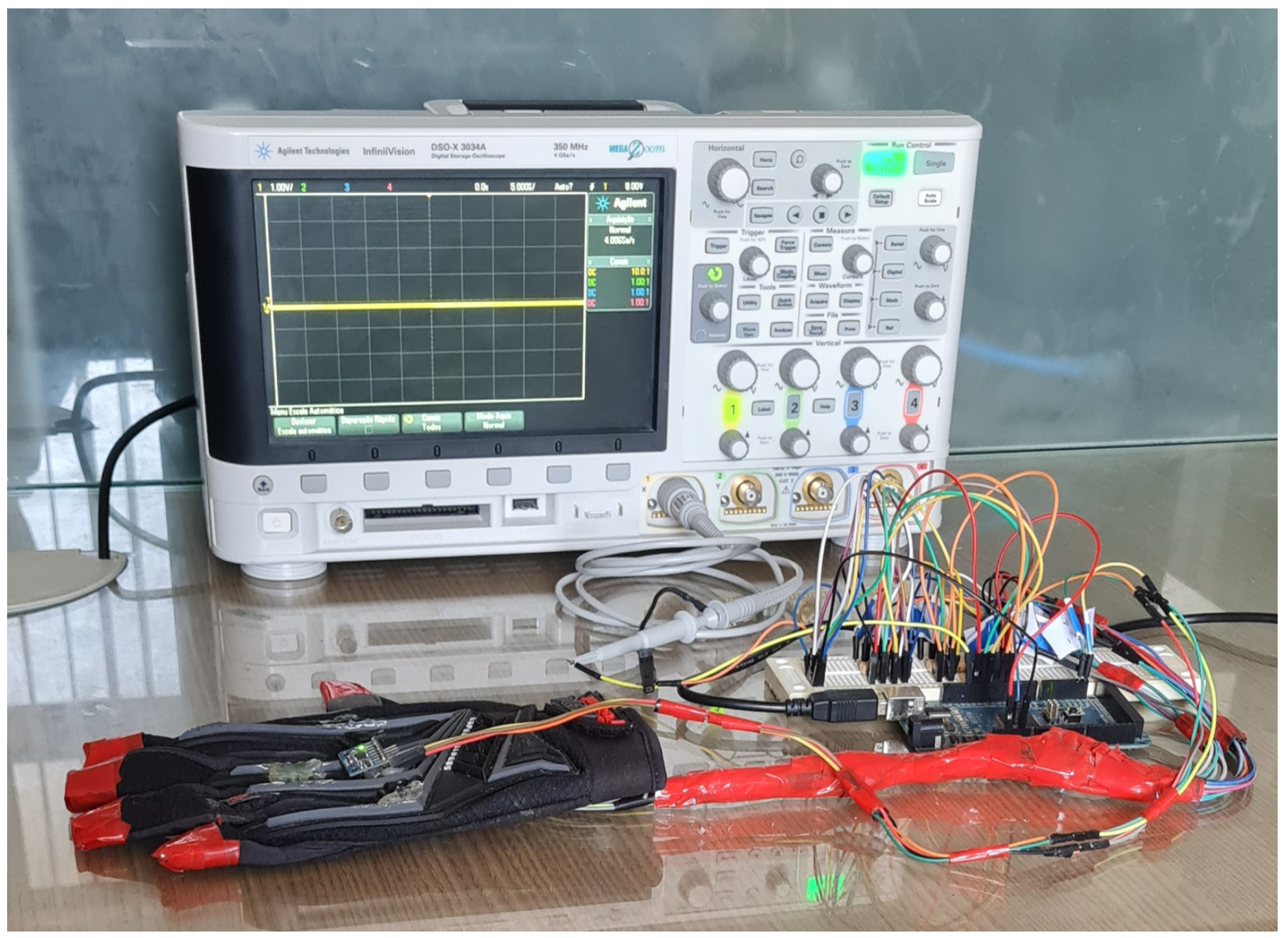

4. Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aijaz, A.; Dohler, M.; Aghvami, A.H.; Friderikos, V.; Frodigh, M. Realizing the tactile Internet: Haptic communications over next generation 5G cellular networks. IEEE Wirel. Commun. 2016, 24, 82–89. [Google Scholar] [CrossRef]

- Meryem, S.; Adnan, A.; Mischa, D. The 5G-Enabled Tactile Internet: Applications, Requirements, and Architecture. In Proceedings of the IEEE Wireless Communications and Networking Conference (WCNC), Doha, Qatar, 3–6 April 2016; pp. 1–6. [Google Scholar]

- Fettweis, G.P. The tactile internet: Applications and challenges. IEEE Veh. Technol. Mag. 2014, 9, 64–70. [Google Scholar] [CrossRef]

- Dohler, M.; Fettweis, G. The tactile internet IoT, 5G and cloud on steroids. In Proceedings of the 5G Radio Technology Seminar. Exploring Technical Challenges in the Emerging 5G Ecosystem, London, UK, 17 March 2015. [Google Scholar]

- Aijaz, A. Towards 5G-enabled tactile internet: Radio resource allocation for haptic communications. In Proceedings of the 2016 IEEE Wireless Communications and Networking Conference Workshops (WCNCW), Chennai, India, 23–25 March 2016; pp. 145–150. [Google Scholar]

- Junior, J.C.; Torquato, M.F.; Noronha, D.H.; Silva, S.N.; Fernandes, M.A. Proposal of the tactile glove device. Sensors 2019, 19, 5029. [Google Scholar] [CrossRef] [PubMed]

- Junior, J.C.; Silva, S.N.; Torquato, M.F.; Mahmoodi, T.; Dohler, M.; Fernandes, M.A. FPGA Applied to Latency Reduction for the Tactile Internet. Sensors 2022, 22, 7851. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Li, C.P.; Hosseini, K.; Lee, S.B.; Jiang, J.; Chen, W.; Horn, G.; Ji, T.; Smee, J.E.; Li, J. 5G-based systems design for tactile Internet. Proc. IEEE 2018, 107, 307–324. [Google Scholar] [CrossRef]

- Nasrallah, A.; Thyagaturu, A.S.; Alharbi, Z.; Wang, C.; Shao, X.; Reisslein, M.; ElBakoury, H. Ultra-low latency (ULL) networks: The IEEE TSN and IETF DetNet standards and related 5G ULL research. IEEE Commun. Surv. Tutor. 2018, 21, 88–145. [Google Scholar] [CrossRef]

- Bera, S.; Das, H.; Nayak, S.; Patgiri, R. Future Tactile Internet: Issues, Challenges and Applications. In Proceedings of the 2021 6th International Conference on Signal Processing, Computing and Control (ISPCC), Solan, India, 7–9 October 2021; pp. 625–630. [Google Scholar]

- D’Abbraccio, J.; Massari, L.; Prasanna, S.; Baldini, L.; Sorgini, F.; Airò Farulla, G.; Bulletti, A.; Mazzoni, M.; Capineri, L.; Menciassi, A.; et al. Haptic glove and platform with gestural control for neuromorphic tactile sensory feedback in medical telepresence. Sensors 2019, 19, 641. [Google Scholar] [CrossRef] [PubMed]

- Kolovou, G.; Oteafy, S.; Chatzimisios, P. A Remote Surgery Use Case for the IEEE P1918.1 Tactile Internet Standard. In Proceedings of the ICC 2021—IEEE International Conference on Communications, Montreal, QC, Canada, 14–23 June 2021; pp. 1–6. [Google Scholar]

- Bianco, G.M.; Vivarelli, C.; Amendola, S.; Marrocco, G. Experimentation and calibration of near-field UHF epidermal communication for emerging tactile internet. In Proceedings of the 2020 5th International Conference on Smart and Sustainable Technologies (SpliTech), Split, Croatia, 23–26 September 2020; pp. 1–4. [Google Scholar]

- Li, S.; Tong, X.; Huang, J.; Wu, X.; Yang, W.; Pan, Z. A Thermal and Vibrational Feedback Glove Based on the Tactile Characteristics of Human Hand Skin. IEEE Access 2020, 8, 226671–226684. [Google Scholar] [CrossRef]

- Masmoudi, M.; Zenati, N.; Benbelkacem, S.; Hadjadj, Z.; Djekoune, O.; Guerroudji, M.A.; Izountar, Y. Low-cost haptic glove for grasp precision improvement in Virtual Reality-Based Post-Stroke Hand Rehabilitation. In Proceedings of the 2021 International Conference on Artificial Intelligence for Cyber Security Systems and Privacy (AI-CSP), El Oued, Algeria, 20–21 November 2021; pp. 1–3. [Google Scholar]

- Pohtongkam, S.; Srinonchat, J. Object Recognition Using Glove Tactile Sensor. In Proceedings of the 2022 International Electrical Engineering Congress (iEECON), Khon Kaen, Thailand, 9–11 March 2022; pp. 1–4. [Google Scholar]

- Cui, Z.; Gao, T.; Wang, J.; Deng, B. Tactile glove-decode and classify the human grasping process. In Proceedings of the 2021 40th Chinese Control Conference (CCC), Shanghai, China, 26–28 July 2021; pp. 8004–8009. [Google Scholar]

- Oteafy, S.M.; Hassanein, H.S. Leveraging tactile internet cognizance and operation via IoT and edge technologies. Proc. IEEE 2018, 107, 364–375. [Google Scholar] [CrossRef]

- Lin, B.-S.; Lee, I.-J.; Yang, S.-Y.; Lo, Y.-C.; Lee, J.; Chen, J.-L. Design of an inertial-sensor-based data glove for hand function evaluation. Sensors 2018, 18, 1545. [Google Scholar] [CrossRef] [PubMed]

- Lobo, J.; Trindade, P. Inertouchhand system-ith-demonstration of a glove device with distributed inertial sensors and vibro-tactile feedback. Int. J. Online Eng. (IJOE) 2013, 9, 56–58. [Google Scholar] [CrossRef]

- Arjun, N.; Ashwin, S.; Polachan, K.; Prabhakar, T.; Singh, C. An end to end tactile cyber physical system design. In Proceedings of the 2018 4th International Workshop on Emerging Ideas and Trends in the Engineering of Cyber-Physical Systems (EITEC), Porto, Portugal, 11 April 2018; pp. 9–16. [Google Scholar]

- Weber, P.; Rueckert, E.; Calandra, R.; Peters, J.; Beckerle, P. A low-cost sensor glove with vibrotactile feedback and multiple finger joint and hand motion sensing for human-robot interaction. In Proceedings of the 2016 25th IEEE International Symposium on Robot and Human Interactive Communication (RO-MAN), New York, NY, USA, 26–31 August 2016; pp. 99–104. [Google Scholar]

- Yang, D.; Choi, Y. Palm glove: Wearable glove based on palm-camera for thumb-to-finger tap recognition. In Proceedings of the 2018 International Conference on Information and Communication Technology Convergence (ICTC), Jeju Island, Republic of Korea, 17–19 October 2018; pp. 549–551. [Google Scholar]

- Muramatsu, Y.; Niitsuma, M.; Thomessen, T. Building a cognitive model of tactile sensations based on vibrotactile stimuli. In Proceedings of the 2013 IEEE 4th International Conference on Cognitive Infocommunications (CogInfoCom), Budapest, Hungary, 2–5 December 2013; pp. 149–154. [Google Scholar]

| Tactile Sensations | (ms) | (ms) | d (%) | f (Hz) |

|---|---|---|---|---|

| Coarse roughness | 45 | 94 | 32 | 7.2 |

| Fine roughness | 22 | 42 | 34 | 15.6 |

| Smoothness | 2 | 1 | 67 | 333 |

| Drip | 100 | 500 | 17 | 1.7 |

| Softness | 1 | 5 | 16.7 | 166.7 |

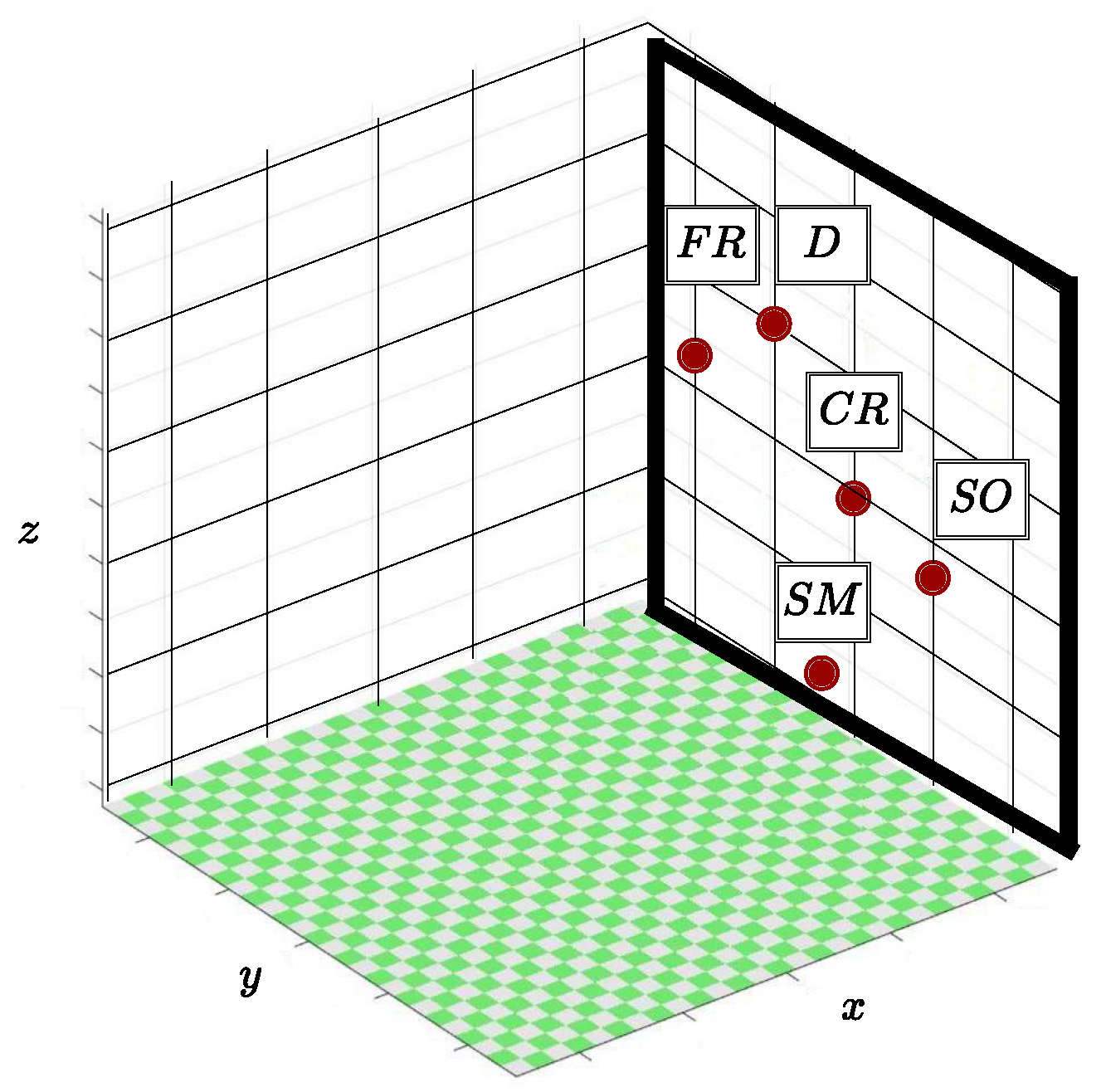

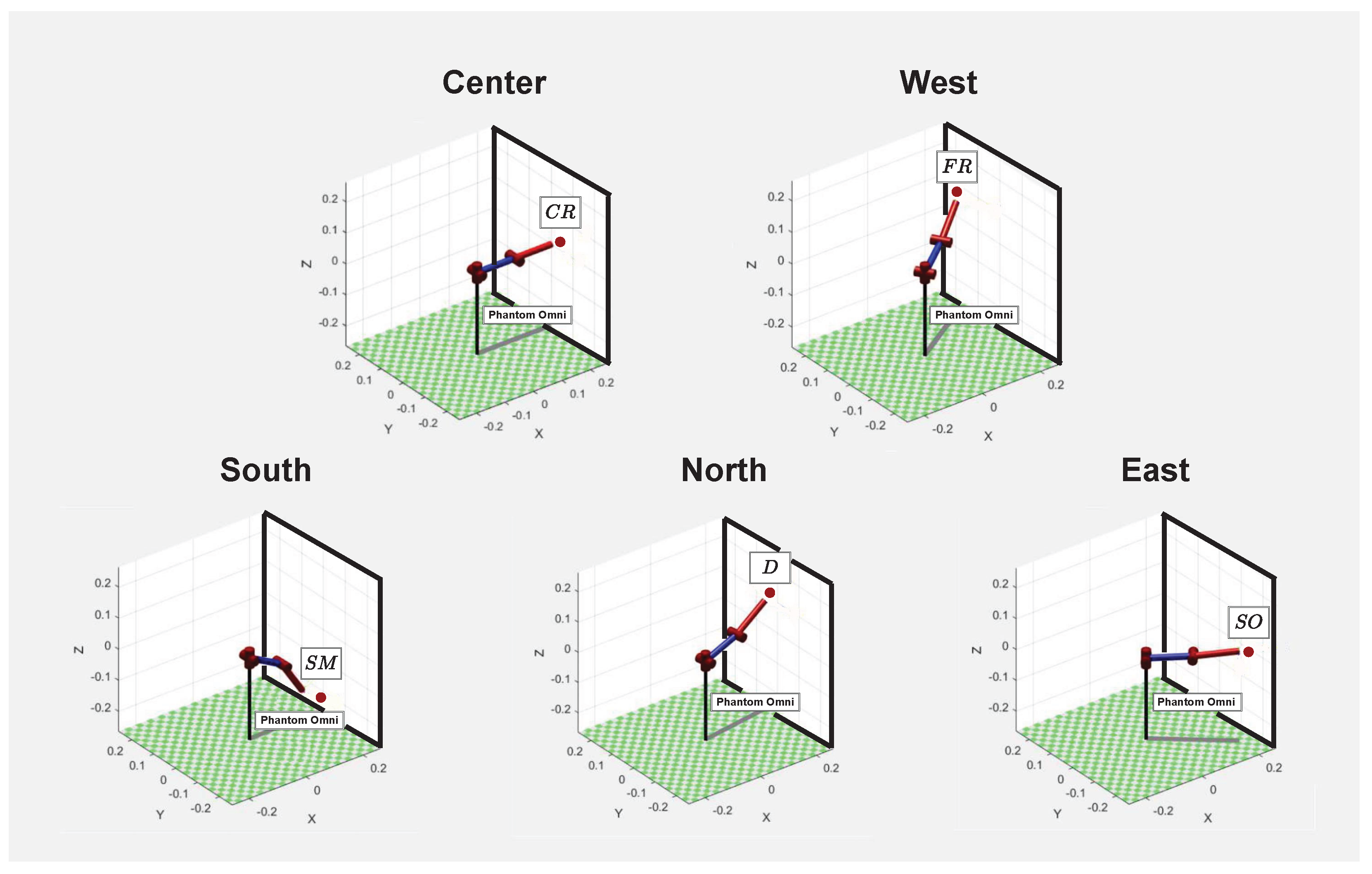

| Direction | Texture | x | y | z | Id |

|---|---|---|---|---|---|

| Center | Coarse roughness | 0.1 | 0.1 | 2.09 | 1 |

| West | Fine roughness | −0.6 | 0.3 | 0.79 | 2 |

| South | Smoothness | 0.5 | −0.85 | 1.46 | 3 |

| North | Drip | 0.34 | 0.62 | 2.09 | 4 |

| East | Softness | 2.07 | 0.27 | 2.29 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alves, P.V.A.; Plentz, P.D.M.; Fernandes, M.A.C. Proposal of a Real-Time Test Platform for Tactile Internet Systems. Sensors 2022, 22, 9865. https://doi.org/10.3390/s22249865

Alves PVA, Plentz PDM, Fernandes MAC. Proposal of a Real-Time Test Platform for Tactile Internet Systems. Sensors. 2022; 22(24):9865. https://doi.org/10.3390/s22249865

Chicago/Turabian StyleAlves, Pedro V. A., Patricia D. M. Plentz, and Marcelo A. C. Fernandes. 2022. "Proposal of a Real-Time Test Platform for Tactile Internet Systems" Sensors 22, no. 24: 9865. https://doi.org/10.3390/s22249865

APA StyleAlves, P. V. A., Plentz, P. D. M., & Fernandes, M. A. C. (2022). Proposal of a Real-Time Test Platform for Tactile Internet Systems. Sensors, 22(24), 9865. https://doi.org/10.3390/s22249865