Thermal Strain Detection for Concrete Structure Cold Shrinkage under Stress Constraint with FBG

Abstract

:1. Introduction

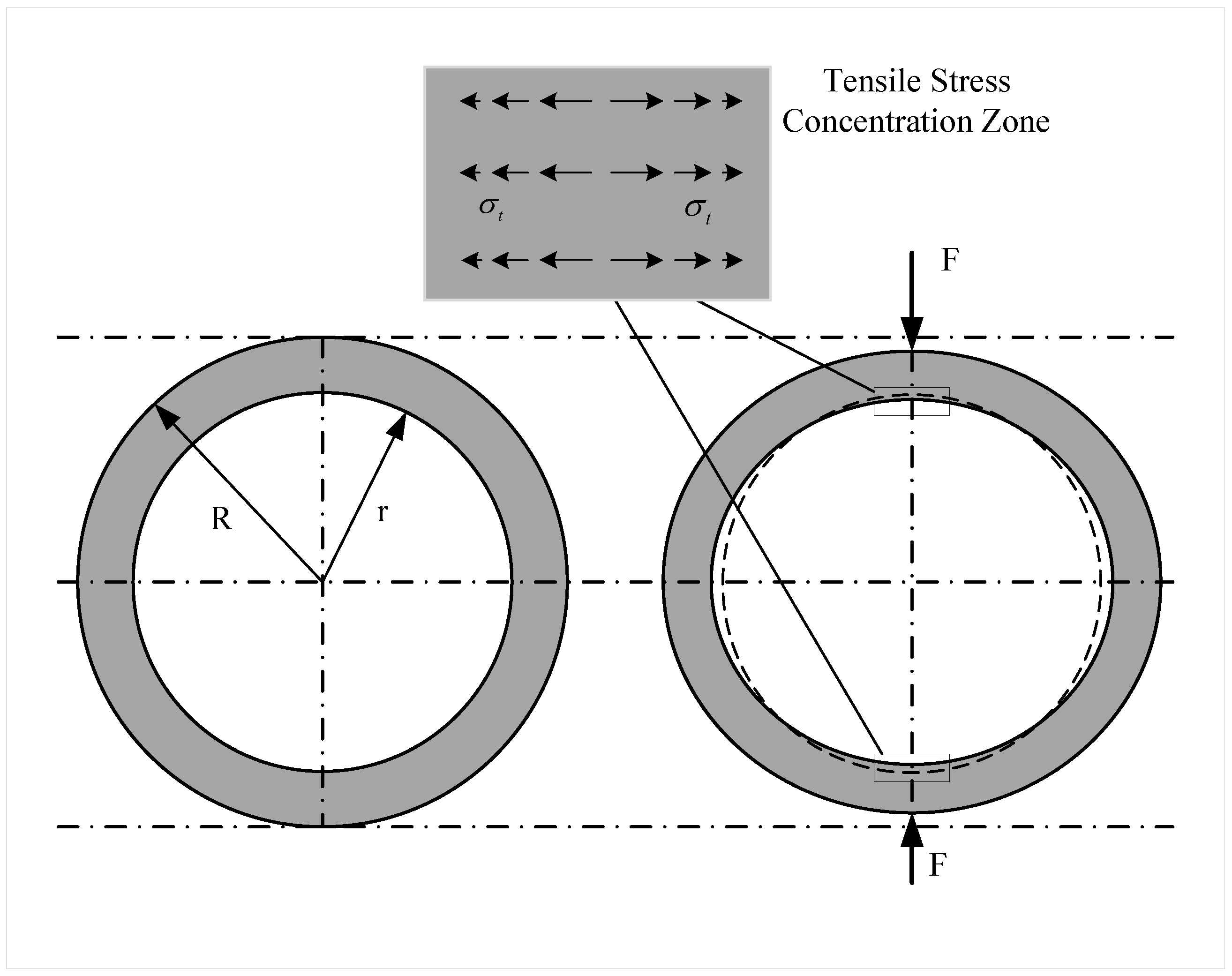

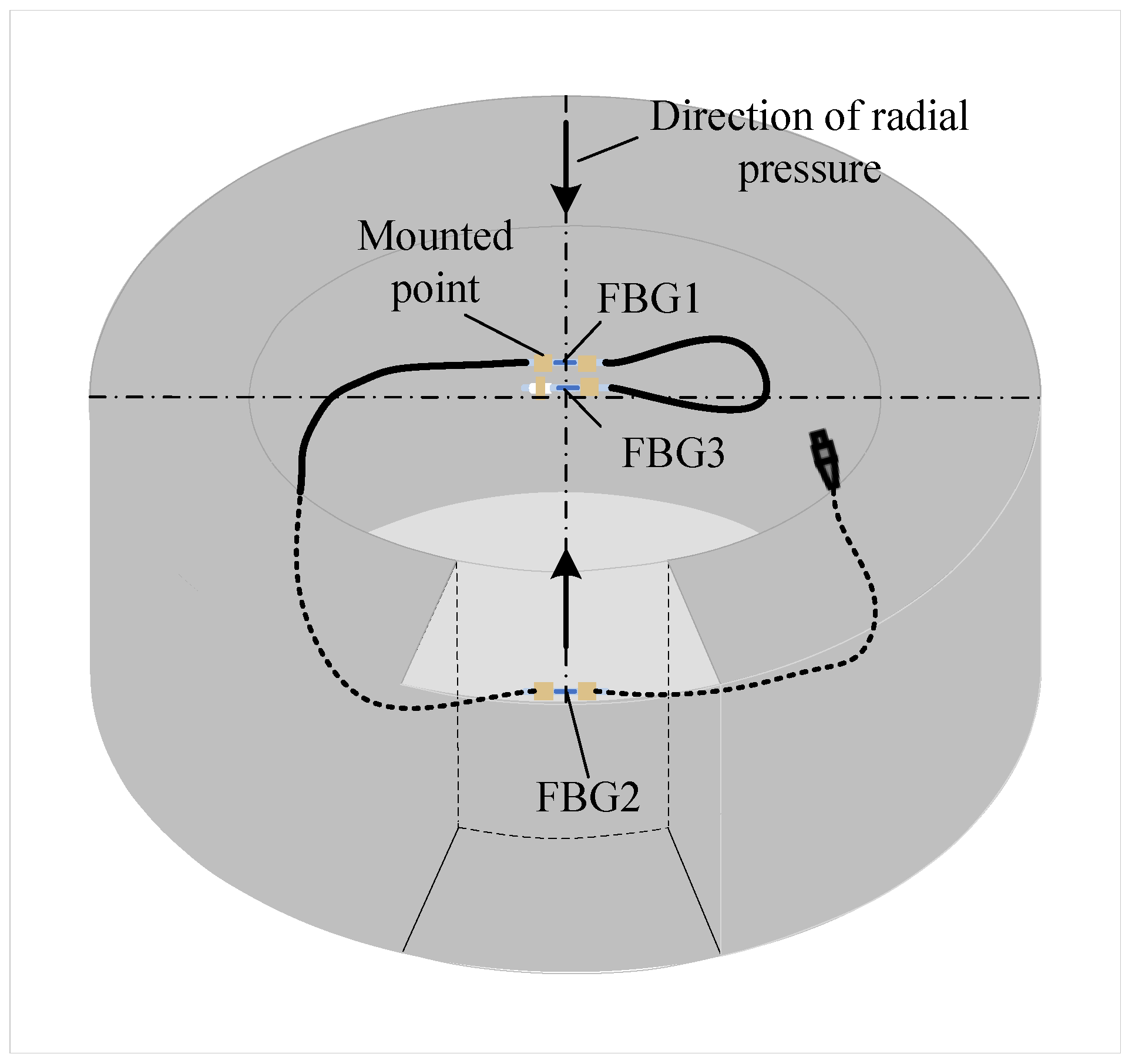

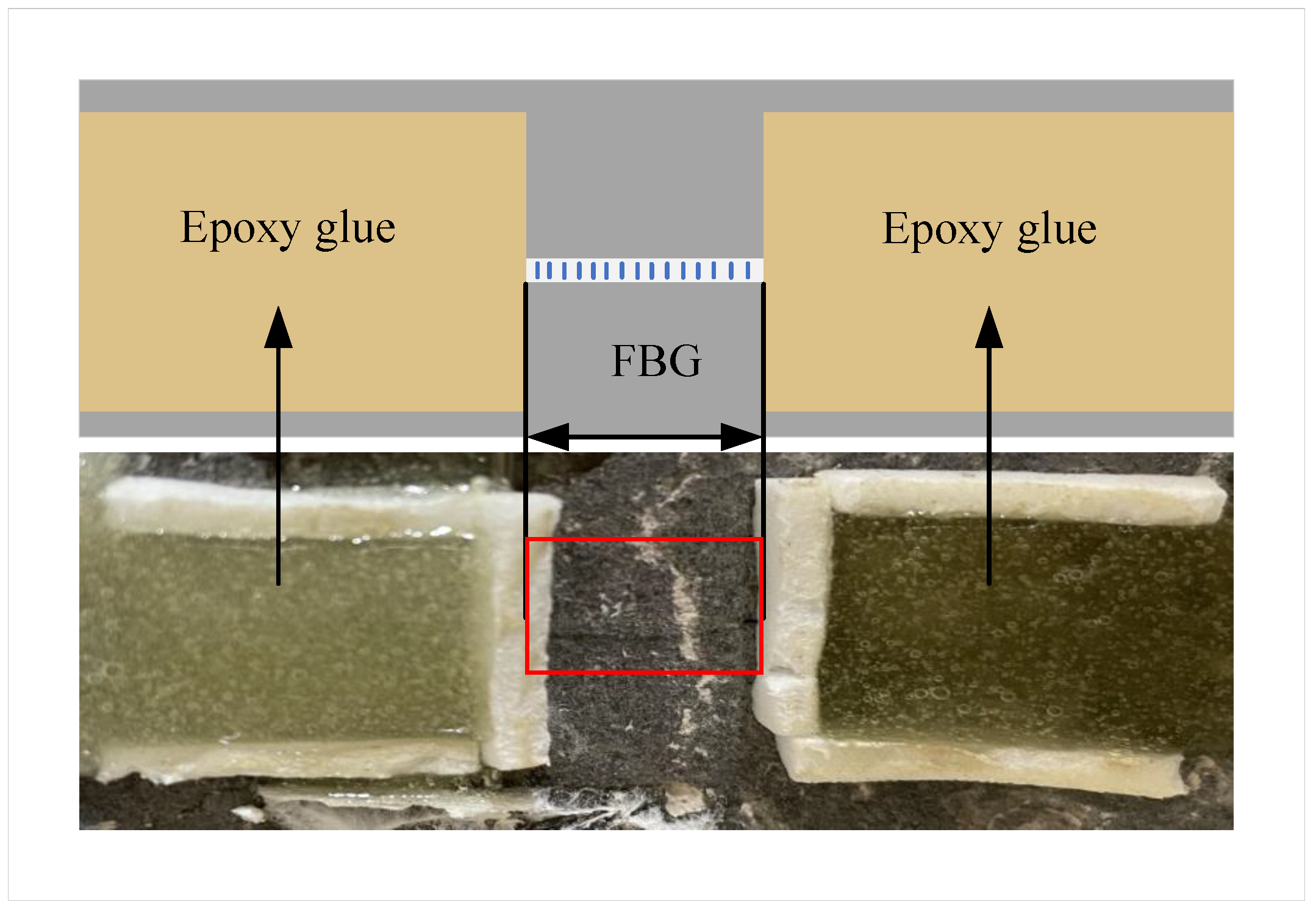

2. Principle of Thermal Strain Detection for Concrete Structures under Stress Confinement with FBG

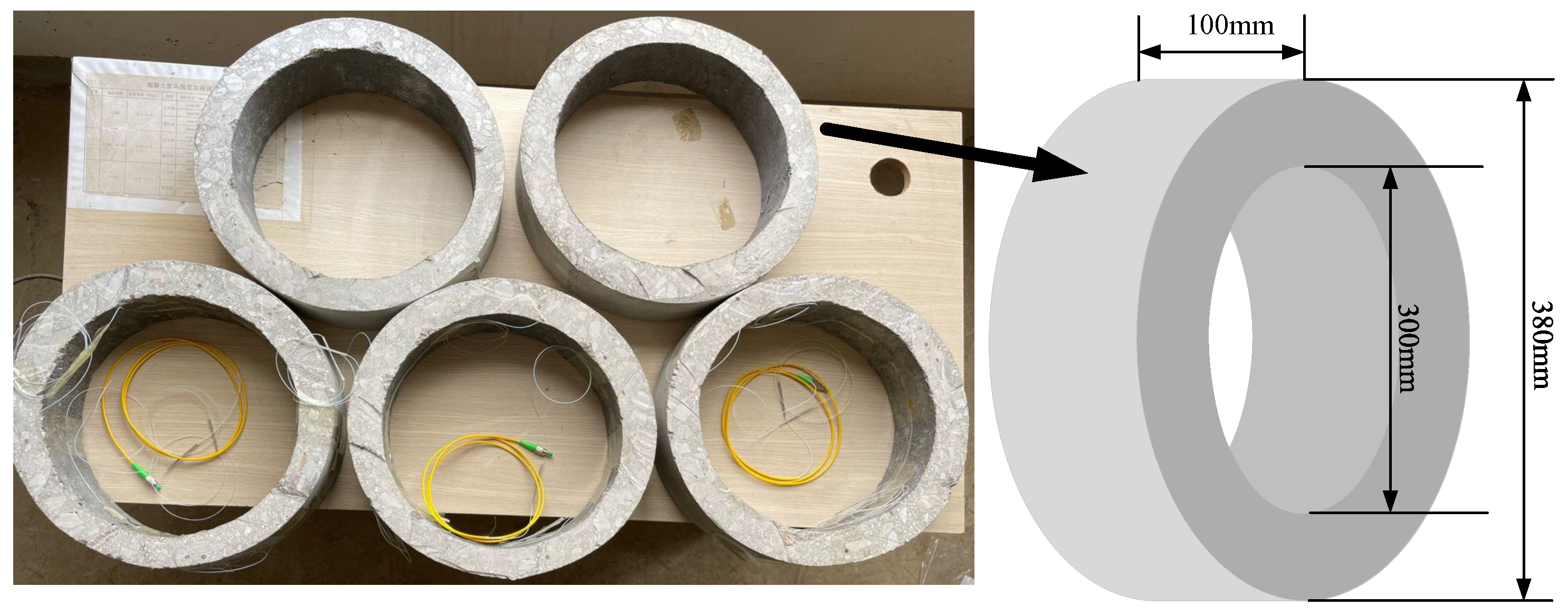

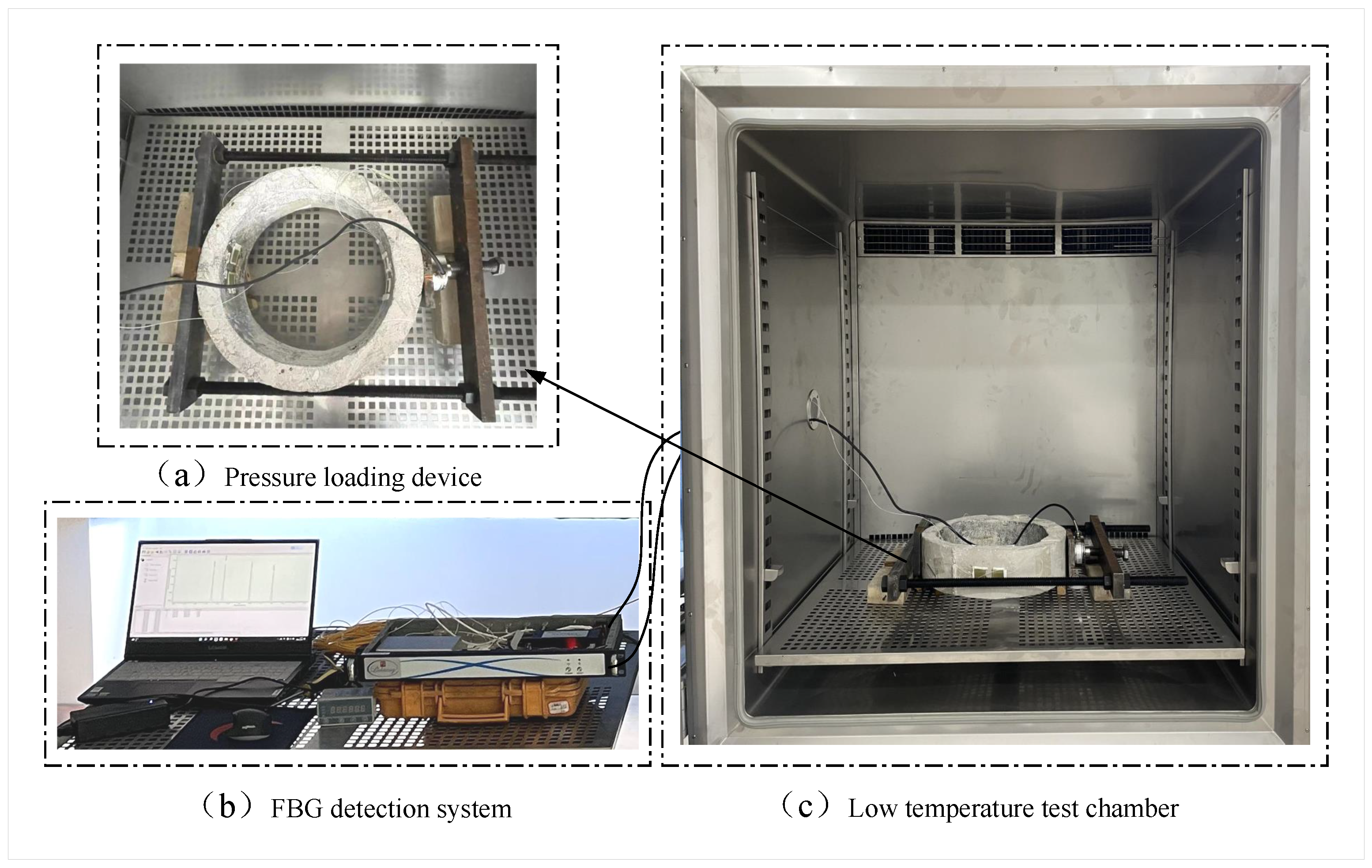

3. Experimental Setup and Methods

4. Analysis of Experimental Results

4.1. Applied Stress-Strain Analysis of the Structure under Radial Pressure

4.2. State Analysis of FBG in Structural Strain Detection

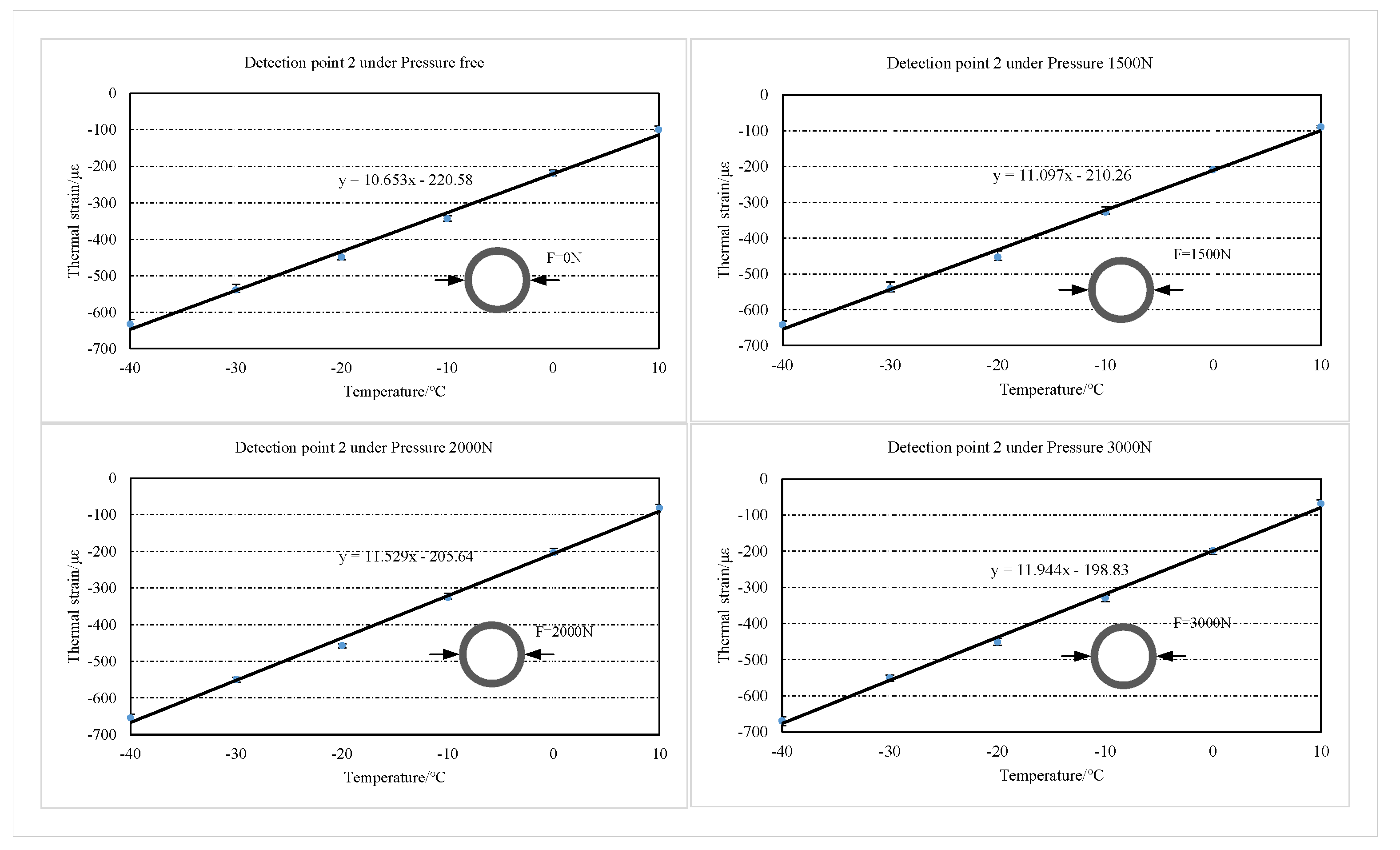

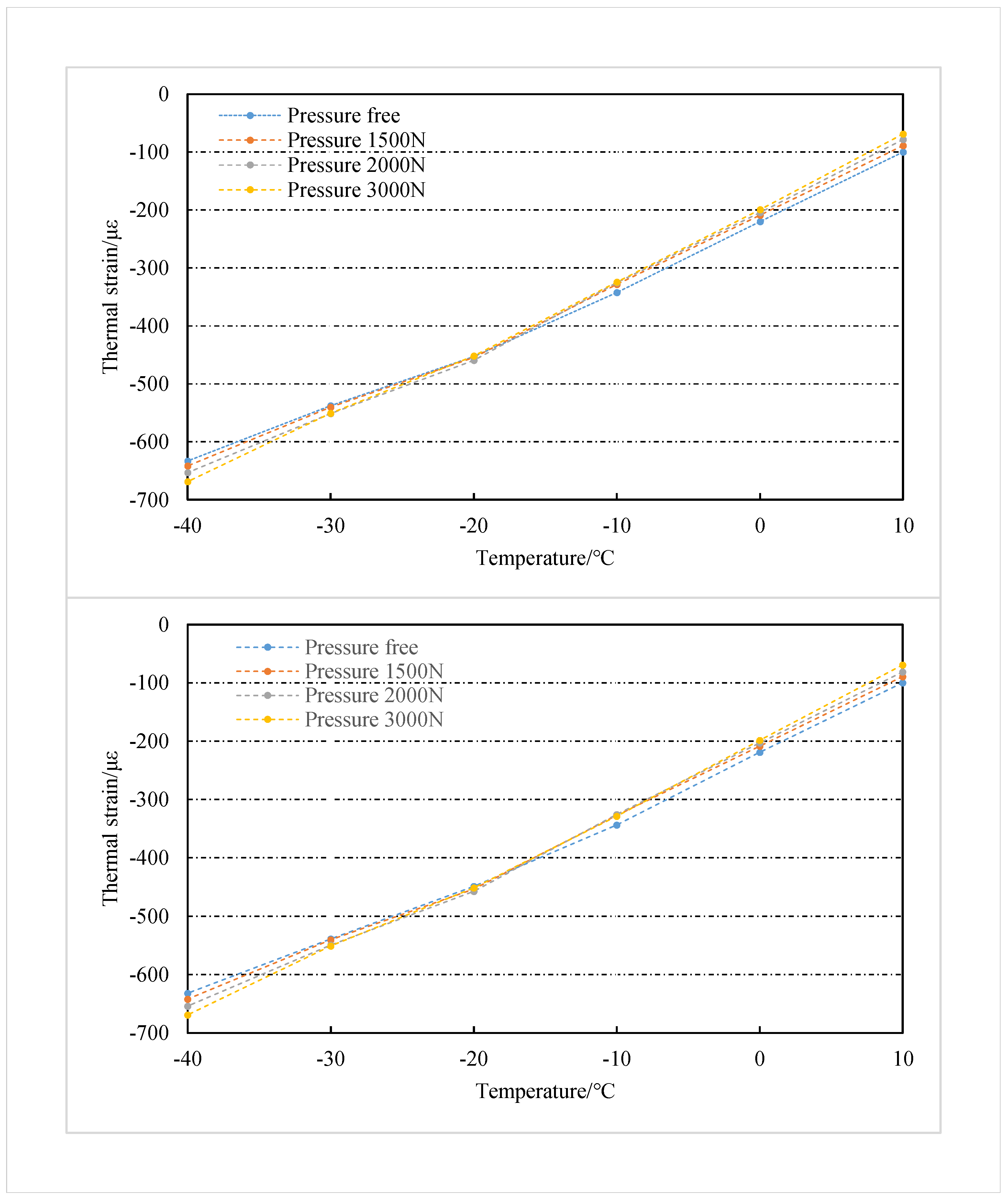

4.3. Extraction of Structural Thermal Strain

4.4. Calculation of the Coefficient of Thermal Expansion of the Structure

5. Conclusions

- The central wavelength of the FBG for temperature compensation is only modulated by temperature. Thus, the center wavelength of the grating is stabilized rapidly with temperature changes in the experimental chamber. The central wavelength of the FBG strain sensors is modulated by both temperature and structural strain. There is a time delay for the concrete structure temperature to reach the experiment’s preset temperature. Thus, the center wavelength of the FBG strain sensors takes a certain amount of time to reach stability.

- The thermal strain of the concrete structure gradually increases with decreasing temperature. In the temperature range of , the thermal strain of the structure subjected to the stress constraint decreases significantly compared to the free thermal strain. In addition, the thermal strain decrease with increasing stress at the same temperature point. Under the experimental conditions of and 3000 N radial pressure, the greatest reduction in thermal strain is observed at the two detected points, by and , respectively.

- The difference between the thermal strain under stress constraint and the free thermal strain decreases as the temperature decreases. In addition, the higher the tensile stress, the smaller the thermal strain at the same temperature point.

- In the temperature range of , the free thermal expansion coefficient of concrete structures fluctuates around , with a tendency to increase and then decrease. The thermal expansion coefficient of concrete under tensile stress conditions is significantly reduced compared to the free thermal expansion coefficient. This difference is maximum at and then decreases with decreasing temperature. Under the experimental conditions of and 3000 N radial pressure, the thermal expansion coefficients for the two tested points were and , respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ispir, M.; Ates, A.O.; Ilki, A. Low Strength Concrete: Stress-Strain Curve, Modulus of Elasticity and Tensile Strength. Structures 2022, 38, 1615–1632. [Google Scholar] [CrossRef]

- Huang, J.N.; Hu, M.Y. Meso-Scale Analysis of Failure Characteristics and Mechanical Properties of Lightweight Aggregate Concrete (LWAC) with Different Aggregate Volume Fractions and Shapes under Axial Tension. Constr. Build. Mater. 2022, 321, 125503. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, B.; Liu, C.; Hui, D.; Xu, Q.; Zhao, Q.; Wei, J.; Hong, X. Experimental Study on Basic Mechanical Properties of Recycled Steel Fiber Reinforced Concrete. Rev. Adv. Mater. Sci. 2022, 61, 417–429. [Google Scholar] [CrossRef]

- Qin, C.; Li, Y.; Yu, J.; Chen Chian, S.; Liu, H. Closed-Form Solutions for Collapse Mechanisms of Tunnel Crown in Saturated Non-Uniform Rock Surrounds. Tunn. Undergr. Space Technol. 2022, 126, 104529. [Google Scholar] [CrossRef]

- Qiao, S.; Cai, Z.; Xu, P.; Tan, J.; Zhang, Y. Investigation on the Scope and Influence Factors of Surrounding Rock Loose Circle of Shallow Tunnel under Bias Pressure: A Case Study. Arab. J. Geosci. 2021, 14, 1428. [Google Scholar] [CrossRef]

- Lei, P.; Han, X.; Tang, J.; Xia, Y.; Chai, L.; Liang, X. Theoretical Solutions for the Vertical Compressive Stress of Shallow Neighbourhood Loess Tunnel Foundation. Asian Archit. Build. Eng. 2020, 20, 1–14. [Google Scholar] [CrossRef]

- Sun, M.; Zhu, Y.; Li, X.; Zhu, Z.; He, B. Experimental Study of Mechanical Characteristics of Tunnel Support System in Hard Cataclastic Rock with High Geostress. Shock Vib. 2020, 20, 2020. [Google Scholar] [CrossRef]

- Jun, K.J.; Hwang, Y.C.; Yune, C.Y. Experimental Field Measurement of Temperature inside Tunnel in Winter in Gangwon, Korea. Cold Reg. Sci. Technol. 2017, 143, 32–42. [Google Scholar] [CrossRef]

- Inokuma, A.; Inano, S. Road tunnels in Japan: Deterioration and countermeasures. Tunn. Undergr. Space Technol. 1996, 11, 305–309. [Google Scholar] [CrossRef]

- Howard, A.J.; Inano, S. Report on the Damaging Effects of Water on Tunnels during Their Working Life. Tunn. Undergr. Space Technol. 1991, 6, 11–76. [Google Scholar]

- Yu, Y.; Ph, D.; Ling, X.; Tang, L.; Han, X. Cold Regions Science and Technology Analytical Solution for the Soil-Lining Interaction in Cold Region Deep Tunnel Considering the Delayed Installation of the Lining. Cold Reg. Sci. Technol. 2021, 189, 103329. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, K.; Zhu, X.; Tian, Z.; Zhang, Q. Study on the Freeze-Thaw Process of the Lining Structures of a Tunnel on Qinghai-Tibet Plateau with the Consideration of Lining Frost Damage. Adv. Mater. Sci. Eng. 2021, 2021, 4921365. [Google Scholar] [CrossRef]

- Li, C.; Yang, L.; Luo, C.; Liu, H.; Wan, X. Frost Heaving Strain Monitoring for Lining Structure in Extreme Cold and High-Altitude Area with FBG Strain Sensors. Meas. J. Int. Meas. Confed. 2022, 196, 110918. [Google Scholar] [CrossRef]

- Ling, X.Z.; Yu, Y.; Tang, L.; Geng, L.; Han, X. The Lining Responses for Shallow Mountain Tunnels Subjected to Frost Heaving. J. Mt. Sci. 2022, 19, 529–546. [Google Scholar] [CrossRef]

- Shadab, A.; Raghuwanshi, S.K.; Kumar, S. Advances in Micro-Fabricated Fiber Bragg Grating for Detection of Physical, Chemical, and Biological Parameters—A Review. IEEE Sens. 2022, 22, 15650–15660. [Google Scholar] [CrossRef]

- Zhaobo, Z.; Sheng, L.; Yibo, W.; Hongnan, L. Structural Health Monitoring for Bridge Crane Based on Low Temperature-Sensitivity FBG Sensors. Front. Phys. 2021, 9, 346. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Theodosiou, A.; Marques, C.; Pontes, M.J.; Kalli, K.; Frizera, A. Thermal Treatments and Compensation Techniques for the Improved Response of FBG Sensors in POFs. J. Light. Technol. 2018, 36, 3611–3617. [Google Scholar] [CrossRef]

- Muyang, L.; Ragini, S.; Soares, M.S.; Carlos, M.; Bingyuan, Z. Convex fiber-tapered seven core fiber-convex fiber (CTC) structure-based biosensor for creatinine detection in aquaculture. Opt. Express 2022, 30, 13898–13914. [Google Scholar]

- Leal-Junior, A.; Avellar, L.; Biazi, V.; Soares, M.S.; Frizera, A. Multifunctional flexible optical waveguide sensor: On the bioinspiration for ultrasensitive sensors development. Opto-Electron. Adv. 2022, 5, 210098-1–210098-11. [Google Scholar] [CrossRef]

- Zhao, X.; Lv, X.; Wang, L.; Zhu, Y.; Dong, H.; Chen, W.; Li, J.; Ji, B.; Ding, Y. Research of Concrete Residual Strains Monitoring Based on WLI and FBG Following Exposure to Freeze-Thaw Tests. Cold Reg. Sci. Technol. 2015, 116, 40–48. [Google Scholar] [CrossRef]

- Zhengwu, J.; Cong, Z.; Zilong, D.; Xinping, Z.; Wenting, L. Thermal Strain of Cement-Based Materials under Cryogenic Temperatures and Its Freeze-Thaw Cycles Using Fibre Bragg Grating Sensor. Cryogenics 2019, 100, 1–10. [Google Scholar] [CrossRef]

- Tokovyy, Y.V.; Hung, K.; Ma, C. Determination of Stresses and Displacements in a thin Annular Disk Subjected to Diametral Compression. J. Mt. Sci. 2010, 165, 152–162. [Google Scholar] [CrossRef]

- Wang, S.Y.; Sloan, S.W.; Tang, C.A. Three-Dimensional Numerical Investigations of the Failure Mechanism of a Rock Disc with a Central or Eccentric Hole. Rock Mech. Rock Eng. 2013, 47, 2117–2137. [Google Scholar] [CrossRef]

- Haeri, H.; Khaloo, A.; Fatehi, M. Fracture Analyses of Different Pre-Holed Concrete Specimens under Compression. Acta Mech. Sin. 2015, 31, 855–870. [Google Scholar] [CrossRef]

- Hobbs, D.W. An Assessment of a Technique for Determining the Tensile Strength of Rock. Br. J. Appl. Phys. 1965, 16, 259–268. [Google Scholar] [CrossRef]

- Han, N.; Tian, W. Experimental Study on the Dynamic Mechanical Properties of Concrete under Freeze—Thaw Cycles. Struct. Concr. 2018, 19, 1353–1362. [Google Scholar] [CrossRef]

- Xia, J.; Xi, Y.; Jin, W. Temperature-Dependent Coefficient of Thermal Expansion of Concrete in Freezing Process. J. Eng. Mech. 2017, 143, 1–8. [Google Scholar] [CrossRef]

- Kogbara, R.B.; Iyengar, S.R.; Grasley, Z.C.; Rahman, S.; Masad, E.A. Correlation between Thermal Deformation and Microcracking in Concrete during Cryogenic Cooling. NDT E Int. 2016, 77, 1–10. [Google Scholar] [CrossRef]

| Measurement Range | Measurement Accuracy | Sampling Frequency | Operating Temperature | Relative Humidity |

|---|---|---|---|---|

| 0–5000 N | 80 Times/s | CC | ≤85% RH |

| N | N | N | N | |

|---|---|---|---|---|

| Detection point 1 | ||||

| Detection point 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Li, C.; Luo, C. Thermal Strain Detection for Concrete Structure Cold Shrinkage under Stress Constraint with FBG. Sensors 2022, 22, 9660. https://doi.org/10.3390/s22249660

Yang L, Li C, Luo C. Thermal Strain Detection for Concrete Structure Cold Shrinkage under Stress Constraint with FBG. Sensors. 2022; 22(24):9660. https://doi.org/10.3390/s22249660

Chicago/Turabian StyleYang, Lubing, Chuan Li, and Chuan Luo. 2022. "Thermal Strain Detection for Concrete Structure Cold Shrinkage under Stress Constraint with FBG" Sensors 22, no. 24: 9660. https://doi.org/10.3390/s22249660

APA StyleYang, L., Li, C., & Luo, C. (2022). Thermal Strain Detection for Concrete Structure Cold Shrinkage under Stress Constraint with FBG. Sensors, 22(24), 9660. https://doi.org/10.3390/s22249660