Design and Implementation of an Open-Source SCADA System for a Community Solar-Powered Reverse Osmosis System

Abstract

1. Introduction

2. Literature Review

- With the latest SCADA architecture, this study stands out, particularly with respect to its use for reverse osmosis systems.

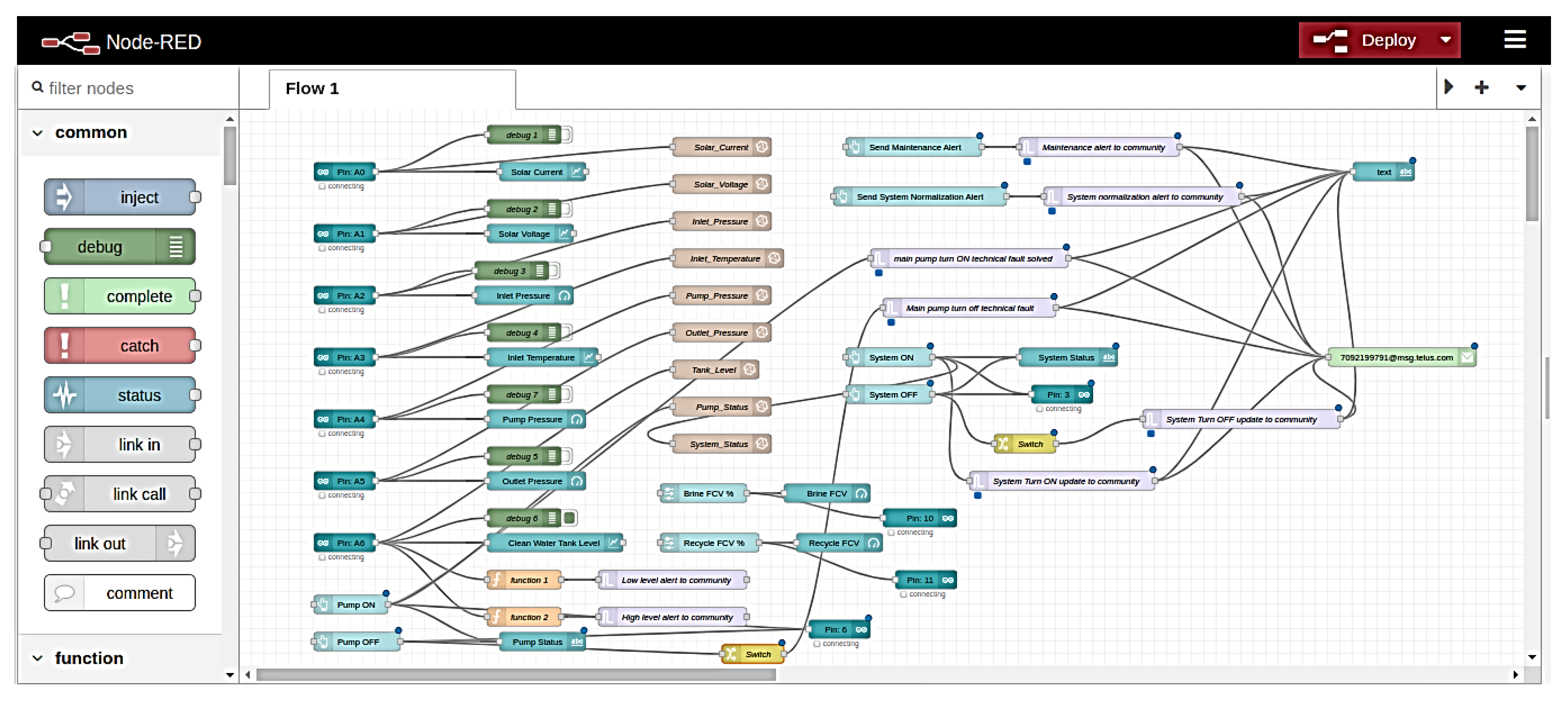

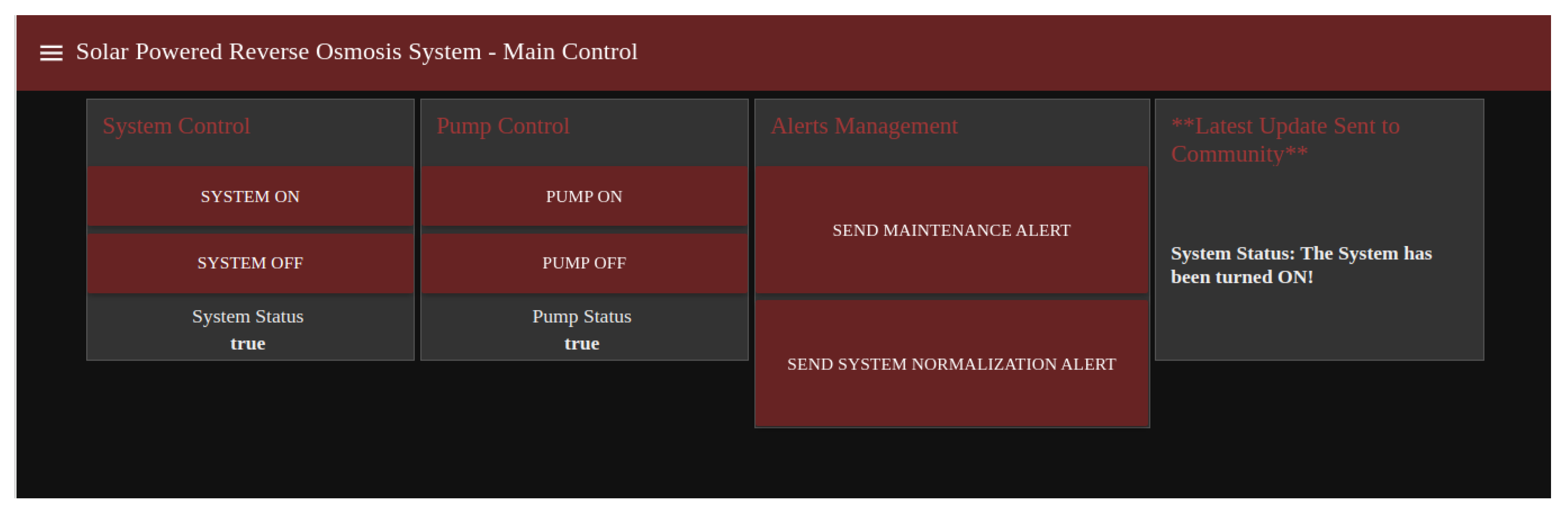

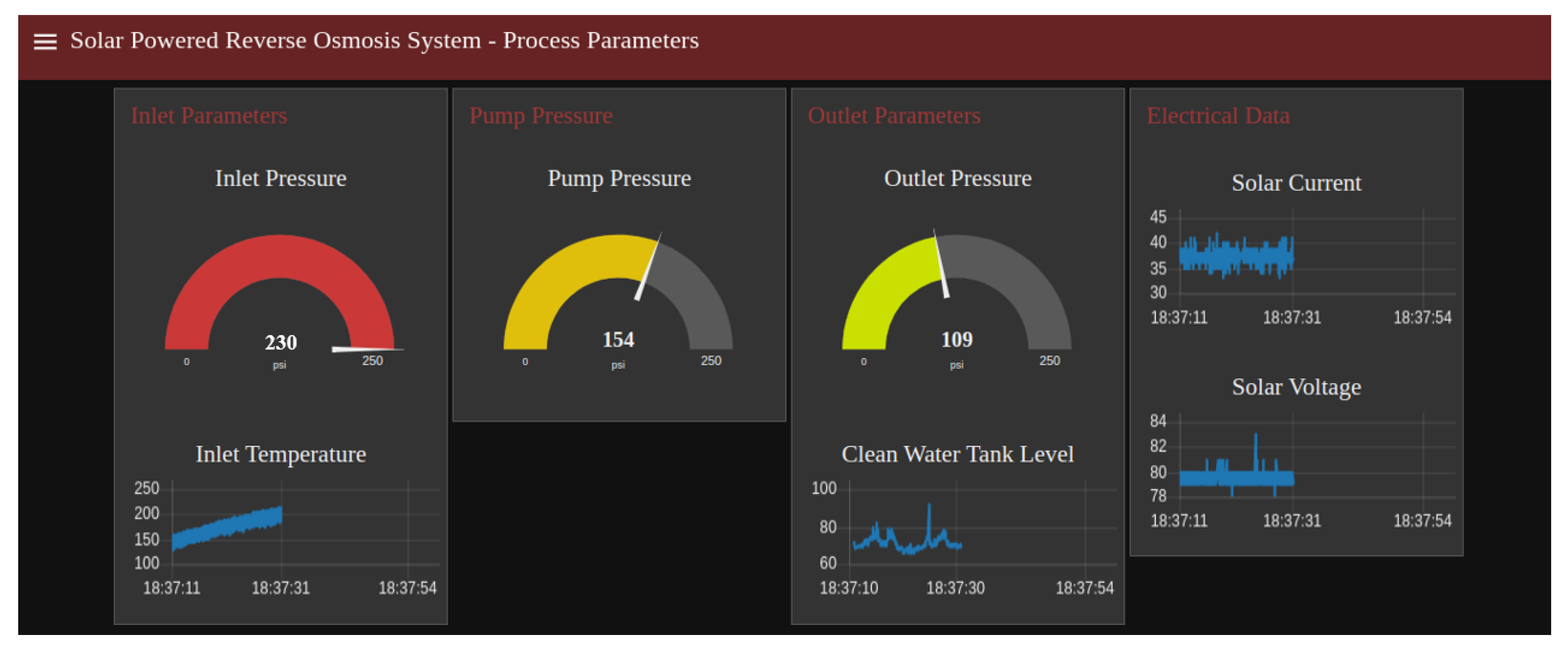

- The designed system is configured on a local machine through Node-Red visual programming language that is accessible through the browser for easy control.

- The system incorporates local storage with restricted user authorization only.

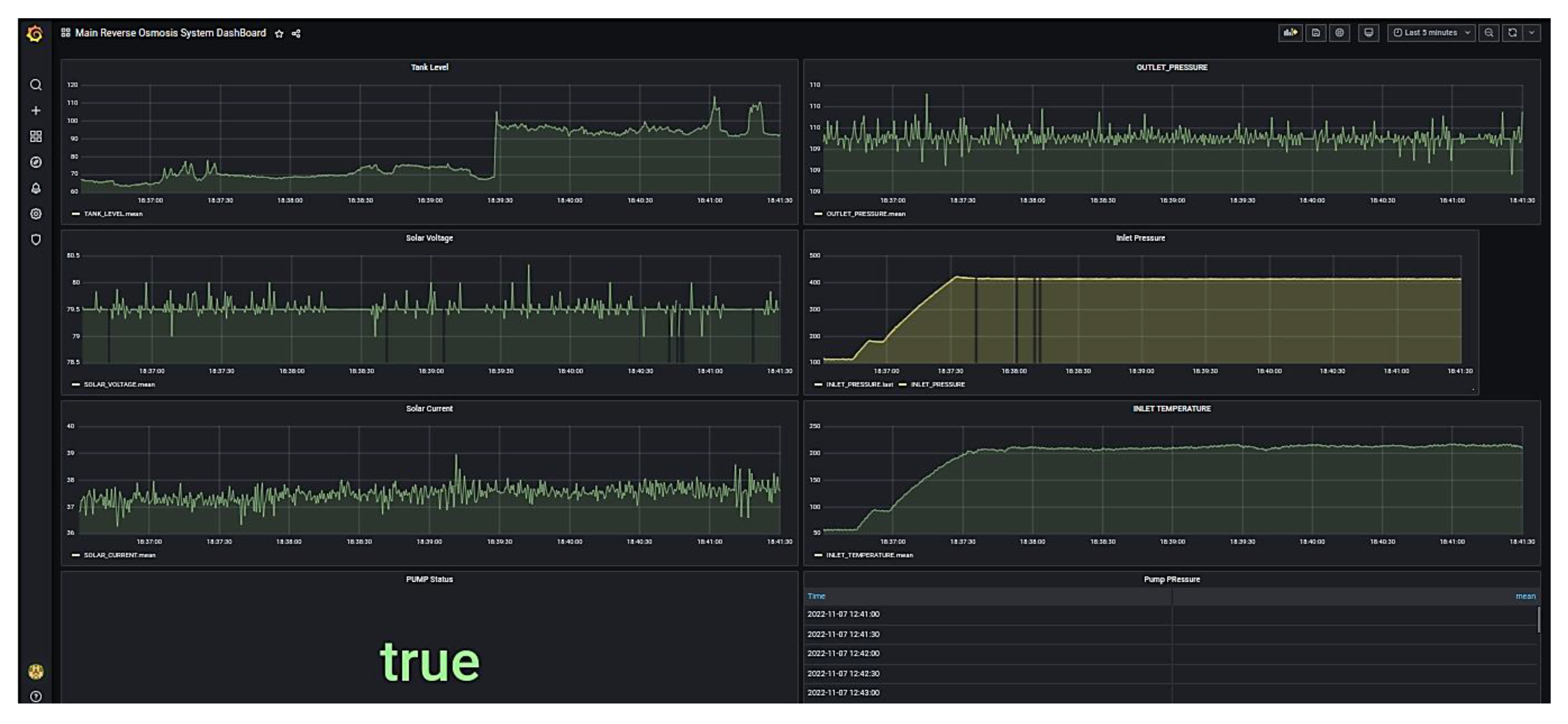

- Intuitive dashboards and data analytics are provided with a Web-based real-time and historian monitoring and control system.

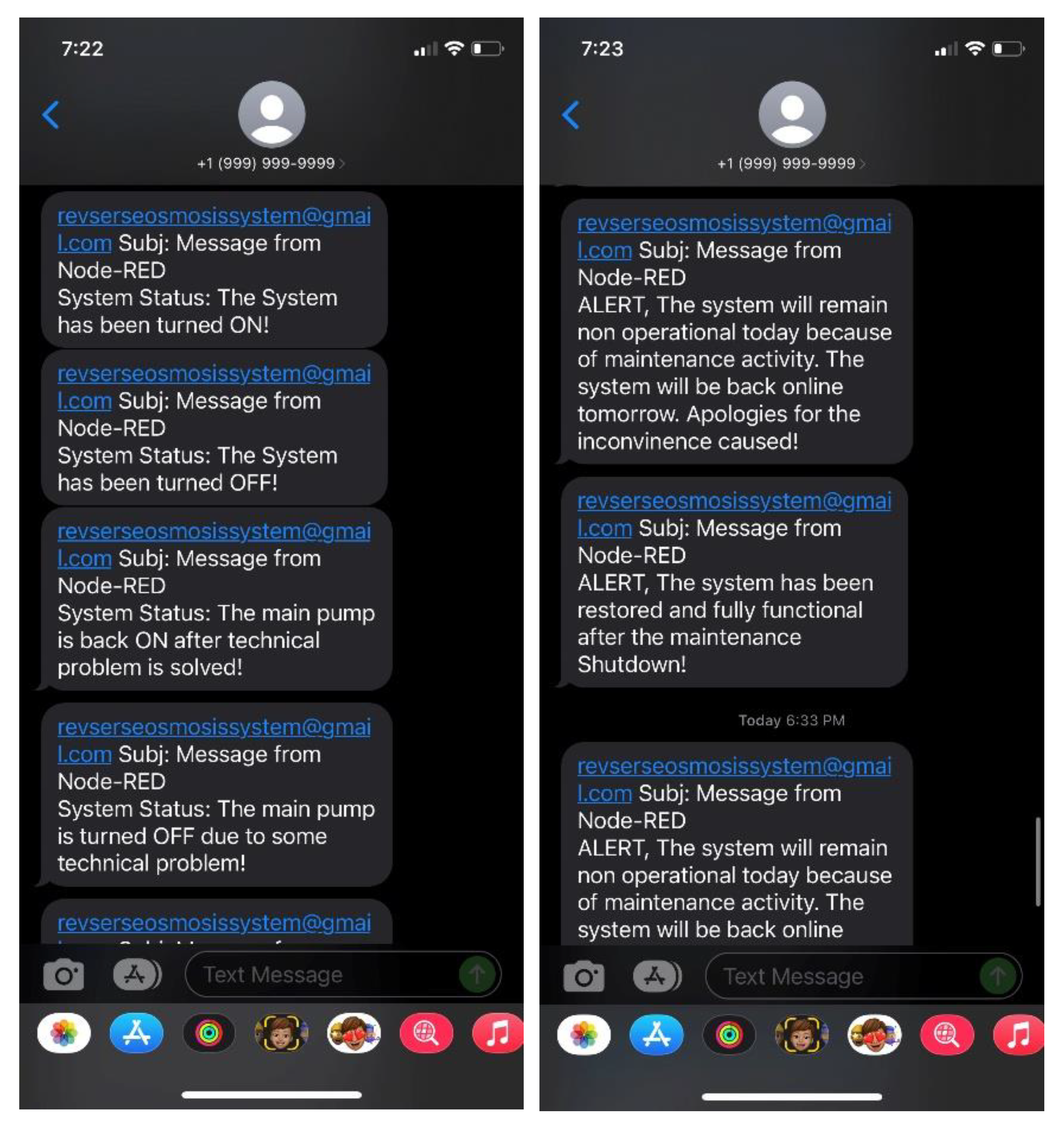

- Maintains an alert system to inform the community of the system status and updates.

- The designed system uses 100% open-source technology.

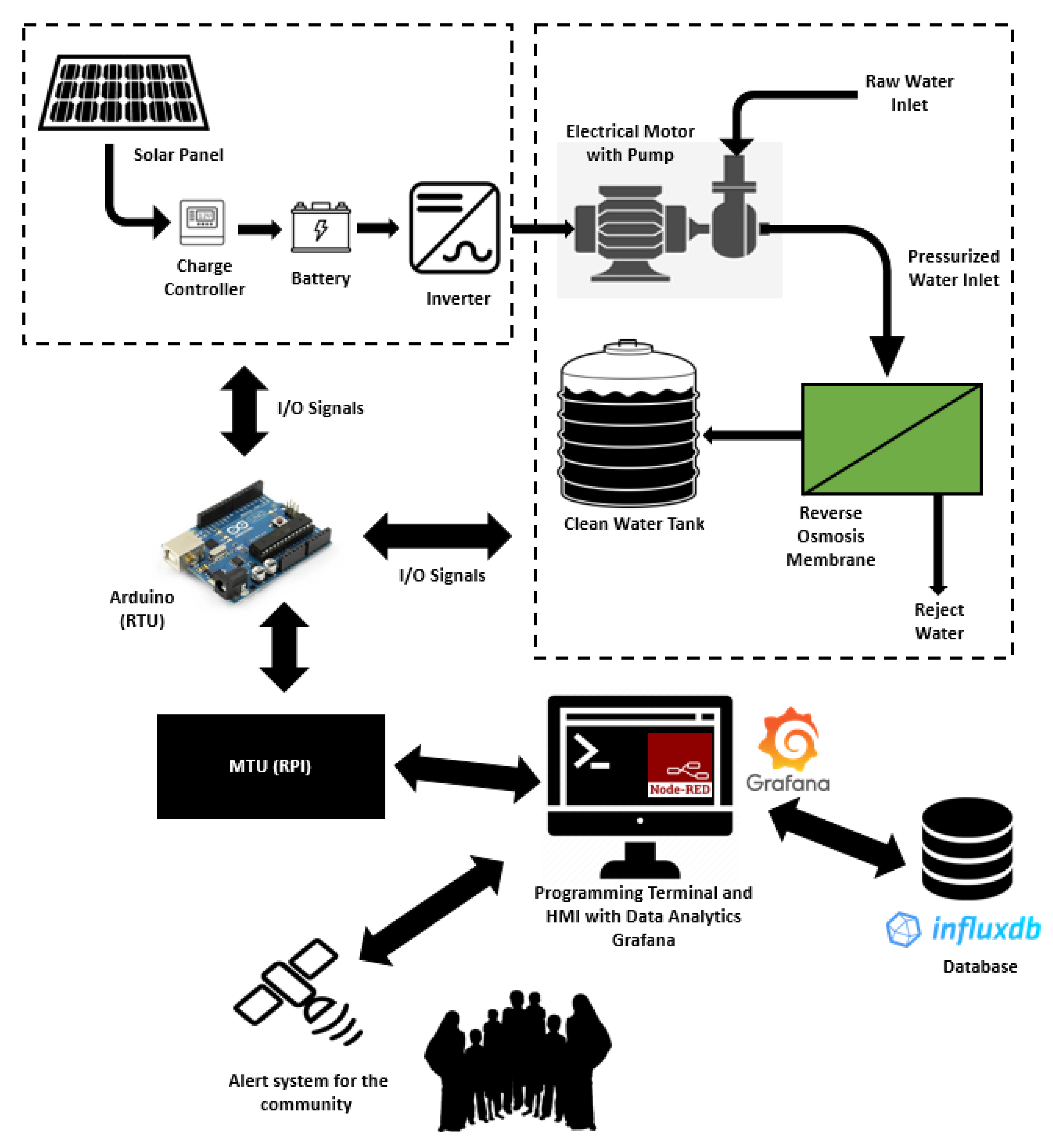

3. System Description

4. Components of the Designed System

4.1. Field Instrument Devices

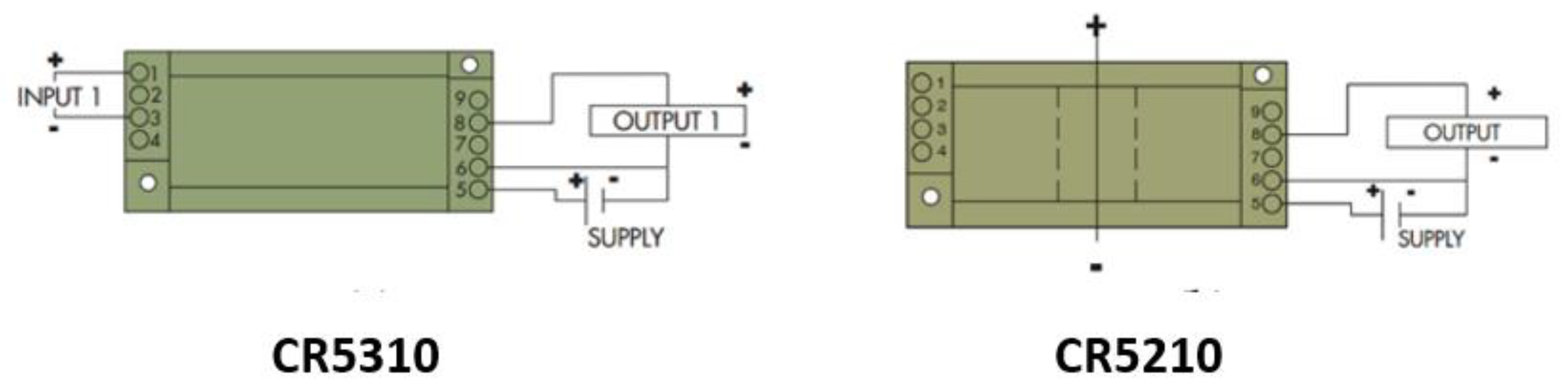

- Electrical System FIDs

- Reverse Osmosis Desalination System FIDs

- Actuators and Simulators FIDs

4.1.1. Electrical System FIDs

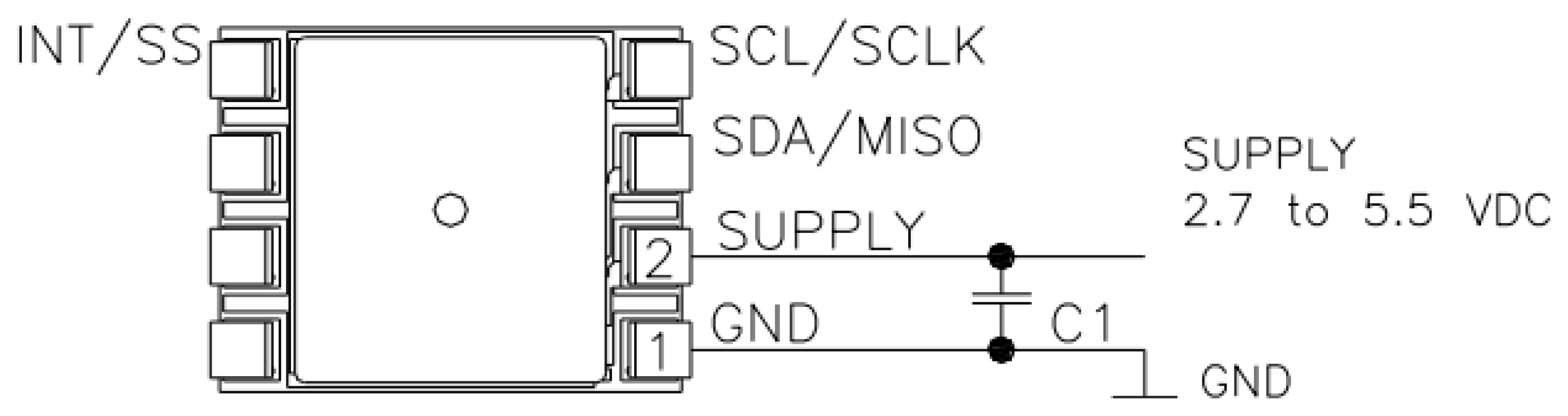

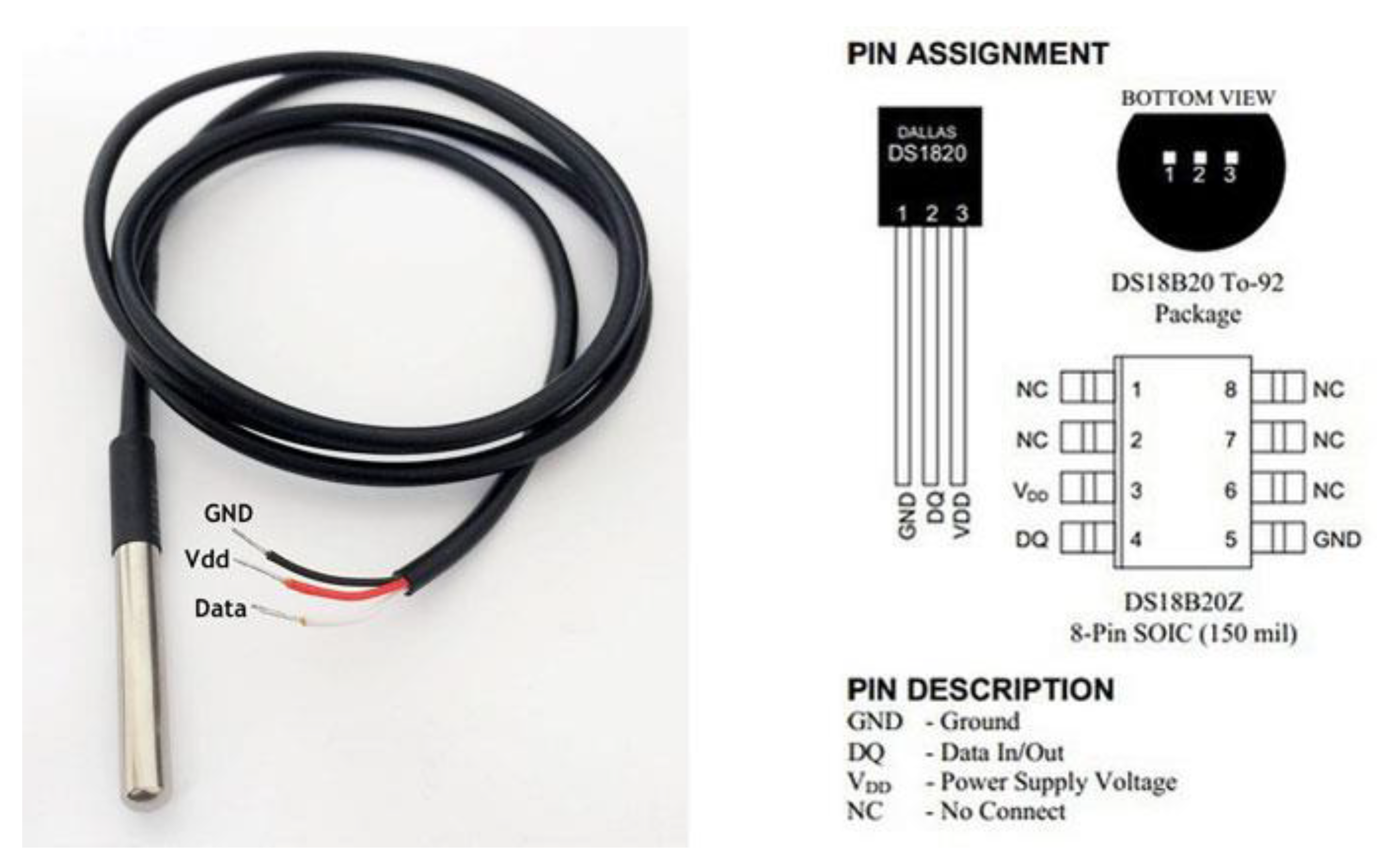

4.1.2. Reverse Osmosis System FIDs

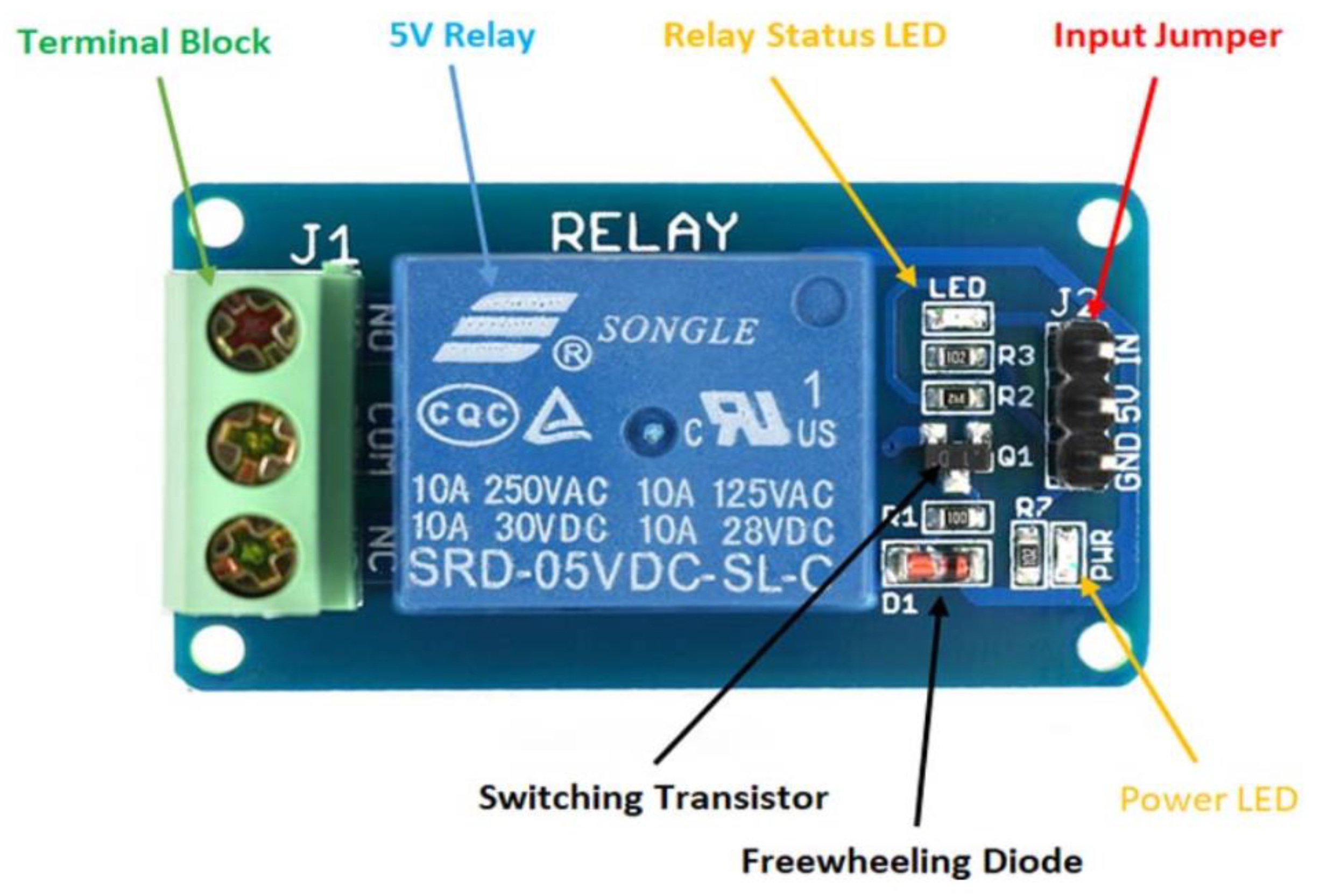

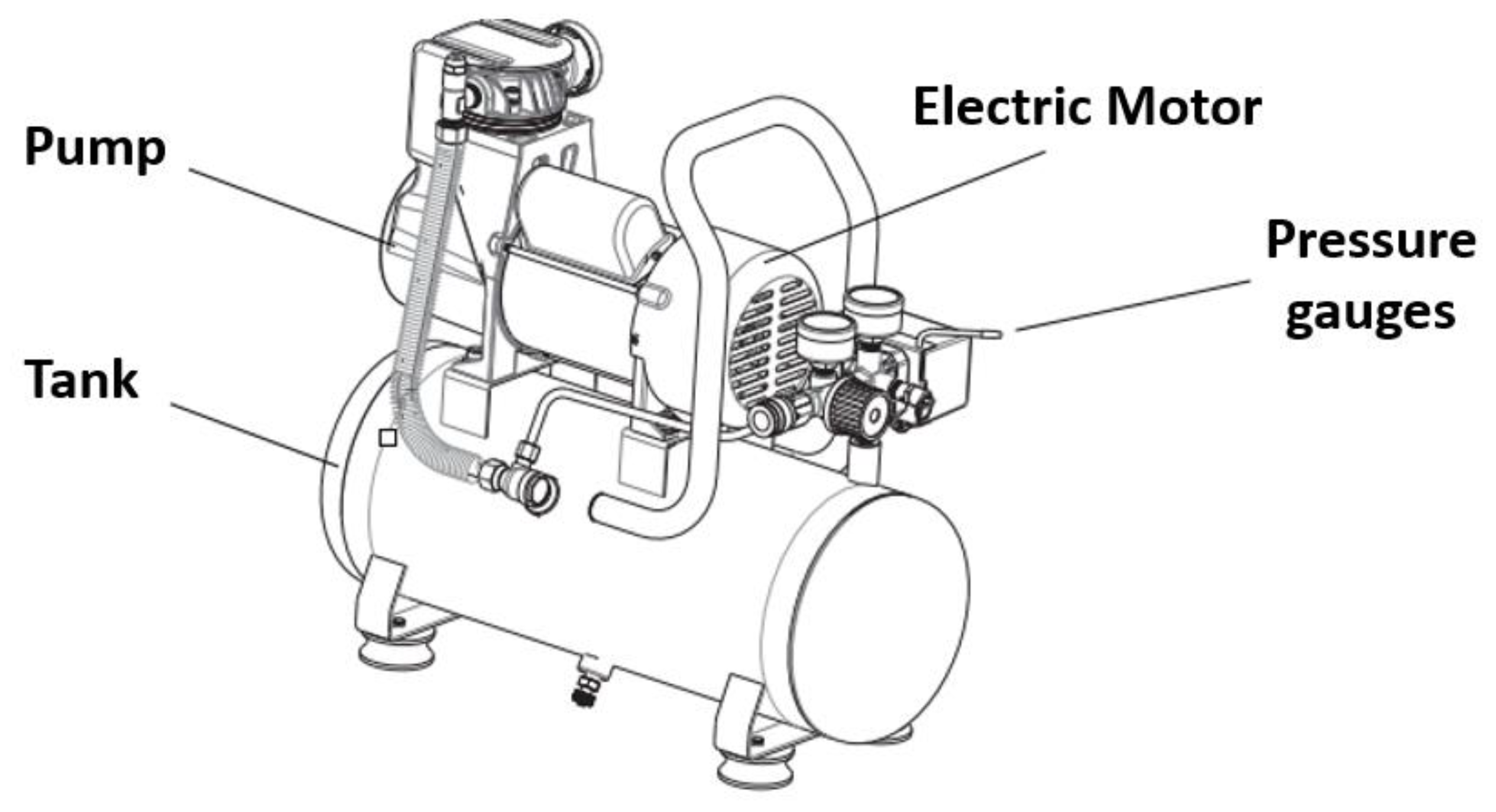

4.1.3. Actuators and Simulators FIDs

4.2. Remote Terminal Unit (Arduino Mega 2560)

4.3. Main Terminal Unit

4.3.1. Hardware (Physical Device)

4.3.2. Software (Operating System, Applications, and Database)

- Operating System

- Applications

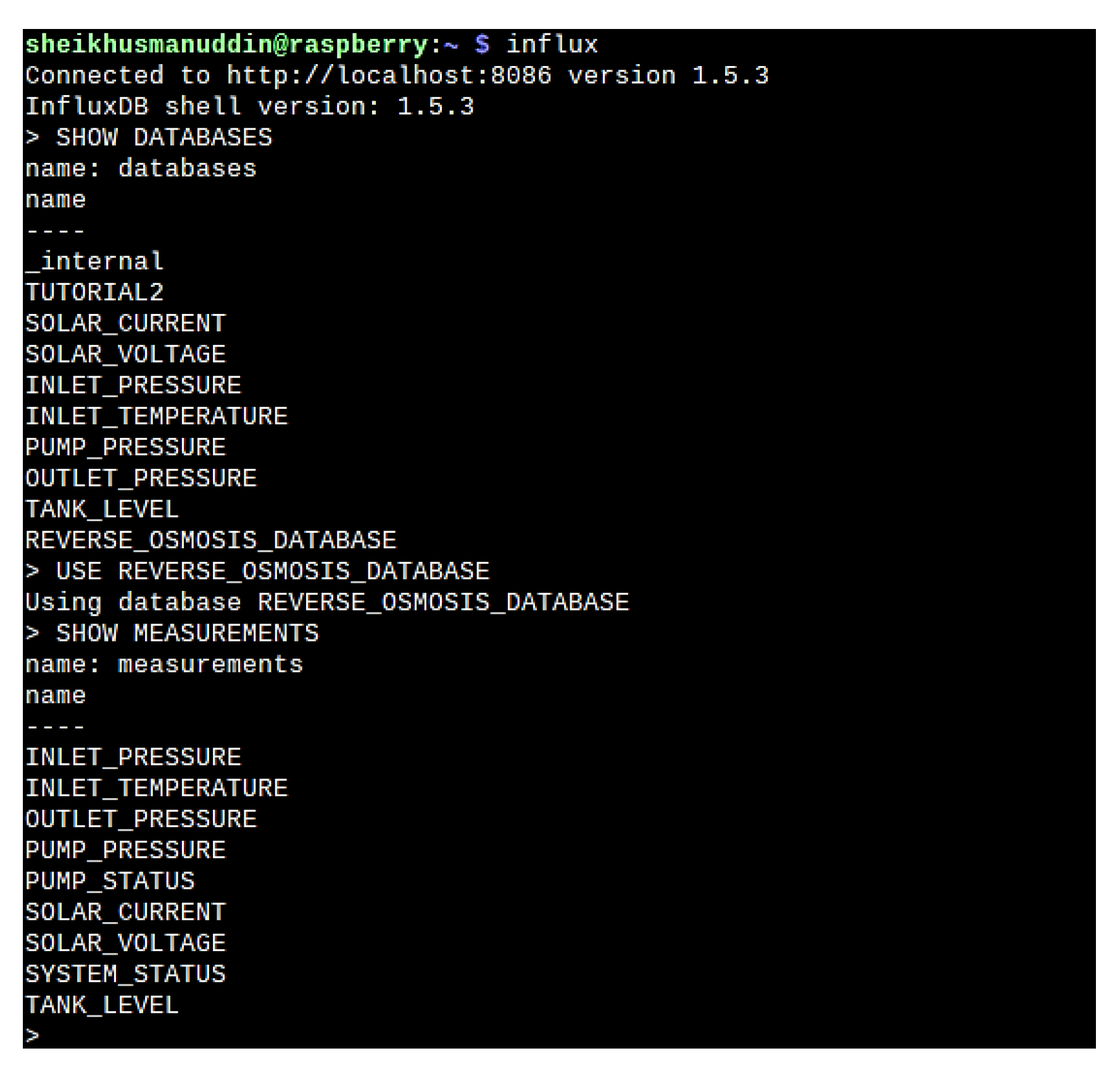

- Database

Operating System

Applications

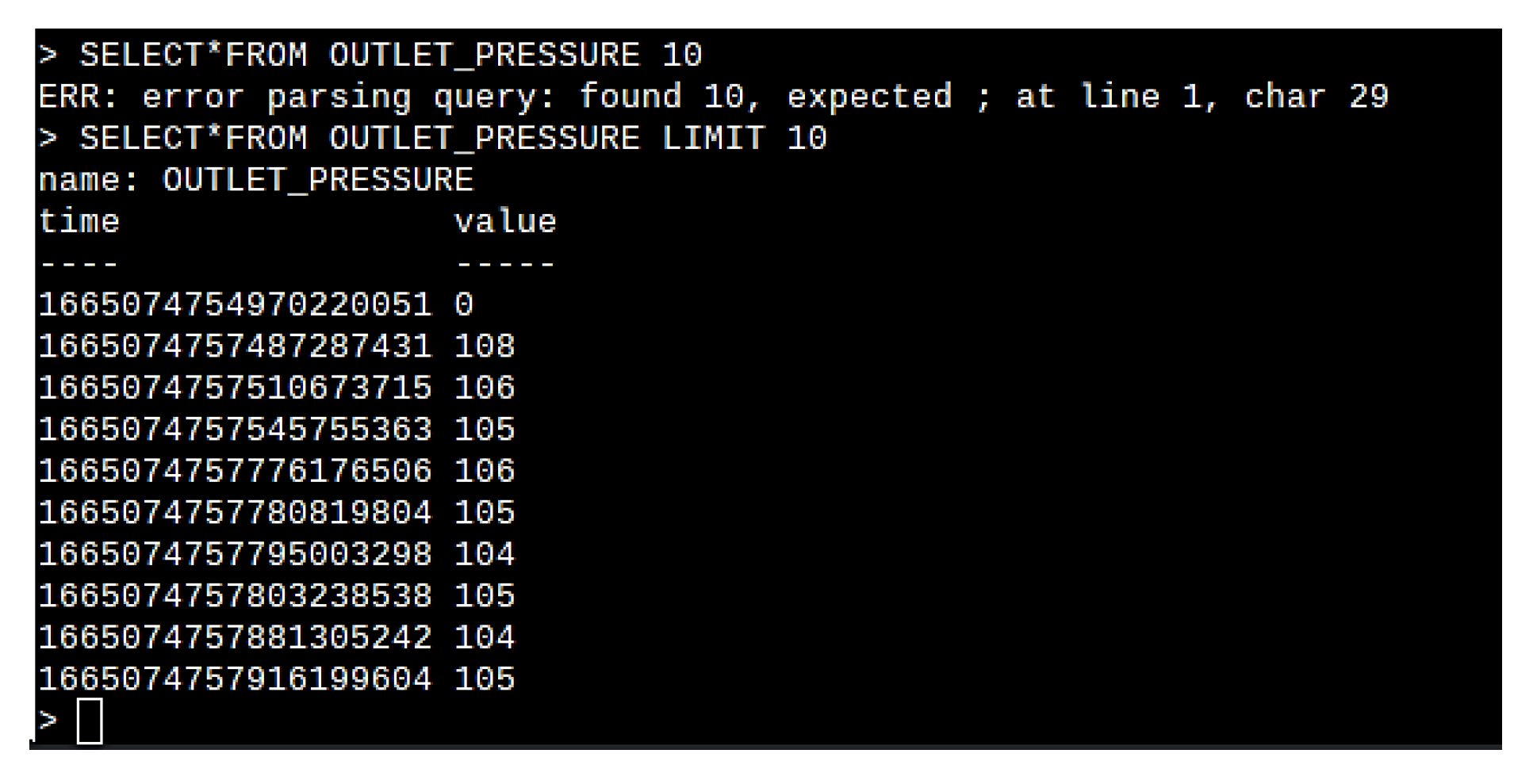

Database

5. Implementation Methodology

| Algorithm 1: Field Sensor Data Acquisition, Storage, and Display |

| Initialization; 1. Start Service Node-Red 2. Check Service Node-Red 3. If Running a. Open localhost:1880 b. While Read and store data from pins A0, A1, A2, A3, A4, A5 and A6 using /dev/ttyACM0 i. Send A0, A1, A3 and A6 to chart display ii. Send A2, A4 and A5 to gauge display iii. Send A0 to Solar Current tag database iv. Send A1 to Solar Voltage tag database v. Send A2 to Inlet Pressure tag database vi. Send A3 to Inlet Temperature tag database vii. Send A4 to Pump Pressure tag database viii. Send A5 to Outlet Pressure tag database ix. Send A6 to Tank level tag database c. End 4. Else Check System 5. End |

| Algorithm 2: System Operation |

| Initialization; 1. Start Service Node-Red 2. Check Service Node-Red 3. If Running a. Go to localhost:1880/ui b. Click System On button c. Click Pump On button 4. Else a. Click Pump Off button 5. Else If a. Click System Off button b. Pump Off button Automatically activated by interlocking 6. End Check System 7. End |

| Algorithm 3: Alert System for Community |

| Initialization; 1. Start Service Node-Red 2. Check Service Node-Red 3. If Running a. Open localhost:1880/ui b. Set Clean Water Level Lower Set Point Variable c. Set Clean Water Level Upper Set Point Variable d. While Read Dashboard button status and Pin A6 i. If A6 value is less than the Clean Water Level Lower Set Point 1. Send Message to community: “Warning, The clean water level availability is very low” ii. End iii. If A6 value is greater than the Clean Water Level Upper Set Point 1. Send Message to community: “Notification, The clean water level availability is very High” iv. End v. If System ON button is active 1. Send Message to the community “System Status: The System has been turned ON!” vi. Else If System OFF button is active 1. Send Message to the community “System Status: The System has been turned OFF!” vii. Else If Pump ON button is active 1. Send Message to the community “System Status: The Main Pump is running!” viii. Else if Pump OFF button is active 1. Send Message to the community “System Status: The Main Pump turned OFF!” ix. Else if Send Maintenance Alert Button is active 1. Send Message to the community “Alert, The System will remain non-operational today because of maintenance activity. The system will be back online tomorrow. Apologies for the inconvenience caused!” x. Else if Send System Normalization Alert Button is active 1. Send Message to the community “Alert, The system has been restored and fully functional after the maintenance shutdown” xi. End e. End 4. End Check System 5. End |

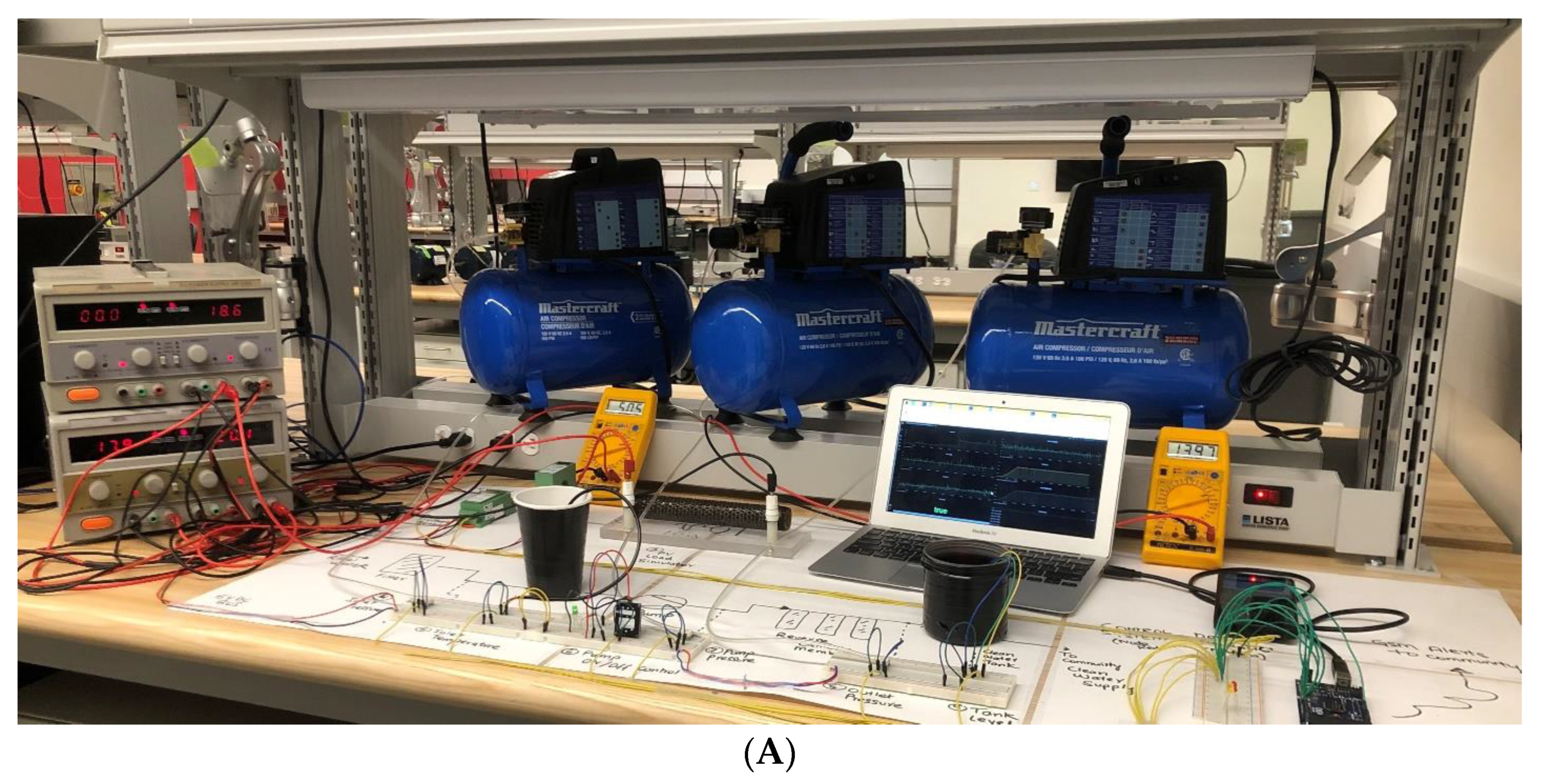

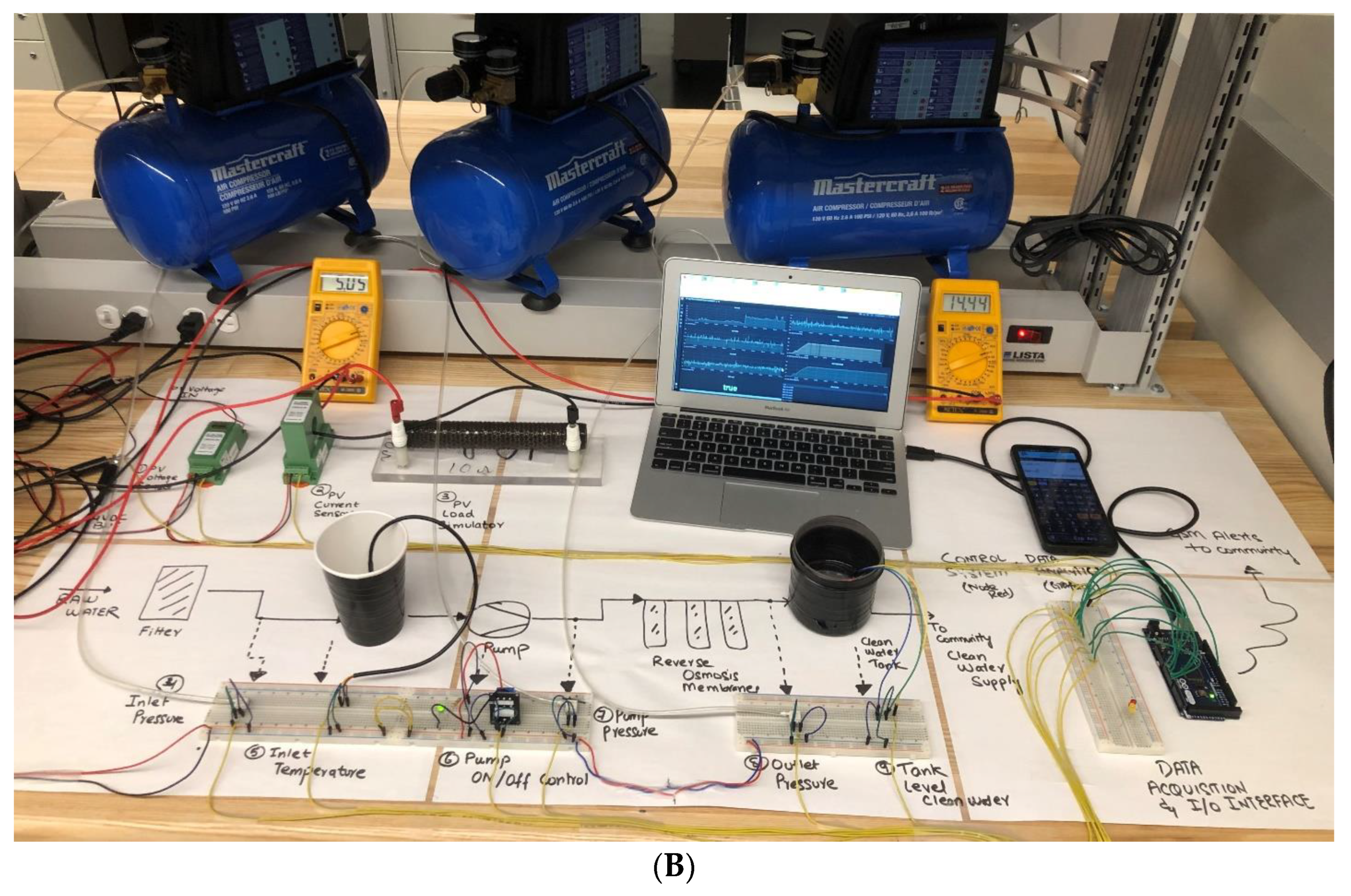

6. Prototype Design and Results

7. Discussion

- System Configuration: The System is designed in a unique configuration where a web-based approach is used for both logical programming and data analytics.

- System safety: As a measure of system safety, the field devices are isolated using an RTU to ensure that the system side is protected in the event of abnormal conditions.

- Open Source: The complete system is based on free and open-source software that can be easily installed on any operating system. There is no license fee or yearly fee associated with the operation of the system. Hence, eliminating the operational cost of the system.

- Availability and Reliability of System: Since all the components used in the system are easily available in the market and all work is done locally, including the creation of a local database ensures the user has a continuously reliable and available system.

- Data Acquisition, Monitoring, and Control: All data is locally collected using the RTU and monitored on a web-based monitoring and control system for operation and maintenance.

- Data Storage: Data is locally stored in a local server using InfluxDB, where using the Grafana-based system you can view historical data.

- Alert System for the Community: All important alerts regarding the system are promptly communicated to community members that rely on this water source for their daily needs. Consequently, if there is an abnormal water situation, the community is informed and can respond appropriately.

- User-Friendly Dashboard: An easy-to-use dashboard provides easy access to real-time and historical data.

- Security: Due to the fact that the system stores data locally and does not transmit any information to a remote server, the system is a fully private and secure system.

- Easy-to-Use System: The system will require one-time training for any operator and can be easily used by any user.

- Data Analytics: The System has the capability to carry out extensive data analytics as the data is now available on at Grafana server that has very high processing and data analytics power.

- Comprehensive guide for future research: The results of this research will serve as a guide for the development of clean water systems that are easy to install in any community, regardless of whether it is connected to the grid or not.

- System Limitations: The SCADA system is designed for the selected RO system. It has some limits, e.g., selected sensors could be used for the selected RO system; after a power interruption SCADA server needs to be restarted by switching on the computer and running node-Red and Grafana manually. Another system limit is that it lacks RO system user feedback. The system will send an alert, but it cannot determine whether users received that alert or not. Users cannot send a message/email to check the system status. More features may be added in future versions of this SCADA system.

8. Conclusions

- Globally, the use of clean energy and clean water scarcity remain the two biggest challenges. This paper discusses an elaborate system design that ensures the reverse osmosis desalination system is powered exclusively by renewable energy. There is a detailed description of the majority of field instrument devices required to monitor and control the system in the paper. Field devices are integrated with RTUs to acquire data, which is then transmitted to the MTUs for processing and control. A highly interactive and real-time monitoring and control HMI was also developed with the use of the Node-Red visual programming language. Furthermore, the most challenging aspect of the operation of any system is to ensure that its security is not compromised. Thus, in order to ensure the security of the system, InfluxDB is used as the database and is executed locally on the same MTU, storing the data on the local server so that only authorized personnel will be able to access it. As data-driven decisions and predictive analyses play a pivotal role in increasing the efficiency and performance of any system, Grafana is subsequently deployed on the same MTU as a web-based data analytics and predictive analytics application. A major advantage of all these applications is that they are free of charge and do not require a license or an annual fee, as well as being open source with easy access to updates. As a final point, the most important gap in all such systems and previous research work was the absence of a user alert system, as in a typical situation, users would have to visit the system in person to know the status and quantity of water available.

- Research such as this can be applied to many existing reverse osmosis-based desalination plants in many parts of the world to ensure that data analytics can be used to make better data-driven decisions. It offers a programming-based integration method without any external hardware for extensive alert systems that can be used separately with a variety of systems. Renewable energy is used throughout the system, thereby contributing to its environmental friendliness. Based on the testing of the system, it has been demonstrated that it can be used to remotely control and log data accurately in real time.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| SCADA | Supervisory Control and Data Acquisition |

| HMI | Human Machine Interface |

| PLC | Programmable Logic Controller |

| MTU | Master Terminal Unit |

| RTU | Remote Terminal Unit |

| FID | Field Instrument Device |

| PV | Photovoltaic |

| GSM | Global System for Mobile Communication |

| RO | Reverse Osmosis |

| DCS | Distributed Control System |

Appendix A

References

- Tükez, E.T.; Kaya, A. SCADA System for Next-Generation Smart Factory Environments. Icontech. Int. J. 2022, 6, 48–52. [Google Scholar] [CrossRef]

- What is SCADA (Supervisory Control and Data Acquisition). Available online: https://www.techtarget.com/whatis/definition/SCADA-supervisory-control-and-data-acquisition (accessed on 5 October 2022).

- Water Scarcity. Available online: https://www.worldwildlife.org/threats/water-scarcity (accessed on 7 October 2022).

- Wilf, M. Fundamentals of RO-NF Technology. In Proceedings of the International Conference on Desalination, Limassol, Cyprus, 6–7 December 2004. [Google Scholar]

- Uddin, S.U.; Iqbal, T. Design and Economic Analysis of Solar Powered Drinking Water Reverse Osmosis Desalination System for a Community in Pakistan. In Proceedings of the 2022 IEEE 12th Annual Computing and Communication Workshop and Conference (CCWC), Las Vegas, NV, USA, 26–29 January 2022; pp. 1059–1064. [Google Scholar] [CrossRef]

- Uddin, S.U.; Rideout, G. Dynamic Modelling and Analysis of Solar Powered Reverse Osmosis Desalination System for Pakistan using the Bond Graph Model. In Proceedings of the 2022 IEEE International IOT, Electronics and Mechatronics Conference (IEMTRONICS), Toronto, ON, Canada, 1–4 June 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Morsi, I.; El Deeb, M.; El Zwawi, A. SCADA/HMI Development for a Multi Stage Desalination Plant. In Proceedings of the 2009 Computation World: Future Computing, Service Computation, Cognitive, Adaptive, Content, Patterns, Athens, Greece, 15–20 November 2009; pp. 67–71. [Google Scholar] [CrossRef]

- Torky, O.M.; Elamvazuthi, I.; Hanif, N.H.H.B.M. PC based SCADA system for reverse osmosis desalination plants. In Proceedings of the 2009 IEEE Student Conference on Research and Development (SCOReD), Serdang, Malaysia, 16–18 November 2009; pp. 442–445. [Google Scholar] [CrossRef]

- Kumar, B.; Dewal, M.L.; Mukherjee, S. Control and monitoring of MSF-RO hybrid desalination process. In Proceedings of the 2013 International Conference on Control, Automation, Robotics and Embedded Systems (CARE), Jabalpur, India, 16–18 December 2013; pp. 1–5. [Google Scholar] [CrossRef]

- Prabhavathy, M.; Ramesh, B.; Reddy, T.K. An alternative distributed control using Labview. In Proceedings of the 2014 International Conference on Computation of Power, Energy, Information and Communication (ICCPEIC), Chennai, India, 16–17 April 2014; pp. 174–180. [Google Scholar] [CrossRef]

- Nuñez, J.; Pina IF, B.; Martínez, A.R.; Pérez, S.D.; de Oliveira, D.L. Tools for the Implementation of a SCADA System in a Desalination Process. IEEE Lat. Am. Trans. 2019, 17, 1858–1864. [Google Scholar] [CrossRef]

- Campbell, R.L.; Hanlon, J.; Seamon, F.; Jones, A.T. Retrofit of a California coastal desalination plant: Add technology, lower costs. In Proceedings of the Oceans 2003. Celebrating the Past… Teaming Toward the Future (IEEE Cat. No.03CH37492), San Diego, CA, USA, 22–26 September 2003; Volume 1, pp. 246–248. [Google Scholar] [CrossRef]

- Achbi, M.S.; Kechida, S. Fault tolerant control of Reverse Osmosis Desalination Plant with the application of SCADA system. In Proceedings of the 2nd International Conference on Applied Automation and Industrial Diagnostics, Djelfa, Algeria, 16–17 September 2017; Volume ICAAID 2017. [Google Scholar]

- Avlonitis, S.A.; Pappas, M.; Moutesidis, K.; Avlonitis, D.; Kouroumbas, K.; Vlachakis, N. PC based SCADA system and additional safety measures for small desalination plants. Desalination 2004, 165, 165–176. [Google Scholar] [CrossRef]

- Fareigh, D.M.K.; Arazzini, S. Description and mathematical model of a large MSF desalination plant in SCADA configuration. Desalination 1985, 55, 91–106. [Google Scholar] [CrossRef]

- In the World: Small Mexican Village Produces Clean Water with Solar Powered System. Available online: https://news.mit.edu/2013/clean-water-solar-powered-system-0911 (accessed on 17 January 2022).

- Abdelkareem, M.A.; Assad, M.E.H.; Sayed, E.T.; Soudan, B. Recent progress in the use of renewable energy sources to power water desalination plants. Desalination 2018, 435, 97–113. [Google Scholar] [CrossRef]

- Idrees, M.F. Performance Analysis and Treatment technologies of Reverse Osmosis Plant. Case Stud. Chem. Environ. Eng. 2020, 2, 100007. [Google Scholar] [CrossRef]

- Fredkin, E.; Banks, R. Computerized Instrumentation and Control for Reverse Osmosis Systems. Desalination 1989, 75, 141–148. [Google Scholar] [CrossRef]

- Latorre FJ, G.; Báez SO, P.; Gotor, A.G. Energy performance of a reverse osmosis desalination plant operating with variable pressure and flow. Desalination 2015, 366, 146–153. [Google Scholar] [CrossRef]

- Thomson, A.M. Reverse-Osmosis Desalination of Seawater Powered by Photovoltaics without Batteries. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2003. Available online: https://ethos.bl.uk/OrderDetails.do?uin=uk.bl.ethos.416745 (accessed on 16 November 2022).

- Glueckstern, P.; Wilf, M.; Etgar, J.; Ricklis, J. Use of microprocessors for control, data aquisition and on line performance evaluation in a reverse osmosis plant. Desalination 1985, 55, 469–480. [Google Scholar] [CrossRef]

- Vargas-Salgado, C.; Aguila-Leon, J.; Chiñas-Palacios, C.; Hurtado-Perez, E. Low-cost web-based Supervisory Control and Data Acquisition system for a microgrid testbed: A case study in design and implementation for academic and research applications. Heliyon 2019, 5, e02474. [Google Scholar] [CrossRef]

- Portalo, J.M.; González, I.; Calderón, A.J. Monitoring system for tracking a PV generator in an experimental smart microgrid: An open-source solution. Sustainability 2021, 13, 8182. [Google Scholar] [CrossRef]

- Yasin, A.; Pang, T.Y.; Cheng, C.T.; Miletic, M. A roadmap to integrate digital twins for small and medium-sized enterprises. Appl. Sci. 2021, 11, 9479. [Google Scholar] [CrossRef]

- Nițulescu, I.V.; Korodi, A. Supervisory Control and Data Acquisition Approach in Node-RED: Application and Discussions. IoT 2020, 1, 76–91. [Google Scholar] [CrossRef]

- Lopez-Ballester, J.; Pastor-Aparicio, A.; Felici-Castell, S.; Segura-Garcia, J.; Cobos, M. Enabling Real-Time Computation of Psycho-Acoustic Parameters in Acoustic Sensors Using Convolutional Neural Networks. IEEE Sens. J. 2020, 20, 11429–11438. [Google Scholar] [CrossRef]

- Garcia-Pineda, M.; Felici-Castell, S.; Segura-Garcia, J. Using Factor Analysis Techniques to Find Out Objective Video Quality Metrics for Live Video Streaming over Cloud Mobile Media Services. Netw. Protoc. Algorithms 2016, 8, 126. [Google Scholar] [CrossRef]

- Segura-Garcia, J.; Felici-Castell, S.; Garcia-Pineda, M. Performance evaluation of different techniques to estimate subjective quality in live video streaming applications over LTE-Advance mobile networks. J. Netw. Comput. Appl. 2018, 107, 22–37. [Google Scholar] [CrossRef]

- What Is Reverse Osmosis System and How Does It Work. Available online: https://www.freshwatersystems.com/blogs/blog/what-is-reverse-osmosis (accessed on 12 July 2022).

- DC Voltage Transducer–CR Magnetics. Available online: https://www.crmagnetics.com/Assets/ProductPDFs/CR5300%20Series%20Catalog%20Page.pdf (accessed on 9 September 2022).

- DC Current Transducer–CR Magnetics. Available online: https://www.crmagnetics.com/Assets/ProductPDFs/CR5200%20Series%20Catalog%20Page.pdf (accessed on 9 September 2022).

- MS4525D0 Pressure Sensor–TE. Available online: https://www.te.com/commerce/DocumentDelivery/DDEController?Action=showdoc&DocId=Data+Sheet%7FMS4525DO%7FB10%7Fpdf%7FEnglish%7FENG_DS_MS4525DO_B10.pdf%7FCAT-BLPS0002 (accessed on 15 September 2022).

- Programmable Resolution 1-Wire Digital Thermometer. Available online: https://datasheets.maximintegrated.com/en/ds/DS18B20.pdf (accessed on 19 September 2022).

- Liquid Level Indicator with Arduino. Available online: https://create.arduino.cc/projecthub/electropeak/make-a-liquid-level-indicator-with-arduino-596bd3 (accessed on 20 September 2022).

- 5V Single Channel Relay Module. Available online: https://components101.com/switches/5v-single-channel-relay-module-pinout-features-applications-working-datasheet (accessed on 1 October 2022).

- Master Craft 2 Gallon Compressor. Available online: https://www.manualslib.com/manual/813344/Mastercraft-2-Gallon-7-6-L-Air-Compressor.html (accessed on 12 October 2022).

- Arduino Mega Pinout. Available online: https://www.electronicshub.org/arduino-mega-pinout/ (accessed on 12 October 2022).

- Ahsan, L.; Baig, M.J.A.; Iqbal, M.T. Low-Cost, Open-Source, Emoncms-Based SCADA System for a Large GridConnected PV System. Sensors 2022, 22, 6733. [Google Scholar] [CrossRef] [PubMed]

- Baig, M.J.A.; Iqbal, M.T.; Jamil, M.; Khan, J. A Low-Cost, Open-Source Peer-to-Peer Energy Trading System for a Remote Community Using the Internet-of-Things, Blockchain, and Hypertext Transfer Protocol. Energies 2022, 15, 4862. [Google Scholar] [CrossRef]

- Baig, M.J.A.; Iqbal, M.T.; Jamil, M.; Khan, J. Design and implementation of an open-Source IoT and blockchain-based peer-to-peer energy trading platform using ESP32-S2, Node-Red and, MQTT protocol. Energy Rep. 2021, 7, 5733–5746. [Google Scholar] [CrossRef]

- Baig, M.J.A.; Iqbal, M.T.; Jamil, M.; Khan, J. Peer-to-Peer Energy Trading in a Micro-grid Using Internet of Things and Blockchain. Electron. J. 2021, 25. [Google Scholar] [CrossRef]

| Manufacturer | Model | Function | References |

|---|---|---|---|

| CR Magnetics | CR5310 | DC Voltage Transducer | [31] |

| CR Magnetics | CR5210 | DC Current Transducer | [32] |

| TE Connectivity Measurements Specialties | 4525-15AP | Inlet Pressure Transducer | [33] |

| Maxim | DS18B20 | Inlet Temperature Transducer | [34] |

| TE Connectivity Measurements Specialties | 4525-15AP | Pump Pressure Transducer | [33] |

| TE Connectivity Measurements Specialties | 4525-15AP | Outlet Pressure Transducer | [33] |

| SongHe | B07THDH7Y4 | Clean Water Tank Level Transducer | [35] |

| Lychee Limited | 06-061-024 | Relay Module for Pump On/Off | [36] |

| Mastercraft | 2 Gallon Air | Compressor for Inlet Pressure Simulation | [37] |

| Mastercraft | 2 Gallon Air | Compressor for Pump Pressure Simulation | [37] |

| Mastercraft | 2 Gallon Air | Compressor for Outlet Pressure Simulation | [37] |

| Specification | Value | Units |

|---|---|---|

| Accuracy | 1.0 | % |

| Linearity | 10 to 100 | % FS |

| Thermal Drift | 500 | PPM/C |

| Operating Temperature | 0 to 50 | C |

| Response Time | 250 | Ms |

| Supply Voltage | 24 | V DC |

| Supply Current | 35 | mA |

| Specification | Value | Units |

|---|---|---|

| Supply Voltage | 2.7 to 5.5 | V DC |

| Output Current | 3 | mA |

| Over Pressure | 300 | Psi |

| Accuracy | −0.25 to 0.25 | % of Span |

| Operating Temperature | −25 to 105 | C |

| Response Time | 0.5 | ms |

| Specification | Value | Units |

|---|---|---|

| Supply Voltage | 3.0 to 5.5 | V DC |

| Thermometer Error | +/−2 | C |

| Standby Current | 750 | nA |

| Active Current | 1 | mA |

| Specification | Value | Units |

|---|---|---|

| Operating Voltage | 3.0 to 5.5 | V DC |

| Working Current | <20 | mA |

| Working Temperature | 10 to 30 | C |

| Output Voltage | 0 to 4.2 | V DC |

| Specification | Value | Units |

|---|---|---|

| Maximum Output | 30 | V DC |

| 250 | V AC | |

| Voltage Input | 5 | V DC |

| Operation Time | 10 | ms |

| Release Time | 5 | ms |

| Maximum On–Off Switching | 30 | Operations/min |

| Operating Temperature | −25 to 70 | C |

| Specification | Value | Units |

|---|---|---|

| Power | 1.0 | Hp |

| Voltage Input | 120 | V AC |

| Frequency | 60 | Hz |

| Duty Cycle | 50 | % |

| Tank Size | 3 | U.S. Gallons |

| Pressure Range | 0–125 | PSI |

| Compressor Capacity | 3 @ 40 PSI 2 @ 90 PSI | CFM |

| Specification | Value | Units |

|---|---|---|

| Operating Voltage | 5 | V DC |

| Input Voltage (Recommended) | 7–12 | V DC |

| Input Voltage (Limits) | 6–20 | V DC |

| Digital I/O | 54 | Pins |

| Analog Input | 16 | Pins |

| Current Per I/O Pin | 40 | mA |

| Flash Memory | 256 | KB |

| Static Random Access Memory | 8 | KB |

| Electrically Erasable Programmable Read-Only Memory | 4 | KB |

| Clock Speed | 16 | MHz |

| Sr. # | Specification | Value | Arduino Pin |

|---|---|---|---|

| 1 | Solar Voltage Senor | Analogue | A0 |

| 2 | Solar Current Sensor | Analogue | A1 |

| 3 | Inlet Pressure | Analogue | A2 |

| 4 | Inlet Temperature | Analogue | A3 |

| 5 | Pump Pressure | Analogue | A4 |

| 6 | Outlet Pressure | Analogue | A5 |

| 7 | Clean Water Tank Level | Analogue | A6 |

| 8 | Pump On/Off Control Relay | Digital | D6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uddin, S.U.; Baig, M.J.A.; Iqbal, M.T. Design and Implementation of an Open-Source SCADA System for a Community Solar-Powered Reverse Osmosis System. Sensors 2022, 22, 9631. https://doi.org/10.3390/s22249631

Uddin SU, Baig MJA, Iqbal MT. Design and Implementation of an Open-Source SCADA System for a Community Solar-Powered Reverse Osmosis System. Sensors. 2022; 22(24):9631. https://doi.org/10.3390/s22249631

Chicago/Turabian StyleUddin, Sheikh Usman, Mirza Jabbar Aziz Baig, and Mohammad Tariq Iqbal. 2022. "Design and Implementation of an Open-Source SCADA System for a Community Solar-Powered Reverse Osmosis System" Sensors 22, no. 24: 9631. https://doi.org/10.3390/s22249631

APA StyleUddin, S. U., Baig, M. J. A., & Iqbal, M. T. (2022). Design and Implementation of an Open-Source SCADA System for a Community Solar-Powered Reverse Osmosis System. Sensors, 22(24), 9631. https://doi.org/10.3390/s22249631