XGBoost-Based Remaining Useful Life Estimation Model with Extended Kalman Particle Filter for Lithium-Ion Batteries

Abstract

1. Introduction

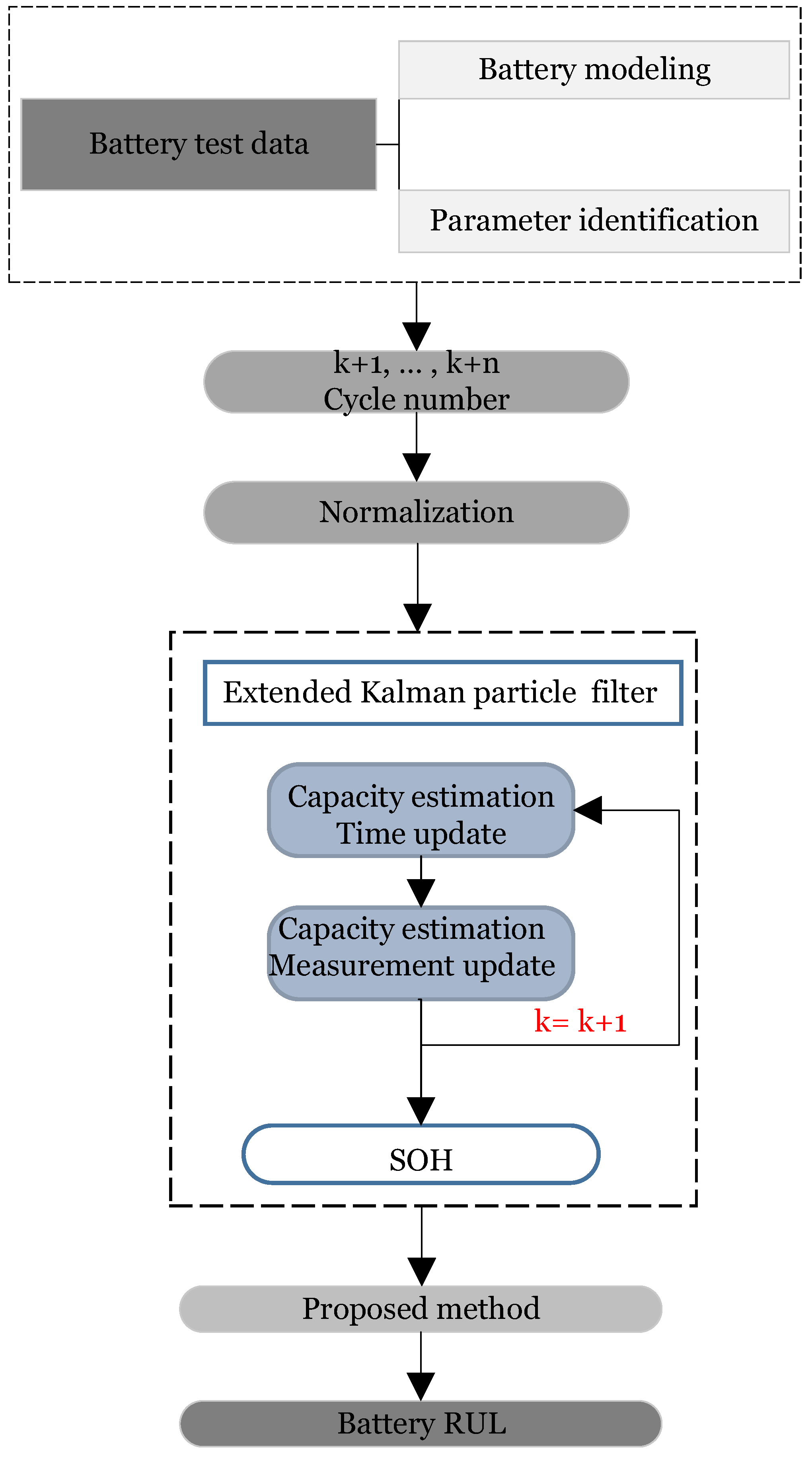

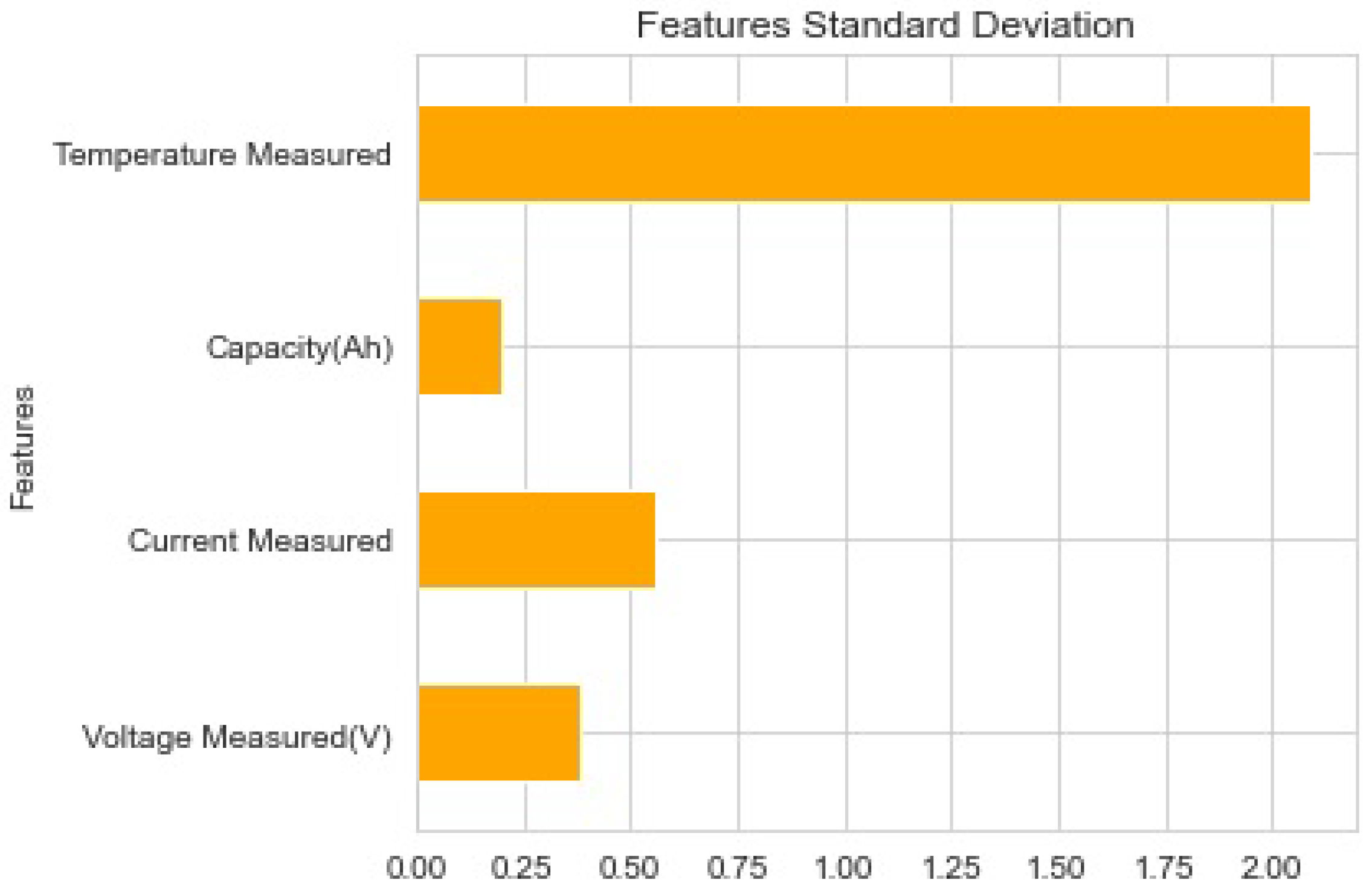

- Along with the discharge capacity degradation profile, the suggested approach considers input factors from the charging profiles, such as voltage, current, and temperature.

- XGBoost model uses the associated characteristics collected by the PF. technique as the reference input.

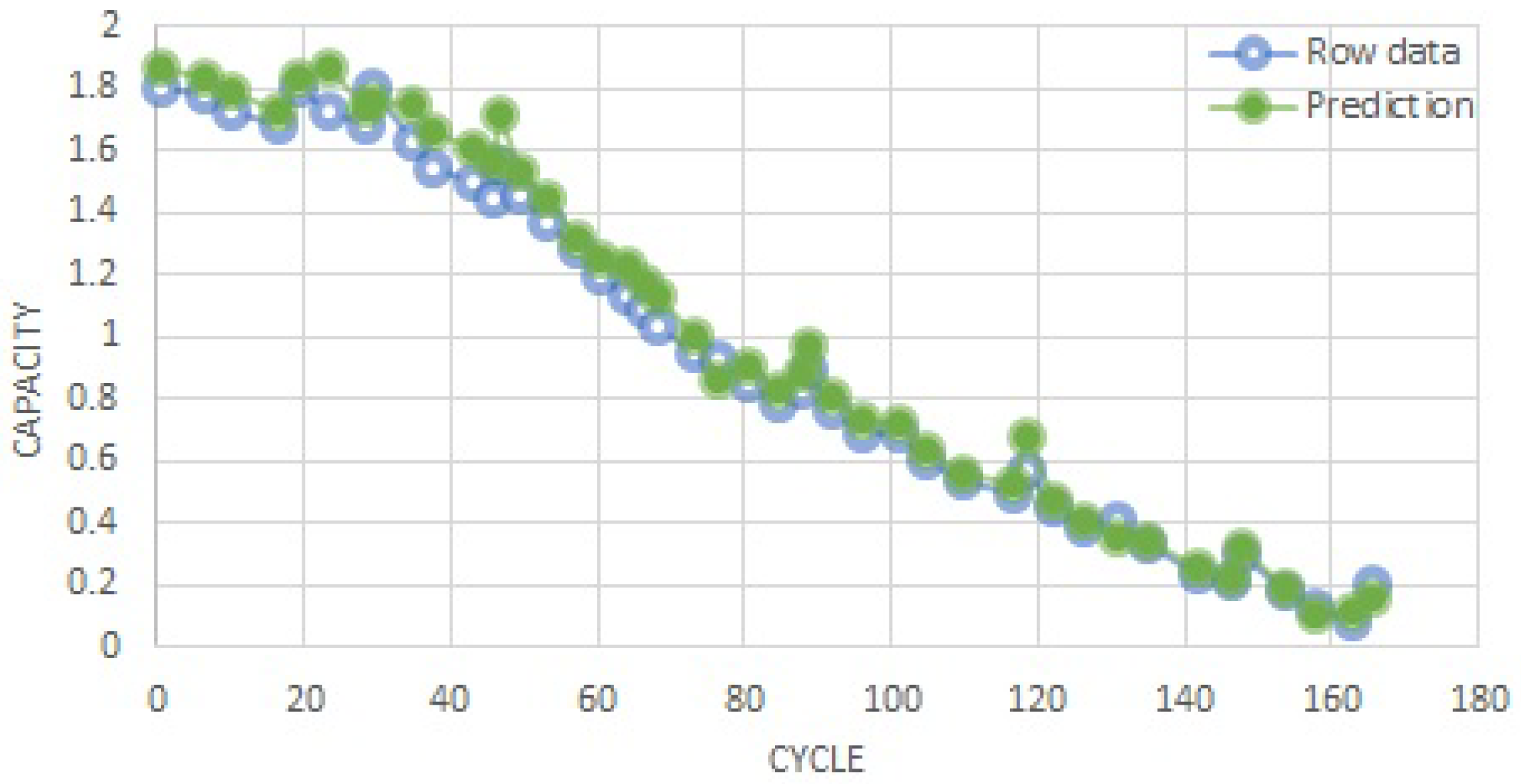

- The RUL estimate results are obtained using the XGBoost model.

- We conduct extensive experiments to show the changes in the estimation accuracy.

- The innovative aspect of the proposed study is the creation of a clever framework for a lithium-ion battery’s RUL prediction and the algorithm’s training using multiple dataset combinations made available by NASA. Moreover, in the paper’s final portion, we compare the proposed method with the recent work on the XGBoost model’s performance with other methods.

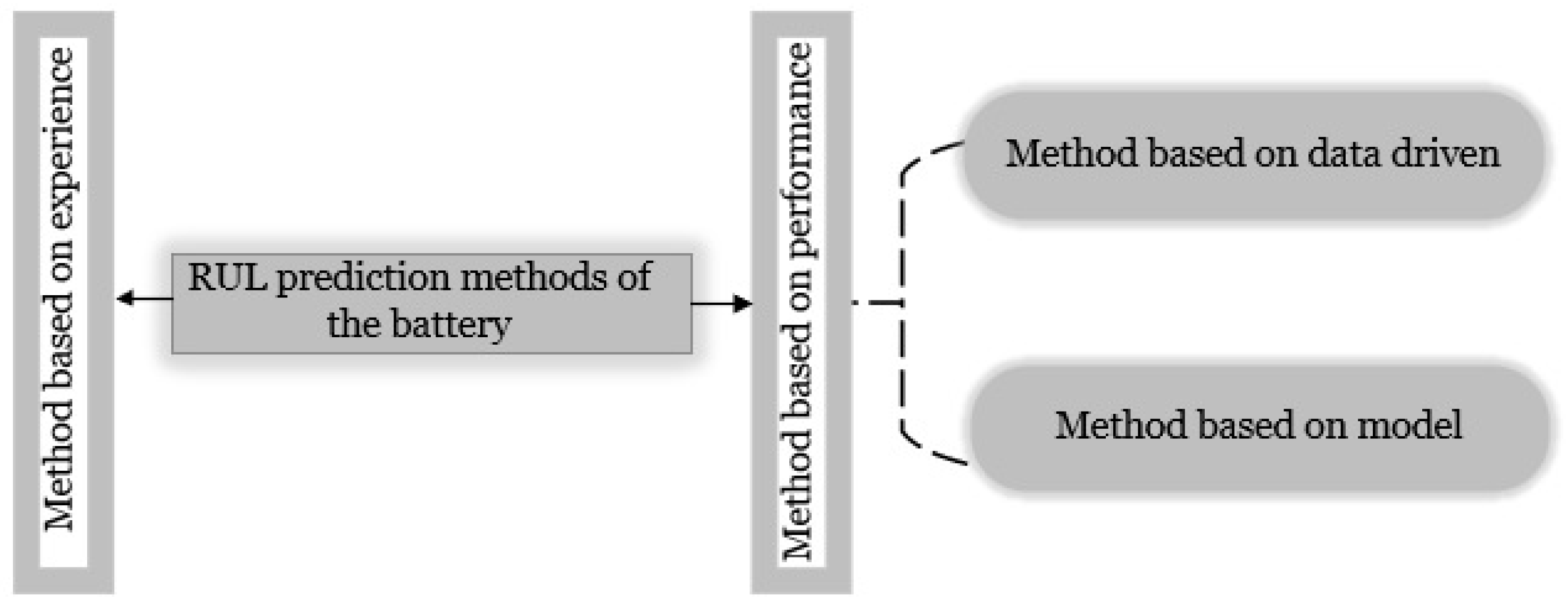

2. Related Work

3. Methodology

3.1. The Standard Theory of Particle Filtering

3.2. Explanation of the Extended Kalman–PF Approach

3.3. XGBoost Method

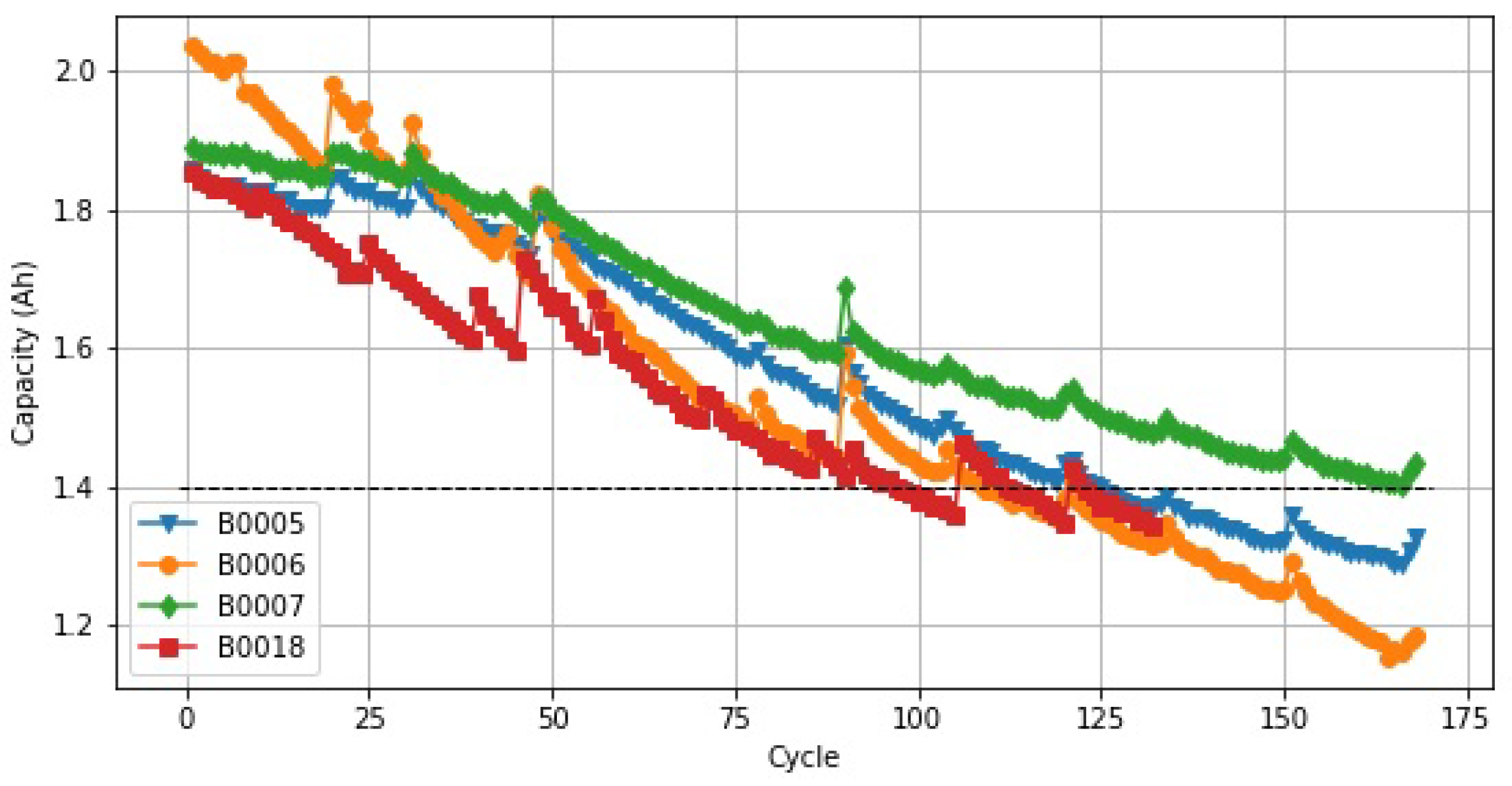

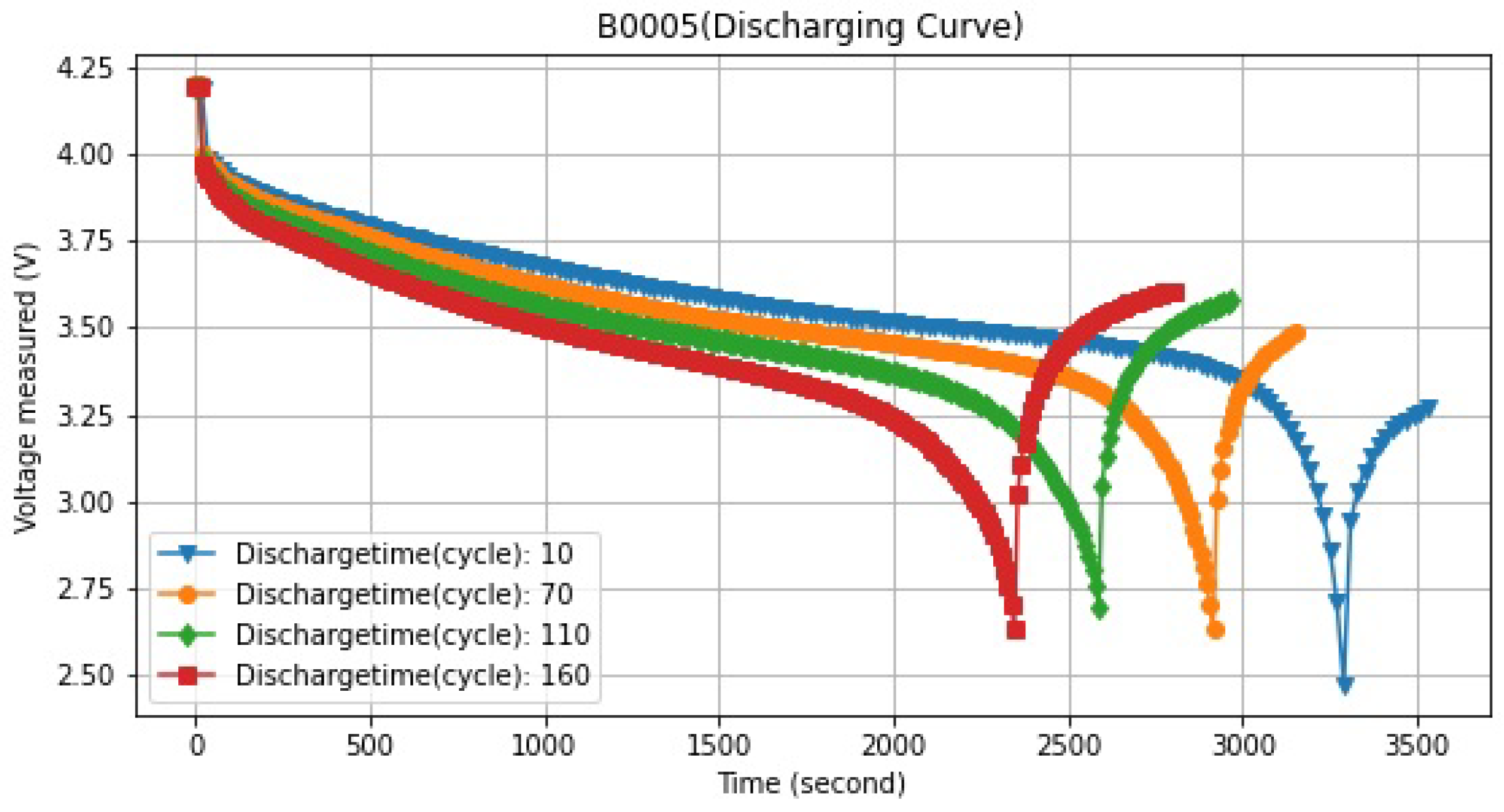

4. Dataset Description

Lithium-Ion Battery Dataset

5. Result and Discussion

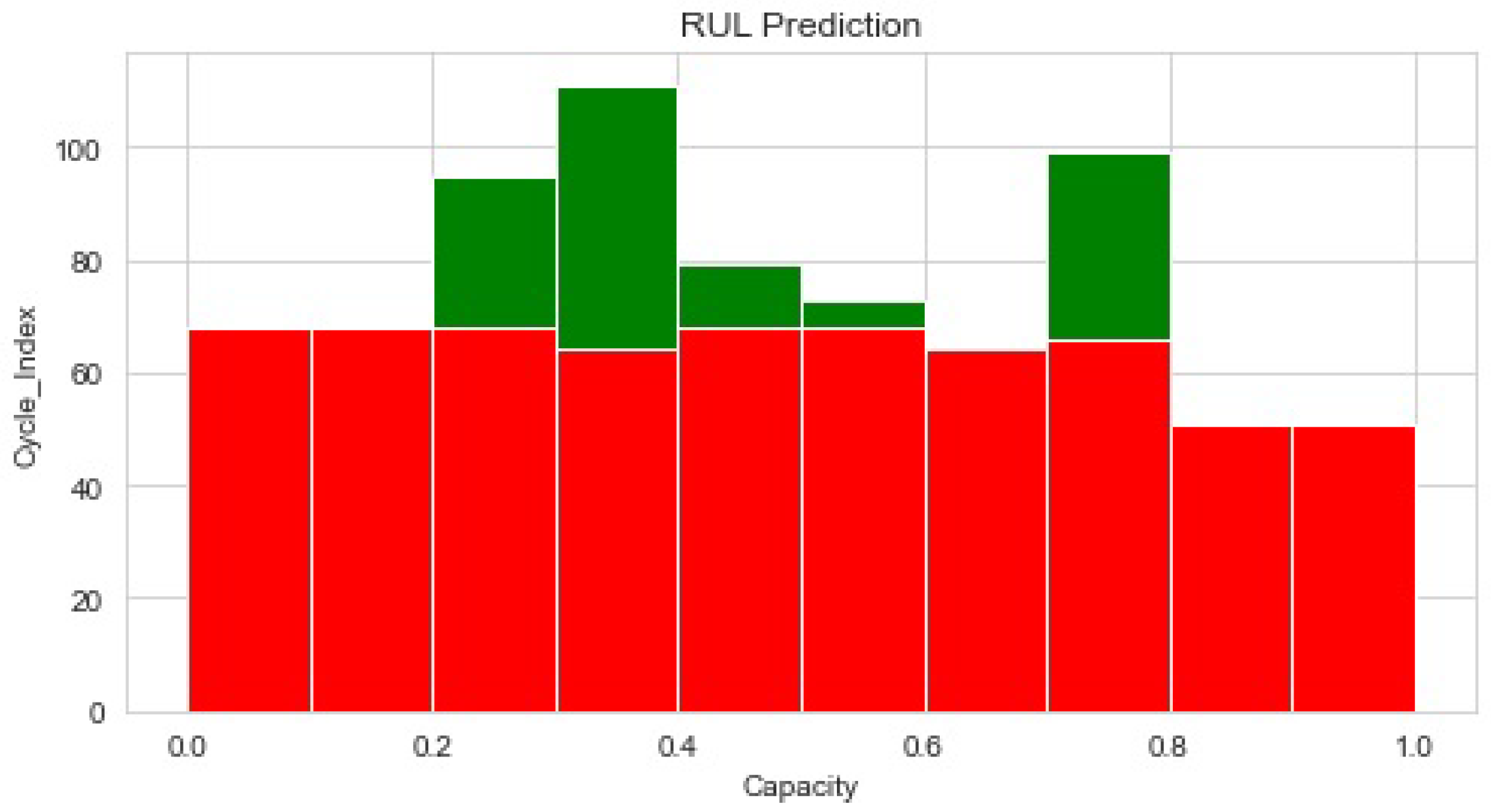

5.1. Battery RUL Prediction

5.2. The Parameters of XGBoost

5.3. Evaluation Index

6. Conclusions

7. Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Zhang, C.; Chen, Z. A method for joint estimation of state-of-charge and available energy of LiFePO4 batteries. Appl. Energy 2014, 135, 81–87. [Google Scholar] [CrossRef]

- Jafari, S.; Shahbazi, Z.; Byun, Y.C.; Lee, S.J. Lithium-Ion Battery Estimation in Online Framework Using Extreme Gradient Boosting Machine Learning Approach. Mathematics 2022, 10, 888. [Google Scholar] [CrossRef]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; Van Mierlo, J.; Van den Bossche, P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Hu, X.; Feng, F.; Liu, K.; Zhang, L.; Xie, J.; Liu, B. State estimation for advanced battery management: Key challenges and future trends. Renew. Sustain. Energy Rev. 2019, 114, 109334. [Google Scholar] [CrossRef]

- Jafari, S.; Shahbazi, Z.; Byun, Y.C. Improving the Road and Traffic Control Prediction Based on Fuzzy Logic Approach in Multiple Intersections. Mathematics 2022, 10, 2832. [Google Scholar] [CrossRef]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. ETransportation 2019, 1, 100005. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Z.; Zhang, C. On-line remaining energy prediction: A case study in embedded battery management system. Appl. Energy 2017, 194, 688–695. [Google Scholar] [CrossRef]

- Tong, S.; Klein, M.P.; Park, J.W. On-line optimization of battery open circuit voltage for improved state-of-charge and state-of-health estimation. J. Power Sources 2015, 293, 416–428. [Google Scholar] [CrossRef]

- Choi, Y.; Ryu, S.; Park, K.; Kim, H. Machine learning-based lithium-ion battery capacity estimation exploiting multi-channel charging profiles. IEEE Access 2019, 7, 75143–75152. [Google Scholar] [CrossRef]

- Jafari, S.; Shahbazi, Z.; Byun, Y.C. Lithium-Ion Battery Health Prediction on Hybrid Vehicles Using Machine Learning Approach. Energies 2022, 15, 4753. [Google Scholar] [CrossRef]

- Bi, J.; Zhang, T.; Yu, H.; Kang, Y. State-of-health estimation of lithium-ion battery packs in electric vehicles based on genetic resampling particle filter. Appl. Energy 2016, 182, 558–568. [Google Scholar] [CrossRef]

- Hu, X.; Jiang, J.; Cao, D.; Egardt, B. Battery health prognosis for electric vehicles using sample entropy and sparse Bayesian predictive modeling. IEEE Trans. Ind. Electron. 2015, 63, 2645–2656. [Google Scholar] [CrossRef]

- Khan, P.W.; Byun, Y.C. Smart contract centric inference engine for intelligent electric vehicle transportation system. Sensors 2020, 20, 4252. [Google Scholar] [CrossRef]

- Liao, L.; Köttig, F. Review of hybrid prognostics approaches for remaining useful life prediction of engineered systems, and an application to battery life prediction. IEEE Trans. Reliab. 2014, 63, 191–207. [Google Scholar] [CrossRef]

- Lyu, C.; Lai, Q.; Ge, T.; Yu, H.; Wang, L.; Ma, N. A lead-acid battery’s remaining useful life prediction by using electrochemical model in the Particle Filtering framework. Energy 2017, 120, 975–984. [Google Scholar] [CrossRef]

- Wu, Y.; Xue, Q.; Shen, J.; Lei, Z.; Chen, Z.; Liu, Y. State of health estimation for lithium-ion batteries based on healthy features and long short-term memory. IEEE Access 2020, 8, 28533–28547. [Google Scholar] [CrossRef]

- Xian, W.; Long, B.; Li, M.; Wang, H. Prognostics of lithium-ion batteries based on the verhulst model, particle swarm optimization and particle filter. IEEE Trans. Instrum. Meas. 2013, 63, 2–17. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, L.; Zhang, L.; Huang, C. State-of-charge estimation of lithium-ion battery pack by using an adaptive extended Kalman filter for electric vehicles. J. Energy Storage 2021, 37, 102457. [Google Scholar] [CrossRef]

- Vidal, C.; Malysz, P.; Kollmeyer, P.; Emadi, A. Machine learning applied to electrified vehicle battery state of charge and state of health estimation: State-of-the-art. IEEE Access 2020, 8, 52796–52814. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, W.; Yang, K.; Zhang, S. Remaining useful life prediction of lithium-ion batteries based on attention mechanism and bidirectional long short-term memory network. Measurement 2022, 204, 112093. [Google Scholar] [CrossRef]

- Ansari, S.; Ayob, A.; Lipu, M.H.; Hussain, A.; Saad, M.H.M. Particle swarm optimized data-driven model for remaining useful life prediction of lithium-ion batteries by systematic sampling. J. Energy Storage 2022, 56, 106050. [Google Scholar] [CrossRef]

- Reda, M.; Rachid, C. Control Strategy for DC Bus Voltage Regulation in Photovoltaic System with Battery Energy. Int. J. Eng. Tech. Res 2015, 4, 315–322. [Google Scholar]

- Cao, Y.; Abu Qahouq, J.A. Evaluation of bi-directional single-inductor multi-input battery system with state-of-charge balancing control. IET Power Electron. 2018, 11, 2140–2150. [Google Scholar] [CrossRef]

- Cao, Y.; Qahouq, J.A.A. Controller Evaluation of Wirelessly Distributed and Enabled Battery Energy Storage System under Unequal Battery Modules Capacity Values. In Proceedings of the 2019 IEEE Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 17–21 March 2019; pp. 1738–1742. [Google Scholar]

- Jafari, S.; Shahbazi, Z.; Byun, Y.C. Designing the Controller-Based Urban Traffic Evaluation and Prediction Using Model Predictive Approach. Appl. Sci. 2022, 12, 1992. [Google Scholar] [CrossRef]

- Peng, J.; Zhou, Z.; Wang, J.; Wu, D.; Guo, Y. Residual remaining useful life prediction method for lithium-ion batteries in satellite with incomplete healthy historical data. IEEE Access 2019, 7, 127788–127799. [Google Scholar] [CrossRef]

- Gabbar, H.A.; Othman, A.M.; Abdussami, M.R. Review of battery management systems (BMS) development and industrial standards. Technologies 2021, 9, 28. [Google Scholar] [CrossRef]

- Jafari, S.; Shahbazi, Z.; Byun, Y.C. Improving the Performance of Single-Intersection Urban Traffic Networks Based on a Model Predictive Controller. Sustainability 2021, 13, 5630. [Google Scholar] [CrossRef]

- Shahbazi, Z.; Byun, Y.C. Machine Learning-Based Analysis of Cryptocurrency Market Financial Risk Management. IEEE Access 2022, 10, 37848–37856. [Google Scholar] [CrossRef]

- Xing, Y.; Ma, E.W.; Tsui, K.L.; Pecht, M. Battery management systems in electric and hybrid vehicles. Energies 2011, 4, 1840–1857. [Google Scholar] [CrossRef]

- Liu, K.; Hu, X.; Wei, Z.; Li, Y.; Jiang, Y. Modified Gaussian process regression models for cyclic capacity prediction of lithium-ion batteries. IEEE Trans. Transp. Electrif. 2019, 5, 1225–1236. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Y.; Gao, Y.; Wang, F.; Mu, B.; Zhang, W. Accelerated fading recognition for lithium-ion batteries with Nickel-Cobalt-Manganese cathode using quantile regression method. Appl. Energy 2019, 256, 113841. [Google Scholar] [CrossRef]

- Liu, H.; Chen, F.; Tong, Y.; Wang, Z.; Yu, X.; Huang, R. Impacts of Driving Conditions on EV Battery Pack Life Cycle. World Electr. Veh. J. 2020, 11, 17. [Google Scholar] [CrossRef]

- Ma, J.; Xu, S.; Shang, P.; Qin, W.; Cheng, Y.; Lu, C.; Su, Y.; Chong, J.; Jin, H.; Lin, Y.; et al. Cycle life test optimization for different Li-ion power battery formulations using a hybrid remaining-useful-life prediction method. Appl. Energy 2020, 262, 114490. [Google Scholar] [CrossRef]

- Khumprom, P.; Yodo, N. A data-driven predictive prognostic model for lithium-ion batteries based on a deep learning algorithm. Energies 2019, 12, 660. [Google Scholar] [CrossRef]

- Shahbazi, Z.; Byun, Y.C. NLP-Based Digital Forensic Analysis for Online Social Network Based on System Security. Int. J. Environ. Res. Public Health 2022, 19, 7027. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, G.; Bu, S.; Han, J.; Tang, X.; Pecht, M. Particle learning framework for estimating the remaining useful life of lithium-ion batteries. IEEE Trans. Instrum. Meas. 2016, 66, 280–293. [Google Scholar] [CrossRef]

- Zhang, H.; Mo, Z.; Wang, J.; Miao, Q. Nonlinear-drifted fractional brownian motion with multiple hidden state variables for remaining useful life prediction of lithium-ion batteries. IEEE Trans. Reliab. 2019, 69, 768–780. [Google Scholar] [CrossRef]

- Chatterjee, S.; Byun, Y.C. EEG-Based Emotion Classification Using Stacking Ensemble Approach. Sensors 2022, 22, 8550. [Google Scholar] [CrossRef]

- Ma, J.; Shang, P.; Zou, X.; Ma, N.; Ding, Y.; Su, Y.; Chong, J.; Jin, H.; Lin, Y. Remaining Useful Life Transfer Prediction and Cycle Life Test Optimization for Different Formula Li-ion Power Batteries Using a Robust Deep Learning Method. IFAC-PapersOnLine 2020, 53, 54–59. [Google Scholar] [CrossRef]

- Hong, J.; Lee, D.; Jeong, E.R.; Yi, Y. Towards the swift prediction of the remaining useful life of lithium-ion batteries with end-to-end deep learning. Appl. Energy 2020, 278, 115646. [Google Scholar] [CrossRef]

- Lee, C.J.; Kim, B.K.; Kwon, M.K.; Nam, K.; Kang, S.W. Real-time prediction of capacity fade and remaining useful life of lithium-ion batteries based on charge/discharge characteristics. Electronics 2021, 10, 846. [Google Scholar] [CrossRef]

- Tang, X.; Liu, K.; Wang, X.; Gao, F.; Macro, J.; Widanage, W.D. Model migration neural network for predicting battery aging trajectories. IEEE Trans. Transp. Electrif. 2020, 6, 363–374. [Google Scholar] [CrossRef]

- Khan, P.W.; Byun, Y.C. Optimal Photovoltaic Panel Direction and Tilt Angle Prediction Using Stacking Ensemble Learning. Front. Energy Res. 2022, 10. [Google Scholar] [CrossRef]

- She, C.; Wang, Z.; Sun, F.; Liu, P.; Zhang, L. Battery aging assessment for real-world electric buses based on incremental capacity analysis and radial basis function neural network. IEEE Trans. Ind. Inform. 2019, 16, 3345–3354. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, C.; Chen, Z. An online method for lithium-ion battery remaining useful life estimation using importance sampling and neural networks. Appl. Energy 2016, 173, 134–140. [Google Scholar] [CrossRef]

- Zhang, L.; Mu, Z.; Sun, C. Remaining useful life prediction for lithium-ion batteries based on exponential model and particle filter. IEEE Access 2018, 6, 17729–17740. [Google Scholar] [CrossRef]

- Pan, H.; Chen, C.; Gu, M. A Method for Predicting the Remaining Useful Life of Lithium Batteries Considering Capacity Regeneration and Random Fluctuations. Energies 2022, 15, 2498. [Google Scholar] [CrossRef]

- Patil, M.A.; Tagade, P.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Yeo, T.; Doo, S. A novel multistage Support Vector Machine based approach for Li ion battery remaining useful life estimation. Appl. Energy 2015, 159, 285–297. [Google Scholar] [CrossRef]

- Zheng, Y.; Shi, Z.; Guo, D.; Dai, H.; Han, X. A simplification of the time-domain equivalent circuit model for lithium-ion batteries based on low-frequency electrochemical impedance spectra. J. Power Sources 2021, 489, 229505. [Google Scholar] [CrossRef]

- Zheng, S.; Ristovski, K.; Farahat, A.; Gupta, C. Long short-term memory network for remaining useful life estimation. In Proceedings of the 2017 IEEE International Conference on Prognostics and Health Management (ICPHM), Dallas, TX, USA, 19–21 June 2017; pp. 88–95. [Google Scholar]

- Zheng, Y.; Ouyang, M.; Han, X.; Lu, L.; Li, J. Investigating the error sources of the online state of charge estimation methods for lithium-ion batteries in electric vehicles. J. Power Sources 2018, 377, 161–188. [Google Scholar] [CrossRef]

- Zhao, G.; Zhang, G.; Liu, Y.; Zhang, B.; Hu, C. Lithium-ion battery remaining useful life prediction with deep belief network and relevance vector machine. In Proceedings of the 2017 IEEE International Conference on Prognostics and Health Management (ICPHM), Dallas, TX, USA, 19–21 June 2017; pp. 7–13. [Google Scholar]

- Zhou, B.; Cheng, C.; Ma, G.; Zhang, Y. Remaining useful life prediction of lithium-ion battery based on attention mechanism with positional encoding. IOP Conf. Ser. Mater. Sci. Eng. 2020, 895, 012006. [Google Scholar] [CrossRef]

- Jafari, S.; Shahbazi, Z.; Byun, Y.C. Traffic Control Prediction Design Based on Fuzzy Logic and Lyapunov Approaches to Improve the Performance of Road Intersection. Processes 2021, 9, 2205. [Google Scholar] [CrossRef]

- Park, K.; Choi, Y.; Choi, W.J.; Ryu, H.Y.; Kim, H. LSTM-based battery remaining useful life prediction with multi-channel charging profiles. IEEE Access 2020, 8, 20786–20798. [Google Scholar] [CrossRef]

- Ungurean, L.; Micea, M.V.; Carstoiu, G. Online state of health prediction method for lithium-ion batteries, based on gated recurrent unit neural networks. Int. J. Energy Res. 2020, 44, 6767–6777. [Google Scholar] [CrossRef]

- Tao, T.; Zio, E.; Zhao, W. A novel support vector regression method for online reliability prediction under multi-state varying operating conditions. Reliab. Eng. Syst. Saf. 2018, 177, 35–49. [Google Scholar] [CrossRef]

- Li, Y.; Li, K.; Liu, X.; Wang, Y.; Zhang, L. Lithium-ion battery capacity estimation—A pruned convolutional neural network approach assisted with transfer learning. Appl. Energy 2021, 285, 116410. [Google Scholar] [CrossRef]

- Fan, L.; Wang, P.; Cheng, Z. A remaining capacity estimation approach of lithium-ion batteries based on partial charging curve and health feature fusion. J. Energy Storage 2021, 43, 103115. [Google Scholar] [CrossRef]

- Xu, X.; Tang, S.; Yu, C.; Xie, J.; Han, X.; Ouyang, M. Remaining useful life prediction of lithium-ion batteries based on wiener process under time-varying temperature condition. Reliab. Eng. Syst. Saf. 2021, 214, 107675. [Google Scholar] [CrossRef]

- Wu, Y.; Li, W.; Wang, Y.; Zhang, K. Remaining useful life prediction of lithium-ion batteries using neural network and bat-based particle filter. IEEE Access 2019, 7, 54843–54854. [Google Scholar] [CrossRef]

- Gou, B.; Xu, Y.; Feng, X. State-of-health estimation and remaining-useful-life prediction for lithium-ion battery using a hybrid data-driven method. IEEE Trans. Veh. Technol. 2020, 69, 10854–10867. [Google Scholar] [CrossRef]

- Sorenson, H.W.; Alspach, D.L. Recursive Bayesian estimation using Gaussian sums. Automatica 1971, 7, 465–479. [Google Scholar] [CrossRef]

- Carpenter, J.; Clifford, P.; Fearnhead, P. Improved particle filter for nonlinear problems. IEE Proc.-Radar Sonar Navig. 1999, 146, 2–7. [Google Scholar] [CrossRef]

- Kalman, R.E. A new approach to linear filtering and prediction problems. J. Basic Eng. 1960, 82, 35–45. [Google Scholar] [CrossRef]

- Khan, P.W.; Byun, Y.C.; Lee, S.J.; Park, N. Machine Learning Based Hybrid System for Imputation and Efficient Energy Demand Forecasting. Energies 2020, 13, 2681. [Google Scholar]

- Saha, B.; Goebel, K. Battery Data Set. NASA Ames Prognostics Data Repository, NASA Ames Research Center, Moffett Field, CA. 2007. Available online: https://www.nasa.gov/intelligent-systems-division (accessed on 19 September 2022).

- Kong, Z.; Cui, Y.; Xia, Z.; Lv, H. Convolution and long short-term memory hybrid deep neural networks for remaining useful life prognostics. Appl. Sci. 2019, 9, 4156. [Google Scholar] [CrossRef]

- Ma, Z.; Chen, M.; Cao, J.; Yao, Y.; Liu, Y. Suitable feature selection for prediction of lithium-ion batteries remaining useful life. In Proceedings of the 2020 7th International Conference on Information, Cybernetics, and Computational Social Systems (ICCSS), Guangzhou, China, 13–15 November 2020; pp. 728–732. [Google Scholar]

| Author | Proposed Approach | Type | Benefit |

|---|---|---|---|

| Ungurean et al. [57] | Gated recurrent unit neural network | AI-based | Fast, simple input |

| Tao et al. [58] | Support vector regression | AI-based | Easy implementation, easily updated, robust to outliers |

| Li et al. [59] | Convolutional neural network | AI-based | Cost and time remain on top, high quality and accuracy |

| Fan et al. [60] | Gaussian process regression | Stochastic-based | Ability to provide uncertainty measurements |

| Xu et al. [61] | Wiener process | Stochastic-based | Instrument errors in filtering theory and disturbances |

| Wu et al. [62] | Neural network and bat-based particle filter | Hybrid methods | Optimization, improved accuracy |

| Gou et al. [63] | Hybrid ensemble data-driven | Hybrid methods | Improved accuracy, increased stability and effectiveness |

| Battery Number | Charging Constant Current (A) | Charging Charge Cut-Off Voltage (V) | Discharging Constant Current (A) | Discharge Cutoff (V) | Operating Temperature |

|---|---|---|---|---|---|

| B_5 | 1.5 | 4.2 | 2.0 | 2.7 | 24 °C |

| B_6 | 1.5 | 4.2 | 2.0 | 2.5 | 24 °C |

| B_7 | 1.5 | 4.2 | 2.0 | 2.2 | 24 °C |

| B_18 | 1.5 | 4.2 | 2.0 | 2.5 | 24 °C |

| Sr | Parameter | XGBoost |

|---|---|---|

| 1 | n_estimators | 300 |

| 2 | max_depth | 8 |

| 3 | min_child_weight | 0.01 |

| 4 | n_jobs | 12 |

| 5 | random_state | 42 |

| 6 | verbosity | None |

| 7 | base_score | 0.5 |

| 8 | booster | gbtree |

| Ref-No | Method | RMSE | MAE |

|---|---|---|---|

| [69] | Convolution and long short-term memory hybrid deep neural networks | 16.12% | 13.26% |

| [70] | XCART (classification and regression tree based extreme gradient boosting) | 0.0262% | 0.0184% |

| Proposed method | XGBoost | 0.0179% | 0.0173% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jafari, S.; Byun, Y.-C. XGBoost-Based Remaining Useful Life Estimation Model with Extended Kalman Particle Filter for Lithium-Ion Batteries. Sensors 2022, 22, 9522. https://doi.org/10.3390/s22239522

Jafari S, Byun Y-C. XGBoost-Based Remaining Useful Life Estimation Model with Extended Kalman Particle Filter for Lithium-Ion Batteries. Sensors. 2022; 22(23):9522. https://doi.org/10.3390/s22239522

Chicago/Turabian StyleJafari, Sadiqa, and Yung-Cheol Byun. 2022. "XGBoost-Based Remaining Useful Life Estimation Model with Extended Kalman Particle Filter for Lithium-Ion Batteries" Sensors 22, no. 23: 9522. https://doi.org/10.3390/s22239522

APA StyleJafari, S., & Byun, Y.-C. (2022). XGBoost-Based Remaining Useful Life Estimation Model with Extended Kalman Particle Filter for Lithium-Ion Batteries. Sensors, 22(23), 9522. https://doi.org/10.3390/s22239522