Combined Acoustic Emission and Digital Image Correlation for Early Detection and Measurement of Fatigue Cracks in Rails and Train Parts under Dynamic Loading

Abstract

1. Introduction

2. Experimental Protocol

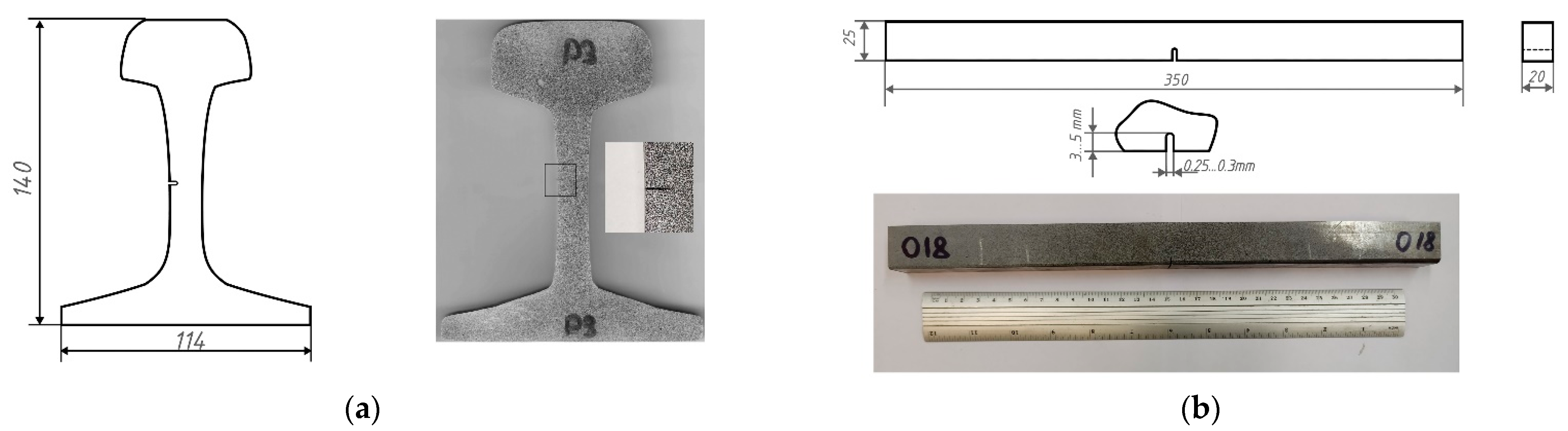

2.1. Samples Preparation

2.2. Experimental Setup

2.3. Data Processing

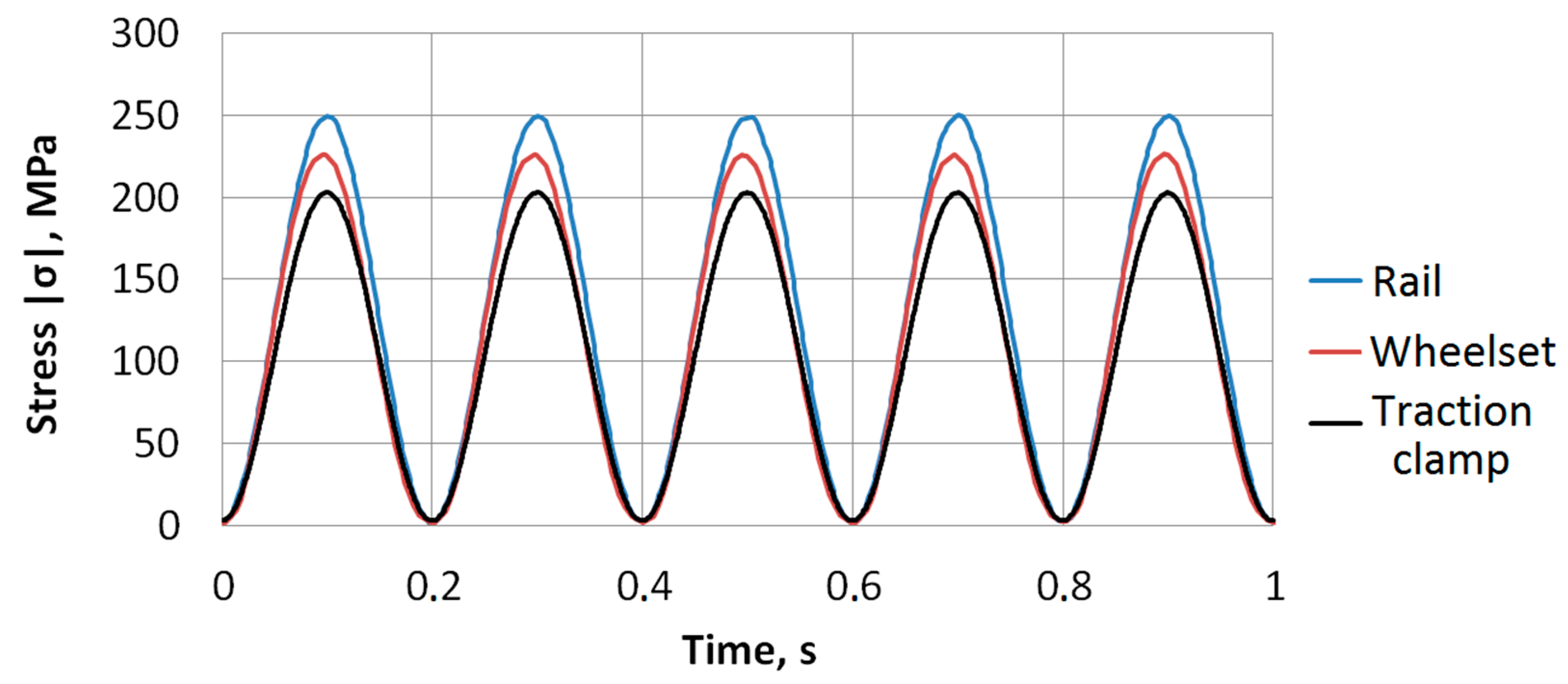

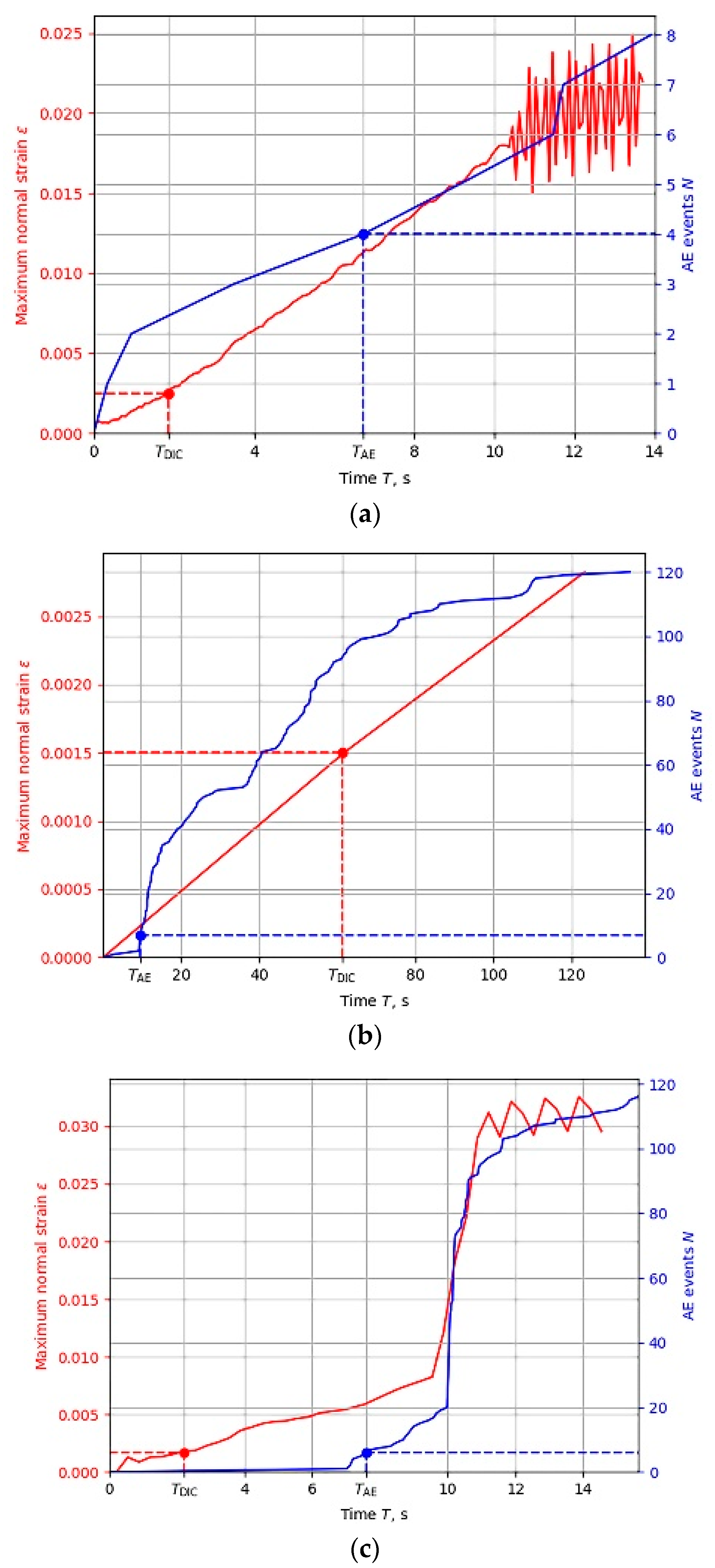

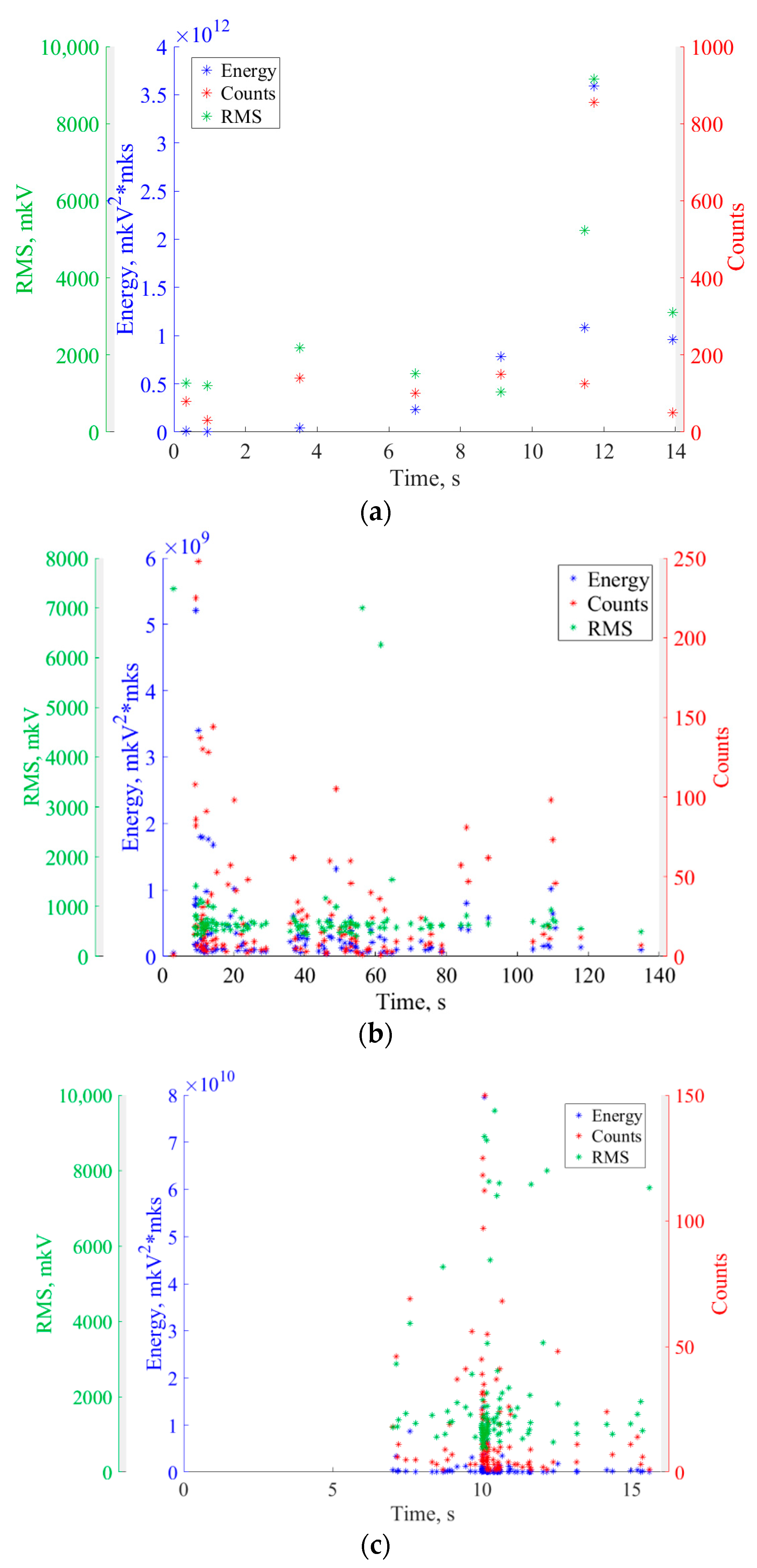

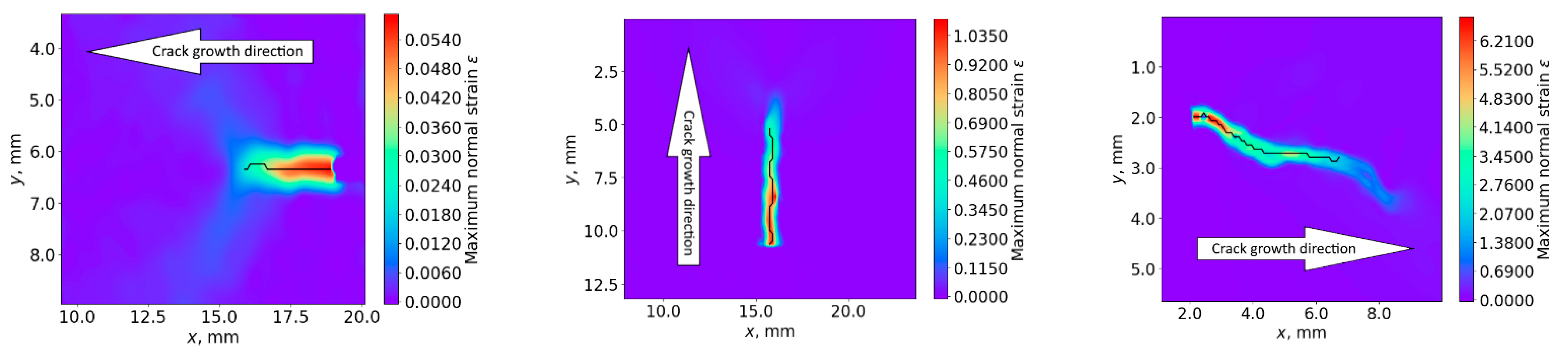

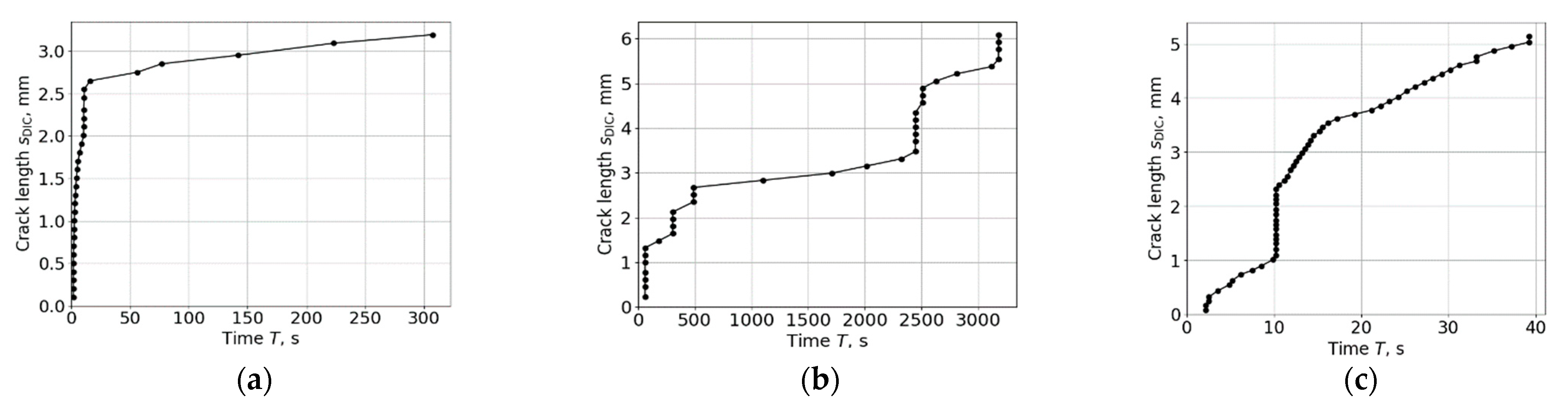

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bowler, N.; Gibson, H.R. Fatigue and Its Contribution to Railway Incidents. 2015. Available online: https://www.sintef.no/globalassets/project/hfc/2015-02-str-fatigue-contribution-to-railway-incidents.pdf (accessed on 1 February 2015).

- Li, Y.D.; Xu, N.; Wu, X.F.; Guo, W.M.; Shi, J.B. A failure study of the railway rail serviced for heavy cargo trains. Case Stud. Eng. Fail. Anal 2013, 1, 243–248. [Google Scholar] [CrossRef]

- Smith, R.A. Railway fatigue failures: An overview of a long standing problem. Mater. Werkst. Entwickl. Fert. Prüfung Eig. Anwend. Tech. Werkst. 2005, 36, 697–705. [Google Scholar] [CrossRef]

- Ekberg, A.; Elena, K. Fatigue of railway wheels and rails under rolling contact and thermal loading—An overview. Wear 2005, 258, 1288–1300. [Google Scholar] [CrossRef]

- Vairagi, P.; Surve, T.; Mandavkar, S.; Mhatre, Y.; Hadal, R. Review of Fatigue Crack Growth and Microstructure of Rail. Int. J. Eng. Res. (IJERT) NTASU 2021, 9, 575–578. [Google Scholar] [CrossRef]

- Chunin, V.V.; Knyazev, D.A.; Timakov, M.V. The simulation of crack growth in rolling stock running wheel disk. IOP Conf. Ser. Mater. Sci. Eng. 2020, 747, 012015. [Google Scholar] [CrossRef]

- Ph Papaelias, M.; Davis, C.R.; Claire, L.D. A review on non-destructive evaluation of rails: State-of-the-art and future development. Proc. Inst. Mech. Eng. F J. Rail Rapid Transit. 2008, 222, 367–384. [Google Scholar] [CrossRef]

- Meleshko, N.V.; Makarova, T.I.; Shazinov, S.E. Ultrasonic Testing of Railway Transport Units with Phased Array Flaw Detectors. NDT World 2015, 18, 72–76. [Google Scholar]

- Kuppan Chetty, R.M.; Joshuva, A.; Nikhit Mathew, S.P.; Lokeshwaran, M.; Mohamed Shiham, S.; Rajasekaran, C. A comprehensive review on rail wheel crack inspection system. J. Mech. 2020, 15, 168–184. [Google Scholar] [CrossRef][Green Version]

- Grosse, C.; Ohtsu, M. Acoustic Emission Testing, Basics for Research-Applications in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2008; p. 406. [Google Scholar] [CrossRef]

- McCrory, J.P.; Pearson, M.R.; Pullin, R.; Holford, K.M. Optimisation of acoustic emission wavestreaming for structural health monitoring. Struct. Health Monit. 2020, 19, 2007–2022. [Google Scholar] [CrossRef]

- Harris, D.O.; Dunegan, H.L. Continuous monitoring of fatigue-crack growth by acoustic-emission techniques. Exp. Mech. 1974, 14, 71–81. [Google Scholar] [CrossRef]

- Barat, V.; Marchenkov, A.; Elizarov, S. Estimation of Fatigue Crack AE Emissivity Based on the Palmer–Heald Model. Appl. Sci. 2019, 9, 4851. [Google Scholar] [CrossRef]

- Roberts, T.M.; Talebzadeh, M. Acoustic emission monitoring of fatigue crack propagation. J. Constr. Steel Res. 2003, 59, 695–712. [Google Scholar] [CrossRef]

- Megid, W.A.; Chainey, M.-A.; Lebrun, P.; Hay, D.R. Monitoring fatigue cracks on eyebars of steel bridges using acoustic emission: A case study. Eng. Fract. Mech. 2019, 211, 198–208. [Google Scholar] [CrossRef]

- Saeedifar, M.; Zarouchas, D. Damage characterization of laminated composites using acoustic emission: A review. Compos. Part B-Eng. 2020, 195, 108039. [Google Scholar] [CrossRef]

- Bruzelius, K.; Mba, D. An initial investigation on the potential applicability of Acoustic Emission to rail track fault detection. NDT&E Int 2004, 37, 507–516. [Google Scholar] [CrossRef]

- Bassim, M.N.; St Lawrence, S.; Liu, C.D. Detection of the onset of fatigue crack growth in rail steels using acoustic emission. Eng. Fract. Mech. 1994, 47, 207–214. [Google Scholar] [CrossRef]

- Hao, Q.; Zhang, X.; Wang, K.; Shen, Y.; Wang, Y. A signal-adapted wavelet design method for acoustic emission signals of rail cracks. Appl. Acoust. 2018, 139, 251–258. [Google Scholar] [CrossRef]

- Li, D.; Sze, K.; Kuang, C.; Ghee Koh, C. Rail crack monitoring based on Tsallis synchrosqueezed wavelet entropy of acoustic emission signals: A field study. Struct. Health Monit. 2018, 17, 1410–1424. [Google Scholar] [CrossRef]

- Suwansin, W.; Phasukkit, P. Deep learning-based acoustic emission scheme for nondestructive localization of cracks in train rails under a load. Sensors 2021, 21, 272. [Google Scholar] [CrossRef]

- Carboni, M.; Andrea, G. Feasibility of an Acoustic emission based structural health monitoring for railway axle under fretting fatigue damage. In Proceedings of the 14th International Conference of the Slovenian Society for Non-Destructive Testing Application of Contemporary Non-Destructive Testing in Engineering, Portorož, Slovenia, 4–6 September 2017; pp. 65–72. [Google Scholar]

- Deng, X.-J.; Xui, G.-J.; Liu, S.-Q. Research on Fatigue Crack Detection of Rail Vehicle Axle Based on Acoustic Emission. In Proceedings of the 10th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 1–3 September 2015. [Google Scholar] [CrossRef]

- Bruni, S.; Carboni, M.; Crivelli, D.; Guagliano, M.; Rolek, P. A Preliminary Analysis about the Application of Acoustic Emission and low Frequency Vibration Methods to the Structural Health Monitoring of Railway Axles. Chem. Eng. Trans. 2013, 33, 697–702. [Google Scholar] [CrossRef]

- Bobrov, A.L.; Stepanova, L.N. Studying the parameters of acoustic emission signals during inspection of cast parts of a freight car truck. Russ. J. Nondestruct 2013, 49, 722–727. [Google Scholar] [CrossRef]

- Stepanova, L.N.; Kabanov, S.I.; Lebedev, E.Y. Acoustic Emission Diagnostics of Freight Car Bogie Cast Pieces. Transp. Res. Proc. 2022, 61, 547–555. [Google Scholar] [CrossRef]

- Schreier, H.; Orteu, J.-J.; Sutton, M.A. Image Correlation for Shape, Motion and Deformation Measurements; Springer: New York, NY, USA, 2009; p. 322. [Google Scholar] [CrossRef]

- Brynk, T.; Kurzydlowski, K.J. Coupling of ultrasounds with the Portevin–Le Chatelier serrations as observed in aluminium-magnesium alloy in mini-samples tensile tests. Scr. Mater. 2020, 174, 14–18. [Google Scholar] [CrossRef]

- Gu, J.; Pathak, N.; Freed, S.; Todorov, E.; Kim, H. Application of the Nondestructive Evaluation (NDE) Method to Evaluate the Sheared Edge Quality and Edge Cracking. Form. Future 2021, 1585–1593. [Google Scholar] [CrossRef]

- Bakuckas, J.G., Jr.; Stonaker, K.; Stanley, D.; Tian, Y.; Kulak, M.; Chang, P.-Y.; Freisthler, M.; Rodrigues, M.R.B.; Chaves, C.E. Evaluation of adhesively bonded repairs to fuselage structure subjected to environmental conditions. In Proceedings of the 34th ICAF Conference and 28th ICAF Symposium, Helsinki, Finland, 1–5 June 2015; Volume 1, pp. 349–366. [Google Scholar]

- Alam, S.Y.; Saliba, J.; Loukili, A. Fracture examination in concrete through combined digital image correlation and acoustic emission techniques. Constr. Build. Mater. 2014, 69, 232–242. [Google Scholar] [CrossRef]

- Rouchier, S.; Foray, G.; Godin, N.; Woloszyn, M.; Roux, J.-J. Damage monitoring in fibre reinforced mortar by combined digital image correlation and acoustic emission. Constr. Build. Mater. 2013, 38, 371–380. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Verbruggen, S.; Tsangouri, E.; Tysmans, T.; Hemelrijck, V. Characterization of mechanical performance of concrete beams with external reinforcement by acoustic emission and digital image correlation. Constr. Build. Mater. 2013, 47, 1037–1045. [Google Scholar] [CrossRef]

- Pullin, R.; Eaton, M.J.; Hensman, J.J.; Holford, K.M.; Worden, K.; Evans, S.L. Validation of Acoustic Emission (AE) Crack Detection in Aerospace Grade Steel Using Digital Image Correlation. Int. J. Appl. Mech. Mater. 2010, 24, 221–226. [Google Scholar] [CrossRef]

- Pullin, R.; Clarke, A.; Eaton, M.J.; Holford, K.M.; Evans, S.L.; McCory, J.P. Detection of cracking in gear teeth using Acoustic Emission. Appl. Mech. Mater. 2010, 24, 45–50. [Google Scholar] [CrossRef]

- Shrama, K.; Al-Jumaili, S.K.; Pullin, R.; Clarke, A.; Evans, S.L. On the Use of Acoustic Emission and Digital Image Correlation for Welded Joints Damage Characterization. J. Appl. Comput. Mech. 2019, 5, 381–389. [Google Scholar] [CrossRef]

- Swain, D.; Binu, B.; Purushothaman, K.K.; Rao, G.S.; Thomas, B.P.; Kurian, T.; Narayanan, R.; Philip, J. Use of full-field measurements for understanding acoustic emission (AE) signals from 15CDV6 ESR steel specimens. Procedia Struct. Integr. 2019, 14, 207–214. [Google Scholar] [CrossRef]

- Tanvir, F.; Sattar, T.; Mba, D.; Edwards, G. Identification of fatigue damage evaluation using entropy of acoustic emission waveform. SN Appl. Sci. 2020, 2, 1–15. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, G.; Hu, K. Prediction of Fatigue Crack Growth in Gas Turbine Engine Blades Using Acoustic Emission. Sensors 2018, 18, 1321. [Google Scholar] [CrossRef] [PubMed]

- Meyer, K.A.; Gren, D.; Ahlström, J.; Ekberg, A. A method for in-field railhead crack detection using digital image correlation. Int. J. Rail Transp. 2022, 10, 675–694. [Google Scholar] [CrossRef]

- Barat, V.; Marchenkov, A.; Ivanov, V.; Bardakov, V.; Elizarov, S.; Machikhin, A. Empirical Approach to Defect Detection Probability by Acoustic Emission Testing. Appl. Sci. 2021, 11, 9429. [Google Scholar] [CrossRef]

- Gehri, N.; Mata-Falcón, J.; Kaufmann, W. Automated crack detection and measurement based on digital image correlation. Constr. Build. Mater. 2020, 256, 119383. [Google Scholar] [CrossRef]

- Panwitt, H.; Köster, P.; Sander, M. Automated crack length measurement for mixed mode fatigue cracks using digital image correlation. Procedia Struct. Integr. 2022, 39, 20–33. [Google Scholar] [CrossRef]

- Chai, M.; Lai, C.; Xu, W.; Duan, Q.; Zhang, Z.; Song, Y. Characterization of Fatigue Crack Growth Based on Acoustic Emission Multi-Parameter Analysis. Materials 2022, 15, 6665. [Google Scholar] [CrossRef] [PubMed]

- Aggelis, D.; Kordatos, E.; Matikas, T. Acoustic emission for fatigue damage characterization in metal plates. Mech. Res. Commun. 2011, 38, 106–110. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Kannan, V.P. Application of different acoustic emission descriptors in damage assessment of fiber reinforced plastics: A comprehensive review. Eng. Fract. Mech. 2020, 235, 107083. [Google Scholar] [CrossRef]

- Chai, M.; Hou, X.; Zhang, Z.; Duan, Q. Identification and prediction of fatigue crack growth under different stress ratios usingacoustic emission data. Int. J. Fatigue 2022, 160, 106860. [Google Scholar] [CrossRef]

- EN 13554:2011; Non-Destructive Testing—Acoustic Emission Testing—General Principles. Available online: https://standards.iteh.ai/catalog/standards/cen/1818c70a-d3d8-47f6-a360-e0216f2ff2b1/en-13554-2011 (accessed on 15 March 2011).

- Sebastian, C.; Patterson, E.A. Calibration of a digital image correlation system. Exp. Tech. 2015, 39, 21–29. [Google Scholar] [CrossRef]

- Bardakov, V.; Marchenkov, A.; Poroykov, A.; Machikhin, A.; Sharikova, M.; Meleshko, N. Feasibility of Digital Image Correlation for Fatigue Cracks Detection under Dynamic Loading. Sensors 2021, 21, 6457. [Google Scholar] [CrossRef] [PubMed]

- Bjørheim, F.; Siriwardane, S.C.; Pavlou, D. A review of fatigue damage detection and measurement techniques. Int. J. Fatigue 2022, 154, 106556. [Google Scholar] [CrossRef]

| Acronym | Description | Symbol | Description |

|---|---|---|---|

| NDT | non-destructive testing | σy | yield strength |

| AE | acoustic emission | σ | cycle amplitude |

| DIC | digital image correlation | l | position of the AE source |

| EDM | electrical discharge machining | dlAE | inaccuracy of the AE source position |

| ε | maximum normal strain | N | number of AE events |

| Vx and Vy | displacements detected by DIC | ηTAE | ratio of Nmax and Nmean, when the crack is detected |

| εTDIC | threshold value defined by transition from elastic deformation to plastic in the notch area | Nmax | location maximum of histogram |

| sDIC | crack’s dimension as a length of skeletonized line obtained after processing the field of maximum normal strain | Nmean | mean value over all intervals, except for the maximum |

| f | focal length of the lens | TAE | moment of crack appearance |

| L | distance to the inspected sample | TDIC | moment of crack initiation |

| Δ | pixel pitch of the camera | εx | deformation in x directions |

| n | measured crack’s length in pixels | εy | deformation in y directions |

| Part | Steel | Composition, wt. % | |||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | V | S | P | ||

| Rail | E76F | 0.71–0.82 | 0.25–0.60 | 0.75–1.15 | 0.03–0.15 | ≤0.025 | ≤0.025 |

| Wheelset | OsV | 0.40–0.48 | 0.15–0.35 | 0.55–0.85 | - | ≤0.045 | ≤0.04 |

| Traction clamp | 20GL | 0.15–0.25 | 0.20–0.40 | 1.20–1.60 | - | ≤0.04 | ≤0.04 |

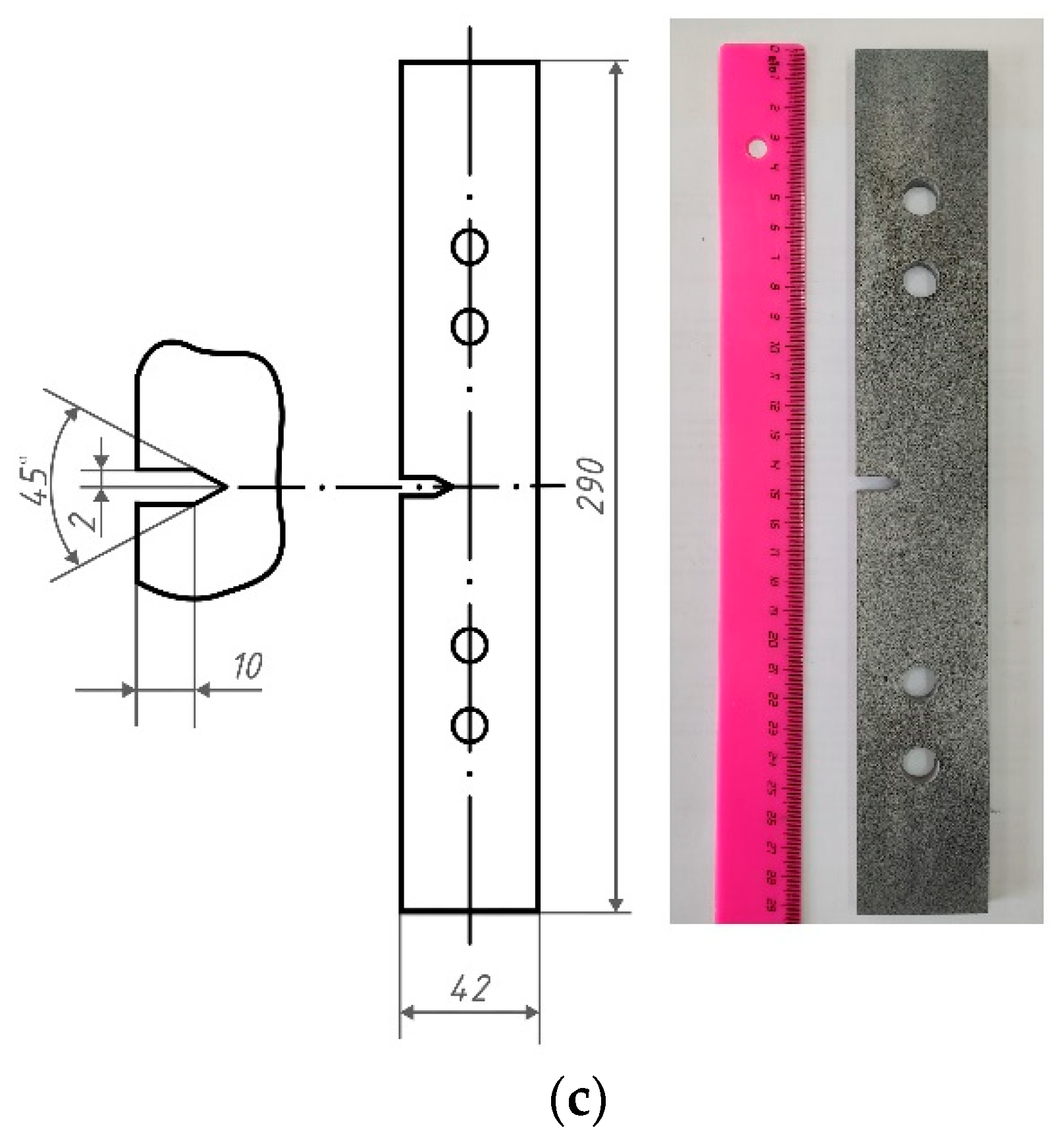

| Part | Type of Stress | Cycle | Frequency, Hz | Cycle Amplitude σ, MPa | Material Yield Stress σy, MPa | σ/σy |

|---|---|---|---|---|---|---|

| Rail | Compressive | Sinusoidal | 5 | 250 | 520 | 0.48 |

| Wheelset | 3-point bending | 230 | 320 | 0.72 | ||

| Traction clamp | Tensile | 200 | 360 | 0.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Machikhin, A.; Poroykov, A.; Bardakov, V.; Marchenkov, A.; Zhgut, D.; Sharikova, M.; Barat, V.; Meleshko, N.; Kren, A. Combined Acoustic Emission and Digital Image Correlation for Early Detection and Measurement of Fatigue Cracks in Rails and Train Parts under Dynamic Loading. Sensors 2022, 22, 9256. https://doi.org/10.3390/s22239256

Machikhin A, Poroykov A, Bardakov V, Marchenkov A, Zhgut D, Sharikova M, Barat V, Meleshko N, Kren A. Combined Acoustic Emission and Digital Image Correlation for Early Detection and Measurement of Fatigue Cracks in Rails and Train Parts under Dynamic Loading. Sensors. 2022; 22(23):9256. https://doi.org/10.3390/s22239256

Chicago/Turabian StyleMachikhin, Alexander, Anton Poroykov, Vladimir Bardakov, Artem Marchenkov, Daria Zhgut, Milana Sharikova, Vera Barat, Natalia Meleshko, and Alexander Kren. 2022. "Combined Acoustic Emission and Digital Image Correlation for Early Detection and Measurement of Fatigue Cracks in Rails and Train Parts under Dynamic Loading" Sensors 22, no. 23: 9256. https://doi.org/10.3390/s22239256

APA StyleMachikhin, A., Poroykov, A., Bardakov, V., Marchenkov, A., Zhgut, D., Sharikova, M., Barat, V., Meleshko, N., & Kren, A. (2022). Combined Acoustic Emission and Digital Image Correlation for Early Detection and Measurement of Fatigue Cracks in Rails and Train Parts under Dynamic Loading. Sensors, 22(23), 9256. https://doi.org/10.3390/s22239256