Piezoelectric Micromachined Ultrasonic Transducers (PMUTs): Performance Metrics, Advancements, and Applications

Abstract

1. Introduction

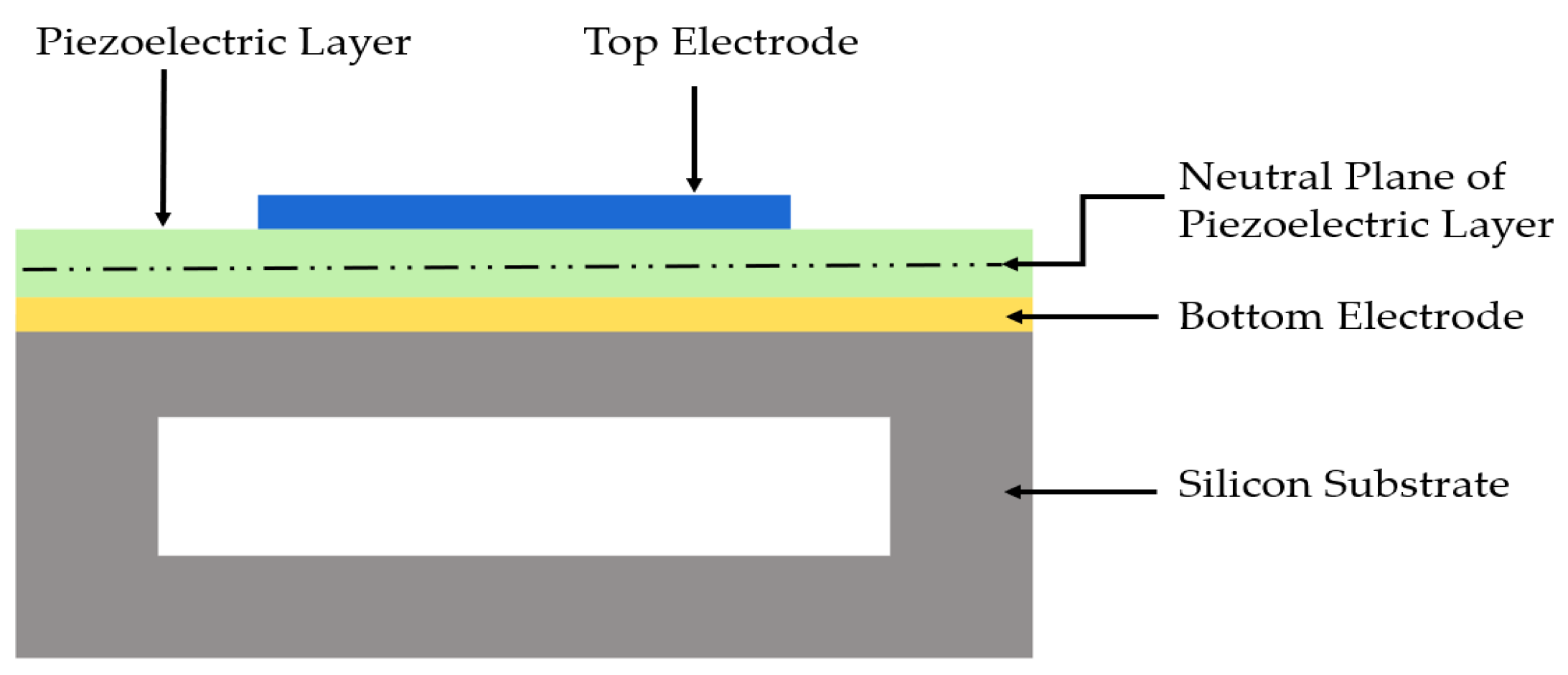

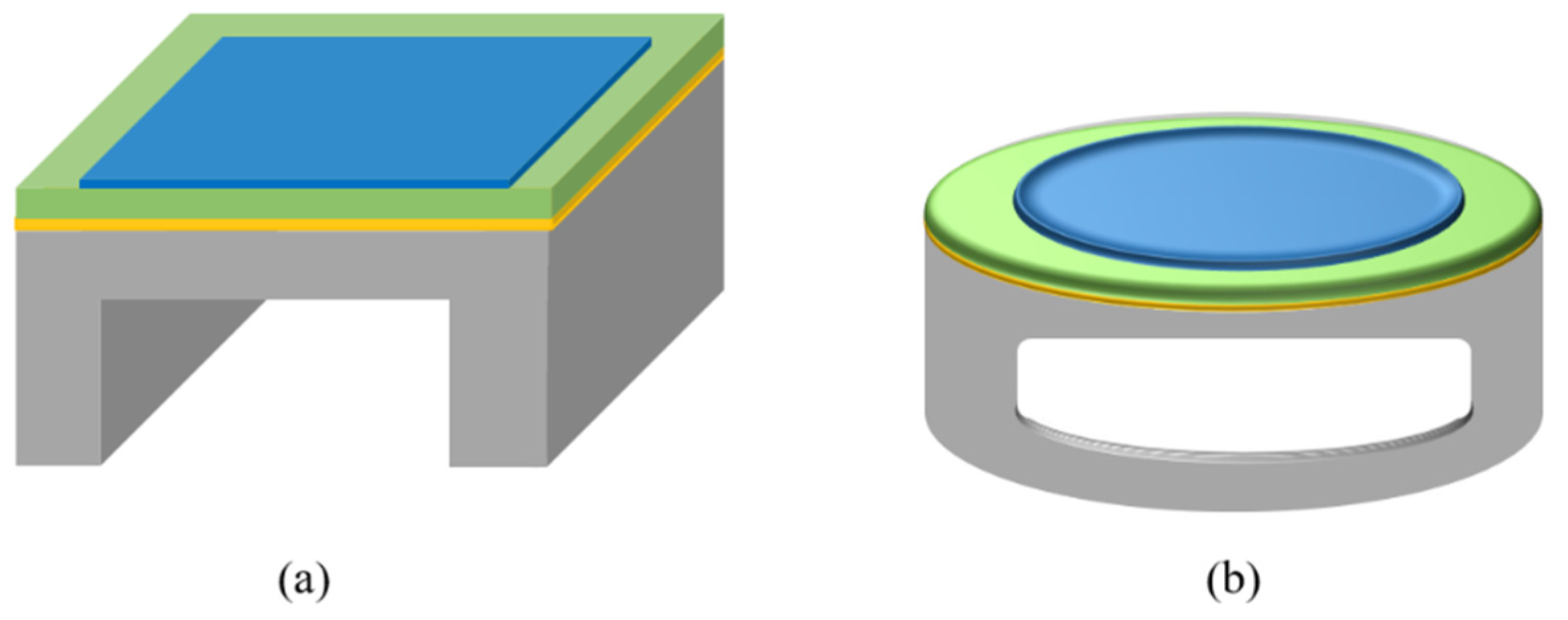

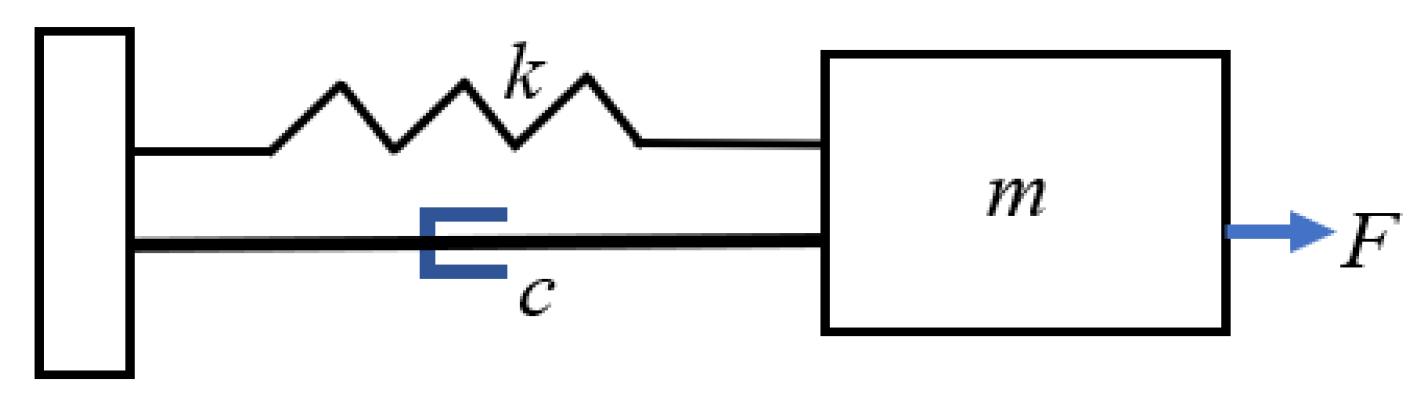

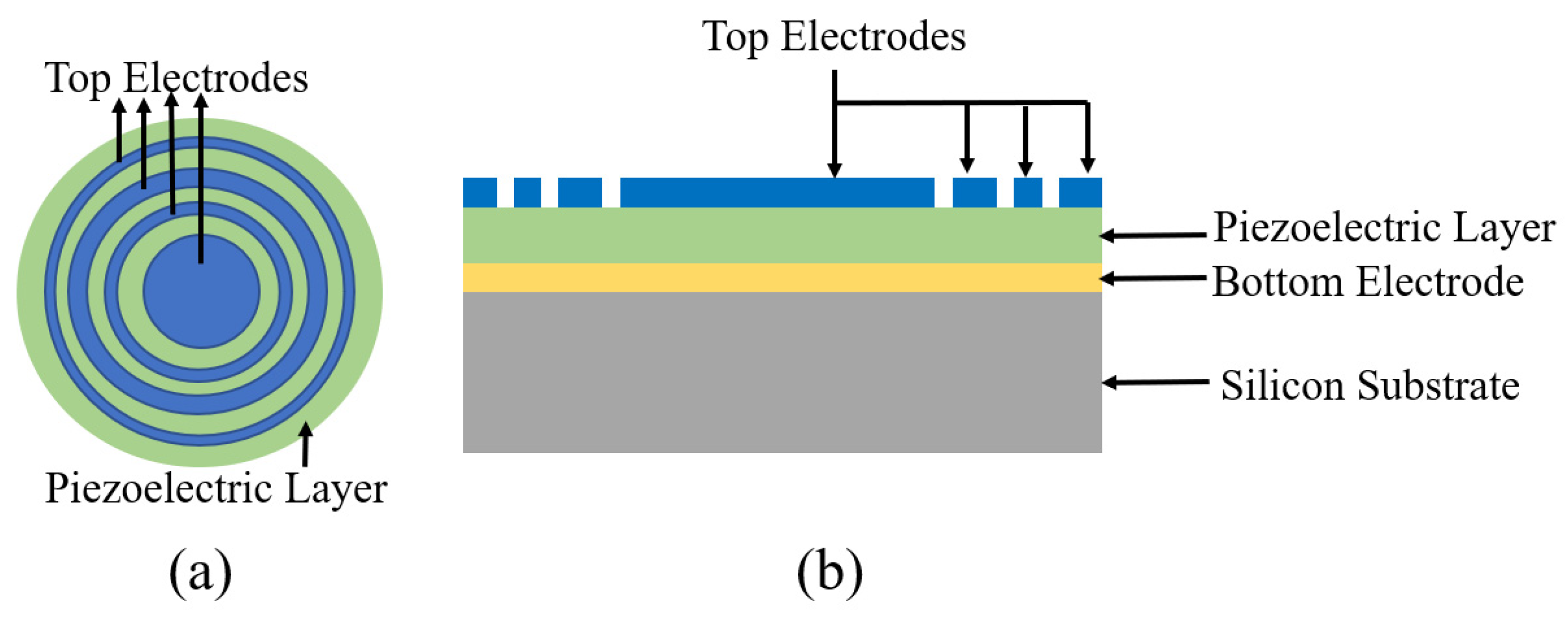

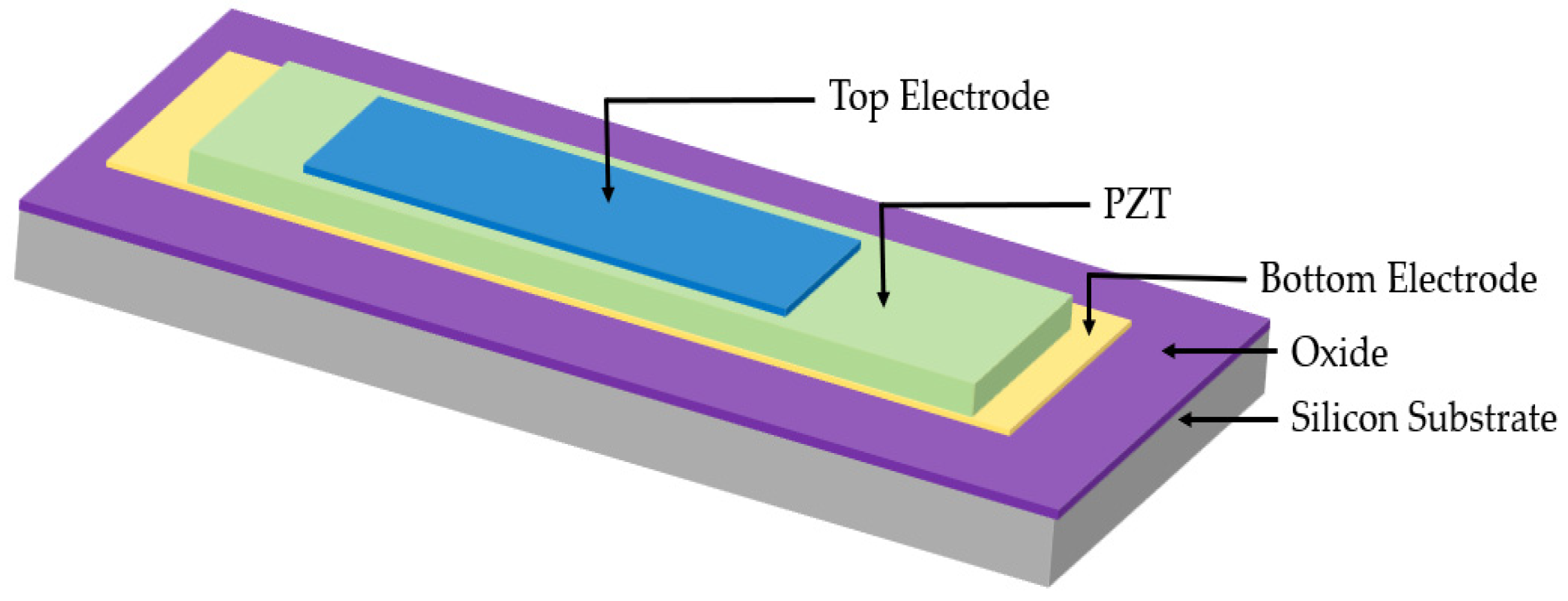

2. PMUT Principle of Operation

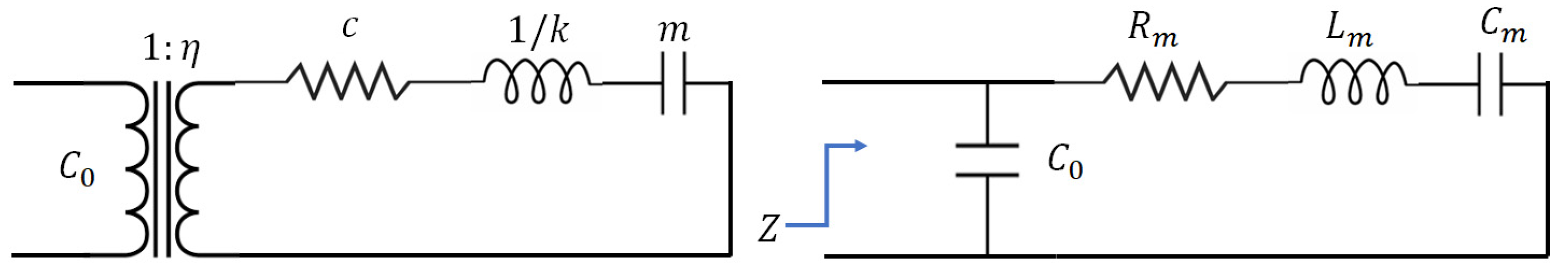

3. PMUT Equivalent Circuit Model and Mechanical Modeling

4. Piezoelectric Materials and Fabrication Techniques for PMUT

4.1. Back-Side Etching

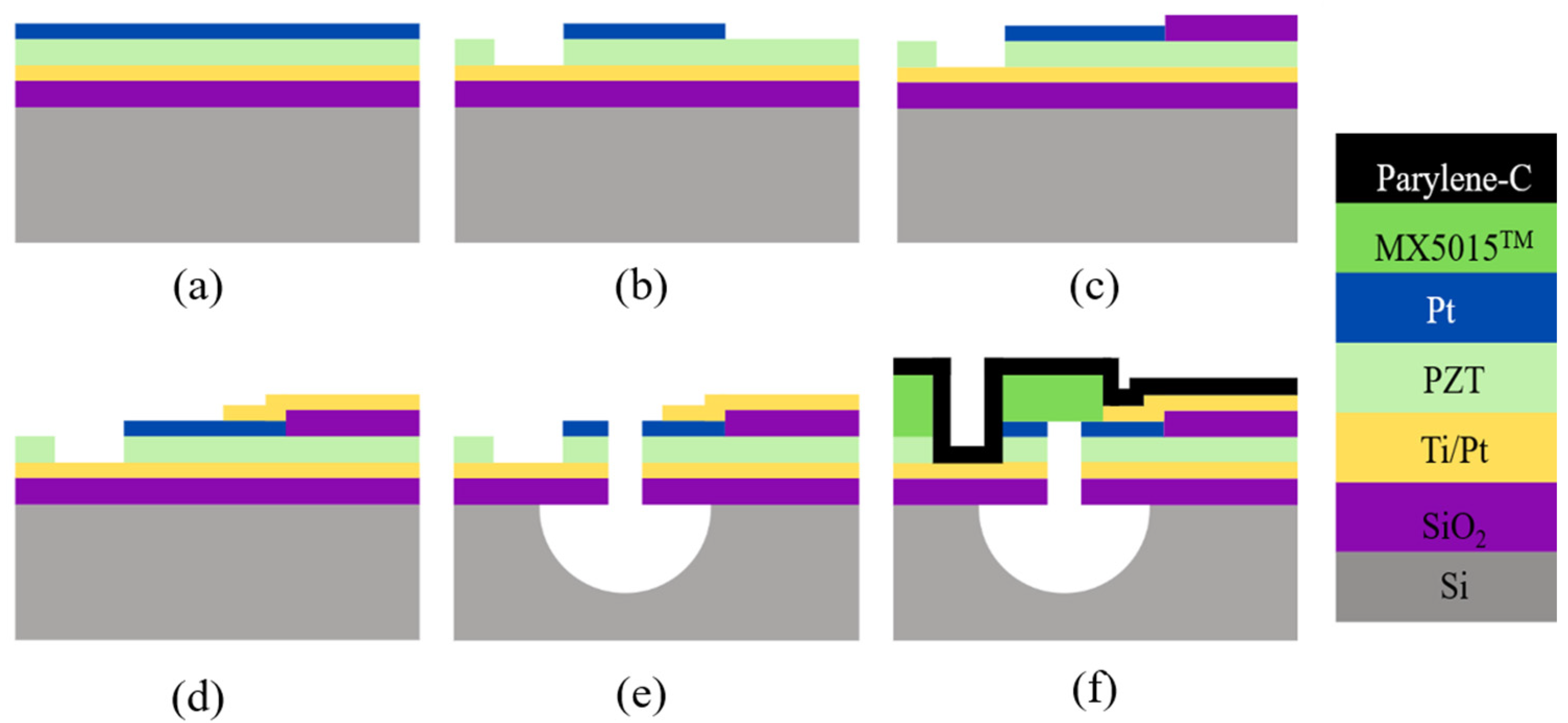

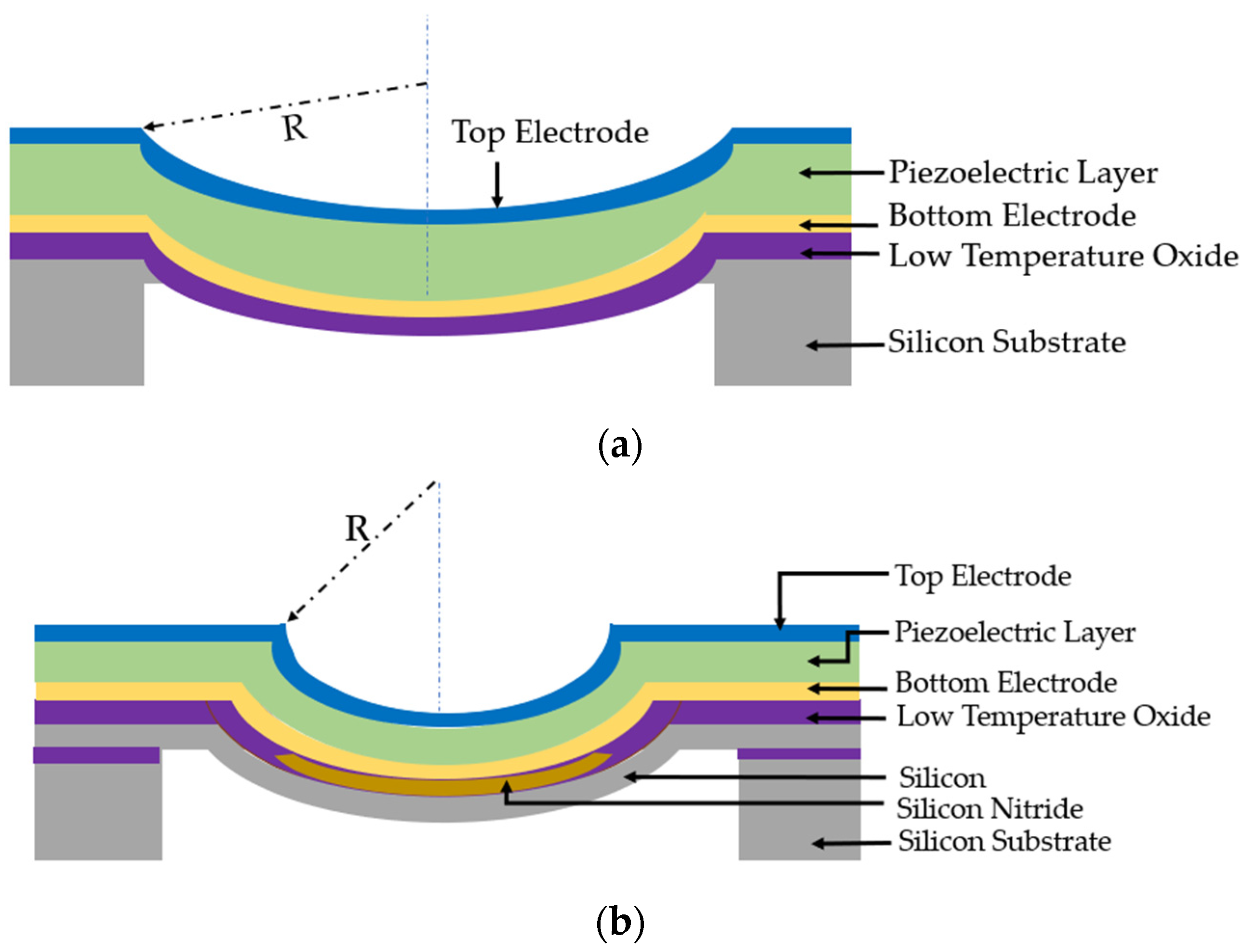

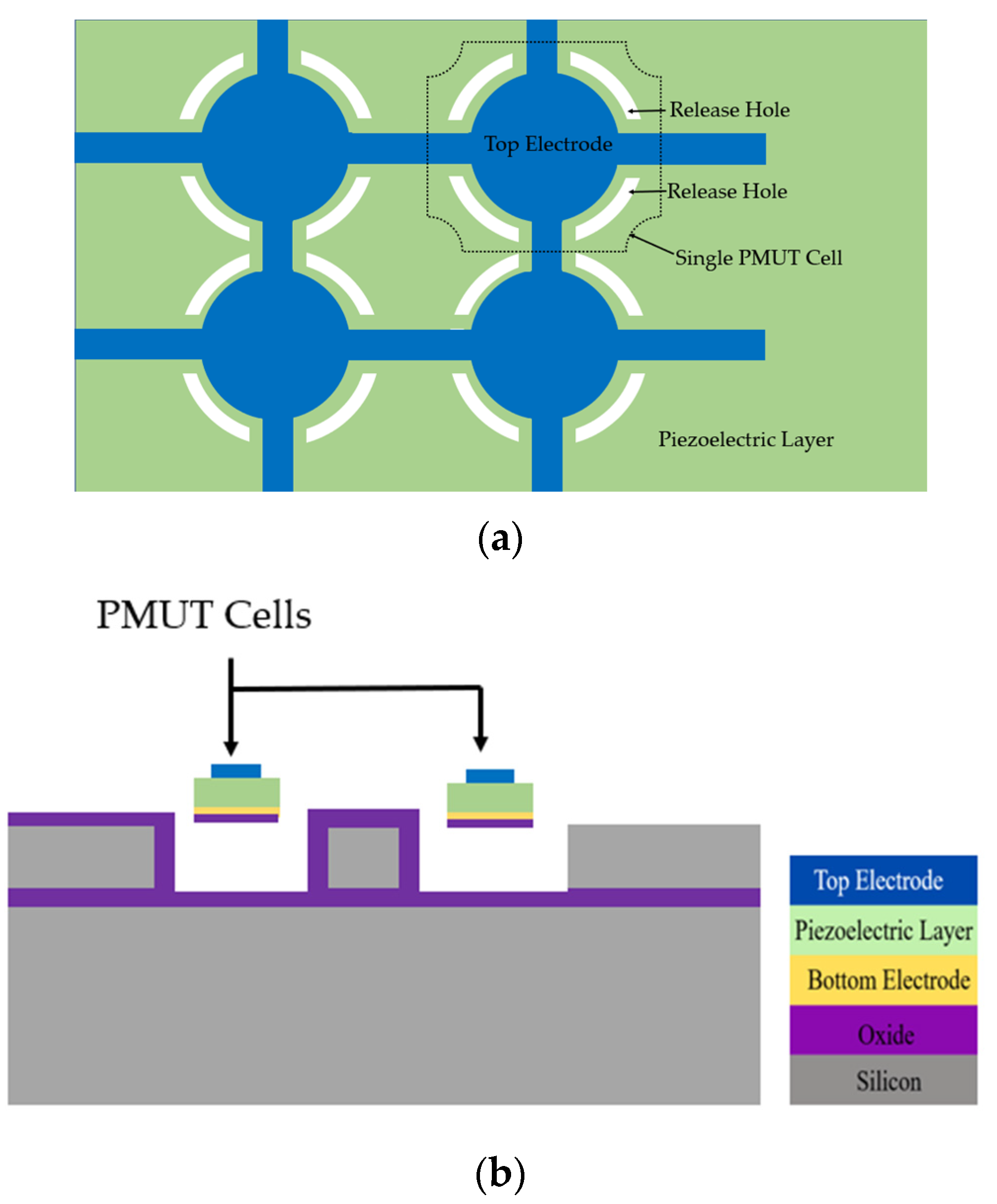

4.2. Front-Side Etching

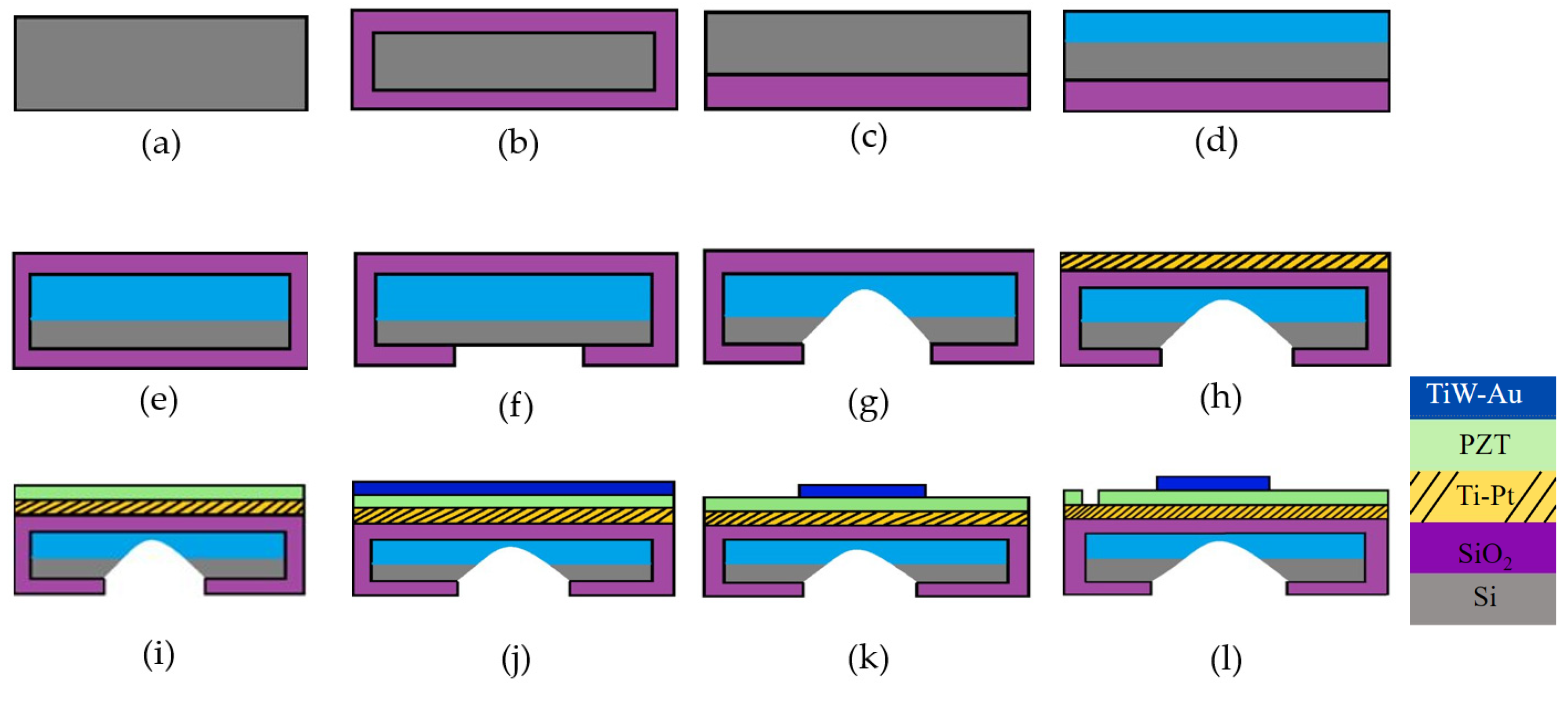

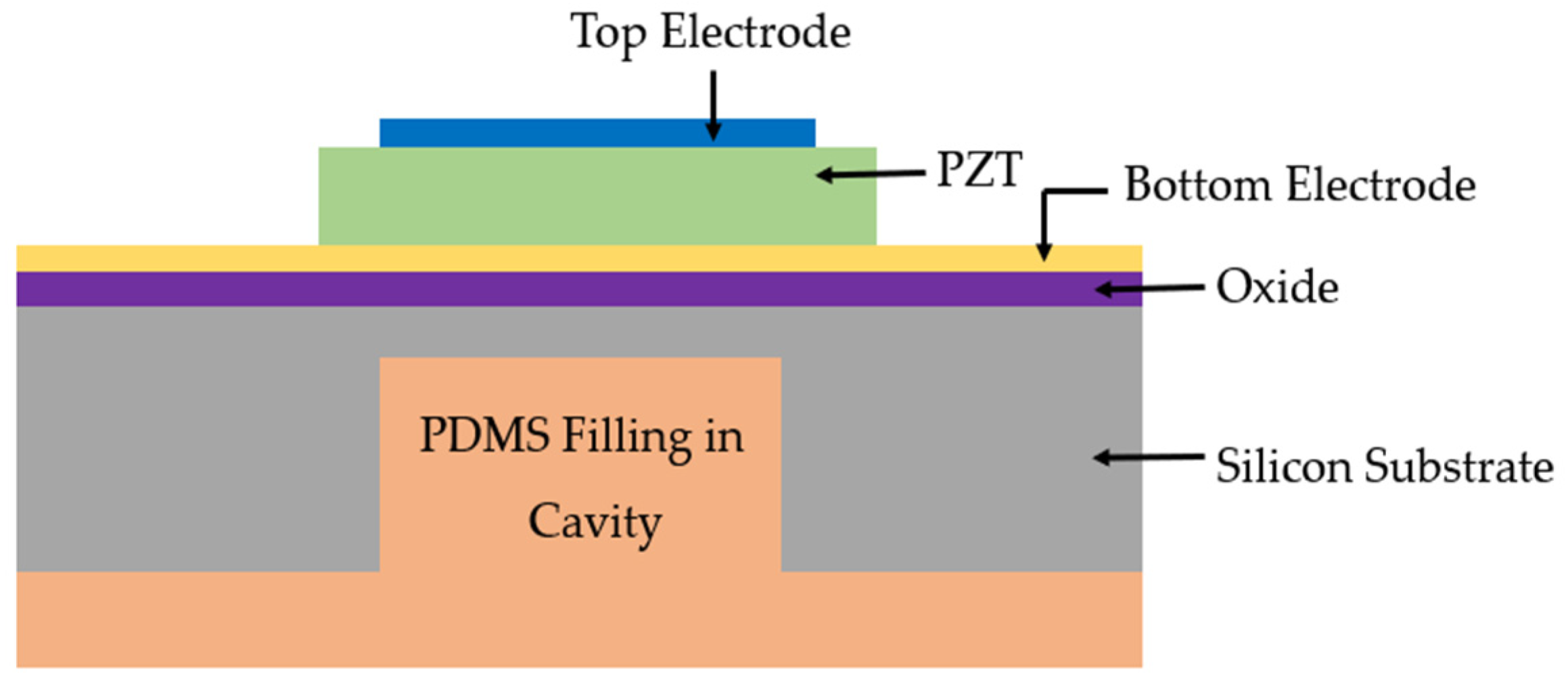

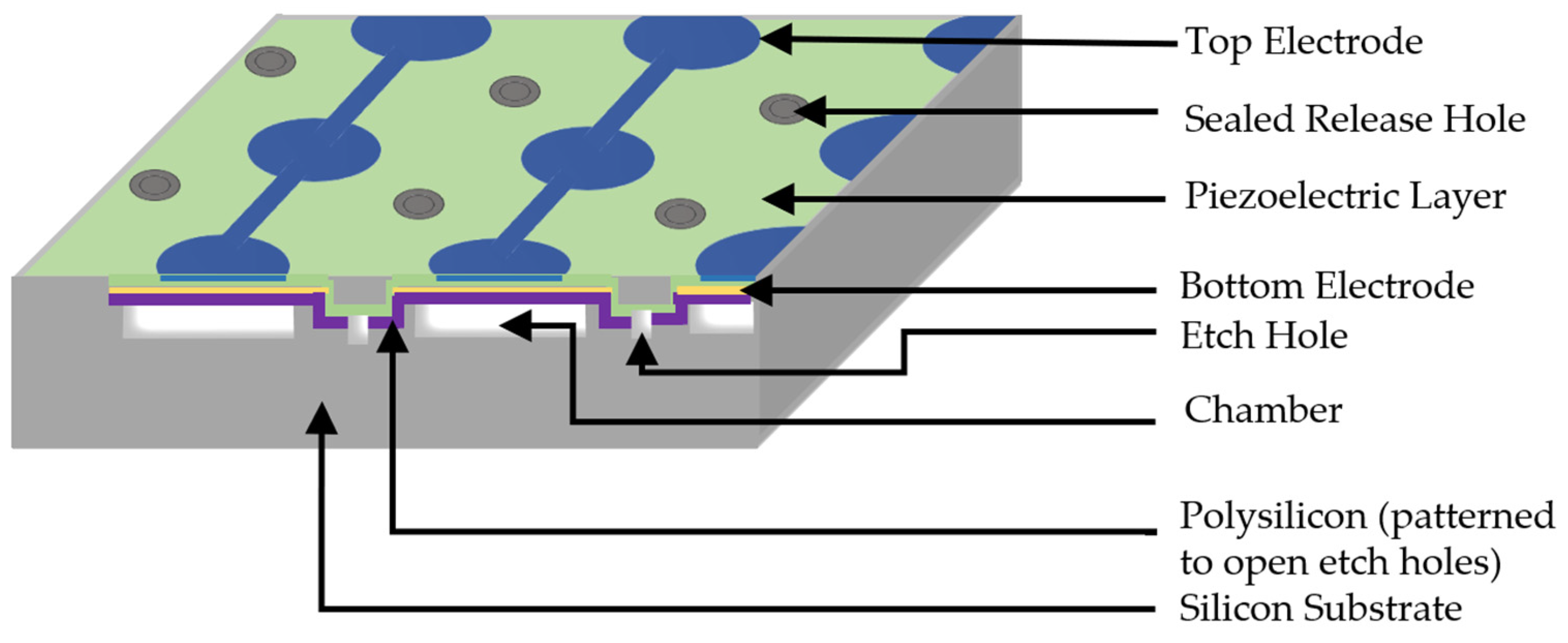

4.3. Sacrificial Layer Release

5. PMUT Performance Metrics and Critical Design Parameters

5.1. Electromechanical Coupling Coefficient (EMCC)

5.2. Bandwidth

5.3. Acoustic Pressure Output

6. PMUT Applications

6.1. Medical Imaging

6.2. Acoustic and Mass-Based Sensing

6.3. Ultrasonic Fingerprint Sensing

6.4. Ultrasound Haptic Technology

6.5. Acoustic Power Transmission

6.6. Energy Harvesting

6.7. Particle Manipulation

7. Conclusions and Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lethiecq, M.; Levassort, F.; Certon, D.; Tran-Huu-Hue, L.P. Piezoelectric Transducer Design for Medical Diagnosis and NDE. In Piezoelectric and Acoustic Materials for Transducer Applications; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 9780387765389. [Google Scholar]

- Akasheh, F.; Myers, T.; Fraser, J.D.; Bose, S.; Bandyopadhyay, A. Development of Piezoelectric Micromachined Ultrasonic Transducers. Sens. Actuators A Phys. 2004, 111, 275–287. [Google Scholar] [CrossRef]

- Aldrich, J.E. Basic Physics of Ultrasound Imaging. Crit. Care Med. 2007, 35, S131–S137. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Lam, K.H.; Zheng, H.; Qiu, W.; Shung, K.K. Piezoelectric Single Crystal Ultrasonic Transducers for Biomedical Applications. Prog. Mater. Sci. 2014, 66, 87–111. [Google Scholar] [CrossRef] [PubMed]

- Muralt, P.; Baborowski, J. Micromachined Ultrasonic Transducers and Acoustic Sensors Based on Piezoelectric Thin Films; Kluwer Academic Publishers: Alphen aan den Rijn, The Netherlands, 2004; Volume 12. [Google Scholar]

- Perçin, G.; Khuri-Yakub, B.T. Piezoelectrically Actuated Flextensional Micromachined Ultrasound Transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2002, 49, 585–595. [Google Scholar] [CrossRef] [PubMed]

- Heywang, W.; Lubitz, K.; Wersing, W. Piezoelectricity; Springer: Berlin/Heidelberg, Germany, 2008; Volume 114. [Google Scholar] [CrossRef]

- Carter, R.; Kensley, R. Introduction to Piezoelectricity|PIEZO.COM. Available online: https://piezo.com/pages/intro-to-piezoelectricity (accessed on 21 October 2022).

- Dangi, A.; Hulge, A.; Somasundaran, A.; Valsalam, R.S.; Pratap, R. Complete Development of a Single Cell PMUT Transducer: Design, Fabrication, Characterization, and Integration. J. Inst. Smart Struct. Syst. 2015, 4, 61–69. [Google Scholar]

- Jung, J.; Lee, W.; Kang, W.; Shin, E.; Ryu, J.; Choi, H. Review of Piezoelectric Micromachined Ultrasonic Transducers and Their Applications. J. Micromech. Microeng. 2017, 27, 113001. [Google Scholar] [CrossRef]

- Sherman, C.H.; Butler, J.L. Transducers and Arrays for Underwater Sound; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 0387329404. [Google Scholar]

- Sadeghpour, S.; Pobedinskas, P.; Haenen, K.; Puers, R. A Piezoelectric Micromachined Ultrasound Transducers (PMUT) Array, for Wide Bandwidth Underwater Communication Applications. Proceedings 2017, 1, 364. [Google Scholar] [CrossRef]

- Qiu, Y.; Gigliotti, J.V.; Wallace, M.; Griggio, F.; Demore, C.E.M.; Cochran, S.; Trolier-McKinstry, S. Piezoelectric Micromachined Ultrasound Transducer (PMUT) Arrays for Integrated Sensing, Actuation and Imaging. Sensors 2015, 15, 8020–8041. [Google Scholar] [CrossRef]

- Yamashita, K.; Katata, H.; Okuyama, M.; Miyoshi, H.; Kato, G.; Aoyagi, S.; Suzuki, Y. Arrayed Ultrasonic Microsensors with High Directivity for In-Air Use Using PZT Thin Film on Silicon Diaphragms. Sens. Actuators A Phys. 2002, 97–98, 302–307. [Google Scholar] [CrossRef]

- Kusano, Y.; Wang, Q.; Luo, G.L.; Lu, Y.; Rudy, R.Q.; Polcawich, R.G.; Horsley, D.A. Effects of DC Bias Tuning on Air-Coupled PZT Piezoelectric Micromachined Ultrasonic Transducers. J. Microelectromech. Syst. 2018, 27, 296–304. [Google Scholar] [CrossRef]

- Mitchell, A.K.; Hazell, C.R. A Simple Frequency Formula for Clamped Rectangular Plates. J. Sound Vib. 1987, 118, 271–281. [Google Scholar] [CrossRef]

- Shelton, S.; Chan, M.L.; Park, H.; Horsley, D.; Boser, B.; Izyumin, I.; Przybyla, R.; Frey, T.; Judy, M.; Nunan, K.; et al. CMOS-Compatible AlN Piezoelectric Micromachined Ultrasonic Transducers. In Proceedings of the 2009 IEEE International Ultrasonics Symposium, Rome, Italy, 20–23 September 2009. [Google Scholar]

- Cho, J.; Anderson, M.; Richards, R.; Bahr, D.; Richards, C. Optimization of Electromechanical Coupling for a Thin-Film PZT Membrane: II. Experiment. J. Micromech. Microeng. 2005, 15, 1804. [Google Scholar] [CrossRef]

- Cho, J.; Anderson, M.; Richards, R.; Bahr, D.; Richards, C. Optimization of Electromechanical Coupling for a Thin-Film PZT Membrane: I. Modeling. J. Micromech. Microeng. 2005, 15, 1797. [Google Scholar] [CrossRef]

- Jung, J.; Kim, S.; Lee, W.; Choi, H. Fabrication of a Two-Dimensional Piezoelectric Micromachined Ultrasonic Transducer Array Using a Top-Crossover-to-Bottom Structure and Metal Bridge Connections. J. Micromech. Microeng. 2013, 23, 125037. [Google Scholar] [CrossRef]

- Amar, A.B.; Cao, H.; Kouki, A.B. Modeling and Process Design Optimization of a Piezoelectric Micromachined Ultrasonic Transducers (PMUT) Using Lumped Elements Parameters. Microsyst. Technol. 2017, 23, 4659–4669. [Google Scholar] [CrossRef]

- Mo, J.H.; Robinson, A.L.; Fitting, D.W.; Terry, F.L.; Carson, P.L. Micromachining for Improvement of Integrated Ultrasonic Transducer Sensitivity. IEEE Trans. Electron. Devices 1990, 37, 134–140. [Google Scholar] [CrossRef]

- Guedes, A.; Shelton, S.; Przybyla, R.; Izyumin, I.; Boser, B.; Horsley, D.A. Aluminum Nitride PMUT Based on a Flexurally-Suspended Membrane. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011. [Google Scholar]

- Zhou, Q.; Lau, S.; Wu, D.; Kirk Shung, K. Piezoelectric Films for High Frequency Ultrasonic Transducers in Biomedical Applications. Prog. Mater. Sci. 2011, 56, 139–174. [Google Scholar] [CrossRef]

- Holz, S.; Kiricenko, S.; Rissing, L. Integration of PVDF (Polyvinylidene Fluoride) in MEMS Production. ECS Trans. 2014, 64, 189. [Google Scholar] [CrossRef]

- Setter, N.; Damjanovic, D.; Eng, L.; Fox, G.; Gevorgian, S.; Hong, S.; Kingon, A.; Kohlstedt, H.; Park, N.Y.; Stephenson, G.B.; et al. Ferroelectric Thin Films: Review of Materials, Properties, and Applications. J. Appl. Phys. 2006, 100, 051606. [Google Scholar] [CrossRef]

- Tadigadapa, S.; Mateti, K. Piezoelectric MEMS Sensors: State-of-the-Art and Perspectives. Meas. Sci. Technol. 2009, 20, 092001. [Google Scholar] [CrossRef]

- Dausch, D.E.; Gilchrist, K.H.; Carlson, J.B.; Hall, S.D.; Castellucci, J.B.; von Ramm, O.T. In Vivo Real-Time 3-D Intracardiac Echo Using PMUT Arrays. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 1754–1764. [Google Scholar] [CrossRef] [PubMed]

- Trolier-Mckinstry, S.; Muralt, P. Thin Film Piezoelectrics for MEMS. J. Electroceram. 2004, 12, 7–17. [Google Scholar] [CrossRef]

- Dangi, A.; Cheng, C.Y.; Agrawal, S.; Tiwari, S.; Datta, G.R.; Benoit, R.R.; Pratap, R.; Trolier-Mckinstry, S.; Kothapalli, S.R. A Photoacoustic Imaging Device Using Piezoelectric Micromachined Ultrasound Transducers (PMUTs). IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2020, 67, 801–809. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Yang, H.; Chen, Z.; Zheng, Q.; Jiang, H.; Feng, P.X.L.; Xie, H. Development of Dual-Frequency PMUT Arrays Based on Thin Ceramic PZT for Endoscopic Photoacoustic Imaging. J. Microelectromech. Syst. 2021, 30, 770–782. [Google Scholar] [CrossRef]

- Liu, Z.; Yoshida, S.; Horsley, D.A.; Tanaka, S. Fabrication and Characterization of Row-Column Addressed PMUT Array with Monocrystalline PZT Thin Film toward Creating Ultrasonic Imager. Sens. Actuators A Phys. 2022, 342, 113666. [Google Scholar] [CrossRef]

- Safari, A.; Akdoǧan, E.K. Piezoelectric and Acoustic Materials for Transducer Applications; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 9780387765389. [Google Scholar]

- Kholkin, A. Piezoelectric Materials and DevicesApplications in Engineering and Medical Science. Mater. Today 2013, 16, 94–95. [Google Scholar] [CrossRef]

- Ledesma, E.; Zamora, I.; Uranga, A.; Torres, F.; Barniol, N. Enhancing Aln Pmuts’ Acoustic Responsivity within a Mems-on-Cmos Process. Sensors 2021, 21, 8447. [Google Scholar] [CrossRef]

- Pandian, M.S.; Ferrer, E.M.; Tay, W.S.; Madhaven, V.; Kantimahanti, A.K.; Sobreviela, G.; Uranga, A.; Barniol, N. Thin Film Piezoelectric Devices Integrated on CMOS. In Proceedings of the 2016 Symposium on Piezoelectricity, Acoustic Waves, and Device Applications (SPAWDA), Xi’an, China, 21–24 October 2016. [Google Scholar]

- Tsai, J.M.; Daneman, M.; Boser, B.; Horsley, D.; Rais-Zadeh, M.; Tang, H.Y.; Lu, Y.; Rozen, O.; Liu, F.; Lim, M.; et al. Versatile CMOS-MEMS Integrated Piezoelectric Platform. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems, TRANSDUCERS, Anchorage, AK, USA, 21–25 June 2015. [Google Scholar]

- Dubois, M.A.; Muralt, P. Properties of Aluminum Nitride Thin Films for Piezoelectric Transducers and Microwave Filter Applications. Appl. Phys. Lett. 1999, 74, 3032–3034. [Google Scholar] [CrossRef]

- Ballato, A.; Gualtieri, J.G.; Kosinski, J.A. Ferroelectric Materials for Thin-Film and Membrane Resonators. In Proceedings of the IEEE International Symposium on Applications of Ferroelectrics, University Park, PA, USA, 7–10 August 1994. [Google Scholar]

- Wang, Z.; Zhu, W.; Zhu, H.; Miao, J.; Chao, C.; Zhao, C.; Tan, O.K. Fabrication and Characterization of Piezoelectric Micromachined Ultrasonic Transducers with Thick Composite PZT Films. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2289–2297. [Google Scholar] [CrossRef]

- Muralt, P.; Ledermann, N.; Paborowski, J.; Barzegar, A.; Gentil, S.; Belgacem, B.; Petitgrand, S.; Bosseboeuf, A.; Setter, N. Piezoelectric Micromachined Ultrasonic Transducers Based on PZT Thin Films. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2276–2288. [Google Scholar] [CrossRef]

- Dausch, D.E.; Castellucci, J.B.; Chou, D.R.; von Ramm, O.T. Theory and Operation of 2-D Array Piezoelectric Micromachined Ultrasound Transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 2484–2492. [Google Scholar] [CrossRef] [PubMed]

- Griggio, F.; Demore, C.E.M.; Kim, H.; Gigliotti, J.; Qiu, Y.; Jackson, T.N.; Choi, K.; Tutwiler, R.L.; Cochran, S.; Trolier-Mckinstry, S. Micromachined Diaphragm Transducers for Miniaturised Ultrasound Arrays. In Proceedings of the IEEE International Ultrasonics Symposium, Dresden, Germany, 7–10 October 2012. [Google Scholar]

- Akai, D.; Yogi, T.; Kamja, I.; Numata, Y.; Ozaki, K.; Sawada, K.; Okada, N.; Higuchi, K.; Ishida, M. Miniature Ultrasound Acoustic Imaging Devices Using 2-D PMUTs Array on Epitaxial PZT/SrRuO3/Pt/-Al2O3/Si Structure. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011. [Google Scholar]

- Perçin, G.; Atalar, A.; Levent Degertekin, F.; Khuri-Yakub, B.T. Micromachined Two-Dimensional Array Piezoelectrically Actuated Transducers. Appl. Phys. Lett. 1998, 72, 1397–1399. [Google Scholar] [CrossRef]

- Percin, G.; Khuri-Yakub, B.T. Micromachined 2-D Array Piezoelectrically Actuated Flextensional Transducers. In Proceedings of the IEEE Ultrasonics Symposium, Toronto, ON, Canada, 5–8 October 1997. [Google Scholar]

- Smyth, K.M.; Sodini, C.G.; Kim, S.G. High Electromechanical Coupling Piezoelectric Micro-Machined Ultrasonic Transducer (PMUT) Elements for Medical Imaging. In Proceedings of the TRANSDUCERS 2017—19th International Conference on Solid-State Sensors, Actuators and Microsystems, Kaohsiung, Taiwan, 18–22 June 2017. [Google Scholar]

- Lu, Y.; Heidari, A.; Shelton, S.; Guedes, A.; Horsley, D.A. High Frequency Piezoelectric Micromachined Ultrasonic Transducer Array for Intravascular Ultrasound Imaging. In Proceedings of the IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014. [Google Scholar]

- Meyers, M.; Rodrigues, N.; Ari, A. High-Frequency Oscillatory Ventilation: A Narrative Review. Can. J. Respir. Ther. 2019, 55, 40–46. [Google Scholar] [CrossRef]

- Ledesma, E.; Tzanov, V.; Zamora, I.; Torres, F.; Uranga, A.; Barniol, N.; Marigo, E.; Soundara-Pandian, M. ALN Pmut with Crossed-Cavity for Better Acoustic Pressure Outputs in Liquid at High Frequency. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (Transducers & Eurosensors XXXIII), Berlin, Germany, 23–27 June 2019. [Google Scholar]

- Smyth, K.; Kim, S.G. Experiment and Simulation Validated Analytical Equivalent Circuit Model for Piezoelectric Micromachined Ultrasonic Transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 62, 744–765. [Google Scholar] [CrossRef]

- Wang, Q.; Lu, Y.; Fung, S.; Jiang, X.; Mishin, S.; Oshmyansky, Y.; Horsley, D.A. Scandium Doped Aluminum Nitride Based Piezoelectric Micromachined Ultrasound Transducers. In Proceedings of the 2016 Solid-State Sensors, Actuators and Microsystems Workshop, Hilton Head, SC, USA, 5–9 June 2016. [Google Scholar]

- Guo, J.Q.; Liu, C.C.; Han, T.; Miao, J.M. Model of Scandium Doped Aluminum Nitride Based PMUT with High Transmitting Performance. In Proceedings of the 2017 Symposium on Piezoelectricity, Acoustic Waves, and Device Applications, SPAWDA, Chengdu, China, 27–30 October 2017; Volume 2018. [Google Scholar]

- Sammoura, F.; Akhari, S.; Aqab, N.; Mahmoud, M.; Lin, L. Multiple Electrode Piezoelectric Micromachined Ultrasonic Transducers. In Proceedings of the IEEE International Ultrasonics Symposium, Chicago, IL, USA, 3–6 September 2014. [Google Scholar]

- Akhbari, S.; Sammoura, F.; Shelton, S.; Yang, C.; Horsley, D.; Lin, L. Highly Responsive Curved Aluminum Nitride PMUT. In Proceedings of the IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014. [Google Scholar]

- Feng, G.H.; Sharp, C.C.; Zhou, Q.F.; Pang, W.; Kim, E.S.; Shung, K.K. Fabrication of MEMS ZnO Dome-Shaped-Diaphragm Transducers for High-Frequency Ultrasonic Imaging. J. Micromech. Microeng. 2005, 15, 586. [Google Scholar] [CrossRef]

- Hajati, A.; Latev, D.; Gardner, D.; Hajati, A.; Imai, D.; Torrey, M.; Schoeppler, M. Three-Dimensional Micro Electromechanical System Piezoelectric Ultrasound Transducer. Appl. Phys. Lett. 2012, 101, 253101. [Google Scholar] [CrossRef]

- Sammoura, F.; Akhbari, S.; Lin, L. An Analytical Solution for Curved Piezoelectric Micromachined Ultrasonic Transducers with Spherically Shaped Diaphragms. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 61, 1533–1544. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Q.; Horsley, D.A. Piezoelectric Micromachined Ultrasonic Transducers with Increased Coupling Coefficient via Series Transduction. In Proceedings of the 2015 IEEE International Ultrasonics Symposium, Taipei, Taiwan, 21–24 October 2015. [Google Scholar]

- Lu, Y.; Horsley, D.A. Modeling, Fabrication, and Characterization of Piezoelectric Micromachined Ultrasonic Transducer Arrays Based on Cavity SOI Wafers. J. Microelectromech. Syst. 2015, 24, 1142–1149. [Google Scholar] [CrossRef]

- Wang, T.; Kobayashi, T.; Lee, C. Broadband Piezoelectric Micromachined Ultrasonic Transducer (PMUT) Using Mode-Merged Design. In Proceedings of the 2015 IEEE 10th International Conference on Nano/Micro Engineered and Molecular Systems, Xi’an, China, 7–11 April 2015. [Google Scholar]

- Eovino, B.E.; Akhbari, S.; Lin, L. Broadband Ring-Shaped PMUTS Based on an Acoustically Induced Resonance. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Las Vegas, NV, USA, 22–26 January 2017. [Google Scholar]

- Wang, X.B.; He, L.M.; Ma, Y.C.; Liu, W.J.; Xu, W.J.; Ren, J.Y.; Riaud, A.; Zhou, J. Development of Broadband High-Frequency Piezoelectric Micromachined Ultrasonic Transducer Array. Sensors 2021, 21, 1823. [Google Scholar] [CrossRef]

- Horsley, D.; Lu, Y.; Rozen, O. Flexural Piezoelectric Resonators. In Piezoelectric MEMS Resonators; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Wang, M.; Zhou, Y.; Randles, A. Enhancement of the Transmission of Piezoelectric Micromachined Ultrasonic Transducer with an Isolation Trench. J. Microelectromech. Syst. 2016, 25, 691–700. [Google Scholar] [CrossRef]

- Liang, Y.; Eovino, B.E.; Lin, L. Pinned Boundary Piezoelectric Micromachined Ultrasonic Transducers. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Seoul, Republic of Korea, 27–31 January 2019; Volume 2019. [Google Scholar]

- Rozen, O.; Block, S.T.; Shelton, S.E.; Horsley, D.A. Piezoelectric Micromachined Ultrasonic Transducer with Increased Output Pressure via Concentric Venting Rings. In Proceedings of the 2015 Transducers—18th International Conference on Solid-State Sensors, Actuators and Microsystems, Anchorage, AK, USA, 21–25 June 2015. [Google Scholar]

- Akhbari, S.; Sammoura, F.; Lin, L. Equivalent Circuit Models for Large Arrays of Curved and Flat Piezoelectric Micromachined Ultrasonic Transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 432–447. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Heidari, A.; Horsley, D.A. A High Fill-Factor Annular Array of High Frequency Piezoelectric Micromachined Ultrasonic Transducers. J. Microelectromech. Syst. 2015, 24, 904–913. [Google Scholar] [CrossRef]

- Akhbari, S.; Sammoura, F.; Yang, C.; Heidari, A.; Horsley, D.; Lin, L. Self-Curved Diaphragms by Stress Engineering for Highly Responsive PMUT. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; Volume 2015. [Google Scholar]

- Chen, Y.-Q.; Li, Y.-X.; Chen, Y.; Ju, Z.-Y.; Tao, L.-Q.; Pang, Y.; Yang, Y.; Ren, T. Large-Scale and High-Density PMUT Array Based on Isolated Sol-Gel PZT Membranes for Fingerprint Imaging. J. Electrochem. Soc. 2017, 164, B377. [Google Scholar] [CrossRef]

- Jiao, D.; Ni, Z.; Wang, J.; Li, X. High Fill Factor Array of Piezoelectric Micromachined Ultrasonic Transducers with Large Quality Factor. Sens. Mater. 2020, 32, 1785. [Google Scholar] [CrossRef]

- Rozen, O.; Block, S.T.; Mo, X.; Bland, W.; Hurst, P.; Tsai, J.M.; Daneman, M.; Amirtharajah, R.; Horsley, D.A. Monolithic MEMS-CMOS Ultrasonic Rangefinder Based on Dual-Electrode PMUTs. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Shanghai, China, 24–28 January 2016; Volume 2016. [Google Scholar]

- Wang, T.; Lee, C. Electrically Switchable Multi-Frequency Piezoelectric Micromachined Ultrasonic Transducer (PMUT). In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Shanghai, China, 24–28 January 2016; Volume 2016. [Google Scholar]

- Kazari, H.; Kabir, M.; Mostavi, A.; Ozevin, D. Multi-Frequency Piezoelectric Micromachined Ultrasonic Transducers. IEEE Sens. J. 2019, 19, 11090–11099. [Google Scholar] [CrossRef]

- Liu, L.; Ji, W.; Xing, Z.; Sun, X.; Chen, Y.; Du, Y.; Qin, F. A Dual-Frequency Piezoelectric Micromachined Ultrasound Transducer Array with Low Inter-Element Coupling Effects. J. Micromech. Microeng. 2021, 31, 045005. [Google Scholar] [CrossRef]

- Lu, Y.; Tang, H.; Fung, S.; Wang, Q.; Tsai, J.M.; Daneman, M.; Boser, B.E.; Horsley, D.A. Ultrasonic Fingerprint Sensor Using a Piezoelectric Micromachined Ultrasonic Transducer Array Integrated with Complementary Metal Oxide Semiconductor Electronics. Appl. Phys. Lett. 2015, 106, 3503. [Google Scholar] [CrossRef]

- Wang, T.; Lee, C. Zero-Bending Piezoelectric Micromachined Ultrasonic Transducer (PMUT) With Enhanced Transmitting Performance. J. Microelectromech. Syst. 2015, 24, 2083–2091. [Google Scholar] [CrossRef]

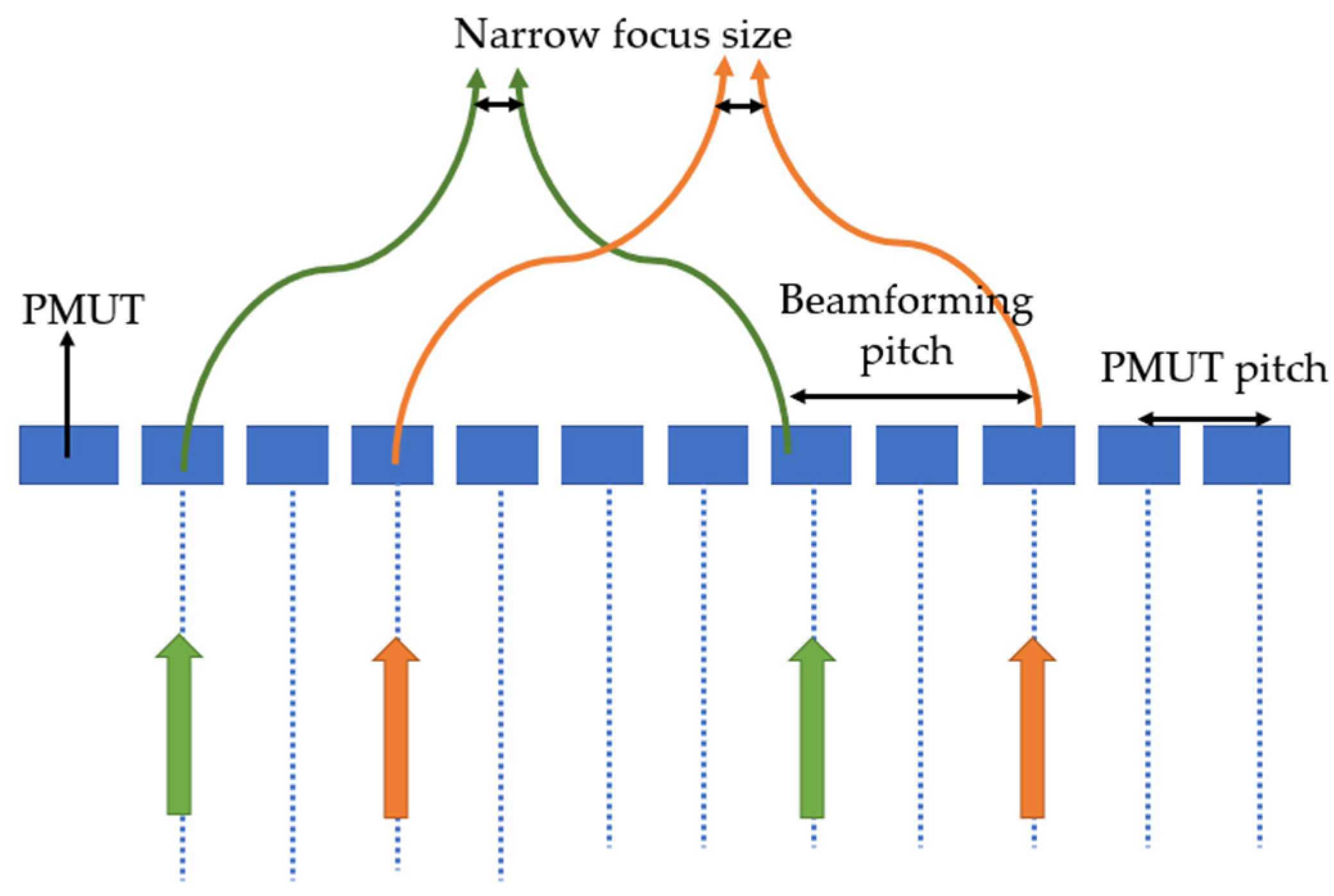

- Lu, Y.; Tang, H.Y.; Fung, S.; Boser, B.E.; Horsley, D.A. Pulse-Echo Ultrasound Imaging Using an AlN Piezoelectric Micromachined Ultrasonic Transducer Array with Transmit Beam-Forming. J. Microelectromech. Syst. 2016, 25, 179–187. [Google Scholar] [CrossRef]

- Jiang, X.; Tang, H.Y.; Lu, Y.; Ng, E.J.; Tsai, J.M.; Boser, B.E.; Horsley, D.A. Ultrasonic Fingerprint Sensor with Transmit Beamforming Based on a PMUT Array Bonded to CMOS Circuitry. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2017, 64, 1401–1408. [Google Scholar] [CrossRef]

- Sun, C.; Shi, Q.; Yazici, M.S.; Kobayashi, T.; Liu, Y.; Lee, C. Investigation of Broadband Characteristics of Multi-Frequency Piezoelectric Micromachined Ultrasonic Transducer (MF-PMUT). IEEE Sens. J. 2019, 19, 860–867. [Google Scholar] [CrossRef]

- Wang, H.; Yang, H.; Jiang, H.; Chen, Z.; Feng, P.X.L.; Xie, H. A Multi-Frequency PMUT Array Based on Ceramic PZT for Endoscopic Photoacoustic Imaging. In Proceedings of the 21st International Conference on Solid-State Sensors, Actuators and Microsystems, Orlando, FL, USA, 20–24 June 2021. [Google Scholar]

- Kim, E.S.; Muller, R.S.; Gray, P.R. Integrated Microphone with CMOS Circuits on a Single Chip. In Proceedings of the International Technical Digest on Electron Devices Meeting, Washington, DC, USA, 3–6 December 1989. [Google Scholar]

- Zamora, I.; Ledesma, E.; Uranga, A.; Barniol, N. Miniaturized 0.13-μm CMOS Front-End Analog for AlN PMUT Arrays. Sensors 2020, 20, 1205. [Google Scholar] [CrossRef] [PubMed]

- Zamora, I.; Ledesma, E.; Uranga, A.; Barniol, N. Monolithic Single PMUT-on-CMOS Ultrasound System with +17 DB SNR for Imaging Applications. IEEE Access 2020, 8, 142785–142794. [Google Scholar] [CrossRef]

- Khuri-Yakub, B.T.; Oralkan, Ö.; Kupnik, M. Next-Gen Ultrasound. IEEE Spectr. 2009, 46, 44–54. [Google Scholar] [CrossRef]

- Billen, M.; Gao, H.; Tabruyn, D.; Marigo, E.; Soundara-Pandian, M.; Helin, P.; Rochus, V. Multi-Frequency Imaging with a CMOS Compatible Scandium Doped Aluminum Nitride PMUT Array. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Gainesville, FL, USA, 25–29 January 2021; Volume 2021. [Google Scholar]

- Savoia, A.S.; Casavola, M.; Boni, E.; Ferrera, M.; Prelini, C.; Tortoli, P.; Giusti, D.; Quaglia, F. Design, Fabrication, Characterization, and System Integration of a 1-D PMUT Array for Medical Ultrasound Imaging. In Proceedings of the IEEE International Ultrasonics Symposium, IUS, Xi’an, China, 11–16 September 2021. [Google Scholar]

- Boni, E.; Bassi, L.; Dallai, A.; Giannini, G.; Guidi, F.; Meacci, V.; Matera, R.; Ramalli, A.; Ricci, S.; Scaringella, M.; et al. ULA-OP 256: A Portable High-Performance Research Scanner. In Proceedings of the 2015 IEEE International Ultrasonics Symposium, Taipei, Taiwan, 21–24 October 2015. [Google Scholar]

- Attia, A.B.E.; Balasundaram, G.; Moothanchery, M.; Dinish, U.S.; Bi, R.; Ntziachristos, V.; Olivo, M. A Review of Clinical Photoacoustic Imaging: Current and Future Trends. Photoacoustics 2019, 16, 100144. [Google Scholar] [CrossRef]

- Cai, J.; Wang, Y.; Jiang, D.; Gu, Y.; Lou, L.; Gao, F.; Wu, T. Photoacoustic Imaging Based on AlN MF-PMUT with Broadened Bandwidth. arXiv 2022, arXiv:2203.16806. [Google Scholar]

- Nazemi, H.; Balasingam, J.A.; Swaminathan, S.; Ambrose, K.; Nathani, M.U.; Ahmadi, T.; Lopez, Y.B.; Emadi, A. Mass Sensors Based on Capacitive and Piezoelectric Micromachined Ultrasonic Transducers—CMUT and PMUT. Sensors 2020, 20, 2010. [Google Scholar] [CrossRef]

- Balasingam, J.A.; Swaminathan, S.; Nazemi, H.; Love, C.; Birjis, Y.; Emadi, A. Chemical Sensors: Gas Sensors, Acoustic Sensors. In Reference Module in Biomedical Sciences; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

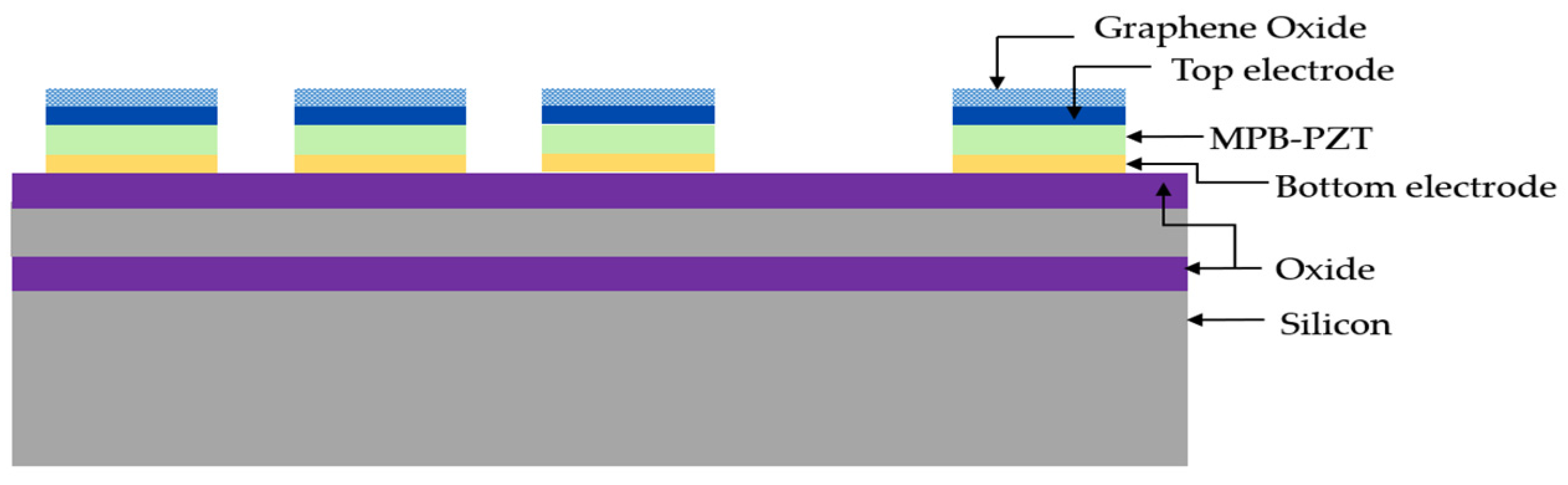

- Sun, C.; Shi, Q.; Yazici, M.S.; Lee, C.; Liu, Y. Development of a Highly Sensitive Humidity Sensor Based on a Piezoelectric Micromachined Ultrasonic Transducer Array Functionalized with Graphene Oxide Thin Film. Sensors 2018, 18, 4352. [Google Scholar] [CrossRef]

- Tang, Y.; Li, Z.; Ma, J.; Wang, L.; Yang, J.; Du, B.; Yu, Q.; Zu, X. Highly Sensitive Surface Acoustic Wave (SAW) Humidity Sensors Based on Sol-Gel SiO2 Films: Investigations on the Sensing Property and Mechanism. Sens. Actuators B Chem. 2015, 215, 283–291. [Google Scholar] [CrossRef]

- Qiu, X.; Tang, R.; Zhu, J.; Oiler, J.; Yu, C.; Wang, Z.; Yu, H. Experiment and Theoretical Analysis of Relative Humidity Sensor Based on Film Bulk Acoustic-Wave Resonator. Sens. Actuators B Chem. 2010, 147, 381–384. [Google Scholar] [CrossRef]

- Roy, K.; Gupta, H.; Shastri, V.; Dangi, A.; Jeyaseelan, A.; Dutta, S.; Pratap, R. Fluid Density Sensing Using Piezoelectric Micromachined Ultrasound Transducers. IEEE Sens. J. 2020, 20, 6802–6809. [Google Scholar] [CrossRef]

- Roy, K.; Gupta, H.; Shastri, V.; Dangi, A.; Pratap, R. Fluid Density Sensing Using PMUTs. In Proceedings of the IEEE Sensors, New Delhi, India, 28–31 October 2018; Volume 2018. [Google Scholar]

- Roy, K.; Mandal, A.; Ashok, A.; Gupta, H.; Shastri, V.; Pratap, R. A Single Cell PMUT as a Bio-Fluid Density Sensor. In Proceedings of the IEEE International Ultrasonics Symposium, IUS, Las Vegas, NV, USA, 7–11 September 2020; Volume 2020. [Google Scholar]

- Roy, K.; Kalyan, K.; Ashok, A.; Shastri, V.; Jeyaseelan, A.A.; Mandal, A.; Pratap, R. A PMUT Integrated Microfluidic System for Fluid Density Sensing. J. Microelectromech. Syst. 2021, 30, 642–649. [Google Scholar] [CrossRef]

- Zhang, Q.M.; Zhao, J. Electromechanical Properties of Lead Zirconate Titanate Piezoceramics under the Influence of Mechanical Stresses. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1999, 46, 1518–1526. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Wang, Q.M. The Effective Electromechanical Coupling Coefficient of Piezoelectric Thin-Film Resonators. Appl. Phys. Lett. 2005, 86, 022904. [Google Scholar] [CrossRef]

- Aïm, F.; Lonjon, G.; Hannouche, D.; Nizard, R. Effectiveness of Virtual Reality Training in Orthopaedic Surgery. Arthrosc. J. Arthrosc. Relat. Surg. 2016, 32, 224–232. [Google Scholar] [CrossRef]

- Liu, Y.-H.; Su, H.-Y.; Lin, H.-C.; Li, C.-Y.; Wang, Y.-H.; Huang, C.-H. Investigation of Achieving Ultrasonic Haptic Feedback Using Piezoelectric Micromachined Ultrasonic Transducer. Electronics 2022, 11, 2131. [Google Scholar] [CrossRef]

- Herrera, B.; Pop, F.; Cassella, C.; Rinaldi, M. AlN PMUT-Based Ultrasonic Power Transfer Links for Implantable Electronics. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019. [Google Scholar]

- Dogheche, K.; Cavallier, B.; Delobelle, P.; Hirsinger, L.; Ballandras, S.; Cattan, E.; Rèmiens, D.; Marzencki, M.; Charlot, B.; Basrour, S. Piezoelectric Micro-Machined Ultrasonic Transducer (PMUT) for Energy Harvesting. In Proceedings of the IEEE Ultrasonics Symposium, Rotterdam, The Netherlands, 18–21 September 2005; Volume 2. [Google Scholar]

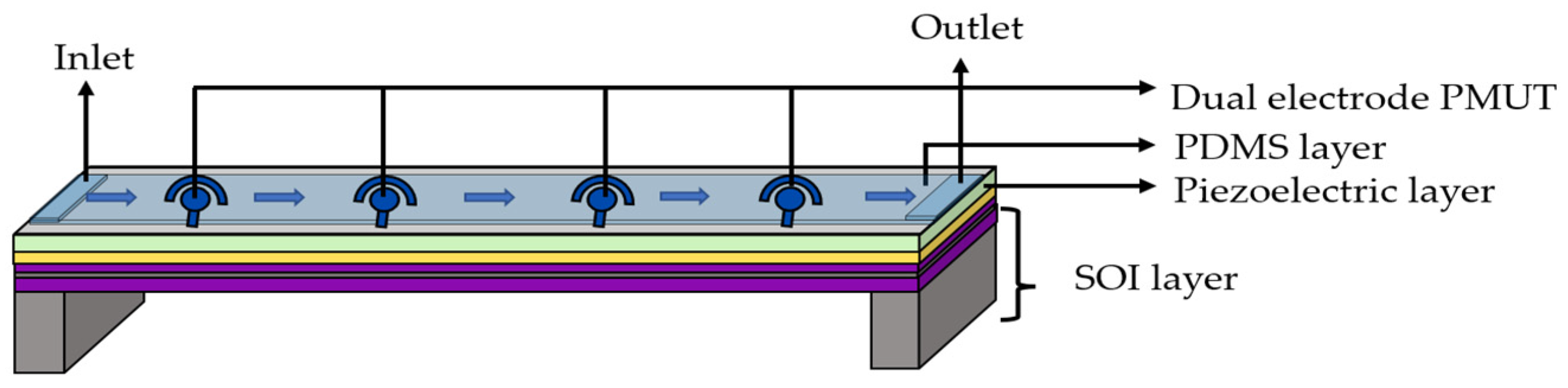

- Cheng, C.Y.; Dangi, A.; Ren, L.; Tiwari, S.; Benoit, R.R.; Qiu, Y.; Lay, H.S.; Agrawal, S.; Pratap, R.; Kothapalli, S.R.; et al. Thin Film PZT-Based PMUT Arrays for Deterministic Particle Manipulation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2019, 66, 1606–1615. [Google Scholar] [CrossRef]

- Sammoura, F.; Smyth, K.; Kim, S.G. Working Equations of a Circular Multimorph Piezoelectric Micromachined Ultrasonic Transducer. In Proceedings of the IECON 2012—38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012. [Google Scholar]

- Sammoura, F.; Smyth, K.; Kim, S.G. Optimizing the Electrode Size of Circular Bimorph Plates with Different Boundary Conditions for Maximum Deflection of Piezoelectric Micromachined Ultrasonic Transducers. Ultrasonics 2013, 53, 328–334. [Google Scholar] [CrossRef]

| Property | Units | PZT [26] | AlN [38] | ZnO [39] |

|---|---|---|---|---|

| Density | Kg/cm3 | 7500 | 3260 | 5680 |

| Young’s Modulus | GPa | 127 | 410 | 209 |

| Piezoelectric Coefficient e31 | C/m2 | −8 to −12 | −1.05 | −1.0 |

| Converse Piezoelectric Coefficient d33 | pm/V | 60–130 | 3.9 | 5.9 |

| PMUT | Element Size (µm) | Operating Frequency (MHz) | Displacement Sensitivity (nm/V) | Pressure Sensitivity (kPa/V) | Electromechanical Coupling | Bandwidth | Fill Factor |

|---|---|---|---|---|---|---|---|

| Dome Shaped PMUT array, Niobium doped (13%) PZT [57] | 74 to 94 | 5 | -- | 85 | 45% | 55% | 57 domes with pitch 400 µm |

| 50 × 50 PMUT array, AlN [72] | 48 | 12.62 | 3.25 | -- | 1.6% | -- | 67%, pitch 52 µm |

| 15 × 9 PMUT array, PZT [60] | 40 | 10 | -- | 450 | 12.5% | -- | High, pitch 60 µm |

| Annular PMUT array with 1261 cells, AlN [69] | 25 | 18.6 | 2.5 | 9 | -- | 4.9 MHz | High, pitch 30 µm, 1061 cells/mm2 |

| 24 × 8 PMUT array, AlN [77] | 50 | 22 | 1.8 | 14 | -- | 11.5 | 17%, pitch 100 |

| 128 + 128 PMUT array, Thin PZT ceramic [31] | 220, 120 | 1.2, 3.4 | 110, 30 | -- | 6.3%, 5.7% | 0.84 MHz—54%, 2.4 MHz—17% | Pitch 380 µm |

| 120 + 192 PMUT array Sputtered PZT [76] | 410, 230 | 0.77, 2.3 | 595, 112 | 53, 73 | 4.3%, 5.6% | -- | -- |

| Square PMUT, AlN [35] | 80 | 1.5 | -- | 4.9 | 1.14% | -- | -- |

| Curved PMUT, AlN [55] | 120 membrane diameter, 550 radius of curvature | 3.86 | 45 | -- | 2.1% | -- | Low |

| Zero-Bending Square PMUT [78] | 200 | 2.21 | 123 | -- | 0.406% | -- | -- |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Birjis, Y.; Swaminathan, S.; Nazemi, H.; Raj, G.C.A.; Munirathinam, P.; Abu-Libdeh, A.; Emadi, A. Piezoelectric Micromachined Ultrasonic Transducers (PMUTs): Performance Metrics, Advancements, and Applications. Sensors 2022, 22, 9151. https://doi.org/10.3390/s22239151

Birjis Y, Swaminathan S, Nazemi H, Raj GCA, Munirathinam P, Abu-Libdeh A, Emadi A. Piezoelectric Micromachined Ultrasonic Transducers (PMUTs): Performance Metrics, Advancements, and Applications. Sensors. 2022; 22(23):9151. https://doi.org/10.3390/s22239151

Chicago/Turabian StyleBirjis, Yumna, Siddharth Swaminathan, Haleh Nazemi, Gian Carlo Antony Raj, Pavithra Munirathinam, Aya Abu-Libdeh, and Arezoo Emadi. 2022. "Piezoelectric Micromachined Ultrasonic Transducers (PMUTs): Performance Metrics, Advancements, and Applications" Sensors 22, no. 23: 9151. https://doi.org/10.3390/s22239151

APA StyleBirjis, Y., Swaminathan, S., Nazemi, H., Raj, G. C. A., Munirathinam, P., Abu-Libdeh, A., & Emadi, A. (2022). Piezoelectric Micromachined Ultrasonic Transducers (PMUTs): Performance Metrics, Advancements, and Applications. Sensors, 22(23), 9151. https://doi.org/10.3390/s22239151