A Modified Prandtl–Ishlinskii Hysteresis Model for Modeling and Compensating Asymmetric Hysteresis of Piezo-Actuated Flexure-Based Systems

Abstract

:1. Introduction

2. Hysteresis Mathematical Model

2.1. Digitized Representation

2.2. DPI Model

2.3. Inverse DPI Model

2.4. Comparison of the Inverse Model Parameters Using the Digitized and the Classical Representation

3. Experimental Results

3.1. Experimental Setup

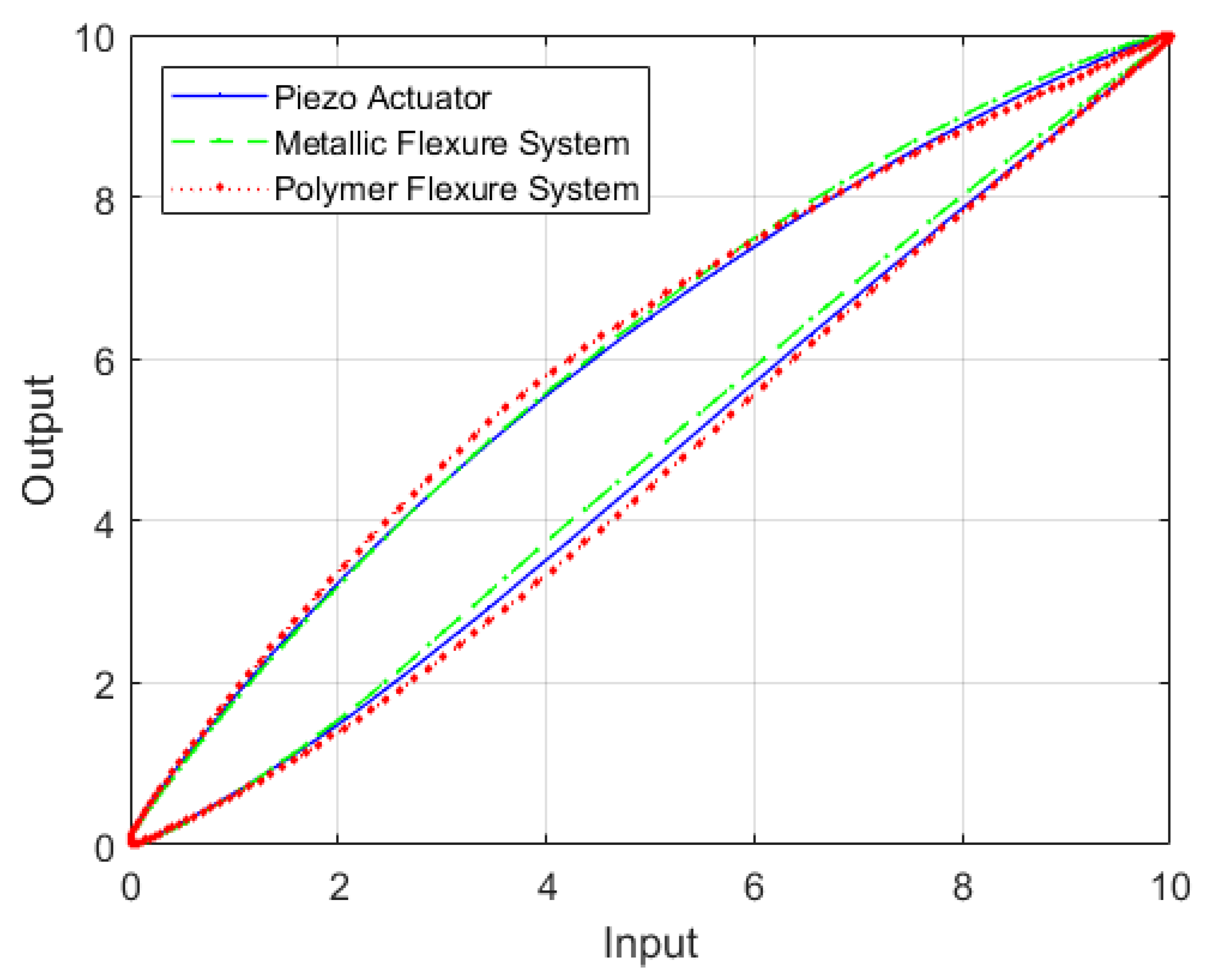

3.2. Modeling Results

3.3. Compensation Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Woronko, A.; Huang, J.; Altintas, Y. Piezoelectric tool actuator for precision machining on conventional CNC turning centers. Precis. Eng. 2003, 27, 335–345. [Google Scholar]

- Okazaki, Y. A micro-positioning tool post using a piezoelectric actuator for diamond turning machines. Precis. Eng. 1990, 12, 151–156. [Google Scholar] [CrossRef]

- Abis, C.; Unal, F.; Mugan, A. Active vibration control with piezoelectric actuator on a lathe machine with a gain controller. In Proceedings of the 2011 IEEE International Conference on Mechatronics, Beijing, China, 7–10 August 2011; pp. 19–22. [Google Scholar]

- Bravo-Zanoguera, M.E.; Laris, C.A.; Nguyen, L.K.; Oliva, M.; Price, J.H. Dynamic autofocus for continuous-scanning time-delay-and-integration image acquisition in automated microscopy. J. Biomed. Opt. 2007, 12, 034011. [Google Scholar] [CrossRef] [PubMed]

- Aguirre, A.D.; Sawinski, J.; Huang, S.W.; Zhou, C.; Denk, W.; Fujimoto, J.G. High speed optical coherence microscopy with autofocus adjustment and a miniaturized endoscopic imaging probe. Opt. Express 2010, 18, 4222–4239. [Google Scholar] [PubMed] [Green Version]

- Chen, X.; Chen, Z.; Li, X.; Shan, L.; Sun, W.; Wang, X.; Xie, T.; Dong, S. A spiral motion piezoelectric micromotor for autofocus and auto zoom in a medical endoscope. Appl. Phys. Lett. 2016, 108, 052902. [Google Scholar] [CrossRef]

- Ang, W.T.; Riviere, C.N.; Khosla, P.K. An active hand-held instrument for enhanced microsurgical accuracy. In Proceedings of the International Conference on Medical Image Computing and Computer-Assisted Intervention, Pittsburgh, PA, USA, 11–14 October 2000; Springer: Berlin/Heidelberg, Germany, 2000; pp. 878–886. [Google Scholar]

- Latt, W.; Tan, U.X.; Shee, C.; Ang, W. A compact hand-held active physiological tremor compensation instrument. In Proceedings of the 2009 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Singapore, 14–17 July 2009; pp. 711–716. [Google Scholar]

- Tan, U.X.; Latt, W.T.; Shee, C.Y.; Ang, W.T. A low-cost flexure-based handheld mechanism for micromanipulation. IEEE ASME Trans. Mechatron. 2010, 16, 773–778. [Google Scholar] [CrossRef]

- Junwu, K.; Zhigang, Y.; Taijiang, P.; Guangming, C.; Boda, W. Design and test of a high-performance piezoelectric micropump for drug delivery. Sens. Actuators A Phys. 2005, 121, 156–161. [Google Scholar]

- Mori, K.; Munemoto, T.; Otsuki, H.; Yamaguchi, Y.; Akagi, K. A dual-stage magnetic disk drive actuator using a piezoelectric device for a high track density. IEEE Trans. Magn. 1991, 27, 5298–5300. [Google Scholar]

- Chu, C.L.; Fan, S.H. A novel long-travel piezoelectric-driven linear nanopositioning stage. Precis. Eng. 2006, 30, 85–95. [Google Scholar]

- Bertotti, G.; Mayergoyz, I.D. The Science of Hysteresis: Hysteresis in Materials; Gulf Professional Publishing: Oxford, UK, 2006; Volume 3. [Google Scholar]

- Mei, H.; Cheng, L. Comparison of the mechanical hysteresis of carbon/ceramic-matrix composites with different fiber preforms. Carbon 2009, 47, 1034–1042. [Google Scholar] [CrossRef]

- Berry, E.; Hillerton, E. Monitoring mastitis and maintaining biosecurity. Vet. Rec. 2001, 149, 531. [Google Scholar] [PubMed]

- Ewing, J.A. On hysteresis in the relation of strain to stress. Br. Assoc. Rep. 1889, 502. [Google Scholar]

- Love, A.E.H. A Treatise on the Mathematical Theory of Elasticity; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Pomerening, J.R.; Sontag, E.D.; Ferrell, J.E. Building a cell cycle oscillator: Hysteresis and bistability in the activation of Cdc2. Nat. Cell Biol. 2003, 5, 346–351. [Google Scholar] [PubMed]

- Ball, L.M. Hysteresis in Unemployment: Old and New Evidence; Technical report; National Bureau of Economic Research: Cambridge, MA, USA, 2009. [Google Scholar]

- Yu, Y.; Zhang, C.; Wang, Y.; Zhou, M. Neural network-based iterative learning control for hysteresis in magnetic shape memory alloy actuator. IEEE/ASME Trans. Mechatron. 2021, 27, 928–939. [Google Scholar]

- Chen, P.; Bai, X.X.; Qian, L.J.; Choi, S.B. An approach for hysteresis modeling based on shape function and memory mechanism. IEEE/ASME Trans. Mechatron. 2018, 23, 1270–1278. [Google Scholar]

- Si, Z.Y.; Bai, X.X.; Qian, L.J.; Zhong, W.M. An enhanced Duhem model of magnetostrictive material-based actuators. In Behavior and Mechanics of Multifunctional Materials XIII; International Society for Optics and Photonics: Bellingham, WA, USA, 2019; Volume 10968, p. 1096818. [Google Scholar]

- Rakotondrabe, M. Bouc–Wen modeling and inverse multiplicative structure to compensate hysteresis nonlinearity in piezoelectric actuators. IEEE Trans. Autom. Sci. Eng. 2010, 8, 428–431. [Google Scholar]

- Kang, S.; Wu, H.; Li, Y.; Yang, X.; Yao, J. A fractional-order normalized bouc-wen model for piezoelectric hysteresis nonlinearity. IEEE ASME Trans. Mechatron. 2021, 27, 126–136. [Google Scholar]

- Farrokh, M. Hysteresis simulation using least-squares support vector machine. J. Eng. Mech. 2018, 144, 04018084. [Google Scholar]

- Zhang, L.; Shi, B.; Zhu, H.; Yu, X.B.; Han, H.; Fan, X. PSO-SVM-based deep displacement prediction of Majiagou landslide considering the deformation hysteresis effect. Landslides 2021, 18, 179–193. [Google Scholar] [CrossRef]

- Kim, T.; Kwon, O.S.; Song, J. Response prediction of nonlinear hysteretic systems by deep neural networks. Neural Netw. 2019, 111, 1–10. [Google Scholar]

- Fu, C.; Wang, Q.G.; Yu, J.; Lin, C. Neural network-based finite-time command filtering control for switched nonlinear systems with backlash-like hysteresis. IEEE Trans. Neural Netw. Learn. Syst. 2020, 32, 3268–3273. [Google Scholar]

- Al Janaideh, M.; Rakheja, S.; Su, C.Y. An analytical generalized Prandtl–Ishlinskii model inversion for hysteresis compensation in micropositioning control. IEEE ASME Trans. Mechatron. 2010, 16, 734–744. [Google Scholar]

- Yang, M.J.; Gu, G.Y.; Zhu, L.M. Parameter identification of the generalized Prandtl–Ishlinskii model for piezoelectric actuators using modified particle swarm optimization. Sens. Actuators Phys. 2013, 189, 254–265. [Google Scholar]

- Ang, W.T.; Garmón, F.A.; Khosla, P.K.; Riviere, C.N. Modeling rate-dependent hysteresis in piezoelectric actuators. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003) (Cat. No. 03CH37453), Las Vegas, NV, USA, 27–31 October 2003; Volume 2, pp. 1975–1980. [Google Scholar]

- Tan, U.X.; Latt, W.T.; Shee, C.Y.; Riviere, C.N.; Ang, W.T. Feedforward controller of ill-conditioned hysteresis using singularity-free Prandtl–Ishlinskii model. IEEE ASME Trans. Mechatron. 2009, 14, 598–605. [Google Scholar]

- Kuhnen, K. Modeling, identification and compensation of complex hysteretic nonlinearities: A modified Prandtl-Ishlinskii approach. Eur. J. Control 2003, 9, 407–418. [Google Scholar]

- Gu, G.Y.; Zhu, L.M.; Su, C.Y. Modeling and compensation of asymmetric hysteresis nonlinearity for piezoceramic actuators with a modified Prandtl–Ishlinskii model. IEEE Trans. Ind. Electron. 2013, 61, 1583–1595. [Google Scholar]

- Al Janaideh, M.; Rakheja, S.; Su, C.Y. A generalized Prandtl–Ishlinskii model for characterizing the hysteresis and saturation nonlinearities of smart actuators. Smart Mater. Struct. 2009, 18, 045001. [Google Scholar] [CrossRef]

- Zhang, J.; Merced, E.; Sepúlveda, N.; Tan, X. Inversion of an extended generalized Prandtl-Ishlinskii hysteresis model: Theory and experimental results. In Proceedings of the 2014 American Control Conference, Portland, OR, USA, 4–6 June 2014; pp. 4765–4770. [Google Scholar]

- Sun, Z.; Song, B.; Xi, N.; Yang, R.; Hao, L.; Yang, Y.; Chen, L. Asymmetric hysteresis modeling and compensation approach for nanomanipulation system motion control considering working-range effect. IEEE Trans. Ind. Electron. 2017, 64, 5513–5523. [Google Scholar]

- Zhou, C.; Feng, C.; Aye, Y.N.; Ang, W.T. A Digitized Representation of the Modified Prandtl–Ishlinskii Hysteresis Model for Modeling and Compensating Piezoelectric Actuator Hysteresis. Micromachines 2021, 12, 942. [Google Scholar] [PubMed]

| RMSE | RMSE/p-p ampl. (%) | Max Error | |

|---|---|---|---|

| PI | 16.08 | 5.27 | 38.56 |

| MPI | 3.69 | 1.21 | 9.73 |

| DPI | 0.56 | 0.18 | 4.15 |

| RMSE (m) | RMSE/p-p ampl. (%) | Max Error (m) | ||||

|---|---|---|---|---|---|---|

| Fixed | Changing | Fixed | Changing | Fixed | Changing | |

| PI | 15.19 | 7.50 | 5.42% | 2.70% | 32.66 | 19.90 |

| MPI | 3.77 | 2.51 | 1.35% | 0.90% | 7.64 | 9.74 |

| DPI | 1.75 | 1.76 | 0.62% | 0.63% | 3.80 | 6.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, C.; Yuan, M.; Feng, C.; Ang, W.T. A Modified Prandtl–Ishlinskii Hysteresis Model for Modeling and Compensating Asymmetric Hysteresis of Piezo-Actuated Flexure-Based Systems. Sensors 2022, 22, 8763. https://doi.org/10.3390/s22228763

Zhou C, Yuan M, Feng C, Ang WT. A Modified Prandtl–Ishlinskii Hysteresis Model for Modeling and Compensating Asymmetric Hysteresis of Piezo-Actuated Flexure-Based Systems. Sensors. 2022; 22(22):8763. https://doi.org/10.3390/s22228763

Chicago/Turabian StyleZhou, Chao, Meng Yuan, Chen Feng, and Wei Tech Ang. 2022. "A Modified Prandtl–Ishlinskii Hysteresis Model for Modeling and Compensating Asymmetric Hysteresis of Piezo-Actuated Flexure-Based Systems" Sensors 22, no. 22: 8763. https://doi.org/10.3390/s22228763