Eddy Current Measurement for Planar Structures

Abstract

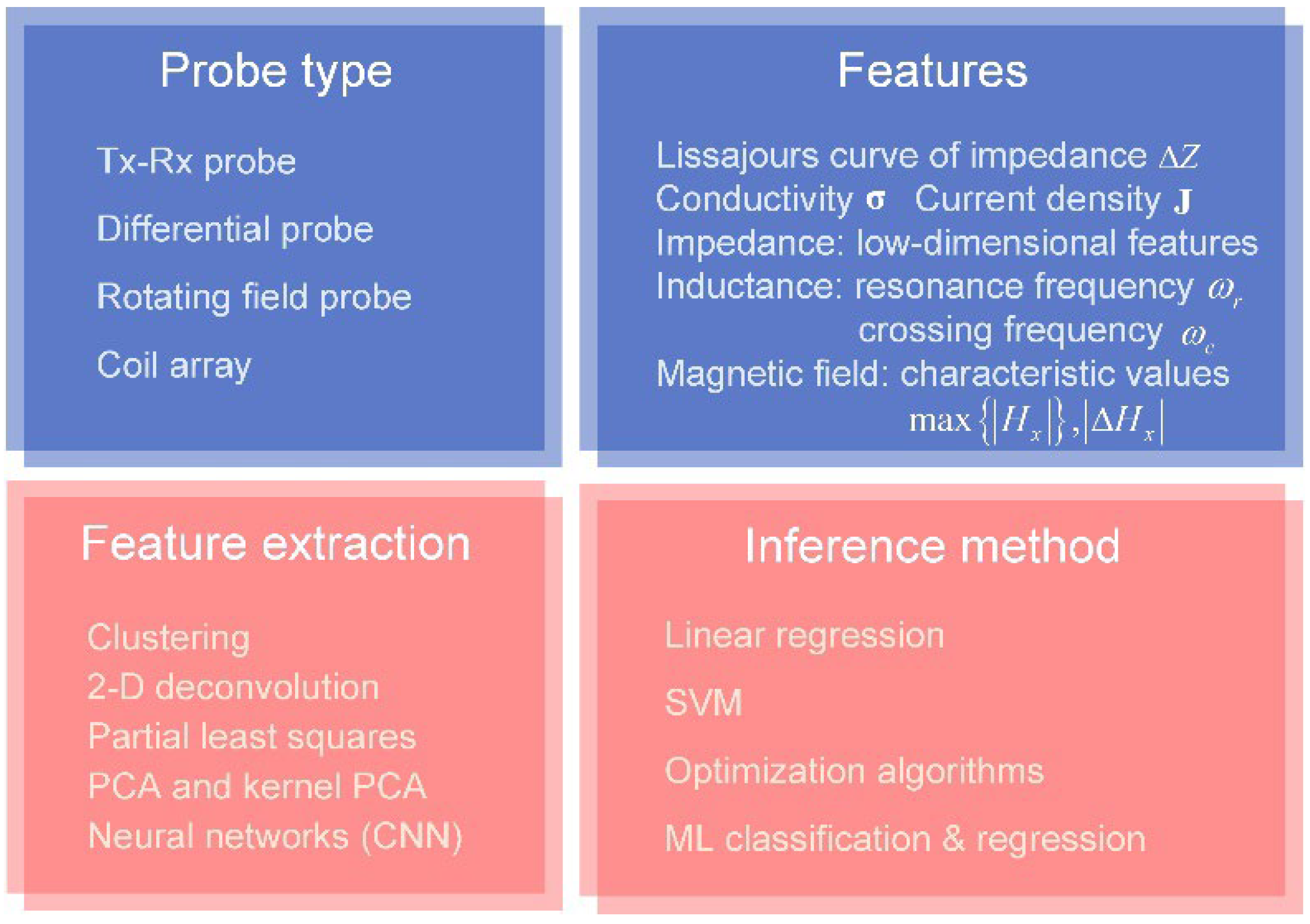

:1. Introduction

2. Computational Models

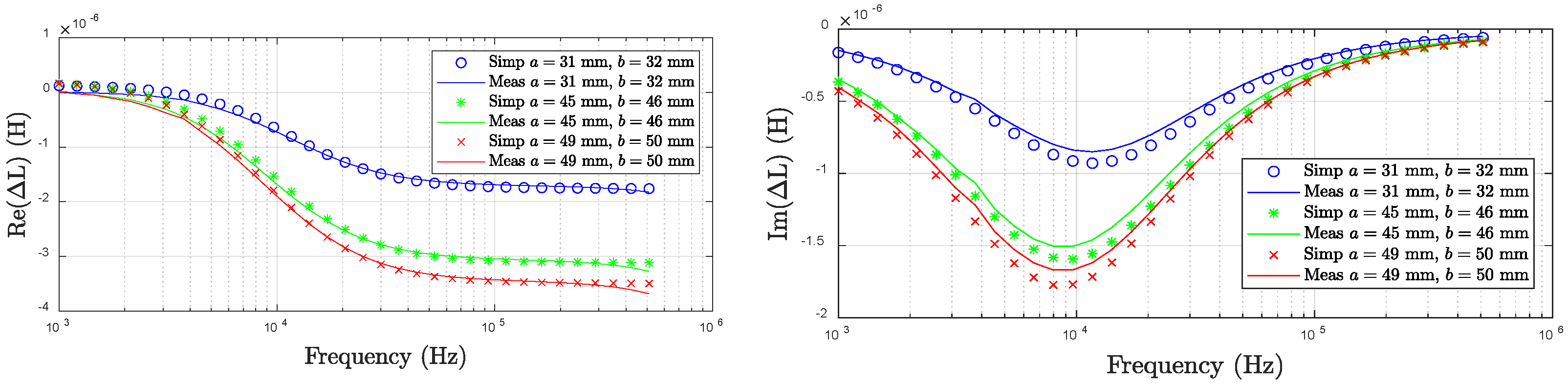

2.1. Analytical Models

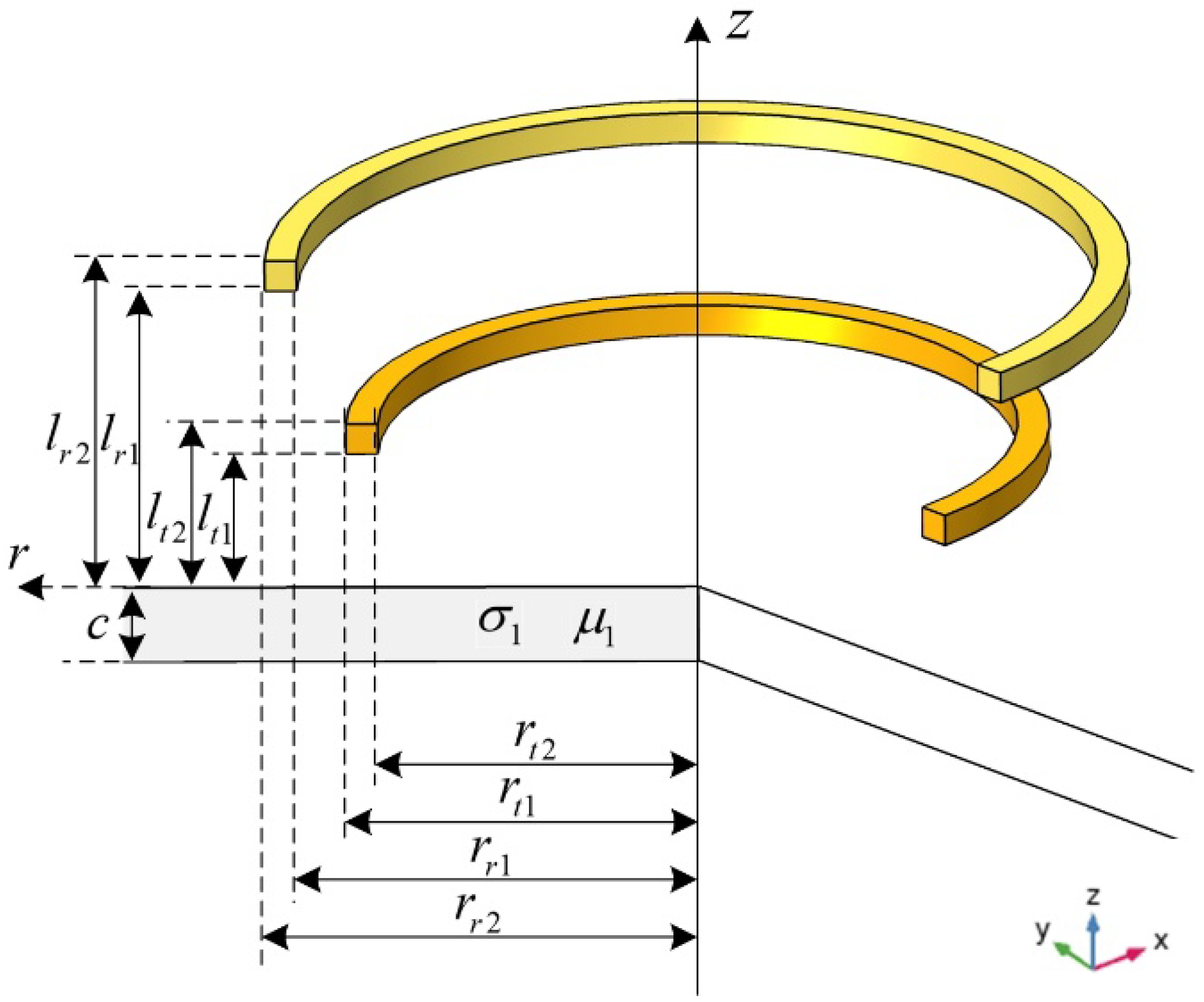

2.1.1. Dodd and Deeds and Associated Simplified Models

2.1.2. Model for the Finite-Size Plate

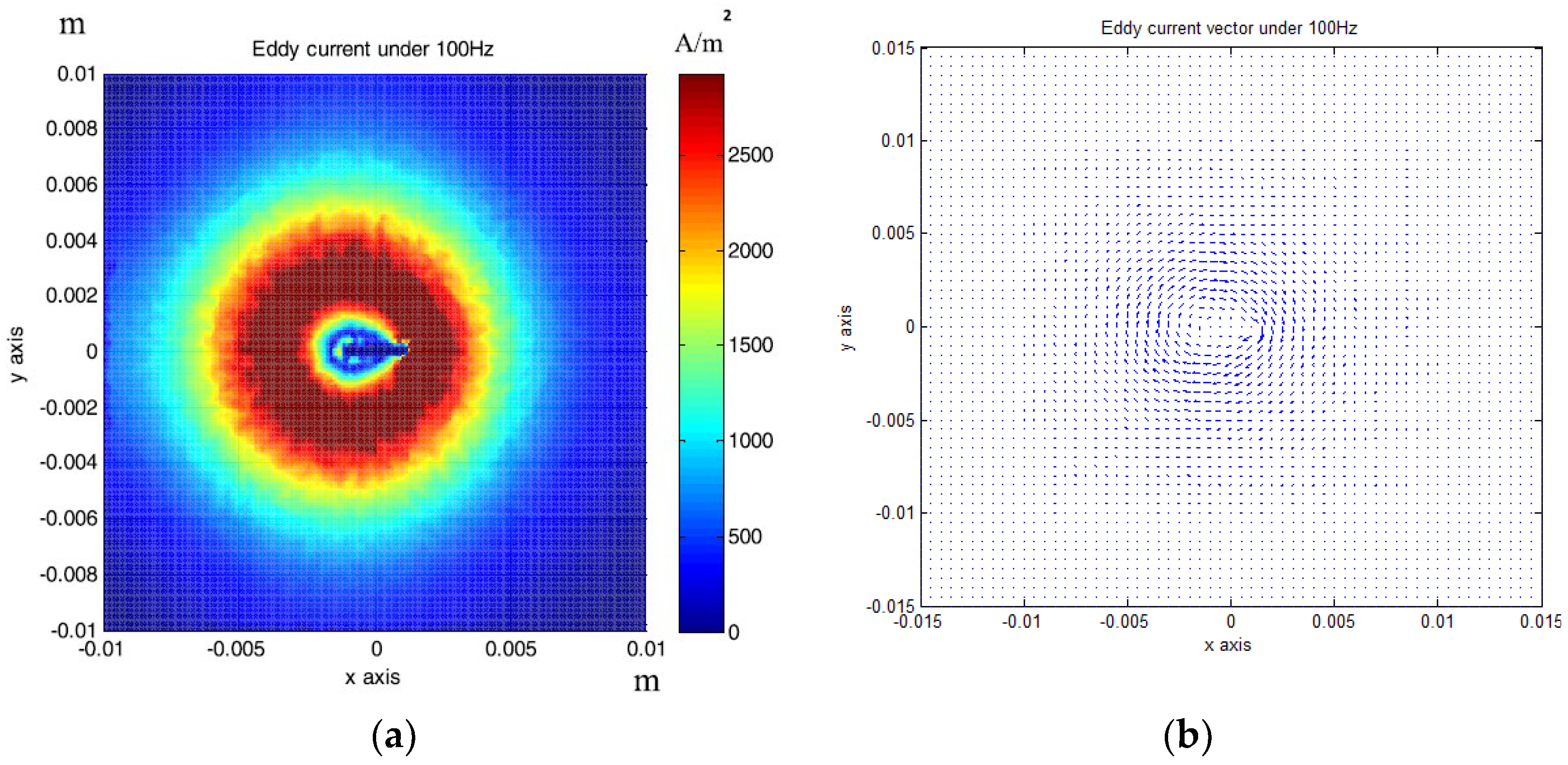

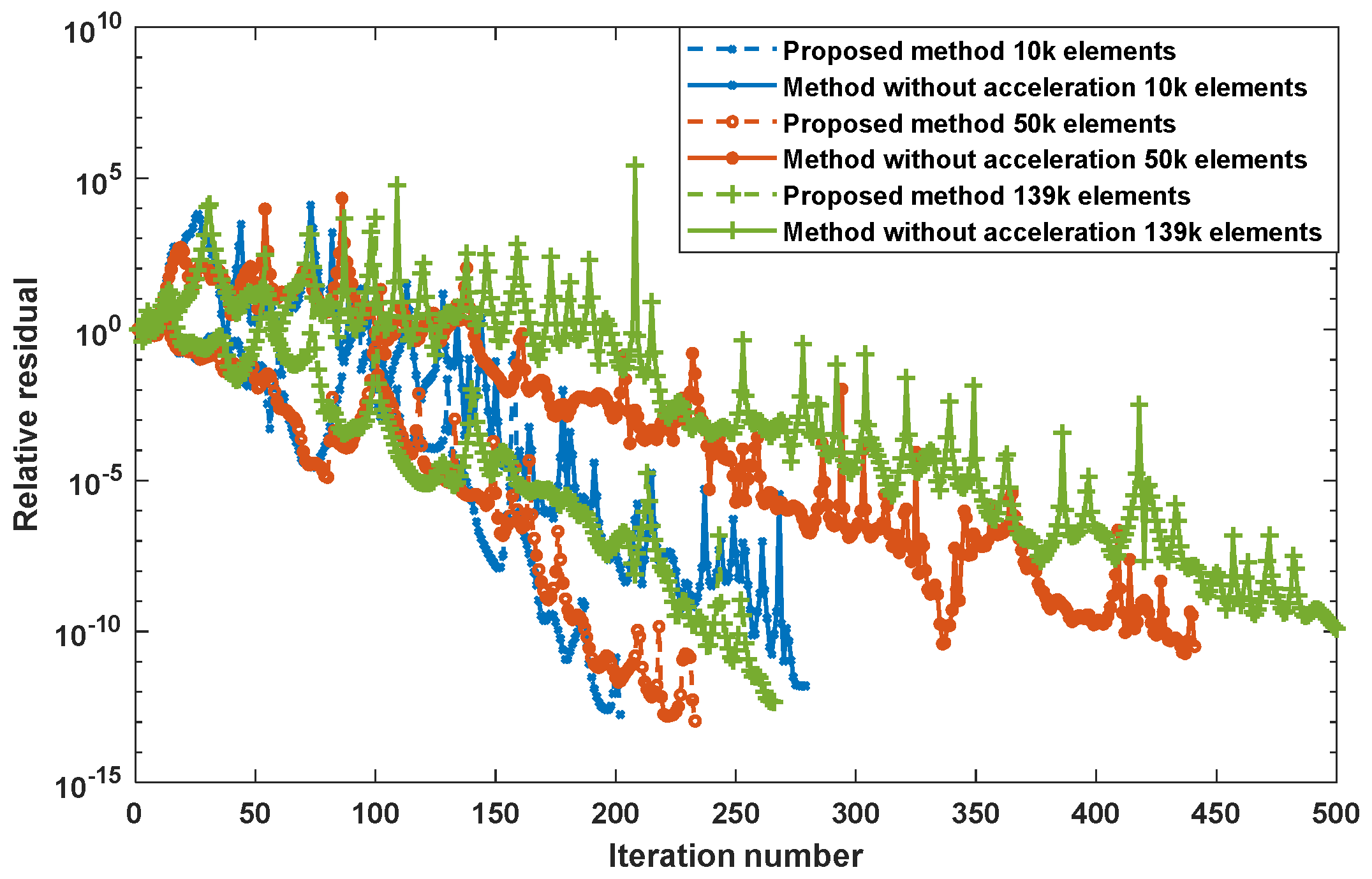

2.2. Finite Element Method

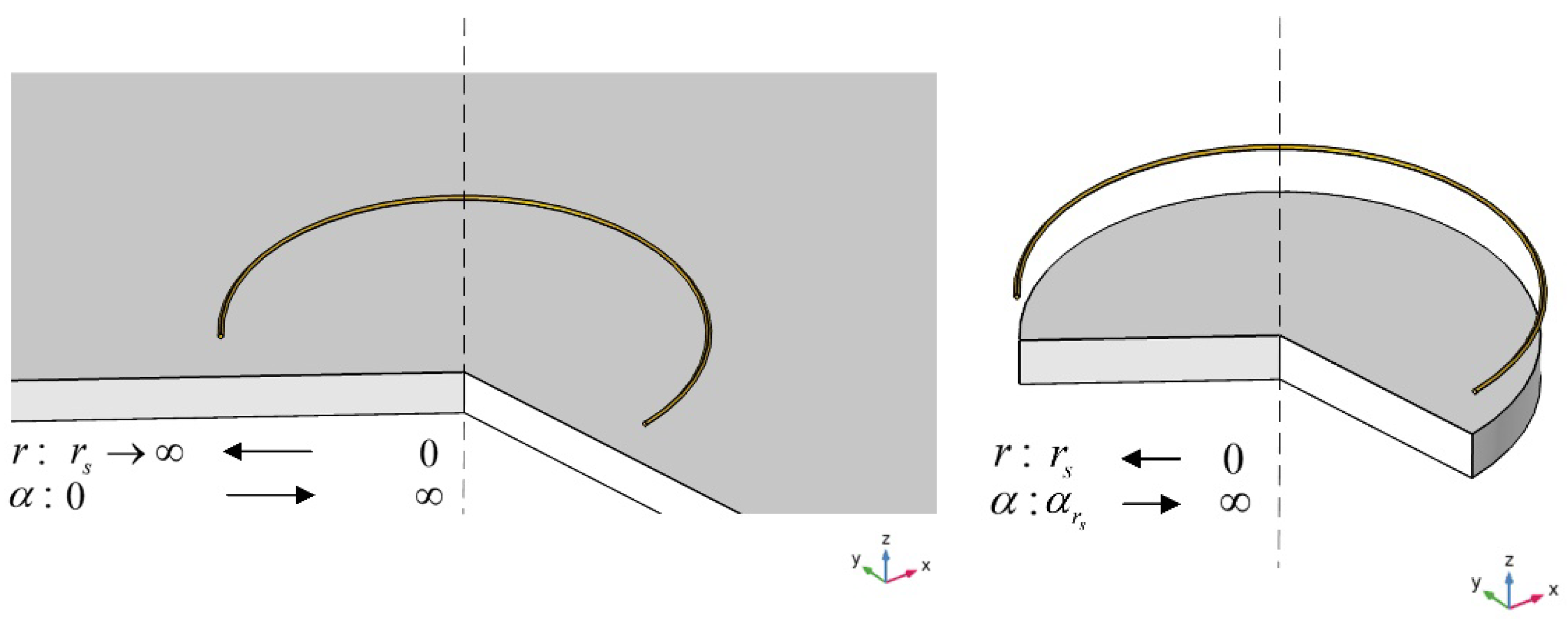

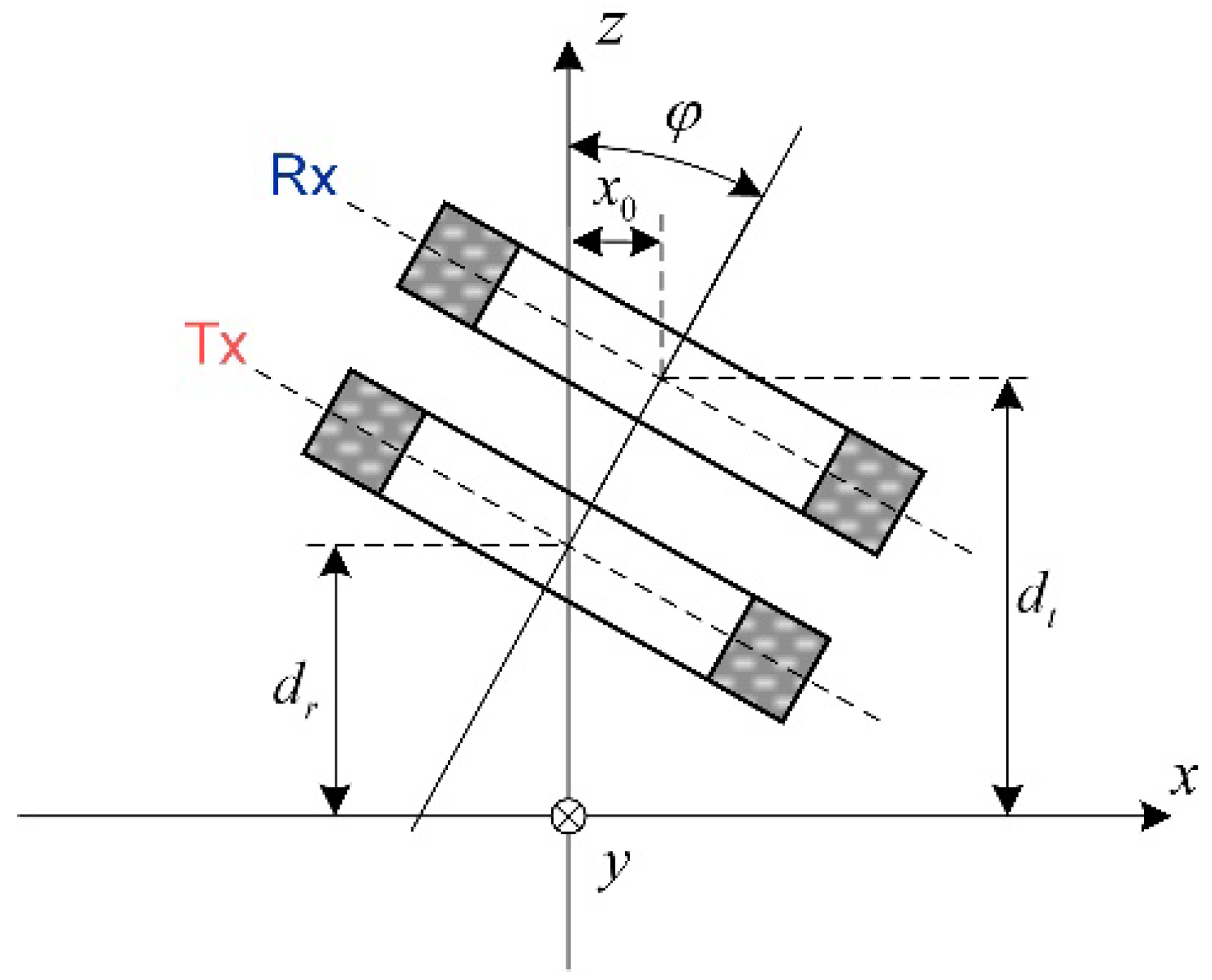

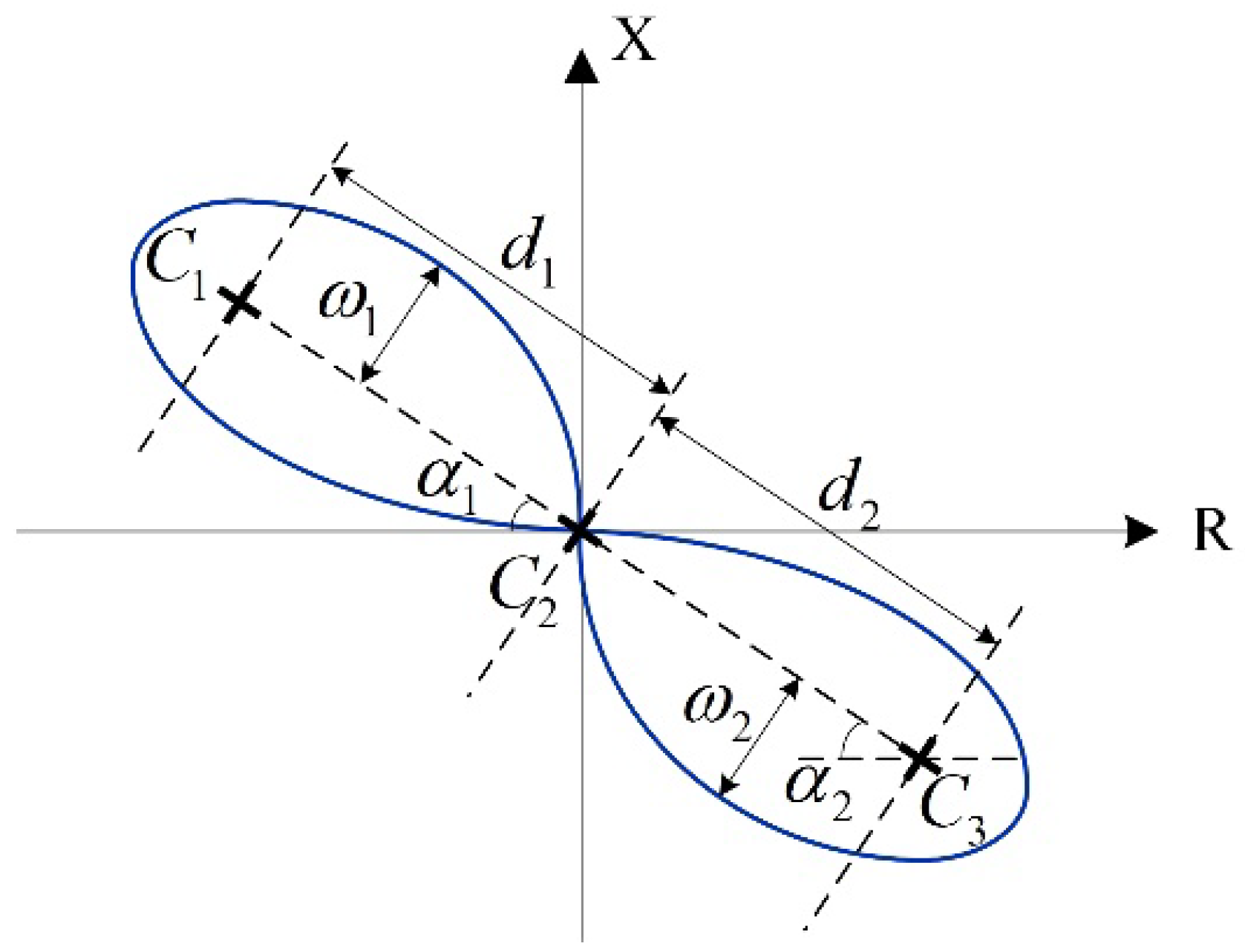

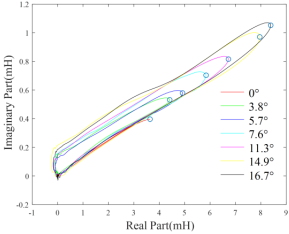

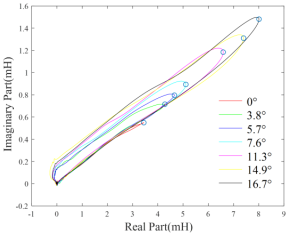

2.3. Tilted Structure Measurement

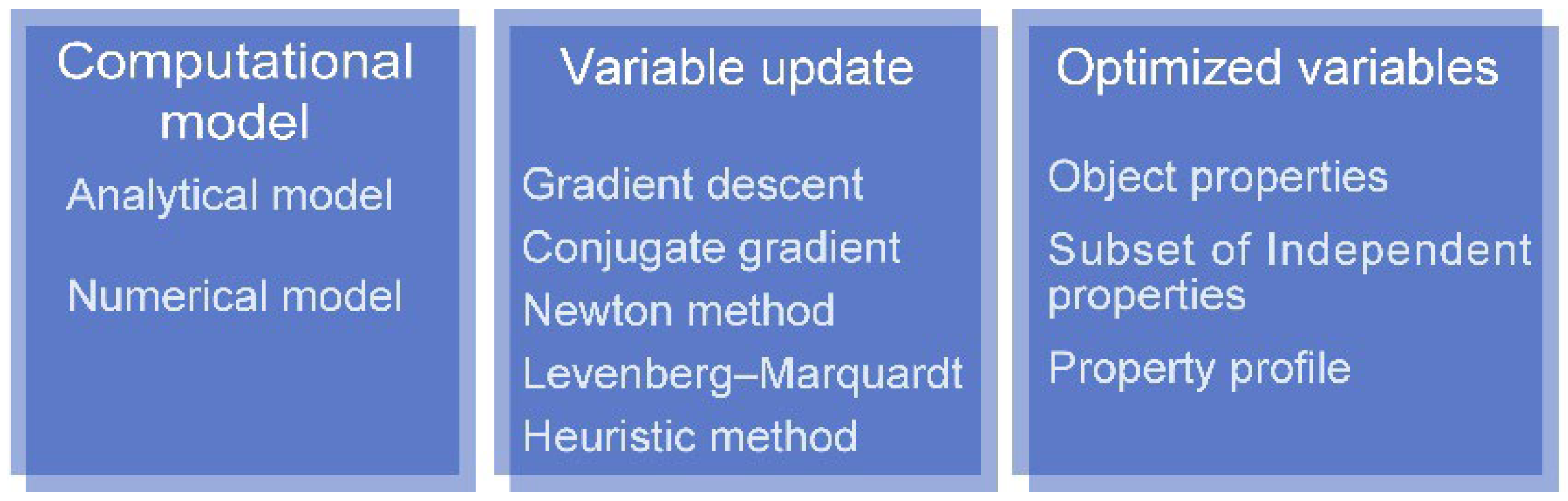

2.4. Multivariable Inversion

3. Measurement System

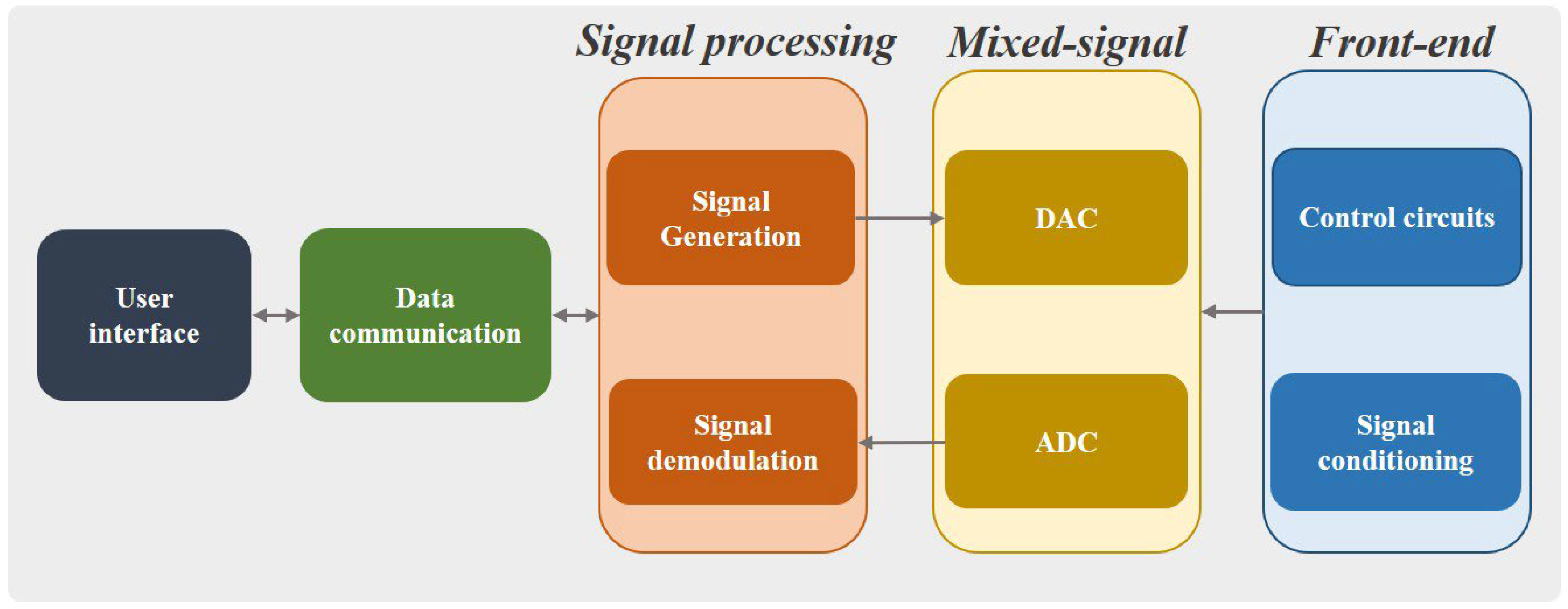

3.1. Impedance Measurement System

3.1.1. Overview of EC Testing Instruments

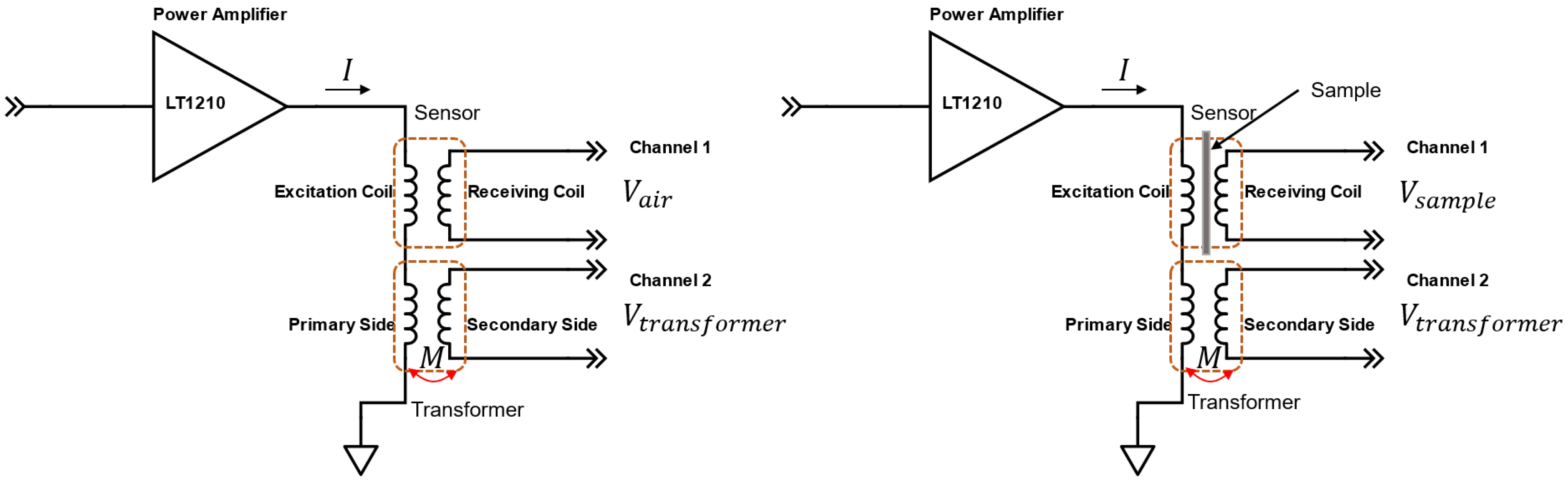

3.1.2. Customized EC Testing Instrument

3.1.3. Commercial Impedance Analyzers

3.1.4. Calibration

3.2. Probe Design

4. Planar Structure Measurements and Applications

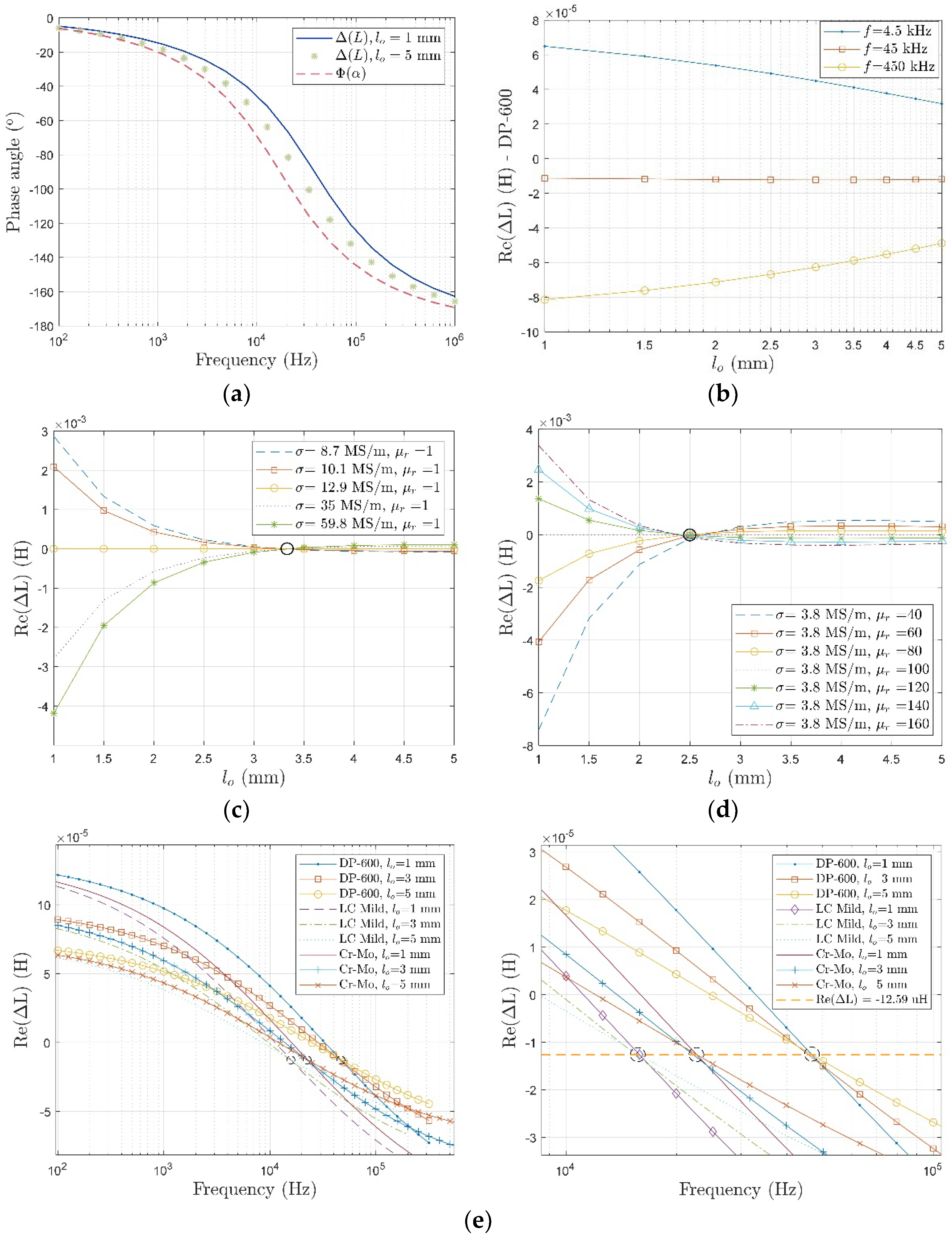

4.1. Reducing the Lift-Off Effects

4.1.1. Lift-Off Compensation Using Multiple Measurements

4.1.2. Lift-Off Compensating Algorithms

4.1.3. Lift-Off Invariance Phenomenon

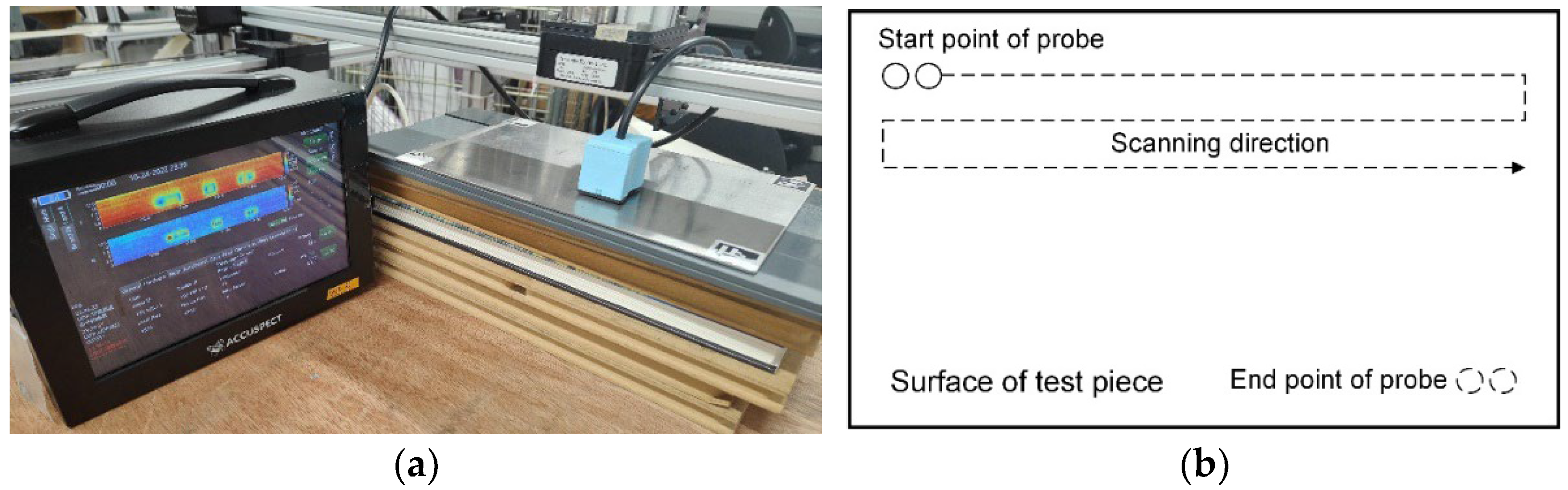

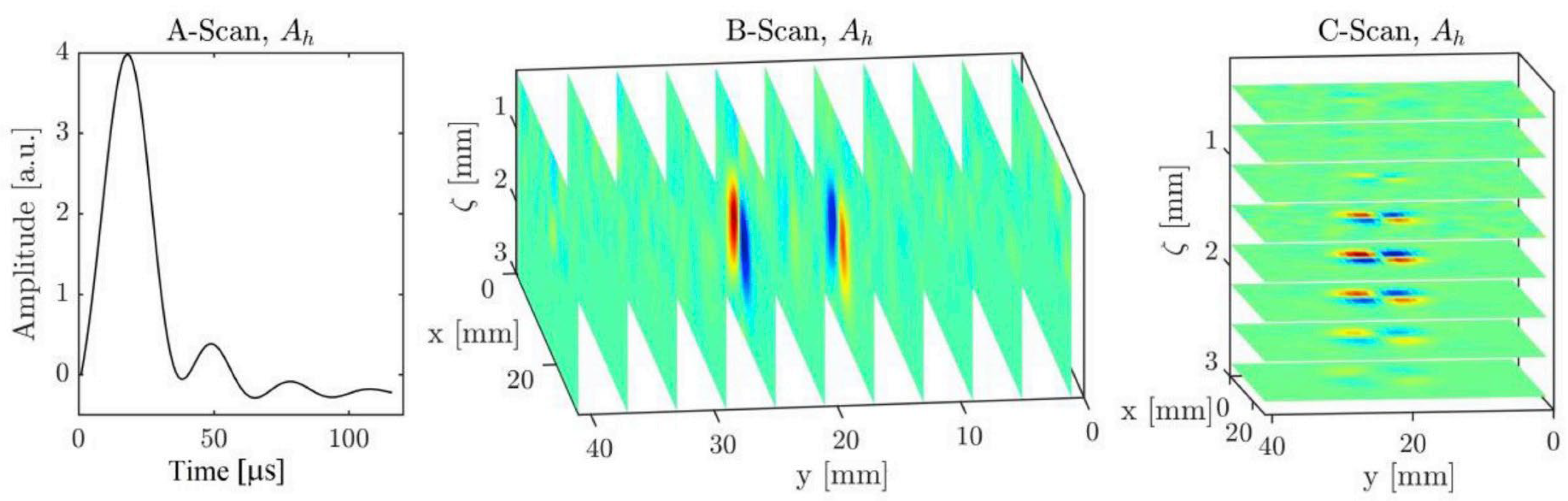

4.2. Defect Scanning

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, J.; Wu, J.; Xin, W.; Ge, Z.L. Measuring Ultrathin Metallic Coating Properties Using Swept-Frequency Eddy-Current Technique. IEEE Trans. Instrum. Meas. 2020, 69, 5772–5781. [Google Scholar] [CrossRef]

- Cheng, W.Y. Swept-frequency eddy current testing to characterize a nonmagnetic metallic plate and a nonconductive coating over it. Int. J. Appl. Electromagn. Mech. 2019, 59, 1169–1178. [Google Scholar] [CrossRef]

- Xu, J.; Wu, J.; Xin, W.; Ge, Z.L. Fast Measurement of the Coating Thickness and Conductivity Using Eddy Currents and Plane Wave Approximation. IEEE Sens. J. 2021, 21, 306–314. [Google Scholar] [CrossRef]

- AbdAlla, A.N.; Faraj, M.A.; Samsuri, F.; Rifai, D.; Ali, K.; Al-Douri, Y. Challenges in improving the performance of eddy current testing: Review. Meas. Control 2019, 52, 46–64. [Google Scholar] [CrossRef] [Green Version]

- Hohmann, R.; Lomparski, D.; Krause, H.J.; Von Kreurzbruck, M.; Becker, W. Aircraft wheel testing with remote eddy current technique using a HTS SQUID magnetometer. IEEE Trans. Appl. Supercond. 2001, 11, 1279–1282. [Google Scholar] [CrossRef]

- Qi, G.J.; Lei, H.; Fu, G.Q.; Jing, P.; Lin, J.M. In Situ Eddy-Current Testing on Low-Pressure Turbine Blades of Aircraft Engine. J. Test. Eval. 2012, 40, 553–556. [Google Scholar] [CrossRef]

- Liu, Z.; Li, W.; Xue, F.Q.; Xiafang, J.Y.; Bu, B.; Yi, Z. Electromagnetic Tomography Rail Defect Inspection. IEEE Trans. Magn. 2015, 51, 1–7. [Google Scholar] [CrossRef]

- Augustyniak, M.; Borzyszkowski, P.; Bulawa, M. Towards an Universal Method for Predicting Eddy-Current Sensor Characteristics in the Railway Industry. Nondestruct. Eval. 2019, 38, 29. [Google Scholar] [CrossRef] [Green Version]

- Guilizzoni, R.; Finch, G.; Harmon, S. Subsurface corrosion detection in industrial steel structures. IEEE Magn. Lett. 2019, 10, 1–5. [Google Scholar] [CrossRef]

- Qu, Z.; Zhao, Q.; Meng, Y. Improvement of sensitivity of eddy current sensors for nano-scale thickness measurement of Cu films. NDT E Int. 2014, 61, 53–57. [Google Scholar] [CrossRef]

- Qu, Z.; Meng, Y.; Zhao, Q. Eddy current measurement of the thickness of top Cu film of the multilayer interconnects in the integrated circuit (IC) manufacturing process. Front. Mech. Eng. 2015, 10, 1–6. [Google Scholar] [CrossRef]

- Li, H.; Zhao, Q.; Lu, X.; Luo, J. Signal processing and analysis for copper layer thickness measurement within a large variation range in the CMP process. Rev. Sci. Instrum. 2017, 88, 115103. [Google Scholar] [CrossRef] [PubMed]

- Dodd, C.V.; Luquire, J.; Deeds, W.; Spoeri, W. Some Eddy-Current Problems and Their Integral Solutions; Oak Ridge National Lab.: Oak Ridge, TN, USA, 1969. [Google Scholar]

- Dodd, C.; Deeds, W. Analytical solutions to eddy-current probe-coil problems. J. Appl. Phys. 1968, 39, 2829–2838. [Google Scholar] [CrossRef] [Green Version]

- Theodoulidis, T.; Kriezis, E.E. Application of the TREE method to Axisymmetric Problems. In Eddy Current Canonical Problems (with Applications to Nondestructive Evaluation); Tech Science Press: Henderson, NV, USA, 2006; pp. 152–182. [Google Scholar]

- Huang, R.; Lu, M.; Zhang, Z.; Zhao, Q.; Xie, Y.; Tao, Y.; Meng, T.; Peyton, A.; Theodoulidis, T.; Yin, W. Measurement of the radius of metallic plates based on a novel finite region eigenfunction expansion (FREE) method. IEEE Sens. J. 2020, 20, 15099–15106. [Google Scholar] [CrossRef]

- Lu, M.; Yin, L.; Peyton, A.J.; Yin, W. A novel compensation algorithm for thickness measurement immune to lift-off variations using eddy current method. IEEE Trans. Instrum. Meas. 2016, 65, 2773–2779. [Google Scholar]

- Zeng, Z.W.; Jiao, S.N.; Du, F.; Sun, L.; Li, J. Eddy Current Testing of Delamination in Carbon Fiber Reinforced Polymer (CFRP): A Finite Element Analysis. Res. Nondestruct. Eval. 2018, 29, 199–211. [Google Scholar] [CrossRef]

- Tian, Q.Z.; Zeng, Z.W. Hybrid Formulation Domain-Decomposition Finite-Element Method for Simulating Eddy-Current Testing. IEEE Trans. Magn. 2020, 56, 1–6. [Google Scholar] [CrossRef]

- Barbato, L.; Poulakis, N.; Tamburrino, A.; Theodoulidis, T.; Ventre, S. Solution and Extension of a New Benchmark Problem for Eddy-Current Nondestructive Testing. IEEE Trans. Magn. 2015, 51, 1–7. [Google Scholar] [CrossRef]

- Tesfalem, H.; Fletcher, A.D.; Brown, M.; Chapman, B.; Peyton, A.J. Study of asymmetric gradiometer sensor configurations for eddy current based non-destructive testing in an industrial environment. NDT E Int. 2018, 100, 1–10. [Google Scholar] [CrossRef]

- Huang, R.; Lu, M.; Chen, Z.; Shao, Y.; Xia, Z.; Hu, G.; Peyton, A.; Yin, W. A novel acceleration method for crack computation using finite element analysis in eddy current testing. IEEE Trans. Instrum. Meas. 2022, 71, 1–9. [Google Scholar] [CrossRef]

- Huang, R.; Lu, M.; Peyton, A.; Yin, W. A novel perturbed matrix inversion based method for the acceleration of finite element analysis in crack-scanning eddy current NDT. IEEE Access 2020, 8, 12438–12444. [Google Scholar] [CrossRef]

- Lu, M.; Meng, X.; Huang, R.; Chen, L.; Peyton, A.; Yin, W. Inversion of distance and magnetic permeability based on material-independent and liftoff insensitive algorithms using eddy current sensor. IEEE Trans. Instrum. Meas. 2020, 70, 6001609. [Google Scholar] [CrossRef]

- Cui, Z.; Wang, Q.; Xue, Q.; Fan, W.; Zhang, L.; Cao, Z.; Sun, B.; Wang, H.; Yang, W. A review on image reconstruction algorithms for electrical capacitance/resistance tomography. Sens. Rev. 2016, 36, 429–445. [Google Scholar] [CrossRef]

- Lu, M.; Xie, Y.; Zhu, W.; Peyton, A.; Yin, W. Determination of the magnetic permeability, electrical conductivity, and thickness of ferrite metallic plates using a multifrequency electromagnetic sensing system. IEEE Trans. Ind. Inform. 2018, 15, 4111–4119. [Google Scholar] [CrossRef] [Green Version]

- Ali, K.B.; Abdalla, A.N.; Rifai, D.; Faraj, M.A. Review on system development in eddy current testing and technique for defect classification and characterization. IET Circuits, Devices Syst. 2017, 11, 338–351. [Google Scholar] [CrossRef] [Green Version]

- García-Martín, J.; Gómez-Gil, J.; Vázquez-Sánchez, E. Non-destructive techniques based on eddy current testing. Sensors 2011, 11, 2525–2565. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Sun, Y.; Jiang, X.; Kang, Y. A review of wire rope detection methods, sensors and signal processing techniques. J. Nondestr. Eval. 2020, 39, 85. [Google Scholar] [CrossRef]

- Sophian, A.; Tian, G.; Fan, M. Pulsed eddy current non-destructive testing and evaluation: A review. Chin. J. Mech. Eng. 2017, 30, 500–514. [Google Scholar] [CrossRef] [Green Version]

- Cheng, W. Measurement of magnetic plates at a few hertz with two concentric coils and thickness estimation using mutual inductance. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Theodoulidis, T.P.; Bowler, J.R. The Truncated Region Eigenfunction Expansion Method for the Solution of Boundary Value Problems in Eddy Current Nondestructive Evaluation. AIP Conf. Proc. 2005, 760, 403–408. [Google Scholar] [CrossRef]

- Yin, W.; Peyton, A.J.; Dickinson, S.J. Simultaneous measurement of distance and thickness of a thin metal plate with an electromagnetic sensor using a simplified model. IEEE Trans. Instrum. Meas. 2004, 53, 1335–1338. [Google Scholar] [CrossRef]

- Huang, R.; Lu, M.; He, X.; Peyton, A.; Yin, W. Measuring coaxial hole size of finite-size metallic disk based on a dual-constraint integration feature using multifrequency eddy current testing. IEEE Trans. Instrum. Meas. 2020, 70, 1–7. [Google Scholar] [CrossRef]

- Huang, R.; Lu, M.; Peyton, A.; Yin, W. Thickness measurement of metallic plates with finite planar dimension using eddy current method. IEEE Trans. Instrum. Meas. 2020, 69, 8424–8431. [Google Scholar] [CrossRef]

- Pavo, J.; Miya, K. Reconstruction of crack shape by optimization using eddy current field measurement. IEEE Trans. Magn. 1994, 30, 3407–3410. [Google Scholar] [CrossRef]

- Yin, W.; Tang, J.; Lu, M.; Xu, H.; Huang, R.; Zhao, Q.; Zhang, Z.; Peyton, A. An equivalent-effect phenomenon in eddy current non-destructive testing of thin structures. IEEE Access 2019, 7, 70296–70307. [Google Scholar] [CrossRef]

- Bowler, J.R.; Theodoulidis, T.P.; Poulakis, N. Eddy current probe signals due to a crack at a right-angled corner. IEEE Trans. Magn. 2012, 48, 4735–4746. [Google Scholar] [CrossRef]

- Du, Y.; Xie, S.; Li, X.; Chen, Z.; Uchimoto, T.; Takagi, T. A fast forward simulation scheme for eddy current testing of crack in a structure of carbon fiber reinforced polymer laminate. IEEE Access 2019, 7, 152278–152288. [Google Scholar] [CrossRef]

- Zhao, K.; Vouvakis, M.N.; Lee, J.-F. Solving electromagnetic problems using a novel symmetric FEM-BEM approach. IEEE Trans. Magn. 2006, 42, 583–586. [Google Scholar] [CrossRef]

- Bíró, O. Edge element formulations of eddy current problems. Comput. Methods Appl. Mech. Eng. 1999, 169, 391–405. [Google Scholar] [CrossRef]

- Lu, M.; Peyton, A.; Yin, W. Acceleration of frequency sweeping in eddy-current computation. IEEE Trans. Magn. 2017, 53, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Yin, W.; Lu, M.; Yin, L.; Zhao, Q.; Meng, X.; Zhang, Z.; Peyton, A. Acceleration of eddy current computation for scanning probes. Insight Non-Destr. Test. Cond. Monit. 2018, 60, 547–555. [Google Scholar] [CrossRef]

- Theodoulidis, T. Analytical model for tilted coils in eddy-current nondestructive inspection. IEEE Trans. Magn. 2005, 41, 2447–2454. [Google Scholar] [CrossRef]

- Chao, X.; Li, Y.; Nie, J. Tilt angle measurement based on arrayed eddy current sensors. J. Magn. 2016, 21, 524–528. [Google Scholar] [CrossRef] [Green Version]

- Burke, S. Eddy-current induction in a uniaxially anisotropic plate. J. Appl. Phys. 1990, 68, 3080–3090. [Google Scholar] [CrossRef]

- Beissner, R.; Sablik, M. Theory of eddy currents induced by a nonsymmetric coil above a conducting half-space. J. Appl. Phys. 1984, 56, 448–454. [Google Scholar] [CrossRef]

- Burke, S.; Ibrahim, M. Mutual impedance of air-cored coils above a conducting plate. J. Phys. D Appl. Phys. 2004, 37, 1857. [Google Scholar] [CrossRef]

- Harfield, N.; Bowler, J.R. Theory of thin-skin eddy-current interaction with surface cracks. J. Appl. Phys. 1997, 82, 4590–4603. [Google Scholar] [CrossRef]

- Ditchburn, R.; Burke, S.; Posada, M. Eddy-current nondestructive inspection with thin spiral coils: Long cracks in steel. J. Nondestruct. Eval. 2003, 22, 63–77. [Google Scholar] [CrossRef]

- Lu, M.; Meng, X.; Huang, R.; Peyton, A.; Yin, W. Analysis of tilt effect on notch depth profiling using thin-skin regime of driver-pickup eddy-current sensor. Sensors 2021, 21, 5536. [Google Scholar] [CrossRef]

- O’Toole, M.D.; Karimian, N.; Peyton, A.J. Classification of nonferrous metals using magnetic induction spectroscopy. IEEE Trans. Ind. Inform. 2017, 14, 3477–3485. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zhang, Z.; Yin, W.; Chen, H.; Yu, Z.; Wang, Q. A Novel Conductivity Classification Technique for Nonmagnetic Metal Immune to Tilt Variations Using Eddy Current Testing. IEEE Access 2021, 9, 135334–135342. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, Z.; Yin, W.; Zhu, S.; Chen, Z.; Xu, H. Conductivity classification of non-magnetic tilting metals by eddy current sensors. Sensors 2020, 20, 2608. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Zhang, Z.; Yin, W.; Tytko, G. Sloping-invariance for nonferrous metallic slabs at multiple frequencies by eddy current sensors. IEEE Access 2021, 9, 59949–59956. [Google Scholar] [CrossRef]

- Hampton, J.; Fletcher, A.; Tesfalem, H.; Peyton, A.; Brown, M. A comparison of non-linear optimisation algorithms for recovering the conductivity depth profile of an electrically conductive block using eddy current inspection. NDT E Int. 2022, 125, 102571. [Google Scholar] [CrossRef]

- Uzal, E.; Moulder, J.; Rose, J. Experimental determination of the near-surface conductivity profiles of metals from electromagnetic induction (eddy current) measurements. Inverse Probl. 1994, 10, 753. [Google Scholar] [CrossRef]

- Cai, W.; Jomdecha, C.; Zhao, Y.; Wang, L.; Xie, S.; Chen, Z. Quantitative evaluation of electrical conductivity inside stress corrosion crack with electromagnetic NDE methods. Philos. Trans. R. Soc. London. Ser. A 2020, 378, 20190589. [Google Scholar] [CrossRef]

- Ge, J.; Yusa, N.; Fan, M. Frequency component mixing of pulsed or multi-frequency eddy current testing for nonferromagnetic plate thickness measurement using a multi-gene genetic programming algorithm. NDT E Int. 2021, 120, 102423. [Google Scholar] [CrossRef]

- Meng, X.; Lu, M.; Yin, W.; Bennecer, A.; Kirk, K.J. Inversion of lift-off distance and thickness for nonmagnetic metal using eddy current testing. IEEE Trans. Instrum. Meas. 2020, 70, 1–8. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Wang, Z. Inversion method in pulsed eddy current testing for wall thickness of ferromagnetic pipes. IEEE Trans. Instrum. Meas. 2020, 69, 9766–9773. [Google Scholar] [CrossRef]

- Haddar, H.; Jiang, Z.; Riahi, M.K. A robust inversion method for quantitative 3D shape reconstruction from coaxial eddy current measurements. J. Sci. Comput. 2017, 70, 29–59. [Google Scholar] [CrossRef] [Green Version]

- Du, Y.; Li, X.; Xie, S.; Yang, S.; Chen, Z. Reconstruction of cracks in a carbon fiber-reinforced polymer laminate plate from signals of eddy current testing. J. Compos. Mater. 2020, 54, 3527–3536. [Google Scholar] [CrossRef]

- Adewale, I.D.; Tian, G.Y. Decoupling the influence of permeability and conductivity in pulsed eddy-current measurements. IEEE Trans. Magn. 2012, 49, 1119–1127. [Google Scholar] [CrossRef]

- Vasic, D.; Bilas, V.; Ambrus, D. Validation of a coil impedance model for simultaneous measurement of electromagnetic properties and inner diameter of a conductive tube. IEEE Trans. Instrum. Meas. 2006, 55, 337–342. [Google Scholar] [CrossRef]

- Vasić, D.; Bilas, V. Lumped representation in inductive measurement of metal casing properties. In Proceedings of 2010 IEEE Instrumentation & Measurement Technology Conference Proceedings, Austin, TX, USA, 3–6 May 2010; pp. 841–844. [Google Scholar]

- Ghaffari, A.; Krstić, M.; Nešić, D. Multivariable Newton-based extremum seeking. Automatica 2012, 48, 1759–1767. [Google Scholar] [CrossRef]

- Schöbi, R. Surrogate models for uncertainty quantification in the context of imprecise probability modelling. IBK Ber. 2019, 505, 1–259. [Google Scholar]

- Zhang, J.; Yin, J.; Wang, R. Basic framework and main methods of uncertainty quantification. Math. Probl. Eng. 2020, 2020, 6068203. [Google Scholar] [CrossRef]

- Aster, R.C.; Borchers, B.; Thurber, C.H. Chapter Three—Rank Deficiency and Ill-Conditioning. In Parameter Estimation and Inverse Problems, 3rd ed.; Aster, R.C., Borchers, B., Thurber, C.H., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 55–91. [Google Scholar] [CrossRef]

- Salcedo-Sanz, S. Modern meta-heuristics based on nonlinear physics processes: A review of models and design procedures. Phys. Rep. 2016, 655, 1–70. [Google Scholar] [CrossRef]

- Parouha, R.P.; Verma, P. State-of-the-art reviews of meta-heuristic algorithms with their novel proposal for unconstrained optimization and applications. Arch. Comput. Methods Eng. 2021, 28, 4049–4115. [Google Scholar] [CrossRef]

- Lu, M. Forward and Inverse Analysis for non-Destructive Testing Based on Electromagnetic Computation Methods. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2018. [Google Scholar]

- Hampton, J.; Tesfalem, H.; Dorn, O.; Fletcher, A.; Peyton, A.; Brown, M. Calibration of a Finite Element Forward Model in Eddy Current Inspection. IEEE Sens. J. 2022, 22, 10699–10707. [Google Scholar] [CrossRef]

- Wu, J.; Zhou, D.; Wang, J.; Guo, X.; You, L.; An, W.; Zhang, H. Surface crack detection for carbon fiber reinforced plastic (CFRP) materials using pulsed eddy current testing. In Proceedings of 2014 IEEE Far East Forum on Nondestructive Evaluation/Testing, Chengdu, China, 20–23 June 2014; pp. 181–185. [Google Scholar]

- O’Toole, M.D.; Karimian, N.; Peyton, A.J. Fast classification of non-magnetic metal targets using eddy-current based impedance spectroscopy. In Proceedings of 2017 IEEE SENSORS, Glasgow, UK, 29 October–1 November 2017; pp. 1–3. [Google Scholar]

- Tao, Y.; Xu, H.; Chen, Z.; Huang, R.; Yin, W. Automatic feature extraction method for crack detection in eddy current testing. In Proceedings of 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019. [Google Scholar]

- Tao, Y.; Ktistis, C.; Zhao, Y.; Yin, W.; Peyton, A.J. A Class D Power Amplifier for Multifrequency Eddy Current Testing Based on Multisimultaneous-Frequency Selective Harmonic Elimination Pulsewidth Modulation. IEEE Trans. Ind. Electron. 2019, 67, 8799–8807. [Google Scholar] [CrossRef] [Green Version]

- Bernieri, A.; Betta, G.; Ferrigno, L.; Laracca, M. Multi-frequency ECT method for defect depth estimation. In Proceedings of IEEE Sensors Applications Symposium, Brescia, Italy, 7–9 February 2012; pp. 1–6. [Google Scholar]

- Yin, W.; Dickinson, S.J.; Peyton, A.J. A multi-frequency impedance analysing instrument for eddy current testing. Meas. Sci. Technol. 2006, 17, 393–402. [Google Scholar] [CrossRef]

- Avila, J.; Chen, Z.; Xu, H.; Yin, W. A multi-frequency NDT system for imaging and detection of cracks. In Proceedings of 2018 IEEE International Symposium on Circuits and Systems (ISCAS), Florence, Italy, 27–30 May 2018. [Google Scholar]

- Betta, G.; Ferrigno, L.; Laracca, M.; Burrascano, P.; Ricci, M. Optimized complex signals for eddy current testing. In Proceedings of 2014 IEEE International Instrumentation and Measurement Technology Conference (I2MTC) Proceedings, Montevideo, Uruguay, 12–15 May 2014; pp. 1120–1125. [Google Scholar]

- Yin, W.; Chen, G.; Chen, L.; Wang, B. The Design of a Digital Magnetic Induction Tomography (MIT) System for Metallic Object Imaging Based on Half Cycle Demodulation. IEEE Sens. J. 2011, 11, 2233–2240. [Google Scholar]

- Yin, W.; Chen, G.; Jian, J.; Cui, Z. The design of a FPGA-based digital magnetic induction tomography (MIT) system for metallic object imaging. In Proceedings of IEEE Instrumentation & Measurement Technology Conference, Austin, TX, USA, 3–6 May 2010. [Google Scholar]

- Wei, H.Y.; Soleimani, M. Hardware and software design for a National Instrument-based magnetic induction tomography system for prospective biomedical applications. Physiol. Meas. 2012, 33, 863. [Google Scholar] [CrossRef] [PubMed]

- Hanyang, X.; Avila, S.; Ricardo, J.; Fanfu, W.; Roy, M.J.; Xie, Y.; Zhou, F. Imaging x70 weld cross-section using electromagnetic testing. NDT E Int. 2018, 98, 155–160. [Google Scholar]

- Zhu, W.; Yang, H.; Luinenburg, A.; Van Den Berg, F.; Dickinson, S.; Yin, W.; Peyton, A.J. Development and deployment of online multifrequency electromagnetic system to monitor steel hot transformation on runout table of hot strip mill. Ironmak. Steelmak. 2014, 41, 685–693. [Google Scholar] [CrossRef]

- Yin, W.; Peyton, A.J. A planar EMT system for the detection of faults on thin metallic plates. Meas. Sci. Technol. 2006, 17, 2130–2135. [Google Scholar] [CrossRef]

- Chao, W.; He, H.; Cui, Z.; Cao, Q.; Ping, Z.; Wang, H. A novel EMT system based on TMR sensors for reconstruction of permeability distribution. Meas. Sci. Technol. 2018, 29, 104008. [Google Scholar]

- Ma, X.; Peyton, A.J.; Higson, S.R.; Lyons, A.; Dickinson, S.J. Hardware and software design for an electromagnetic induction tomography (EMT) system for high contrast metal process applications. Meas. Sci. Technol. 2006, 17, 111–118. [Google Scholar] [CrossRef]

- Kekelj, M.; Bulic, N.; Sucic, V. An FPGA implementation of the Goertzel algorithm in a Non-Destructive Eddy current Testing. In Proceedings of 2017 International Conference on Signals and Systems (ICSigSys), Bali, Indonesia, 16–18 May 2017; pp. 180–184. [Google Scholar]

- Hamel, M.; Mohellebi, H. A LabVIEW-based real-time acquisition system for crack detection in conductive materials. Math. Comput. Simul. 2020, 167, 381–388. [Google Scholar] [CrossRef]

- Zhang, N.; Peng, L.; He, Y.; Ye, C. Flexible Probe With Array Tunneling Magnetoresistance Sensors for Curved Structure Inspection. IEEE Trans. Instrum. Meas. 2022, 71, 1–9. [Google Scholar] [CrossRef]

- Soni, A.K.; Rao, B.P. Lock-in Amplifier Based Eddy Current Instrument for Detection of Sub-surface Defect in Stainless Steel Plates. Sens. Imaging 2018, 19, 32. [Google Scholar] [CrossRef]

- Aguiam, D.E.; Rosado, L.S.; Ramos, P.M.; Piedade, M. Heterodyning based portable instrument for eddy currents non-destructive testing. Measurement 2015, 73, 146–157. [Google Scholar] [CrossRef]

- Zhang, G.; Xie, X.; You, Y. Multi-Channel Eddy Current Detector Based on Virtual Instrument Technology and Self-Balancing Technology. Sens. Imaging 2021, 22, 12. [Google Scholar] [CrossRef]

- Dingley, G.; Soleimani, M. Multi-Frequency Magnetic Induction Tomography System and Algorithm for Imaging Metallic Objects. Sensors 2021, 21, 3671. [Google Scholar] [CrossRef] [PubMed]

- Technologies Keysight. Impedance Measurement Handbook. Available online: www.keysight.com (accessed on 18 September 2022).

- Lu, M.; Meng, X.; Yin, W.; Qu, Z.; Wu, F.; Tang, J.; Xu, H.; Huang, R.; Chen, Z.; Zhao, Q. Thickness measurement of non-magnetic steel plates using a novel planar triple-coil sensor. NDT E Int. 2019, 107, 102148. [Google Scholar] [CrossRef]

- Yin, W.; Xu, K. A novel triple-coil electromagnetic sensor for thickness measurement immune to lift-off variations. IEEE Trans. Instrum. Meas. 2015, 65, 164–169. [Google Scholar] [CrossRef]

- Rosell-Ferrer, J.; Merwa, R.; Brunner, P.; Scharfetter, H. A multifrequency magnetic induction tomography system using planar gradiometers: Data collection and calibration. Physiol. Meas. 2006, 27, S271–S280. [Google Scholar] [CrossRef]

- Abdel-Rehim, O.A.; Davidson, J.L.; Marsh, L.A.; O’Toole, M.D.; Peyton, A.J. Magnetic Polarizability Tensor Spectroscopy for Low Metal Anti-personnel Mine Surrogates. IEEE Sens. J. 2016, 16, 3775–3783. [Google Scholar] [CrossRef]

- Chen, Z.; Salas-Avlia, J.R.; Tao, Y.; Yin, W.; Ricardo, J. A novel hybrid serial/parallel multi-frequency measurement method for impedance analysis in eddy current testing. Rev. Sci. Instrum. 2020, 91, 024703. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, X.; Deng, Y. Rotating focused field Eddy-current sensing for arbitrary orientation defects detection in carbon steel. Sensors 2020, 20, 2345. [Google Scholar] [CrossRef] [Green Version]

- Center for Nondestructive Evaluation. Nondestructive Evaluation Techniques. Available online: https://www.nde-ed.org/NDETechniques/EddyCurrent/ProbesCoilDesign/ProbesConfig.xhtml (accessed on 18 September 2022).

- Gao, P.; Wang, C.; Li, Y.; Cong, Z. Electromagnetic and eddy current NDT in weld inspection: A review. Insight Non-Destruct. Test. Cond. Monit. 2015, 57, 337–345. [Google Scholar] [CrossRef]

- Sharif, N.A.; Ramli, R.; Nuawi, M.Z.; Mohamed, A.Z. Theory and development of magnetic flux leakage sensor for flaws detection: A review. J. Kejuruter. 2020, 32, 385–395. [Google Scholar] [CrossRef] [Green Version]

- Halchenko, V.; Trembovetskaya, R.; Tychkov, V. Surface Eddy Current Probes: Excitation Systems of the Optimal Electromagnetic Field (Review). Devices Methods Meas. 2020, 11, 91–104. [Google Scholar] [CrossRef]

- Hoshikawa, H.; Koyama, K. Eddy current distribution using parameters normalized by standard penetration depth. In Review of Progress in Quantitative Nondestructive Evaluation; Springer: Berlin/Heidelberg, Germany, 1999; pp. 515–521. [Google Scholar]

- Mook, G.; Hesse, O.; Uchanin, V. Deep penetrating eddy currents and probes. Mater. Test. 2007, 49, 258–264. [Google Scholar] [CrossRef]

- Jiao, S.; Liu, X.; Zeng, Z. Intensive study of skin effect in eddy current testing with pancake coil. IEEE Trans. Magn. 2017, 53, 1–8. [Google Scholar] [CrossRef]

- Zeng, Z.; Ding, P.; Li, J.; Jiao, S.; Lin, J.; Dai, Y. Characteristics of Eddy Current Attenuation and Thickness Measurement of Metallic Plate. Chin. J. Mech. Eng. 2019, 32, 106. [Google Scholar] [CrossRef] [Green Version]

- Hayashi, M.; Saito, T.; Nakamura, Y.; Sakai, K.; Kiwa, T.; Tanikura, I.; Tsukada, K. Extraction Method of Crack Signal for Inspection of Complicated Steel Structures Using A Dual-Channel Magnetic Sensor. Sensors 2019, 19, 3001. [Google Scholar] [CrossRef] [Green Version]

- Yin, W.; Peyton, A.J. Thickness measurement of non-magnetic plates using multi-frequency eddy current sensors. NDT E Int. 2007, 40, 43–48. [Google Scholar] [CrossRef]

- Mori, H.; Kagaya, H.; Inamoto, Y.; Izumi, S.I.; Yashima, K.; Takagi, T. Numerical Analysis of Eddy Current Distribution in Submental Region Induced by Magnetic Stimulation for Treating Dysphagia. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 1178–1186. [Google Scholar] [CrossRef]

- Chen, D.; Li, Y.; Pan, M.; Tian, W. Flexible planar electromagnetic sensor array fabricated with printing electronic technology. Measurement 2018, 129, 499–503. [Google Scholar] [CrossRef]

- Daura, L.U.; Tian, G.; Yi, Q.; Sophian, A. Wireless power transfer-based eddy current non-destructive testing using a flexible printed coil array. Philos. Trans. R. Soc. London. Ser. A 2020, 378, 20190579. [Google Scholar] [CrossRef] [PubMed]

- Avila, J.R.S.; How, K.Y.; Lu, M.; Yin, W. A novel dual modality sensor with sensitivities to permittivity, conductivity, and permeability. IEEE Sens. J. 2017, 18, 356–362. [Google Scholar] [CrossRef] [Green Version]

- Hamia, R.; Cordier, C.; Dolabdjian, C. Eddy-current non-destructive testing system for the determination of crack orientation. NDT E Int. 2014, 61, 24–28. [Google Scholar] [CrossRef] [Green Version]

- Dogaru, T.; Smith, C.H.; Schneider, R.W.; Smith, S.T. Deep crack detection around fastener holes in airplane multi-layered structures using GMR-based eddy current probes. AIP Conf. Proc. 2004, 700, 398–405. [Google Scholar]

- Ye, C.; Huang, Y.; Udpa, L.; Udpa, S.S. Differential sensor measurement with rotating current excitation for evaluating multilayer structures. IEEE Sens. J. 2015, 16, 782–789. [Google Scholar] [CrossRef]

- Ye, C.; Rosell, A.; Haq, M.; Stitt, E.; Udpa, L.; Udpa, S. EC probe with orthogonal excitation coils and TMR sensor for CFRP inspection. Int. J. Appl. Electromagn. Mech. 2019, 59, 1247–1255. [Google Scholar] [CrossRef]

- Ripka, P.; Janosek, M. Advances in magnetic field sensors. IEEE Sens. J. 2010, 10, 1108–1116. [Google Scholar] [CrossRef] [Green Version]

- Hainz, S.; de la Torre, E.; Güttinger, J. Comparison of magnetic field sensor technologies for the use in wheel speed sensors. In Proceedings of 2019 IEEE International Conference on Industrial Technology (ICIT), Melbourne, VIC, Australia, 13–15 February 2019; pp. 727–731. [Google Scholar]

- Hadjigeorgiou, N.; Asimakopoulos, K.; Papafotis, K.; Sotiriadis, P.P. Vector Magnetic Field Sensors: Operating Principles, Calibration, and Applications. IEEE Sens. J. 2020, 21, 12531–12544. [Google Scholar] [CrossRef]

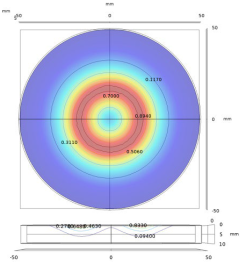

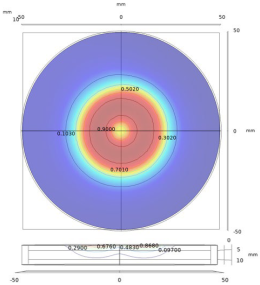

- Lu, M.; Meng, X.; Huang, R.; Chen, L.; Peyton, A.; Yin, W.; Qu, Z. Thickness measurement of circular metallic film using single-frequency eddy current sensor. NDT E Int. 2021, 119, 102420. [Google Scholar] [CrossRef]

- Lu, M.; Meng, X.; Huang, R.; Chen, L.; Peyton, A.; Yin, W. A high-frequency phase feature for the measurement of magnetic permeability using eddy current sensor. NDT E Int. 2021, 123, 102519. [Google Scholar] [CrossRef]

- Wang, C.; Wang, R.C.; Liang, X.; Ye, J.M.; Chen, X.Y. Design and optimization of electromagnetic tomography and electrical resistance tomography dual-modality sensor. Meas. Sci. Technol. 2022, 33, 105120. [Google Scholar] [CrossRef]

- Arellano, Y.; Hunt, A.; Haas, O.; Ahmed, H.; Ma, L. Multiple regression-based prediction correlations for enhanced sensor design of magnetic induction tomography systems. Meas. Sci. Technol. 2019, 31, 024002. [Google Scholar] [CrossRef]

- She, S.; Chen, Y.; He, Y.; Zou, X. Optimal design of remote field eddy current testing probe for ferromagnetic pipeline inspection. Measurement 2021, 168, 108306. [Google Scholar] [CrossRef]

- Avila, J.R.S.; Lu, M.; Huang, R.; Chen, Z.; Zhu, S.; Yin, W. Accurate measurements of plate thickness with variable lift-off using a combined inductive and capacitive sensor. NDT E Int. 2020, 110, 102202. [Google Scholar] [CrossRef]

- Lu, M.; Huang, R.; Yin, W.; Zhao, Q.; Peyton, A. Measurement of permeability for ferrous metallic plates using a novel lift-off compensation technique on phase signature. IEEE Sens. J. 2019, 19, 7440–7446. [Google Scholar] [CrossRef]

- Lu, M.; Meng, X.; Huang, R.; Chen, L.; Peyton, A.; Yin, W. Measuring lift-off distance and electromagnetic property of metal using dual-frequency linearity feature. IEEE Trans. Instrum. Meas. 2020, 70, 6001409. [Google Scholar] [CrossRef]

- Dinh, C.-H.; Jeng, J.-T.; Huang, G.-W.; Chen, J.-Y.; Chiang, Y.-S.; Doan, V.-D.; Pham, T.-T. Real-time thickness measurement using resonant eddy-current sensor. IEEE Trans. Instrum. Meas. 2021, 70, 6007609. [Google Scholar] [CrossRef]

- Lu, M.; Zhu, W.; Yin, L.; Peyton, A.J.; Yin, W.; Qu, Z. Reducing the lift-off effect on permeability measurement for magnetic plates from multifrequency induction data. IEEE Trans. Instrum. Meas. 2017, 67, 167–174. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Li, W.; Feng, Z. Noncontact thickness measurement of metal films using eddy-current sensors immune to distance variation. IEEE Trans. Instrum. Meas. 2015, 64, 2557–2564. [Google Scholar] [CrossRef]

- Li, W.; Wang, H.; Feng, Z. Non-contact online thickness measurement system for metal films based on eddy current sensing with distance tracking technique. Review of Scientific Instrum. 2016, 87, 045005. [Google Scholar] [CrossRef] [Green Version]

- Yin, W.; Dickinson, S.J.; Peyton, A. Imaging the continuous conductivity profile within layered metal structures using inductance spectroscopy. IEEE Sens. J. 2005, 5, 161–166. [Google Scholar]

- Lu, M.; Xu, H.; Zhu, W.; Yin, L.; Zhao, Q.; Peyton, A.; Yin, W. Conductivity Lift-off Invariance and measurement of permeability for ferrite metallic plates. NDT E Int. 2018, 95, 36–44. [Google Scholar] [CrossRef]

- Yin, W.; Meng, X.; Lu, M.; Zhao, Q.; Xu, H.; Zhang, Z.; Peyton, A. Permeability invariance phenomenon and measurement of electrical conductivity for ferrite metallic plates. Insight—Non-Destruct. Test. Cond. Monit. 2019, 61, 472–479. [Google Scholar] [CrossRef]

- Cheng, W. Thickness measurement of metal plates using swept-frequency eddy current testing and impedance normalization. IEEE Sens. J. 2017, 17, 4558–4569. [Google Scholar] [CrossRef]

- Yin, W.; Peyton, A.J. Thickness measurement of metallic plates with an electromagnetic sensor using phase signature analysis. IEEE Trans. Instrum. Meas. 2008, 57, 1803–1807. [Google Scholar]

- Angani, C.S.; Ramos, H.G.; Ribeiro, A.L.; Rocha, T.J.; Baskaran, P. Lift-off point of intersection feature in transient eddy-current oscillations method to detect thickness variation in stainless steel. IEEE Trans. Magn. 2016, 52, 1–8. [Google Scholar] [CrossRef]

- Lu, M.; Meng, X.; Huang, R.; Chen, L.; Peyton, A.; Yin, W. Lift-off invariant inductance of steels in multi-frequency eddy-current testing. NDT E Int. 2021, 121, 102458. [Google Scholar] [CrossRef]

- Mohseni, E.; Habibzadeh Boukani, H.; Ramos França, D.; Viens, M. A study of the automated eddy current detection of cracks in steel plates. J. Nondestruct. Eval. 2020, 39, 6. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Chen, G.; Ge, J.; Yin, X.; Li, K. High sensitivity rotating alternating current field measurement for arbitrary-angle underwater cracks. NDT E Int. 2016, 79, 123–131. [Google Scholar] [CrossRef]

- Pasadas, D.J.; Ribeiro, A.L.; Ramos, H.G.; Rocha, T.J. Inspection of cracks in aluminum multilayer structures using planar ECT probe and inversion problem. IEEE Trans. Instrum. Meas. 2017, 66, 920–927. [Google Scholar] [CrossRef]

- Yin, L.; Ye, B.; Zhang, Z.; Tao, Y.; Xu, H.; Avila, J.R.S.; Yin, W. A novel feature extraction method of eddy current testing for defect detection based on machine learning. NDT E Int. 2019, 107, 102108. [Google Scholar] [CrossRef]

- Bajracharya, S.; Sasaki, E.; Tamura, H. Numerical study on corrosion profile estimation of a corroded steel plate using eddy current. Struct. Infrastruct. Eng. 2019, 15, 1151–1164. [Google Scholar] [CrossRef]

- Xu, H.; Lu, M.; Avila, J.; Zhao, Q.; Zhou, F.; Meng, X.; Yin, W. Imaging a weld cross-section using a novel frequency feature in multi-frequency eddy current testing. Insight—Non-Destructive Test. Cond. Monit. 2019, 61, 738–743. [Google Scholar] [CrossRef]

- Ribeiro, A.L.; Alegria, F.; Postolache, O.A.; Ramos, H.M.G. Liftoff correction based on the spatial spectral behavior of eddy-current images. IEEE Trans. Instrum. Meas. 2010, 59, 1362–1367. [Google Scholar] [CrossRef]

- Shao, Y.; Meng, T.; Yu, K.; Xia, Z.; Huang, R.; Tao, Y.; Chen, Z.; Avila, J.R.S.; Yin, W. Automatic Detection and Imaging of Rivet Hole Defects for Aircraft Structures with Optimised Sensor Array Using Eddy Current Method and Image Analysis. IEEE Sens. J. 2022; early access. [Google Scholar] [CrossRef]

- Ferrigno, L.; Laracca, M.; Malekmohammadi, H.; Tian, G.Y.; Ricci, M. Comparison of time and frequency domain features’ immunity against lift-off in pulse-compression eddy current imaging. NDT E Int. 2019, 107, 102152. [Google Scholar] [CrossRef]

- Betta, G.; Ferrigno, L.; Laracca, M.; Ramos, H.; Ricci, M.; Ribeiro, A.; Silipigni, G. Fast 2D crack profile reconstruction by image processing for Eddy-Current Testing. In Proceedings of 2015 IEEE Metrology for Aerospace (MetroAeroSpace), Benevento, Italy, 4–5 June 2015; pp. 341–345. [Google Scholar]

- Wang, Y.; Chen, Y.; Zhang, Y.; Chen, H.; Yu, S. Generalised Hermite–Gaussian beams and mode transformations. J. Opt. 2016, 18, 055001. [Google Scholar] [CrossRef]

- Ahmed, S.; Reboud, C.; Lhuillier, P.-E.; Calmon, P.; Miorelli, R. An adaptive sampling strategy for quasi real time crack characterization on eddy current testing signals. NDT E Int. 2019, 103, 154–165. [Google Scholar] [CrossRef]

- Fan, M.; Wang, Q.; Cao, B.; Ye, B.; Sunny, A.I.; Tian, G. Frequency optimization for enhancement of surface defect classification using the eddy current technique. Sensors 2016, 16, 649. [Google Scholar] [CrossRef] [Green Version]

- Rosado, L.S.; Janeiro, F.M.; Ramos, P.M.; Piedade, M. Defect characterization with eddy current testing using nonlinear-regression feature extraction and artificial neural networks. IEEE Trans. Instrum. Meas. 2013, 62, 1207–1214. [Google Scholar] [CrossRef]

- Deng, W.; Bao, J.; Ye, B. Defect Image Recognition and Classification for Eddy Current Testing of Titanium Plate Based on Convolutional Neural Network. Complexity 2020, 2020, 8868190. [Google Scholar] [CrossRef]

- Meng, T.; Tao, Y.; Chen, Z.; Avila, J.R.S.; Ran, Q.; Shao, Y.; Huang, R.; Xie, Y.; Zhao, Q.; Zhang, Z. Depth evaluation for metal surface defects by eddy current testing using deep residual convolutional neural networks. IEEE Trans. Instrum. Meas. 2021, 70, 1–13. [Google Scholar] [CrossRef]

- Hampe, N.; Katscher, U.; Van den Berg, C.A.; Tha, K.K.; Mandija, S. Investigating the challenges and generalizability of deep learning brain conductivity mapping. Phys. Med. Biol. 2020, 65, 135001. [Google Scholar] [CrossRef]

| Element Number | Calculation Time of the Method without Acceleration (s) | Calculation Time of the Proposed Method (s) | Accelerated Rate (Times) | Calculation Deviation (%) |

|---|---|---|---|---|

| 10 k | 7.69 | 2.03 | 3.79 | 2.56 |

| 51 k | 57.74 | 3.56 | 16.22 | 3.22 |

| 139 k | 306.79 | 8.96 | 34.24 | 3.56 |

| # | Copper | Aluminium |

|---|---|---|

| Inductance trajectory |  |  |

| Algorithm | Updating Direction, | Convergence Rate | Stability |

|---|---|---|---|

| Gradient descent | Slow | High | |

| Conjugate gradient | +, | Fast | Medium |

| Newton method | Fast | Low | |

| LM | Medium | Medium | |

| PSO | is an inertial constant, and are step length, and are random variables, and as well as indicate the estimated local and global optimum.) | Medium | High |

| Researcher | Controller | Applied Excitation Frequency | SNR | Software | Main Application |

|---|---|---|---|---|---|

| M. Kekelj et al. [91] | Cyclone V SoC | 100~400 kHz | Up to 56 dB | MATLAB | Pipe defects |

| M. Hamel et al. [92] | NI DAQ | 50~150 kHz | - | LabVIEW | Plate with crack |

| N. Zhang et al. [93] | NI DAQ | 0.1~1 kHz | - | MATLAB | Cylindrical samples |

| A. K. Soni et al. [94] | NI DAQ with lock-in amplifier | 0.5~80 kHz | 38 dB | LabVIEW | Plate with crack |

| D. E. Aguiam et al. [95] | ADSP | Up to 10 MHz | - | LabVIEW | Block with crack |

| G. Zhang et al. [96] | NI DAQ with lock-in amplifier | 50 kHz | - | LabVIEW | Plate with crack |

| G. Dingley et al. [97] | AVR MCU | 0.1~100 kHz | Up to 90 dB | - | EMT |

| - | Basic Accuracy | Frequency Range | Impedance Range | Data Speed | No. of Channels |

|---|---|---|---|---|---|

Zurich MFIA | 0.05% | 1 mHz to 500 kHz/5 MHz | 1 mΩ to 1 TΩ | 20 msec/point for f > 10 kHz | 1 Current, 1 Voltage |

| Solartron 1260A impedance analyzer  | 0.1%, 0.1° | 10 µHz to 32 MHz | 100 mΩ to 100 TΩ | No specified | 1 Current, 2 Voltage |

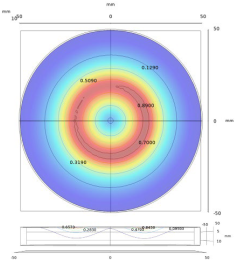

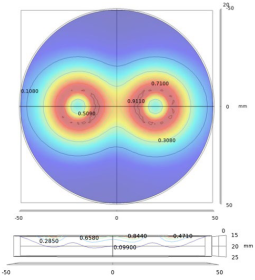

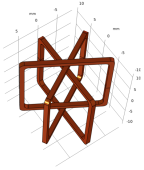

| Coil Structure | Magnetic Field Distribution, | Coil Structure | Magnetic Field Distribution, |

|---|---|---|---|

Pancake coil |  | Spiral coil |  |

Solenoid coil |  | U-shaped (ferrite core) coil  |  |

| Tangential coil (rectangular)  |  | Rotating field coils |  (Varying with time) |

| Probe Type | Plate Materials | Applied Frequency for Estimation | Lift-Off (mm) | Estimated Variables and Range | Relative Error of Estimation |

|---|---|---|---|---|---|

| Triple-coil [100] | Al | Peak frequency | Up to 6 | Thickness (22~100 um) | <5% |

| Triple-coil [132] | DP 800, DP 1000 | Zero-crossing frequency | Up to 4 | <2% | |

| Triple-coil [133] | DP 600, Cr-Mo | Dual frequency | Up to 20 | <4.5% | |

| Triple-coil [126] | Al, Cu | Single frequency (16 kHz) | Up to 5 | Thickness (~66 um) | <5% |

| Triple-coil [99] | Al, Cu | Single frequency (200 kHz) | Up to 4 | Thickness (0.4, 0.5 mm) | <3% |

| Phenomenon | Plate Materials | Applied Frequency for Estimation | Lift-Off (mm) | Estimated Variables and Range | Relative Error of Estimation |

|---|---|---|---|---|---|

| Phase invariance phenomenon [143] | Al, Cu | 100~1 MHz | - | Thickness (22 μm~5 mm) | <3% |

| Lift-off invariance inductance [24] | DP 600, DP 800 | Single frequency depending on material | Up to 12 | <1% | |

| Lift-off invariance inductance [144] | DP 600, LC-Mild, Cr-Mo | Single frequency depending on material | Up to 5 | <1% | |

| Conductivity invariance phenomenon [139] | DP 600, DP 800, DP 1000 | Single frequency (90 kHz) | 1.9 | <3% | |

| Permeability- independent frequency [141] | Al, Al alloy, SUS304 | 4~200 kHz | - | Thickness (1~8 mm) | - |

| Slope of lift-off curve [136] | Cu, Al, SS, Ti | 1 MHz | 0.04 to 0.4 | Thickness (~100 um) | <3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, Z.; Huang, R.; Chen, Z.; Yu, K.; Zhang, Z.; Salas-Avila, J.R.; Yin, W. Eddy Current Measurement for Planar Structures. Sensors 2022, 22, 8695. https://doi.org/10.3390/s22228695

Xia Z, Huang R, Chen Z, Yu K, Zhang Z, Salas-Avila JR, Yin W. Eddy Current Measurement for Planar Structures. Sensors. 2022; 22(22):8695. https://doi.org/10.3390/s22228695

Chicago/Turabian StyleXia, Zihan, Ruochen Huang, Ziqi Chen, Kuohai Yu, Zhijie Zhang, Jorge Ricardo Salas-Avila, and Wuliang Yin. 2022. "Eddy Current Measurement for Planar Structures" Sensors 22, no. 22: 8695. https://doi.org/10.3390/s22228695

APA StyleXia, Z., Huang, R., Chen, Z., Yu, K., Zhang, Z., Salas-Avila, J. R., & Yin, W. (2022). Eddy Current Measurement for Planar Structures. Sensors, 22(22), 8695. https://doi.org/10.3390/s22228695