Multi-Gas Analyzer Based on Tunable Filter Non-Dispersive Infrared Sensor: Application to the Monitoring of Eco-Friendly Gas Insulated Switchgears

Abstract

1. Introduction

2. Materials and Methods

2.1. Optical Layout

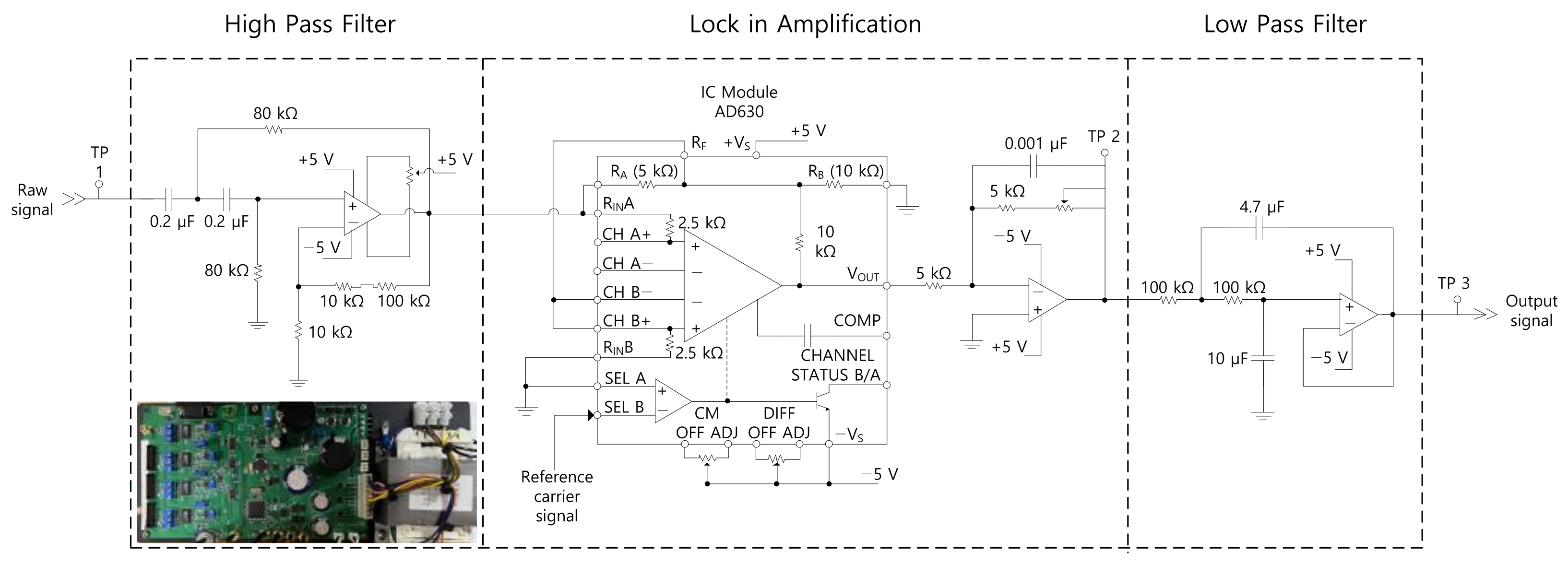

2.2. Electronic Circuit

3. Experimental Section

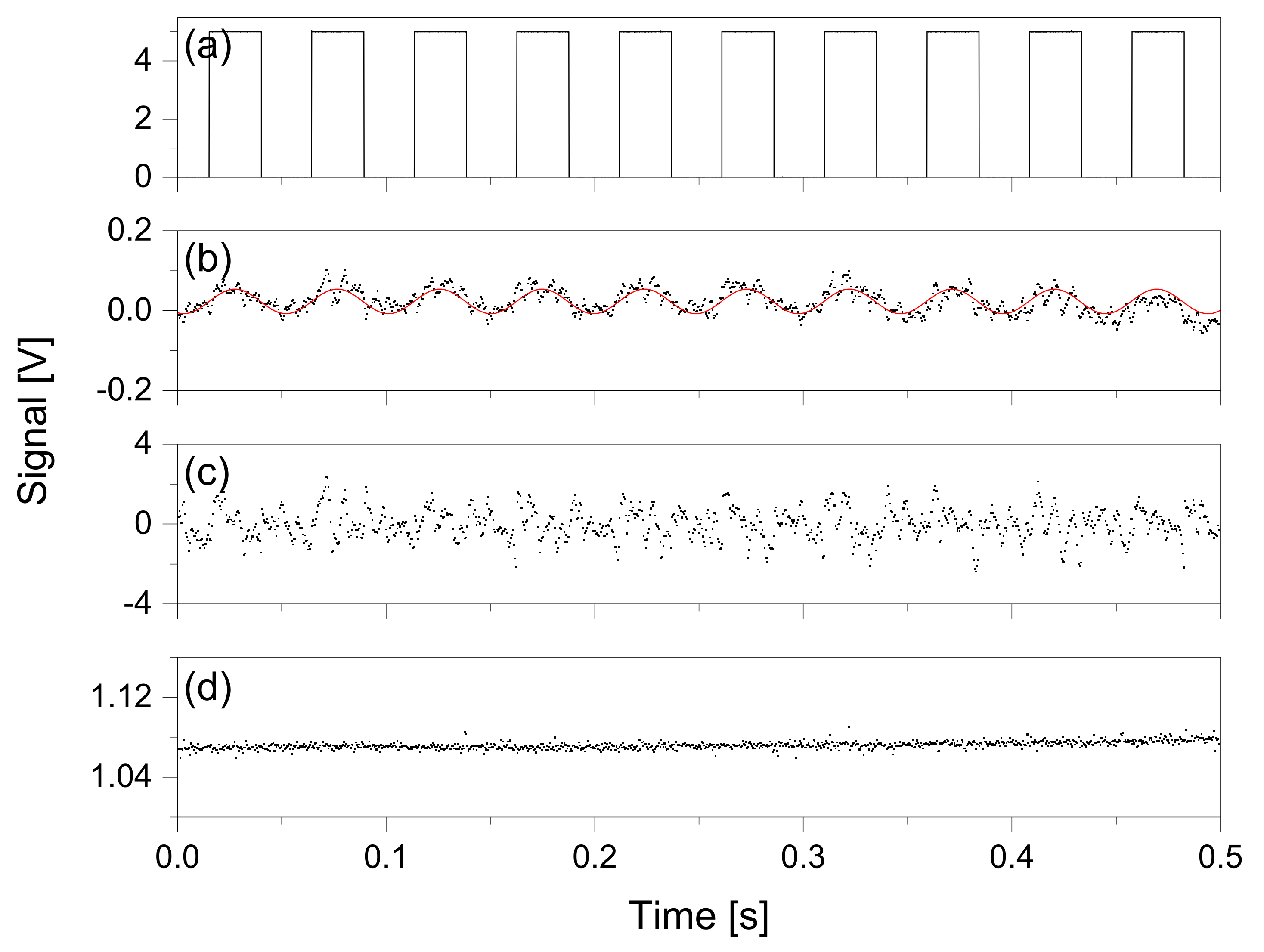

3.1. Signal Processing

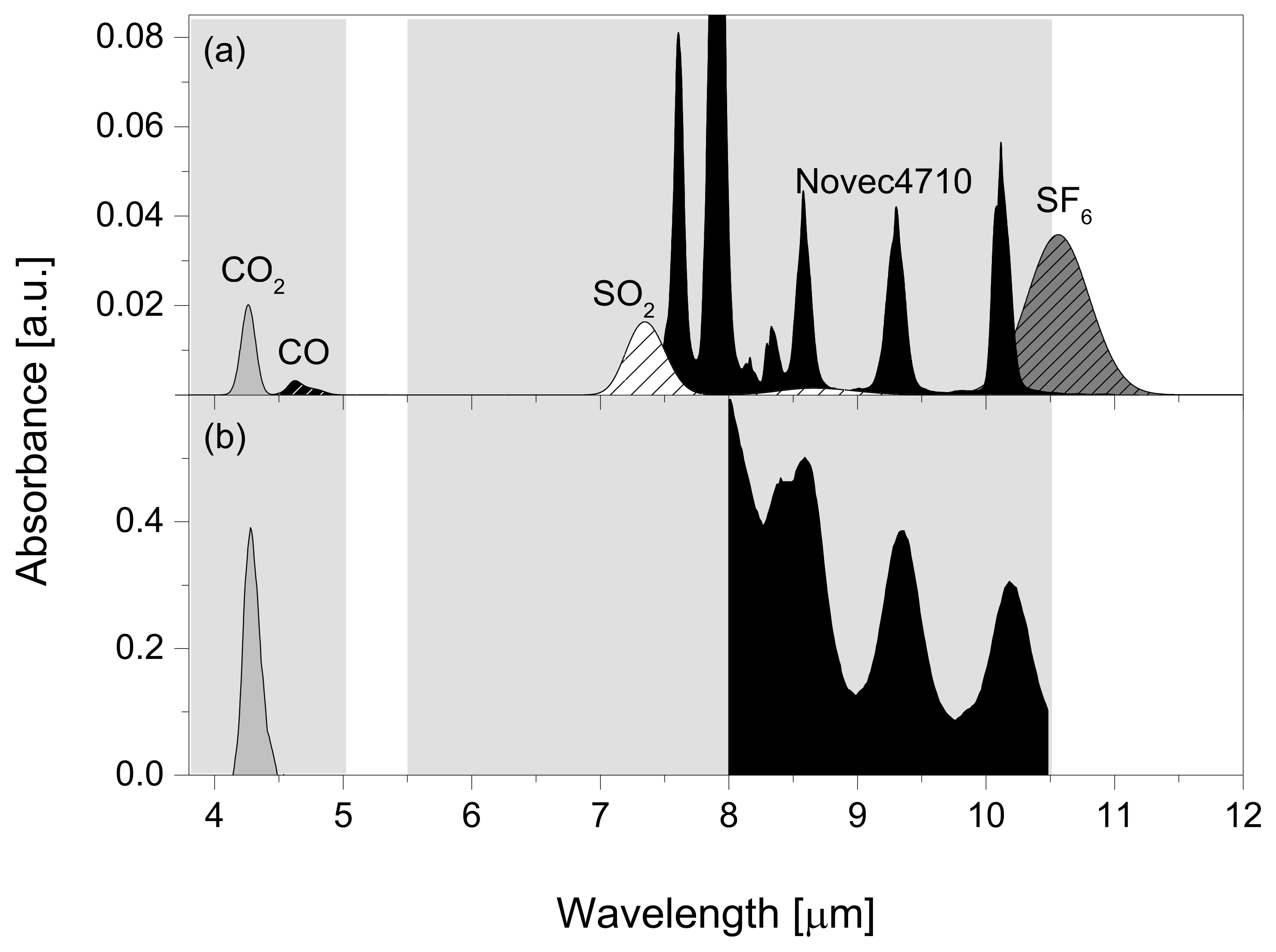

3.2. Spectroscopy

4. Result and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goldenstein, C.S.; Spearrin, R.M.; Jeffries, J.B.; Hanson, R.K. Infrared laser-absorption sensing for combustion gases. Prog. Energy Combust. Sci. 2017, 60, 132–176. [Google Scholar] [CrossRef]

- Willer, U.; Saraji, M.; Khorsandi, A.; Geiser, P.; Schade, W. Near- and mid-infrared laser monitoring of industrial processes, environment and security applications. Opt. Lasers Eng. 2006, 44, 699–710. [Google Scholar] [CrossRef]

- Metsälä, M. Optical techniques for breath analysis: From single to multi-species detection. J. Breath Res. 2018, 12, 27104. [Google Scholar] [CrossRef] [PubMed]

- Hodgkinson, J.; Tatam, R.P. Optical gas sensing: A review. Meas. Sci. Technol. 2013, 24, 12004. [Google Scholar] [CrossRef]

- Popa, D.; Udrea, F. Towards integrated mid-infrared gas sensors. Sensors 2019, 19, 2076. [Google Scholar] [CrossRef]

- Esfahani, S.; Tiele, A.; Agbroko, S.O.; Covington, J.A. Development of a Tuneable NDIR Optical Electronic Nose. Sensors 2020, 20, 6875. [Google Scholar] [CrossRef]

- Dinh, T.-V.; Choi, I.-Y.; Son, Y.-S.; Kim, J.-C. A review on non-dispersive infrared gas sensors: Improvement of sensor detection limit and interference correction. Sens. Actuators B 2016, 231, 529–538. [Google Scholar] [CrossRef]

- Ye, W.; Tu, Z.; Xiao, X.; Simeone, A.; Yan, J.; Wu, T.; Wu, F.; Zheng, C.; Tittel, F.K. A NDIR Mid-Infrared Methane Sensor with a Compact Pentahedron Gas-Cell. Sensors 2020, 20, 5461. [Google Scholar] [CrossRef]

- Park, J.; Cho, H.; Yi, S. NDIR CO2 gas sensor with improved temperature compensation. Procedia Eng. 2010, 5, 303–306. [Google Scholar] [CrossRef]

- Mendes, L.B.; Ogink, N.W.M.; Edouard, N.; Van Dooren, H.J.C.; Tinôco, I.F.; Mosquera, J. NDIR gas sensor for spatial monitoring of carbon dioxide concentrations in naturally ventilated livestock buildings. Sensors 2015, 15, 11239–11257. [Google Scholar] [CrossRef]

- Kwon, J.; Ahn, G.; Kim, G.; Kim, J.C.; Kim, H. A study on NDIR-based CO2 sensor to apply remote air quality monitoring system. In Proceedings of the Iccas-Sice, Fukuoka, Japan, 18–21 August 2009; pp. 1683–1687. [Google Scholar]

- Tan, X.; Zhang, H.; Li, J.; Wan, H.; Guo, Q.; Zhu, H.; Liu, H.; Yi, F. Non-dispersive infrared multi-gas sensing via nanoantenna integrated narrowband detectors. Nat. Commun. 2020, 11, 5245. [Google Scholar] [CrossRef]

- Vincent, T.A.; Gardner, J.W. A low cost MEMS based NDIR system for the monitoring of carbon dioxide in breath analysis at ppm levels. Sens. Actuators B 2016, 236, 954–964. [Google Scholar] [CrossRef]

- Vincent, T.A.; Urasinska-Wojcik, B.; Gardner, J.W. Development of a low-cost NDIR system for ppm detection of carbon dioxide in exhaled breath analysis. Procedia Eng. 2015, 120, 388–391. [Google Scholar] [CrossRef]

- Sklorz, A.; Janßen, S.; Lang, W. Detection limit improvement for NDIR ethylene gas detectors using passive approaches. Sens. Actuators B 2012, 175, 246–254. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Ma, X.; Chen, W.; Chen, D.; Li, Q. Note: A NDIR instrument for multicomponent gas detection using the galvanometer modulation. Rev. Sci. Instrum. 2017, 88, 116103. [Google Scholar] [CrossRef]

- Tan, Q.; Tang, L.; Yang, M.; Xue, C.; Zhang, W.; Liu, J.; Xiong, J. Three-gas detection system with IR optical sensor based on NDIR technology. Opt. Lasers Eng. 2015, 74, 103–108. [Google Scholar] [CrossRef]

- Rubio, R.; Santander, J.; Fonseca, L.; Sabate, N.; Gracia, I.; Cane, C.; Udina, S.; Marco, S. Non-selective NDIR array for gas detection. Sens. Actuators B 2007, 127, 69–73. [Google Scholar] [CrossRef]

- Xu, M.; Peng, B.; Zhu, X.; Guo, Y. Multi-Gas Detection System Based on Non-Dispersive Infrared(NDIR) Spectral Technology. Sensors 2022, 22, 836. [Google Scholar] [CrossRef]

- Majder-Lopatka, M.; Wesierski, T.; Dmochowska, A.; Salamonowicz, Z.; Polanczyk, A. The Influence of Hydrogen on the Indications of the Electrochemical Carbon Monoxide Sensors. Sustainability 2020, 12, 14. [Google Scholar] [CrossRef]

- Neumann, N.; Ebermann, M.; Kurth, S.; Hiller, K. Tunable infrared detector with integrated micromachined Fabry-Perot filter. J. Micro/Nanolithogr. MEMS MOEMS 2008, 7, 21004. [Google Scholar] [CrossRef]

- Spisser, A.; Ledantec, R.; Seassal, C.; Leclercq, J.L.; Benyattou, T.; Rondi, D.; Blondeau, R.; Guillot, G.; Viktorovitch, P. Highly selective and widely tunable 1.55-μm, InP/air-gap micromachined Fabry-Perot filter for optical communications. IEEE Photonics Technol. Lett. 1998, 101998, 1259–1261. [Google Scholar] [CrossRef]

- Song, H.; Dong, H.; Zhang, L. Application of lock-in amplifier to weak magnetic field detection. In Proceedings of the 2014 International Conference on Mechatronics, Electronic, Industrial and Control Engineering, Shenyang, China, 15–17 November 2014; pp. 1092–1096. [Google Scholar] [CrossRef]

- Gordon, I.E.; Rothman, L.S.; Hill, C.; Kochanov, R.V.; Tan, Y.; Bernath, P.F.; Birk, M.; Boudon, V.; Campargue, A.; Chance, K.V.; et al. The HITRAN2016 molecular spectroscopic database. J. Quant. Spectrosc. Radiat. Transf. 2017, 203, 3–69. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, B.; Yang, T.; Deng, Y.; Li, X.; Murphy, A.B. Thermal decomposition characteristics and kinetic analysis of C4F7N/CO2 gas mixture. J. Phys. D Appl. Phys. 2020, 53, 55502. [Google Scholar] [CrossRef]

- Swinehart, D.F. The Beer–Lambert law. J. Chem. Educ. 1962, 39, 333. [Google Scholar] [CrossRef]

- Walters, C.; Keeney, A.; Wigal, C.T.; Johnston, C.R.; Cornelius, R.D. The spectrophotometric analysis and modeling of sunscreens. J. Chem. Educ. 1997, 74, 99. [Google Scholar] [CrossRef]

- Mayerhöfer, T.G.; Mutschke, H.; Popp, J. Employing theories far beyond their limits—The case of the (Boguer-) Beer-Lambert law. ChemPhysChem 2016, 17, 1948–1955. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Q.; Zhang, J.; Li, Y.; Xiao, S.; Zhuo, R.; Tang, J. Experimental Study on Power Frequency Breakdown Characteristics of C4F7N/CO2 Gas Mixture Under Quasi-Homogeneous Electric Field. IEEE Access 2019, 7, 19100–19108. [Google Scholar] [CrossRef]

- Shrivastava, A.; Gupta, V.B. Methods for the determination of limit of detection and limit of quantitation of the analytical methods. Chronicles Young Sci. 2011, 2, 21–25. [Google Scholar] [CrossRef]

- Armbruster, D.A.; Pry, T. Limit of blank, limit of detection and limit of quantitation. Clin. Biochem. Rev. 2008, 29 (Suppl. S1), S49–S52. [Google Scholar]

| FFM 1 | FFM 2 | Passed Cell | Detector |

|---|---|---|---|

| on | on | SP | D3 |

| on | off | SP | D1 |

| off | on | MP | D3 |

| off | off | MP | D1 |

| on | anything | MP | D2 |

| Component | Wavelength [μm] | LOD [ppmv] |

|---|---|---|

| Novec-4710 | 8.6 | 54.7 |

| CO | 4.6 | 112.8 |

| CO2 | 4.3 | 118.1 |

| SO2 | 7.4 | 69.5 |

| SF6 | 10.5 | 33.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; Goo, S.-g.; Lim, J.S. Multi-Gas Analyzer Based on Tunable Filter Non-Dispersive Infrared Sensor: Application to the Monitoring of Eco-Friendly Gas Insulated Switchgears. Sensors 2022, 22, 8662. https://doi.org/10.3390/s22228662

Kim Y, Goo S-g, Lim JS. Multi-Gas Analyzer Based on Tunable Filter Non-Dispersive Infrared Sensor: Application to the Monitoring of Eco-Friendly Gas Insulated Switchgears. Sensors. 2022; 22(22):8662. https://doi.org/10.3390/s22228662

Chicago/Turabian StyleKim, Yera, Sun-geun Goo, and Jeong Sik Lim. 2022. "Multi-Gas Analyzer Based on Tunable Filter Non-Dispersive Infrared Sensor: Application to the Monitoring of Eco-Friendly Gas Insulated Switchgears" Sensors 22, no. 22: 8662. https://doi.org/10.3390/s22228662

APA StyleKim, Y., Goo, S.-g., & Lim, J. S. (2022). Multi-Gas Analyzer Based on Tunable Filter Non-Dispersive Infrared Sensor: Application to the Monitoring of Eco-Friendly Gas Insulated Switchgears. Sensors, 22(22), 8662. https://doi.org/10.3390/s22228662