Muscle Engagement Monitoring Using Self-Adhesive Elastic Nanocomposite Fabrics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Nanocomposite Fabric Sensor Fabrication

2.2. Sensing Characterization

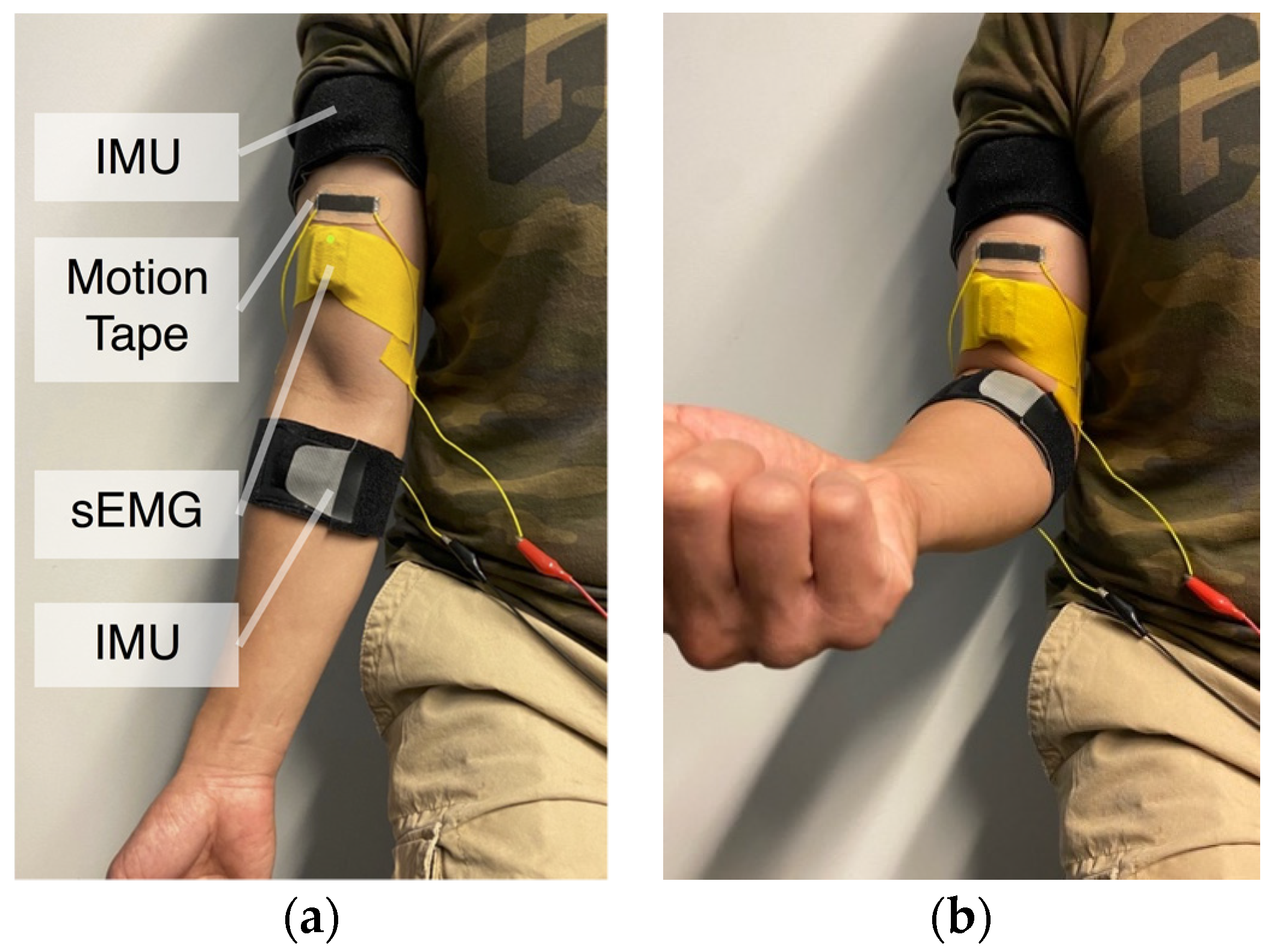

2.3. Human Subject Testing

3. Results and Discussion

3.1. Strain Sensing Properties

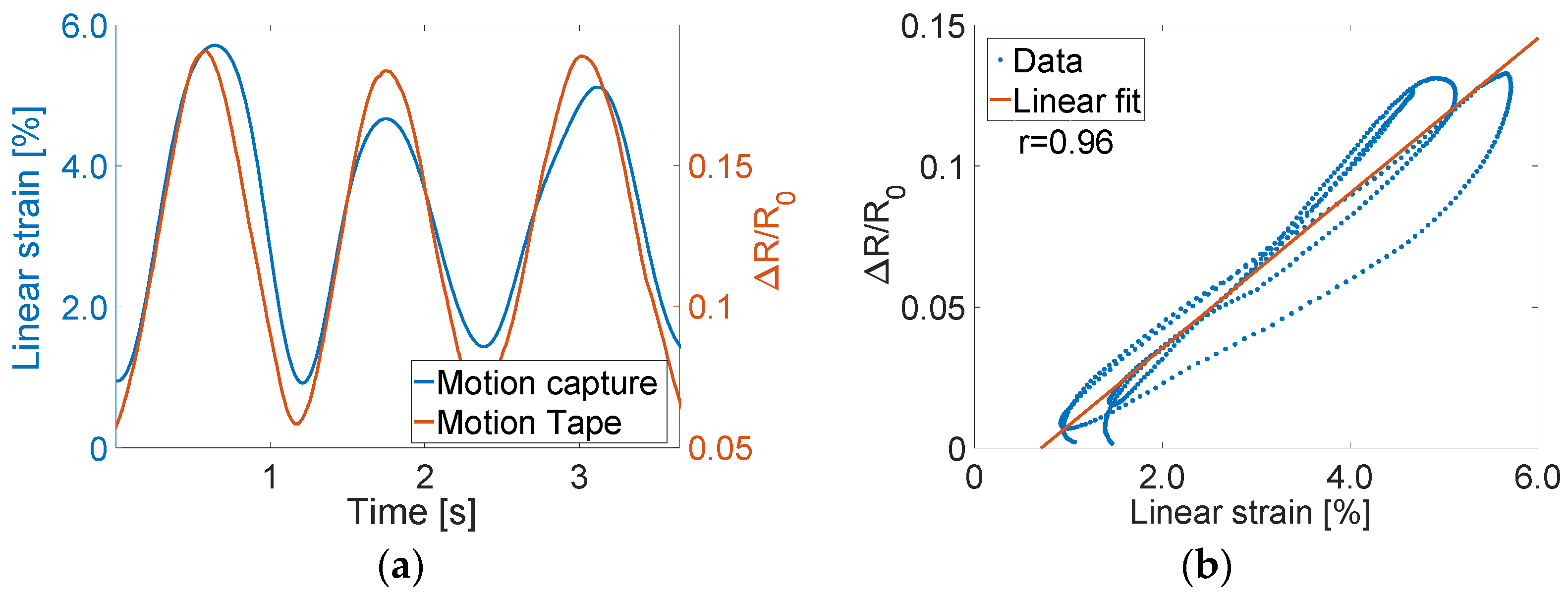

3.2. Verification of Motion Tape for Skin-Strain Monitoring

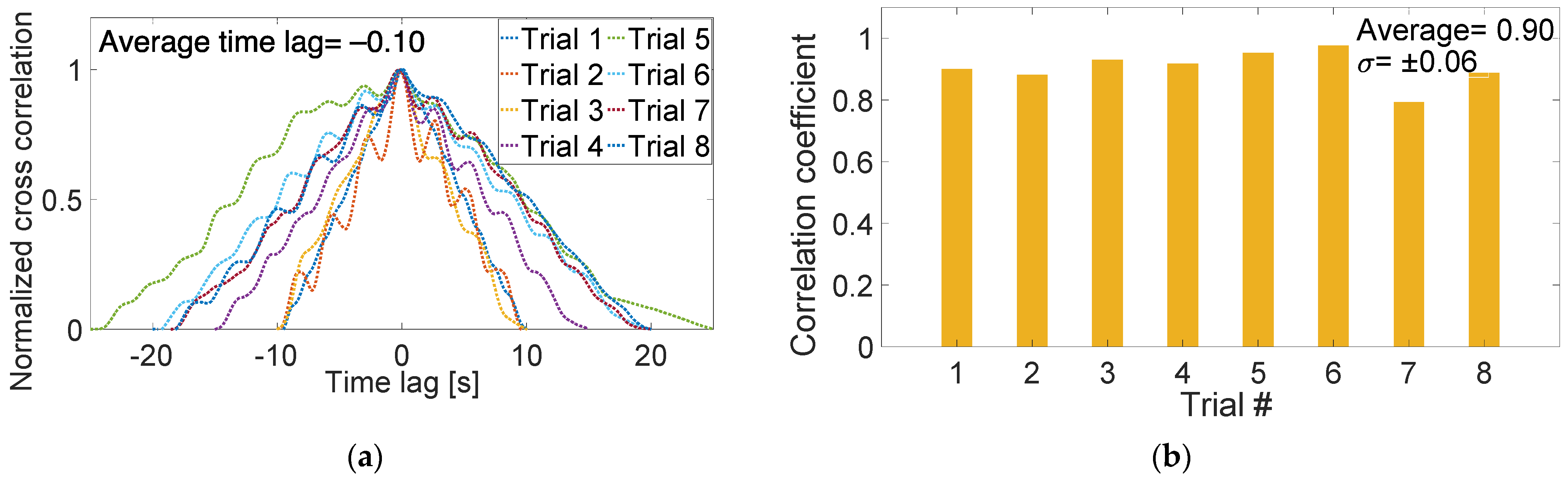

3.3. Verification of Motion Tape for Measuring Muscle Engagement

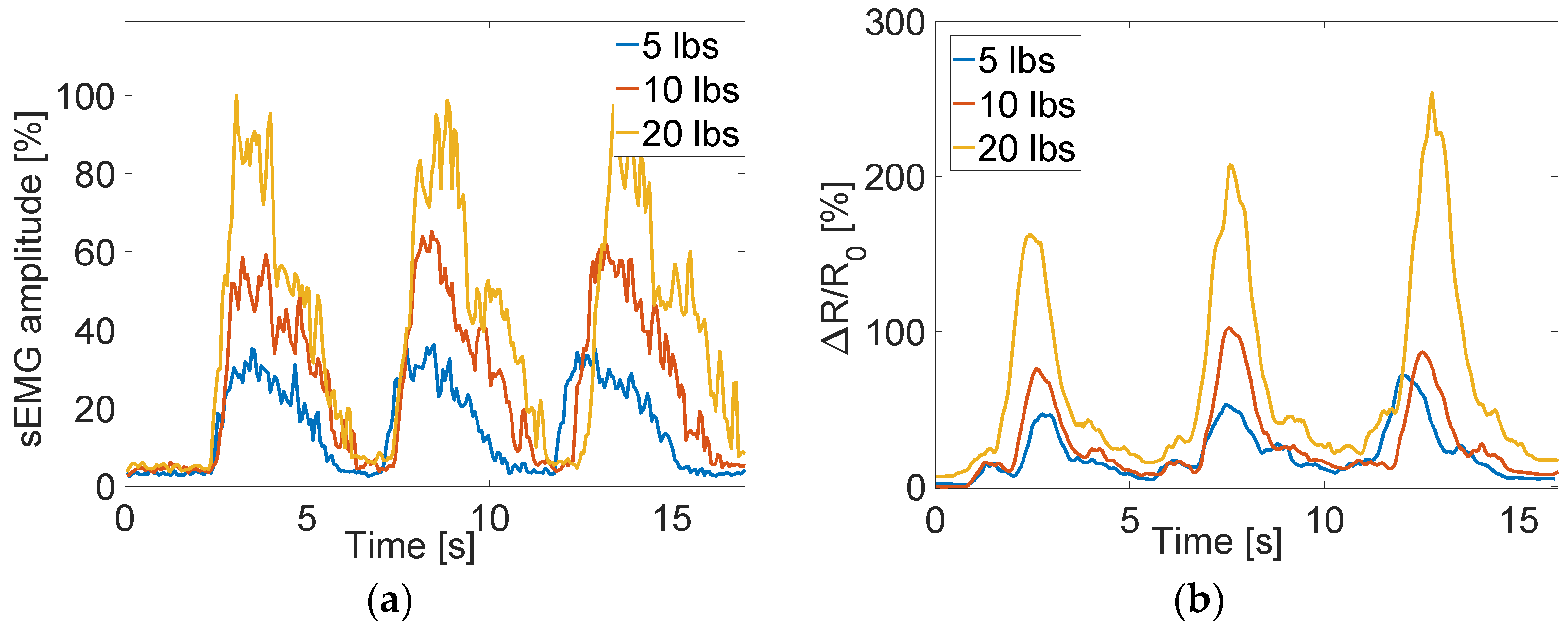

3.4. Validation of Motion Tape for Measuring Muscle Engagement

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Disclaimer

References

- Young, A.J.; Hargrove, L.J.; Kuiken, T.A. The effects of electrode size and orientation on the sensitivity of myoelectric pattern recognition systems to electrode shift. IEEE Trans. Biomed. Eng. 2011, 58, 2537–2544. [Google Scholar] [CrossRef] [PubMed]

- Johansson, H.; Bergenheim, M.; Pedersen, J.; Djupsjöbacka, M. Recording of Electrical Activity of Neuronal Populations. In Modern Techniques in Neuroscience Research; Windhorst, U., Johansson, H., Eds.; Springer: Berlin/Heidelberg, Germany, 1999; pp. 487–502. [Google Scholar]

- Merletti, R.; Parker, P.J. Electromyography: Physiology, Engineering, and Non-Invasive Applications; John Wiley & Sons: Hoboken, NJ, USA, 2004; Volume 11. [Google Scholar]

- De Luca, C. Encyclopedia of Medical Devices and Instrumentation; John Wiley & Sons: Hoboken, NJ, USA, 2006; pp. 98–109. [Google Scholar]

- Elamvazuthi, I.; Zulkifli, Z.; Ali, Z.; Khan, M.K.A.A.; Parasuraman, S.; Balaji, M.; Chandrasekaran, M. Development of Electromyography Signal Signature for Forearm Muscle. Procedia Comput. Sci. 2015, 76, 229–234. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Edwards, D.J.; Pärn, E.A.; Seo, J.; Wong, A.Y.L. Biomechanical analysis of risk factors for work-related musculoskeletal disorders during repetitive lifting task in construction workers. Autom. Constr. 2017, 83, 41–47. [Google Scholar] [CrossRef]

- De Luca, C.J. Use of the Surface EMG Signal for Performance Evalution of Back Muscles. Muscle Nerve 1993, 16, 210–216. [Google Scholar] [CrossRef] [PubMed]

- Fratini, A.; Cesarelli, M.; Bifulco, P.; Romano, M. Relevance of motion artifact in electromyography recordingsduring vibration treatment. J. Electromyogr. Kinesiol. 2008, 19, 710–718. [Google Scholar] [CrossRef]

- De Talhouet, H.; Webster, J.G. The origin of skin-stretch-caused motion artifacts under electrodes. Physiol. Meas. 1996, 17, 81–93. [Google Scholar] [CrossRef] [PubMed]

- Türker, K.S. Electromyography: Some Methodological Problems and Issues. Phys. Ther. Rehabil. J. 1993, 73, 698–710. [Google Scholar] [CrossRef] [PubMed]

- Basmajian, J.V.; De Luca, C.J. Muscles Alive: Their Functions Revealed by Electromyography, 5th ed.; Williams & Wilkins: Baltimore, MD, USA, 1985. [Google Scholar]

- Xu, H.; Xiong, A. Advances and Disturbances in sEMG-Based Intentions and Movements Recognition: A Review. IEEE Sens. J. 2021, 21, 13019–13028. [Google Scholar] [CrossRef]

- Kanoga, S.; Kanemura, A.; Asoh, H. Are armband sEMG devices dense enough for long-term use?—Sensor placement shifts cause significant reduction in recognition accuracy. Biomed. Signal Process. Control. 2020, 60, 101981. [Google Scholar] [CrossRef]

- Blanc, Y.; Dimanico, U. Electrode placement in surface electromyography (sEMG) “Minimal Crosstalk Area” (MCA). Open Rehabil. J. 2010, 3, 110–126. [Google Scholar] [CrossRef] [Green Version]

- De Luca, C.J.; Merletti, R. Surface myoelectric signal cross-talk among muscles of the leg. Electroencephalogr. Clin. Neurophysiol. 1988, 69, 568–575. [Google Scholar] [CrossRef]

- De Luca, C.J.; Kuznetsov, M.; Gilmore, L.D.; Roy, S.H. Inter-electrode spacing of surface EMG sensors: Reduction of crosstalk contamination during voluntary contractions. J. Biomech. 2021, 45, 555–561. [Google Scholar] [CrossRef] [PubMed]

- Tanweer, M.; Halonen, K.A.I. Development of Wearable Hardware Platform to Measure the ECG and EMG with IMU to Detect Motion Artifacts. In Proceedings of the 22nd International Symposium on Design and Diagnostics of Electronic Circuits & Systems, Cluj-Napoca, Romania, 30 May 2019; IEEE: Cluj-Napoca, Romania, 2019. [Google Scholar]

- Mithun, P.; Pandey, P.C.; Sebastian, T.; Mishra, P.; Pandey, V.K. A Wavelet Based Technique for Suppression of EMG Noise and Motion Artifact in Ambulatory ECG. In Proceedings of the 33rd Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Boston, MA, USA, 30 August–3 September 2011; IEEE: Boston, MA, USA, 2011. [Google Scholar]

- Basmajian, J.; Blumenstein, R. Electrode Placement in EMG Biofeedback; Williams & Wilkins: Balttimore, MD, USA, 1980. [Google Scholar]

- Lin, Y.-A.; Zhao, Y.; Wang, L.; Park, Y.; Yeh, Y.-J.; Chiang, W.-H.; Loh, K.J.L. Graphene K-Tape Meshes for Densely Distributed Human Motion Monitoring. Adv. Mater. Technol. 2021, 6, 2000861. [Google Scholar] [CrossRef]

- Manna, K.; Wang, L.; Loh, K.J.L.; Chiang, W.-H. Printed Strain Sensors Using Graphene Nanosheets Prepared by Water-Assisted Liquid Phase Exfoliation. Adv. Mater. Interfaces 2019, 6, 1900034. [Google Scholar] [CrossRef]

- Anaya, D.V.; Yuce, M.R. Stretchable triboelectric sensor for measurement of the forearm muscles movements and fingers motion for Parkinson’s disease assessment and assisting technologies. Med. Devices Sens. 2021, 4, e10154. [Google Scholar]

- Yang, S.; Li, C.; Chen, X.; Zhao, Y.; Zhang, H.; Wen, N.; Fan, Z.; Pan, L. Facile Fabrication of High-Performance Pen Ink-Decorated Textile Strain Sensors for Human Motion Detection. ACS Appl. Mater. Interfaces 2020, 12, 19874–19881. [Google Scholar] [CrossRef] [PubMed]

- Reddy, K.R.; Gandla, S.; Gupta, D. Highly Sensitive, Rugged, and Wearable Fabric Strain Sensor Based on Graphene Clad Polyester Knitted Elastic Band for Human Motion Monitoring. Adv. Mater. Interfaces 2019, 6, 1900409. [Google Scholar] [CrossRef]

- Lin, Y.-A.; Zhao, X.; Silder, A.; Sessoms, P.; Fraser, J.J.; Loh, K.J.L. Graphene kinesiology tape for monitoring distributed human movements of the ankle-foot complex. In Nano-, Bio-, Info-Tech Sensors and Wearable Systems; SPIE: Bellingham, WA, USA, 2021. [Google Scholar]

- Gupta, A.; Sayed, T.; Garg, R.; Shreyam, R. Emg Signal Analysis of Healthy and Neuropathic Individuals. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; p. 012128. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.-A.; Mhaskar, Y.; Silder, A.; Sessoms, P.H.; Fraser, J.J.; Loh, K.J. Muscle Engagement Monitoring Using Self-Adhesive Elastic Nanocomposite Fabrics. Sensors 2022, 22, 6768. https://doi.org/10.3390/s22186768

Lin Y-A, Mhaskar Y, Silder A, Sessoms PH, Fraser JJ, Loh KJ. Muscle Engagement Monitoring Using Self-Adhesive Elastic Nanocomposite Fabrics. Sensors. 2022; 22(18):6768. https://doi.org/10.3390/s22186768

Chicago/Turabian StyleLin, Yun-An, Yash Mhaskar, Amy Silder, Pinata H. Sessoms, John J. Fraser, and Kenneth J. Loh. 2022. "Muscle Engagement Monitoring Using Self-Adhesive Elastic Nanocomposite Fabrics" Sensors 22, no. 18: 6768. https://doi.org/10.3390/s22186768

APA StyleLin, Y.-A., Mhaskar, Y., Silder, A., Sessoms, P. H., Fraser, J. J., & Loh, K. J. (2022). Muscle Engagement Monitoring Using Self-Adhesive Elastic Nanocomposite Fabrics. Sensors, 22(18), 6768. https://doi.org/10.3390/s22186768