A Primer on the Factories of the Future

Abstract

1. Introduction

2. A Historical Narrative: The Past, Present and Future of the Factory and Its Ecosystem

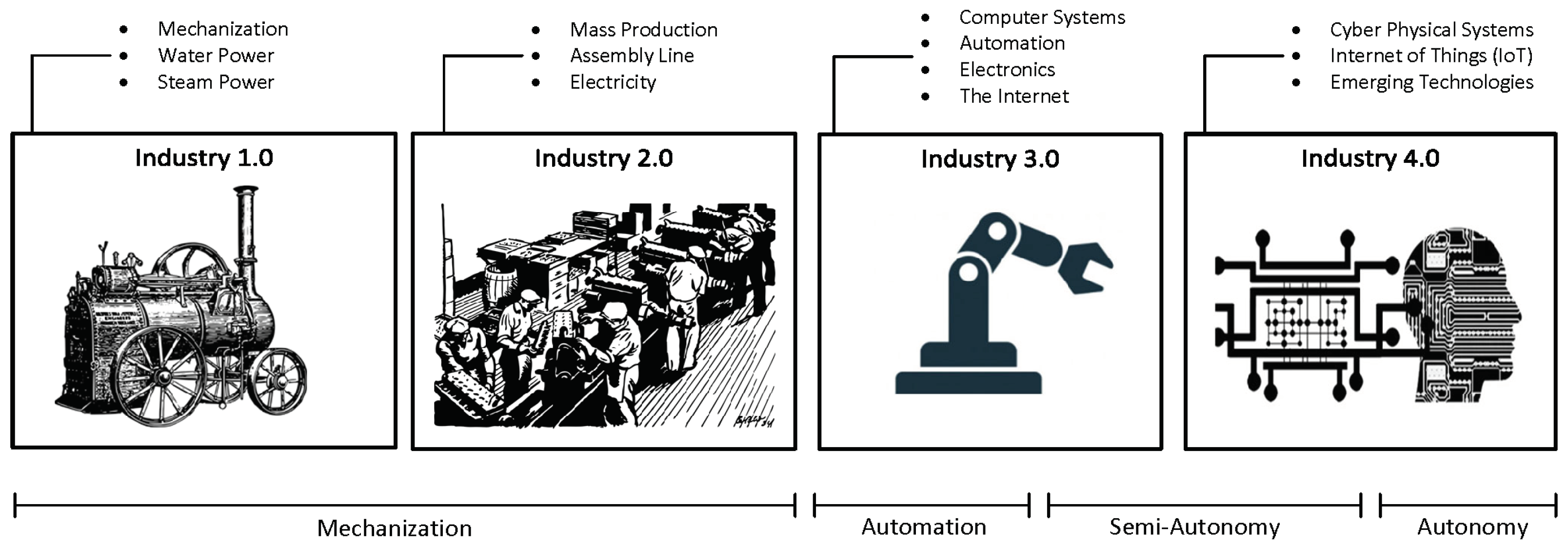

2.1. The Industrial Revolutions

2.2. Levels of System Sovereignty (L2S): A System Maturity Model

2.2.1. Mechanization

2.2.2. Automation

2.2.3. Semi-Autonomy

2.2.4. Autonomy

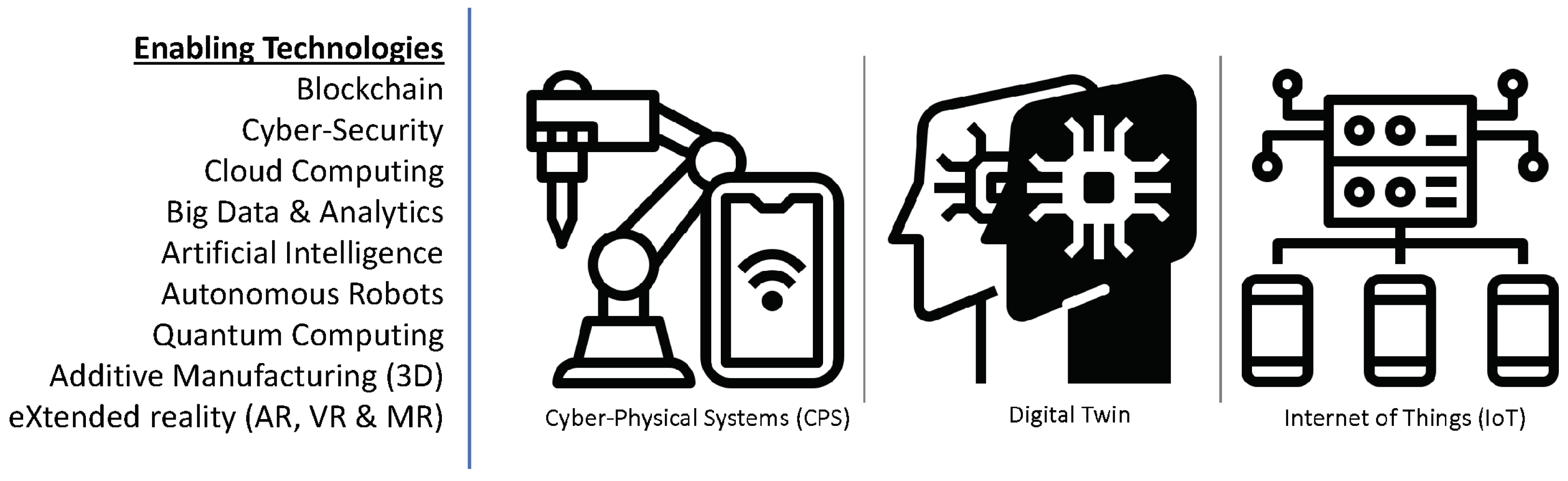

2.3. Industry 4.0 and the Future Factory

3. Research Methodology

3.1. Research Approach

3.2. Search Goals

3.3. Data Sources

3.4. Search Methodology

4. Understanding the Future Factory

4.1. The Future Factory in the Context of the Manufacturing Ecosystem (ME-S)

4.2. Describing the Factory of the Future

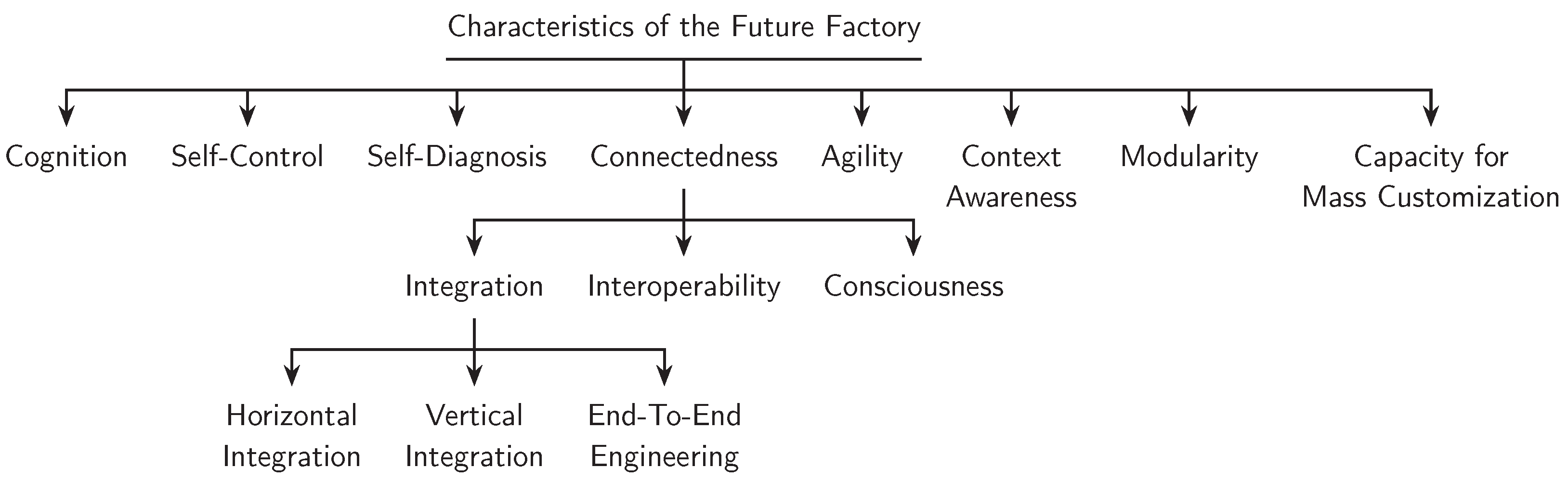

4.3. The Characteristics of the Future Factory

4.3.1. Cognition

4.3.2. Self-Control

4.3.3. Self-Diagnosis (Machine Health)

4.3.4. Connectedness

4.3.5. Agility

4.3.6. Context Awareness

4.3.7. Modularity

4.3.8. Capacity for Mass Customization

4.4. Enabling Connectedness: Integration, Interoperability, and Consciousness

4.4.1. Integration

- (a)

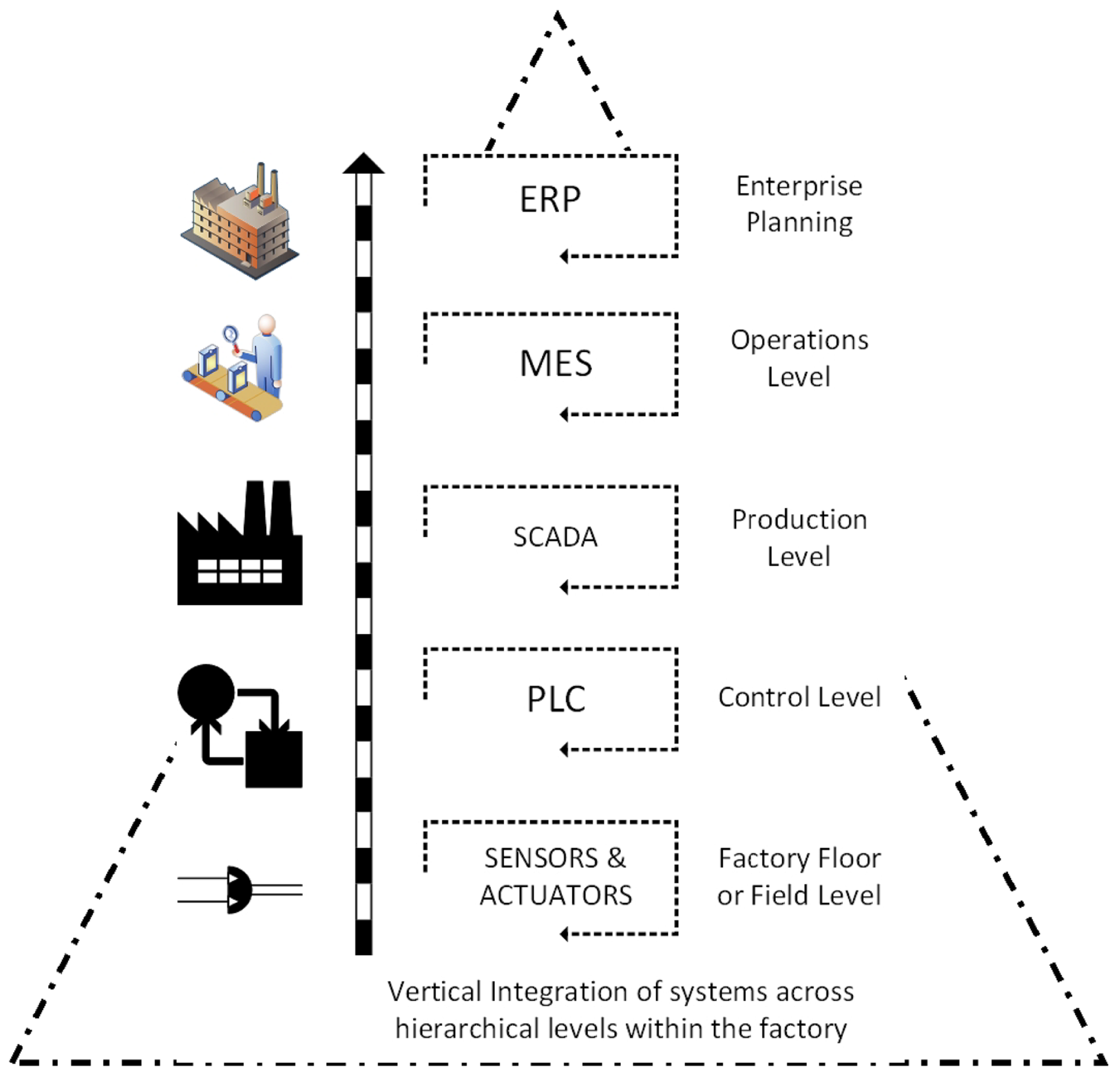

- Vertical integration: Vertical integration is the integration of all hierarchical physical and informational subsystems within a factory to achieve a flexible, self-managing (autonomous), self-organized, and reconfigurable manufacturing system that can respond to production uncertainties quickly, flexibly, and effectively.For example, if a client requests specific product customizations, the business development unit should not be on a call to engineering all day. All the information requested by the engineering department will already have been logged in the ERP system—essentially everyone has access to the same information (albeit different versions on a need-to-know basis). With this this level of transparency and the seamless flow of information, a vertically integrated system can be easily reconfigured to produce the customized product or manufacture small-lot sizes, at short notice without a significant technical or fiscal penalty. The integration typically cuts across different hierarchical stages beginning from the field (factory floor) and going right up to the enterprise resource planning (ERP) level. The joint implementation of all three integration options can result in a fully integrated factory comprising digitally connected entities (machines, people, products, and services). The overall goal is the integration of all digitized physical assets into an ecosystem that includes all elements of a local factory and all other entities or partners within their value chain. The ecosystems resulting from these integrations enable increased autonomy for system elements, decentralized control, improved efficiency, and transparency given the seamless transmission of data and information between all entities.

- (b)

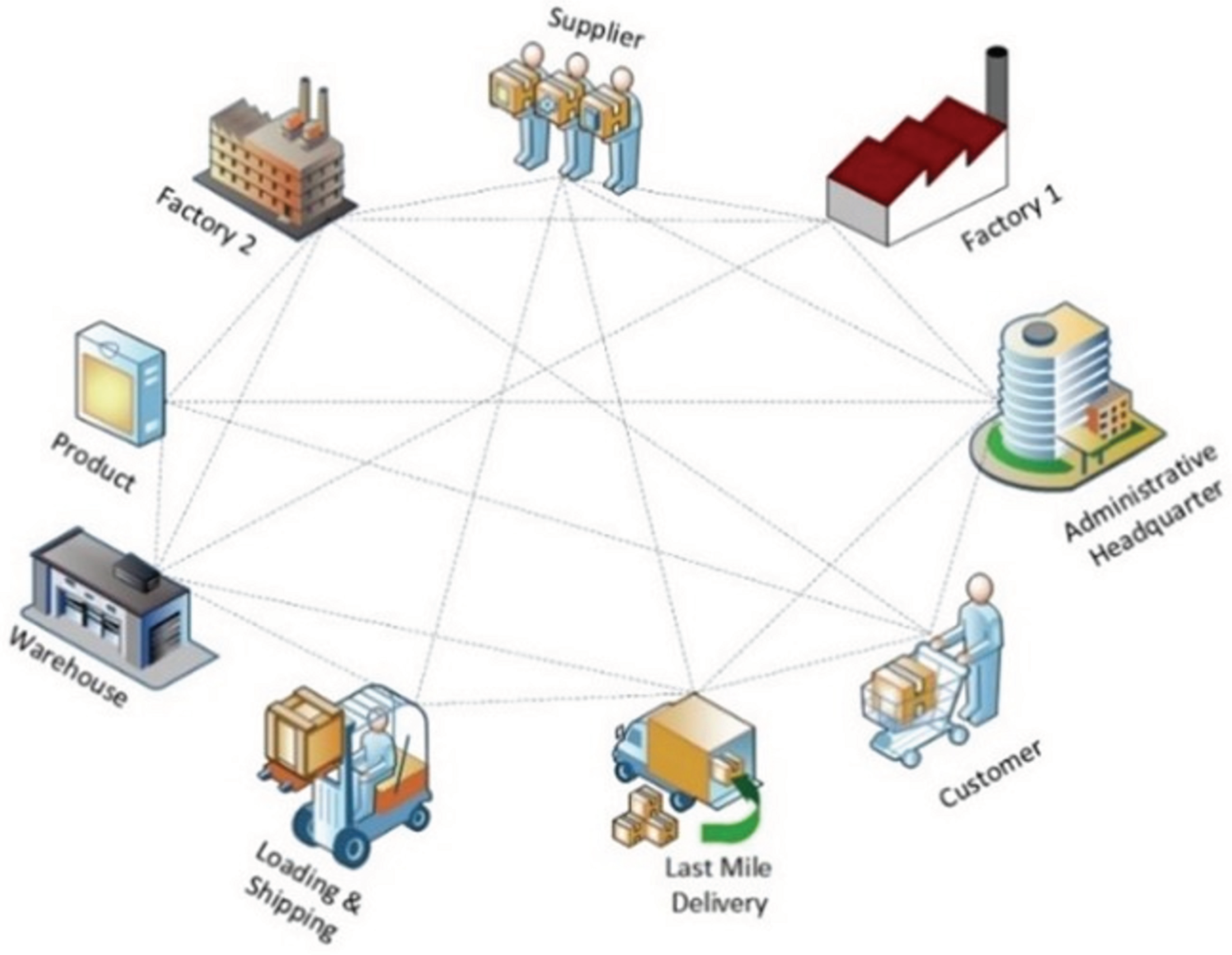

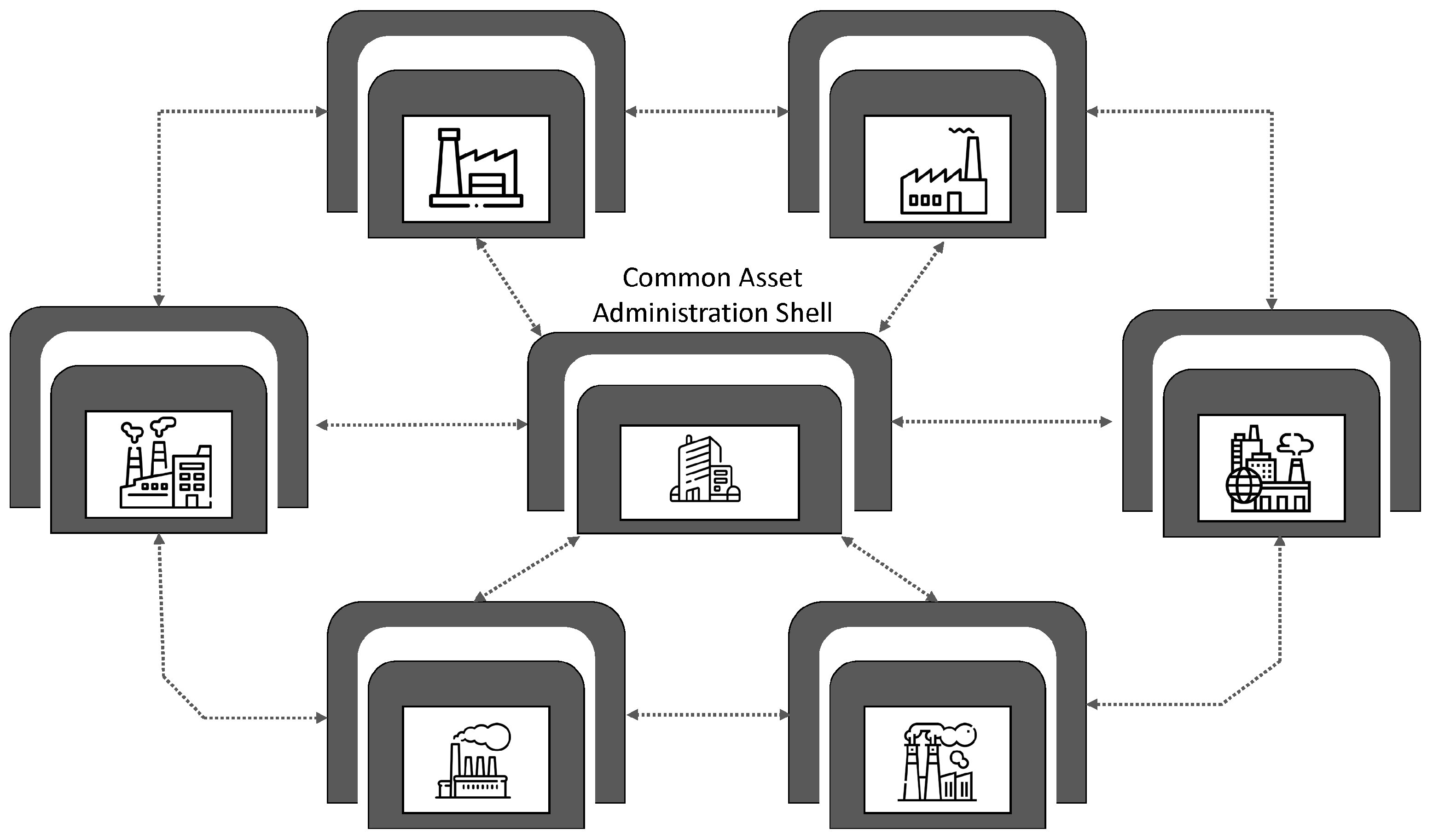

- Horizontal integration: Horizontal integration involves the digital connection of a factory to other external entities and processes across its value chain. It is illustrated in Figure 6.This arrangement would include a digitally developed network of warehousing systems, transportation assets, and production facilities that feature ICT-based integration of everything from inbound logistics to production, marketing, outbound logistics, and services [134]. The connectedness makes it possible for real time data to be obtained, analyzed, and shared in real-time to facilitate rapid and accurate decision making. All nodes on the network can have access (on a need-to-know basis) to information about production status, inventory levels, available resources, and other critical information necessary for streamlined production. A factory so connected is said to be horizontally integrated. Horizontal integration can take place at different scales and at several levels. Optimal value can be created by a factory that can harness value from data gleaned from activities and processes, both internal and external to the factory. As part of the horizontal integration of a factory, suppliers, contractors, and even other factories, whether located in the same or different geographical locations, can be connected into an efficient ecosystem where there is seamless transmission of data and information. The efficiency gained by this arrangement can be mutually shared by all parties. For example, a factory can have regulated remote access to a resource (machine, device, software, etc.) within a company in another location. These outcomes can result in efficiency of scale, improvements in turn-around time, and higher productivity levels. Other advantages include transparency, better knowledge sharing, and improved communication.

- (c)

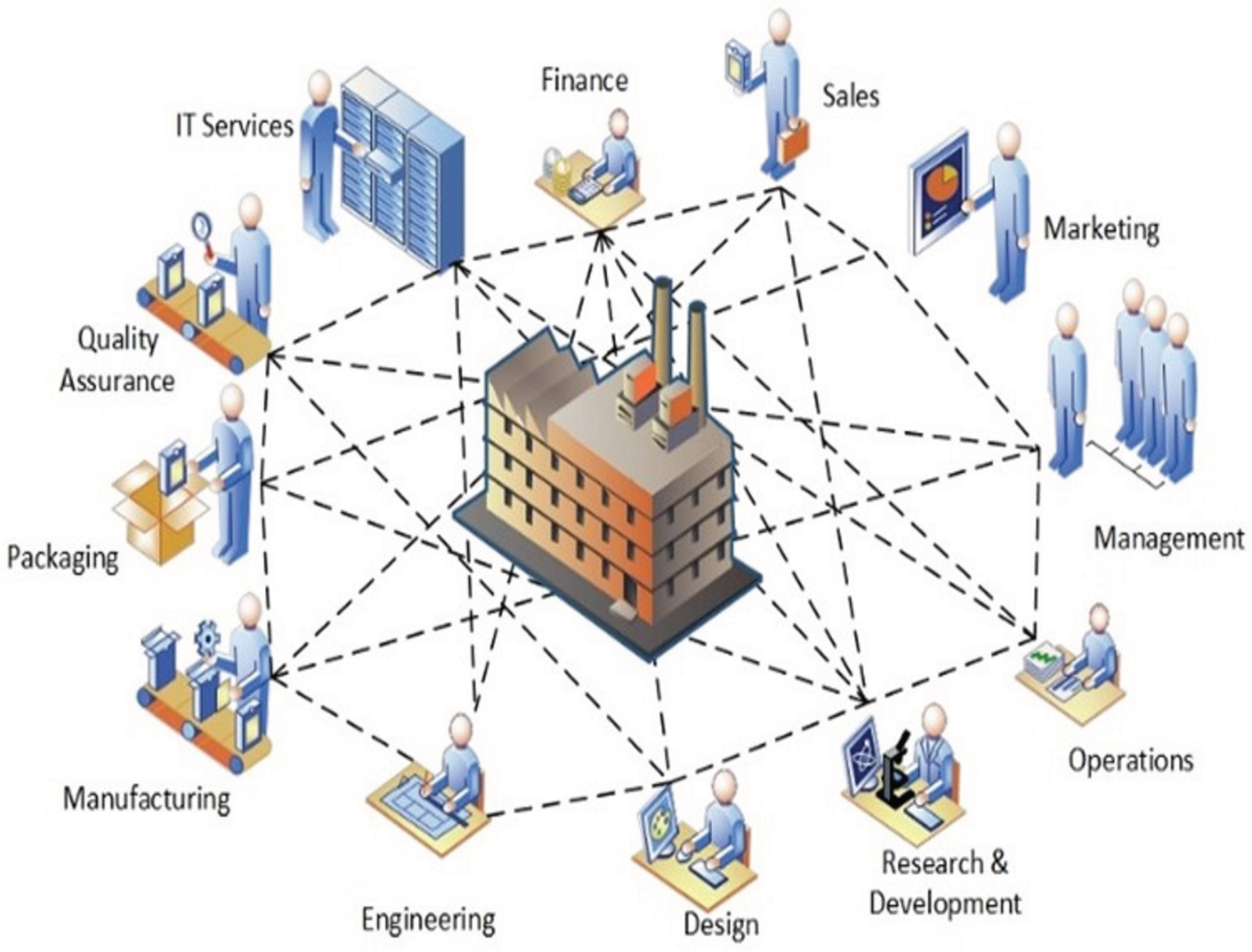

- End-to-end digital integration of engineering across the entire value chain: Though many factories have successfully digitized different aspects of their businesses, some have also ended up with segmented or siloed organizations where the systems of various units are unable to talk to one another. Though most manufacturing processes are supported by ICT, many of the systems and technologies that rely on them remain static and inflexible [75]. The result is that information flow is inhibited, throwing manual transmission of data across the individual aspects back into the discussion. Digitally connecting these different systems and technologies can be referred to as End-to-end engineering integration. More broadly, it involves the digital integration of all aspects of the value chain (sourcing, product development, production, logistics, operations, marketing/sales, after-sale services, etc.) to enable the seamless flow of data across the network for the purpose of delivering real-time information about production status to all stakeholders, enabling the development of new efficiency, supporting product customization [152], streamlining of processes, and a reduction in the unnecessary expenditure on manual activities. Figure 7 provides a graphical illustration of end-to-end digital integration.

4.4.2. Interoperability

4.4.3. Consciousness

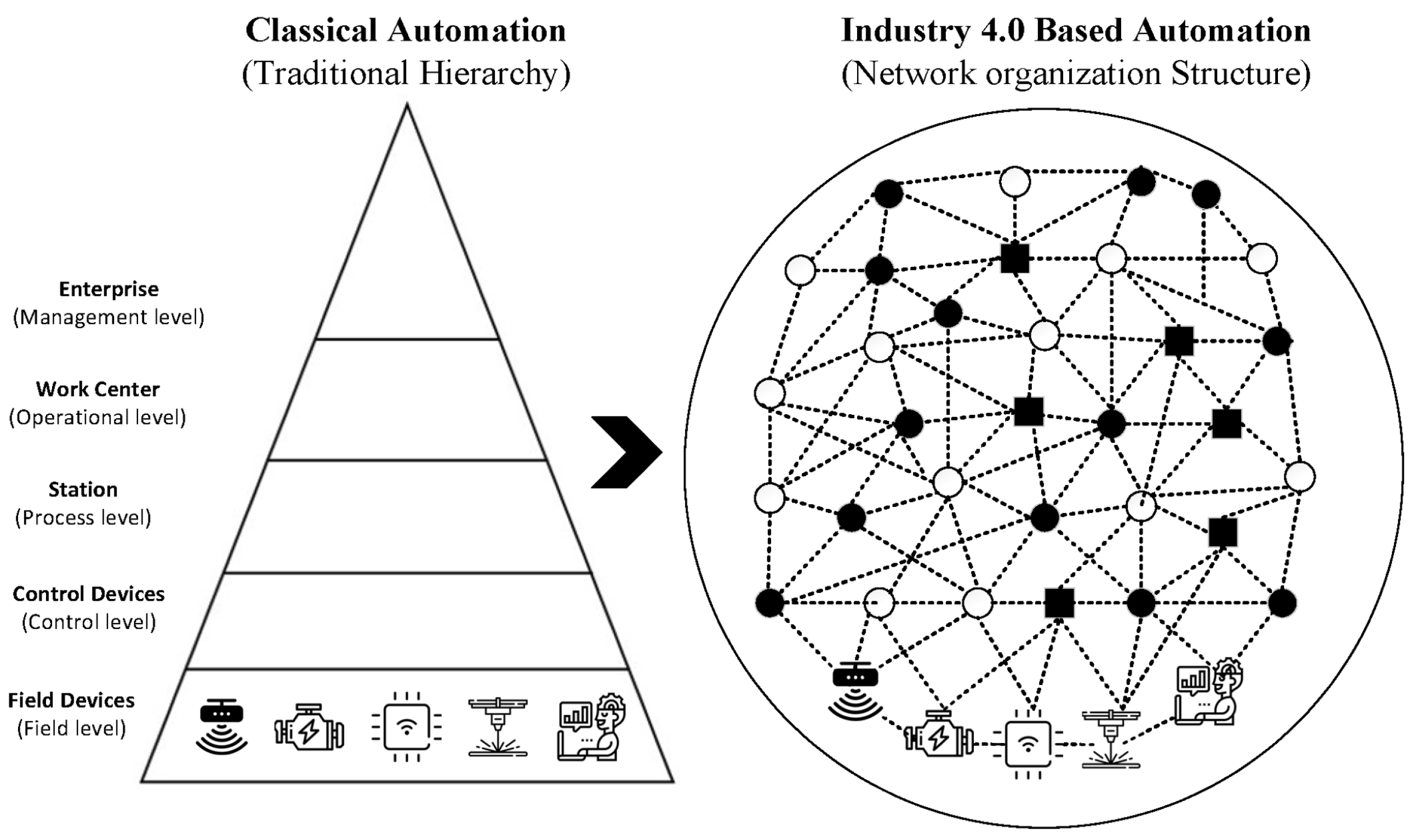

4.5. From the Automation Pyramid to a Decentralized and Distributed Network

5. Conceptual Frameworks and Reference Architectures

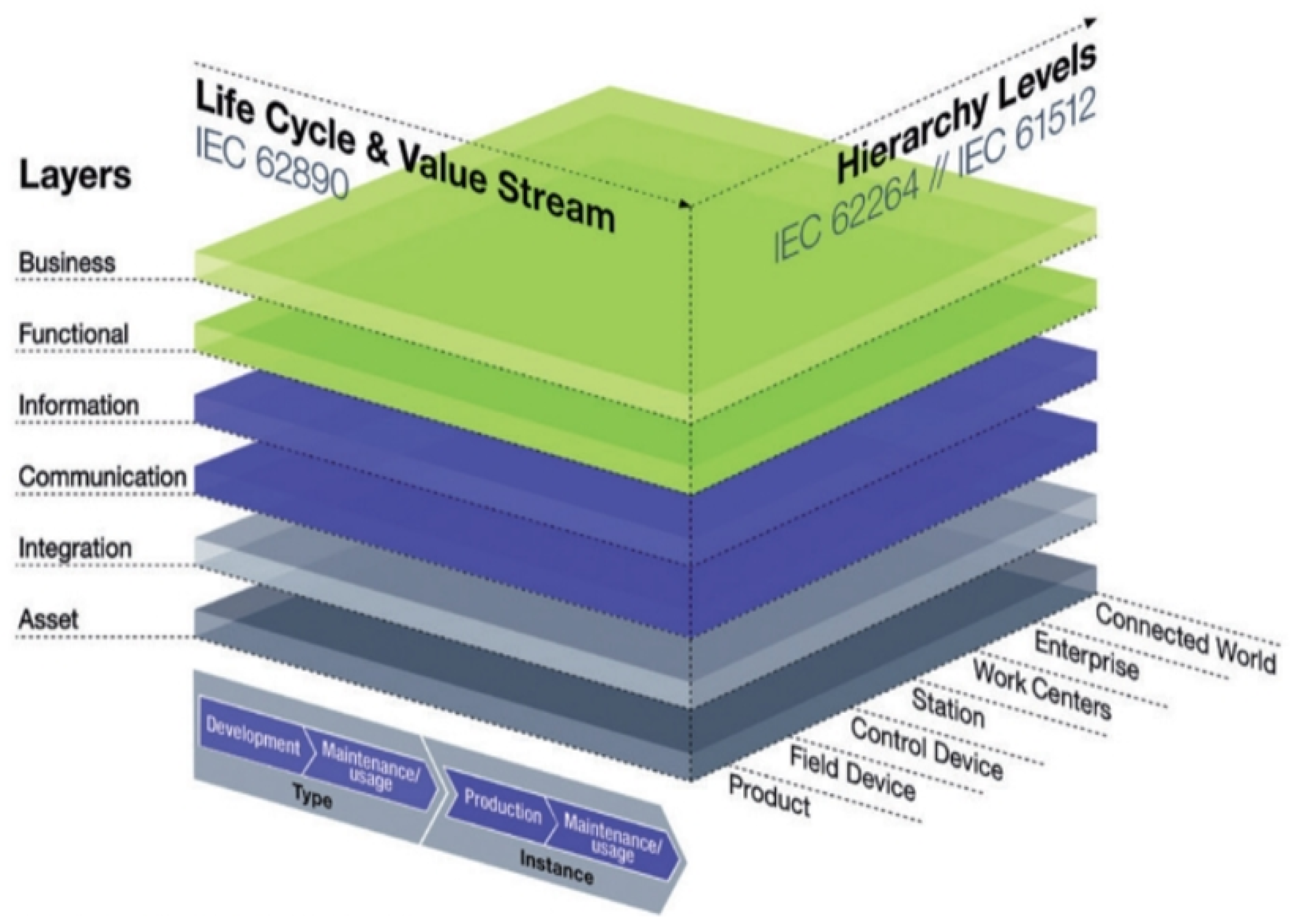

5.1. The Reference Architectural Model Industrie 4.0 (RAMI 4.0)

5.1.1. Horizontal Axis (Right)

- (a)

- Level 0(Products): Refers to intelligent (communicating) products. They can interact with users and makers with or without embedded sensors, labels, or tags. Data pulled from these products enable product enhancement, maintenance, and future design improvements. Conversely, data can also be pushed to the products (example updates).

- (b)

- Level 1(Field Device): The functional level comprising intelligent devices that enable smart and intelligent control of machines and systems. It includes sensors, actuators and all other devices required to protect, control, and monitor manufacturing systems and processes. Process and machine health data can be pulled from these assets. Actionable information can also be pushed to some (e.g., actuators).

- (c)

- Level 2(Control Device): Represents industrial control systems that are responsible for the logical control of field devices. Examples include distributed control systems (DCS) and programmable devices, prominent among which are the programmable logic controllers (PLCs).

- (d)

- Level 3((Work Unit OR Station): A lower-level element in the manufacturing architecture where production planning and scheduling (including supervision of machines) based on events and processes are performed. This is usually done using supervisory control tools such as supervisory control and data acquisition (SCADA).

- (e)

- Level 4(Work Centers): Work centers are the highest-level manufacturing elements that perform and manage end-to-end manufacturing processes and functions, including planning, scheduling, and production activities. They typically include process cells, production units, production lines, and storage zones. Management execution systems (MES) and manufacturing operations management (MOM) applications are used to build traceable records of the manufacturing process, build supply chain visibility, and keep track of information of everything from labor to materials, machine health, product shipment, and job orders.

- (f)

- Level 5(Enterprise): Strategic business decisions are made at this level. Enterprise resource planning (ERP) tools are commonly used. The enterprise is a collection of business functions operating together to set and implement and manage the realization of strategic business imperatives.

- (g)

- Level 6(Connected World:) This level is one of two enhancements to the traditional automation pyramid. It is the level that enables connection to super-ordinate cloud services, the Internet of Things (IoT), and the Internet of Services (IoS), helping link assets in one organization to the assets in external organizations. The flow of data from the shop floor to plant operating systems (MES), business systems (enterprise resource planning, ERP), and then the external world (e.g., other smart factories or external elements of the value chain or supply chain).

5.1.2. Horizontal Axis (Left)

5.1.3. Vertical Axis

- (a)

- Asset Layer: The aggregation of all physical instances of assets and components required to provide functionality to the system. This would include physical objects, such as sensors, actuators, and devices. It would also include humans, products, plans, documents, applications etc.

- (b)

- Integration Layer: This layer manages the digital representations of physical assets and is responsible for the transitions from the physical to the digital world. It contains asset documentation, applications, and assets (i.e., HMI devices, QR-code readers, sensors, control systems, etc.) that manage the transitions, generate events from assets (e.g., equipment and machinery), and provide computer aided control of technical processes, system drivers, and other collaterals.

- (c)

- Communication Layer: Responsible for data integration and standardization of communication between the integration and the information layers. This layer includes standards, communication protocols, and services that support interoperability and integration.

- (d)

- Information Layer: This level manages and stores data in an organized fashion. It is associated with data services and standards that regulate the flow and exchange of information between components, services, and their functions. It also ensures consistency in the integration of different data formats and interoperability between components and services.

- (e)

- Functional Layer: This layer is responsible for production rules, decision making logic, and the provisioning and management of the run time and modeling environment for services that support business processes. It also hosts the descriptions of functions and supports remote access serving as a platform for the horizontal integration of various components and functions.

- (f)

- Business Layer: This level maps out the business model, links the various business processes, and hosts the business rules that the system must follow. Said rules are based on information drawn from the value stream, the supply chain, the regulatory regime, and subsisting laws. It also orchestrates (or arranges) services in the functional layer and receives events that help track the progress of business processes. Standard run-times for executable business processes are essentially provided in both the Functional and Business layers [187].

6. Communication Standards and Technologies of the Future

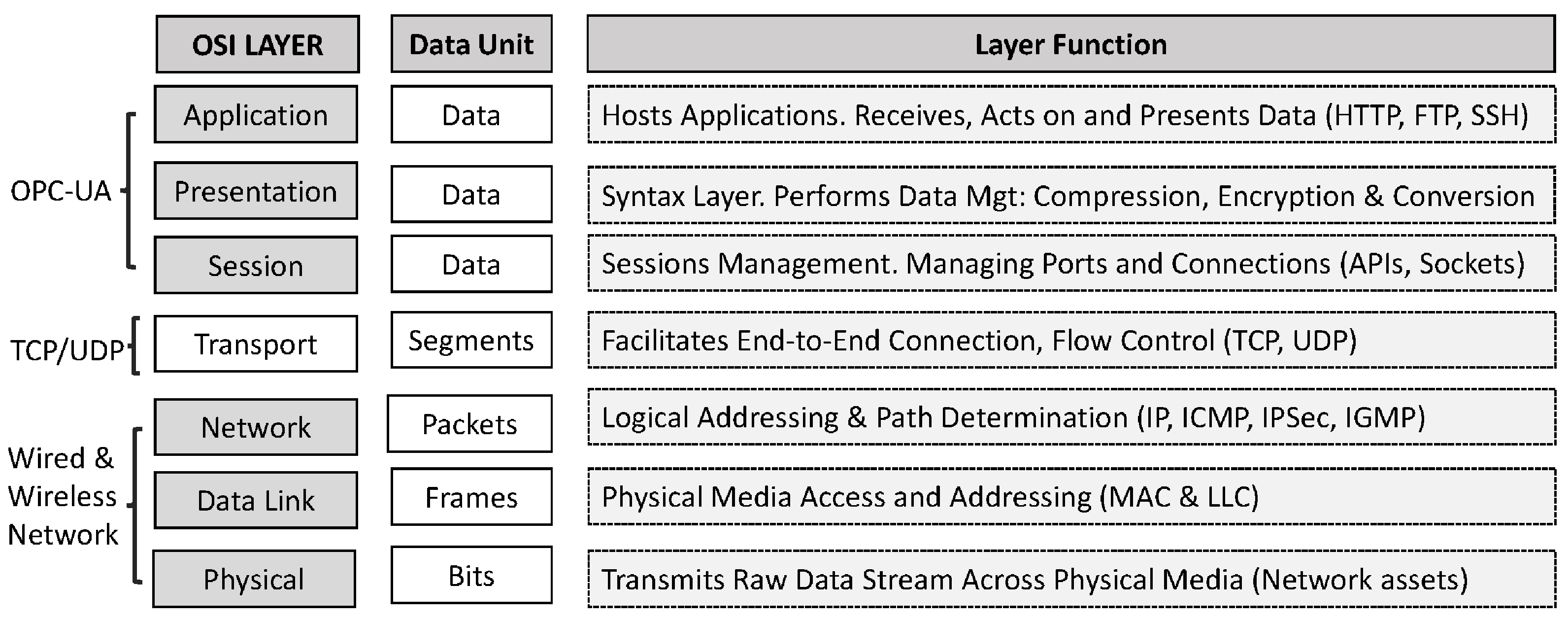

6.1. Open Platform Communication-Unified Architecture (OPC-UA)

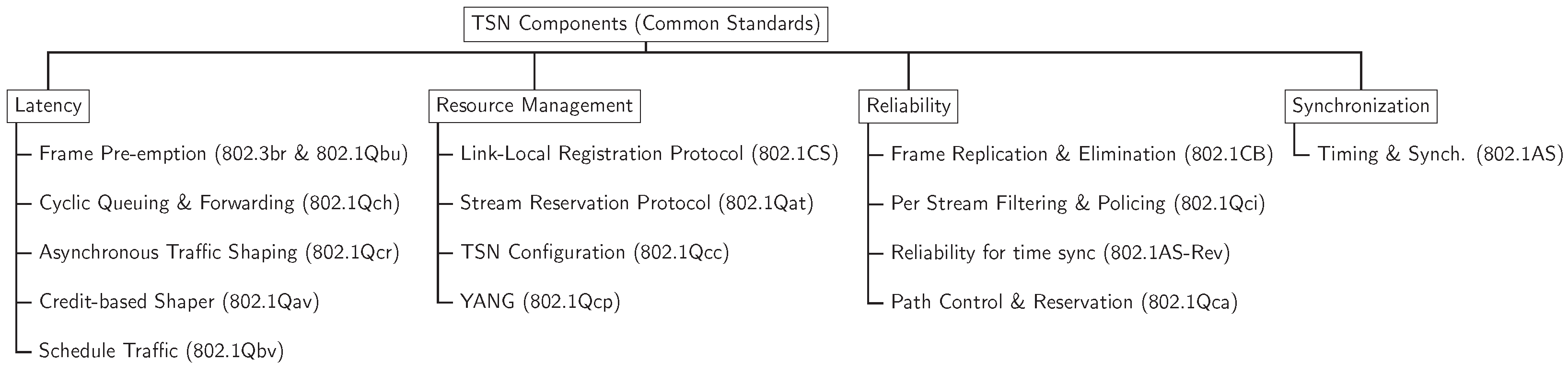

6.2. Time-Sensitive Networking (TSN)

6.3. 5th Generation Mobile Network

- (a)

- Enhanced Mobile Broadband (eMBB) services are geared towards applications that require high data rates across a wide coverage areas. Compared to 4G, they can handle large payloads and are stable over an extended time interval. Complimentary deployment of Enhanced Mobile Broadband (eMBB) alongside existing 4G broadband services could enable substantial improvements in traffic and the efficiency of the industrial network at the core network level.

- (b)

- Ultra-Reliable Low-Latency Communications [URLLC] is almost deterministic in time bounds on packet delivery. It is ideal for applications that require end-to-end security and where reliability and speed are critical, though bandwidth might not be as much. Mission-critical applications that require quick reaction times would fall into this category. As 5G URLLC delivers ultra-low latency and guarantees against triggering undesirable safety stops in production lines, it has been employed in automating factory processes and related power systems. For example, it has been used to run industry technical standards such as PROFINET. Industrial robots have become ubiquitous on manufacturing floors. The transmission of time-critical communication messages to them using Ultra-Reliable Low-Latency Communication (URLLC) might be necessary to accommodate for instances where decision time for responding to an incident or accident is almost non-existent. Combining 5G and MEC results in a significant reduction in network latency, which can improve the performance of previously tethered-only AR/VR, haptic, and tactile-based applications.

- (c)

- Massive Machine-Type Communications (mMTC) is a service that provides mainly wireless connections to massive numbers (tens of billions) of network-enabled devices that intermittently transmit payload sizes (small data packets) at low traffic [216]. While low transmission latency is not a requirement, it has low latency, is secure, is reliable, and is scalable. As mMTC transmit small payload sizes at low transmission rates and frequencies, they require lower energy consumption, making them well suited for battery powered, low maintenance end devices (i.e., low-cost sensors, smart meters, wearables, trackers, diverse monitoring devices, etc.). NB-IoT (narrowband IoT) and Cat-M1 (operated at 1.4 MHz bandwidth) are two 3GPP standardized technologies that support these network-enabled devices. NB-IoT supports ultra-low complexity devices with very narrow bandwidth and data rate peaks of approximately, around 200 kHz and 250 kbs per second, respectively. Conversely, Cat-M1 supports relatively more complex devices and operates at a bandwidth of 1.4 MHz, with lower latency and better location and asset tracking capabilities. Both can also sleep for extended periods and maintain excellent power-saving mode (PSM) abilities and extended discontinuous reception [217].

7. Realizing the Promise of Industry 4.0 through the Digitization of Physical Assets

7.1. Industry 4.0 Components: Assets and the Asset Administration Shell (AAS)

7.1.1. Key Elements of Industry 4.0 Components:

- (a)

- Asset: An asset is anything (physical or non-physical) within the production system that requires a connection to another asset or an Industry 4.0 solution, e.g., simple devices, components, machines, assembly lines, or even entire production systems. Other examples of assets include automation components, services, and even applications/software platforms. Each asset within the production system must be identifiable to the system (in the first instance), and to all other assets (including devices, systems, and services). To be considered compatible, each asset must have a set of defined properties and must be able to collect and share all relevant data to similarly networked entities (other assets; stakeholders, e.g., companies participating both in the value and supply chains) throughout its lifecycle. This means they each need to read, interpret, and understand all asset data, including identity (asset type, model number, etc.), operational status, and all other asset-related data.

- (b)

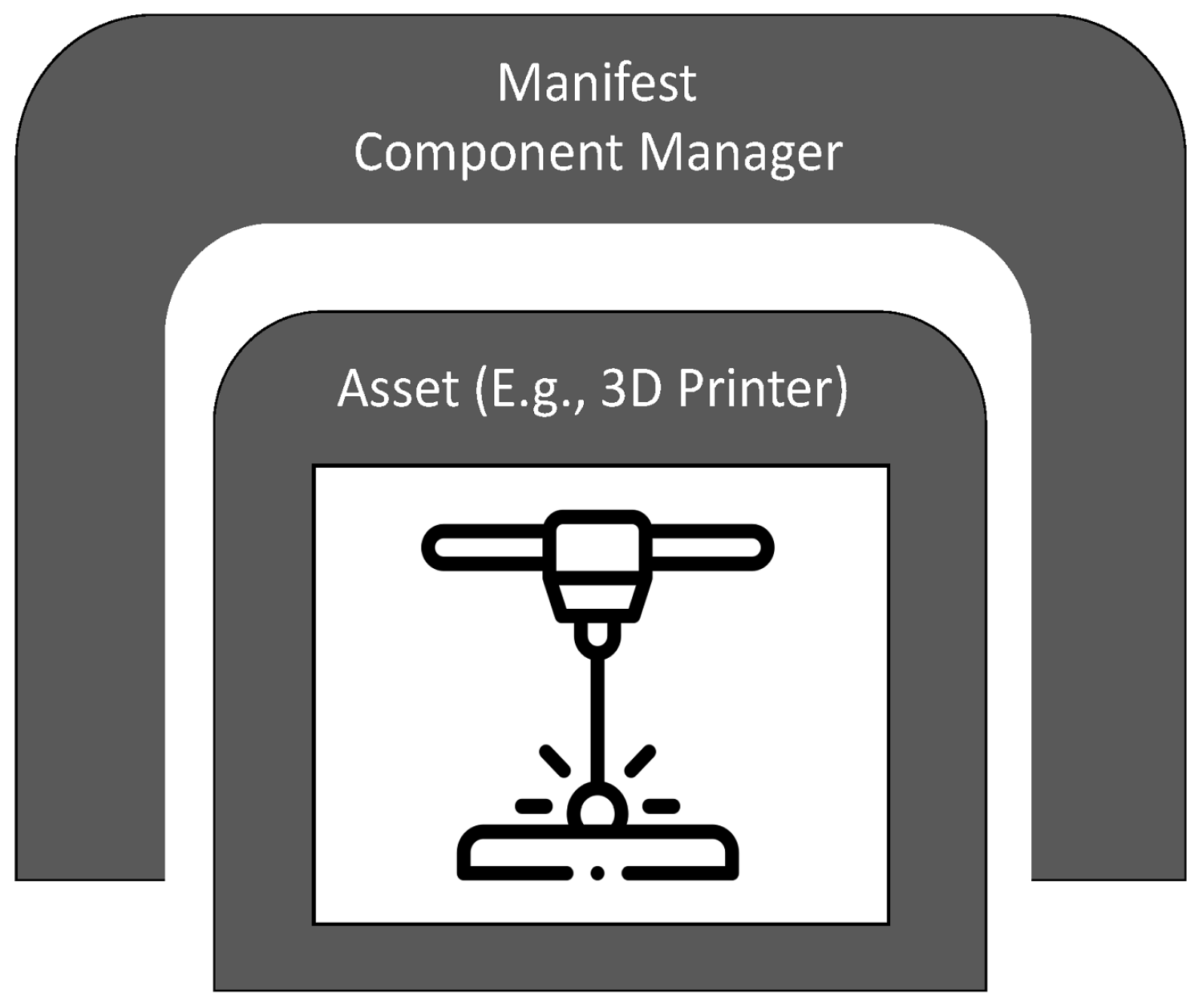

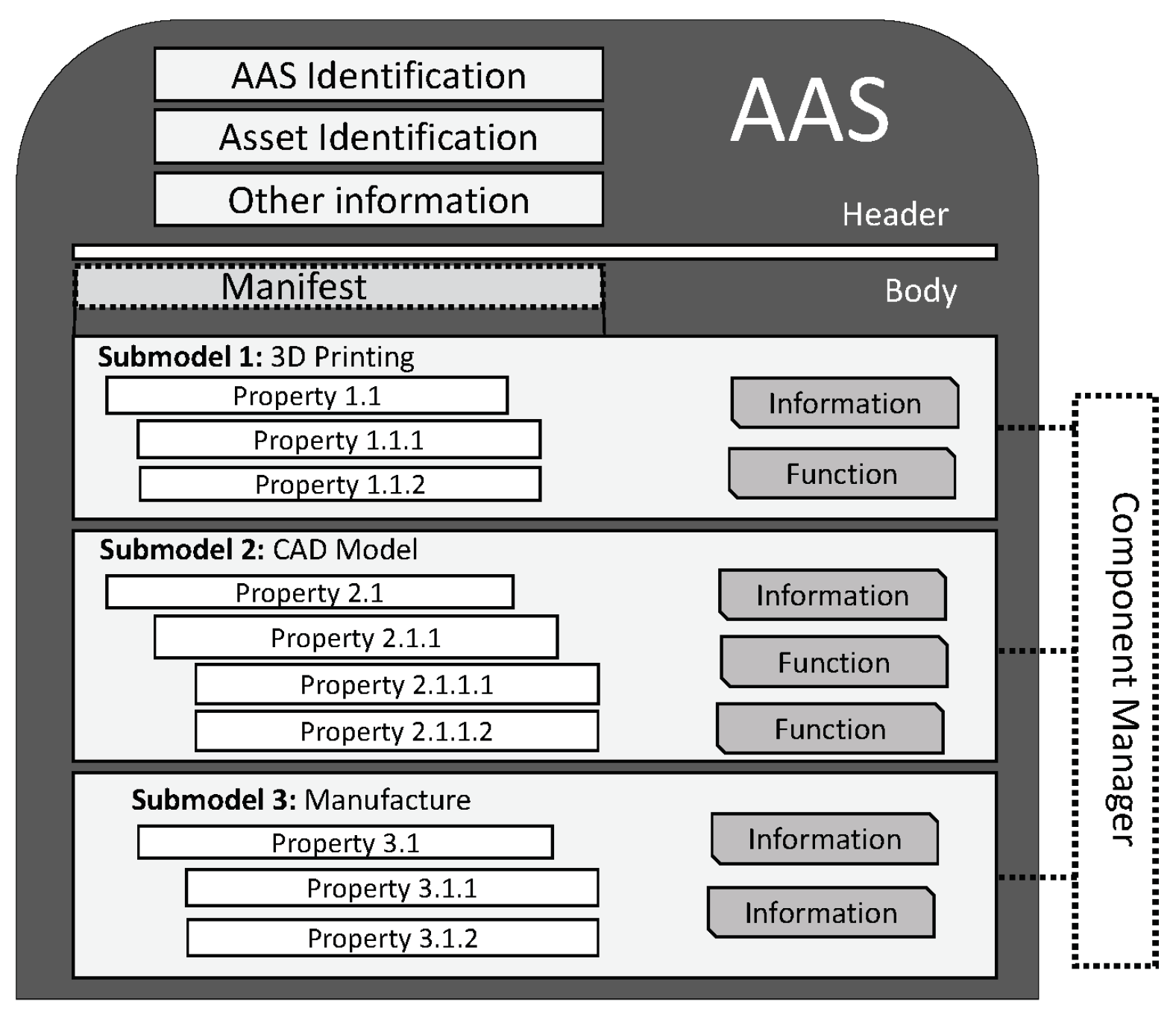

- Asset Administration Shell (AAS): Industrie 4.0 recommends the asset administration shell (AAS) as an important building block of the Factory of the Future [75,186,230,231]. Multiple articles in the literature provide reviews on asset administration shells (AAS) [232,233]. The asset administration shell (AAS) is a mechanism for digitally representing physical assets and other abstract entities. In practice, it helps provide descriptions of the properties and capabilities of an asset and serves as a platform for interaction between the asset and other assets.As an industrial application, a digital twin (DT) helps transform an asset to its digital equivalent, serving as a bridge between a tangible asset and the virtual or IoT world. A typical AAS holds identifying, operational, status, and technical information about the asset it represents, over its lifetime. It contains the communication methods and stores all asset related data [149]. Some of the information the AAS stores is related to the configuration of the asset, its maintenance record, or data related to its connectivity with other devices. Diagrammatically, an asset is enclosed within an asset administration shell (AAS), as shown in Figure 12.Each asset in the production system has its own administration shell, i.e., Figure 12. Two or more assets can be grouped into a unit [234]. The unit (much like an individual asset) can map to its own administration shell. A common administration shell i.e., Figure 13 can be used to manage the communication of multiple asset administration shells (AAS) at a higher hierarchical level. The configuration shown in Figure 14 is also suited for Factory-to-Factory communication. This architecture can allow the transparent and seamless flow of data between sister factories and other associated assets within a value or supply chain Figure 15 shows a different configuration of assets, each mapped to its own administration shell, and connected to other assets through open communication protocols to facilitate the seamless flow of dataBeyond acting as a store for important asset data, the AAS also serves as a reliable and consistent mechanism for managing data and related functions and services.

7.1.2. The Anatomy of an Asset Administration Shell (AAS)

7.2. Seamless Transfer of Data: OPC-UA, AAS, and Companion Specifications

7.3. Data Exchange: The Administration Shell and the Semantic Web

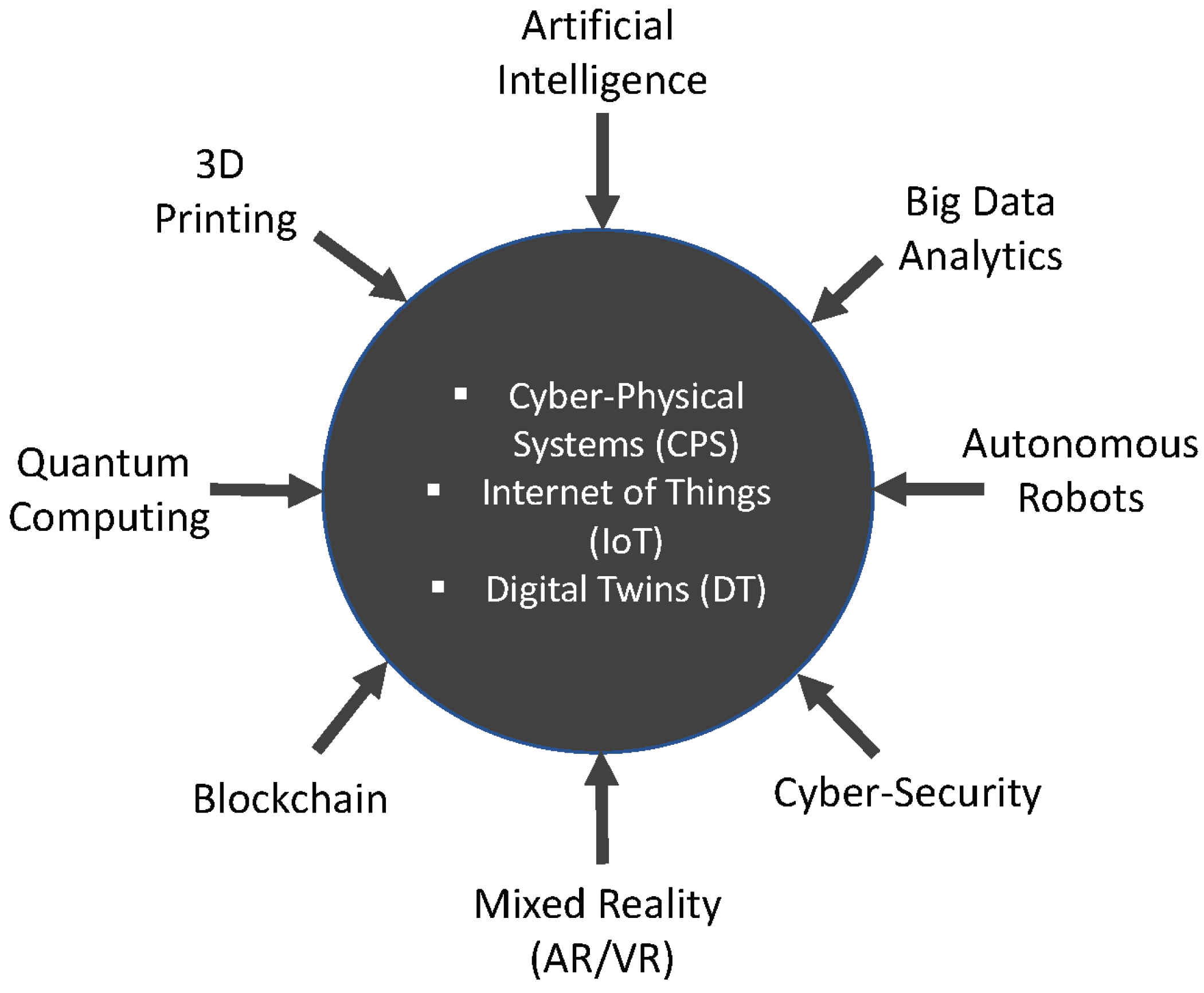

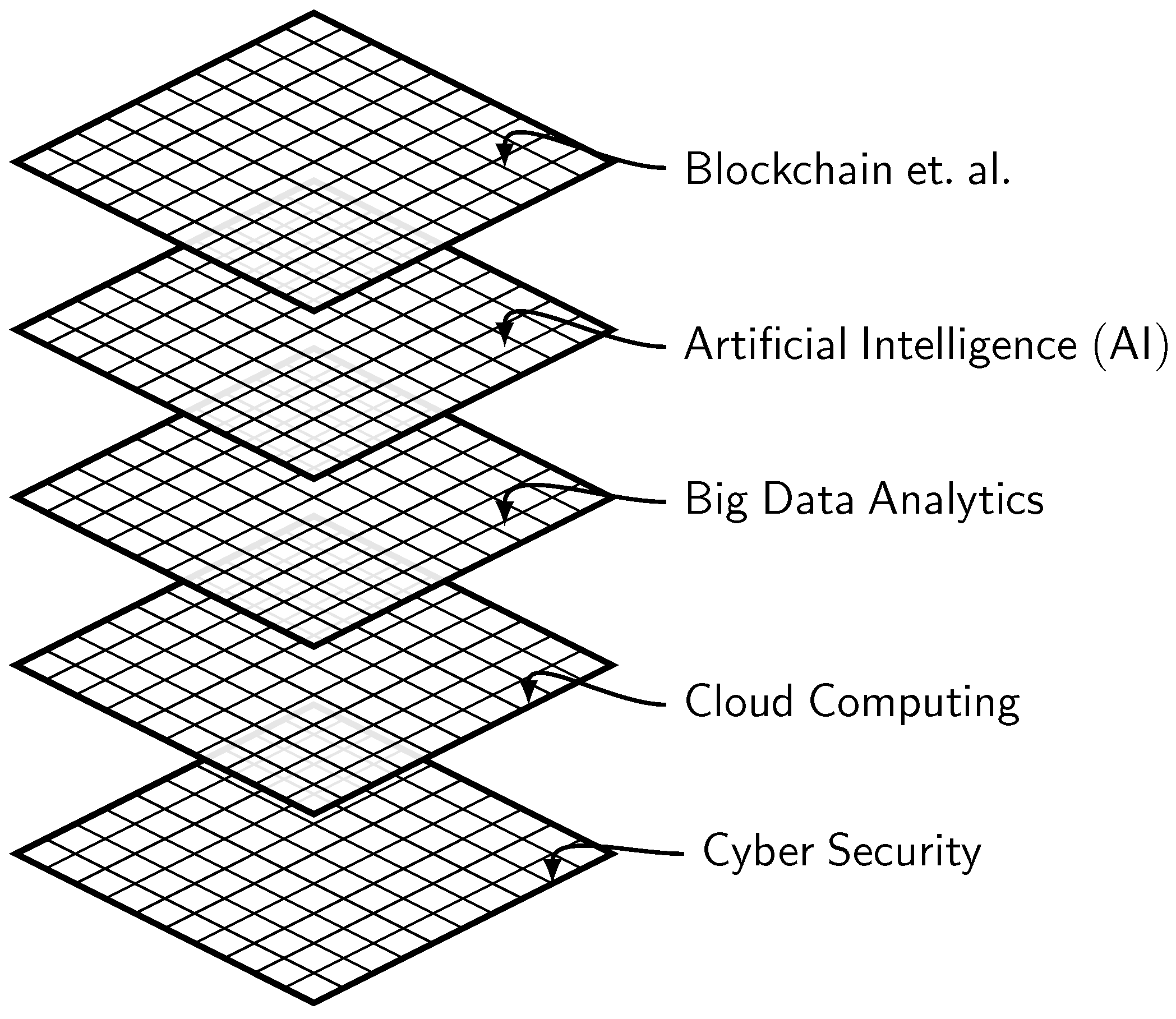

8. Key Building Blocks, Technology Enablers, and Innovation Accelerators

8.1. The Core Elements of the Factory of the Future

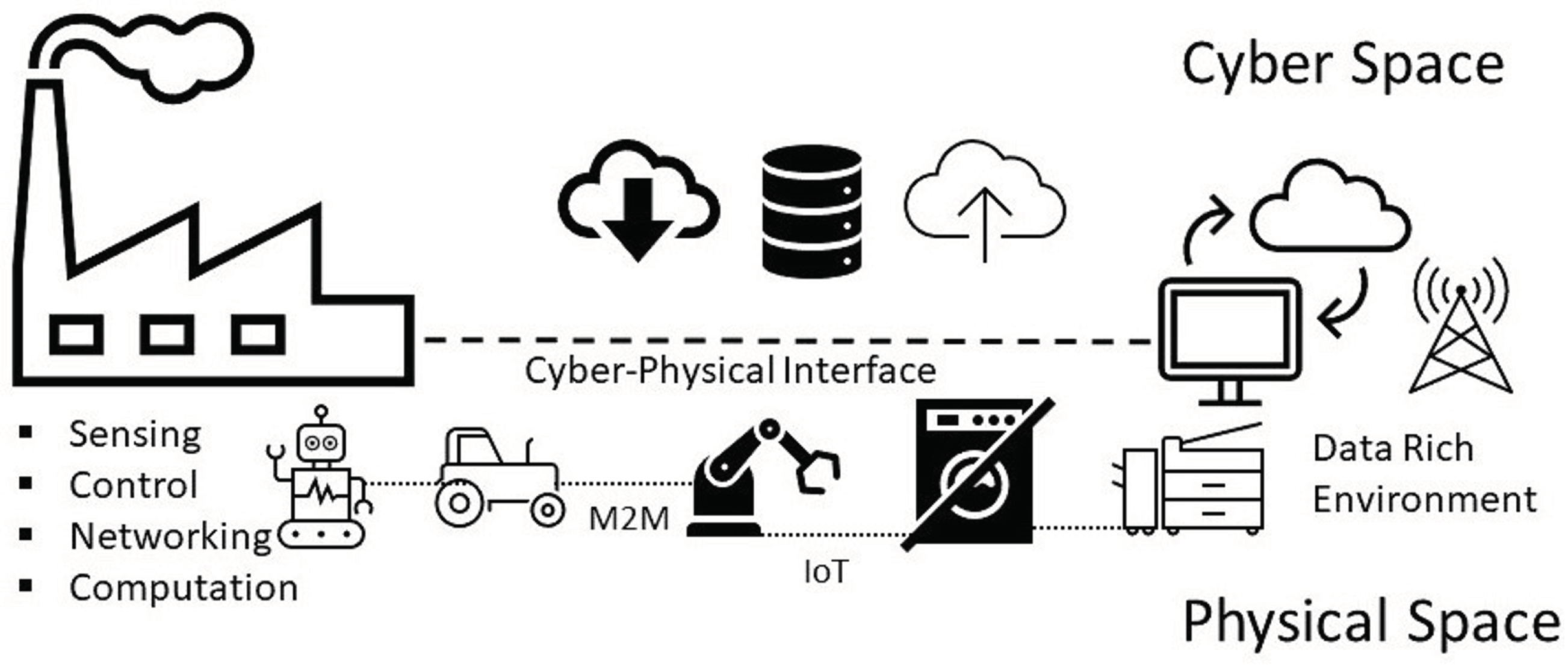

8.1.1. Cyber-Physical Systems (CPS)

8.1.2. Industrial Internet of Things (IIoT)

8.1.3. Digital Twins

8.2. Peripheral Elements of the Factory of the Future

8.2.1. Cloud Computing

- (a)

- “Cloud-Only” Computing: Cloud services make it possible for businesses to increase storage and computing capacities on-demand and on the fly without the need to invest in new infrastructure, applications, or IT personnel. Eliminating concerns about the availability of IT resources enables companies to focus on innovation and creating business value while simultaneously cutting down on maintenance and administrative costs associated with managing their own IT infrastructure.

- (b)

- Fog Computing: Another compute paradigm that has since emerged is fog computing. Hierarchically, it stands mid-way between the cloud and the edge and lives on the LAN. Programmable fog nodes serve as traffic hubs where decisions about the routing of data, inter-node peer-to-peer (P2P) communication, and service orchestration are made. They facilitate the decentralization of control and facilitate increase reliability, efficiency, and flexibility [283]. While fog computing and edge computing have been treated in some texts as interchangeable terms or overlapping terminology, it is important to clarify that they are indeed interrelated but also different in many ways. The OpenFog Consortium Architecture Working Group (now part of the Industrial Internet Consortium), an academia–industry group dedicated to the acceleration of the growth of the industrial Internet, called attention to some of the differences in a report entitled “OpenFog Reference Architecture for Fog Computing” [284]. While both computing paradigms bring processing power and intelligence closer to the data source, the major difference between them comes down to where data processing is performed. In the case of edge computing, data is processed directly on the devices on which the sensors are embedded or attached, or on some gateway device within their proximity. In the case of fog computing, processing is performed by processors connected to the LAN (i.e., a micro-data center) or within a LAN hardware. In either fog configuration, processing occurs further away from the sensors and actuators than in edge computing. Further to this, most edge devices only process data collected at one touch point, whereas fog computing is about processing data aggregated from multiple devices. Thus, the fundamental construct of the fog architecture is the aggregation and high-level processing of data and the almost instantaneous return transmission of the acquired intelligence.

- (c)

- Edge Computing: Edge computing has since emerged as a viable alternative to the “cloud-only” or central cloud computing standard or architecture [285]. This distributed computing paradigm involves the transfer of computer power, networking, application services, and data storage capabilities to where they are most needed, which is at multiple decision points that are usually as close as possible to the data sources [286,287]. It also enables dynamic monitoring and control of manufacturing processes [288]. By building in flexibility around where computations can be performed and extending cloud computing standards to the far reaches of the edges of the network, many of the latency, bandwidth, and data throughput issues that have bedeviled cloud computing can be addressed [289]. The proliferation of edge computing as a concept has been facilitated by the growing adoption of faster networking technologies, such as 5G wireless; the integration of edge devices into manufacturing IT and OT networks; and the connecting of all these using IIoT. In this arrangement, algorithms can now run locally on edge servers or gateways, and data can be processed at a high level; then, some forms of analytics can be reported so that insights are provided in real time and human and machine queries are responded to in seconds. Some of this intelligence can be used to actuate other connected devices or systems where necessary, and actionable results can be instantly made available to workers on the factory floor and executives in offices. This is reminiscent of the autonomous vehicle, whose systems require instant feedback to make travel decisions, even while the vehicle is in motion, and in some cases even at high speed. Edge devices (nodes) enable edge computing by providing entry points into manufacturing core networks. They are usually mobile or fixed assets, often embedded or connected to machines or equipment. They are typically distributed throughout the factory floor and other remote locations, such as nodes across a wide network or stars strewn across a dark sky. Large IIoT operations, such as those in manufacturing facilities, typically host hundreds (or even thousands) of edge devices (nodes), which together form a network of edge devices that recognize and communicate with each other. The edge devices continuously and autonomously collect, process, and broadcast data, which provides significant visibility and awareness about events across the network. Some edge devices serve a dual purpose as sensing devices for capturing sensory information and actuators that can trigger or control other devices or systems. Some common examples of sensors and actuators in edge devices within manufacturing facilities include: (a) Sensors: pressure and temperature sensors; real time location systems (RTLS); cameras; near-field communication (NFC) sensors; light, proximity, motion, acoustics, and radio-frequency identification (RFID) sensors; ultrasonic sensors; flow meters; and fluid sensors. (b) Actuators: hydraulic and pneumatic ones, switches, relays, programmable logic controllers (PLCs), motors, and light and acoustics actuators. Under the edge computing arrangement, data are processed, and analysis results are distributed by the same device used to acquire it or by a nearby server instead of a centralized cloud. The results of implementing edge architecture include the ability to process and store data faster, improved application performance, low latency, and significant reductions in bandwidth cost. Notwithstanding, it is important to note that edge computing does not eliminate the need for deeper data analytics, large data storage facilities, and extended archival capabilities, all functions that the cloud is better suited for. The main advantage of edge computing is its capacity to reduce the compute requirements and data volume that must be transferred to data centers or cloud-based locations within short notice. In the Future Factory, it is expected that more complex data processing will be performed at the edge, as new system modules that incorporate advanced artificial intelligence functionalities are built into them. Edge computing has also helped in the management of many security and privacy related concerns within industry.

- (i)

- “The Cloud-Only” model: In the cloud-only model, no intermediate processing of data occurs. All data captured by multiple sensors are transmitted to the cloud, where 100% of the processing occurs, before the results are pushed down to all the sources that require the intelligence.

- (ii)

- The Cloud–Fog Computing model: In this model, data from multiple sensors and devices are transmitted to the fog gateways. Depending on the urgency of the request, some high-level processing of data occurs at the fog layer, and intelligence pushed back to the various nodes (machines and humans) in real-time. Non-time-sensitive data and some pre-processed data that require further (deep learning) processing are transmitted to the cloud.

- (iii)

- Cloud–Fog–Edge Computing Model: This is a massive, distributed computing infrastructure that consists of three inter-connected computing tiers (cloud, fog, and edge).

8.2.2. Big Data Analytics

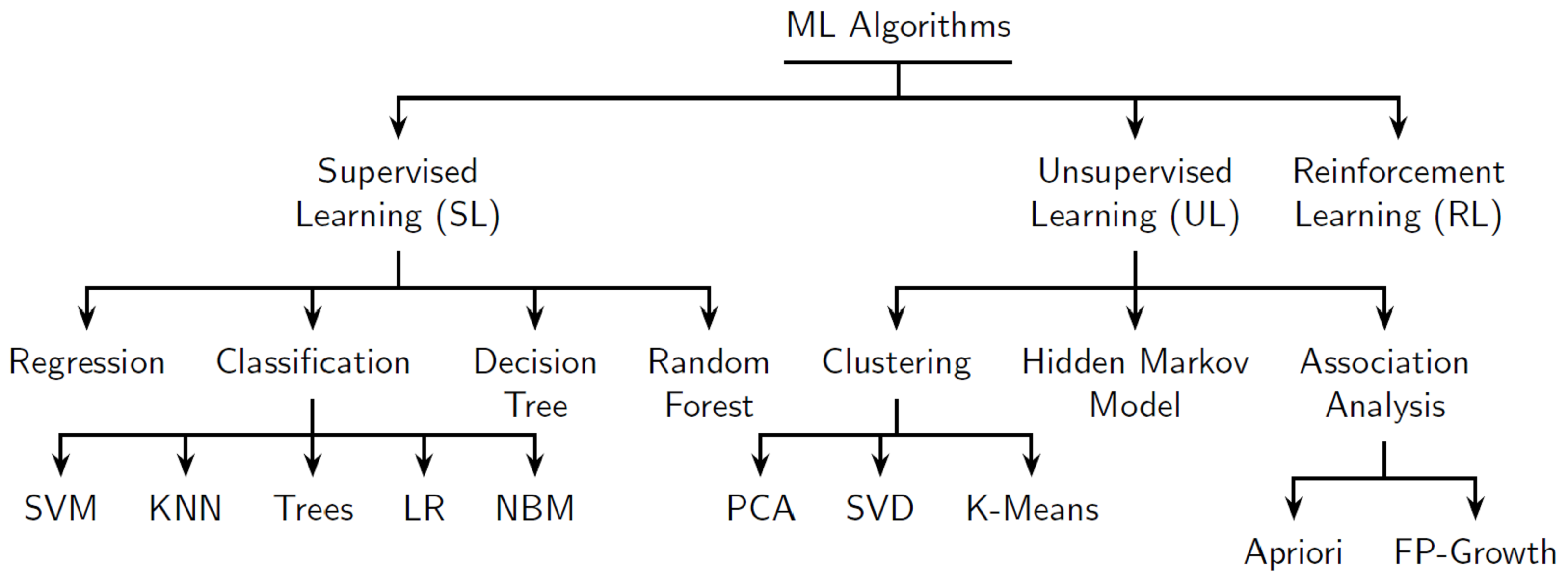

8.2.3. Artificial and Cognitive Intelligence

8.2.4. Blockchain

8.2.5. Mixed Reality

- (a)

- Types of Augmented Reality (AR) Systems: There are several types of augmented reality (AR) systems, differentiated by application, functionality, or design. Of these, four main types stand out: (a) Marker-based AR: AR systems of this class display content (video, text, animation, 3D figures, etc.) on surfaces contingent with the detection of a predefined marker embedded on a static image (trigger photo) or a QR code, often using AR devices such as smart phones. (b) Markerless AR: Unlike Marker-based AR systems, they do not require physical markers for the overlay information to be triggered. They merely scan their environments to get their bearings and are generally guided by localization or positioning systems, such as GPS, accelerometers, and digital compasses. (c) Projection-based AR works just like typical projectors. They utilize image or video-based projection (with audio prompts, in some cases) to guide the pace, direction, and “every step” of a process. They help operators or factory workers through manual processes, enabling them to complete tasks quickly, efficiently, and consistently without recourse to hard-copy manuals and instructions. (d) Superimposition-based AR relies on the object recognition technique to first identify an object and then replace it or a portion thereof with an equivalent augmented image. An often-cited application of superimposition-based AR is in the medical field, where doctors sometimes superimpose live feeds (X-ray images) of a patient’s body part directly from an X-ray machine unto the patient’s actual body to better understand the internal condition of the body part.

- (i)

- Hardware Devices: Hardware devices are a necessary and integral part of augmented reality (AR) systems. There are several types of AR devices in common use. Some of these include handheld devices (HHD) [388,389,390] holographic displays, head-mounted displays (HMD), smart glasses/lenses and virtual retinal displays (VRDs), mobile phones (including smart phones) [390], wearable data-gloves [391], haptic devices [392], tablets, iPads, and computers.

- (ii)

- Software Systems: Software (or applications) also forms an important part of AR systems. Of particular interest are (a) tracking and registration algorithms and (b) development platforms (or content-creation applications). The primary function of the tracking and registration algorithms is the alignment of the two (real and virtual) environments or object categories. On the other hand, development platforms are the applications used for the creation of AR content. They include anything from low-level programming libraries to the more complex AR applications that integrate features for sensor data acquisition and integration, image, and audio rendering, and in some cases, even application engines.

- (b)

- Industrial Applications of Augmented Reality: Over the years, AR technology has continued to mature. Since it can simulate processes, augment tasks, provide remote assistance, enhance communication between teammates, and provide elaborate guidance to users, it has demonstrated relevance to manufacturing amidst the on-going re-imagination of the sector. There have been proposals [393], proof of concept studies, and actual applications [394] in a wide array of industries [48,52]. Its successful application at various manufacturing stages (planning, design [395,396], assembly [394,397], maintenance, etc.) is particularly notable. It has also found applications in different manufacturing processes and functions. A few of these are discussed below:

- (i)

- Interactions with Process Information: They have been used to digitally access and interact with procedural and process information, including IIOT related data [398] acquired in real-time, rather than relying on physical manuals and paper documents. Some have been used to display augmented 3D images, making it possible to view system components in multiple configurations, including exploded, cross-sectional, and internal views. For example, internal views come highly recommended for providing insights into the internal sections of opaque structures or systems where accessibility or worker safety is an issue [399].

- (ii)

- Quality Control: AR systems are already playing a huge role in automated real-time, in-production quality control. The mobile nature of most AR systems supports the relocation of the quality control functions away from static (fixed) input locations to mobile terminals, permitting intermediate inspections, and facilitating the flexible and cost-effective use of software license seats. The online, real-time, and decentralized characteristics of the AR systems provide the added advantage of instant access to and flexible flow of information to various manufacturing points where they are most needed. It also enables fast variance inspection, continuous, real-time error reporting, and documentation. Finally, the instant generation of enhanced quality assurance reports [400] immediately after the completion of each instance of an inspection routine [401] is not a possibility.

- (iii)

- Process Support, Training, and Simulation: AR technology has also been used to assist technicians and operators working on mechanical or technical tasks such as welding [402], machinery repair, and assembly operations, and even in controlling robots [403,404]. Some AR inspection systems incorporate features that provide graphic step-by-step instructions that can be used for process training. The step-wise design of these routines ensure that processes are performed in a consistent, accurate, and reliable manner. They can also be used as simulators for practice runs to help users develop and perfect their skills, ensuring that manufacturing tasks and processes are carried out right the first time. In the long-term, this helps with limiting errors and eliminating the need for rework. This level of expertise and dedication is useful for high-stress tasks where precision is critical.

- (iv)

- Repair and Maintenance: The repair and maintenance of complex machinery will be one of most consequential areas of AR application in manufacturing. Next generation AR-inspired maintenance systems are becoming important elements of the Factory of the Future [405]. They are now more often the products of the intersection of AI, IIoT, big data, and associated technologies and capabilities. Excellent condition monitoring, combined with dynamic predictive modeling, make for a successful predictive maintenance program. In the Factory of the Future, technicians going about in the normal course of their daily duties can be prompted by their wearable IAR devices (such as smart glasses or mobile devices) about “just-beginning” maintenance problems, way in advance of actual system or component failures. These AR systems not only detect and warn operators and technicians about these anomalies, but also offer on-the-spot visual analysis of the problem, display the service histories of the machinery, and deliver step-wise service instructions to aid in their resolution. For off-site maintenance, the AR systems can serve as remote collaboration tools where a technician can contact each other, collaborate with colleagues for resolving tough problems, or be remotely guided by a more experienced supervisor [406].

- (v)

- Collaborative Product Design and Prototyping: Almost all aspects of product design, for early to late stages, can now be collaboratively performed (end-to-end), streamlined, sped-up, and optimized using AR. These stages include ideation, conceptual design (encompassing generic functionality management [407]), preliminary design, the interactive generation of models or virtual product prototyping [397,406,408], design review, and evaluation [409]. Free-form surface generation features in some AR applications have been used to support easy creation of design alternatives and to enable parameter adjustments [407]. In automotive design, for example, AR-based design tools have been used to evaluate multiple interior design options by simply overlaying different photo-realistic 3D car interior mock-ups over real cars [408], eliminating the need for physical prototypes. AR-based design tools often generate sharable, high quality, 1:1 scale, photo-realistic 3D visualization of augmented design models that can be converted into AR compatible format and transmittable to stakeholder’s devices for easy and enhanced viewing. Availability and real-time remote access to these models make collaboration easy. They are enabling stakeholders (both designers and other collaborators, downstream in the product pipeline) to inspect and interact with the design models, and provide timely and objective feedback for design improvements, in advance of design approval and production [16]. The early detection of flaws facilitates design improvements and eliminates expensive post-production redesign costs. Several user-friendly, computer-aided AR design environments, such as ARCADE, are now available [410].

- (c)

- The Challenge with current AR Systems: Though there is growing interest in the use of augmented reality (AR) as a support tool across industry [411,412], one drawback of most AR-based maintenance systems is that most applications are currently passive and static in nature. They merely push information and provide no feedback mechanism capable of ingesting, analyzing, and looping back explicit and implicit user and environmental responses. A feedback system of this sort can enable the output of targeted information to users, continuous process refinement, and better tailored solutions. Examples of responses (data points) that can be routed back to through the feedback system include such data points as effectiveness of prior guidance, the experience of users, or even the user actions or inactions that could help preempt user intent. There is a need for more adaptive AR, with creative feedback loops that can actively engage users and help them to solve problems more creatively. Attempts have been made in the literature to spotlight this challenge and suggest creative ways of solving this problem [413].

8.2.6. 3D Printing (Additive Manufacturing:)

8.2.7. Autonomous Robotics

- (a)

- Traditional Robots: The technologies underpinning traditional robots are generally more mature. They generally have high payloads, have longer reaches, and are able to achieve very high efficiency levels, even at high production speeds.

- (b)

- Collaborative Robots (Cobots): ISO 10218-2 defined cobots as robots designed for direct interaction with a human within a defined collaborative workspace. Workspace refers to the safeguarded space where the robot and a human can perform tasks simultaneously during production operation. Generally, they are relatively easier to program, enable more efficient production adjustments, and can more flexibly adapt to new requirements than traditional robots. For implementation, they require minimal changes to existing production layout and can be easily redeployed for different tasks, as necessary. A defining characteristic of these robots is that they work collaboratively with human workers, without concerns for worker safety. They possess several integrated safety features, including collision detection technologies, minimized pinch points, safety-rated monitored stops, and well controlled force and speed. Human workers can focus on tasks that require strong cognitive abilities, whereas the robots can be assigned repetitive tasks and other activities that require precision or heavy lifting. Robots that work alongside humans are referred to as cobots.

- (c)

- Mobile Robots: Mobile robots have a general awareness of their environment and the ability to effectively navigate through it in the process of accomplishing assigned tasks. While traditional robots are usually stationed at fixed locations and are mostly assigned tasks that do not require a lot of flexibility. Mobile robots, on the other hand, are usually ambulatory and they are best suited for constantly changing factory environments. Using their navigation systems, they transverse entire factory floors autonomously, seamlessly integrating themselves into the manufacturing ecosystem. They can stop, move, slow down, or navigate away from obstacles using sensory information obtained from a wide array of localization and navigation sensors embedded within their bodies or attached to their surfaces. Two main classes of robot sensors exist, i.e., exteroceptive and proprioceptive sensors. Exteroceptive sensors help the robots discern and understand their environments. Examples of exteroceptive sensors include stereo cameras, pan/tilt/zoom cameras, lasers and 3D lidar systems, projection-based systems, audio/video feedback systems, touch sensors (whiskers or bump sensors), and GPS, proximity, and certified safety sensors. Then there are proprioceptive sensors, which are sensors that gather information about the robot itself. Examples of proprioceptive sensors include accelerometers, gyroscopes, magnetometers, compasses, wheel encoders, and temperature sensors). These sensors, alongside accompanying algorithms, enable the mobile robots to both understand and safely navigate their environments. For this reason, they are very safe to deploy alongside human workers, with whom they sometimes work collaboratively, transforming them from mere machines to fellow workers. The basic idea of the mobile robot is essentially moving the robot to the work instead of moving the work to the robot. Mobile robots would best benefit such tasks as automated assembly, inspection, painting, or welding of huge industrial components, such as airplane frames, large engines, and giant offshore or space structures. Due to their large sizes, working on such components with two or three stationary robots can be inadequate because of the limitations on the reaches of such robots. Alternative courses of action could be to either add more robots (a costly option) or employ mobile robots which are not limited by reach due to their ability to move around the entire structure. Compared to traditional robots, mobile robots are more flexible and adaptable. Their ability to maneuver through space and structures helps shorten throughput times, improving efficiency and cutting down on production time. Mobile robots have a variety of locomotion mechanisms [435,436], e.g., flying (drones) [437], rolling, walking (legged), swimming or water-based movement (underwater vehicle manipulator system) [438], crawling, moving on tracks, and using propellers. Automated guided vehicles or automatic guided vehicles (AGVs) are amongst the most common mobile robots within the manufacturing industry today. Additionally, they are poised to become even more ubiquitous as adoption continues to grow. They are currently used for moving materials, supplies, and products around manufacturing facilities. Unmanned aerial vehicles (such as the drone) are the next set of robots that will grow in relevance within manufacturing. They would be especially useful for picking up and dropping items, and product and quality inspections, especially the inspection of equipment or machinery at hard-to-reach locations (e.g., high elevation or dangerous locations) using thermal and video cameras.

9. Discussion: Recommendations and Future Research Directions

9.1. Communication Protocols and Technologies

9.2. Digital Infrastructure

9.3. Data Collection and Characterization

9.4. Virtualization

9.5. Interoperability

9.6. IT/OT Security

10. Implementations of the Factories of the Future

10.1. Industry and Implementation of Smart Manufacturing Solutions

10.2. Industry Alliances and Research Institutes

10.3. Smart Manufacturing in Academia

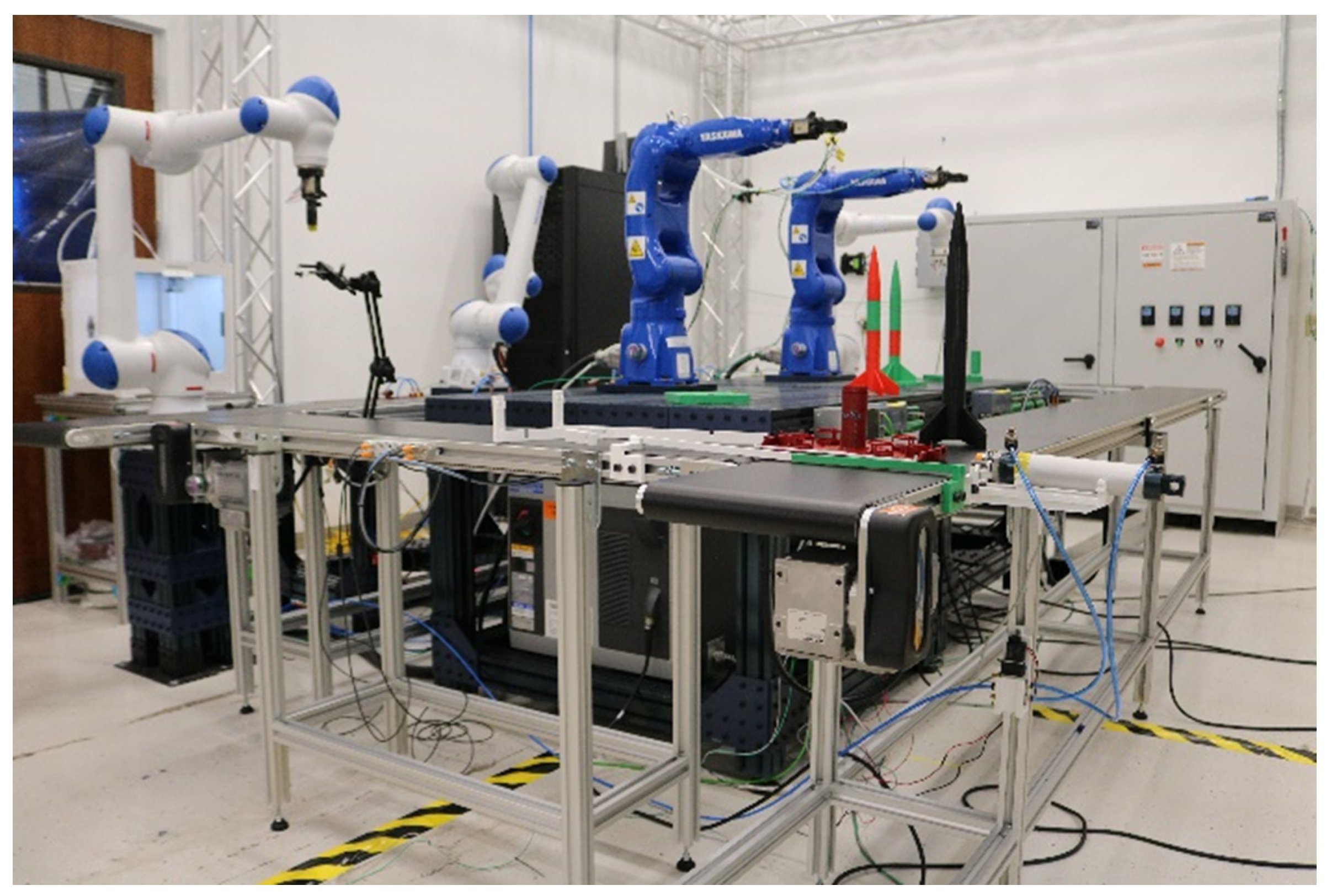

10.3.1. The “neXt Future Factory” Test Bed

10.3.2. Collaborations

11. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Acronyms

| 4IR | Fourth Industrial Revolution | IT/OT | Information Technology/Operational Technology |

| AAS | Asset Administration Shell | KNN | K-Nearest Neighbors |

| AI | Artificial Intelligence | L2S | Levels of System Sovereignty |

| B2MML | Business to Manufacturing Markup Language | LR | Logistical Regression |

| BatchML | Batch Markup Language | M2D | Machine-to-Device |

| BMBF | German Federal Ministry of Education and Research | M2M | Machine-to-Machine |

| BPMN | Specification-Business Process Model and Notation | MDPI | Multidisciplinary Digital Publishing Institute |

| CMS | Cyber Manufacturing Systems | ME-S | Manufacturing Ecosystem |

| CPS | Cyber-Physical Systems | MES | Manufacturing Execution Systems |

| CPPS | Cyber-Physical Production systems | ML/DL | Machine Learning/Deep Learning |

| CRM | Customer Relationship Management | MOM | Manufacturing Operation Management |

| DCS | Distributed Control System | MQTT | Message Queuing Telemetry Transport |

| DMIS | Dimensional Measuring Interface Standard | NBM | Naïve Bayes Multinomial |

| DMN | Decision Model and Notation | OAGIS | Open Applications Group Integration Specification |

| ERP | Enterprise Resource Planning | OPC-UA | Open Platform Communications-Unified Architecture |

| EtherCAT | Ethernet for Control Automation Technology | PAC | Programmable Automation Controller |

| F2H | Factory-to-Human | PACKML | Packaging Machine Language |

| F2P | Factory-to-Product | PC | Personal Computer |

| F2SC | Factory-to-Supply Chain | PCA | Principle Component Analysis |

| FDI | Field Device Integration | PLC | Programmable Logic Controller |

| FF | Future Factory | PMML | Predictive Model Markup Language |

| FoF | The Factory of the Future | QIF | Quality Information Framework |

| FP-Growth | Frequent Pattern-Growth | QR | Quick Response |

| GPU | Graphical Processing Units | REST | REpresentational State Transfer |

| H2D | Human-to-Device | RFID | Radio Frequency Identification |

| HART | Highway Addressable Remote Transducer | RL | Reinforcement Learning |

| HMI | Human–Machine Interface | SCADA | Supervisory Control and Data Acquisition |

| HTTP | HyperText Transfer Protocol | SL | Supervised Learning |

| ICT | Information and communications technology | SVD | Singular Value Decomposition |

| IEC | International Electro-technical Commission | SVM | Support Vector Machines |

| IoT | Internet of Things | ISA | International Society of Automation |

| IIoT | Industrial Internet of Things | UL | Unsupervised Learning |

| IoS | Internet of Services | ||

| ISO | International Organization for Standardization |

References

- Deane, P.M.; Deane, P.M. The First Industrial Revolution; Cambridge University Press: Cambridge, UK, 1979. [Google Scholar]

- Crafts, N.F. The first industrial revolution: A guided tour for growth economists. Am. Econ. Rev. 1996, 86, 197–201. [Google Scholar]

- Crafts, N. Explaining the first Industrial Revolution: Two views. Eur. Rev. Econ. Hist. 2011, 15, 153–168. [Google Scholar] [CrossRef]

- Greasley, D.; Oxley, L. Causality and the first industrial revolution. Ind. Corp. Chang. 1998, 7, 33–47. [Google Scholar] [CrossRef]

- Mokyr, J.; Strotz, R.H. The second industrial revolution, 1870–1914. Stor. dell’Econ. Mond. 1998, 21945, 1–14. [Google Scholar]

- Jevons, H.S. The second industrial revolution. Econ. J. 1931, 41, 1–18. [Google Scholar] [CrossRef]

- Agarwal, H.; Agarwal, R. First Industrial Revolution and Second Industrial Revolution: Technological differences and the differences in banking and financing of the firms. Saudi J. Humanit. Soc. Sci. 2017, 2, 1062–1066. [Google Scholar]

- Janicke, M.; Jacob, K. A third industrial revolution. In Long-Term Governance for Social-Ecological Change; Routledge: New York, NY, USA, 2013; pp. 47–71. [Google Scholar]

- Cooper, C.; Kaplinsky, R. Technology and Development in the Third Industrial Revolution; Routledge: London, UK, 2005. [Google Scholar]

- Heinonen, S.; Karjalainen, J.; Ruotsalainen, J. Towards the third industrial revolution. Finl. Findland Future Res. Cent. FFRC EBook 2015, 6, 2015. [Google Scholar]

- Posada, J.; Toro, C.; Barandiaran, I.; Oyarzun, D.; Stricker, D.; de Amicis, R.; Pinto, E.B.; Eisert, P.; Döllner, J.; Vallarino, I. Visual Computing as a Key Enabling Technology for Industrie 4.0 and Industrial Internet. IEEE Comput. Graph. Appl. 2015, 35, 26–40. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Securing the Future of German Manufacturing Industry: Recommendations for Implementing the Strategic Initiative Industrie 4.0. Final Report of the Industrie. 2013. Available online: https://www.din.de/resource/blob/76902/e8cac883f42bf28536e7e8165993f1fd/recommendations-for-implementing-industry-4-0-data.pdf (accessed on 5 June 2022).

- Xu, M.; David, J.M.; Kim, S.H. The fourth industrial revolution: Opportunities and challenges. Int. J. Financ. Res. 2018, 9, 90–95. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Redelinghuys, A.; Basson, A.H.; Kruger, K. A six-layer architecture for the digital twin: A manufacturing case study implementation. J. Intell. Manuf. 2020, 31, 1383–1402. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A review of the roles of digital twin in CPS-based production systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital twin: Enabling technologies, challenges and open research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Zuo, Y.; Zhao, D. Digital twin service towards smart manufacturing. Procedia Cirp 2018, 72, 237–242. [Google Scholar] [CrossRef]

- Al Faruque, M.A.; Muthirayan, D.; Yu, S.Y.; Khargonekar, P.P. Cognitive digital twin for manufacturing systems. In Proceedings of the 2021 Design, Automation & Test in Europe Conference & Exhibition (DATE), Grenoble, France, 1–5 February 2021; pp. 440–445. [Google Scholar]

- Zeba, G.; Dabić, M.; Čičak, M.; Daim, T.; Yalcin, H. Technology mining: Artificial intelligence in manufacturing. Technol. Forecast. Soc. Chang. 2021, 171, 120971. [Google Scholar] [CrossRef]

- Chien, C.F.; Dauzère-Pérès, S.; Huh, W.T.; Jang, Y.J.; Morrison, J.R. Artificial intelligence in manufacturing and logistics systems: Algorithms, applications, and case studies. Int. J. Prod. Res. 2020, 58, 2730–2731. [Google Scholar] [CrossRef]

- Crandall, D.J. Artificial Intelligence and Manufacturing. Smart Factories: Issues of Information Governance. 2019, pp. 10–16. Available online: https://policyinstitute.iu.edu/doc/mpi/smart-factories.pdf#page=12 (accessed on 5 June 2022).

- Bullers, W.I.; Nof, S.Y.; Whinston, A.B. Artificial intelligence in manufacturing planning and control. AIIE Trans. 1980, 12, 351–363. [Google Scholar] [CrossRef]

- Arinez, J.F.; Chang, Q.; Gao, R.X.; Xu, C.; Zhang, J. Artificial intelligence in advanced manufacturing: Current status and future outlook. J. Manuf. Sci. Eng. 2020, 142, 110804. [Google Scholar] [CrossRef]

- Li, B.H.; Hou, B.C.; Yu, W.T.; Lu, X.B.; Yang, C.W. Applications of artificial intelligence in intelligent manufacturing: A review. Front. Inf. Technol. Electron. Eng. 2017, 18, 86–96. [Google Scholar] [CrossRef]

- Buchmeister, B.; Palcic, I.; Ojstersek, R. Artificial Intelligence in Manufacturing Companies And Broader: An Overview. DAAAM International Scientific Book. 2019. Available online: https://daaam.info/sc-book-2019 (accessed on 5 June 2022).

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial Artificial Intelligence for industry 4.0-based manufacturing systems. Manuf. Lett. 2018, 18, 20–23. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Bernidaki, D. Simulation in manufacturing: Review and challenges. Procedia Cirp 2014, 25, 213–229. [Google Scholar] [CrossRef]

- Lugaresi, G.; Matta, A. Real-time simulation in manufacturing systems: Challenges and research directions. In Proceedings of the 2018 Winter Simulation Conference (WSC), Gothenburg, Sweden, 9–12 December 2018; pp. 3319–3330. [Google Scholar]

- Negahban, A.; Smith, J.S. Simulation for manufacturing system design and operation: Literature review and analysis. J. Manuf. Syst. 2014, 33, 241–261. [Google Scholar] [CrossRef]

- Hollocks, B. A well-kept secret? Simulation in manufacturing industry reviewed. Insight 1992, 5, 12–17. [Google Scholar]

- Hollocks, B.W. The impact of simulation in manufacturing decision making. Control Eng. Pract. 1995, 3, 105–112. [Google Scholar] [CrossRef]

- Ingemansson, A.; Bolmsjö, G.; Harlin, U. A survey of the use of the discrete-event simulation in manufacturing industry. In Proceedings of the 10th International Manufacturing Conference, Singapore, 11–14 March 2002. [Google Scholar]

- McGinnis, L.F.; Rose, O. History and perspective of simulation in manufacturing. In Proceedings of the 2017 Winter Simulation Conference (WSC), Las Vegas, NV, USA, 3–6 December 2017; pp. 385–397. [Google Scholar]

- Abeyratne, S.A.; Monfared, R.P. Blockchain ready manufacturing supply chain using distributed ledger. Int. J. Res. Eng. Technol. 2016, 5, 1–10. [Google Scholar]

- Angrish, A.; Craver, B.; Hasan, M.; Starly, B. A case study for Blockchain in manufacturing: “FabRec”: A prototype for peer-to-peer network of manufacturing nodes. Procedia Manuf. 2018, 26, 1180–1192. [Google Scholar] [CrossRef]

- Li, Z.; Barenji, A.V.; Huang, G.Q. Toward a blockchain cloud manufacturing system as a peer to peer distributed network platform. Robot. Comput.-Integr. Manuf. 2018, 54, 133–144. [Google Scholar] [CrossRef]

- Kasten, J.E. Engineering and manufacturing on the blockchain: A systematic review. IEEE Eng. Manag. Rev. 2020, 48, 31–47. [Google Scholar] [CrossRef]

- Ko, T.; Lee, J.; Ryu, D. Blockchain technology and manufacturing industry: Real-time transparency and cost savings. Sustainability 2018, 10, 4274. [Google Scholar] [CrossRef]

- Mohamed, N.; Al-Jaroodi, J. Applying blockchain in industry 4.0 applications. In Proceedings of the 2019 IEEE 9th annual computing and communication workshop and conference (CCWC), Las Vegas, NV, USA, 7–9 January 2019; pp. 0852–0858. [Google Scholar]

- Belhadi, A.; Zkik, K.; Cherrafi, A.; Sha’ri, M.Y. Understanding big data analytics for manufacturing processes: Insights from literature review and multiple case studies. Comput. Ind. Eng. 2019, 137, 106099. [Google Scholar] [CrossRef]

- Dai, H.N.; Wang, H.; Xu, G.; Wan, J.; Imran, M. Big data analytics for manufacturing internet of things: Opportunities, challenges and enabling technologies. Enterp. Inf. Syst. 2020, 14, 1279–1303. [Google Scholar] [CrossRef]

- Sahoo, S. Big data analytics in manufacturing: A bibliometric analysis of research in the field of business management. Int. J. Prod. Res. 2021, 1–29. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Blome, C.; Papadopoulos, T. Big data and predictive analytics and manufacturing performance: Integrating institutional theory, resource-based view and big data culture. Br. J. Manag. 2019, 30, 341–361. [Google Scholar] [CrossRef]

- Bashar, A. Intelligent development of big data analytics for manufacturing industry in cloud computing. J. Ubiquitous Comput. Commun. Technol. (UCCT) 2019, 1, 13–22. [Google Scholar]

- Ong, S.K.; Nee, A.Y.C. Virtual and Augmented Reality Applications in Manufacturing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Ong, S.; Nee, A. A brief introduction of VR and AR applications in manufacturing. In Virtual and Augmented Reality Applications in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2004; pp. 1–11. [Google Scholar]

- Siedler, C.; Glatt, M.; Weber, P.; Ebert, A.; Aurich, J.C. Engineering changes in manufacturing systems supported by AR/VR collaboration. Procedia CIRP 2021, 96, 307–312. [Google Scholar] [CrossRef]

- Fast-Berglund, Å.; Gong, L.; Li, D. Testing and validating Extended Reality (xR) technologies in manufacturing. Procedia Manuf. 2018, 25, 31–38. [Google Scholar] [CrossRef]

- Doolani, S.; Wessels, C.; Kanal, V.; Sevastopoulos, C.; Jaiswal, A.; Nambiappan, H.; Makedon, F. A review of extended reality (xr) technologies for manufacturing training. Technologies 2020, 8, 77. [Google Scholar] [CrossRef]

- Ong, S.; Yuan, M.; Nee, A. Augmented reality applications in manufacturing: A survey. Int. J. Prod. Res. 2008, 46, 2707–2742. [Google Scholar] [CrossRef]

- Nee, A.Y.; Ong, S.; Chryssolouris, G.; Mourtzis, D. Augmented reality applications in design and manufacturing. CIRP Ann. 2012, 61, 657–679. [Google Scholar] [CrossRef]

- Doil, F.; Schreiber, W.; Alt, T.; Patron, C. Augmented reality for manufacturing planning. In Proceedings of the Workshop on Virtual Environments, Zurich, Switzerland, 22–23 May 2003; pp. 71–76. [Google Scholar]

- Goel, R.; Gupta, P. Robotics and industry 4.0. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Springer: Berlin/Heidelberg, Germany, 2020; pp. 157–169. [Google Scholar]

- Bayram, B.; İnce, G. Advances in Robotics in the Era of Industry 4.0. In Industry 4.0: Managing The Digital Transformation; Springer: Berlin/Heidelberg, Germany, 2018; pp. 187–200. [Google Scholar]

- Heyer, C. Human-robot interaction and future industrial robotics applications. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 4749–4754. [Google Scholar]

- Hägele, M.; Nilsson, K.; Pires, J.N.; Bischoff, R. Industrial robotics. In Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1385–1422. [Google Scholar]

- Parmar, H.; Khan, T.; Tucci, F.; Umer, R.; Carlone, P. Advanced robotics and additive manufacturing of composites: Towards a new era in Industry 4.0. Mater. Manuf. Process. 2022, 37, 483–517. [Google Scholar] [CrossRef]

- Tantawi, K.H.; Sokolov, A.; Tantawi, O. Advances in industrial robotics: From industry 3.0 automation to industry 4.0 collaboration. In Proceedings of the 2019 4th Technology Innovation Management and Engineering Science International Conference (TIMES-iCON), Bangkok, Thailand, 11–13 December 2019; pp. 1–4. [Google Scholar]

- Li, M.; Milojević, A.; Handroos, H. Robotics in manufacturing—The past and the present. In Technical, Economic and Societal Effects of Manufacturing 4.0; Palgrave Macmillan: Cham, Switerland, 2020; pp. 85–95. [Google Scholar]

- Groover, M.P. Fundamentals of Modern Manufacturing: Materials, Processes, and Systems; J. Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Rosen, R.; Von Wichert, G.; Lo, G.; Bettenhausen, K.D. About the importance of autonomy and digital twins for the future of manufacturing. IFAC-Papersonline 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Pustišek, M.; Chen, M.; Kos, A.; Kos, A. Decentralized Machine Autonomy for Manufacturing Servitization. Sensors 2022, 22, 338. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; From Automation to Autonomy—A new trend for Smart Manufacturing. DAAAM International Scientific Book. 2013. Available online: https://daaam.info/sc-book-2013 (accessed on 5 June 2022).

- Park, H.S.; Tran, N.H. Autonomy for smart manufacturing. J. Korean Soc. Precis. Eng. 2014, 31, 287–295. [Google Scholar] [CrossRef]

- Horvitz, E.; Selman, B. Interim report from the panel chairs: AAAI Presidential Panel on Long-Term AI Futures. In Singularity Hypotheses; Springer: Berlin/Heidelberg, Germany, 2012; pp. 301–308. [Google Scholar]

- Pohl, J. Artificial Super Intelligence: Extinction or Nirvana. Intern Symposium. 2015. Available online: https://www.researchgate.net/profile/Jens-Pohl/publication/281748315_Artificial_Superintelligence_Extinction_or_Nirvana/links/55f723c908aeafc8abfa21ca/Artificial-Superintelligence-Extinction-or-Nirvana.pdf (accessed on 5 June 2022).

- Almada-Lobo, F. The Industry 4.0 revolution and the future of Manufacturing Execution Systems (MES). J. Innov. Manag. 2015, 3, 16–21. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, X. Industry 4.0 and cloud manufacturing: A comparative analysis. J. Manuf. Sci. Eng. 2017, 139, 034701. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Thames, L.; Schaefer, D. Industry 4.0: An overview of key benefits, technologies, and challenges. In Cybersecurity for Industry 4.0; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–33. [Google Scholar]

- Porter, M.E.; Heppelmann, J.E. How smart, connected products are transforming companies. Harv. Bus. Rev. 2015, 93, 96–114. [Google Scholar]

- Thoben, K.D.; Wiesner, S.; Wuest, T. “Industrie 4.0” and smart manufacturing—A review of research issues and application examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Securing the Future of German Manufacturing Industry. Final Report of the Industrie 4.0 Working Group; Technical Report, Forschungsunion. Available online: https://en.acatech.de/publication/recommendations-for-implementing-the-strategic-initiative-industrie-4-0-final-report-of-the-industrie-4-0-working-group/ (accessed on 5 June 2022).

- Henning Kagermann, P.D.W.W.; Helbig, D.J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0-Final Report of the Industrie 4.0 Working Group; Technical Report; German Federal Ministry of Education and Research (BMBF): Bonn, Germany, 2013. [Google Scholar]

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in industry 4.0. Procedia Cirp 2016, 40, 536–541. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios: A Literature Review; Technische Universität Dortmund: Dortmund, Germany, 2015. [Google Scholar]

- Kagermann, H. Chancen von Industrie 4.0 nutzen. In Industrie 4.0 in Produktion, Automatisierung und Logistik: Anwendung, Technologien; ten Hompel, M., Vogel-Heuser, B., Bauernhansl, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Bitkom, F.I. Industrie 4.0–Volkswirtschaftliches Potenzial für Deutschland. Berlin/Stuttgart. 2014. Available online: https://www.produktionsarbeit.de/content/dam/produktionsarbeit/de/documents/Studie-Industrie-4-0-Volkswirtschaftliches-Potential-fuer-Deutschland.pdf (accessed on 5 June 2022).

- 2017: State of the IIoT-Key Trends and Predictions for the Industrial Internet of Things. Available online: https://www.opto22.com/support/resources-tools/documents/2215-white-paper-state-of-the-iiot-2017 (accessed on 5 June 2022).

- Bezerra, F.; Favacho, C.H.; Souza, R.; de Souza, C. Towards supporting systematic mappings studies: An automatic snowballing approach. In Proceedings of the Simpósio Brasileiro de Banco de Dados (SBBD), Curitiba, Brazil, 6–9 October 2014. [Google Scholar]

- van Haastrecht, M.; Sarhan, I.; Yigit Ozkan, B.; Brinkhuis, M.; Spruit, M. SYMBALS: A systematic review methodology blending active learning and snowballing. Front. Res. Metrics Anal. 2021, 6, 33. [Google Scholar] [CrossRef] [PubMed]

- Michael Lyman, R.R.; Wright, O. Accenture Strategy: Cornerstone of Future Growth: Ecosystems; Technical Report; Accenture: Dublin, Ireland, 2018. [Google Scholar]

- Gaub, H. Customization of mass-produced parts by combining injection molding and additive manufacturing with Industry 4.0 technologies. Reinf. Plast. 2016, 60, 401–404. [Google Scholar] [CrossRef]

- Prasad, D.; Jayswal, S. Reconfigurable manufacturing system–a new class of manufacturing system. Manag. Prod. Eng. Rev. 2019, 10, 37–47. [Google Scholar]

- Koren, Y. Reconfigurable manufacturing and beyond. In Proceedings of the CIRP 3rd International Conference on Reconfigurable Manufacturing, Ann Arbor, MI, USA, 10 May 2005. [Google Scholar]

- Pansare, R.; Yadav, G.; Nagare, M.R. Reconfigurable manufacturing system: A systematic review, meta-analysis and future research directions. J. Eng. Des. Technol. 2021. [Google Scholar] [CrossRef]

- Mehrabi, M.G.; Ulsoy, A.G.; Koren, Y. Reconfigurable manufacturing systems: Key to future manufacturing. J. Intell. Manuf. 2000, 11, 403–419. [Google Scholar] [CrossRef]

- Bi, Z.M.; Lang, S.Y.; Shen, W.; Wang, L. Reconfigurable manufacturing systems: The state of the art. Int. J. Prod. Res. 2008, 46, 967–992. [Google Scholar] [CrossRef]

- Koren, Y.; Heisel, U.; Jovane, F.; Moriwaki, T.; Pritschow, G.; Ulsoy, G.; Van Brussel, H. Reconfigurable manufacturing systems. CIRP Ann. 1999, 48, 527–540. [Google Scholar] [CrossRef]

- ElMaraghy, H.A. Flexible and reconfigurable manufacturing systems paradigms. Int. J. Flex. Manuf. Syst. 2005, 17, 261–276. [Google Scholar] [CrossRef]

- Shivanand, H. Flexible Manufacturing System; New Age International: New Delhi, India, 2006. [Google Scholar]

- Browne, J.; Dubois, D.; Rathmill, K.; Sethi, S.P.; Stecke, K.E. Classification of flexible manufacturing systems. FMS Mag. 1984, 2, 114–117. [Google Scholar]

- Yadav, A.; Jayswal, S. Modelling of flexible manufacturing system: A review. Int. J. Prod. Res. 2018, 56, 2464–2487. [Google Scholar] [CrossRef]

- MacCarthy, B.; Liu, J. A new classification scheme for flexible manufacturing systems. Int. J. Prod. Res. 1993, 31, 299–309. [Google Scholar] [CrossRef]

- Stam, A.; Kuula, M. Selecting a flexible manufacturing system using multiple criteria analysis. Int. J. Prod. Res. 1991, 29, 803–820. [Google Scholar] [CrossRef]

- Florescu, A.; Barabas, S.A. Modeling and simulation of a flexible manufacturing system—A basic component of industry 4.0. Appl. Sci. 2020, 10, 8300. [Google Scholar] [CrossRef]

- Park, S.C. A methodology for creating a virtual model for a flexible manufacturing system. Comput. Ind. 2005, 56, 734–746. [Google Scholar] [CrossRef]

- Greenwood, N.R. Implementing Flexible Manufacturing Systems; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar]

- Srai, J.S.; Kumar, M.; Graham, G.; Phillips, W.; Tooze, J.; Ford, S.; Beecher, P.; Raj, B.; Gregory, M.; Tiwari, M.K.; et al. Distributed manufacturing: Scope, challenges and opportunities. Int. J. Prod. Res. 2016, 54, 6917–6935. [Google Scholar] [CrossRef]

- Leitão, P. Agent-based distributed manufacturing control: A state-of-the-art survey. Eng. Appl. Artif. Intell. 2009, 22, 979–991. [Google Scholar] [CrossRef]

- Huang, C.Y. Distributed manufacturing execution systems: A workflow perspective. J. Intell. Manuf. 2002, 13, 485–497. [Google Scholar] [CrossRef]

- Rauch, E.; Dallasega, P.; Matt, D.T. Distributed manufacturing network models of smart and agile mini-factories. Int. J. Agil. Syst. Manag. 2017, 10, 185–205. [Google Scholar] [CrossRef]

- Xu, X. From cloud computing to cloud manufacturing. Robot. Comput.-Integr. Manuf. 2012, 28, 75–86. [Google Scholar] [CrossRef]

- Ren, L.; Zhang, L.; Wang, L.; Tao, F.; Chai, X. Cloud manufacturing: Key characteristics and applications. Int. J. Comput. Integr. Manuf. 2017, 30, 501–515. [Google Scholar] [CrossRef]

- Ren, L.; Zhang, L.; Tao, F.; Zhao, C.; Chai, X.; Zhao, X. Cloud manufacturing: From concept to practice. Enterp. Inf. Syst. 2015, 9, 186–209. [Google Scholar] [CrossRef]

- Li, W.; Mehnen, J. (Eds.) Cloud Manufacturing: Distributed Computing Technologies for Global and Sustainable Manufacturing; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Adamson, G.; Wang, L.; Holm, M.; Moore, P. Cloud manufacturing–a critical review of recent development and future trends. Int. J. Comput. Integr. Manuf. 2017, 30, 347–380. [Google Scholar] [CrossRef]

- He, W.; Xu, L. A state-of-the-art survey of cloud manufacturing. Int. J. Comput. Integr. Manuf. 2015, 28, 239–250. [Google Scholar] [CrossRef]

- Hozdić, E. Smart factory for industry 4.0: A review. Int. J. Mod. Manuf. Technol. 2015, 7, 28–35. [Google Scholar]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Lucke, D.; Constantinescu, C.; Westkämper, E. Smart factory-a step towards the next generation of manufacturing. In Manufacturing Systems and Technologies for the New Frontier; Springer: Berlin/Heidelberg, Germany, 2008; pp. 115–118. [Google Scholar]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Radziwon, A.; Bilberg, A.; Bogers, M.; Madsen, E.S. The smart factory: Exploring adaptive and flexible manufacturing solutions. Procedia Eng. 2014, 69, 1184–1190. [Google Scholar] [CrossRef]

- Shi, Z.; Xie, Y.; Xue, W.; Chen, Y.; Fu, L.; Xu, X. Smart factory in Industry 4.0. Syst. Res. Behav. Sci. 2020, 37, 607–617. [Google Scholar] [CrossRef]

- Shafiq, S.I.; Velez, G.; Toro, C.; Sanin, C.; Szczerbicki, E. Designing intelligent factory: Conceptual framework and empirical validation. Procedia Comput. Sci. 2016, 96, 1801–1808. [Google Scholar] [CrossRef]

- Reimann, J.; Sziebig, G. The intelligent factory space–a concept for observing, learning and communicating in the digitalized factory. IEEE Access 2019, 7, 70891–70900. [Google Scholar] [CrossRef]

- Lu, B.; Shao, X.; Zhang, J.; Wang, L. Development strategy for intelligent factory in discrete manufacturing. Strateg. Study Chin. Acad. Eng. 2018, 20, 44–50. [Google Scholar] [CrossRef]

- Larrabee, G.B. The intelligent microelectronics factory of the future. In Proceedings of the 1991 Proceedings IEEE/SEMI International Semiconductor Manufacturing Science Symposium, Burlingame, CA, USA, 20–22 May 1991; pp. 30–34. [Google Scholar]

- Erdogan, S.; Wahab, A. A Family of Reconfigurable Neurocomputers For The “Intelligent Factory”. In Proceedings of the IEEE International Workshop on Emerging Technologies and Factory Automation, Melbourne, VIC, Australia, 11–14 August 1992; pp. 369–374. [Google Scholar]

- Bracht, U.; Masurat, T. The Digital Factory between vision and reality. Comput. Ind. 2005, 56, 325–333. [Google Scholar] [CrossRef]

- Kuhn, W. Digital factory-simulation enhancing the product and production engineering process. In Proceedings of the 2006 Winter Simulation Conference, Monterey, CA, USA, 3–6 December 2006; pp. 1899–1906. [Google Scholar]

- Worn, H.; Frey, D.; Keitel, J. Digital factory-planning and running enterprises of the future. In Proceedings of the 2000 26th Annual Conference of the IEEE Industrial Electronics Society. IECON 2000. 2000 IEEE International Conference on Industrial Electronics, Control and Instrumentation. 21st Century Technologies, Nagoya, Japan, 22–28 October 2000; Volume 2, pp. 1286–1291. [Google Scholar]

- Tchoffa, D.; Figay, N.; Ghodous, P.; Expósito, E.; Kermad, L.; Vosgien, T.; El Mhamedi, A. Digital factory system for dynamic manufacturing network supporting networked collaborative product development. Data Knowl. Eng. 2016, 105, 130–154. [Google Scholar] [CrossRef]

- Gregor, M.; Medvecky, S. Digital factory–theory and practice. In Engineering the Future; IntechOpen: London, UK, 2010. [Google Scholar]

- Lee, J. Smart factory systems. Informatik-Spektrum 2015, 38, 230–235. [Google Scholar] [CrossRef]

- Mabkhot, M.M.; Al-Ahmari, A.M.; Salah, B.; Alkhalefah, H. Requirements of the smart factory system: A survey and perspective. Machines 2018, 6, 23. [Google Scholar] [CrossRef]

- Panetto, H.; Iung, B.; Ivanov, D.; Weichhart, G.; Wang, X. Challenges for the cyber-physical manufacturing enterprises of the future. Annu. Rev. Control 2019, 47, 200–213. [Google Scholar] [CrossRef]

- Gierej, S. The framework of business model in the context of Industrial Internet of Things. Procedia Eng. 2017, 182, 206–212. [Google Scholar] [CrossRef]

- Dujovne, D.; Watteyne, T.; Vilajosana, X.; Thubert, P. 6TiSCH: Deterministic IP-enabled industrial internet (of things). IEEE Commun. Mag. 2014, 52, 36–41. [Google Scholar] [CrossRef]

- Lu, Y.; Asghar, M.R. Semantic communications between distributed cyber-physical systems towards collaborative automation for smart manufacturing. J. Manuf. Syst. 2020, 55, 348–359. [Google Scholar] [CrossRef]

- Wong, G.; Greenhalgh, T.; Westhorp, G.; Buckingham, J.; Pawson, R. RAMESES publication standards: Realist syntheses. BMC Med. 2013, 11, 21. [Google Scholar]

- Liu, C.; Jiang, P. A cyber-physical system architecture in shop floor for intelligent manufacturing. Procedia Cirp 2016, 56, 372–377. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, G.; Wang, J.; Sun, S.; Si, S.; Yang, T. Real-time information capturing and integration framework of the internet of manufacturing things. Int. J. Comput. Integr. Manuf. 2015, 28, 811–822. [Google Scholar] [CrossRef]

- Liu, X.F.; Shahriar, M.R.; Al Sunny, S.N.; Leu, M.C.; Hu, L. Cyber-physical manufacturing cloud: Architecture, virtualization, communication, and testbed. J. Manuf. Syst. 2017, 43, 352–364. [Google Scholar] [CrossRef]

- Kühnle, H.; Bitsch, G. Smart manufacturing units. In Foundations & Principles of Distributed Manufacturing; Springer: Berlin/Heidelberg, Germany, 2015; pp. 55–70. [Google Scholar]

- Davis, J. Cyberinfrastructure in Chemical and Biological Process Systems: Impact and Directions. Proc. NSF Workshop Rep. 2006. Available online: https://www.nsf.gov/awardsearch/showAward?AWDID=0645024HistoricalAwards=false (accessed on 5 June 2022).

- Baldwin, C.Y.; Clark, K.B.; Clark, K.B. Design Rules: The Power of Modularity; MIT Press: Cambridge, MA, USA, 2000; Volume 1. [Google Scholar]

- Singh, A.; Gupta, S.; Asjad, M.; Gupta, P. Reconfigurable manufacturing systems: Journey and the road ahead. Int. J. Syst. Assur. Eng. Manag. 2017, 8, 1849–1857. [Google Scholar] [CrossRef]

- Renzi, C.; Leali, F.; Cavazzuti, M.; Andrisano, A.O. A review on artificial intelligence applications to the optimal design of dedicated and reconfigurable manufacturing systems. Int. J. Adv. Manuf. Technol. 2014, 72, 403–418. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, H.S.; Yang, J.H.; Wang, K.S. Industry 4.0: A way from mass customization to mass personalization production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Pech, M.; Vrchota, J. The Product Customization Process in Relation to Industry 4.0 and Digitalization. Processes 2022, 10, 539. [Google Scholar] [CrossRef]

- Anshari, M.; Almunawar, M.N.; Lim, S.A.; Al-Mudimigh, A. Customer relationship management and big data enabled: Personalization & customization of services. Appl. Comput. Inform. 2019, 15, 94–101. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Song, X.; Wang, S.; Xie, P.; Wei, Z. Manufacturing Flexibility, Business Model Design, and Firm Performance. In Academy of Management Proceedings; Academy of Management: Briarcliff Manor, NY, USA, 2017; Volume 2017, p. 13195. [Google Scholar]

- Qin, J.; Liu, Y.; Grosvenor, R. A categorical framework of manufacturing for industry 4.0 and beyond. Procedia Cirp 2016, 52, 173–178. [Google Scholar] [CrossRef]

- Wang, L.; Törngren, M.; Onori, M. Current status and advancement of cyber-physical systems in manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Azevedo, A.; Almeida, A. Factory templates for digital factories framework. Robot. Comput.-Integr. Manuf. 2011, 27, 755–771. [Google Scholar] [CrossRef]

- Ferreira, F.; Azevedo, A.; Faria, J.; Rojas, E. Virtual enterprise process management: An application to industrial maintenance. In Working Conference on Virtual Enterprises; Springer: Berlin/Heidelberg, Germany, 2014; pp. 71–79. [Google Scholar]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industrie 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Morris, E.; Levine, L.; Meyers, C.; Place, P.; Plakosh, D. Systems of Systems Interoperability. SEI, Carnegie Mellon University, USA. 2004. Available online: https://resources.sei.cmu.edu/library/asset-view.cfm?assetid=7045 (accessed on 5 June 2022).

- Chituc, C.M.; Toscano, C.; Azevedo, A. Interoperability in Collaborative Networks: Independent and industry-specific initiatives–The case of the footwear industry. Comput. Ind. 2008, 59, 741–757. [Google Scholar] [CrossRef]

- Berre, A.J.; Hahn, A.; Akehurst, D.; Bezivin, J.; Tsalgatidou, A.; Vermaut, F.; Kutvonen, L.; Linington, P.F. State-of-the Art for Interoperability Architecture Approaches. InterOP Network of Excellence-Contract no.: IST-508. 2004, Volume 11. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.106.9713&rep=rep1&type=pdf (accessed on 5 June 2022).

- Curts, R.J.; Campbell, D.E. Architecture: The road to interoperability. In Command & Control Research & Technology Symposium (CCRTS); US Naval War College: Newport, RI, USA, 1999. [Google Scholar]

- Heiler, S. Semantic interoperability. ACM Comput. Surv. (CSUR) 1995, 27, 271–273. [Google Scholar] [CrossRef]

- Ford, T.C.; Colombi, J.M.; Graham, S.R.; Jacques, D.R. Survey on Interoperability Measurement; Technical Report; Air Force Institute of Tech Wright-Patterson AFB OH: Greene County, OH, USA, 2007. [Google Scholar]

- Kasunic, M. Measuring Systems Interoperability: Challenges and Opportunities; Technical Report; Carnegie-Mellon Univ Pittsburgh Pa Software Engineering Inst: Pittsburgh, PA, USA, 2001. [Google Scholar]

- Zeid, A.; Sundaram, S.; Moghaddam, M.; Kamarthi, S.; Marion, T. Interoperability in smart manufacturing: Research challenges. Machines 2019, 7, 21. [Google Scholar] [CrossRef]

- Information Technology-Message Queuing Telemetry Transport (MQTT) v3.1.1; Technical Report; ISO/IEC: Geneva, Switzerland, 2016.

- Brunnermeier, S.; Martin, S. Interoperability Cost Analysis of the US Automotive Supply Chain; Center for Economics Research (Research Triangle Institute): Research Triangle Park, NC, USA, 1999. [Google Scholar]

- Vogel-Heuser, G.; Kegel, G.; Bender, K.K.; Wucherer, K. Global information architecture for industrial automation. Automatisierungstechnische Praxis (ATP) 2009, 51, 108–115. [Google Scholar] [CrossRef]

- Levis, A.H.; Rouse, W.B. Systems architecture. In Handbook of Systems Engineering and Management, 2nd ed.; Sage, A.P., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 479–506. [Google Scholar]

- Christopher, N.; Feng, S.C.; Fowler, J.E.; Frechette, S.P.; Jones, A.; Jurrens, K.; Lyons, K.; McLean, C.R.; Pratt, M.; Scott, H.A.; et al. SIMA Reference Architecture Part 1: Activity Models; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1996.

- Han, S. A review of smart manufacturing reference models based on the skeleton meta-model. J. Comput. Des. Eng. 2020, 7, 323–336. [Google Scholar] [CrossRef]

- DIN SPEC. 91345: 2016-04 Reference Architecture Model Industrie 4.0 (RAMI4. 0). DIN 2016, 4, 2016. [Google Scholar]

- Lin, S.W.; Miller, B.; Durand, J.; Joshi, R.; Didier, P.; Chigani, A.; Torenbeek, R.; Duggal, D.; Martin, R.; Bleakley, G.; et al. Industrial Internet Reference Architecture; Techonol Report; Industrial Internet Consortium (IIC): Boston, MA, USA, 2015. [Google Scholar]