A Survey on Modelling of Automotive Radar Sensors for Virtual Test and Validation of Automated Driving

Abstract

1. Introduction

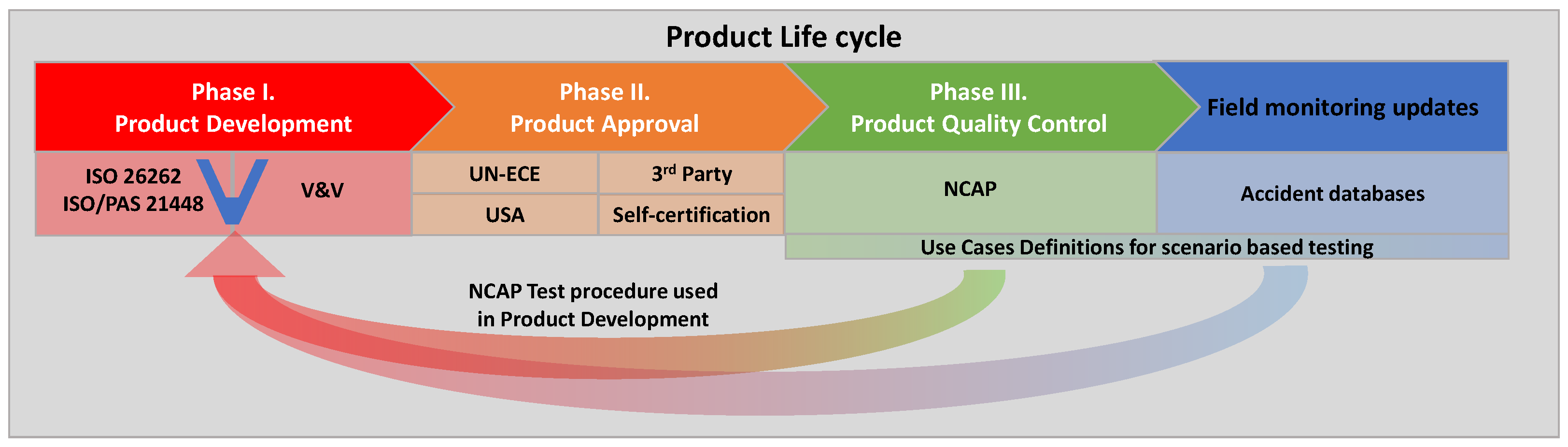

2. The Challenge in Automotive Testing

2.1. Vehicle Development Phase

2.2. Type Approval Phase

2.3. Consumer Protection Phase

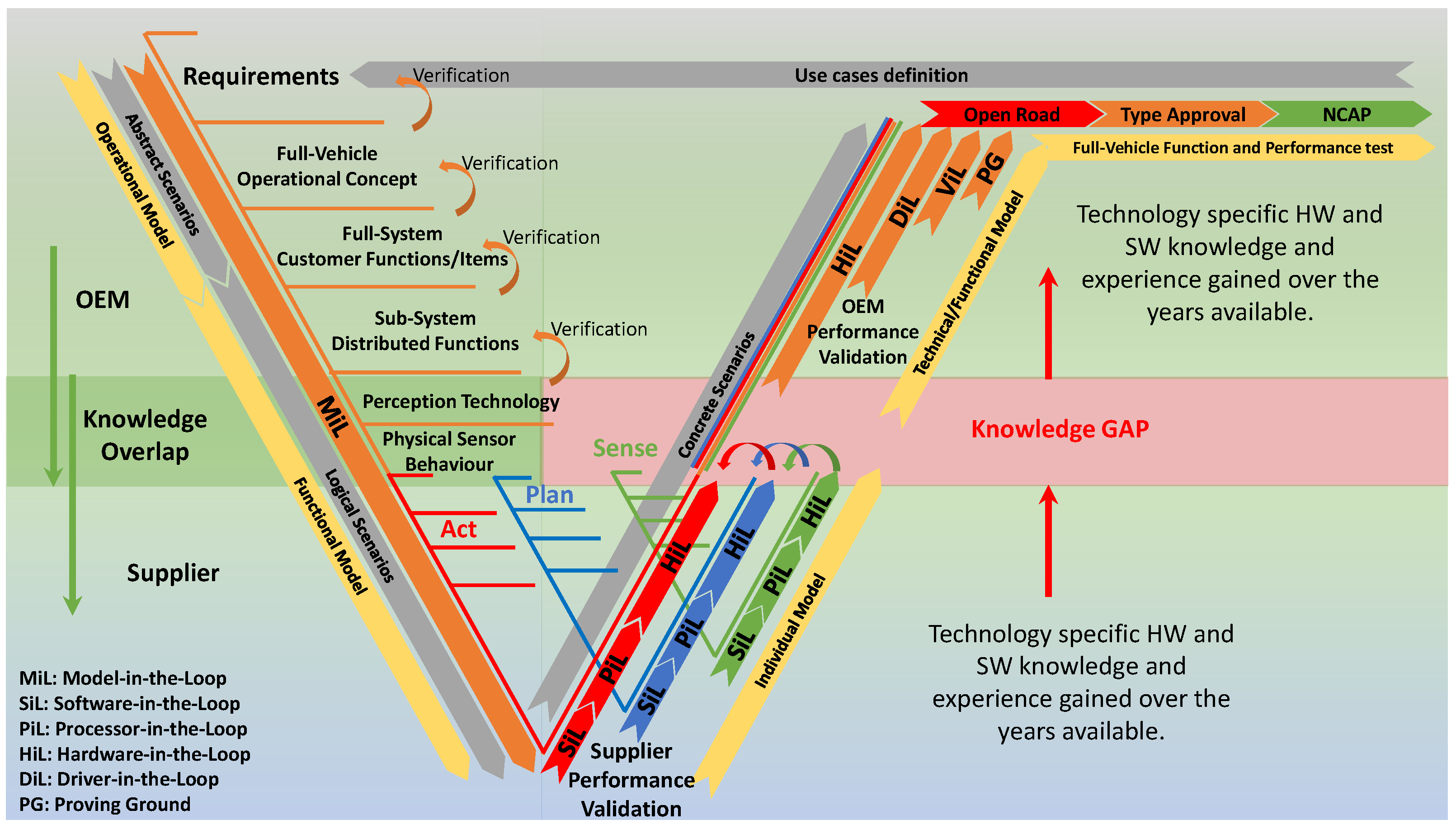

3. Vehicle Development Process

4. State-of-the-Art Radar Sensor Model Classifications

5. Classification from the System Integrator’s Perspective

5.1. Operational Model

5.1.1. Definition

5.1.2. Application

5.2. Functional Models

5.2.1. Definition

5.2.2. Application

5.3. Technical Models

5.3.1. Definition

5.3.2. Application

5.4. Individual Model

5.4.1. Definition

5.4.2. Application

5.5. Classification Overview

6. Discussion

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ACC | Adaptive Cruise Control |

| ADF | Automated Driving Function |

| ADS | Automated Driving Systems |

| AEB | Autonomous Emergency Braking |

| AEBS | Advanced Emergency Braking System |

| ALKS | Automated Lane Keeping Systems |

| C-NCAP | Chinese New Car Assessment Program |

| DAS | Driving Automation System |

| DDM | Data-Driven Model |

| DiL | Driver-In-the-Loop |

| E/E | Electrical and/or Electronic |

| EM | Electro Magnetic |

| EOL | End-Of-Line |

| Euro NCAP | European New Car Assessment Program |

| FDTD | Finite Difference Time Domain |

| FEM | Finite Element Method |

| FOT | Field Operational Test |

| FOV | Field of View |

| FPGA | Field Programmable Gate Array |

| GT | Ground Truth |

| HiFi | High Fidelity |

| HiL | Hardware-In-the-Loop |

| HMI | Human-Machine Interface |

| IRM | Ideal Radar Model |

| ISO | International Organization for Standardization |

| JNCAP | Japanese New Car Assessment Program |

| LCDAS | Lane Change Decision Aid System |

| LDW | Lane Departure Warning |

| LIDAR | Light Detection and Ranging |

| LKAS | Lane Keeping Assistance System |

| MBS | Multi-Body Simulation |

| MBSE | Model-Based Systems Engineering |

| MiL | Model-In-the-Loop |

| ML | Machine Learning |

| NCAP | New Car Assessment Program |

| NHTSA | National Highway Traffic Safety Administration |

| OEM | Original Equipment Manufacturer |

| OIOO | Object In Object Out |

| OTA | Over-The-Air |

| PALS | Partially Automated Lane Change System |

| PEC | Perfect Conductors |

| PiL | Processor-In-the-Loop |

| RADAR | Radio Detection and Ranging |

| RCS | Radar Cross Section |

| RIDO | Rendering In Detection Out |

| RIOO | Raw Input Object Output |

| RIRO | Raw Input Raw output |

| RSI | Raw Signal Interface |

| RTM | Ray-Tracing based Model |

| SAE | Society of Automotive Engineers |

| SC | Scattering Centre |

| SiL | Software-In-the-Loop |

| SOA | State-Of-the-Art |

| SOTIF | Safety Of The Intended Function |

| UN-ECE | United Nations Economic Commission for Europe |

| V&V | Validation and Verification |

| ViL | Vehicle-In-the-Loop |

References

- Szalay, Z. Next Generation X-in-the-Loop Validation Methodology for Automated Vehicle Systems. IEEE Access 2021, 9, 35616–35632. [Google Scholar] [CrossRef]

- Doms, T.; Rauch, B.; Schrammel, B.; Schwald, C.; Spahovic, E.; Schwarzl, C. Highly Automated Driving-The New Challenges for Functional Safety and Cyber Security: White Paper; TÜV Austria Holding AG and Virtual Vehicle: Vienna, Austria, 2018. [Google Scholar]

- ISO 26262; Part 1-12: Road Vehicles—Functional Safety. International Standard of Organisation: Geneva, Switzerland, 2011.

- ISO 15622:2018; Intelligent Transport Systems—Adaptive Cruise Control Systems—Performance Requirements and Test Procedures. International Standard of Organisation: Geneva, Switzerland, 2019.

- ISO 22733-1:2021; Road Vehicles—Test Method to Evaluate the Performance of Autonomous Emergency Braking Systems—Part 1: Car-to-Car. International Standard of Organisation: Geneva, Switzerland, 2021.

- ISO 17361:2017; Intelligent Transport Systems—Lane Departure Warning Systems—Performance Requirements and Test Procedures. International Standard of Organisation: Geneva, Switzerland, 2017.

- ISO 17387:2008; Intelligent Transport Systems—Lane Change Decision Aid Systems (LCDAS)—Performance Requirements and Test Procedures. International Standard of Organisation: Geneva, Switzerland, 2018.

- ISO 21202:2020; Intelligent Transport Systems—Partially Automated Lane Change Systems (PALS)—Functional/Operational Requirements and Test Procedures. International Standard of Organisation: Geneva, Switzerland, 2020.

- ISO 11270:2014; Intelligent Transport Systems—Lane Keeping Assistance Systems (LKAS)—Performance Requirements and Test Procedures. International Standard of Organisation: Geneva, Switzerland, 2012.

- United Regulation No 131 of the Economic Commission for Europe of the United Nations (UN/ECE)-Uniform Provisions Concerning the Approval of Motor Vehicles with Regard to the Advanced Emergency Braking Systems (AEBS); Nations Economic Commission for Europe: Geneva, Switzerland, 2014; pp. 47–62.

- UN Regulation No. 157—Automated Lane Keeping Systems (ALKS); Nations Economic Commission for Europe: Geneva, Switzerland, 2021; pp. 75–137.

- Hutchinson, A.C. (Ed.) Cryptocurrencies and the Regulatory Challenge; Routledge: London, UK, 2021. [Google Scholar] [CrossRef]

- Wishart, J.; Como, S.; Forgione, U.; Weast, J.; Weston, L.; Smart, A.; Nicols, G.; S, R. Literature Review of Verification and Validation Activities of Automated Driving Systems. SAE Int. J. Connect. Autom. Veh. 2020, 3, 267–323. [Google Scholar] [CrossRef]

- Dahmen, U.; Roßmann, J. Simulation-based Verification with Experimentable Digital Twins in Virtual Testbeds. In Tagungsband des 3. Kongresses Montage Handhabung Industrieroboter; Schüppstuhl, T., Tracht, K., Franke, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 139–147. [Google Scholar]

- Schmidt, S.; Schlager, B.; Muckenhuber, S.; Stark, R. Configurable Sensor Model Architecture for the Development of Automated Driving Systems. Sensors 2021, 21, 4687. [Google Scholar] [CrossRef]

- ISO/PAS 21448:2019; Road Vehicles—Safety of the Intended Functionality. International Organization for Standardization: Geneva, Switzerland, 2019.

- Lipa, B.J.; Barrick, D.E. FMCW Signal Processing. 1990. Available online: http://www.codar.com/images/about/1990LipaBarr_FMCW.pdf (accessed on 24 June 2022).

- Muckenhuber, S.; Holzer, H.; Rubsam, J.; Stettinger, G. Object-based sensor model for virtual testing of ADAS/AD functions. In Proceedings of the 8th IEEE International Conference on Connected Vehicles and Expo (ICCVE), Graz, Austria, 4–8 November 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar] [CrossRef]

- Schlager, B.; Muckenhuber, S.; Schmidt, S.; Holzer, H.; Rott, R.; Maier, F.M.; Saad, K.; Kirchengast, M.; Stettinger, G.; Watzenig, D.; et al. State-of-the-Art Sensor Models for Virtual Testing of Advanced Driver Assistance Systems/Autonomous Driving Functions. SAE Int. J. Connect. Autom. Veh. 2020, 3, 233–261. [Google Scholar] [CrossRef]

- Safety First for Automated Driving. Available online: https://wiki.unece.org/download/attachments/87622238/FRAV-01-11.pdf?api=v2 (accessed on 24 June 2022).

- Schnelle, S.C.; Salaani, M.K.; Rao, S.J.; Barickman, F.S.; Elsasser, D. Review of Simulation Frameworks and Standards Related to Driving Scenarios; National Highway Traffic Safety Administration: Washington, DC, USA, 2019. [Google Scholar]

- Rosenberger, P.; Wendler, J.T.; Holder, M.; Linnhoff, C.; Berghöfer, M.; Winner, H.; Maurer, M. Towards a generally accepted validation methodology for sensor models-challenges, metrics, and first results. In Proceedings of the 2019 Graz Symposium Virtual Vehicle, Graz, Austria, 7–8 May 2019; pp. 1–13. [Google Scholar]

- Jun, Z.; Kai, Y.; Xuecai, D.; Zhangu, W.; Huainan, Z.; Chunguang, D. New modeling method of millimeter-wave radar considering target radar echo intensity. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 2857–2870. [Google Scholar] [CrossRef]

- Guo, J.; Deng, W.; Zhang, S.; Qi, S.; Li, X.; Wang, C.; Wang, J. A Novel Method of Radar Modeling for Vehicle Intelligence. SAE Int. J. Passeng.-Cars-Electron. Electr. Syst. 2017, 10, 50–56. [Google Scholar] [CrossRef]

- Holder, M.; Rosenberger, P.; Bert, F.; Winner, H. Data-driven Derivation of Requirements for a Lidar Sensor Model. In Graz Symposium Virtual Vehicle 2018; Universitäts-und Landesbibliothek: Darmstadt, Germany, 2018; pp. 1–10. [Google Scholar]

- Bernsteiner, S.; Magosi, Z.; Lindvai-Soos, D.; Eichberger, A. Radar Sensor Model for the Virtual Development Process. Atzelektronik Worldw. 2015, 10, 46–52. [Google Scholar] [CrossRef]

- Hirsenkorn, N.; Hanke, T.; Rauch, A.; Dehlink, B.; Rasshofer, R.; Biebl, E. A non-parametric approach for modeling sensor behavior. In Proceedings of the 2015 16th International Radar Symposium (IRS), Dresden, Germany, 24–26 June 2015; pp. 131–136. [Google Scholar] [CrossRef]

- Gschwandtner, M.; Kwitt, R.; Uhl, A.; Pree, W. BlenSor: Blender Sensor Simulation Toolbox. In Advances in Visual Computing, Proceedings of the 7th International Symposium, ISVC 2011, Las Vegas, NV, USA, 26–28 September 2011; Bebis, G., Boyle, R., Parvin, B., Koracin, D., Wang, S., Kyungnam, K., Benes, B., Moreland, K., Borst, C., DiVerdi, S., et al., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 199–208. [Google Scholar] [CrossRef]

- Wheeler, T.A.; Holder, M.; Winner, H.; Kochenderfer, M.J. Deep stochastic radar models. In Proceedings of the 2017 IEEE Intelligent Vehicles Symposium (IV), Los Angeles, CA, USA, , 11–14 June 2017; pp. 47–53. [Google Scholar] [CrossRef]

- Jasinski, M. A Generic Validation Scheme for Real-Time Capable Automotive Radar Sensor Models integrated into an Autonomous Driving Simulator. In Proceedings of the 2019 24th International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 26–29 August 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Ling, H.; Chou, R.C.; Lee, S.W. Shooting and bouncing rays: Calculating the RCS of an arbitrarily shaped cavity. IEEE Trans. Antennas Propag. 1989, 37, 194–205. [Google Scholar] [CrossRef]

- Hirsenkorn, N.; Subkowski, P.; Hanke, T.; Schaermann, A.; Rauch, A.; Rasshofer, R.; Biebl, E. A ray launching approach for modeling an FMCW radar system. In Proceedings of the 18th International Radar Symposium IRS 2017, Prague, Czech Republic, 28–30 June 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Martowicz, A.; Gallina, A.; Karpiel, G. Uncertainty propagation for vehicle detections in experimentally validated radar model for automotive application. In Proceedings of the 2019 24th International Conference on Methods and Models in Automation and Robotics (MMAR), Międzyzdroje, Poland, 26–29 August 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Bhalla, R.; Ling, H. Three-dimensional scattering center extraction using the shooting and bouncing ray technique. IEEE Trans. Antennas Propag. 1996, 44, 1445–1453. [Google Scholar] [CrossRef]

- Schuler, K.; Becker, D.; Wiesbeck, W. Extraction of Virtual Scattering Centers of Vehicles by Ray-Tracing Simulations. IEEE Trans. Antennas Propag. 2008, 56, 3543–3551. [Google Scholar] [CrossRef]

- Hirsenkorn, N.; Hanke, T.; Rauch, A.; Dehlink, B.; Rasshofer, R.; Biebl, E. Virtual sensor models for real-time applications. Adv. Radio Sci. 2016, 14, 31–37. [Google Scholar] [CrossRef][Green Version]

- Scheel, A.; Dietmayer, K. Tracking Multiple Vehicles Using a Variational Radar Model. IEEE Trans. Intell. Transp. Syst. 2019, 20, 3721–3736. [Google Scholar] [CrossRef]

- Hanke, T.; Hirsenkorn, N.; Dehlink, B.; Rauch, A.; Rasshofer, R.; Biebl, E. Generic architecture for simulation of ADAS sensors. In Proceedings of the Generic Architecture for Simulation of ADAS Sensors, Dresden, Germany, 24–26 June 2015; pp. 125–130. [Google Scholar] [CrossRef]

- Cao, P. Modeling Active Perception Sensors for Real-Time Virtual Validation of Automated Driving Systems. Ph.D. Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 2017. [Google Scholar]

- Holder, M.; Linnhoff, C.; Rosenberger, P.; Winner, H. The Fourier Tracing Approach for Modeling Automotive Radar Sensors. In Proceedings of the 20th International Radar Symposium (IRS), Ulm, Germany, 26–28 June 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Cao, P.; Wachenfeld, W.; Winner, H. Perception sensor modeling for virtual validation of automated driving. Inf. Technol. 2015, 57, 243–251. [Google Scholar] [CrossRef]

- Ngo, A.; Bauer, M.P.; Resch, M. A Sensitivity Analysis Approach for Evaluating a Radar Simulation for Virtual Testing of Autonomous Driving Functions. In Proceedings of the 2020 5th Asia-Pacific Conference on Intelligent Robot Systems (ACIRS), Singapore, 17–19 July 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Ngo, A.; Bauer, M.P.; Resch, M. A Multi-Layered Approach for Measuring the Simulation-to-Reality Gap of Radar Perception for Autonomous Driving. In Proceedings of the 2021 IEEE International Intelligent Transportation Systems Conference (ITSC), Indianapolis, IN, USA, 19–22 September 2021; pp. 4008–4014. [Google Scholar]

- Holder, M.F. Synthetic Generation of Radar Sensor Data for Virtual Validation of Autonomous Driving. Ph.D. Thesis, TU Darmstadt, Darmstadt, Germany, 2021. [Google Scholar] [CrossRef]

- Dallmann, T.; Mende, J.K.; Wald, S. A Radar Target Simulator for Complex Traffic Scenarios ATRIUM. In Proceedings of the 2018 IEEE MTT-S International Conference on Microwaves for Intelligent Mobility (ICMIM), Munich, Germany, 16–17 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Gowdu, S.B.J.; Asghar, M.E.; Stephan, R.; Hein, M.A.; Nagel, J.; Baumgartner, F. System architecture for installed-performance testing of automotive radars over-the-air. In Proceedings of the 2018 IEEE MTT-S International Conference on Microwaves for Intelligent Mobility (ICMIM), Munich, Germany, 15–17 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Zhu, B.; Sun, Y.; Zhao, J.; Zhang, S.; Zhang, P.; Song, D. Millimeter-Wave Radar in-the-Loop Testing for Intelligent Vehicles. IEEE Trans. Intell. Transp. Syst. 2021, 1–11. [Google Scholar] [CrossRef]

- Sobotka, J.; Novak, J. Digital Vehicle Radar Sensor Target Simulation. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–29 May 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Diewald, A.; Kurz, C.; Kannan, P.V.; Gießler, M.; Pauli, M.; Göttel, B.; Kayser, T.; Gauterin, F.; Zwick, T. Radar Target Simulation for Vehicle-in-the-Loop Testing. Vehicles 2021, 3, 257–271. [Google Scholar] [CrossRef]

- Gadringer, M.E.; Schreiber, H.; Gruber, A.; Vorderderfler, M.; Amschl, D.; Bösch, W.; Metzner, S.; Pflügl, H.; Paulweber, M. Virtual reality for automotive radars. Elektrotechnik Und Informationstechnik 2018, 135, 335–343. [Google Scholar] [CrossRef]

- Cheng, J.J.; Xu, Z.G.; Gao, Y.; Wang, Z.; Wang, W.W.; Zhao, X.M. An Indoor Rapid Testing Platform for Autonomous Vehicles Using Vehicle-in-the-Loop Simulation. In Proceedings of the CICTP 2020, Xi’an, China, 16–19 December 2020; Wei, H., Wang, H., Zhang, L., An, Y., Zhao, X., Eds.; American Society of Civil Engineers: Reston, VA, USA, 2020; pp. 411–422. [Google Scholar] [CrossRef]

- Asghar, M.E.; Buddappagari, S.; Baumgartner, F.; Graf, S.; Kreutz, F.; Loffler, A.; Nagel, J.; Reichmann, T.; Stephan, R.; Hein, M.A. Radar Target Simulator and Antenna Positioner for Real-Time Over-the-air Stimulation of Automotive Radar Systems. In Proceedings of the 2020 17th European Radar Conference (EuRAD), Jaarbeurs Utrecht, Netherlands, 16–18 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 95–98. [Google Scholar] [CrossRef]

- Lutz, S.; Erhart, C.; Walte, T.; Weigel, R. Target simulator concept for chirp modulated 77 GHz automotive radar sensors. In Proceedings of the 2014 11th European Radar Conference, Rome, Italy, 8–10 October 2014; pp. 65–68. [Google Scholar] [CrossRef]

- Maier, F.M.; Makkapati, V.P.; Horn, M. Environment perception simulation for radar stimulation in automated driving function testing. Elektrotechnik Und Informationstechnik 2018, 135, 309–315. [Google Scholar] [CrossRef]

- Herrmann, M.; Schön, H. Efficient Sensor Development Using Raw Signal Interfaces. In Fahrerassistenzsysteme 2018; Bertram, T., Ed.; Springer: Wiesbaden, Germany, 2019; pp. 30–39. [Google Scholar] [CrossRef]

- Schoener, H.P. Automotive Needs and Expectations towards Next Generation Driving Simulation. In Proceedings of the 2018 Driving Simulator Conference, Antibes, France, 5–7 September 2018; pp. 11–16. [Google Scholar]

- Hartstern, M.; Rack, V.; Kaboli, M.; Stork, W. Simulation-based Evaluation of Automotive Sensor Setups for Environmental Perception in Early Development Stages. In Proceedings of the 2020 IEEE Intelligent Vehicles Symposium (IV), Las Vegas, NV, USA, 19 October–13 November 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 858–864. [Google Scholar] [CrossRef]

- Gregory, Y. (GRVA) New Assessment/Test Method for Automated Driving (NATM)-Master Document. 2021. Available online: https://unece.org/sites/default/files/2021-04/ECE-TRANS-WP29-2021-61e.pdf (accessed on 24 June 2022).

- Menzel, T.; Bagschik, G.; Maurer, M. Scenarios for Development, Test and Validation of Automated Vehicles. In Proceedings of the 2018 IEEE Intelligent Vehicles Symposium (IV), Changshu, China, 26–30 June 2018; IEEE: Piscataway, NJ, USA; pp. 1821–1827. [Google Scholar]

- Bringmann, E.; Kr, A. Model-Based Testing of Automotive Systems. In Proceedings of the 2008 International Conference on Software Testing, Verification, and Validation, Lillehammer, Norway, 9–11 April 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 485–493. [Google Scholar] [CrossRef]

- Schutt, B.; Steimle, M.; Kramer, B.; Behnecke, D.; Sax, E. A Taxonomy for Quality in Simulation-Based Development and Testing of Automated Driving Systems. IEEE Access 2022, 10, 18631–18644. [Google Scholar] [CrossRef]

- Linnhoff, C.; Rosenberger, P.; Holder, M.F.; Cianciaruso, N.; Winner, H. Highly Parameterizable and Generic Perception Sensor Model Architecture. In Automatisiertes Fahren 2020; Bertram, T., Ed.; Springer: Wiesbaden, Germany, 2021; pp. 195–206. [Google Scholar] [CrossRef]

- Rosique, F.; Navarro, P.J.; Fernández, C.; Padilla, A. A Systematic Review of Perception System and Simulators for Autonomous Vehicles Research. Sensors 2019, 19, 648. [Google Scholar] [CrossRef]

- Muckenhuber, S.; Museljic, E.; Stettinger, G. Performance evaluation of a state-of-the-art automotive radar and corresponding modeling approaches based on a large labeled dataset. J. Intell. Transp. Syst. 2021, 1–20. [Google Scholar] [CrossRef]

- Choi, W.Y.; Yang, J.H.; Chung, C.C. Data-Driven Object Vehicle Estimation by Radar Accuracy Modeling with Weighted Interpolation. Sensors 2021, 21, 2317. [Google Scholar] [CrossRef] [PubMed]

- Bel Kamel, E.; Peden, A.; Pajusco, P. RCS modeling and measurements for automotive radar applications in the W band. In Proceedings of the 2017 11th European Conference on Antennas and Propagation (EUCAP), Paris, France, 19–24 March 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 2445–2449. [Google Scholar] [CrossRef]

- Thieling, J.; Frese, S.; RoBmann, J. Scalable and Physical Radar Sensor Simulation for Interacting Digital Twins. IEEE Sens. J. 2021, 21, 3184–3192. [Google Scholar] [CrossRef]

- Schuesler, C.; Hoffmann, M.; Braunig, J.; Ullmann, I.; Ebelt, R.; Vossiek, M. A Realistic Radar Ray Tracing Simulator for Large MIMO-Arrays in Automotive Environments. IEEE J. Microwaves 2021, 1, 962–974. [Google Scholar] [CrossRef]

- Dudek, M.; Wahl, R.; Kissinger, D.; Weigel, R.; Fischer, G. Millimeter wave FMCW radar system simulations including a 3D ray tracing channel simulator. In Proceedings of the 2010 Asia-Pacific Microwave Conference, Yokohama, Japan, 7–10 December 2010; pp. 1665–1668. [Google Scholar]

- Zhu, L.; He, D.; Ai, B.; Zhong, Z.; Zhu, F.; Wang, Z. Measurement and Ray-Tracing Simulation for Millimeter-Wave Automotive Radar. In Proceedings of the 2021 IEEE 4th International Conference on Electronic Information and Communication Technology (ICEICT), Xi’an, China, 18–20 August 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 582–587. [Google Scholar] [CrossRef]

- Li, X.; Deng, W.; Zhang, S.; Li, Y.; Song, S.; Wang, S.; Wang, G. Research on Millimeter Wave Radar Simulation Model for Intelligent Vehicle. Int. J. Automot. Technol. 2020, 21, 275–284. [Google Scholar] [CrossRef]

- Roth, E.; Dirndorfer, T.J.; Knoll, A.V.; Neumann-Cosel, K.; Ganslmeier, T.; Kern, A.; Fischer, M.O. Analysis and validation of perception sensor models in an integrated vehicle and environment simulation. In Proceedings of the 22nd Conference on Enhanced Saferty of Vehicles (ESV 2011), Washington, DC, USA, 13–16 June 2011. [Google Scholar]

- Stolz, M.; Nestlinger, G. Fast generic sensor models for testing highly automated vehicles in simulation. Elektrotechnik Und Informationstechnik 2018, 135, 365–369. [Google Scholar] [CrossRef]

- Elgharbawy, M.; Schwarzhaupt, A.; Scheike, G.; Frey, M.; Gauterin, F. A generic architecture of ADAS sensor fault injection for virtual tests. In Proceedings of the 2016 IEEE/ACS 13th International Conference of Computer Systems and Applications (AICCSA), Agadir, Morocco, 29 November–2 December 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–7. [Google Scholar] [CrossRef]

- Velazquez, J.M.R.; Mailly, F.; Nouet, P. A generic model for sensor simulation at system level. In Proceedings of the 2018 Symposium on Design, Test, Integration & Packaging of MEMS and MOEMS (DTIP), Rome, Italy, 22–25 May 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Hanke, T. Virtual Sensorics: Simulated Environmental Perception for Automated Driving Systems. Ph.D. Thesis, TU Darmstadt, Darmstadt, Germany, 2022. [Google Scholar]

- Deng, W.; Dai, J.; Zhao, Q.; Litkouhi, B.; Moshchuk, N.; Nisonger, R. Modeling of range sensing and object detection, for vehicle active safety. In Proceedings of the 2009 12th International IEEE Conference on Intelligent Transportation Systems, St. Louis, MO, USA, 4–7 October 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 1–6. [Google Scholar] [CrossRef]

- Holder, M.; Rosenberger, P.; Winner, H.; Dhondt, T.; Makkapati, V.P.; Maier, M.; Schreiber, H.; Magosi, Z.; Slavik, Z.; Bringmann, O.; et al. Measurements revealing Challenges in Radar Sensor Modeling for Virtual Validation of Autonomous Driving. In Proceedings of the 2018 IEEE Intelligent Transportation Systems Conference, Maui, HI, USA, 4–7 November 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 2616–2622. [Google Scholar] [CrossRef]

- Slavik, Z.; Mishra, K.V. Phenomenological Modeling of Millimeter-Wave Automotive Radar. In Proceedings of the 2019 URSI Asia-Pacific Radio Science Conference (AP-RASC), New Delhi, India, 9–15 March 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Arnelid, H.; Zec, E.L.; Mohammadiha, N. Recurrent Conditional Generative Adversarial Networks for Autonomous Driving Sensor Modelling. In Proceedings of the Recurrent Conditional Generative Adversarial Networks for Autonomous Driving Sensor Modelling, Auckland, New Zealand, 27–30 October 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Zec, E.L.; Mohammadiha, N.; Schliep, A. Statistical Sensor Modelling for Autonomous Driving Using Autoregressive Input-Output HMMs. In Proceedings of the Statistical Sensor Modelling for Autonomous Driving Using Autoregressive Input-Output HMMs, Maui, Hawaii, 4–7 November 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Song, Y.; Wang, Y.; Li, Y. Radar data simulation using deep generative networks. J. Eng. 2019, 2019, 6699–6702. [Google Scholar] [CrossRef]

- Suhre, A., Malik, W., Eds.; Simulating Object Lists Using Neural Networks in Automotive Radar. In Proceedings of the 2018 19th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Toulouse, France, 15–18 April 2018. [Google Scholar] [CrossRef]

- Cao, X.; Lan, J.; Li, X.R.; Liu, Y. Automotive Radar-Based Vehicle Tracking Using Data-Region Association. IEEE Trans. Intell. Transp. Syst. 2021, 23, 1–14. [Google Scholar] [CrossRef]

- Mishra, K.V.; Shankar M.R., B.; Ottersten, B. Stochastic-Geometry-Based Interference Modeling in Automotive Radars Using Matérn Hard-Core Process. In Proceedings of the 2020 IEEE Radar Conference (RadarConf20), lorence, Italy, 21–25 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Choi, W.Y.; Kang, C.M.; Lee, S.H.; Chung, C.C. Radar Accuracy Modeling and Its Application to Object Vehicle Tracking. Int. J. Control. Autom. Syst. 2020, 18, 3146–3158. [Google Scholar] [CrossRef]

- Belyaev, A.A.; Frolov, I.O.; Suanov, T.A.; Trots, D.O. Object Detection in an Urban Environment Using 77 GHz Radar. In Proceedings of the 2019 Radiation and Scattering of Electromagnetic Waves (RSEMW), Divnomorskoe, Russia, 24–28 June 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Buddendick, H., Eibert, T.F., Eds.; Radio channel simulations using multiple scattering center models. In Proceedings of the Radio Channel Simulations Using Multiple Scattering Center Models, North Charleston, SC, USA, 1–5 June 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Schubert, R.; Mattern, N.; Bours, R. Simulation of Sensor Models for the Evaluation of Advanced Driver Assistance Systems. Atzelektronik Worldw. 2014, 9, 26–29. [Google Scholar] [CrossRef]

- Sligar, A.P. Machine Learning-Based Radar Perception for Autonomous Vehicles Using Full Physics Simulation. IEEE Access 2020, 8, 51470–51476. [Google Scholar] [CrossRef]

- Buhren, M.; Yang, B. Initialization Procedure for Radar Target Tracking without Object Movement Constraints. In Proceedings of the 2007 7th International Conference on ITS Telecommunications, Sophia Antipolis, France, 6–8 June 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 1–6. [Google Scholar]

- Ponn, T.; Lanz, T.; Diermeyer, F. Automatic Generation of Road Geometries to Create Challenging Scenarios for Automated Vehicles Based on the Sensor Setup. In Proceedings of the 2020 IEEE Intelligent Vehicles Symposium (IV), Las Vegas, NV, USA, 23–26 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 694–700. [Google Scholar] [CrossRef]

- Haider, A.; Kim, J.; Sachse, M.; Zeh, T.; Schneider, S.A.; Thumann, M.; Eryildirim, A.; Ebeling, T. Automotive Radar Sensor Behavioral Models for Closed Loop Simulations. In Proceedings of the 5th International Symposium on Future Active Safety Technology toward Zero Accidents (FAST-zero’19), Blacksburg, VA, USA, 9–11 September 2019. [Google Scholar]

- Dietmayer, K. Predicting of Machine Perception for Automated Driving. In Autonomous Driving; Maurer, M., Gerdes, J.C., Lenz, B., Winner, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 407–424. [Google Scholar] [CrossRef]

- Doerr, D. Using Virtualization to Accelerate the Development of ADAS & Automated Driving Functions: IPG Presentation; IPG Automotive GmbH: Karlsruhe, Germany, 2017. [Google Scholar]

- Gubelli, D.; Krasnov, O.; Yarovyi, O. Ray-tracing simulator for radar signals propagation in radar networks. Eur. Radar Conf. 2013, 2013, 73–76. [Google Scholar]

- Schneider, R. Modellierung der Wellenausbreitung für ein Bildgebendes Kfz-Radar. Ph.D. Thesis, Universität Karlsruhe, Karlsruhe, Germany, 1998. [Google Scholar]

- Stellet, J.E.; Schumacher, J.; Lange, O.; Branz, W.; Niewels, F.; Zöllner, J.M. Statistical Modelling of Object Detection in Stereo Vision-Based Driver Assistance. In Intelligent Autonomous Systems 13; Menegatti, E., Michael, N., Berns, K., Yamaguchi, H., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2016; Volume 302, pp. 749–761. [Google Scholar] [CrossRef]

- Deng, W.; Zeng, S.; Zhao, Q.; Dai, J. Modeling and simulation of sensor-guided autonomous driving. Int. J. Veh. Des. 2011, 56, 341. [Google Scholar] [CrossRef]

- Gadringer, M.E.; Maier, F.M.; Schreiber, H.; Makkapati, V.P.; Gruber, A.; Vorderderfler, M.; Amschl, D.; Metzner, S.; Pflügl, H.; Bösch, W.; et al. Radar target stimulation for automotive applications. IET Radar Sonar Navig. 2018, 12, 1096–1103. [Google Scholar] [CrossRef]

- van Driesten, C.; Schaller, T. Overall Approach to Standardize AD Sensor Interfaces: Simulation and Real Vehicle. In Fahrerassistenzsysteme 2018; Bertram, T., Ed.; Springer: Wiesbaden, Germany, 2019; pp. 47–55. [Google Scholar] [CrossRef]

- Feilhauer, M.; Häring, J. A real-time capable multi-sensor model to validate ADAS in a virtual environment. In Fahrerassistenzsysteme 2017; Isermann, R., Ed.; Springer: Wiesbaden, Germany, 2017; pp. 227–256. [Google Scholar] [CrossRef]

- Maier, F.M. Radar Perception Simulation for Automated Driving Tests. PH.D. Thesis, Graz University of Technology, Graz, Austria, 2022. [Google Scholar]

- Buhren, M.; Yang, B. Extension of Automotive Radar Target List Simulation to consider further Physical Aspects. In Proceedings of the 2007 7th International Conference on ITS Telecommunications, Sophia Antipolis, France, 6–8 June 2007; pp. 1–6. [Google Scholar] [CrossRef]

- Prinz, A.; Peters, L.T.; Schwendner, J.; Ayeb, M.; Brabetz, L. Automotive Radar Signal and Interference Simulation for Testing Autonomous Driving. In Intelligent Transport Systems, from Research and Development to the Market Uptake; Martins, A.L., Ferreira, J.C., Kocian, A., Costa, V., Eds.; Springer: Cham, Switzerland, 2021; Volume 364, pp. 223–240. [Google Scholar] [CrossRef]

- Maier, M.; Makkapati, V.P.; Horn, M. Adapting Phong into a Simulation for Stimulation of Automotive Radar Sensors. In Proceedings of the 2018 IEEE MTT-S International Conference on Microwaves for Intelligent Mobility (ICMIM), Munich, Germany, 15–17 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Bogdan, T.; Dorina, I. Simulation of Automotive MIMO Radar. In Proceedings of the 2020 International Symposium on Electronics and Telecommunications (ISETC), Timisoara, Romania, 5–6 November 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Blasch, E.; Hensel, M. Fusion of Distributions for Radar Clutter Modeling; Defense Technical Information Center: Fort Belvoir, VA, USA, 2004. [Google Scholar]

- Etinger, A.; Litvak, B.; Pinhasi, Y. Multi Ray Model for Near-Ground Millimeter Wave Radar. Sensors 2017, 17, 1983. [Google Scholar] [CrossRef] [PubMed]

- Hammarstrand, L.; Lundgren, M.; Svensson, L. Adaptive Radar Sensor Model for Tracking Structured Extended Objects. IEEE Trans. Aerosp. Electron. Syst. 2012, 48, 1975–1995. [Google Scholar] [CrossRef]

- Hammarstrand, L.; Svensson, L.; Sandblom, F.; Sorstedt, J. Extended Object Tracking using a Radar Resolution Model. IEEE Trans. Aerosp. Electron. Syst. 2012, 48, 2371–2386. [Google Scholar] [CrossRef]

- Hanke, T.; Schaermann, A.; Matthias, G.; Konstantin, W.; Hirsenkorn, N.; Rauch, A.; Schneider, S.A.; Biebl, E. Generation and validation of virtual point cloud data for automated driving systems. In Proceedings of the 20th International Conference on Intelligent Transportation Systems: Mielparque Yokohama in Yokohama, Kanagawa, Japan, 16–19 October 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Peinecke, N.; Döhler, H.U.; Korn, B.R. Simulation of imaging radar using graphics hardware acceleration. In Proceedings of the Enhanced and Synthetic Vision 2008, Orlando, FL, USA, 20 May 2008; Güell, J.J., Uijt de Haag, M., Eds.; SPIE: Bellingham, WA, USA, 2008; p. 69570L. [Google Scholar] [CrossRef]

- Buhren, M.; Yang, B. Simulation of Automotive Radar Target Lists using a Novel Approach of Object Representation. In Proceedings of the 2006 IEEE Intelligent Vehicles Symposium, Meguro-Ku, Japan, 13–15 June 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 314–319. [Google Scholar] [CrossRef]

- Bühren, M.; Yang, B. Simulation of automotive radar target lists considering clutter and limited resolution. In Proceedings of the International Radar Symposium, Cologne, Germany, 5–7 September 2007; pp. 195–200. [Google Scholar]

- Danielsson, L. Tracking and Radar Sensor Modelling for Automotive Safety Systems 2010; Doktorsavhandlingar vid Chalmers Tekniska Högskola; Chalmers Univercity of Technology: Göteborg, Germany, 2010; Volume 3064. [Google Scholar]

- Schuler, K. Intelligente Antennensysteme für Kraftfahrzeug-Nahbereichs-Radar-sensorik. Ph.D. Thesis, Universität Karlsruhe, Karlsruhe, Germany, 2007. [Google Scholar]

- Hermann, B.; Thomas, E.; Jurgen, H. Object Detection in an Urban Environment Using 77 GHz Radar. In Proceedings of the Bistatic Scattering Center Models for the Simulation of Wave Propagation in Automotive Radar Systems: (GeMiC 2010); Berlin, Germany, 15–17 March 2010, IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Harrington, R.F. Field Computation by Moment Methods; Wiley-IEEE Press: Hoboken, NJ, USA, 1993. [Google Scholar]

- Weinmann, F. Ray Tracing With PO/PTD for RCS Modeling of Large Complex Objects. IEEE Trans. Antennas Propag. 2006, 54, 1797–1806. [Google Scholar] [CrossRef]

- Clemens, M.; Weiland, T. Discrete Electromagnetism with finite integration technique. Prog. Electromagn. Res. 2001, 2001, 65–87. [Google Scholar] [CrossRef]

- Machida, T.; Owaki, T. Rapid and Precise Millimeter-wave Radar Simulation for ADAS Virtual Assessment. In Proceedings of the 2019 IEEE Intelligent Transportation Systems Conference (ITSC), Auckland, New Zealand, 27–30 October 2019; IEEE: Auckland, New Zealand, 2019. [Google Scholar]

- Yee, K. Numerical solution of initial boundary value problems involving maxwell’s equations in isotropic media. IEEE Trans. Antennas Propag. 1966, 14, 302–307. [Google Scholar] [CrossRef]

- Chipengo, U.; Krenz, P.M.; Carpenter, S. From Antenna Design to High Fidelity, Full Physics Automotive Radar Sensor Corner Case Simulation. Model. Simul. Eng. 2018, 2018, 4239725. [Google Scholar] [CrossRef]

- Owaki, T.; Machida, T. Hybrid Physics-Based and Data-Driven Approach to Estimate the Radar Cross- Section of Vehicles. In Proceedings of the 2019 IEEE Intelligent Transportation Systems Conference (ITSC), Auckland, New Zealand, 27–30 October 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Schäferle, S. How Do I Choose the Correct Sensor Model for My Specific Application? CarMaker Tips & Tricks No. 6-004: Choosing the Correct Sensor Model for Your Application; IPG Automotive GmbH: Karlsruhe, Germany, 2019. [Google Scholar]

- Eder, T.; Hachicha, R.; Sellami, H.; van Driesten, C.; Biebl, E. Data Driven Radar Detection Models: A Comparison of Artificial Neural Networks and Non Parametric Density Estimators on Synthetically Generated Radar Data. In Proceedings of the 2019 Kleinheubach Conference, Miltenberg, Germany, 23–25 September 2019. [Google Scholar]

- Koch, W. Verfeinerte Sensormodelle für Tracking-Anwendungen (Advanced Sensor Models for Tracking Applications). Tech. Mess. 2007, 74, 112–120. [Google Scholar] [CrossRef]

- Berthold, P.; Michaelis, M.; Luettel, T.; Meissner, D.; Wuensche, H.J.J. An Abstracted Radar Measurement Model for Extended Object Tracking. In Proceedings of the 2018 21st International Conference on Intelligent Transportation Systems (ITSC), Maui, HI, USA, 4–7 November 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Felbecker, R.; Raschkowski, L.; Keusgen, W.; Peter, M. Electromagnetic wave propagation in the millimeter wave band using the NVIDIA OptiX GPU ray tracing engine. In Proceedings of the 2012 6th European Conference on Antennas and Propagation (EUCAP), Prague, Czech Republic, 26–30 March 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 488–492. [Google Scholar] [CrossRef]

- Yun, Z.; Iskander, M.F. Ray Tracing for Radio Propagation Modeling: Principles and Applications. IEEE Access 2015, 3, 1089–1100. [Google Scholar] [CrossRef]

- Topak, A.E.; Hash, J.; Zwick, T. A system simulation of a 77 GHz phased array radar sensor. In Proceedings of the 12th International Radar Symposium (IRS) 2011, Leipzig, Germany, 7–9 September 2011; pp. 175–180. [Google Scholar]

- Eder, T. Simulation of Automotive Radar Point Clouds in Standardized Frameworks; Cuvillier Verlag: Göttingen, Germany, 2021. [Google Scholar]

- Hirsenkorn, N.Q. Modellbildung und Simulation der Fahrzeugumfeldsensorik. Ph.D. Thesis, Technische Universität München, München, Germany, 2018. [Google Scholar]

- Degen, R.; Ott, H.; Overath, F.; Schyr, C.; Leijon, M.; Ruschitzka, M. Methodical Approach to the Development of a Radar Sensor Model for the Detection of Urban Traffic Participants Using a Virtual Reality Engine. J. Transp. Technol. 2021, 11, 179–195. [Google Scholar] [CrossRef]

- Kedzia, J.C.; de Souza, P.; Gruyer, D. Advanced RADAR sensors modeling for driving assistance systems testing. In Proceedings of the 2016 10th European Conference on Antennas and Propagation (EuCAP); IEEE: Piscataway, NJ, USA, 2016; pp. 1–2. [Google Scholar] [CrossRef]

| [23] | [25] | [71] | [30] | [19] | [41] | [43] | [42] | [44] | [67] | [18] | Sum: | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OPERATIONAL | [72] | x | x | 2 | |||||||||

| [38] | x | x | 2 | ||||||||||

| [73] | x | x | x | 3 | |||||||||

| [18] | x | 1 | |||||||||||

| [74] | x | x | 2 | ||||||||||

| [75] | x | 1 | |||||||||||

| [28] | x | 1 | |||||||||||

| [76] | 0 | ||||||||||||

| [77] | x | 1 | |||||||||||

| FUNCTIONAL | [27] | x | x | x | x | 4 | |||||||

| [36] | x | 1 | |||||||||||

| [26] | x | x | x | x | 4 | ||||||||

| [41] | x | x | x | x | x | 5 | |||||||

| [39] | |||||||||||||

| [65] | 0 | ||||||||||||

| [78] | x | x | x | 3 | |||||||||

| [79] | 0 | ||||||||||||

| [33] | x | x | 2 | ||||||||||

| [64] | 0 | ||||||||||||

| [80] | 0 | ||||||||||||

| [81] | x | 1 | |||||||||||

| [82] | 0 | ||||||||||||

| [83] | x | 1 | |||||||||||

| [29] | x | x | x | x | x | x | 6 | ||||||

| [84] | 0 | ||||||||||||

| [24] | x | x | 2 | ||||||||||

| [71] | x | 1 | |||||||||||

| [85] | 0 | ||||||||||||

| [86] | 0 | ||||||||||||

| [87] | 0 | ||||||||||||

| [37] | x | x | 2 | ||||||||||

| [30] | 0 | ||||||||||||

| [88] | x | 1 | |||||||||||

| [89] | x | 1 | |||||||||||

| [90] | x | 1 | |||||||||||

| [91] | x | 1 | |||||||||||

| [57] | x | 1 | |||||||||||

| [92] | x | 1 | |||||||||||

| [93] | x | 1 | |||||||||||

| [94] | x | 1 | |||||||||||

| [95] | x | 1 | |||||||||||

| [96] | 0 | ||||||||||||

| [97] | 0 | ||||||||||||

| [98] | x | 1 | |||||||||||

| [99] | x | x | 2 | ||||||||||

| TECHNICAL | [45] | 0 | |||||||||||

| [46] | 0 | ||||||||||||

| [47] | 0 | ||||||||||||

| [48] | 0 | ||||||||||||

| [49] | 0 | ||||||||||||

| [50] | x | 1 | |||||||||||

| [100] | 0 | ||||||||||||

| [51] | 0 | ||||||||||||

| [52] | 0 | ||||||||||||

| [53] | x | 1 | |||||||||||

| [101] | x | 1 | |||||||||||

| [102] | x | 1 | |||||||||||

| [103] | 0 | ||||||||||||

| [54] | x | x | 2 | ||||||||||

| FUNCTIONAL | [69] | x | 1 | ||||||||||

| [32] | x | x | x | x | x | 5 | |||||||

| [68] | 0 | ||||||||||||

| [67] | x | 1 | |||||||||||

| [70] | 0 | ||||||||||||

| [104] | x | 1 | |||||||||||

| [105] | 0 | ||||||||||||

| [35] | x | x | x | x | 4 | ||||||||

| [106] | x | x | 2 | ||||||||||

| [40] | x | x | 2 | ||||||||||

| [107] | 0 | ||||||||||||

| [108] | 0 | ||||||||||||

| [109] | x | 1 | |||||||||||

| [110] | x | x | 2 | ||||||||||

| [111] | x | 1 | |||||||||||

| [112] | x | 1 | |||||||||||

| [31] | x | 1 | |||||||||||

| [34] | x | 1 | |||||||||||

| [113] | x | 1 | |||||||||||

| [114] | x | x | 2 | ||||||||||

| [115] | x | 1 | |||||||||||

| [116] | x | 1 | |||||||||||

| [117] | x | 1 | |||||||||||

| [118] | x | x | 2 | ||||||||||

| [119] | x | 1 | |||||||||||

| [120] | x | 1 | |||||||||||

| [121] | x | 1 | |||||||||||

| [122] | x | 1 | |||||||||||

| [123] | x | 1 | |||||||||||

| [124] | x | x | 2 | ||||||||||

| [125] | x | 1 | |||||||||||

| [126] | x | 1 | |||||||||||

| [127] | x | 1 | |||||||||||

| [128] | x | 1 | |||||||||||

| [129] | x | 1 | |||||||||||

| [130] | x | 1 | |||||||||||

| [55] | x | 1 | |||||||||||

| [131] | x | 1 | |||||||||||

| [132] | x | 1 | |||||||||||

| [133] | 0 | ||||||||||||

| [134] | 0 | ||||||||||||

| [135] | 0 | ||||||||||||

| [136] | x | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magosi, Z.F.; Li, H.; Rosenberger, P.; Wan, L.; Eichberger, A. A Survey on Modelling of Automotive Radar Sensors for Virtual Test and Validation of Automated Driving. Sensors 2022, 22, 5693. https://doi.org/10.3390/s22155693

Magosi ZF, Li H, Rosenberger P, Wan L, Eichberger A. A Survey on Modelling of Automotive Radar Sensors for Virtual Test and Validation of Automated Driving. Sensors. 2022; 22(15):5693. https://doi.org/10.3390/s22155693

Chicago/Turabian StyleMagosi, Zoltan Ferenc, Hexuan Li, Philipp Rosenberger, Li Wan, and Arno Eichberger. 2022. "A Survey on Modelling of Automotive Radar Sensors for Virtual Test and Validation of Automated Driving" Sensors 22, no. 15: 5693. https://doi.org/10.3390/s22155693

APA StyleMagosi, Z. F., Li, H., Rosenberger, P., Wan, L., & Eichberger, A. (2022). A Survey on Modelling of Automotive Radar Sensors for Virtual Test and Validation of Automated Driving. Sensors, 22(15), 5693. https://doi.org/10.3390/s22155693