Least-Square-Method-Based Optimal Laser Spots Acquisition and Position in Cooperative Target Measurement

Abstract

1. Introduction

2. Related Works

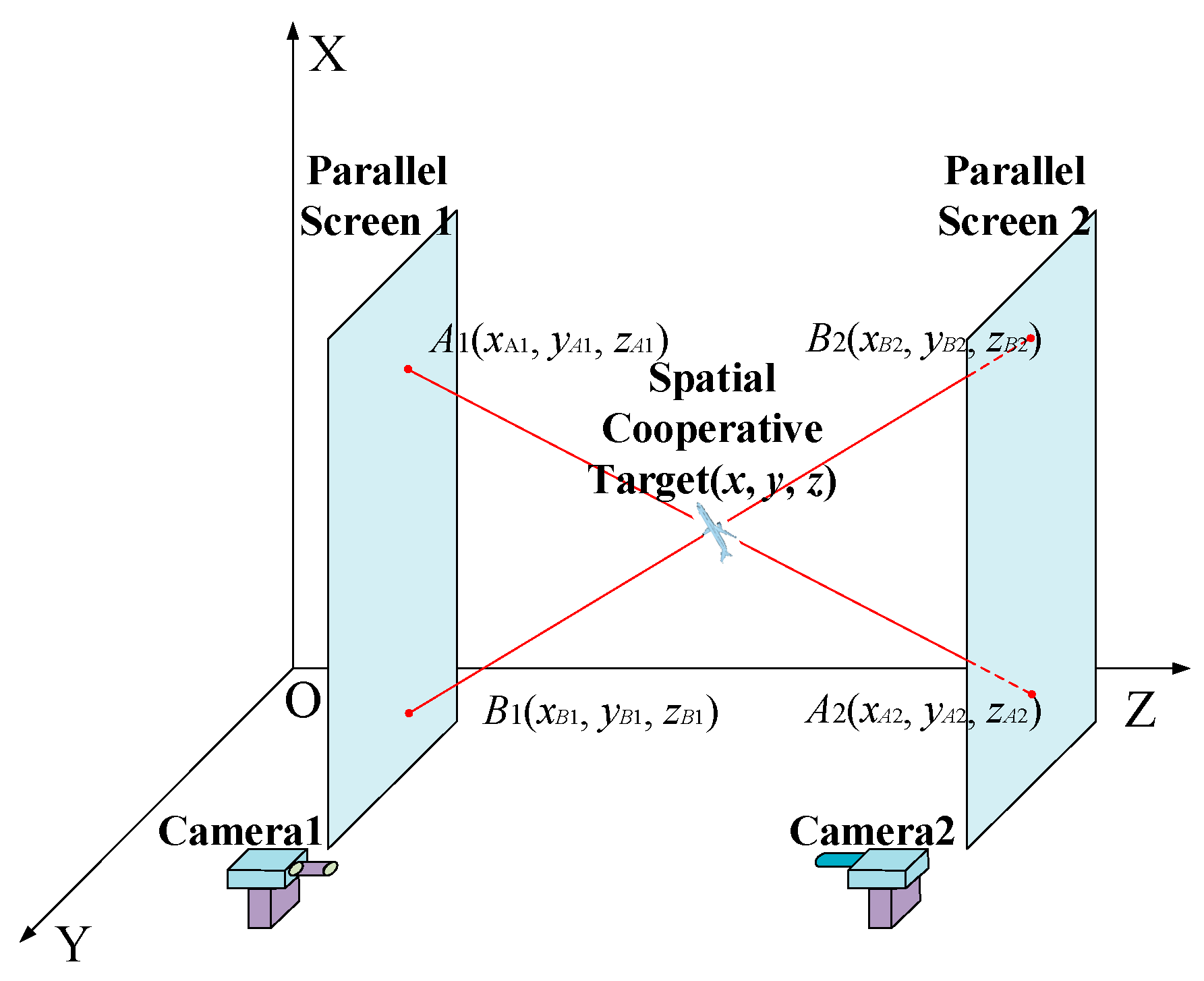

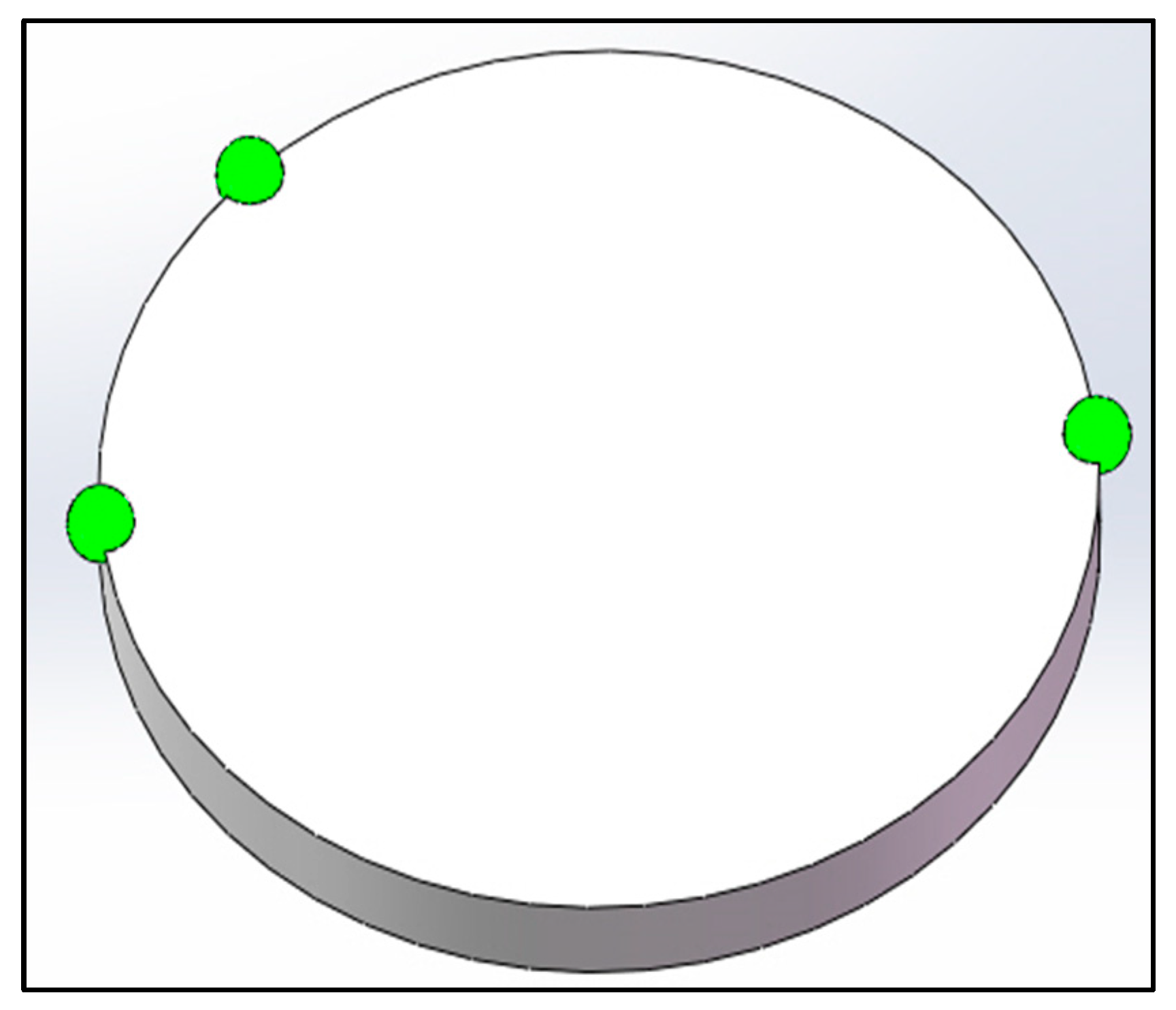

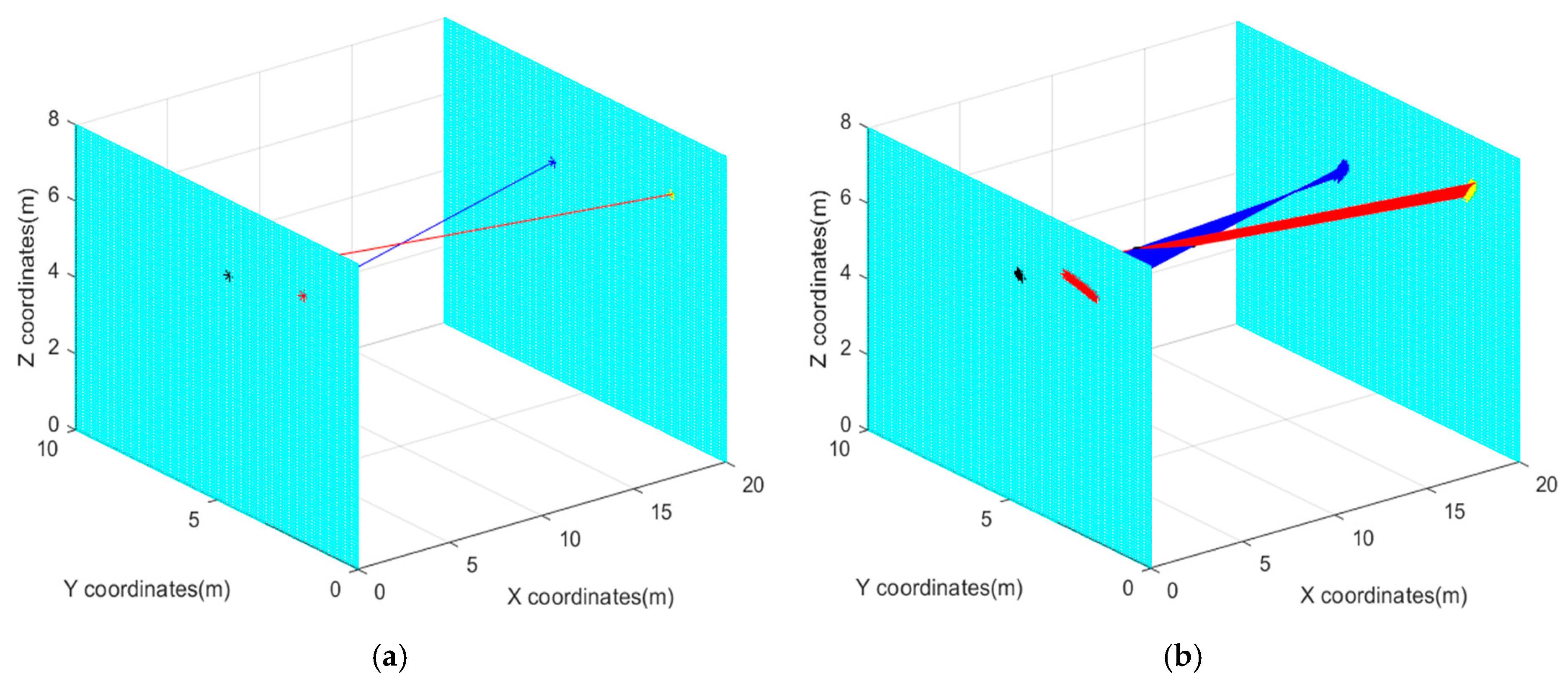

2.1. Position Relationship between Cameras and Target Coordinates

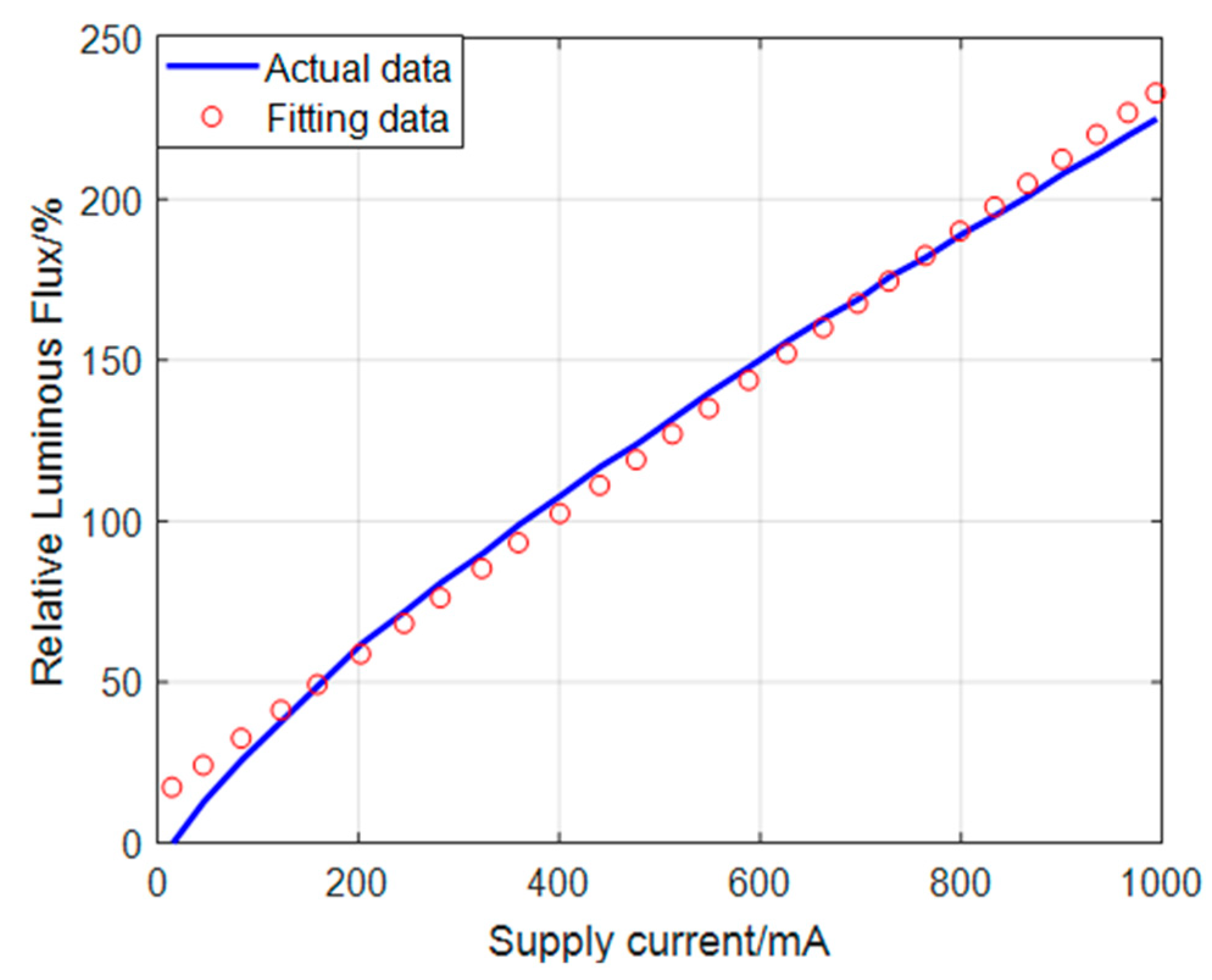

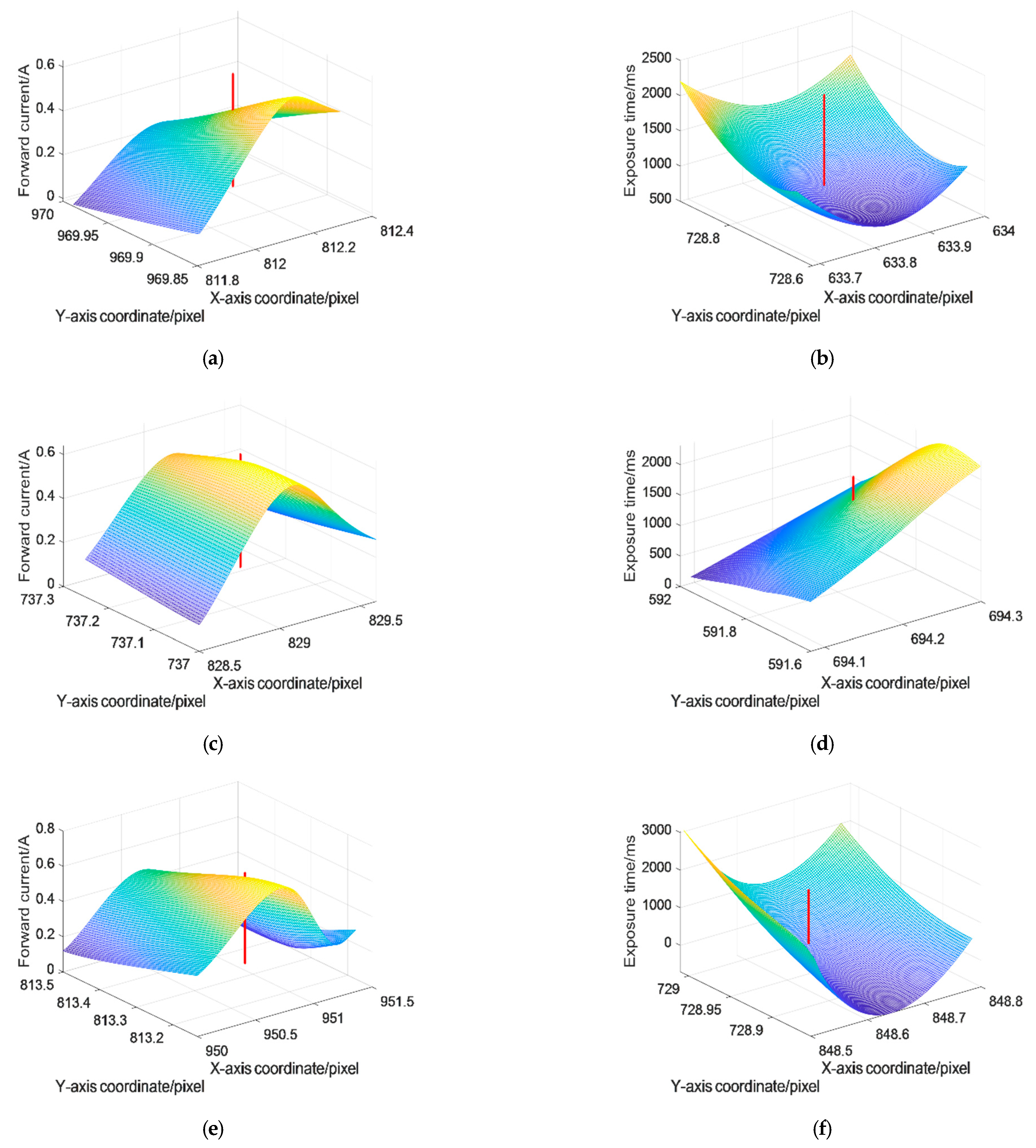

2.2. Laser Lighting Characteristics

2.3. Characteristics of the Camera’s Exposure Time

3. Data and Method

3.1. State Equation of the Imaging System

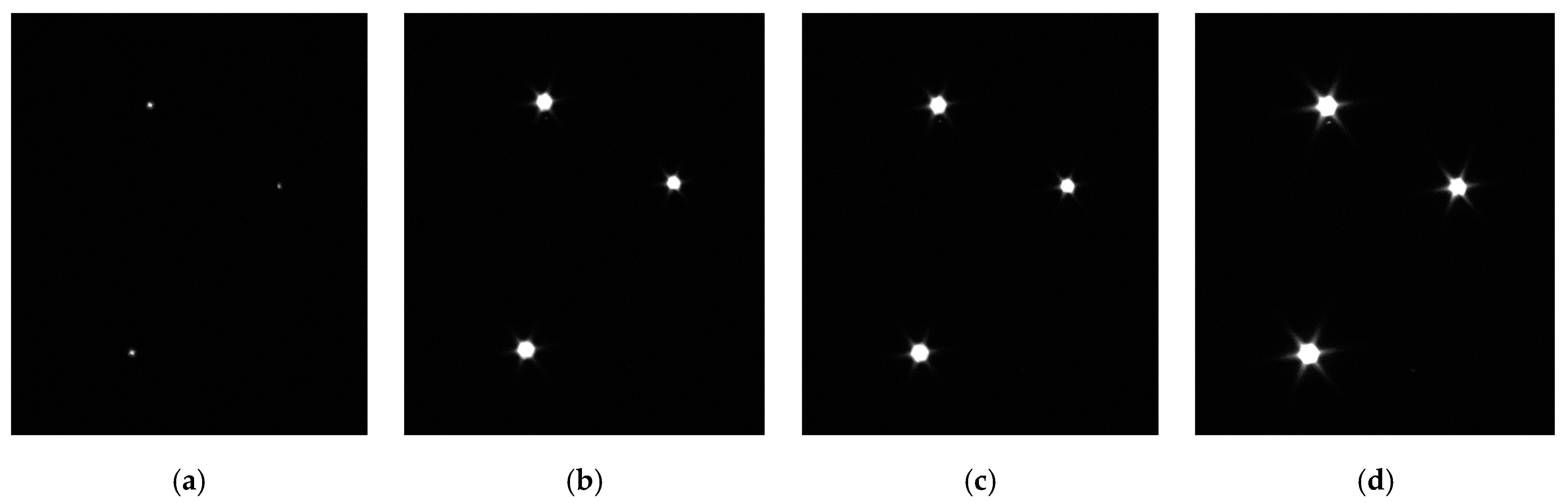

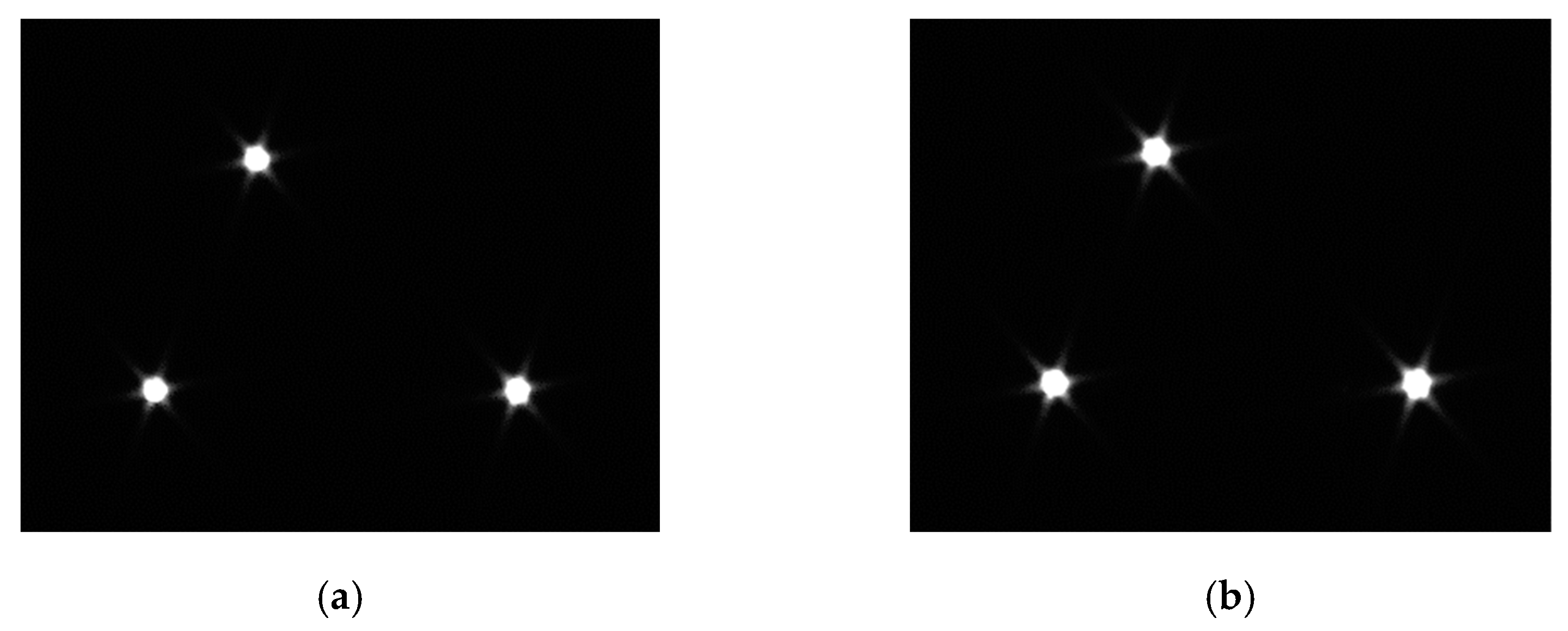

3.2. Acquisition of Experimental Images

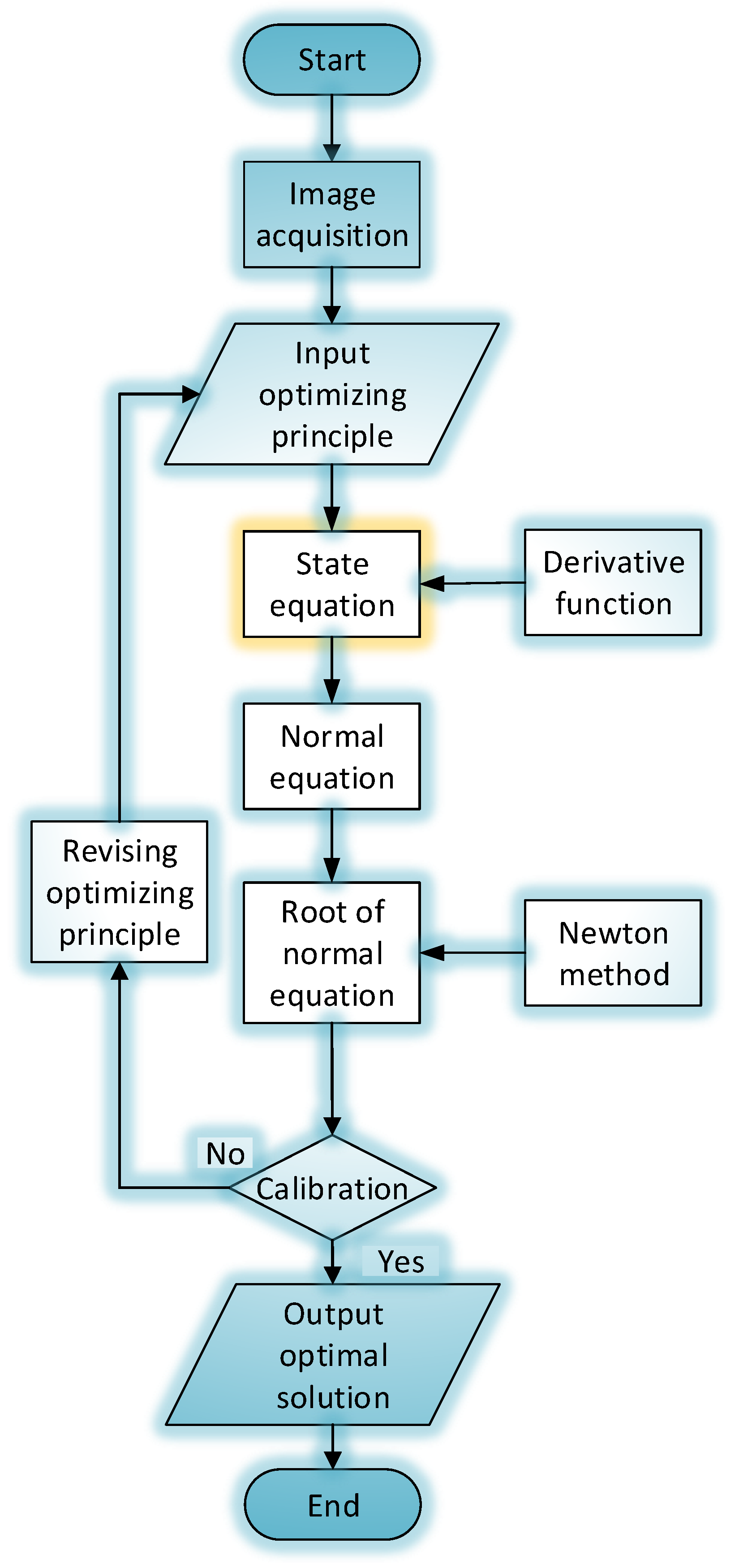

3.3. Optimization Process

3.4. Determination of the Optimal Controllable Variables

4. Experimental Validation

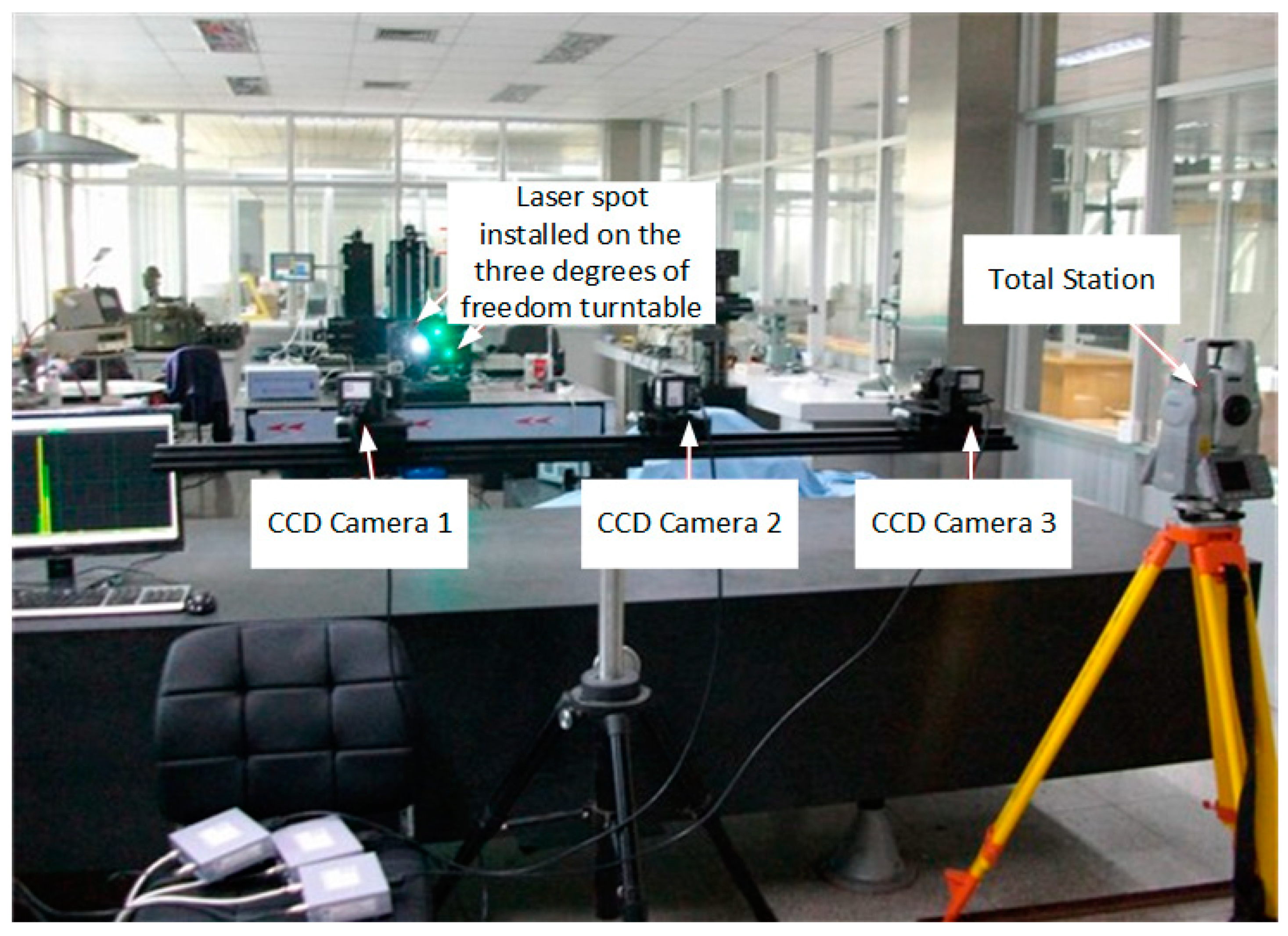

4.1. Experiment Setup

4.2. Experiment Process and Data Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Barnes, R.A.; Brown, S.W.; Lykke, K.R.; Guenther, B.; Xiong, X.; Butler, J.J. Comparison of Two Methodologies for Calibrating Satellite Instruments in the Visible and Near-Infrared. Appl. Opt. 2015, 54, 10376–10395. [Google Scholar] [CrossRef]

- Qi, N.; Xia, Q.; Guo, Y.; Chen, J.; Ma, Z. Pose Measurement Model of Space Cooperative Target Capture based on Zoom Vision System. Adv. Mech. Eng. 2016, 8, 1687814016655954. [Google Scholar] [CrossRef]

- Huo, J.; Yang, N.; Yang, M. Tracking and Recognition of Projective Spots for Cooperation Targets in Vehicle Simulation Test. Opt. Precis. Eng. 2015, 8, 2134–2142. [Google Scholar] [CrossRef]

- Wang, F.; Dong, H.; Chen, Y.; Zheng, N. An Accurate Non-Cooperative Method for Measuring Textureless Spherical Target Based on Calibrated Lasers. Sensors 2016, 16, 2097. [Google Scholar] [CrossRef]

- Yang, N.; Huo, J.; Yang, M. A Method for Attitude Measurement of A Test Vehicle based on the Tracking of Vectors. Meas. Technol. 2015, 26, 085019. [Google Scholar] [CrossRef]

- Feng, Z.; Huang, L.; Gong, M.; Jin, G. Beam Shaping System Design Using Double Freeform Optical Surfaces. Opt. Express 2013, 12, 14728–14735. [Google Scholar] [CrossRef]

- Singh, R.; Hattuniemi, J.M.; Mäkynen, A.J. Analysis of Accuracy of Laser Spot Centroid Estimation. Proc. SPIE Adv. Laser Technol. 2008, 7022, 354–359. [Google Scholar]

- Liu, X.; Lu, Z.; Wang, X.; Ba, D.; Zhu, C. Micrometer Accuracy Method for Small-Scale Laser Focal Spot Centroid Measurement. Opt. Laser Technol. 2015, 66, 58–62. [Google Scholar] [CrossRef]

- Li, W.C.; Gu, J.Q.; Wang, Y.P. Measurement of Light Spot Size of Laser and of Beam Waist. J. Tianjin Univ. 2002, 3, 358–361. [Google Scholar]

- Teschke, M.; Kedzierski, J.; Finantu-Dinu, E.; Korzec, D.; Engemann, J. High-Speed Photographs of a Dielectric Barrier Atmospheric Pressure Plasma Jet. IEEE Trans. Plasma Sci. 2005, 2, 310–311. [Google Scholar] [CrossRef]

- Chen, R.Q.; Cao, G.; Mao, Z.H. Computation Method of Exposure Time for Space Array CCD Imaging. Comput. Eng. 2012, 12, 1–4. [Google Scholar]

- Tao, H.; Yang, H.; Wang, Y.; Ling, Y. Study on Interference to Imaging Process of Visible CCD Camera by Adjustable Light. Infrared Laser Eng. 2014, 5, 1605–1609. [Google Scholar]

- Hain, R.; Kähler, C.J.; Tropea, C. Comparison of CCD, CMOS, and Intensified Cameras. Exp. Fluids 2007, 42, 403–411. [Google Scholar] [CrossRef]

- King, S. Luminous Intensity of an LED as a Function of Input Power. J. Phys. 2008, 2, 1–4. [Google Scholar]

- Lee, J.U. Photovoltaic Effect in Ideal Carbon Nanotube Diodes. Appl. Phys. Lett. 2005, 7, 073101. [Google Scholar] [CrossRef]

- Gan, B.; Feng, H.; Jin, S. Research on Property of High-Power White LED. Opt. Instrum. 2005, 5, 33–37. [Google Scholar]

- Mullikin, J.C.; van Vliet, L.J.; Netten, H.; van der Feltz, F.R.B.G.; Young, I.T. Methods for CCD Camera Characterization. Proc. SPIE 1994, 2173, 72–84. [Google Scholar]

- Nakajima, H.; Fujikawa, M.; Mori, H.; Kan, H.; Ueda, S.; Kosugi, H.; Anabuki, N.; Hayashida, K.; Tsunemi, H.; Doty, J.P.; et al. Single Event Effect Characterization of the Mixed-Signal ASIC Developed for CCD Camera in Space Use. Nucl. Instrum. Methods Phys. Res. A 2013, 731, 166–171. [Google Scholar] [CrossRef][Green Version]

- Lin, H.; Da, Z.S.; Cao, S.K.; Wang, Z.Z. Algorithm of Focal Spot Reconstruction for Laser Measurement Using the Schlieren Method. Optik 2017, 145, 61–65. [Google Scholar] [CrossRef]

- Hazarika, S.; Hazarika, C.; Das, A. Multiple Filamentation and Control of Properties of Self-Guided Super-Gaussian Laser Beam. Optik 2017, 141, 124–129. [Google Scholar] [CrossRef]

- Al Kamal, I.; Al-Alaoui, M. Online Machine Vision Inspection System for Detecting Coating Defects in Metal Lids. Proc. Int. Multi-Conf. Eng. Comput. Sci. 2008, 2, 1319–1322. [Google Scholar]

- Duan, Z.; Wang, N.; Fu, J.; Zhao, W.; Duan, B.; Zhao, J. High Precision Edge Detection Algorithm for Mechanical Parts. Meas. Sci. Rev. 2018, 18, 65–71. [Google Scholar] [CrossRef]

- Shi, Z.; Song, H.; Chen, H.; Sun, Y. Research on Measurement Accuracy of Laser Tracking System Based on Spherical Mirror with Rotation Errors of Gimbal Mount Axes. Meas. Sci. Rev. 2018, 18, 13–19. [Google Scholar] [CrossRef]

- Guillory, J.; Truong, D.; Wallerand, J.P.; Alexandre, C. Absolute Multilateration-based Coordinate Measurement System Using Retroreflecting Glass Spheres. Precis. Eng. 2022, 73, 214–227. [Google Scholar] [CrossRef]

- Del Alamo, M.B.; Soncco, C.; Helaconde, R.; Alba, J.L.B.; Gago, A.M. Laser Spot Measurement Using Simple Devices. AIP Adv. 2021, 11, 075016. [Google Scholar] [CrossRef]

- Zhu, J.; Xu, Z.; Fu, D.; Hu, C. Laser Spot Center Detection and Comparison Test. Photonic Sens. 2019, 9, 49–52. [Google Scholar] [CrossRef]

- Bedoya, A.; González, J.; Rodríguez-Aseguinolaza, J.; Mendioroz, A.; Sommier, A.; Batsale, J.C.; Pradere, C.; Salazar, A. Measurement of In-Plane Thermal Diffusivity of Solids Moving at Constant Velocity Using Laser Spot Infrared Thermography. Measurement 2019, 134, 519–526. [Google Scholar] [CrossRef]

- Krawczyk-Suszek, M.; Martowska, B.; Sapuła, R. Analysis of the Stability of the Body in a Standing Position When Shooting at a Stationary Target—A Randomized Controlled Trial. Sensors 2022, 22, 368. [Google Scholar] [CrossRef]

- Gawlicki, M.; Jankowski, Ł. Trajectory Identification for Moving Loads by Multicriterial Optimization. Sensors 2021, 21, 304. [Google Scholar] [CrossRef]

- Ferdowsi, M.H.; Sabzikar, E. Optical Target Tracking by Scheduled Range Measurements. Opt. Eng. 2015, 54, 044101. [Google Scholar] [CrossRef][Green Version]

- Papoutsidakis, M.; Kalovrektis, K.; Drosos, C.; Stamoulis, G. Intelligent Design and Algorithms to Control a Stereoscopic Camera on a Robotic Workspace. Int. J. Comput. Appl. 2017, 167, 0975–8887. [Google Scholar] [CrossRef]

- Zhang, Z. A Flexible New Technique for Camera Calibration. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1330–1335. [Google Scholar] [CrossRef]

| Supply Current (A) | Laser 1 (Pixel) | Laser 2 (Pixel) | Laser 3 (Pixel) |

|---|---|---|---|

| 0.12 | (811.81, 969.86) | (828.50, 737.00) | (950.00, 813.50) |

| 0.18 | (812.29, 969.99) | (829.60, 737.25) | (951.18, 813.24) |

| 0.35 | (812.19, 969.94) | (829.33, 737.19) | (951.36, 813.13) |

| 0.63 | (812.13, 969.85) | (829.11, 737.10) | (950.84, 813.22) |

| Exposure Time (ms) | Laser 1 (Pixel) | Laser 2 (Pixel) | Laser 3 (Pixel) |

|---|---|---|---|

| 600 | (633.85, 728.64) | (694.08, 591.74) | (848.58, 728.96) |

| 1000 | (634.00, 728.72) | (694.30, 591.97) | (848.51, 728.86) |

| 1500 | (633.88, 728.92) | (694.19, 591.60) | (848.51, 728.86) |

| 2000 | (633.69, 728.89) | (694.23, 591.71) | (848.78, 729.01) |

| Supply Current (A) | Laser 1 (Pixel2) | Laser 2 (Pixel2) | Laser 3 (Pixel2) |

|---|---|---|---|

| 0.12 | 13 | 13 | 4.5 |

| 0.18 | 130 | 127 | 84 |

| 0.35 | 149.5 | 130 | 86 |

| 0.63 | 235.5 | 212.5 | 159.5 |

| Exposure Time (ms) | Laser 1 (Pixel2) | Laser 2 (Pixel2) | Laser 3 (Pixel2) |

|---|---|---|---|

| 600 | 116.5 | 131 | 134.5 |

| 1000 | 157.5 | 176 | 185.5 |

| 1500 | 225.5 | 229.5 | 241 |

| 2000 | 267 | 296.5 | 308.5 |

| Results | Laser 1 (Pixel) | Laser 2 (Pixel) | Laser 3 (Pixel) |

|---|---|---|---|

| Supply current | (812.11, 969.91) | (829.14, 737.14) | (950.85, 813.27) |

| Exposure time | (633.85, 728.79) | (694.20, 591.76) | (848.60, 728.92) |

| Characteristics | Laser 1 | Laser 2 | Laser 3 |

|---|---|---|---|

| Supply current (A) | 0.47 | 0.60 | 0.58 |

| Exposure time (ms) | 734 | 1610 | 997 |

| Camera Type | Resolution | Optical Size | Pixel Size | Frame Frequency | A/D Transfer Precision | Pixel Depth | Exposure Style | Shutter Time | Laser Wavelength | Field of View Distance |

|---|---|---|---|---|---|---|---|---|---|---|

| MER-500-7UM-L | 2592 × 1944 | 1/2.5 inch | 2.2 µm × 2.2 µm | 7 fps | 12 bit | 8 bit | ERS/GRR | 6 µs–1 s | 480–550 nm | 3 m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Yuan, F.; Hu, Y.; Du, Y.; Chen, W.; Lan, C. Least-Square-Method-Based Optimal Laser Spots Acquisition and Position in Cooperative Target Measurement. Sensors 2022, 22, 5110. https://doi.org/10.3390/s22145110

Li K, Yuan F, Hu Y, Du Y, Chen W, Lan C. Least-Square-Method-Based Optimal Laser Spots Acquisition and Position in Cooperative Target Measurement. Sensors. 2022; 22(14):5110. https://doi.org/10.3390/s22145110

Chicago/Turabian StyleLi, Kai, Feng Yuan, Yinghui Hu, Yongbin Du, Wei Chen, and Chunyun Lan. 2022. "Least-Square-Method-Based Optimal Laser Spots Acquisition and Position in Cooperative Target Measurement" Sensors 22, no. 14: 5110. https://doi.org/10.3390/s22145110

APA StyleLi, K., Yuan, F., Hu, Y., Du, Y., Chen, W., & Lan, C. (2022). Least-Square-Method-Based Optimal Laser Spots Acquisition and Position in Cooperative Target Measurement. Sensors, 22(14), 5110. https://doi.org/10.3390/s22145110