Trajectory Planning and Simulation Study of Redundant Robotic Arm for Upper Limb Rehabilitation Based on Back Propagation Neural Network and Genetic Algorithm

Abstract

:1. Introduction

2. Back Propagation Neural Network Algorithm Based on Genetic Algorithm Optimization

2.1. Principles of Back Propagation Neural Network and Genetic Algorithm

2.1.1. Back Propagation Neural Network

2.1.2. Genetic Algorithm

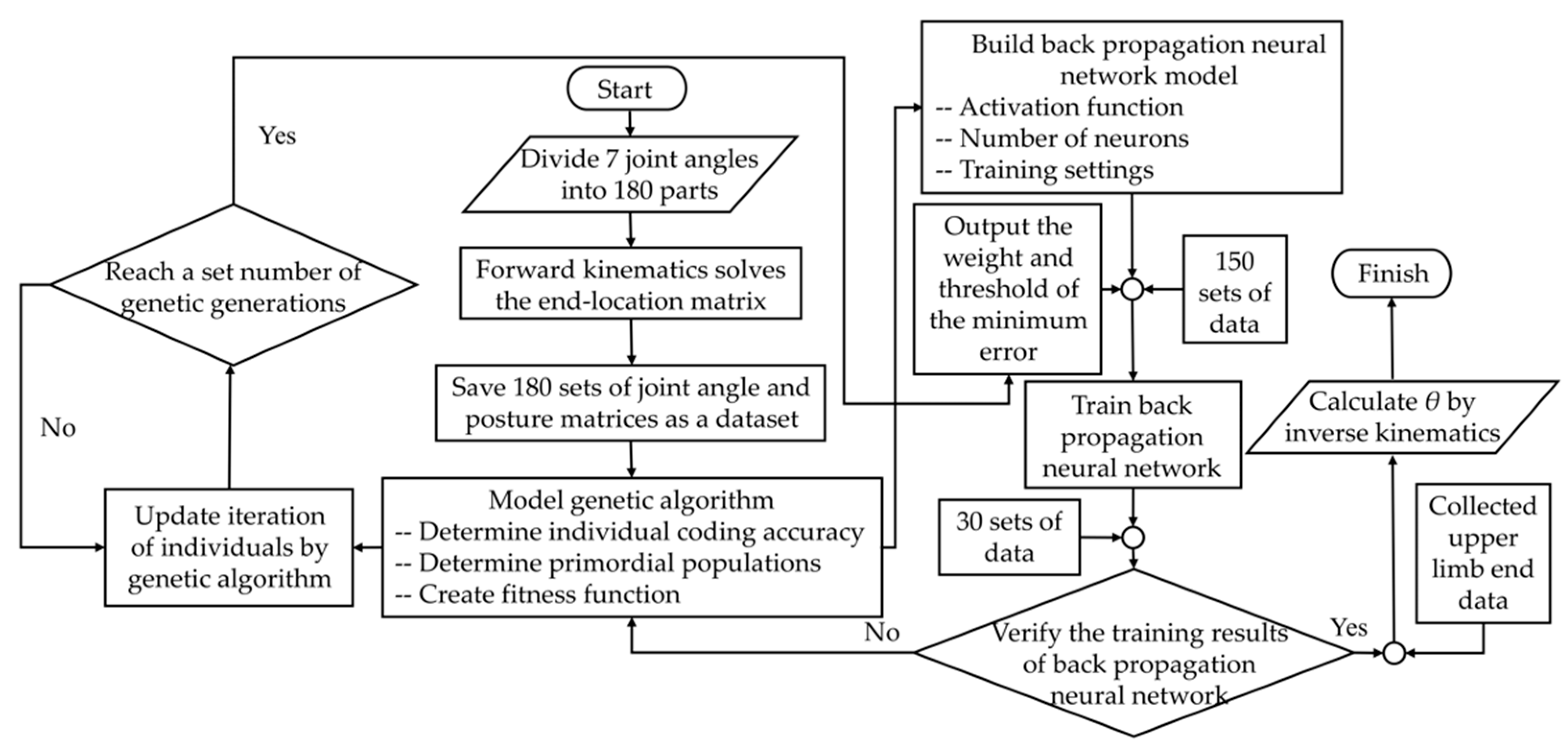

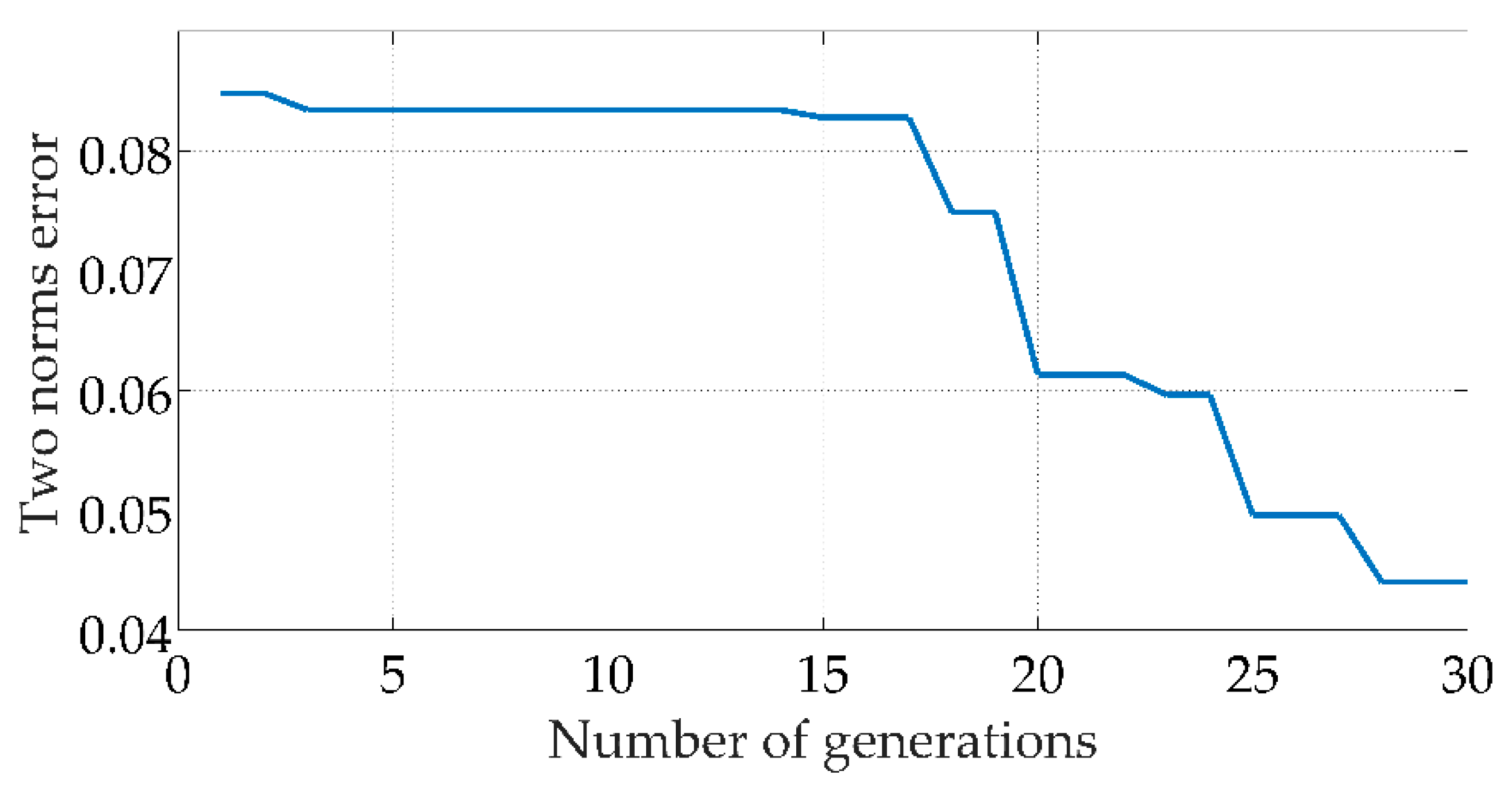

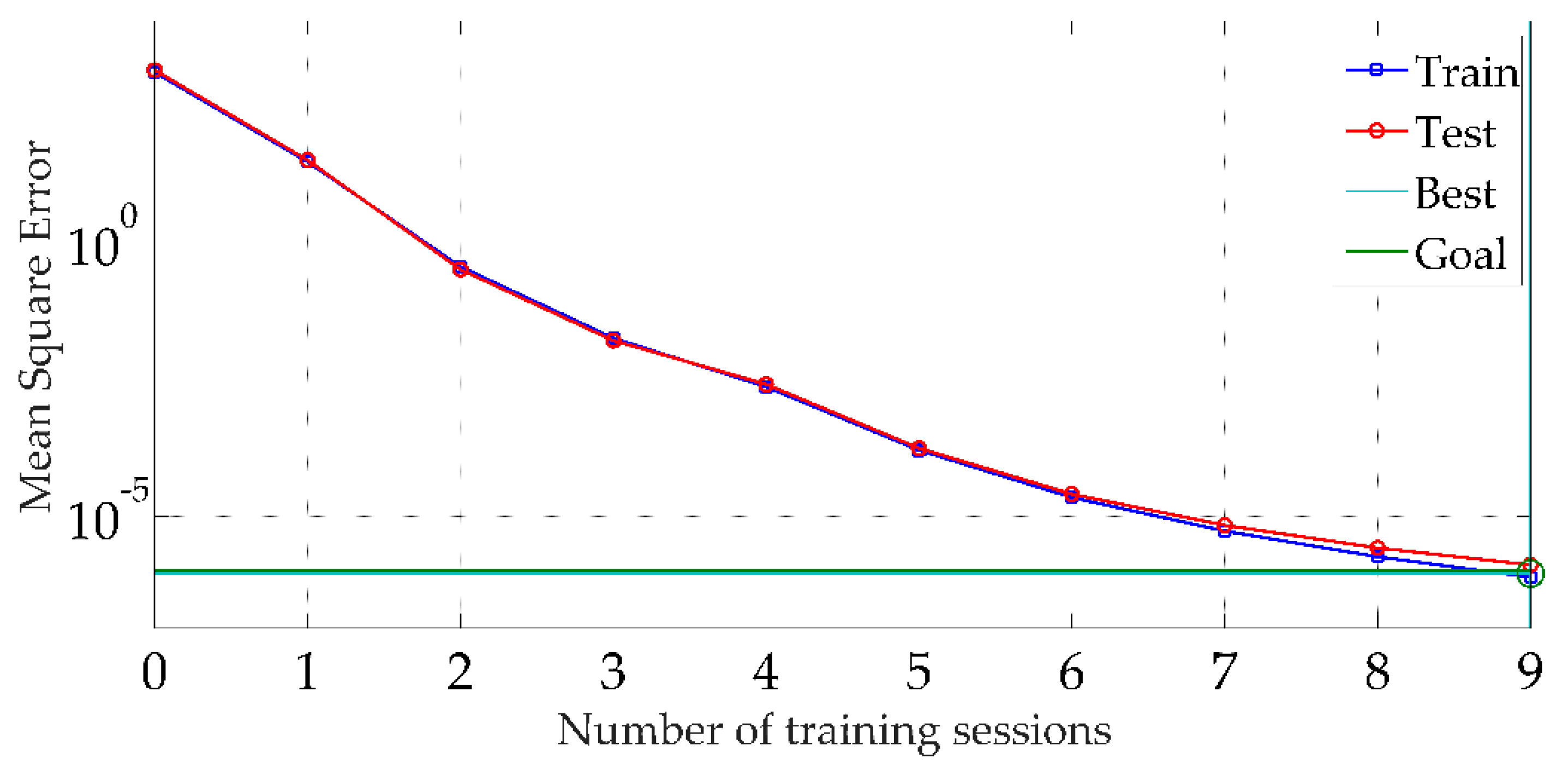

2.2. Computational Procedure of Back Propagation Neural Network Algorithm Based on Genetic Algorithm Optimization

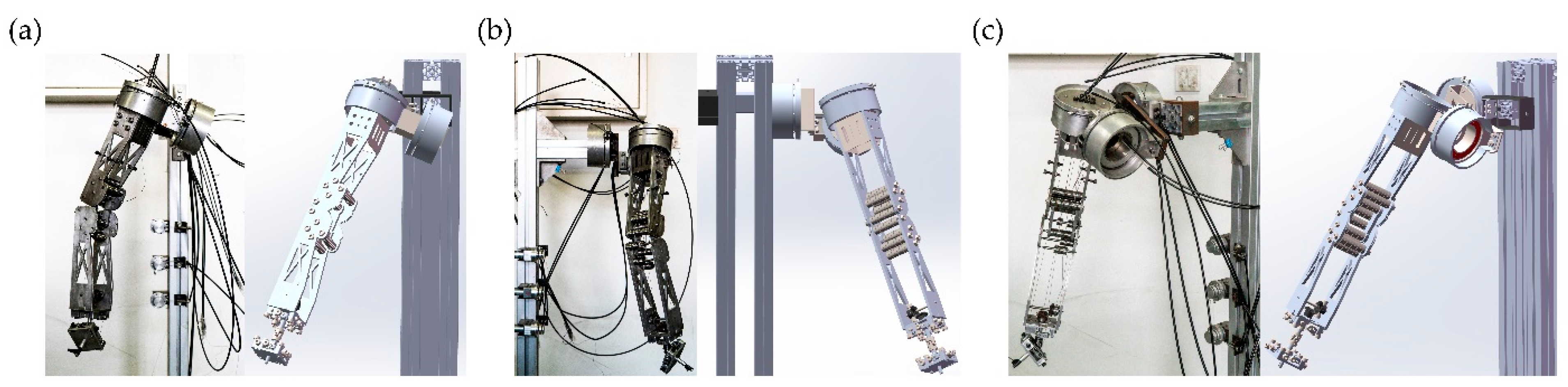

3. Trajectory Planning of Redundant Robotic Arm for Upper Limb Rehabilitation

3.1. Derivation of Cubic B−Spline Interpolation

3.2. Rehabilitation Trajectory Planning for Redundant Robotic Arm for Upper Limb Rehabilitation

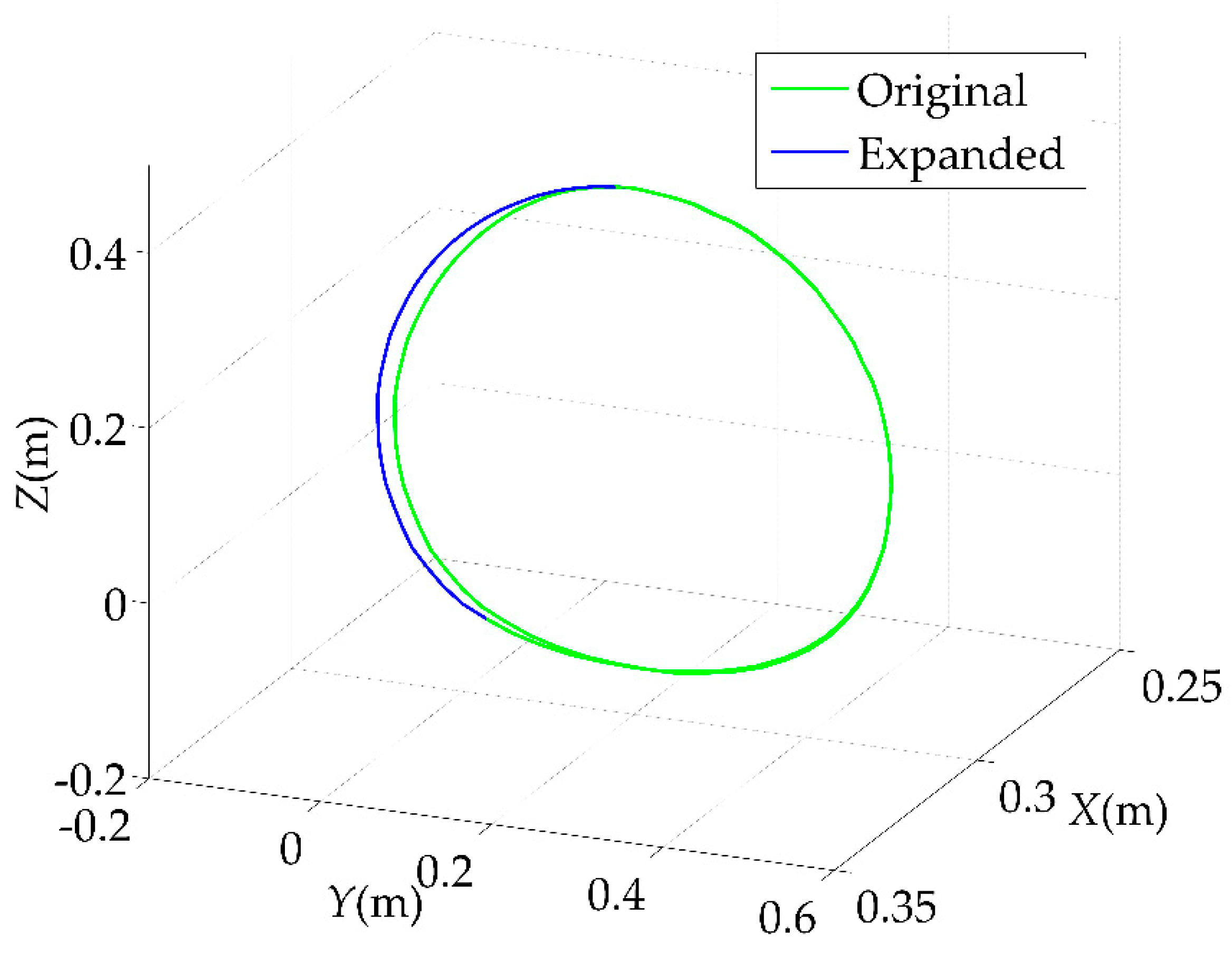

3.2.1. Rehabilitation Trajectory Planning under Cartesian Space

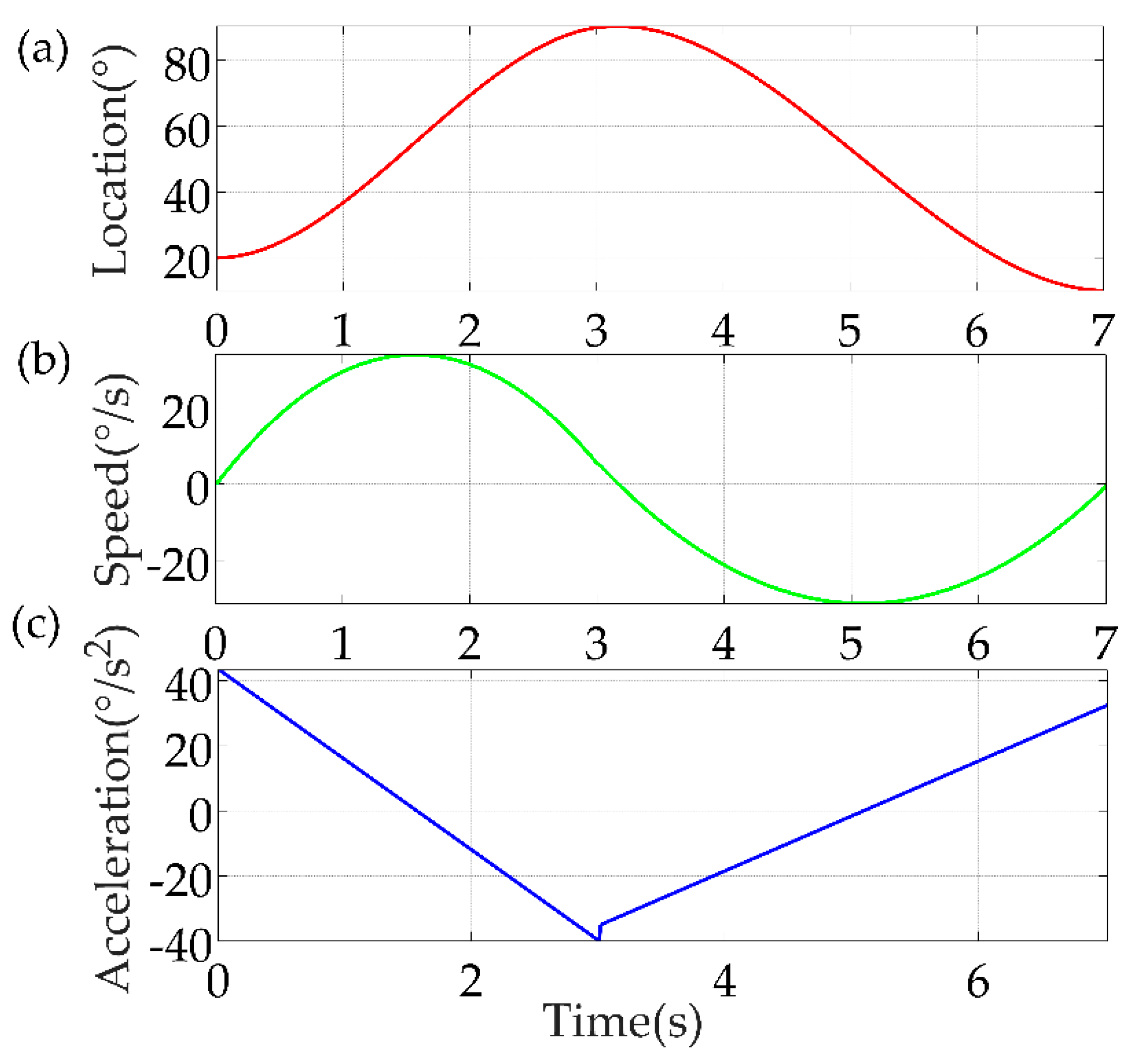

3.2.2. Joint Kinematic Analysis of Redundant Robotic Arm for Upper Limb Rehabilitation

4. Optimization of Rehabilitation Trajectory of Redundant Robotic Arm for Upper Limb Rehabilitation and Its Simulation Experiment

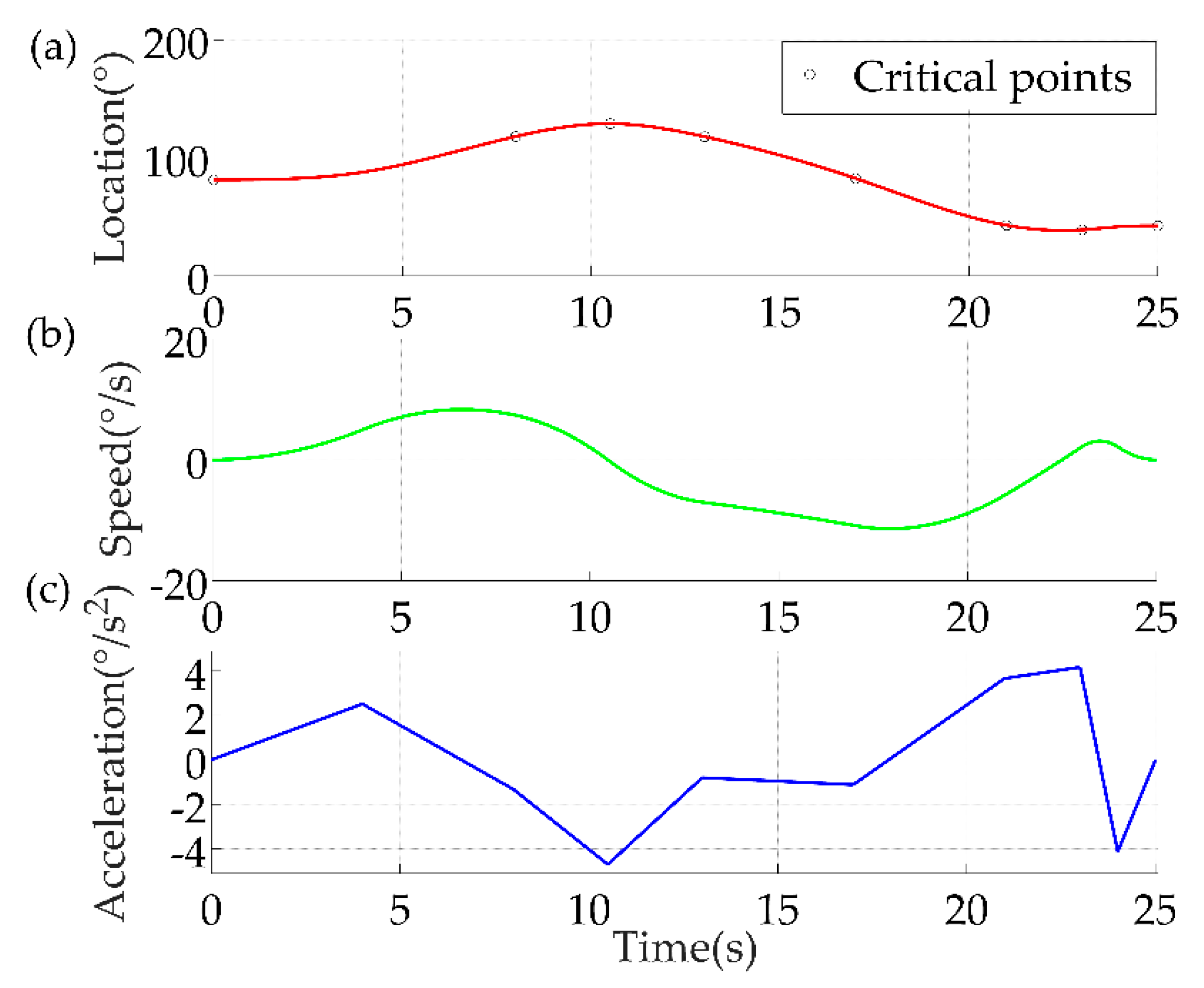

4.1. Optimization of Rehabilitation Trajectories with the Goal of Time Minimization

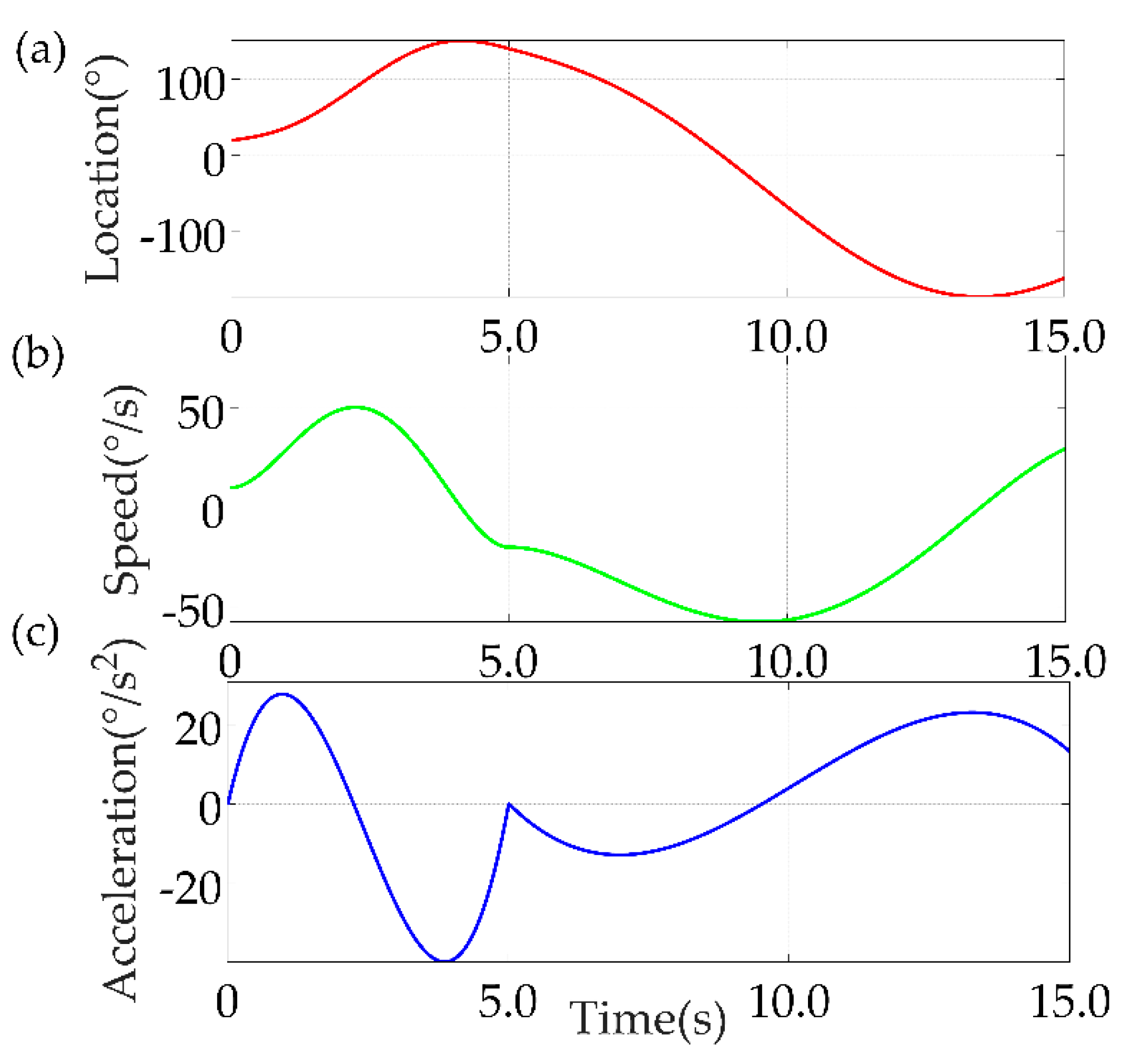

4.2. MATLAB Numerical Simulation of Redundant Robotic Arm for Upper Limb Rehabilitation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, C.; Liu, Z.; Chen, S.; Jiang, X. Circular trajectory weaving welding control algorithm based on space transformation principle. J. Manuf. Processes 2019, 46, 328–336. [Google Scholar] [CrossRef]

- Kang, C.; Shi, C.; Liu, Z.; Liu, Z.; Jiang, X.; Chen, S.; Ma, C. Research on the optimization of welding parameters in high-frequency induction welding pipeline. J. Manuf. Processes 2020, 59, 772–790. [Google Scholar] [CrossRef]

- Li, J.; Hu, M.; Wang, Z.; Lu, Y.; Wang, K.; Zhu, X. The scaling of the ligand concentration and Soret effect induced phase transition in CsPbBr 3 perovskite quantum dots. J. Mater. Chem. A 2019, 7, 27241–27246. [Google Scholar] [CrossRef]

- Bodner, J.; Wykypiel, H.; Wetscher, G.; Schmid, T. First experiences with the da Vinci™ operating robot in thoracic surgery. Eur. J. Cardiothorac. Surg. 2004, 25, 844–851. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Johnston, S.C.; Mendis, S.; Mathers, C.D. Global variation in stroke burden and mortality: Estimates from monitoring, surveillance, and modelling. Lancet Neurol. 2009, 8, 345–354. [Google Scholar] [CrossRef]

- Kim, G.Y.; Ahn, C.S.; Jeon, H.W.; Lee, C.R. Effects of the use of smartphones on pain and muscle fatigue in the upper extremity. J. Phys. Thr. Sci. 2012, 24, 1255–1258. [Google Scholar] [CrossRef] [Green Version]

- Fares, M.Y.; Salhab, H.A.; Khachfe, H.H.; Kane, L.; Fares, Y.; Fares, J.; Abboud, J.A. Upper limb injuries in major league baseball. Phys. Ther. Sport 2020, 41, 49–54. [Google Scholar] [CrossRef]

- Norrving, B.; Kissela, B. The global burden of stroke and need for a continuum of care. Neurology 2013, 80, S5–S12. [Google Scholar] [CrossRef]

- Chen, G.; Xiao, X.; Zhao, X.; Tat, T.; Bick, M.; Chen, J. Electronic textiles for wearable point-of-care systems. Chem. Rev. 2021, 122, 3259–3291. [Google Scholar] [CrossRef]

- Langhorne, P.; Bernhardt, J.; Kwakkel, G. Stroke rehabilitation. Lancet 2011, 377, 1693–1702. [Google Scholar] [CrossRef]

- Richardson, R.; Brown, M.; Bhakta, B.; Levesley, M. Design and control of a three degree of freedom pneumatic physiotherapy robot. Robotica 2003, 21, 589–604. [Google Scholar] [CrossRef]

- Johnson, G.; Carus, D.; Parrini, G.; Marchese, S.; Valeggi, R. The design of a five-degree-of-freedom powered orthosis for the upper limb. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2001, 215, 275–284. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.; Wei, C.; Guo, S.; Xiao, N.; Bu, D.; Xu, H.; Ma, H. Embedded system-based a portable upper limb rehabilitation robot. In Proceedings of the 2018 IEEE International Conference on Mechatronics and Automation (ICMA), Changchun, China, 5–8 August 2018; pp. 631–636. [Google Scholar] [CrossRef]

- Costa, M.A.; Wullt, B.; Norrlöf, M.; Gunnarsson, S. Failure detection in robotic arms using statistical modeling, machine learning and hybrid gradient boosting. Measurement 2019, 146, 425–436. [Google Scholar] [CrossRef] [Green Version]

- Li, X.-Q.; Song, L.-K.; Bai, G.-C. Deep learning regression-based stratified probabilistic combined cycle fatigue damage evaluation for turbine bladed disks. Int. J. Fatigue 2022, 159, 106812. [Google Scholar] [CrossRef]

- Makarem, S.; Delibas, B.; Koc, B. Data-driven tuning of PID controlled piezoelectric ultrasonic motor. Actuators 2021, 10, 148. [Google Scholar] [CrossRef]

- M Zahir, A.; Alhady, S.; Othman, W.; Ahmad, M. Genetic algorithm optimization of PID controller for brushed DC motor. In Intelligent Manufacturing & Mechatronics; Hassan, M., Ed.; Springer: Singapore, 2018; pp. 427–437. [Google Scholar] [CrossRef]

- Xiao, X.; Fang, Y.; Xiao, X.; Xu, J.; Chen, J. Machine-Learning-Aided Self-Powered Assistive Physical Therapy Devices. ACS Nano 2021, 15, 18633–18646. [Google Scholar] [CrossRef]

- Tejomurtula, S.; Kak, S. Inverse kinematics in robotics using neural networks. Inf. Sci. 1999, 116, 147–164. [Google Scholar] [CrossRef]

- Nearchou, A.C. Solving the inverse kinematics problem of redundant robots operating in complex environments via a modified genetic algorithm. Mech. Mach. Theory 1998, 33, 273–292. [Google Scholar] [CrossRef]

- KöKer, R. A genetic algorithm approach to a neural-network-based inverse kinematics solution of robotic manipulators based on error minimization. Inf. Sci. 2013, 222, 528–543. [Google Scholar] [CrossRef]

- Gasparetto, A.; Boscariol, P.; Lanzutti, A.; Vidoni, R. Path planning and trajectory planning algorithms: A general overview. In Motion Operation Planning of Robotic Systems; Carbone, G., Gomez-Bravo, F., Eds.; Springer: Cham, Switzerland, 2015; Volume 29, pp. 3–27. [Google Scholar] [CrossRef]

- Tian, L.; Collins, C. An effective robot trajectory planning method using a genetic algorithm. Mechatronics 2004, 14, 455–470. [Google Scholar] [CrossRef]

- Gasparetto, A.; Zanotto, V. A new method for smooth trajectory planning of robot manipulators. Mech. Mach. Theory 2007, 42, 455–471. [Google Scholar] [CrossRef]

- Ahuactzin, J.M.; Talbi, E.-G.; Bessière, P.; Mazer, E. Using genetic algorithms for robot motion planning. In Geometric Reasoning for Perception and Action; Laugier, C., Ed.; Springer: Berlin/Heidelberg, Germany, 2005; Volume 708, pp. 84–93. [Google Scholar] [CrossRef] [Green Version]

- Han, J.; Moraga, C. The influence of the sigmoid function parameters on the speed of backpropagation learning. In From Natural to Artificial Neural Computation; Mira, J., Sandoval, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; Volume 930, pp. 195–201. [Google Scholar] [CrossRef]

- Sahin, I.; Koyuncu, I. Design and implementation of neural networks neurons with RadBas, LogSig, and TanSig activation functions on FPGA. Elektron. Elektrotechnika 2012, 120, 51–54. [Google Scholar] [CrossRef] [Green Version]

- Rahimi-Ajdadi, F.; Abbaspour-Gilandeh, Y. Artificial neural network and stepwise multiple range regression methods for prediction of tractor fuel consumption. Measurement 2011, 44, 2104–2111. [Google Scholar] [CrossRef]

- Hock, O.; Sedo, J. Inverse kinematics using transposition method for robotic arm. In Proceedings of the 2018 ELEKTRO, Mikulov, Czech Republic, 21–23 May 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Duka, A.-V. Neural network based inverse kinematics solution for trajectory tracking of a robotic arm. Procedia Technol. 2014, 12, 20–27. [Google Scholar] [CrossRef] [Green Version]

- Sui, Z.; Jiang, L.; Tian, Y.-T.; Jiang, W. Genetic algorithm for solving the inverse kinematics problem for general 6r robots. In Proceedings of the 2015 Chinese Intelligent Automation Conference; Deng, Z., Li, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; Volume 338, pp. 151–161. [Google Scholar] [CrossRef]

- Dereli, S.; Köker, R. A meta-heuristic proposal for inverse kinematics solution of 7-DOF serial robotic manipulator: Quantum behaved particle swarm algorithm. Artif. Intell. Rev. 2020, 53, 949–964. [Google Scholar] [CrossRef]

- Jaworski, Ł.; Karpiński, R.; Dobrowolska, A. Biomechanics of the upper limb. J. Technol. Exploit. Mech. Eng. 2016, 2, 53–59. [Google Scholar] [CrossRef]

| Group | Joint #1 (rad) | Joint #2 (rad) | Joint #3 (rad) | Joint #4 (rad) | Joint #5 (rad) | Joint #6 (rad) | Joint #7 (rad) |

|---|---|---|---|---|---|---|---|

| 1 | −1.4765 | 0.1257 | 0.0768 | −1.8431 | −1.4451 | −0.5515 | −0.5515 |

| 2 | −1.4718 | 0.1319 | 0.0806 | −1.8392 | −1.4388 | −0.5486 | −0.5486 |

| 3 | −1.4671 | 0.1382 | 0.0845 | −1.8354 | −1.4326 | −0.5456 | −0.5456 |

| 4 | −1.4624 | 0.1445 | 0.0883 | −1.8315 | −1.4263 | −0.5426 | −0.5426 |

| 5 | −1.4577 | 0.1508 | 0.0922 | −1.8277 | −1.4200 | −0.5397 | −0.5397 |

| 6 | −1.4530 | 0.1571 | 0.0960 | −1.8239 | −1.4137 | −0.5367 | −0.5367 |

| 7 | −1.4483 | 0.1634 | 0.0998 | −1.8200 | −1.4074 | −0.5337 | −0.5337 |

| 8 | −1.4436 | 0.1696 | 0.1037 | −1.8162 | −1.4012 | −0.5308 | −0.5308 |

| 9 | −1.4388 | 0.1759 | 0.1075 | −1.8123 | −1.3949 | −0.5278 | −0.5278 |

| 10 | −1.4341 | 0.1822 | 0.1114 | −1.8085 | −1.3886 | −0.5248 | −0.5248 |

| Group | Joint #1 (rad) | Joint #2 (rad) | Joint #3 (rad) | Joint #4 (rad) | Joint #5 (rad) | Joint #6 (rad) | Joint #7 (rad) |

|---|---|---|---|---|---|---|---|

| 1 | −1.4772 | 0.1253 | 0.0763 | −1.8426 | −1.4448 | −0.5510 | −0.5508 |

| 2 | −1.4723 | 0.1314 | 0.0802 | −1.8389 | −1.4385 | −0.5481 | −0.5480 |

| 3 | −1.4674 | 0.1376 | 0.0841 | −1.8352 | −1.4322 | −0.5452 | −0.5452 |

| 4 | −1.4625 | 0.1438 | 0.0881 | −1.8315 | −1.4259 | −0.5424 | −0.5423 |

| 5 | −1.4576 | 0.1500 | 0.0920 | −1.8278 | −1.4196 | −0.5395 | −0.5395 |

| 6 | −1.4527 | 0.1561 | 0.0959 | −1.8241 | −1.4133 | −0.5366 | −0.5367 |

| 7 | −1.4478 | 0.1632 | 0.0998 | −1.8204 | −1.4071 | −0.5337 | −0.5338 |

| 8 | −1.4429 | 0.1685 | 0.1038 | −1.8167 | −1.4008 | −0.5309 | −0.5310 |

| 9 | −1.4380 | 0.1747 | 0.1077 | −1.8130 | −1.3945 | −0.5280 | −0.5282 |

| 10 | −1.4331 | 0.1809 | 0.1116 | −1.8093 | −1.3882 | −0.5251 | −0.5254 |

| Method | Degree of Freedom | Maximum Error | Mean Square Error |

|---|---|---|---|

| This study | 7DOF | 0.002 rad | Approx. 1 10−6 |

| Jacobian transpose [29] | 3DOF | Approx. 1 27 mm | |

| Neural network [30] | Planar two and three−link manipulators | Approx. 1 0.1 rad | Between 10−2 and 10−3 |

| MPGA 2 [31] | 6DOF | The error is of order 10−2 | |

| FA 3 [32] | 7DOF | 6.538 × 10−2 mm | 1.4547 × 10−5 |

| ABC 4 [32] | 7DOF | 0.5475 mm | 1.1105 × 10−6 |

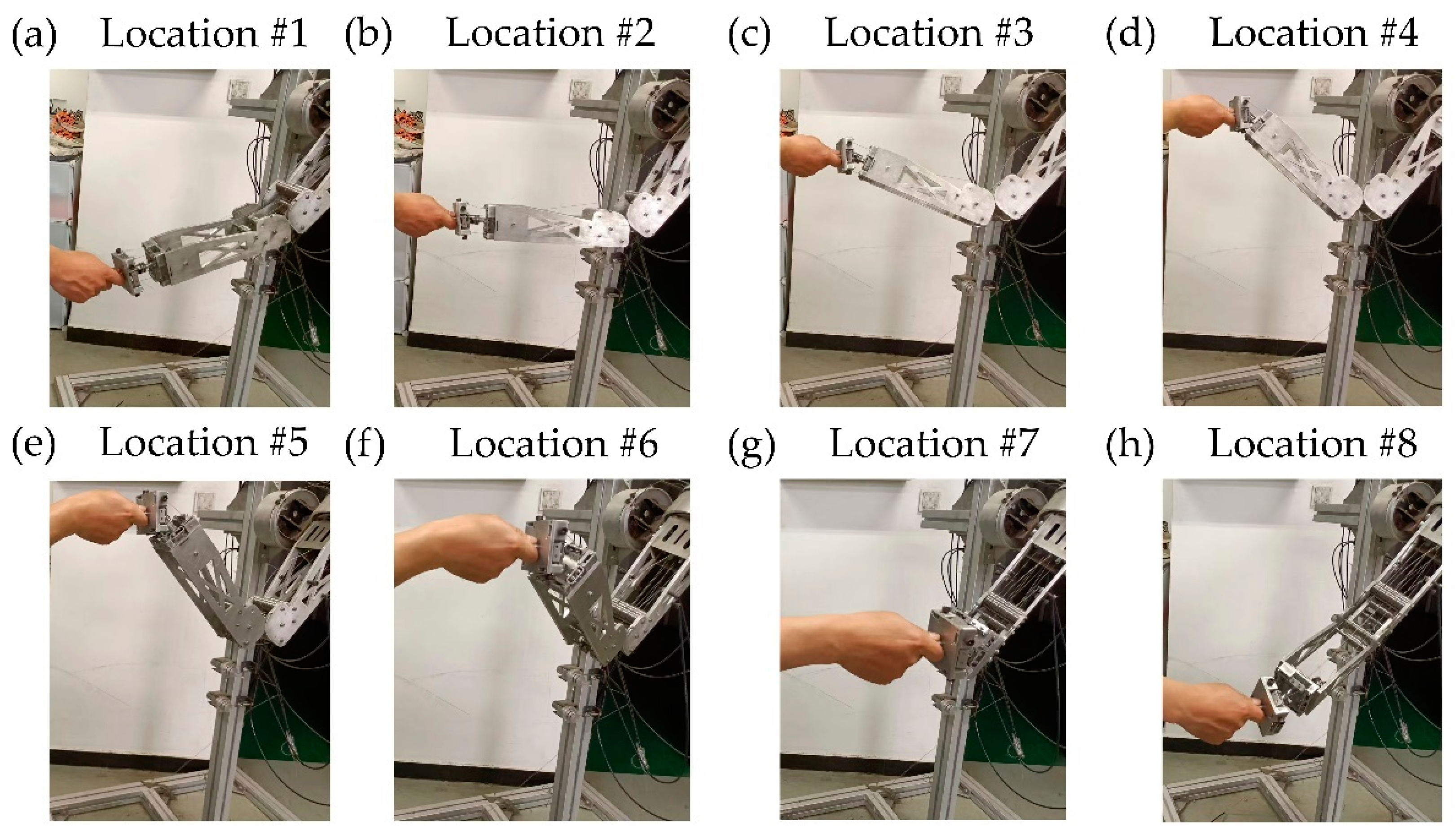

| Track Points | Angle (°) | Specify Time (s) | Optimized Time (s) |

|---|---|---|---|

| 1~2 | 81.40~118.09 | 8.0 | 6.84 |

| 2~3 | 118.09~128.92 | 2.5 | 2.05 |

| 3~4 | 128.92~117.92 | 2.5 | 1.96 |

| 4~5 | 117.92~82.55 | 4.0 | 3.18 |

| 5~6 | 82.55~42.88 | 4.0 | 3.75 |

| 6~7 | 42.88~38.98 | 2.0 | 1.32 |

| 7~8 | 38.98~42.42 | 2.0 | 1.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qie, X.; Kang, C.; Zong, G.; Chen, S. Trajectory Planning and Simulation Study of Redundant Robotic Arm for Upper Limb Rehabilitation Based on Back Propagation Neural Network and Genetic Algorithm. Sensors 2022, 22, 4071. https://doi.org/10.3390/s22114071

Qie X, Kang C, Zong G, Chen S. Trajectory Planning and Simulation Study of Redundant Robotic Arm for Upper Limb Rehabilitation Based on Back Propagation Neural Network and Genetic Algorithm. Sensors. 2022; 22(11):4071. https://doi.org/10.3390/s22114071

Chicago/Turabian StyleQie, Xiaohan, Cunfeng Kang, Guanchen Zong, and Shujun Chen. 2022. "Trajectory Planning and Simulation Study of Redundant Robotic Arm for Upper Limb Rehabilitation Based on Back Propagation Neural Network and Genetic Algorithm" Sensors 22, no. 11: 4071. https://doi.org/10.3390/s22114071

APA StyleQie, X., Kang, C., Zong, G., & Chen, S. (2022). Trajectory Planning and Simulation Study of Redundant Robotic Arm for Upper Limb Rehabilitation Based on Back Propagation Neural Network and Genetic Algorithm. Sensors, 22(11), 4071. https://doi.org/10.3390/s22114071