Estimation of Elbow Wall Thinning Using Ensemble-Averaged Mel-Spectrogram with ResNet-like Architecture

Abstract

1. Introduction

2. Materials and Methods

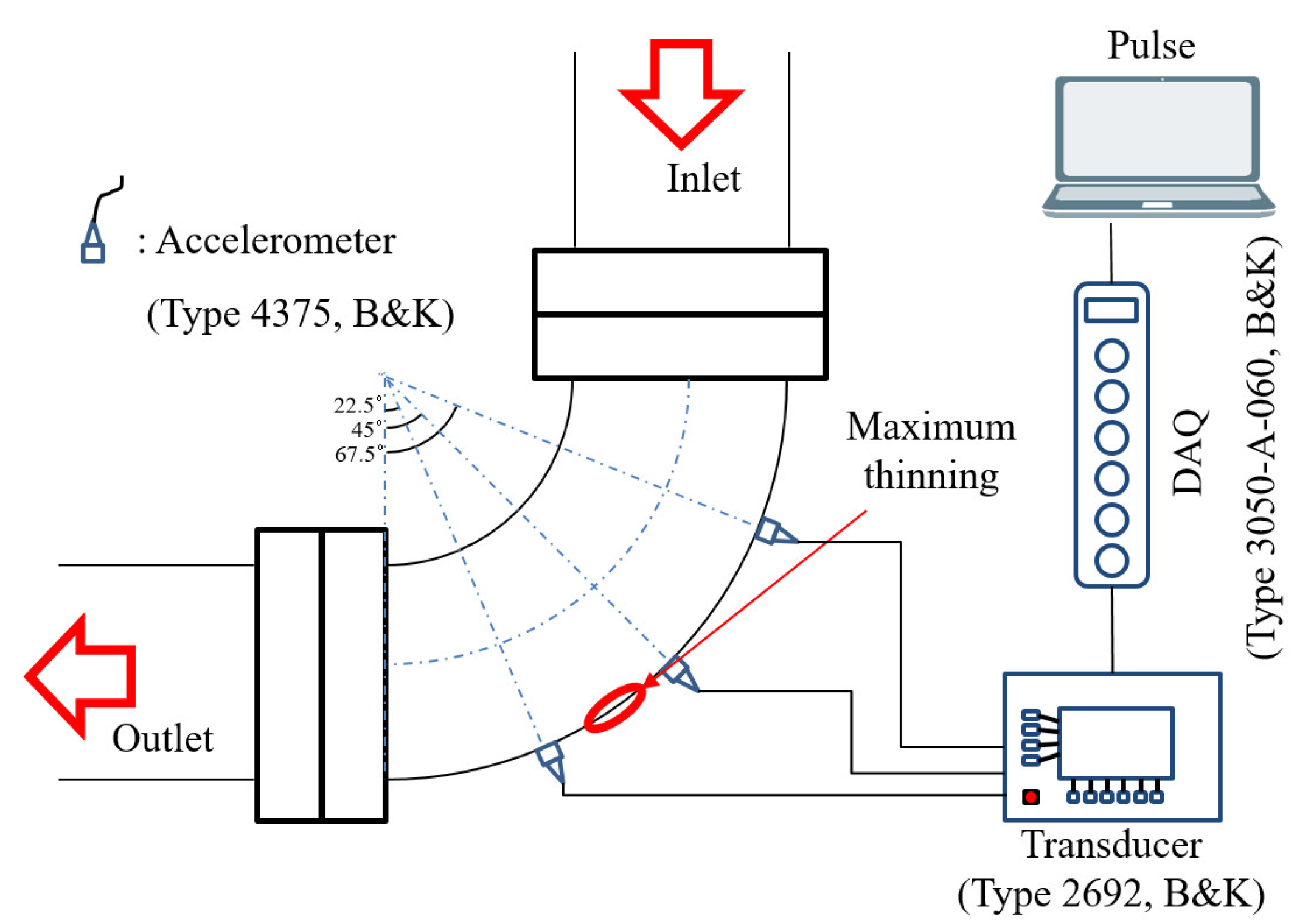

2.1. Fabrication and Experiments of Pipe Wall Thinning

2.2. Data Preparation for Predicting Elbow Wall Thinning

2.3. CNN Model Development for Predicting the Wall Thinning Thickness

3. Results

3.1. CNN Model Evaluation Using Experiments Data

3.1.1. Loss of CNN Model

3.1.2. Model Evaluation Using Test Dataset

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Remy, F.N.; Bouchacourt, M. Flow-assisted corrosion: A method to avoid damage. Nucl. Eng. Des. 1992, 133, 23–30. [Google Scholar] [CrossRef]

- Wu, P.C. Erosion/Corrosion-Induced Pipe Wall Thinning in US Nuclear Power Plants; No. NUREG-1344; US Nuclear Regulatory Commission (NRC): Washington, DC, USA, 1989.

- Matsumura, M. A case study of a pipe line burst in the Mihama Nuclear Power Plant. Mater. Corros. 2006, 57, 872–882. [Google Scholar] [CrossRef]

- Schefski, C.; Hazelton, T. CHECWORKS Integrated Software for Corrosion Control. In Proceedings of the 4th International Conference on CANDU Maintenance, Toronto, ON, Canada, 1 July 1997. [Google Scholar]

- Baier, R.; Zander, A. COMSY-A Software Tool for Aging and Plant Life Management with an Integrated Documentation Tool. In Proceedings of the International Youth Nuclear Congress 2008, Interlaken, Switzerland, 21–26 September 2008. [Google Scholar]

- Hwang, K.M.; Yun, H.; Seo, H.K.; Lee, G.Y.; Kim, K.W. Development of ToSPACE for Pipe Wall Thinning Management in Nuclear Power Plants. World J. Nucl. Sci. Technol. 2018, 9, 1–15. [Google Scholar] [CrossRef]

- Knook, T.; Persoz, M.; Trevin, S.; Friol, S.; Moutrille, M.-P.; Dejoux, L. Pipe wall thinning management at Electricite de France (EDF). E-J. Adv. Maint. 2011, 2, 1–13. [Google Scholar]

- Nishiguchi, I.; Inada, F.; Takahashi, M.; Ogawa, B.; Inagaki, T.; Ohira, T.; Iwahara, K.; Yamakami, K. A Review: Japanese pipe wall thinning management based on JSME rules and recent R&D studies performed to enhance the rules. E-J. Adv. Maint. 2011, 2, 14–24. [Google Scholar]

- Yun, H.; Moon, S.J.; Oh, Y.J. Development of Wall-Thinning Evaluation Procedure for Nuclear Power Plant Piping—Part 1: Quantification of Thickness Measurement Deviation. Nucl. Eng. Technol. 2016, 48, 820–830. [Google Scholar] [CrossRef]

- Yun, H.; Moon, S.J.; Oh, Y.J. Development of wall-thinning evaluation procedure for nuclear power plant piping-Part 2: Local wall-thinning estimation method. Nucl. Eng. Technol. 2020, 52, 2119–2129. [Google Scholar] [CrossRef]

- Katagiri, T.; Chen, G.; Yusa, N.; Hashizume, H. Demonstration of detection of the multiple pipe wall thinning defects using microwaves. Measurement 2021, 175, 109074. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, G.; Katagiri, T.; Yusa, N.; Hashizume, H. Quantitative evaluation of pipe wall thinning defect sizes using microwave NDT. Nondestruct. Test. Eval. 2022, 1–17. [Google Scholar] [CrossRef]

- Jardine, A.K.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Khurmi, R.; Sankaranarayanan, K.; Harvel, G. Condition Based Maintenance in Nuclear Power Plants: Limitations & Practicality. In Proceedings of the 2021 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 13–16 December 2021. [Google Scholar]

- Ryu, K.H.; Lee, T.H.; Kim, J.H.; Hwang, I.S.; Lee, N.Y.; Kim, J.H.; Park, J.H.; Sohn, C.H. Online monitoring method using Equipotential Switching Direct Current potential drop for piping wall loss by flow accelerated corrosion. Nucl. Eng. Des. 2010, 240, 468–472. [Google Scholar] [CrossRef]

- Oh, S.B.; Cheong, Y.M.; Kim, D.J.; Kim, K.M. On-Line Monitoring of pipe wall thinning by a high temperature ultrasonic waveguide system at the flow accelerated corrosion proof facility. Sensors 2019, 19, 1762. [Google Scholar] [CrossRef] [PubMed]

- Han, S.W.; Seo, J.S.; Park, J.H. Pipe Wall-Thinning Inspection using Vibration Modes of Pipes with Circumferentially Varying Thickness. J. Korean Inst. Gas 2017, 21, 18–26. [Google Scholar] [CrossRef][Green Version]

- O’Shea, K.; Nash, R. An Introduction to Convolutional Neural Networks. arXiv 2015, arXiv:1511.08458. [Google Scholar]

- Albawi, S.; Mohammed, T.A.; Al-Zawi, S. Understanding of a convolutional neural network. In Proceedings of the 2017 International Conference on Engineering and Technology, Antalya, Turkey, 21–23 August 2017. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2012, 25. Available online: https://proceedings.neurips.cc/paper/2012/hash/c399862d3b9d6b76c8436e924a68c45b-Abstract.html (accessed on 28 March 2022).

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Van Etten, W.C. Introduction to Random Signals and Noise; John Wiley & Sons: Chichester, UK, 2006; pp. 1–8. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016. [Google Scholar]

- Lecun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Gunn, S.R. Support vector machines for classification and regression. ISIS Tech. Rep. 1998, 14, 5–16. [Google Scholar]

- Hoffmann, F.; Bertram, T.; Mikut, R.; Reischl, M.; Nelles, O. Benchmarking in classification and regression. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2019, 9, e1318. [Google Scholar] [CrossRef]

- Chae, Y.H.; Kim, S.G.; Kim, H.; Kim, J.T.; Seong, P.H. A methodology for diagnosing FAC induced pipe thinning using accelerometers and deep learning models. Ann. Nucl. Energy 2020, 143, 107501. [Google Scholar] [CrossRef]

- Moon, S.; Kim, K.; Lee, G.G.; Yu, Y.; Kim, D.J. Pipeline wall thinning rate prediction model based on machine learning. Nucl. Eng. Technol. 2021, 53, 4060–4066. [Google Scholar] [CrossRef]

- Nair, V.; Hinton, G.E. Rectified linear units improve restricted boltzmann machines. In Proceedings of the 27th International Conference on Machine Learning, Haifa, Israel, 21–24 June 2010. [Google Scholar]

- Scherer, D.; Müller, A.; Behnke, S. Evaluation of pooling operations in convolutional architectures for object recognition. In Proceedings of the 2010 International Conference on Artificial Neural Networks, Thessaloniki, Greece, 15–18 September 2010. [Google Scholar]

| Max. Thinning Ratio | Min. Thickness of the Elbow |

|---|---|

| 0% | 7.48 mm |

| 20.3% | 5.96 mm |

| 30.2% | 5.22 mm |

| 41.4% | 4.38 mm |

| 53.0% | 3.59 mm |

| 77.9% | 2.40 mm |

| Layer | Input Shape | Output Shape |

|---|---|---|

| Input layer | (256, 257, 1) | (256, 257, 1) |

| Skip connection 1 | (256, 257, 1) | (256, 257, 6) |

| Convolutional layer 1 (ReLU) | (256, 257, 1) | (256, 257, 6) |

| Add 1 [Conv1, Skip1] (ReLU) | (256, 257, 6) | (256, 257, 6) |

| Average pooling layer 1 | (256, 257, 6) | (128, 128, 6) |

| Skip connection 2 | (128, 128, 6) | (128, 128, 16) |

| Convolutional layer 2 (ReLU) | (128, 128, 6) | (128, 128, 16) |

| Add 2 [Conv1, Skip1] (ReLU) | (128, 128, 16) | (128, 128, 16) |

| Average pooling layer 2 | (128, 128, 16) | (64, 64, 16) |

| Flatten layer | (64, 64, 16) | (65, 536) |

| FC layer 1 (ReLU) | (65, 536) | (120) |

| FC layer 2 (ReLU) | (120) | (84) |

| Output layer (Linear) | (84) | (1) |

| Model | Mean Squared Error | ||

|---|---|---|---|

| Training Data | Validation Data | Test Data | |

| DNN | 0.003665 | 0.005296 | 0.005493 |

| CNN | 0.000440 | 0.001770 | 0.002042 |

| CNN + residual block | 0.000238 | 0.001186 | 0.001244 |

| Missing Specimen in Training Dataset | Non-Averaged Data | Ensemble-Averaged Data | ||

|---|---|---|---|---|

| Mean | Standard Deviation | Mean | Standard Deviation | |

| 3.59 | 3.34 | 0.236 | 3.49 | 0.205 |

| 4.38 | 4.75 | 0.279 | 4.38 | 0.215 |

| 5.22 | 5.13 | 0.279 | 5.26 | 0.200 |

| 5.96 | 5.75 | 0.223 | 5.94 | 0.178 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Chung, B.; Park, J.; Choi, Y. Estimation of Elbow Wall Thinning Using Ensemble-Averaged Mel-Spectrogram with ResNet-like Architecture. Sensors 2022, 22, 3976. https://doi.org/10.3390/s22113976

Kim J, Chung B, Park J, Choi Y. Estimation of Elbow Wall Thinning Using Ensemble-Averaged Mel-Spectrogram with ResNet-like Architecture. Sensors. 2022; 22(11):3976. https://doi.org/10.3390/s22113976

Chicago/Turabian StyleKim, Jonghwan, Byunyoung Chung, Junhong Park, and Youngchul Choi. 2022. "Estimation of Elbow Wall Thinning Using Ensemble-Averaged Mel-Spectrogram with ResNet-like Architecture" Sensors 22, no. 11: 3976. https://doi.org/10.3390/s22113976

APA StyleKim, J., Chung, B., Park, J., & Choi, Y. (2022). Estimation of Elbow Wall Thinning Using Ensemble-Averaged Mel-Spectrogram with ResNet-like Architecture. Sensors, 22(11), 3976. https://doi.org/10.3390/s22113976