2.5D Flexible Wind Sensor Using Differential Plate Capacitors

Abstract

1. Introduction

2. Design and Simulation

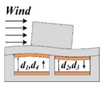

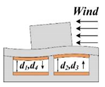

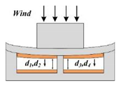

2.1. Design and Principle

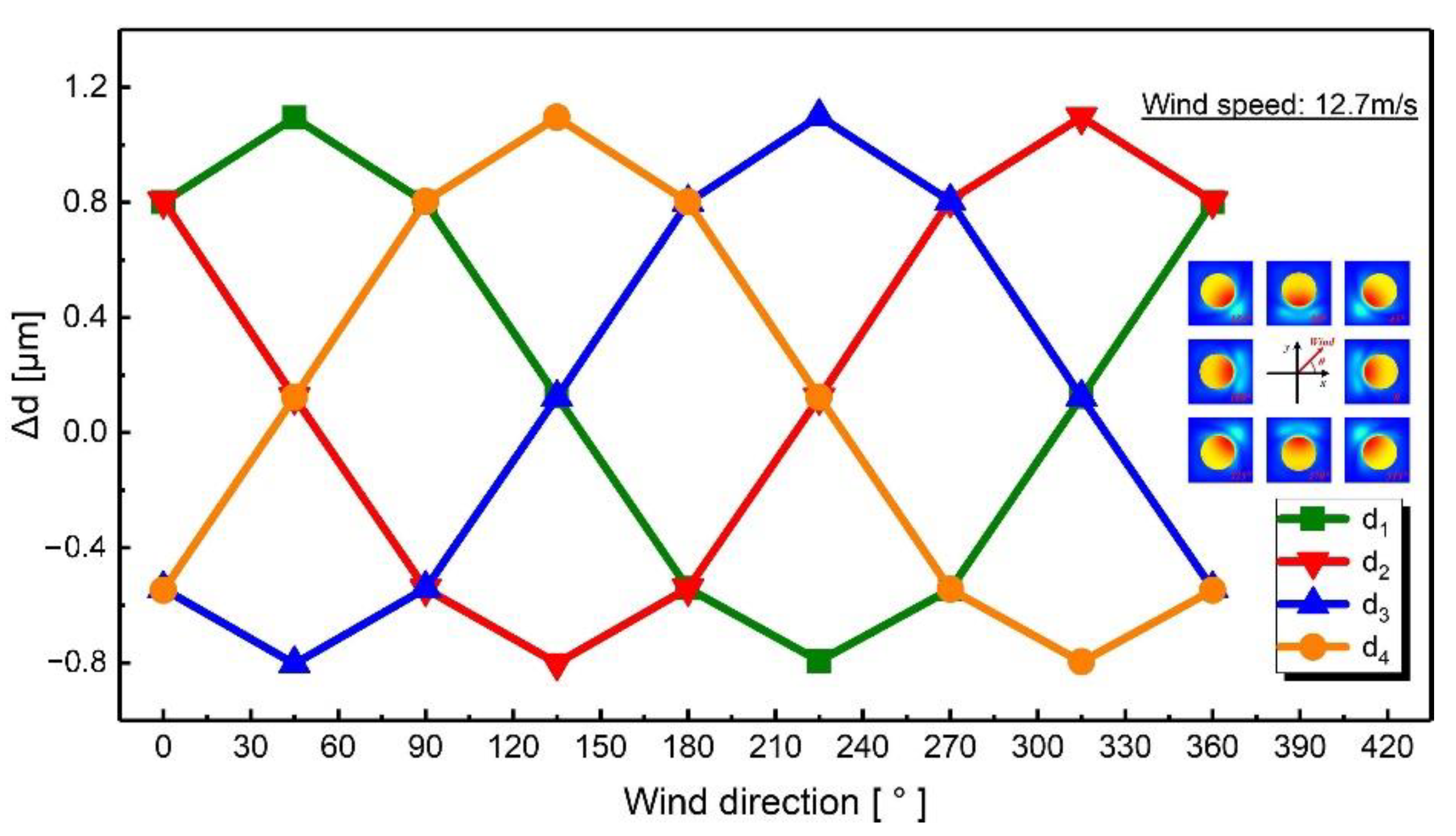

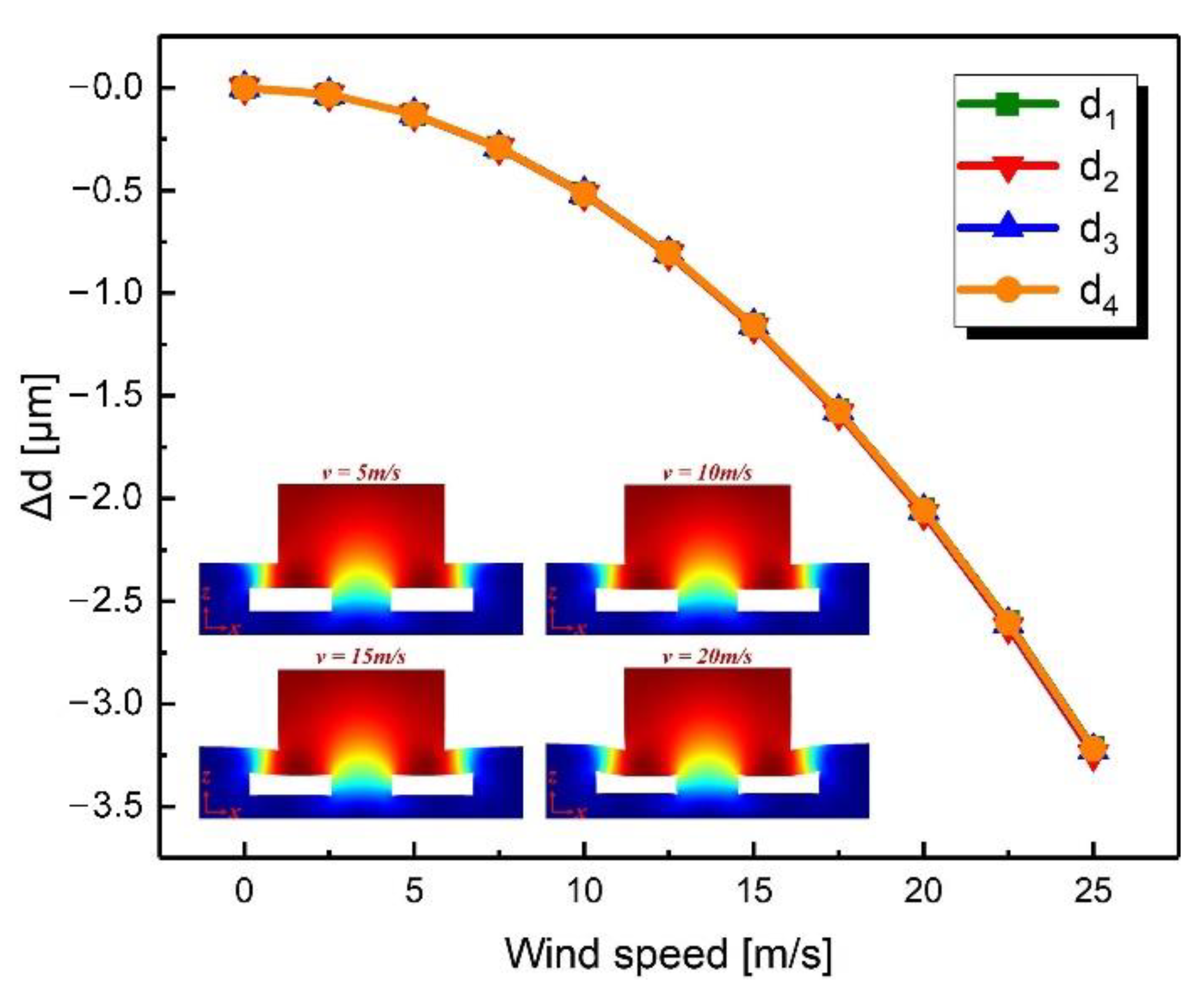

2.2. Simulation by FEM

3. Fabrication

3.1. Material Selection

3.2. Fabrication Process

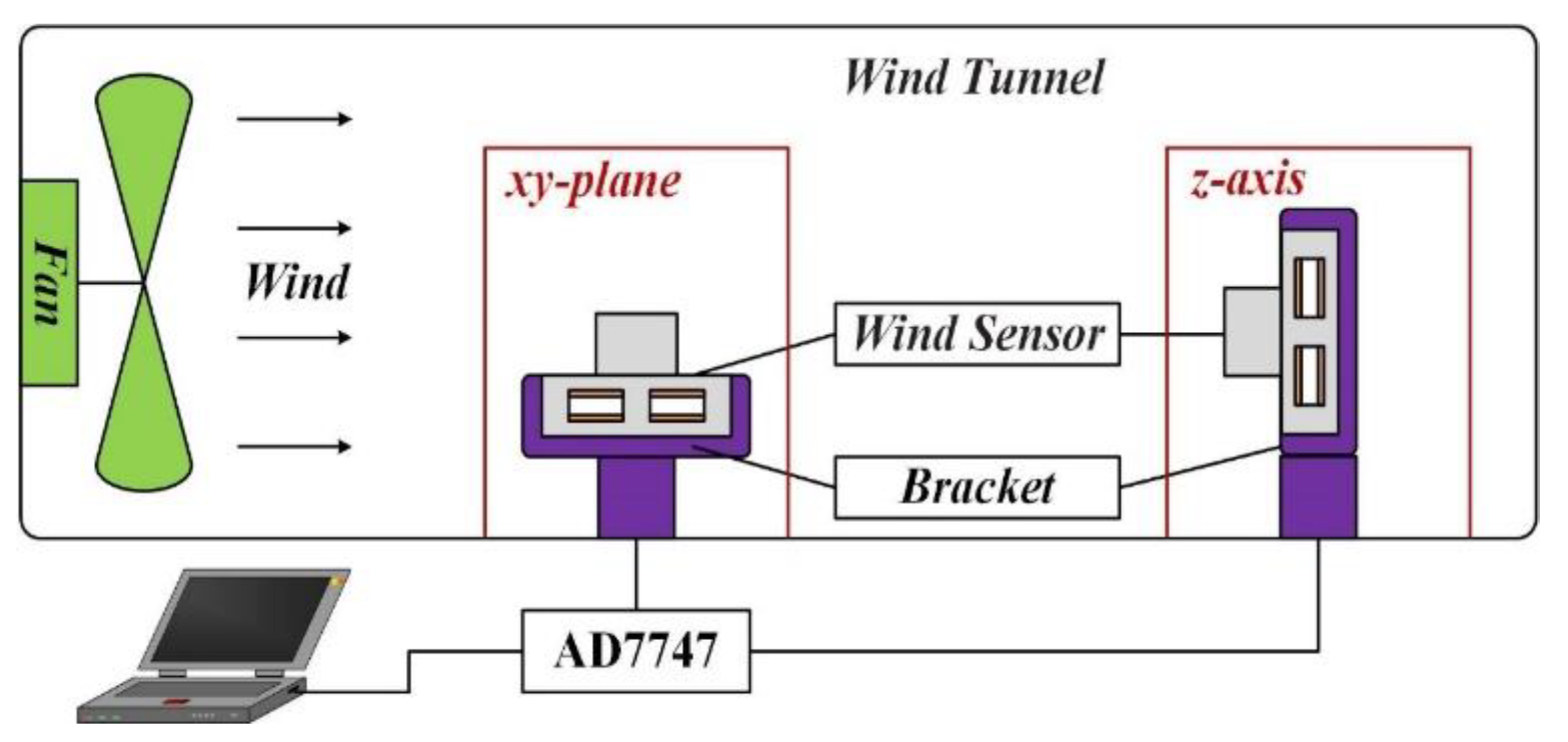

4. Measurements

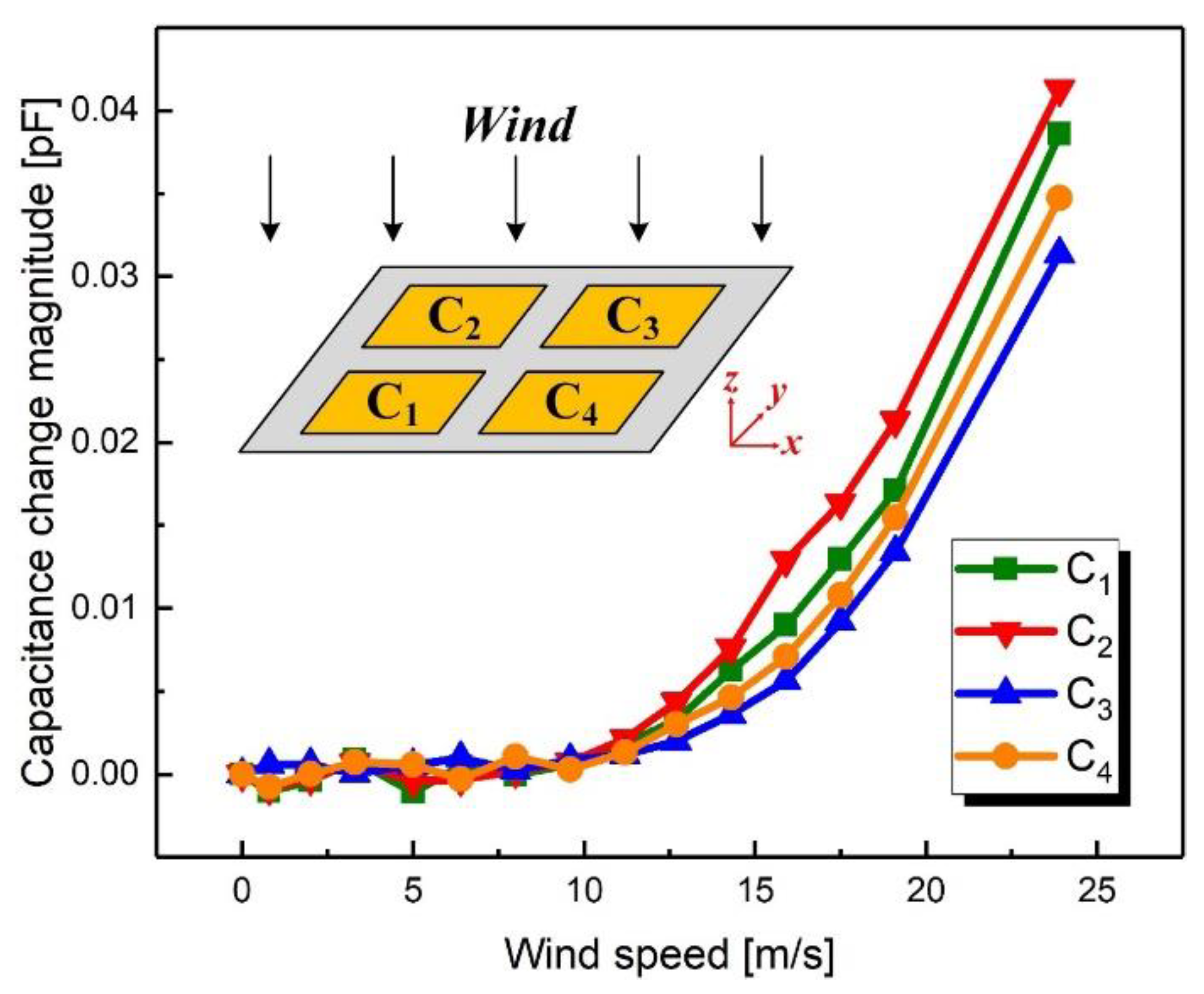

4.1. Wind Speed Experiments in xy-Plane

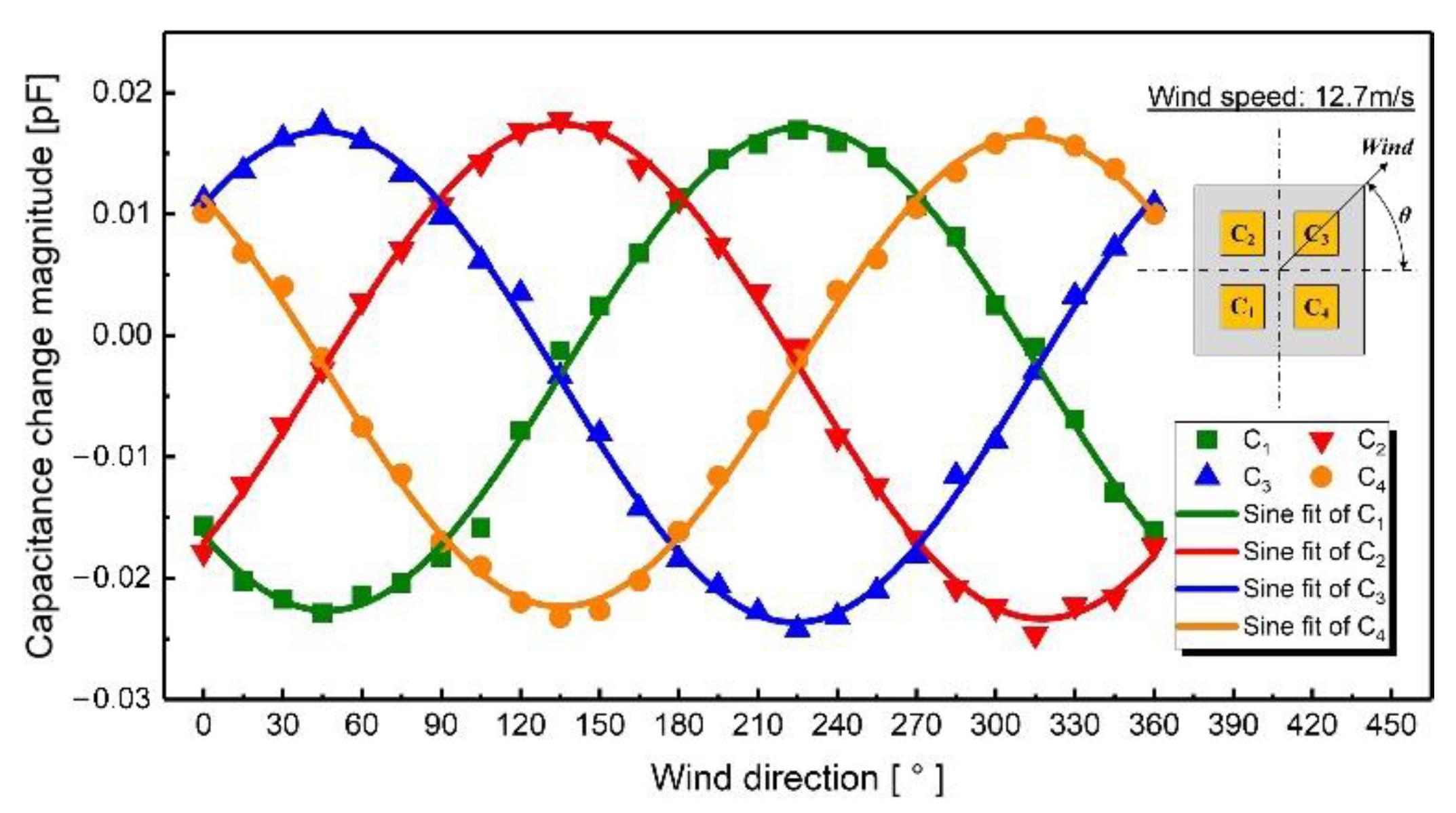

4.2. Wind Direction Experiments in xy-Plane

4.3. Wind Speed Experiments in z-Axis

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Suomi, I.; Vihma, T. Wind Gust Measurement Techniques—From Traditional Anemometry to New Possibilities. Sensors 2018, 18, 1300. [Google Scholar] [CrossRef] [PubMed]

- van Putten AF, P.; Middelhoek, S. Integrated silicon anemometer. Electron. Lett. 1974, 10, 425–426. [Google Scholar] [CrossRef]

- Stemme, G. A CMOS integrated silicon gas-flow sensor with pulse-modulated output. Sens. Actuators 1988, 14, 293–303. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, B.; Qin, M.; Huang, Q.-A. 2-D micromachined thermal wind sensors-A review. IEEE Internet Things J. 2014, 1, 216–232. [Google Scholar] [CrossRef]

- Moser, D.; Lenggenhager, R.; Wachutka, G.; Baltes, H. Fabrication and modelling of CMOS microbridge gas-flow sensors. Sens. Actuators B Chem. 1992, 6, 165–169. [Google Scholar] [CrossRef]

- Neda, T.; Nakamura, K.; Takumi, T. A polysilicon flow sensor for gas flow meters. Sens. Actuator A Phys. 1996, 54, 626–631. [Google Scholar] [CrossRef]

- Hung, S.-T.; Wong, S.-C.; Fang, W. The development and application of microthermal sensors with a mesh-membrane supporting structure. Sens. Actuators A Phys. 2000, 84, 70–75. [Google Scholar] [CrossRef]

- Wang, S.; Yi, Z.; Qin, M.; Huang, Q.-A. Modeling, simulation, and fabrication of a 2-D anemometer based on a temperature-balanced mode. IEEE Sens. J. 2019, 19, 4796–4803. [Google Scholar] [CrossRef]

- Ye, Y.; Yi, Z.; Gao, S.; Qin, M.; Huang, Q.-A. Effect of insulation trenches on micromachined silicon thermal wind sensors. IEEE Sens. J. 2017, 17, 8324–8331. [Google Scholar] [CrossRef]

- Kim, Y.-M.; Seo, C.-T.; Eun, D.-S.; Park, S.-G.; Jo, C.-S.; Lee, J.-H. Characteristics of cantilever beam fabricated by silicon micromachining for flow sensor application. In Proceedings of the Sensors 2003 IEEE, Toronto, ON, Canada, 22–24 October 2003; pp. 642–646. [Google Scholar]

- Wang, Q.; Wang, Y.; Dong, L. MEMS flow sensor using suspended graphene diaphragm with microhole arrays. J. Microelectromech. Syst. 2018, 27, 951–953. [Google Scholar] [CrossRef]

- Tan, Y.K.; Panda, S.K. A novel piezoelectric based wind energy harvester for low-power autonomous wind speed sensor. In Proceedings of the IECON 2007—33rd Annual Conference of the IEEE Industrial Electronics Society, Taipei, Taiwan, 5–8 November 2007; pp. 2175–2180. [Google Scholar]

- Liu, H.; Zhang, S.; Kathiresan, R.; Kobayashi, T.; Lee, C. Development of piezoelectric microcantilever flow sensor with wind-driven energy harvesting capability. Appl. Phys. Lett. 2012, 100, 223905. [Google Scholar] [CrossRef]

- Bruschi, P.; Dei, M.; Piotto, M. A Low-Power 2-D Wind Sensor Based on Integrated Flow Meters. IEEE Sens. J. 2009, 9, 1688–1696. [Google Scholar] [CrossRef]

- Kessler, Y.; Ilic, B.R.; Krylov, S.; Liberzon, A. Flow sensor based on the snap-through detection of a curved micromechanical beam. J. Microelectromech. Syst. 2018, 27, 945–947. [Google Scholar] [CrossRef] [PubMed]

- Yi, Z.; Wan, Y.; Qin, M.; Huang, Q. Novel anemometer based on inductor bending effect. J. Microelectromech. Syst. 2019, 28, 321–323. [Google Scholar] [CrossRef]

- Yi, Z.; Wan, Y.; Qin, M.; Huang, Q. Quadruple sensitivity improvement for wind speed sensor using dual-layer bended inductors. Sens. Actuator A Phys. 2020, 303, 1–4. [Google Scholar] [CrossRef]

- Park, S.; Kim, H.; Vosgueritchian, M.; Cheon, S.; Koo, J.H.; Kim, T.R.; Lee, S.; Schwartz, G.; Chang, H. Stretchable Energy-Harvesting Tactile Electronic Skin Capable of Differentiating Multiple Mechanical Stimuli Modes. Adv. Mater. 2014, 43, 7324–7332. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Park, J.; Kim, Y.; Bae, S.; Kim, T.-W.; Park, K.-I.; Hong, B.H.; Jeong, C.K.; Lee, S.-K. Laser-directed synthesis of strain-induced crumpled MoS2 structure for enhanced triboelectrification toward haptic sensors. Nano Energy 2020, 78, 105266. [Google Scholar] [CrossRef]

- Lai, H.; Yuan, C.; Lin, H. Camber deformation property and fracture strain of flexible film made by polydimethylsiloxane. Opt. Mater. 2020, 107, 110066. [Google Scholar] [CrossRef]

| Axes | v > 0 | v < 0 | |

|---|---|---|---|

| x-axis |  |  |  |

| y-axis |  |  |  |

| z-axis |  | N/A |  |

| Mass Ratio | Young’s Modulus [MPa] |

|---|---|

| 8:1 | 2.15 ± 0.02 |

| 10:1 | 1.97 ± 0.03 |

| 12:1 | 1.62 ± 0.02 |

| 15:1 | 1.25 ± 0.03 |

| Parameters | C1 | C2 | C3 | C4 |

|---|---|---|---|---|

| y0 | −0.00276 | −0.00298 | −0.00342 | −0.00293 |

| A | 0.01993 | 0.02038 | 0.02024 | 0.01942 |

| ω | 1.00065 | 0.98817 | 1.00662 | 1.01593 |

| φ | 136.6596 | 44.39655 | −44.23719 | −136.10507 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, Y.; Yi, Z. 2.5D Flexible Wind Sensor Using Differential Plate Capacitors. Sensors 2021, 21, 3101. https://doi.org/10.3390/s21093101

Wan Y, Yi Z. 2.5D Flexible Wind Sensor Using Differential Plate Capacitors. Sensors. 2021; 21(9):3101. https://doi.org/10.3390/s21093101

Chicago/Turabian StyleWan, Yu, and Zhenxiang Yi. 2021. "2.5D Flexible Wind Sensor Using Differential Plate Capacitors" Sensors 21, no. 9: 3101. https://doi.org/10.3390/s21093101

APA StyleWan, Y., & Yi, Z. (2021). 2.5D Flexible Wind Sensor Using Differential Plate Capacitors. Sensors, 21(9), 3101. https://doi.org/10.3390/s21093101