Classification of Cracks in Composite Structures Subjected to Low-Velocity Impact Using Distribution-Based Segmentation and Wavelet Analysis of X-ray Tomograms

Abstract

:1. Introduction

2. Specimen and Testing Methods

2.1. Specimen Preparation and Introducing Impact Damage

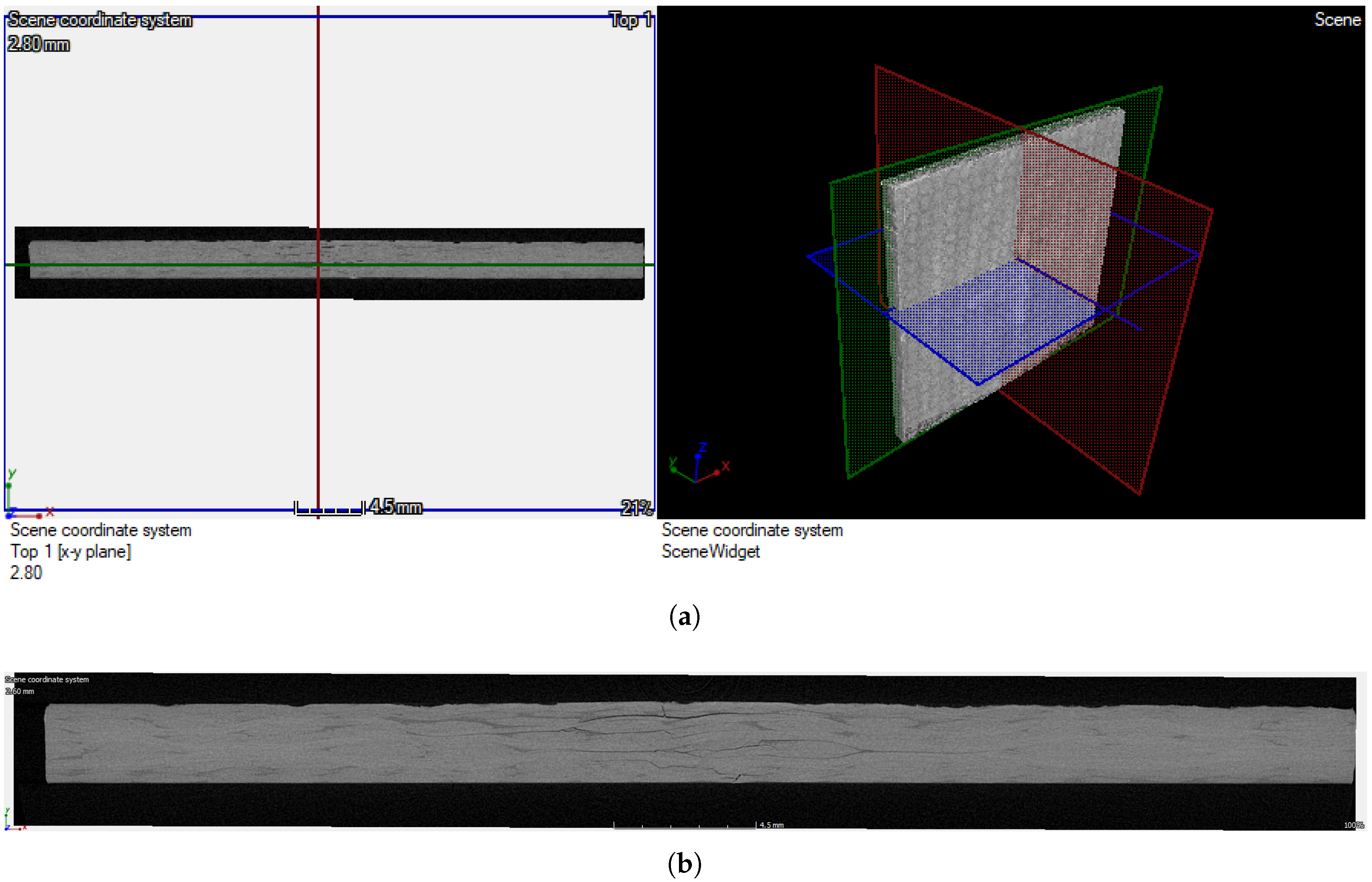

2.2. X-ray Computed Tomography Tests

3. Cracks Recognition

3.1. Short Overview on rebmix Package

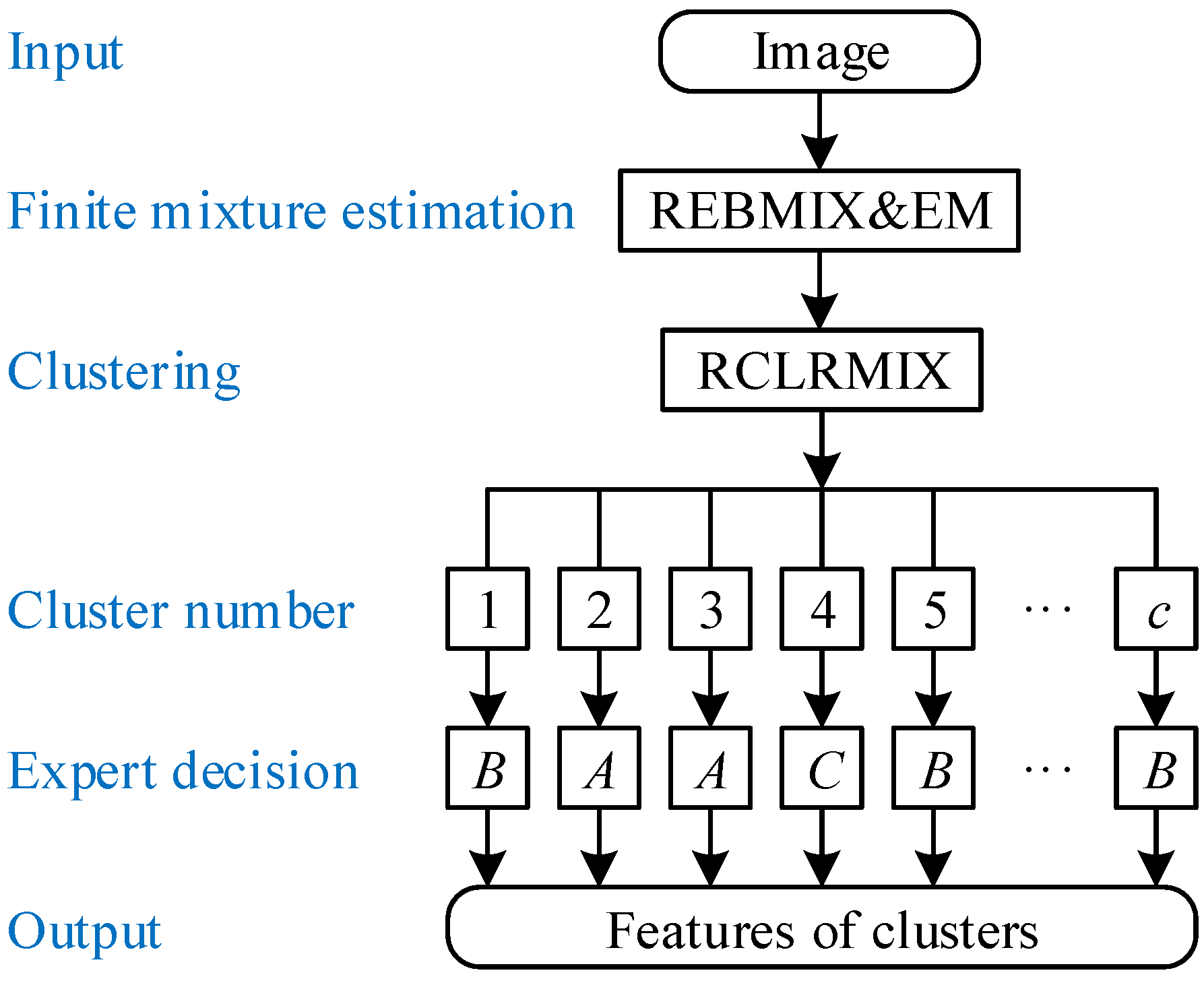

3.2. Image Segmentation by rebmix Package

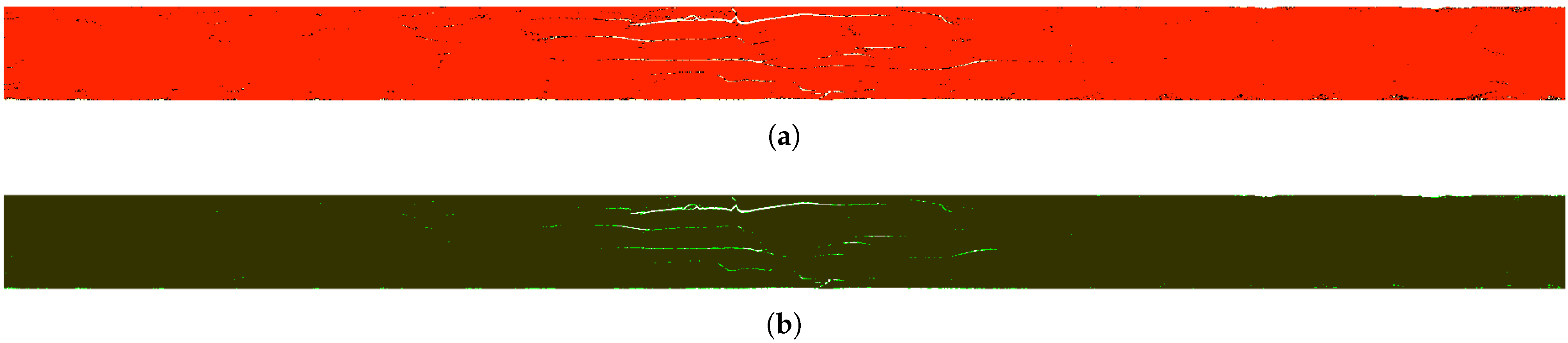

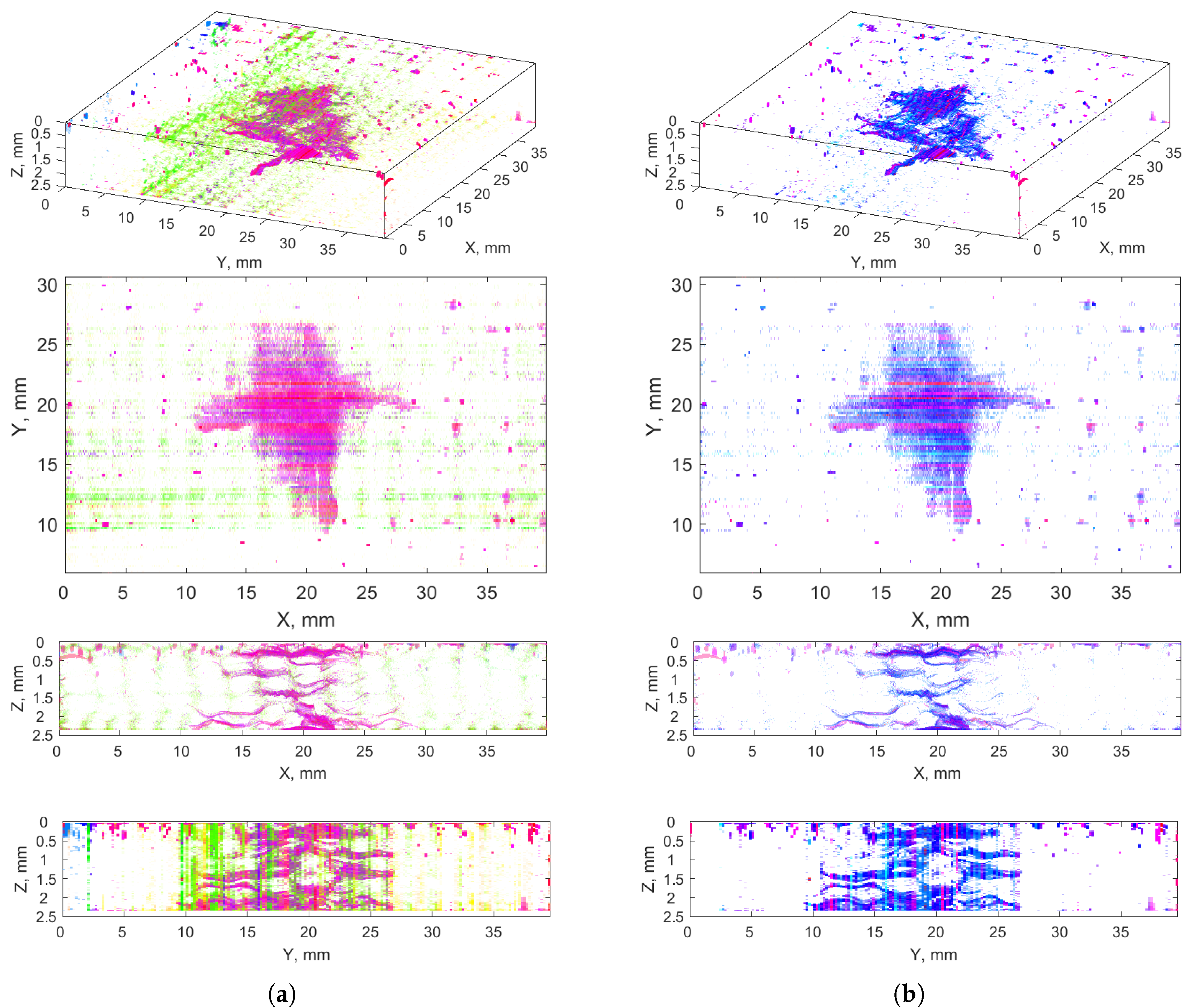

3.3. Analysis of the Crack Recognition Results

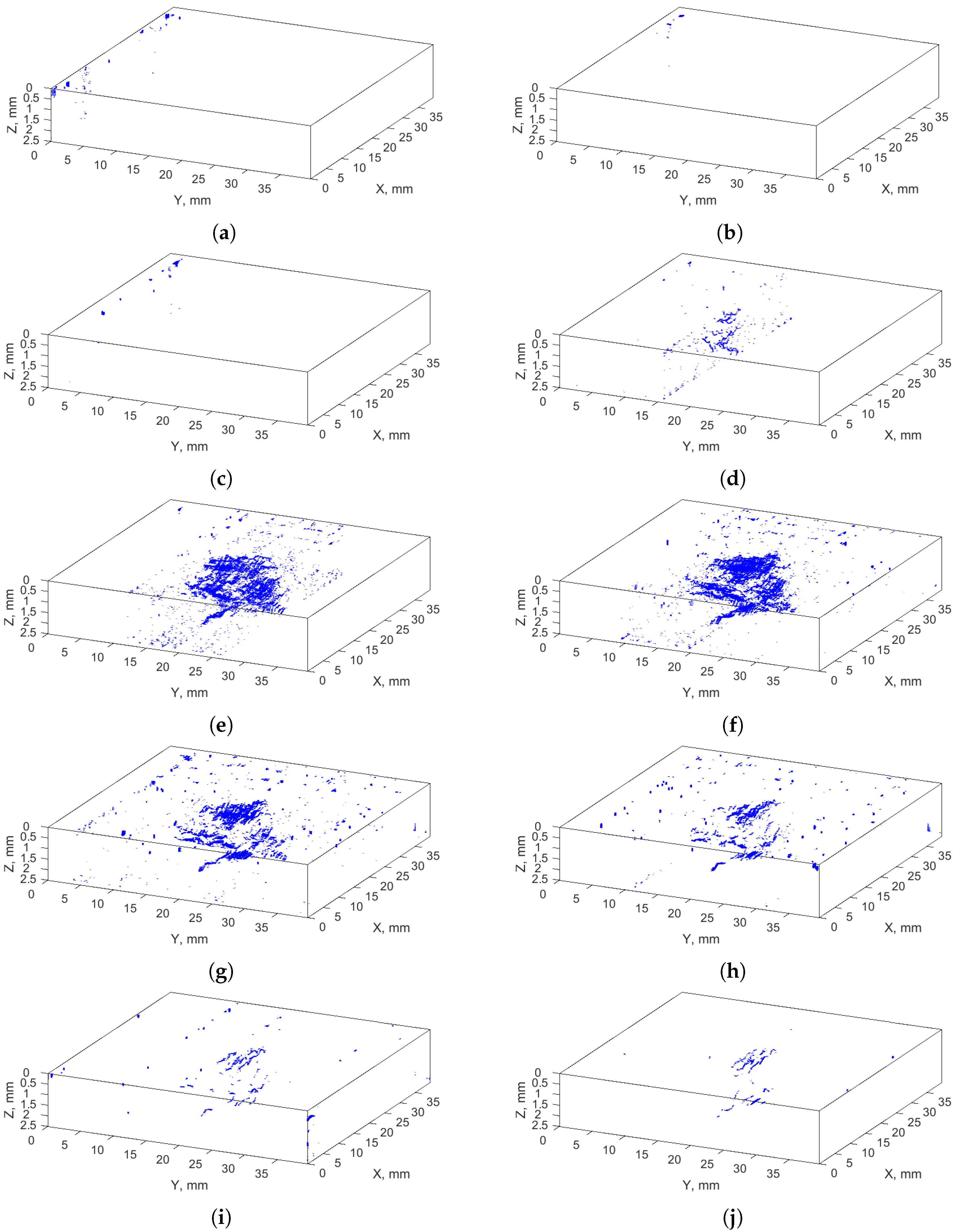

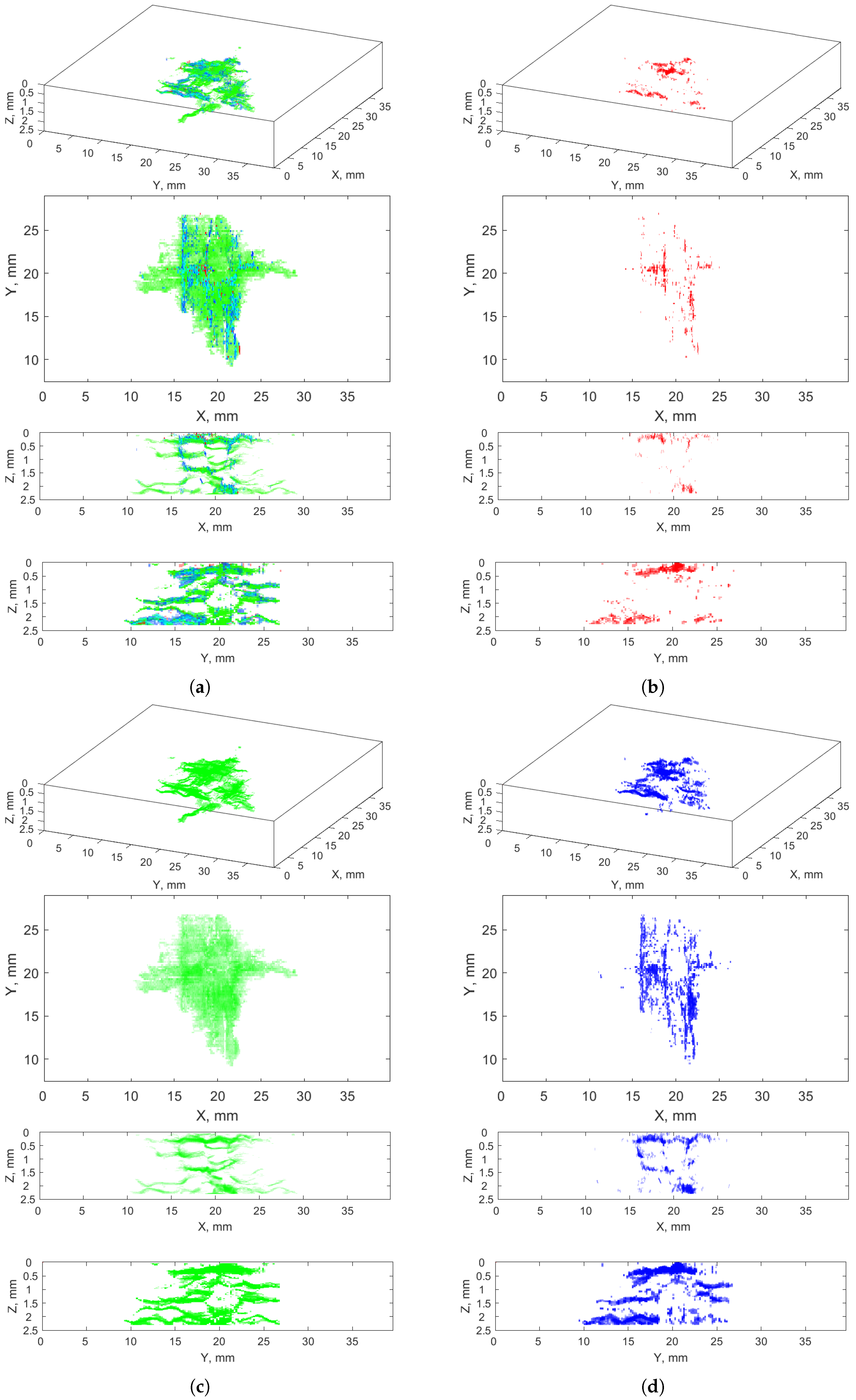

4. Cracks Classification

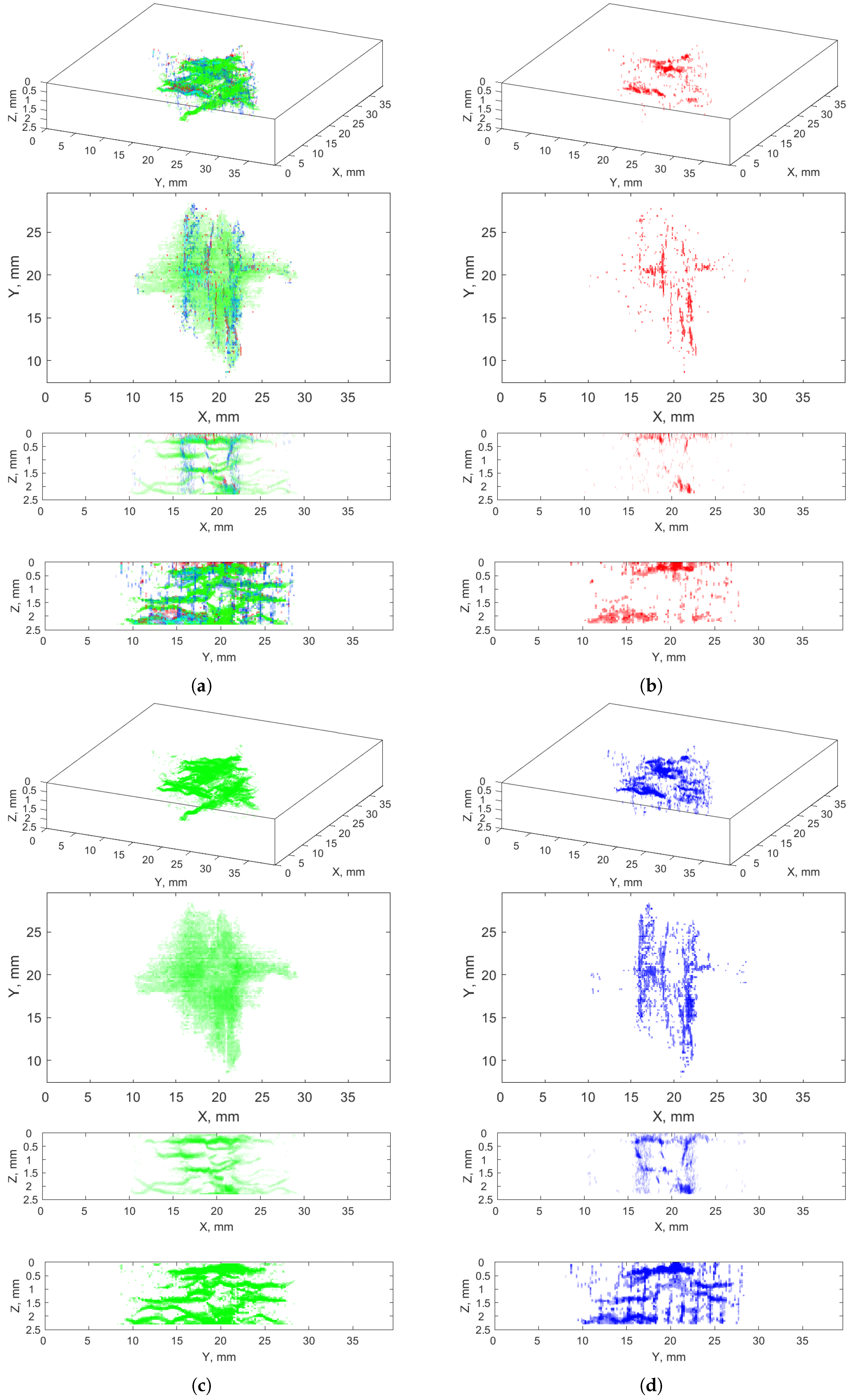

- vertically oriented cracks, being the result of indentation and bending stresses on the opposite side with respect to an impacted surface;

- skew cracks with an inclination of ca. 45° with respect to an impacted surface, which is a result of the acting of shear stresses during impact loading;

- horizontally oriented cracks, that is, delaminations, are the result of the action of shear stresses on the existing vertically oriented and skew cracks in a matrix of a composite structure, triggered by exceeding the critical stress values at the fiber/matrix interfaces of a composite.

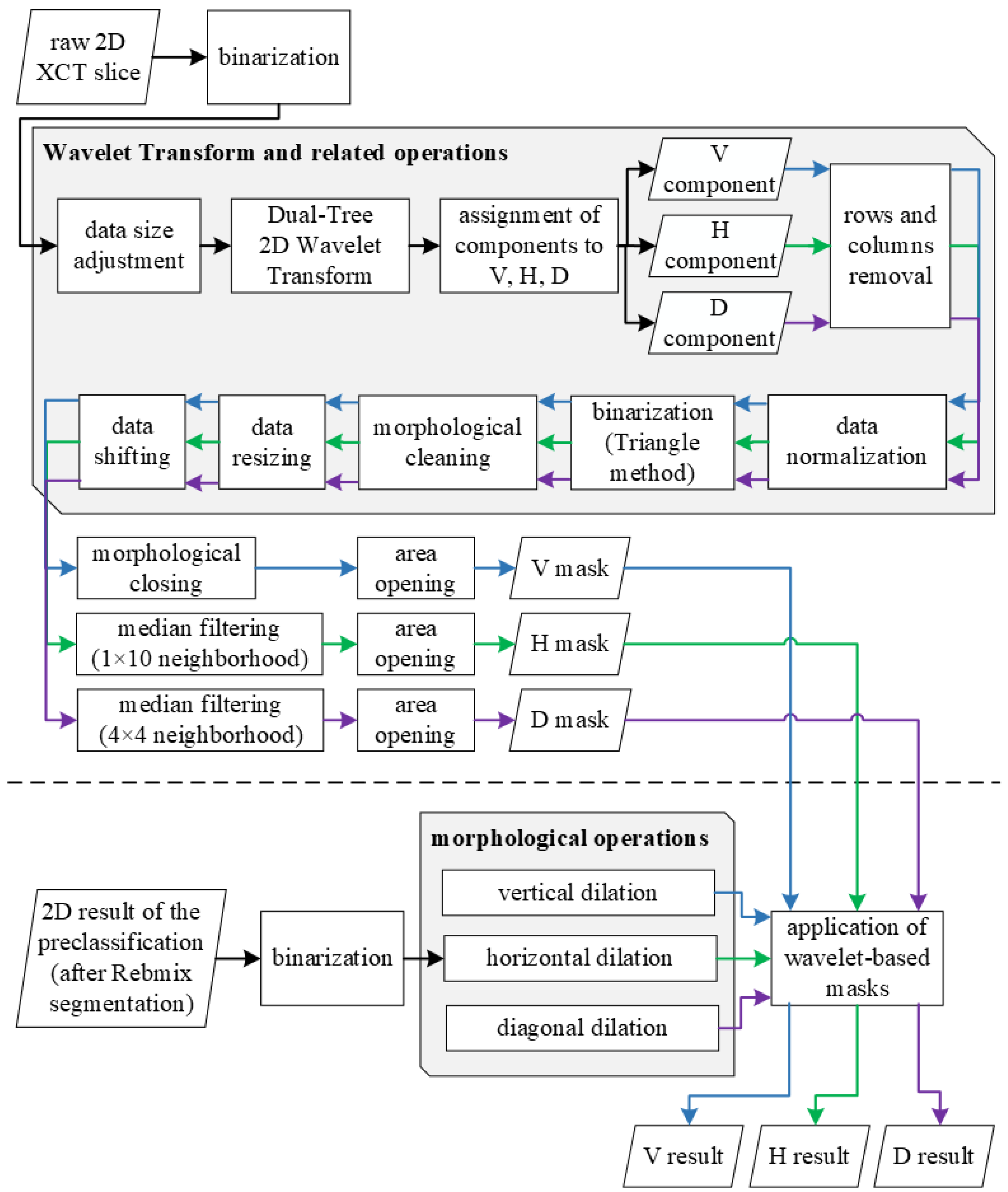

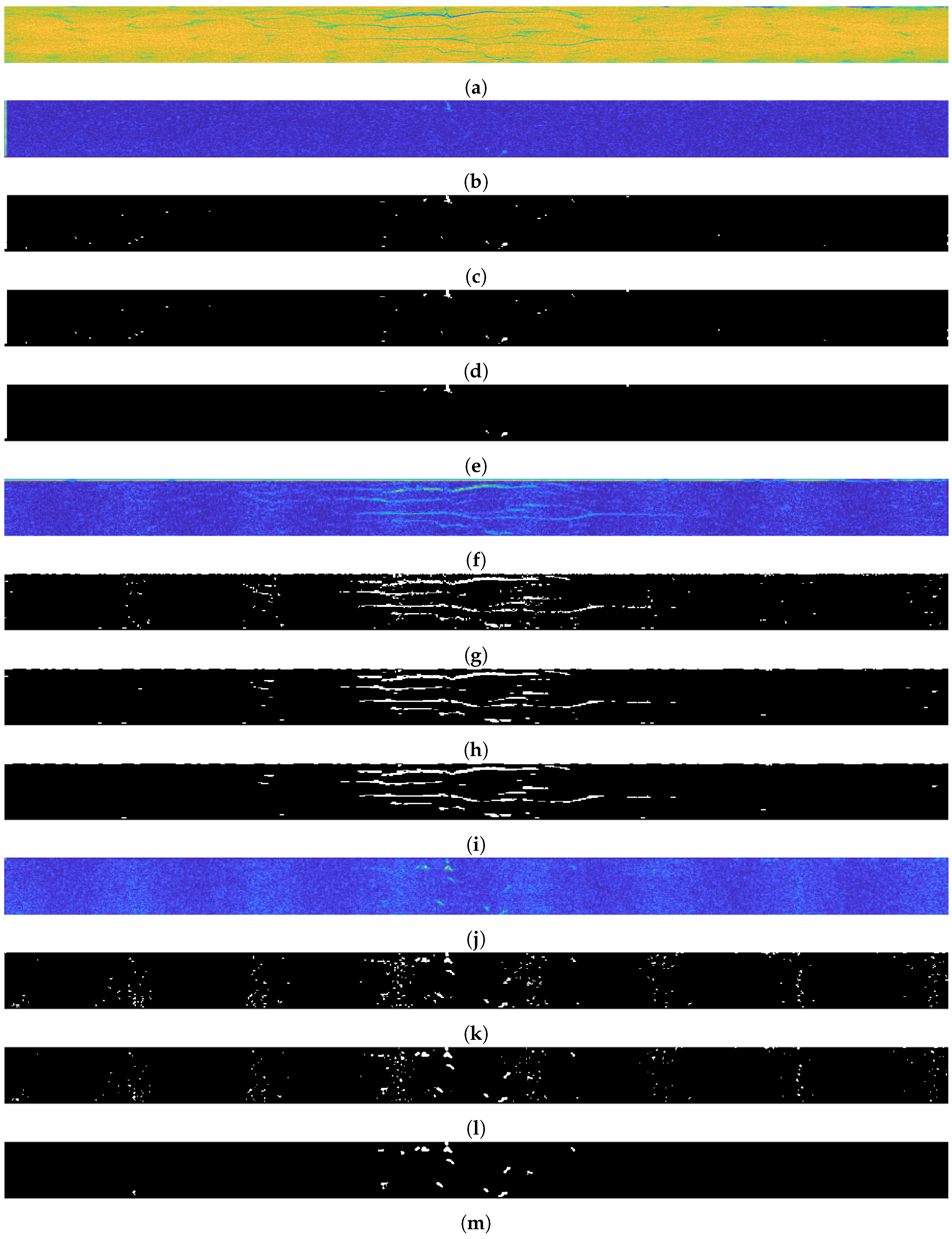

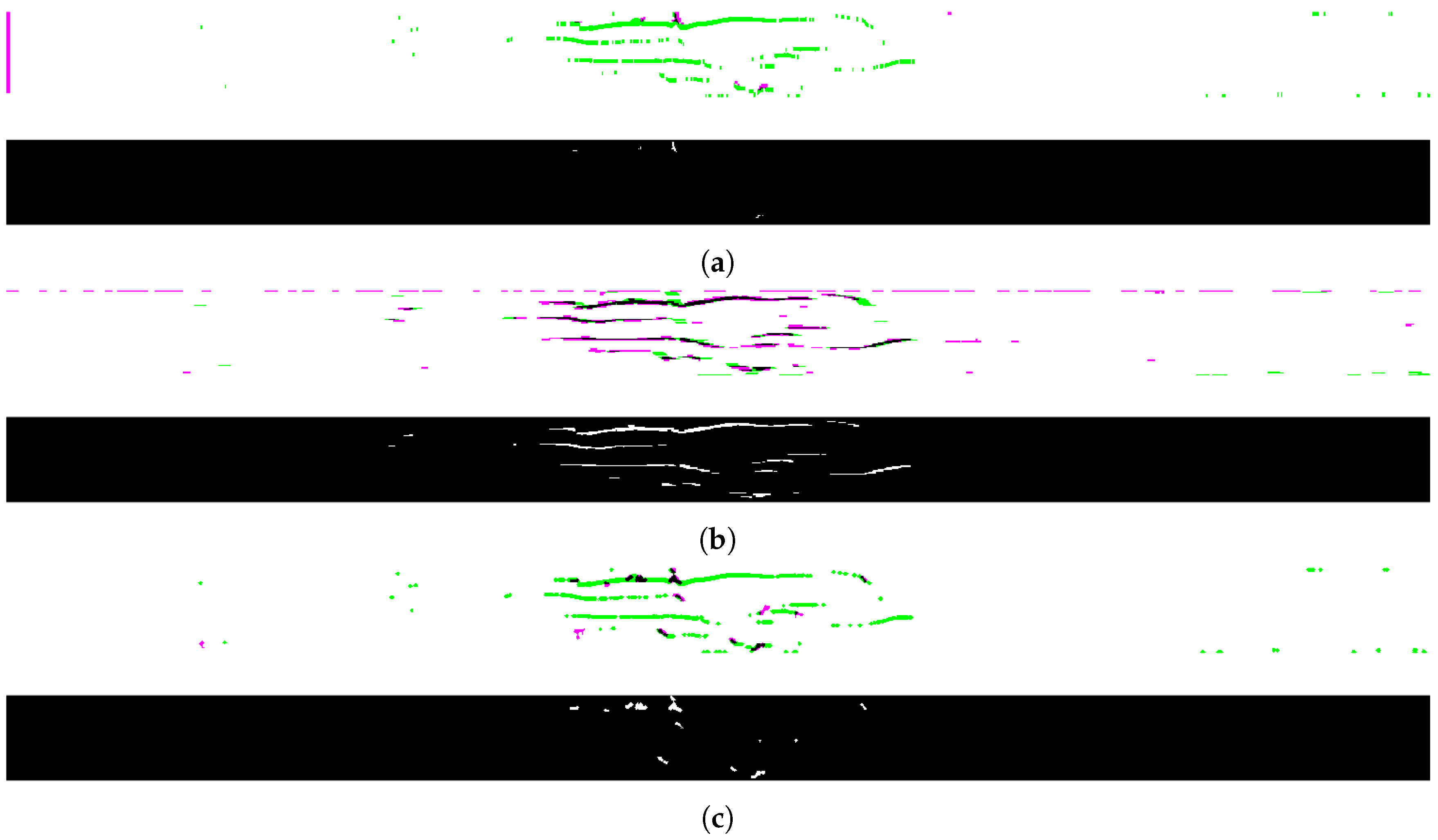

4.1. Wavelet-Based Masks

4.2. Results on Classification of Cracks

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dransfield, K.; Baillie, C.; Mai, Y.W. Improving the delamination resistance of CFRP by stitching—A review. Compos. Sci. Technol. 1994, 50, 305–317. [Google Scholar] [CrossRef]

- Walker, R.; Sohn, M.S.; Hu, X.Z. Improving impact resistance of carbon-fibre composites through interlaminar reinforcement. Compos. Part A Appl. Sci. Manuf. 2002, 33, 893–902. [Google Scholar] [CrossRef]

- Bull, D.; Spearing, S.; Sinclair, I.; Helfen, L. Three-dimensional assessment of low velocity impact damage in particle toughened composite laminates using micro-focus X-ray computed tomography and synchrotron radiation laminography. Compos. Part A Appl. Sci. Manuf. 2013, 52, 62–69. [Google Scholar] [CrossRef] [Green Version]

- Wronkowicz-Katunin, A.; Katunin, A.; Dragan, K. Reconstruction of Barely Visible Impact Damage in Composite Structures Based on Non-Destructive Evaluation Results. Sensors 2019, 19, 4629. [Google Scholar] [CrossRef] [Green Version]

- Jih, C.; Sun, C. Prediction of Delamination in Composite Laminates Subjected to Low Velocity Impact. J. Compos. Mater. 1993, 27, 684–701. [Google Scholar] [CrossRef]

- Seltzer, R.; González, C.; Munoz, R.; Llorca, J.; Blanco-Varela, T. X-ray microtomography analysis of the damage micromechanisms in 3D woven composites under low-velocity impact. Compos. Part A Appl. Sci. Manuf. 2013, 45, 49–60. [Google Scholar] [CrossRef] [Green Version]

- Bates, D.; Smith, G.; Lu, D.; Hewitt, J. Rapid thermal non-destructive testing of aircraft components. Compos. Part B Eng. 2000, 31, 175–185. [Google Scholar] [CrossRef]

- Ružek, R.; Lohonka, R.; Jironč, J. Ultrasonic C-Scan and shearography NDI techniques evaluation of impact defects identification. NDT E Int. 2006, 39, 132–142. [Google Scholar]

- Klepka, A.; Pieczonka, L.; Staszewski, W.; Aymerich, F. Impact damage detection in laminated composites by non-linear vibro-acoustic wave modulations. Compos. Part B Eng. 2014, 65, 99–108. [Google Scholar] [CrossRef]

- Mustapha, S.; Ye, L.; Dong, X.; Alamdari, M. Evaluation of barely visible indentation damage (BVID) in CF/EP sandwich composites using guided wave signals. Mech. Syst. Signal Process. 2016, 76–77, 497–517. [Google Scholar] [CrossRef]

- Dziendzikowski, M.; Dragan, K.; Katunin, A. Localizing impact damage of composite structures with modified RAPID algorithm and non-circular PZT arrays. Arch. Civ. Mech. Eng. 2017, 17, 178–187. [Google Scholar] [CrossRef]

- Fierro, G.; Ginzburg, D.; Ciampa, F.; Meo, M. Imaging of Barely Visible Impact Damage on a Complex Composite Stiffened Panel Using a Nonlinear Ultrasound Stimulated Thermography Approach. J. Nondestruct. Eval. 2017, 36, 69. [Google Scholar] [CrossRef] [Green Version]

- Moran, J.; Rajic, N. Remote line scan thermography for the rapid inspection of composite impact damage. Compos. Struct. 2019, 208, 442–453. [Google Scholar] [CrossRef]

- Katunin, A.; Wronkowicz-Katunin, A.; Dragan, K. Impact Damage Evaluation in Composite Structures Based on Fusion of Results of Ultrasonic Testing and X-ray Computed Tomography. Sensors 2020, 20, 1867. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dziendzikowski, M.; Heesch, M.; Gorski, J.; Dragan, K.; Dworakowski, Z. Application of PZT Ceramic Sensors for Composite Structure Monitoring Using Harmonic Excitation Signals and Bayesian Classification Approach. Materials 2021, 14, 5468. [Google Scholar] [CrossRef] [PubMed]

- Janardhan Padiyar, M.; Fragonara, L.; Petrunin, I.; Raposo, J.; Tsourdos, A.; Gray, I.; Farmaki, S.; Exarchos, D.; Matikas, T.; Dassios, K. Fast, Accurate, and Reliable Detection of Damage in Aircraft Composites by Advanced Synergistic Infrared Thermography and Phased Array Techniques. Appl. Sci. 2021, 11, 2778. [Google Scholar] [CrossRef]

- Kadlec, M.; Ružek, R. A Comparison of Laser Shearography and C-Scan for Assessing a Glass/Epoxy Laminate Impact Damage. Appl. Compos. Mater. 2012, 19, 393–407. [Google Scholar] [CrossRef]

- Saeedifar, M.; Najafabadi, M.; Zarouchas, D.; Toudeshky, H.; Jalalvand, M. Barely visible impact damage assessment in laminated composites using acoustic emission. Compos. Part B Eng. 2018, 152, 180–192. [Google Scholar] [CrossRef] [Green Version]

- Burkov, M.; Lyubutin, P.; Byakov, A. Non-destructive testing of honeycomb CFRP panel by means of shearography. AIP Conf. Proc. 2018, 2051, 020044. [Google Scholar]

- Katunin, A.; Wronkowicz-Katunin, A.; Danek, W.; Wyleżoł, M. Modeling of a realistic barely visible impact damage in composite structures based on NDT techniques and numerical simulations. Compos. Struct. 2021, 267, 113889. [Google Scholar] [CrossRef]

- Garcea, S.; Wang, Y.; Withers, P. X-ray computed tomography of polymer composites. Compos. Sci. Technol. 2018, 156, 305–319. [Google Scholar] [CrossRef]

- Scott, A.; Mavrogordato, M.; Wright, P.; Sinclair, I.; Spearing, S. In situ fibre fracture measurement in carbon-epoxy laminates using high resolution computed tomography. Compos. Sci. Technol. 2011, 71, 1471–1477. [Google Scholar] [CrossRef] [Green Version]

- McCombe, G.; Rouse, J.; Trask, R.; Withers, P.; Bond, I. X-ray damage characterisation in self-healing fibre reinforced polymers. Compos. Part A Appl. Sci. Manuf. 2012, 43, 613–620. [Google Scholar] [CrossRef]

- Sket, F.; Seltzer, R.; Molina-Aldareguía, J.; Gonzalez, C.; Llorca, J. Determination of damage micromechanisms and fracture resistance of glass fiber/epoxy cross-ply laminate by means of X-ray computed microtomography. Compos. Sci. Technol. 2012, 72, 350–359. [Google Scholar] [CrossRef]

- Li, Y.; Sun, B.; Gu, B. Impact shear damage characterizations of 3D braided composite with X-ray micro-computed tomography and numerical methodologies. Compos. Struct. 2017, 176, 43–54. [Google Scholar] [CrossRef]

- Léonard, F.; Stein, J.; Soutis, C.; Withers, P. The quantification of impact damage distribution in composite laminates by analysis of X-ray computed tomograms. Compos. Sci. Technol. 2017, 152, 139–148. [Google Scholar] [CrossRef]

- Bull, D.; Helfen, L.; Sinclair, I.; Spearing, S.; Baumbach, T. A comparison of multi-scale 3D X-ray tomographic inspection techniques for assessing carbon fibre composite impact damage. Compos. Sci. Technol. 2013, 75, 55–61. [Google Scholar] [CrossRef] [Green Version]

- Yu, B.; Blanc, R.; Soutis, C.; Whiters, P. Evolution of damage during the fatigue of 3D woven glass-fibre reinforced composites subjected to tension–tension loading observed by time-lapse X-ray tomography. Compos. Part A Appl. Sci. Manuf. 2016, 82, 279–290. [Google Scholar] [CrossRef]

- Mardanshahi, A.; Nasir, V.; Kazemirad, S.; Shokrieh, M. Detection and classification of matrix cracking in laminated composites using guided wave propagation and artificial neural networks. Compos. Struct. 2020, 246, 112403. [Google Scholar] [CrossRef]

- Yu, B.; Bradley, R.; Soutis, C.; Withers, P. A comparison of different approaches for imaging cracks in composites by X-ray microtomography. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20160037. [Google Scholar] [CrossRef]

- Cho, H.; Yoon, H.J.; Jung, J.Y. Image-Based Crack Detection Using Crack Width Transform (CWT) Algorithm. IEEE Access 2018, 6, 60100–60114. [Google Scholar] [CrossRef]

- Qu, Z.; Chen, Y.X.; Liu, L.; Xie, Y.; Zhou, Q. The Algorithm of Concrete Surface Crack Detection Based on the Genetic Programming and Percolation Model. IEEE Access 2019, 7, 57592–57603. [Google Scholar] [CrossRef]

- Katunin, A.; Wronkowicz, A. Characterization of failure mechanisms of composite structures subjected to fatigue dominated with the self-heating effect. Compos. Struct. 2017, 180, 1–8. [Google Scholar] [CrossRef]

- Fahr, A. Aeronautical Applications of Non-Destructive Testing; DEStech Publications, Inc.: Lancaster, PA, USA, 2014. [Google Scholar]

- Bertovic, M. Human Factors in Non-Destructive Testing (NDT): Risks and Challenges of Mechanised NDT. Ph.D. Thesis, Bundesanstalt für Materialforschung und -prüfung, Berlin, Germany, 2016. [Google Scholar]

- Baaran, J. Visual inspection of composite structures. In Final Report EASA_REP_RESEA_2007_3, Institute of Composite Structures and Adaptive Systems; DLR Braunschweig: Braunschweig, Germany, 2009. [Google Scholar]

- Chouksey, M.; Jha, R.K. A Multiverse Optimization Based Colour Image Segmentation Using Variational Mode Decomposition. Expert Syst. Appl. 2021, 171, 114587. [Google Scholar] [CrossRef]

- Xu, L.; Gao, S.; Shi, L.; Wei, B.; Liu, X.; Zhang, J.; He, Y. Exploiting Vector Attention and Context Prior for Ultrasound Image Segmentation. Neurocomputing 2021, 454, 461–473. [Google Scholar] [CrossRef]

- Liu, N.; Guo, B.; Li, X.; Min, X. Gradient Clustering Algorithm Based on Deep Learning Aerial Image Detection. Pattern Recognit. Lett. 2021, 141, 37–44. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, W.; Lv, Z.; Fan, Y.; Song, Y. Computer vision detection of foreign objects in coal processing using attention CNN. Eng. Appl. Artif. Intell. 2021, 102, 104242. [Google Scholar] [CrossRef]

- Nagode, M. Finite Mixture Modeling via REBMIX. J. Algorithms Optim. 2015, 3, 14–28. [Google Scholar] [CrossRef]

- Panic, B.; Klemenc, J.; Nagode, M. Improved Initialization of the EM Algorithm for Mixture Model Parameter Estimation. Mathematics 2020, 8, 373. [Google Scholar] [CrossRef] [Green Version]

- Panic, B.; Klemenc, J.; Nagode, M. Optimizing the Estimation of a Histogram-Bin Width-Application to the Multivariate Mixture-Model Estimation. Mathematics 2020, 8, 1090. [Google Scholar] [CrossRef]

- Panic, B.; Klemenc, J.; Nagode, M. Gaussian Mixture Model Based Classification Revisited: Application to the Bearing Fault Classification. J. Mech. Eng. 2020, 66, 215–226. [Google Scholar] [CrossRef] [Green Version]

- Nagode, M.; Fajdiga, M. The REBMIX Algorithm for the Univariate Finite Mixture Estimation. Commun. Stat.-Theory Methods 2011, 40, 876–892. [Google Scholar] [CrossRef]

- Nagode, M.; Fajdiga, M. The REBMIX Algorithm for the Multivariate Finite Mixture Estimation. Commun. Stat.-Theory Methods 2011, 40, 2022–2034. [Google Scholar] [CrossRef]

- Nagode, M.; Klemenc, J. Modelling of Load Spectra Containing Clusters of Less Probable Load Cycles. Int. J. Fatigue 2021, 143, 106006. [Google Scholar] [CrossRef]

- Dempster, A.P.; Laird, N.M.; Rubin, D.B. Maximum likelihood from incomplete data via the EM algorithm. J. R. Stat. Soc. Ser. B 1977, 39, 1–38. [Google Scholar]

- Katunin, A. Performance of Damage Identification Based on Directional Wavelet Transforms and Entopic Weights Using Experimental Shearographic Testing Results. Sensors 2021, 21, 714. [Google Scholar] [CrossRef]

- Selesnick, I. The double-density dual-tree DWT. IEEE Trans. Signal Process. 2004, 52, 1304–1314. [Google Scholar] [CrossRef]

- Zack, G.; Rogers, W.; Latt, S. Automatic measurement of sister chromatid exchange frequency. J. Histochem. Cytochem. 1977, 25, 741–753. [Google Scholar] [CrossRef] [PubMed]

- Abrate, S. Impact on Composite Structures; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wronkowicz-Katunin, A.; Katunin, A.; Nagode, M.; Klemenc, J. Classification of Cracks in Composite Structures Subjected to Low-Velocity Impact Using Distribution-Based Segmentation and Wavelet Analysis of X-ray Tomograms. Sensors 2021, 21, 8342. https://doi.org/10.3390/s21248342

Wronkowicz-Katunin A, Katunin A, Nagode M, Klemenc J. Classification of Cracks in Composite Structures Subjected to Low-Velocity Impact Using Distribution-Based Segmentation and Wavelet Analysis of X-ray Tomograms. Sensors. 2021; 21(24):8342. https://doi.org/10.3390/s21248342

Chicago/Turabian StyleWronkowicz-Katunin, Angelika, Andrzej Katunin, Marko Nagode, and Jernej Klemenc. 2021. "Classification of Cracks in Composite Structures Subjected to Low-Velocity Impact Using Distribution-Based Segmentation and Wavelet Analysis of X-ray Tomograms" Sensors 21, no. 24: 8342. https://doi.org/10.3390/s21248342

APA StyleWronkowicz-Katunin, A., Katunin, A., Nagode, M., & Klemenc, J. (2021). Classification of Cracks in Composite Structures Subjected to Low-Velocity Impact Using Distribution-Based Segmentation and Wavelet Analysis of X-ray Tomograms. Sensors, 21(24), 8342. https://doi.org/10.3390/s21248342