Multi-Sensor Fault Diagnosis of Underwater Thruster Propeller Based on Deep Learning

Abstract

:1. Introduction

- (1)

- Current, vibration, and voltage signals have been commonly used to accomplish fault diagnosis. In the present study, the proposed DCNN model diagnoses thruster propeller faults by extracting the current signal from a Hall element and the sound signal from a hydrophone. To the best of our knowledge, this study is the first to use a hydrophone to diagnose propeller faults through deep learning;

- (2)

- Nascimento and Valdenegro-Toro [29] used an RNN model to detect propeller faults. The voltage, rotational speed, and current signals were used as the features. However, the highest accuracy of the results was only 78%. In comparison, the DCNN model proposed in this study achieved a 99.8% accuracy;

- (3)

- Abed et al. [31] used a discrete wavelet transform to extract the features. An orthogonal fuzzy neighborhood discriminant analysis was used to select the best features as the input of the time-delayed neural network to compare the accuracy. However, this preprocessing flow is time-consuming. The present study used only the fast Fourier transform (FFT) to transform the signal from the time domain to the frequency domain. The DCNN had the ability to automatically learn features from the data, which significantly reduced the preprocessing time. The high accuracy of the results demonstrated excellent performance;

- (4)

- This study proposed a multi-signal input for underwater thruster fault diagnosis using the DCNN model. The rotating speed of the thruster ranged from 2200 rpm forward to 2200 rpm reverse, at eight different speeds. Four conditions were proposed for the propeller: healthy, blade half-broken, blade fully broken, and biofouling simulated using silicon.

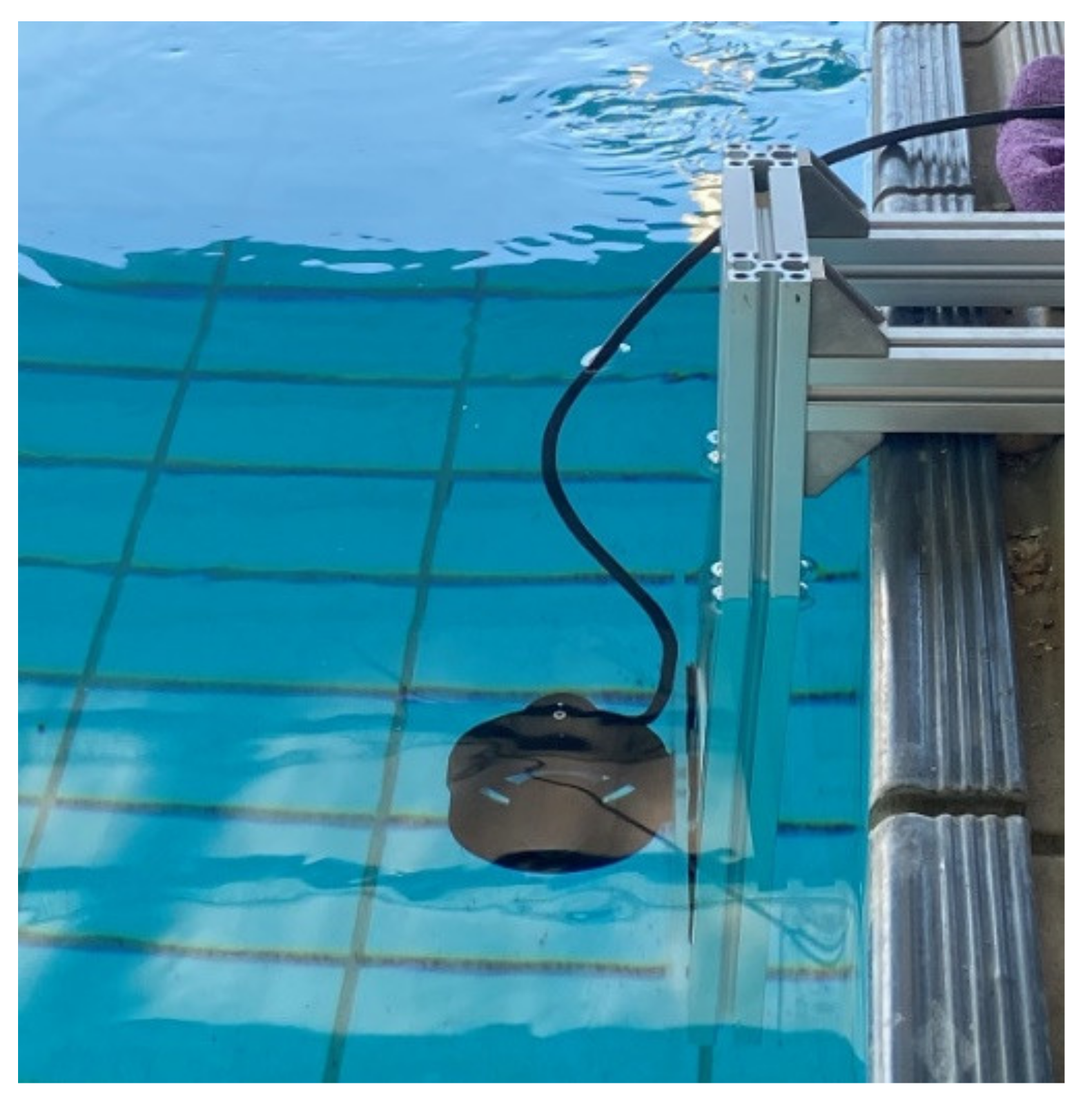

2. Materials

3. Methods

3.1. Data Collection and Signal Preprocessing

3.1.1. Data Collection

3.1.2. Data Preprocessing

3.2. Deep Convolutional Neural Network

3.2.1. Convolution Layer

3.2.2. Maxpooling Layer

3.2.3. Global Maxpooling Layer

3.2.4. Batch Normalization

3.2.5. Dropout

3.2.6. Prediction Layer

3.3. Multi-Sensor Fusion

3.4. t-Distributed Stochastic Neighbor Embedding (t-SNE) Algorithm

4. Results

4.1. Data Preprocessing Results

4.2. Classification Results

4.3. Prediction Time with Different Methods

4.4. Calculation System

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Data preprocessing: | |

| Transformed signal after FFT | |

| Convolution Layer: | |

| Input of convolutional neural | |

| Convolution weight | |

| Calculation count of the convolution filter | |

| Bias of the convolutional filter | |

| Total number of convolution filters | |

| Convolutional neural output | |

| Batch Normalization: | |

| Batch size | |

| Every element for each batch | |

| Mean of the batch | |

| Variance of the batch | |

| Value after normalization | |

| Small value to avoid a zero denominator | |

| Scale learned by the NN | |

| Shift learned by the NN | |

| Output after batch normalization | |

| t-Distributed Stochastic Neighbor Embedding (t-SNE) Algorithm: | |

| A data set | |

| Euclidean distance between a pair of points and | |

| Gaussian distribution center with variance | |

| Other points | |

| Similarity score with center | |

| Similarity score with center | |

| Number of data points | |

| Variance | |

| Center of the Student’s t-distribution | |

| Other points | |

| Kullback–Leibler divergence | |

| Other abbreviations: | |

| UMR | Unmanned marine robots |

| ANN | Artificial neural networks |

| LSTM | Long short-term memory |

| RNN | Recurrent neural networks |

| 1D | One-dimensional |

| UAV | Unmanned aerial vehicle |

| DCNN | Deep convolution neural network |

| TFD | Time frequency domain |

| FCN | Fully connected layer |

| HPR | Hydroacoustic positioning reference |

| DVL | Doppler velocity log |

| FFT | Fast Fourier transform |

| ESC | Electronic speed controller |

| RPM | Revolutions per minute |

| PWM | Pulse-width modulation |

| NN | Neural network |

| GAP | Global average pooling |

| FCN | Fully connected layer |

| t-SNE | t-Distributed stochastic neighbor embedding |

| PCA | Principal component analysis |

References

- Friebe, A.; Olsson, M.; Gallic, M.L.; Springett, J.L.; Dahl, K.; Waller, M. A marine research ASV utilizing wind and solar power. In Proceedings of the OCEANS 2017, Aberdeen, UK, 19–22 June 2017; pp. 1–7. [Google Scholar] [CrossRef]

- Iscar, E.; Johnson-Roberson, M. Autonomous surface vehicle 3D seafloor reconstruction from monocular images and sonar data. In Proceedings of the OCEANS 2015—MTS/IEEE, Washington, DC, USA, 19–22 October 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Vasilijevic, A.; Buxton, B.; Sharvit, J.; Stilinovic, N.; Nad, D.; Miskovic, N.; Planer, D.; Hale, J.; Vukic, Z. An ASV for coastal underwater archaeology: The Pladypos survey of Caesarea Maritima, Israel. In Proceedings of the OCEANS 2015, Genova, Italy, 18–21 May 2015; pp. 1–7. [Google Scholar] [CrossRef]

- Ou, L.; Li, D.; Zeng, X. Ship Propulsion Fault Diagnosis System Design Based on Remote Network. In Proceedings of the 2013 Fifth International Conference on Measuring Technology and Mechatronics Automation, Hong Kong, China, 16–17 January 2013; pp. 993–995. [Google Scholar] [CrossRef]

- Aktas, B.; Atlar, M.; Leivadaros, S.; Sasaki, N.; Fitzsimmons, P. Hydropod: An Onboard Deployed Acoustic–Visual Device for Propeller Cavitation and Noise Investigations. IEEE J. Ocean. Eng. 2018, 44, 72–86. [Google Scholar] [CrossRef] [Green Version]

- Owen, D.; Demirel, Y.K.; Oguz, E.; Tezdogan, T.; Incecik, A. Investigating the effect of biofouling on propeller characteristics using CFD. Ocean Eng. 2018, 159, 505–516. [Google Scholar] [CrossRef] [Green Version]

- Farkas, A.; Degiuli, N.; Martić, I. The impact of biofouling on the propeller performance. Ocean Eng. 2021, 219, 108376. [Google Scholar] [CrossRef]

- Sezen, S.; Uzun, D.; Ozyurt, R.; Turan, O.; Atlar, M. Effect of biofouling roughness on a marine propeller’s performance including cavitation and underwater radiated noise (URN). Appl. Ocean Res. 2021, 107, 102491. [Google Scholar] [CrossRef]

- Ou, L.; Li, D.; Li, J. Shaft center orbit diagnoses technology of broken-blade propeller induced shaft vibration fault. In Proceedings of the 2013 International Conference on Quality, Reliability, Risk, Maintenance and Safety Engineering (QR2MSE), Chengdu, China, 15–18 July 2013; pp. 1777–1780. [Google Scholar] [CrossRef]

- Banerjee, T.P.; Das, S. Multi-sensor data fusion using support vector machine for motor fault detection. Inf. Sci. 2012, 217, 96–107. [Google Scholar] [CrossRef]

- Deng, F.; Guo, S.; Zhou, R.; Chen, J. Sensor multifault diagnosis with improved support vector machines. IEEE Trans. Autom. Sci. Eng. 2017, 14, 1053–1063. [Google Scholar] [CrossRef]

- Jan, S.U.; Lee, Y.-D.; Shin, J.; Koo, I. Sensor fault classification based on support vector machine and statistical time-domain features. IEEE Access 2017, 5, 8682–8690. [Google Scholar] [CrossRef]

- Chen, L.; Ren, C.; Zhang, B.; Wang, Z. Multi-sensor prediction of stand volume by a hybrid model of support vector machine for regression kriging. Forests 2020, 11, 296. [Google Scholar] [CrossRef] [Green Version]

- Moosavi, S.S.; Djerdir, A.; Ait-Amirat, Y.; Khaburi, D.A. ANN based fault diagnosis of permanent magnet synchronous motor under stator winding shorted turn. Electr. Power Syst. Res. 2015, 125, 67–82. [Google Scholar] [CrossRef]

- Wang, C.-S.; Kao, I.H.; Perng, J.-W. Fault Diagnosis and Fault Frequency Determination of Permanent Magnet Synchronous Motor Based on Deep Learning. Sensors 2021, 21, 3608. [Google Scholar] [CrossRef]

- Sun, W.; Shao, S.; Zhao, R.; Yan, R.; Zhang, X.; Chen, X. A sparse auto-encoder-based deep neural network approach for induction motor faults classification. Measurement 2016, 89, 171–178. [Google Scholar] [CrossRef]

- Hsueh, Y.-M.; Ittangihal, V.R.; Wu, W.-B.; Chang, H.-C.; Kuo, C.-C. Fault Diagnosis System for Induction Motors by CNN Using Empirical Wavelet Transform. Symmetry 2019, 11, 1212. [Google Scholar] [CrossRef] [Green Version]

- Yu, D.; Zhang, H. Fault Diagnosis Method for Submersible Reciprocating Pumping Unit Based on Deep Belief Network. IEEE Access 2020, 8, 109940–109948. [Google Scholar] [CrossRef]

- Yu, L.; Qu, J.; Gao, F.; Tian, Y. A Novel Hierarchical Algorithm for Bearing Fault Diagnosis Based on Stacked LSTM. Shock Vib. 2019, 2019, 2756284. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Huang, M.; Lu, Q.; Zhong, M. Rotating Machinery Fault Diagnosis Using Long-short-term Memory Recurrent Neural Network. IFAC-PapersOnLine 2018, 51, 228–232. [Google Scholar] [CrossRef]

- Jiang, H.; Li, X.; Shao, H.; Zhao, K. Intelligent fault diagnosis of rolling bearings using an improved deep recurrent neural network. Meas. Sci. Technol. 2018, 29, 065107. [Google Scholar] [CrossRef]

- Lu, S.; Qian, G.; He, Q.; Liu, F.; Liu, Y.; Wang, Q. In Situ Motor Fault Diagnosis Using Enhanced Convolutional Neural Network in an Embedded System. IEEE Sens. J. 2020, 20, 8287–8296. [Google Scholar] [CrossRef]

- Miao, M.; Liu, C.; Yu, J. Adaptive Densely Connected Convolutional Auto-Encoder-Based Feature Learning of Gearbox Vibration Signals. IEEE Trans. Instrum. Meas. 2021, 70, 1–11. [Google Scholar] [CrossRef]

- Eren, L.; Ince, T.; Kiranyaz, S. A Generic Intelligent Bearing Fault Diagnosis System Using Compact Adaptive 1D CNN Classifier. J. Signal Process. Syst. 2019, 91, 179–189. [Google Scholar] [CrossRef]

- Sun, C.; Ma, M.; Zhao, Z.; Chen, X. Sparse Deep Stacking Network for Fault Diagnosis of Motor. IEEE Trans. Ind. Inform. 2018, 14, 3261–3270. [Google Scholar] [CrossRef]

- Ghalamchi, B.; Jia, Z.; Mueller, M.W. Real-Time Vibration-Based Propeller Fault Diagnosis for Multicopters. IEEE/ASME Trans. Mechatron. 2020, 25, 395–405. [Google Scholar] [CrossRef]

- Iannace, G.; Ciaburro, G.; Trematerra, A. Fault Diagnosis for UAV Blades Using Artificial Neural Network. Robotics 2019, 8, 59. [Google Scholar] [CrossRef] [Green Version]

- Yao, F.; Wang, F.; Zhang, M. Weak thruster fault detection for autonomous underwater vehicle based on artificial immune and signal pre-processing. Adv. Mech. Eng. 2018, 10, 1687814018758739. [Google Scholar] [CrossRef] [Green Version]

- Nascimento, S.; Valdenegro-Toro, M. Modeling and Soft-fault Diagnosis of Underwater Thrusters with Recurrent Neural Networks. IFAC-PapersOnLine 2018, 51, 80–85. [Google Scholar] [CrossRef]

- Shao, S.; Yan, R.; Lu, Y.; Wang, P.; Gao, R.X. DCNN-Based Multi-Signal Induction Motor Fault Diagnosis. IEEE Trans. Instrum. Meas. 2019, 69, 2658–2669. [Google Scholar] [CrossRef]

- Abed, W.; Sharma, S.; Sutton, R. Neural network fault diagnosis of a trolling motor based on feature reduction techniques for an unmanned surface vehicle. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2015, 229, 738–750. [Google Scholar] [CrossRef]

- Zhang, M.; Yin, B.; Liu, W.; Liu, X. Thruster fault feature extraction for autonomous underwater vehicle in time-varying ocean currents based on single-channel blind source separation. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2016, 230, 46–57. [Google Scholar] [CrossRef]

- Jiang, Y.; He, B.; Lv, P.; Guo, J.; Wan, J.; Feng, C.; Yu, F. Actuator Fault Diagnosis in Autonomous Underwater Vehicle Based on Principal Component Analysis. In Proceedings of the 2019 IEEE Underwater Technology (UT), Kaohsiung, Taiwan, 1–5 April 2019. [Google Scholar] [CrossRef]

- Zuev, A.; Zhirabok, A.; Filaretov, V. Fault identification in underwater vehicle thrusters via sliding mode observers. Int. J. Appl. Math. Comput. Sci. 2020, 30, 679–688. [Google Scholar] [CrossRef]

- Wang, X. Active Fault Tolerant Control for Unmanned Underwater Vehicle with Sensor Faults. IEEE Trans. Instrum. Meas. 2020, 69, 9485–9495. [Google Scholar] [CrossRef]

- Zhao, B.; Skjetne, R.; Blanke, M.; Dukan, F. Particle Filter for Fault Diagnosis and Robust Navigation of Underwater Robot. IEEE Trans. Control Syst. Technol. 2014, 22, 2399–2407. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Feng, C.; He, B.; Guo, J.; Wang, D.; Lv, P. Actuator fault diagnosis in autonomous underwater vehicle based on neural network. Sens. Actuators A Phys. 2021, 324, 112668. [Google Scholar] [CrossRef]

- Lin, M.; Chen, Q.; Yan, S. Network in Network. arXiv 2014, arXiv:1312.4400. [Google Scholar]

- Ioffe, S.; Szegedy, C. Batch normalization: Accelerating deep network training by reducing internal covariate shift. In Proceedings of the 32nd International Conference Machine Learning, Lille, France, 7–9 July 2015; Volume 37, pp. 448–456. [Google Scholar]

- Hinton, G.E.; Srivastava, N.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R.R. Improving neural networks by preventing co-adaptation of feature detectors. arXiv 2012, arXiv:1207.0580. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2012, 25, 1097–1105. [Google Scholar] [CrossRef]

- Quinlan, J.R. Induction of decision trees. Mach. Learn. 1986, 1, 81–106. [Google Scholar] [CrossRef] [Green Version]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef] [Green Version]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Van der Maaten, L.; Hinton, G. Visualizing Data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. [Google Scholar]

- Hinton, G.E.; Roweis, S. Stochastic Neighbor Embedding. Proc. Neural Inf. Process. Syst. 2002, 15, 833–840. [Google Scholar]

| Propeller Number | Condition |

|---|---|

| 1 | Healthy blade |

| 2 | Half-broken blade |

| 3 | Fully broken blade |

| 4 | Silicon-attached blade |

| Method | Accuracy for Different Conditions | ||||

|---|---|---|---|---|---|

| Healthy | Half-Broken | Fully Broken | Silicon | Average | |

| Current signal | 96.25% | 90.38% | 87.63% | 99.00% | 93.32% |

| Sound signal | 98.50% | 86.88% | 99.75% | 99.75% | 96.22% |

| Mixing of two signals | 99.06% | 97.56% | 95.00% | 99.56% | 97.80% |

| Stacking of two signals | 99.25% | 99.00% | 99.75% | 99.88% | 99.47% |

| Merging of two signals | 100% | 99.75% | 99.75% | 100% | 99.88% |

| Propeller Condition | Rotating Command | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1300 | 1350 | 1400 | 1450 | 1550 | 1600 | 1650 | 1700 | Average | |

| Healthy | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% |

| Half-broken | 100% | 100% | 100% | 100% | 98% | 100% | 100% | 100% | 99.75% |

| Fully broken | 100% | 100% | 100% | 100% | 100% | 98% | 100% | 100% | 99.75% |

| Silicon | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% |

| Total average | 99.88% | ||||||||

| Method | Prediction Time(s) for 100 Data Points |

|---|---|

| Current signal | 0.0117 |

| Sound signal | 0.0114 |

| Mixing of two signals | 0.0116 |

| Stacking of two signals | 0.0161 |

| Merging of two signals | 0.0198 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, C.-M.; Wang, C.-S.; Chung, Y.-J.; Sun, Y.-D.; Perng, J.-W. Multi-Sensor Fault Diagnosis of Underwater Thruster Propeller Based on Deep Learning. Sensors 2021, 21, 7187. https://doi.org/10.3390/s21217187

Tsai C-M, Wang C-S, Chung Y-J, Sun Y-D, Perng J-W. Multi-Sensor Fault Diagnosis of Underwater Thruster Propeller Based on Deep Learning. Sensors. 2021; 21(21):7187. https://doi.org/10.3390/s21217187

Chicago/Turabian StyleTsai, Chia-Ming, Chiao-Sheng Wang, Yu-Jen Chung, Yung-Da Sun, and Jau-Woei Perng. 2021. "Multi-Sensor Fault Diagnosis of Underwater Thruster Propeller Based on Deep Learning" Sensors 21, no. 21: 7187. https://doi.org/10.3390/s21217187

APA StyleTsai, C.-M., Wang, C.-S., Chung, Y.-J., Sun, Y.-D., & Perng, J.-W. (2021). Multi-Sensor Fault Diagnosis of Underwater Thruster Propeller Based on Deep Learning. Sensors, 21(21), 7187. https://doi.org/10.3390/s21217187