Smart Control and Energy Efficiency in Irrigation Systems Using LoRaWAN

Abstract

:1. Introduction

2. Related Work

- Irrigation algorithm that connects to the Internet to obtain the probability of precipitation and does not irrigate if the probability of precipitation is greater than specified.

- Change of parameters in real time that allows the system to be much more dynamic and can be adjusted to the needs of the installation at any given moment.

- Routine checking of sending and receiving messages to minimise the number of packets of information lost in the LoRaWAN network.

- Development of low cost and open-source prototypes, which allow the system to be adapted to the particular needs of each installation.

3. Methodology and Design

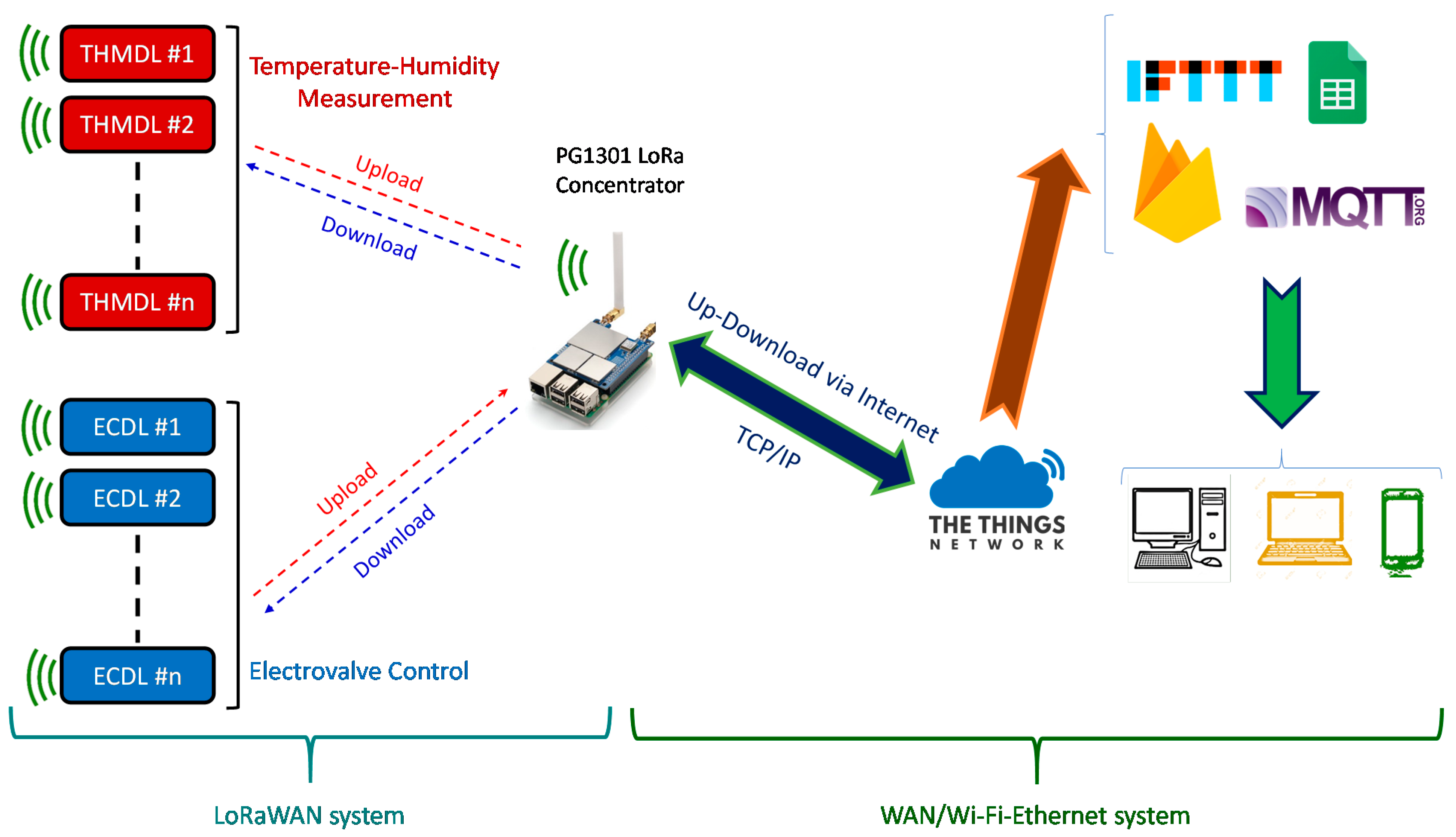

3.1. Network Scheme

3.2. Hardware Design

3.2.1. Design Challenges and Objectives

- Low power consumption: The devices are placed in the field (THMDL) or where the electrovalves are located (ECDL), and a mains power supply is not always available. It is necessary to use batteries and Solar Panels (SPs) to ensure the power supply of the equipment. In this sense, low power consumption is essential for batteries and SPs to be as small as possible.

- Small size: The devices must be installed in the smallest possible space. In the case of the THMDL, the goal is to be as imperceptible as possible in landscaped areas. For the ECDL, the goal is to be close to the electrovalve, but it is not always possible to have large spaces. This design objective is indivisibly linked to the previous one.

- Component integration, modular design and fault response: If one of the components has a problem and develops a malfunction, the device must be able to maintain the other features that have not been affected by the malfunction. The modular design is of vital importance in these scenarios since it allows components to be changed without the system ceasing to function. This results in highly fault-tolerant devices that provide a high degree of security against device malfunctions.

- Operational safety: The devices are designed to operate autonomously and continuously 24/7. It is, therefore, necessary for the design to be as robust as possible in order to minimise operating problems. This, together with the previous objective, gives the designed devices a high tolerance to failures.

- Low price: In addition to meeting all of the above objectives, the devices must have a final cost that is as low as possible. Thus, achieving designs that can be mass-produced and that are accessible to the majority of users is essential.

- Component selection: In achieving the design objectives, the selection of the components to be implemented in the devices is of particular importance. They have a decisive influence on the proper functioning of the devices and on achieving a final system that is fully functional and safe in its operation.

- Modular design: Combined with the design objectives of component integration, modular design, fault response and operational safety, the objective must provide robustness to the devices. Thus, devices cannot be taken out of service in the event of a malfunction. Rather, all features unaffected by the problem must continue to function correctly.

- Evaluation of alternatives leading to an optimal design: It is essential to evaluate the different implementation possibilities for each of the devices and the final system. The choice of the most correct, optimal and appropriate solution will lead to the fulfilment of the objectives set for the design.

- Printed Circuit Board (PCB) design: The design must be optimised to achieve a minimum size that allows the integration of all the selected components in each of the devices. In this case, two PCBs will be created, one for the THMDL and one for the ECDL.

3.2.2. Components

Microcontroller

LoRa Wireless System

Electrical Variables Meter

SHT30 Temperature and Humidity Sensor

Charge Regulator

Solar Panel

Battery

3.2.3. Hardware Implementation for the THMDL

3.2.4. Hardware Implementation for the ECDL

3.3. Software Design

3.3.1. THMDL Software

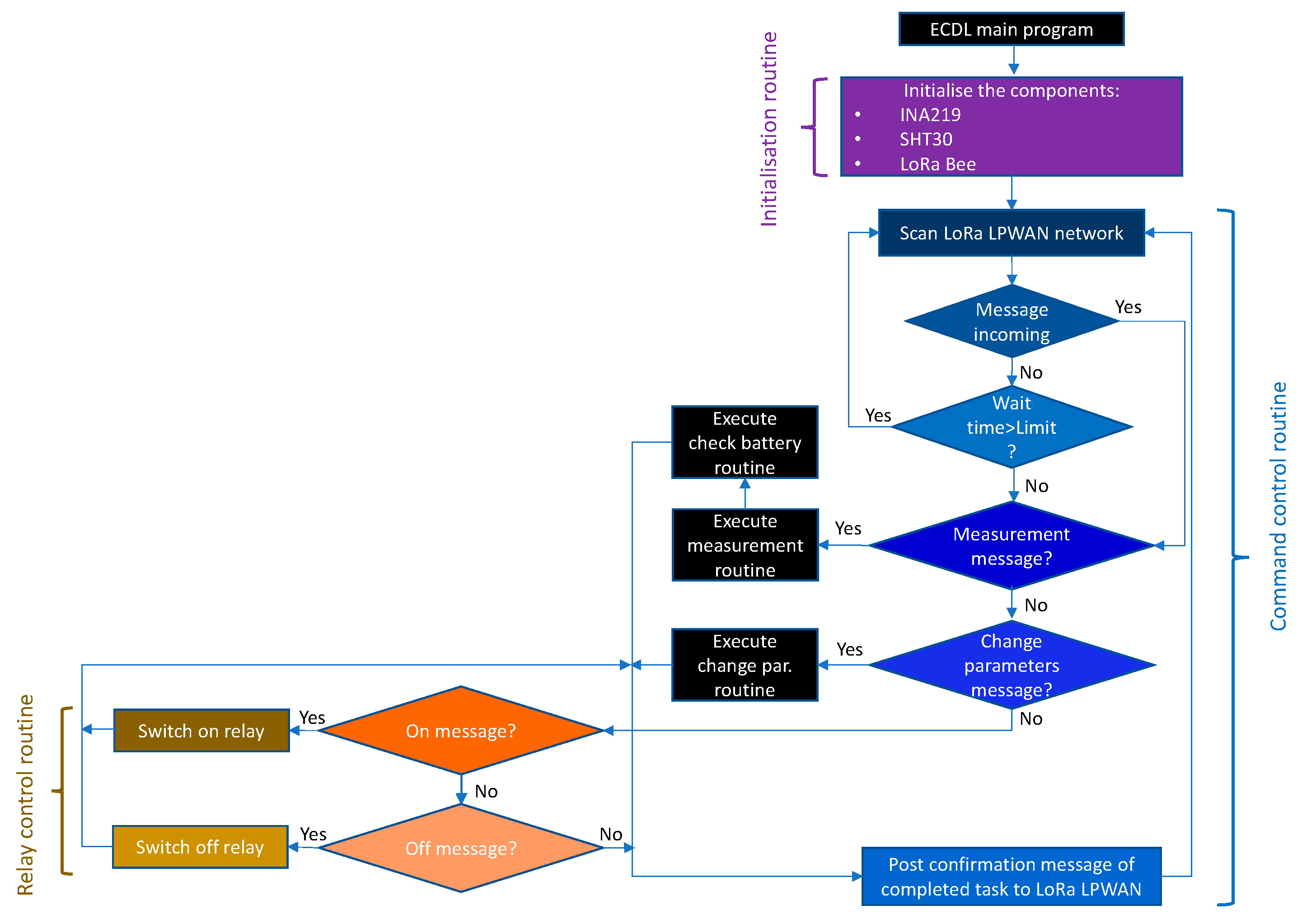

3.3.2. ECDL Software

4. Results and Discussion

4.1. Case Study

4.2. LoRaWAN Configuration

4.3. Measurement of Soil Temperature and Humidity

4.4. Battery Charge

4.5. Battery Discharge

4.6. Energy Consumption Comparative

4.7. Solar Energy Generated

4.8. Analysis of Consumption, Photovoltaic Generation and Battery Life

4.9. LoRaWAN Measurements

4.10. ThingSpeak Integration

4.11. Future Work

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AN | Arduino Nano |

| BW | Bandwidth |

| CR | Code rate |

| DLB | Dragino LoRa Bee |

| ECDL | Electrovalve Control Device for LoRaWAN |

| GPRS | General Packet Radio Service |

| I2C | Inter-Integrated Circuit |

| IFTTT | If This, Then That |

| IoT | Internet of Things |

| LiPo | Lipo Rider Pro |

| LoRa | Long range |

| LoRaWAN | Long-range wide-area network |

| LPWAN | Low-power wide-area network |

| MQTT | Message Queue Telemetry Transport |

| NB-IoT | Narrow-band Internet of Things |

| PCB | Printed Circuit Board |

| SF | Spread factor |

| SP | Solar panel |

| THMDL | Temperature and Humidity Measurement Device for LoRaWAN |

| TTN | The Things Network |

| Wi-Fi | Wireless Fidelity |

References

- Goumopoulos, C.; O’Flynn, B.; Kameas, A. Automated zone-specific irrigation with wireless sensor/actuator network and adaptable decision support. Comput. Electron. Agric. 2014, 105, 20–33. [Google Scholar] [CrossRef]

- Banđur, Đ.; Jakšić, B.; Banđur, M.; Jović, S. An analysis of energy efficiency in Wireless Sensor Networks (WSNs) applied in smart agriculture. Comput. Electron. Agric. 2019, 156, 500–507. [Google Scholar] [CrossRef]

- Kochhar, A.; Kumar, N. Wireless sensor networks for greenhouses: An end-to-end review. Comput. Electron. Agric. 2019, 163, 104877. [Google Scholar] [CrossRef]

- Hamami, L.; Nassereddine, B. Application of wireless sensor networks in the field of irrigation: A review. Comput. Electron. Agric. 2020, 179, 105782. [Google Scholar] [CrossRef]

- Froiz-Míguez, I.; Lopez-Iturri, P.; Fraga-Lamas, P.; Celaya-Echarri, M.; Blanco-Novoa, Ó.; Azpilicueta, L.; Falcone, F.; Fernández-Caramés, T.M. Design, implementation, and empirical validation of an IoT smart irrigation system for fog computing applications based on Lora and Lorawan sensor nodes. Sensors 2020, 20, 6865. [Google Scholar] [CrossRef]

- Valente, A.; Silva, S.; Duarte, D.; Pinto, F.C.; Soares, S. Low-cost lorawan node for agro-intelligence iot. Electronics 2020, 9, 987. [Google Scholar] [CrossRef]

- Ameloot, T.; van Torre, P.; Rogier, H. Variable link performance due to weather effects in a long-range, low-power lora sensor network. Sensors 2021, 21, 3128. [Google Scholar] [CrossRef]

- Cano-Ortega, A.; Sánchez-Sutil, F. Performance optimization Lora network by artificial bee colony algorithm to determination of the load profiles in dwellings. Energies 2020, 13, 517. [Google Scholar] [CrossRef] [Green Version]

- Sánchez-Sutil, F.; Cano-Ortega, A. Design and testing of a power analyzer monitor and programming device in industries with a lora lpwan network. Electronics 2021, 10, 453. [Google Scholar] [CrossRef]

- Sanchez-Sutil, F.; Cano-Ortega, A. Smart regulation and efficiency energy system for street lighting with LoRa LPWAN. Sustain. Cities Soc. 2021, 70, 102912. [Google Scholar] [CrossRef]

- Cruz, N.; Cota, N.; Tremoceiro, J. Lorawan and urban waste management—A trial. Sensors 2021, 21, 2142. [Google Scholar] [CrossRef]

- Singh, R.K.; Aernouts, M.; De Meyer, M.; Weyn, M.; Berkvens, R. Leveraging LoRaWAN Technology for Precision Agriculture in Greenhouses. Sensors 2020, 20, 1827. [Google Scholar] [CrossRef] [Green Version]

- Nam, W.-H.; Kim, T.; Hong, E.-M.; Choi, J.-Y.; Kim, J.-T. A Wireless Sensor Network (WSN) application for irrigation facilities management based on Information and Communication Technologies (ICTs). Comput. Electron. Agric. 2017, 143, 185–192. [Google Scholar] [CrossRef]

- Goap, A.; Sharma, D.; Shukla, A.K.; Krishna, C.R. An IoT based smart irrigation management system using Machine learning and open source technologies. Comput. Electron. Agric. 2018, 155, 41–49. [Google Scholar] [CrossRef]

- Canales-Ide, F.; Zubelzu, S.; Rodríguez-Sinobas, L. Irrigation systems in smart cities coping with water scarcity: The case of valdebebas, Madrid (Spain). J. Environ. Manag. 2019, 247, 187–195. [Google Scholar] [CrossRef]

- Munir, M.S.; Bajwa, I.S.; Naeem, M.A.; Ramzan, B. Design and implementation of an IoT system for smart energy consumption and smart irrigation in tunnel farming. Energies 2018, 11, 3427. [Google Scholar] [CrossRef] [Green Version]

- Migliaccio, K.W.; Morgan, K.T.; Fraisse, C.; Vellidis, G.; Andreis, J.H. Performance evaluation of urban turf irrigation smartphone app. Comput. Electron. Agric. 2015, 118, 136–142. [Google Scholar] [CrossRef]

- Fernández-Ahumada, L.M.; Ramírez-Faz, J.; Torres-Romero, M.; López-Luque, R. Proposal for the design of monitoring and operating irrigation networks based on IoT, cloud computing and free hardware technologies. Sensors 2019, 19, 2318. [Google Scholar] [CrossRef] [Green Version]

- Fraga-Lamas, P.; Celaya-Echarri, M.; Azpilicueta, L.; Lopez-Iturri, P.; Falcone, F.; Fernández-Caramés, T.M. Design and Empirical Validation of a LoRaWAN IoT Smart Irrigation System. Proceedings 2020, 42, 62. [Google Scholar] [CrossRef] [Green Version]

- Chazarra-Zapata, J.; Parras-Burgos, D.; Arteaga, C.; Ruiz-Canales, A.; Molina-Martínez, J.M. Adaptation of a traditional irrigation system of micro-plots to smart agri development: A case study in murcia (Spain). Agronomy 2020, 10, 1365. [Google Scholar] [CrossRef]

- López-Morales, J.A.; Martínez, J.A.; Skarmeta, A.F. Improving energy efficiency of irrigation wells by using an iot-based platform. Electronics 2021, 10, 250. [Google Scholar] [CrossRef]

- Glória, A.; Dionísio, C.; Simões, G.; Cardoso, J.; Sebastião, P. Water management for sustainable irrigation systems using internet-of-things. Sensors 2020, 20, 1402. [Google Scholar] [CrossRef] [Green Version]

- Khan, N.; Ray, R.L.; Sargani, G.R.; Ihtisham, M.; Khayyam, M.; Ismail, S. Current progress and future prospects of agriculture technology: Gateway to sustainable agriculture. Sustainability 2021, 13, 4883. [Google Scholar] [CrossRef]

- Mohammed, M.; Riad, K.; Alqahtani, N. Efficient iot-based control for a smart subsurface irrigation system to enhance irrigation management of date palm. Sensors 2021, 21, 3942. [Google Scholar] [CrossRef] [PubMed]

- Tiglao, N.M.; Alipio, M.; Balanay, J.V.; Saldivar, E.; Tiston, J.L. Agrinex: A low-cost wireless mesh-based smart irrigation system. Measurement 2020, 161, 107874. [Google Scholar] [CrossRef]

- Sanchez-Sutil, F.; Cano-Ortega, A. Smart public lighting control and measurement system using lora network. Electronics 2020, 9, 124. [Google Scholar] [CrossRef] [Green Version]

- Al-Ali, A.R.; Nabulsi, A.A.; Mukhopadhyay, S.; Awal, M.S.; Fernandes, S.; Ailabouni, K. IoT-solar energy powered smart farm irrigation system. J. Electron. Sci. Technol. 2020, 30, 100017. [Google Scholar] [CrossRef]

- Sudharshan, N.; Karthik, A.V.S.K.; Kiran, J.S.S.; Geetha, S. Renewable Energy Based Smart Irrigation System. Procedia Comput. Sci. 2019, 165, 615–623. [Google Scholar] [CrossRef]

- Nawandar, N.K.; Satpute, V.R. IoT based low cost and intelligent module for smart irrigation system. Comput. Electron. Agric. 2019, 162, 979–990. [Google Scholar] [CrossRef]

- Liao, R.; Zhang, S.; Zhang, X.; Wang, M.; Wu, H.; Zhangzhong, L. Development of smart irrigation systems based on real-time soil moisture data in a greenhouse: Proof of concept. Agric. Water Manag. 2021, 245, 106632. [Google Scholar] [CrossRef]

- Eltohamy, K.M.; Liu, C.; Khan, S.; Niyungeko, C.; Jin, Y.; Hosseini, S.H.; Li, F.; Liang, X. An internet-based smart irrigation approach for limiting phosphorus release from organic fertilizer-amended paddy soil. J. Clean. Prod. 2021, 293, 126254. [Google Scholar] [CrossRef]

- The Things Network. Available online: https://www.thethingsnetwork.org (accessed on 10 September 2021).

- AWS IoT. Available online: https://aws.amazon.com/es/iot/ (accessed on 10 September 2021).

- Akenza.io. Available online: https://akenza.io/features (accessed on 10 September 2021).

- DaraCake. Available online: https://datacake.co (accessed on 10 September 2021).

- deZem. Available online: https://www.dezem.de/en/data-acquisition/lorawan/ (accessed on 10 September 2021).

- Influx, DB. Available online: https://docs.influxdata.com/influxdb/v2.0/get-started/ (accessed on 10 September 2021).

- Microsoft Azure. Available online: https://azure.microsoft.com/es-es/ (accessed on 10 September 2021).

- Qubitro. Available online: https://www.qubitro.com (accessed on 10 September 2021).

- Tago, IO. Available online: https://tago.io (accessed on 10 September 2021).

- The Things.io. Available online: https://thethings.io (accessed on 10 September 2021).

- Things Board. Available online: https://thingsboard.io (accessed on 10 September 2021).

- ThingSpeak. Available online: https://thingspeak.com (accessed on 10 September 2021).

- Ubidots. Available online: https://ubidots.com (accessed on 10 September 2021).

- UIB. Available online: https://uib.ai (accessed on 10 September 2021).

- MQTT. Available online: https://mqtt.org (accessed on 10 September 2021).

- LoRa Cloud. Available online: https://www.loracloud.com (accessed on 10 September 2021).

- Node-RED. Available online: https://nodered.org (accessed on 10 September 2021).

- IFTTT. Available online: https://ifttt.com (accessed on 10 September 2021).

- Google Sheets. Available online: https://www.google.es/intl/es/sheets/about/ (accessed on 10 September 2021).

- Firebase. Available online: https://firebase.google.com/ (accessed on 10 September 2021).

- Arduino Nano. Available online: https://store.arduino.cc/arduino-nano (accessed on 10 September 2021).

- Arduino Uno. Available online: https://store.arduino.cc/products/arduino-uno-rev3/ (accessed on 25 September 2021).

- Arduino Mega. Available online: https://store.arduino.cc/products/arduino-mega-2560-rev3 (accessed on 25 September 2021).

- Arduino Micro. Available online: https://store.arduino.cc/products/arduino-micro (accessed on 25 September 2021).

- Semtech SX1308. Available online: https://www.semtech.com/products/wireless-rf/lora-gateways/sx1308 (accessed on 1 September 2021).

- Semtech SX1301. Available online: https://www.semtech.com/products/wireless-rf/lora-gateways/sx1301 (accessed on 10 September 2021).

- Semtech SX1276/SX1278 LoRa Chip. Available online: https://www.semtech.com/products/wirelessrf/loratransceivers/sx1276 (accessed on 10 September 2021).

- Semtech SX1257. Available online: https://www.semtech.com/products/wireless-rf/lora-core/sx1257 (accessed on 10 September 2021).

- HOPERF Chip RFM95/96/97/98. Available online: https://cdn.sparkfun.com/assets/learn_tutorials/8/0/4/RFM95_96_97_98W.pdf (accessed on 10 September 2021).

- Murata Electronics. Available online: https://wireless.murata.com/pub/RFM/data/type_abz.pdf (accessed on 10 September 2021).

- Arduino MKR WAN 1300. Available online: https://store.arduino.cc/mkr-wan-1300 (accessed on 10 September 2021).

- Monteino. Available online: https://lowpowerlab.com/guide/moteino/ (accessed on 10 September 2021).

- Libelium. Available online: http://www.libelium.com/extreme-range-wireless-sensors-connectivity-throughbuildings-incity-lora-868mhz-915mhz/ (accessed on 10 September 2021).

- Lopy4. Available online: https://docs.pycom.io/gettingstarted/connection/lopy4/ (accessed on 10 September 2021).

- Dragino LoRa Bee for Arduino. Available online: https://www.dragino.com/products/lora/item/109-lora-bee.html (accessed on 10 September 2021).

- Dragino Concentrator PG1301. Available online: https://www.dragino.com/products/lora/item/149-lora-gps-hat.html (accessed on 10 September 2021).

- Dragino OLG01. Available online: https://www.dragino.com/products/lora-lorawan-gateway/item/118-olg01.html (accessed on 25 September 2021).

- Dragino OLG02. Available online: https://www.dragino.com/products/lora-lorawan-gateway/item/136-olg02.html (accessed on 25 September 2021).

- Dragino LoRa Hat. Available online: https://www.dragino.com/products/lora/item/106-lora-gps-hat.html (accessed on 25 September 2021).

- FZ0430 Voltage Sensor. Available online: http://www.ekt2.com/pdf/412_ARDUINO_SENSOR_VOLTAGE_DETECTOR.pdf (accessed on 10 September 2021).

- ACS712. Available online: https://www.sparkfun.com/datasheets/BreakoutBoards/0712.pdf (accessed on 10 April 2021).

- INA219. Available online: https://www.ti.com/lit/ds/symlink/ina219.pdf (accessed on 10 September 2021).

- SHT1x. Available online: https://www.sensirion.com/environmental-sensors/humidity-sensors/digital-humidity-sensors-for-accurate-measurements/ (accessed on 10 September 2021).

- SHT2x. Available online: https://www.sensirion.com/en/environmental-sensors/humidity-sensors/humidity-temperature-sensor-sht2x-digital-i2c-accurate/ (accessed on 10 September 2021).

- SHT3x. Available online: https://www.sensirion.com/en/environmental-sensors/humidity-sensors/digital-humidity-sensors-for-various-applications/ (accessed on 10 September 2021).

- DHT11. Available online: https://www.mouser.com/datasheet/2/758/DHT11-Technical-Data-Sheet-Translated-Version-1143054.pdf (accessed on 10 September 2021).

- DHT22. Available online: https://www.sparkfun.com/datasheets/Sensors/Temperature/DHT22.pdf (accessed on 10 September 2021).

- LiPo Rider Pro. Available online: https://wiki.seeedstudio.com/Lipo_Rider_Pro/ (accessed on 10 September 2021).

- LiPo Rider Plus. Available online: https://wiki.seeedstudio.com/Lipo-Rider-Plus/ (accessed on 25 September 2021).

- LiPo Rider v1.3. Available online: https://wiki.seeedstudio.com/Lipo_Rider_V1.3/ (accessed on 25 September 2021).

- Solar Panel. Available online: https://wiki.seeedstudio.com/3W_Solar_Panel_138x160/ (accessed on 10 September 2021).

- Battery. Available online: https://es.rs-online.com/web/p/baterias-recargables/1449408/ (accessed on 10 September 2021).

- Wemos D1 Mini. Available online: https://www.wemos.cc/en/latest/d1/d1_mini.html (accessed on 10 September 2021).

- NodeMCU. Available online: https://components101.com/development-boards/nodemcu-esp8266-pinout-features-anddatasheet (accessed on 10 September 2021).

- Wemos D1 Mini Pro. Available online: https://www.wemos.cc/en/latest/d1/d1_mini_pro.html (accessed on 10 September 2021).

- Wemos D1 R1. Available online: http://www.esp8266learning.com/wemos-d1-esp8266-based-board.php (accessed on 10 September 2021).

- ETSI. Electromagnetic Compatibility and Radio Spectrum Matters (ERM); Short Range Devices (SRD); Radio Equipment To Be Used in the 25 MHz to 1000 MHz Frequency Range with Power Levels Ranging Up To 500 mW. European Harmonized Standard. EN 2019, 300; ETSI: Sophia Antipolis, France, 2019; Volume 3. [Google Scholar]

| Component | Surface (mm2) | Microcontroller | Current Consumption (mA) | Flash Memory (kB) | Clock Speed (MHz) | Unit Price (€) |

|---|---|---|---|---|---|---|

| Arduino Uno [53] | 3663.24 | ATmega328P | 46 | 32 | 16 | 20.00 |

| Arduino Mega [54] | 5421.17 | ATmega2560 | 93 | 256 | 16 | 35.00 |

| Arduino Nano [52] | 810.00 | ATmega328 | 15 | 32 | 16 | 20.00 |

| Arduino Micro [55] | 864.00 | ATmega32U4 | 15 | 32 | 16 | 18.00 |

| Component | Surface (mm2) | Current Consumption (A) | RSSI Range (dBm) | Sensitivity (dBm) | Blocking Immunity | Unit Price (€) |

|---|---|---|---|---|---|---|

| Lopy4 [65] | 1100.00 | Rx 12 mA–0.2 µA register retention | −126 | −148 | High | 33.06 |

| Monteino [63] | 240.05 | RX 10.3 mA–200 nA register retention | −127 | −148 | Excellent | 22.95 |

| Libelium [63] | 775.00 | RX 10.3 mA–200 nA register retention | −127 | −148 | Excellent | 32.35 |

| MKR WAN 1310 [62] | 1693.75 | Rx 23.5 mA | −117.5 | −133.5 | High | 33.00 |

| Dragino LoRa Bee [66] | 775.00 | RX 10.3 mA–200 nA register retention | −127 | −148 | Excellent | 14.50 |

| Component | Number of Channels | Communication Paths | Number of LoRa Devices | Unit Price (€) |

|---|---|---|---|---|

| Dragino OLG01 [68] | 1 | Ethernet—Wi-Fi—3G/4G | 300 | 85.79 |

| Dragino OLG02 [69] | 2 | Ethernet—Wi-Fi—3G/4G | 300 | 95.89 |

| LoRa concentrator [67] | 10 | Ethernet—Wi-Fi provided by Raspberry | 1000 | 100.19 |

| LoRa GPS Hat [70] | 1 | Ethernet—Wi-Fi provided by Raspberry | 300 | 35.90 |

| Component | Measured Variable | Surface (mm2) | Price (€) |

|---|---|---|---|

| FZ0430 [71] | Voltage | 378 | 1.73 |

| ACS712 [72] | Current | 420 | 1.28 |

| IN219 [73] | Voltage, current, PF and power | 2211 | 1.70 |

| Sensor | Humidity Accuracy (%) | Temperature Accuracy (°C) | Supply Voltage (V) | Energy Consumption (µW) | Humidity Range (%) | Temperature Range (°C) | Interface |

|---|---|---|---|---|---|---|---|

| SHT10 [74] | ±4.5 | ±0.5 | 2.4–5.5 | 80 | 0–100 | −40/125 | SBus |

| SHT11 [74] | ±3 | ±0.4 | |||||

| SHT15 [74] | ±2 | ±0.3 | |||||

| SHT20 [75] | ±2 | ±0.3 | 2.1–3.6 | 3.2 | 0–100 | −40/125 | I2C PWM SDM |

| SHT21 [75] | ±2 | ±0.3 | |||||

| SHT25 [75] | ±1.8 | ±0.2 | |||||

| SHT30 [76] | ±2 | ±0.2 | 2.15–5.5 | 4.8 | 0–100 | −40/125 | I2C |

| SHT31 [76] | ±2 | ±0.2 | |||||

| SHT35 [76] | ±1.5 | ±0.1 | |||||

| DHT11 [77] | ±5 | ±5 | 3.3–5 | 100 | 20–80 | 0–50 | Digital pin |

| DHT22 [78] | ±5 | ±5 | 3.3–5 | 100 | 0–100 | −40/125 | Digital pin |

| Sensor | Vin Solar (V) | Icharge (mA) | Iload (mA) | Vbatt (V) | Vsource (%) | Vdestination (°C) |

|---|---|---|---|---|---|---|

| Lipo Rider Pro [79] | 5 | 500 | 1000 | 4.2 | 5 | 5 |

| Lipo Rider Plus [80] | 5 | 250 | 250 | 100 | 3.3 | 3.3 |

| Lipo Rider v1.3 [81] | 5 | 800 | 600 | 4.2 | 5 | 5 |

| Description | Number | Unit Price (€) | Total (€) |

|---|---|---|---|

| Microcontroller Arduino Nano | 2 | 20.00 | 40.00 |

| Dragino LoRa Bee | 1 | 14.50 | 14.50 |

| INA219 | 1 | 1.70 | 1.70 |

| Battery | 1 | 32.96 | 32.96 |

| PCB board | 1 | 0.40 | 0.40 |

| SHT30 sensor | 1 | 6.80 | 6.80 |

| Box container | 1 | 2.54 | 2.54 |

| Auxiliary material and wiring | - | 1.05 | 1.05 |

| Total cost | 99.95 |

| Description | Number | Unit Price (€) | Total (€) |

|---|---|---|---|

| Microcontroller Arduino Nano | 2 | 20.00 | 40.00 |

| Dragino LoRa Bee | 1 | 14.50 | 14.50 |

| INA219 | 3 | 1.70 | 5.10 |

| Battery | 1 | 32.96 | 32.96 |

| Solar panel | 1 | 12.28 | 12.28 |

| Li-Po Rider Pro | 1 | 15.33 | 15.33 |

| PCB board | 1 | 0.40 | 0.40 |

| SHT30 sensor | 1 | 6.80 | 6.80 |

| Box container | 1 | 3.02 | 3.02 |

| Auxiliary material and wiring | - | 1.27 | 1.27 |

| Total cost | 131.66 |

| Description | Number | Unit Price (€) | Total (€) |

|---|---|---|---|

| Microcontroller Arduino Nano | 2 | 20.00 | 40.00 |

| Dragino LoRa Bee | 1 | 14.50 | 14.50 |

| INA219 | 1 | 1.70 | 1.70 |

| Battery | 1 | 32.96 | 32.96 |

| PCB board | 1 | 0.40 | 0.40 |

| Relay | 1 | 0.27 | 0.27 |

| Box container | 1 | 2.54 | 2.54 |

| Auxiliary material and wiring | - | 1.05 | 1.05 |

| Total cost | 93.62 |

| Description | Number | Unit Price (€) | Total (€) |

|---|---|---|---|

| Microcontroller Arduino Nano | 2 | 20.00 | 40.00 |

| Dragino LoRa Bee | 1 | 14.50 | 14.50 |

| INA219 | 3 | 1.70 | 5.10 |

| Battery | 1 | 11.50 | 11.50 |

| Solar panel | 1 | 12.28 | 12.28 |

| Li-Po Rider Pro | 1 | 15.33 | 15.33 |

| PCB board | 1 | 0.55 | 0.55 |

| Relay | 1 | 0.27 | 0.27 |

| Box container | 1 | 3.02 | 3.02 |

| Auxiliary material and wiring | - | 1.27 | 1.27 |

| Total cost | 122.28 |

| Data Rate | Parameters | Airtime | Duty Cycle (1% max) | Fair Access Policy | |||

|---|---|---|---|---|---|---|---|

| Time (s) | Msg/Hour | Avg/s | Avg/Hour | Msg/24h | |||

| DR5 | SF7-BW125 | 66.8 | 6.7 | 538 | 192.4 | 18.7 | 448 |

| DR4 | SF8-BW125 | 123.4 | 12.3 | 291 | 355.4 | 10.1 | 243 |

| DR3 | SF9-BW125 | 226.3 | 22.6 | 159 | 651.8 | 5.5 | 132 |

| DR2 | SF10-BW125 | 441.6 | 41.2 | 87 | 1185.5 | 3.0 | 72 |

| DR1 | SF11-BW125 | 905.2 | 90.5 | 39 | 2607.0 | 1.4 | 33 |

| DR0 | SF12-BW125 | 1646.2 | 164.7 | 21 | 4742.2 | 0.8 | 18 |

| DR6 | SF6-BW250 | 33.4 | 3.3 | 1077 | 96.2 | 37.4 | 897 |

| Month | Energy Generated (Wh) | Sample Daily Mean (Wh) | Sample Variance (Wh2) | Sample Skewness (Wh3) | Sample Kurtosis (Wh4) |

|---|---|---|---|---|---|

| January | 73.6329 | 2.3768 | 0.0026 | 0.0143 | 1.7544 |

| February | 68.7263 | 2.3715 | 0.0025 | 0.0418 | 1.8301 |

| March | 73.5223 | 2.3764 | 0.0025 | −0.0118 | 1.8161 |

| April | 71.2977 | 2.3782 | 0.0026 | −0.0391 | 1.7955 |

| May | 73.6111 | 2.3761 | 0.0025 | 0.0044 | 1.8280 |

| June | 71.2468 | 2.3765 | 0.0025 | 0.0084 | 1.8135 |

| July | 73.4652 | 2.3714 | 0.0025 | 0.0613 | 1.8834 |

| August | 73.5958 | 2.3756 | 0.0026 | 0.0163 | 1.7741 |

| September | 71.3757 | 2.3808 | 0.0025 | −0.0511 | 1.8063 |

| October | 73.5985 | 2.3757 | 0.0025 | −0.0037 | 1.8309 |

| November | 71.1906 | 2.3746 | 0.0025 | 0.0261 | 1.8079 |

| December | 73.7580 | 2.3808 | 0.0025 | −0.0592 | 1.8529 |

| Year | 869.0216 | 2.3762 | 0.0025 | 0.0008 | 1.8140 |

| Month | Energy Generated (Wh) | Sample Daily Mean (Wh) | Sample Variance (Wh2) | Sample Skewness (Wh3) | Sample Kurtosis (Wh4) |

|---|---|---|---|---|---|

| January | 202.19 | 6.5266 | 0.2142 | 1.3553 | 3.4122 |

| February | 276.04 | 9.5255 | 0.2751 | 0.9939 | 2.3714 |

| March | 394.35 | 12.7469 | 0.3600 | 1.0546 | 2.6887 |

| April | 452.60 | 15.0974 | 0.4086 | 1.0099 | 2.5663 |

| May | 538.46 | 17.3816 | 0.4194 | 0.7060 | 1.9756 |

| June | 567.23 | 18.9210 | 0.4213 | 0.4987 | 1.6505 |

| July | 542.87 | 17.5239 | 0.3927 | 0.4846 | 1.5712 |

| August | 496.76 | 16.0353 | 0.3786 | 0.5693 | 1.6509 |

| September | 399.08 | 13.3120 | 0.3475 | 0.8171 | 2.0916 |

| October | 326.09 | 10.5262 | 0.2974 | 0.9640 | 2.3564 |

| November | 204.23 | 6.8126 | 0.2220 | 1.3580 | 3.4074 |

| December | 194.77 | 6.2873 | 0.2103 | 1.3909 | 3.5401 |

| Year | 4594.73 | 12.5639 | 0.3502 | 1.0595 | 2.7639 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez-Sutil, F.; Cano-Ortega, A. Smart Control and Energy Efficiency in Irrigation Systems Using LoRaWAN. Sensors 2021, 21, 7041. https://doi.org/10.3390/s21217041

Sánchez-Sutil F, Cano-Ortega A. Smart Control and Energy Efficiency in Irrigation Systems Using LoRaWAN. Sensors. 2021; 21(21):7041. https://doi.org/10.3390/s21217041

Chicago/Turabian StyleSánchez-Sutil, Francisco, and Antonio Cano-Ortega. 2021. "Smart Control and Energy Efficiency in Irrigation Systems Using LoRaWAN" Sensors 21, no. 21: 7041. https://doi.org/10.3390/s21217041

APA StyleSánchez-Sutil, F., & Cano-Ortega, A. (2021). Smart Control and Energy Efficiency in Irrigation Systems Using LoRaWAN. Sensors, 21(21), 7041. https://doi.org/10.3390/s21217041