Wood Moisture-Content Measurement Accuracy of Impregnated and Nonimpregnated Wood

Abstract

:1. Introduction

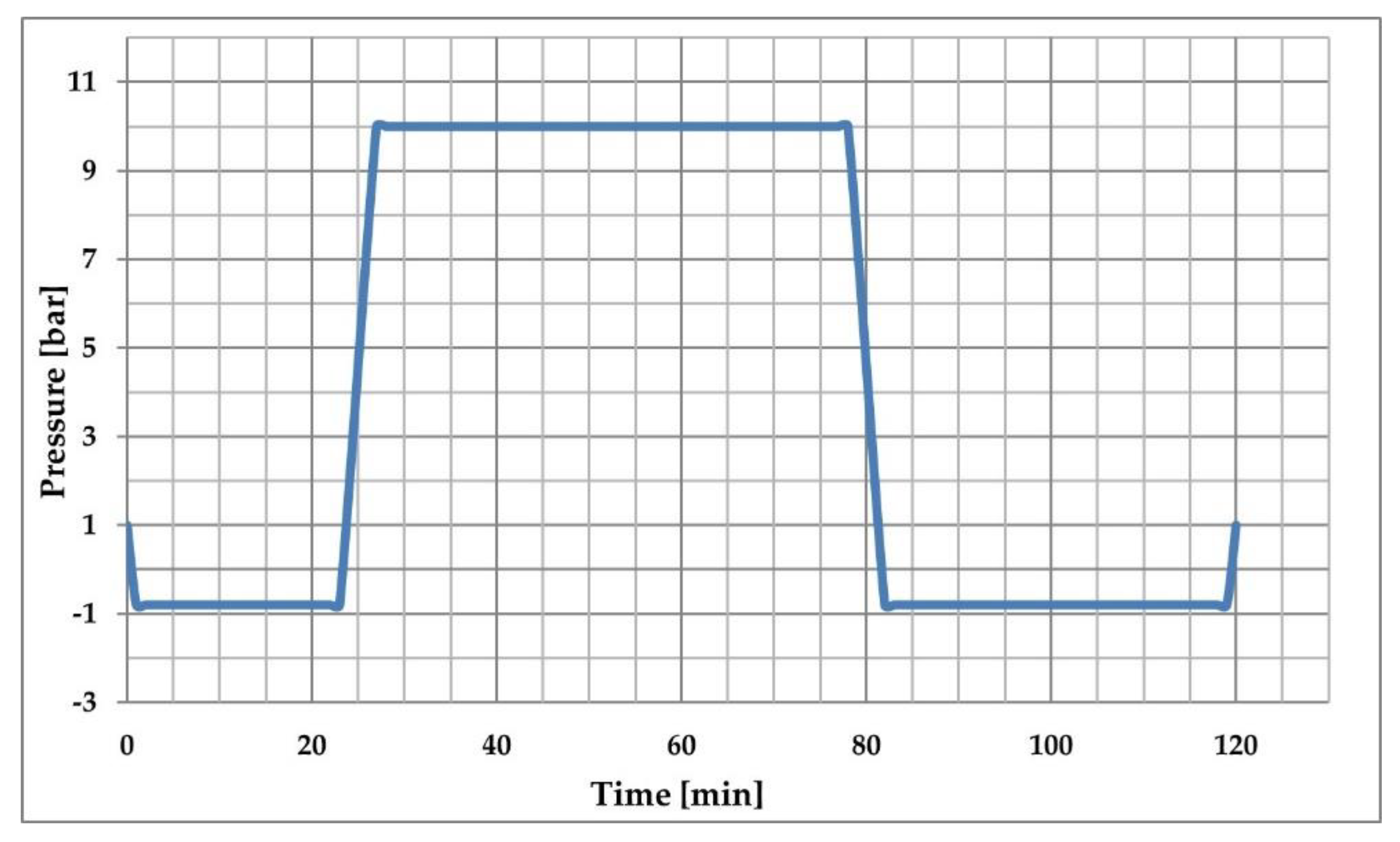

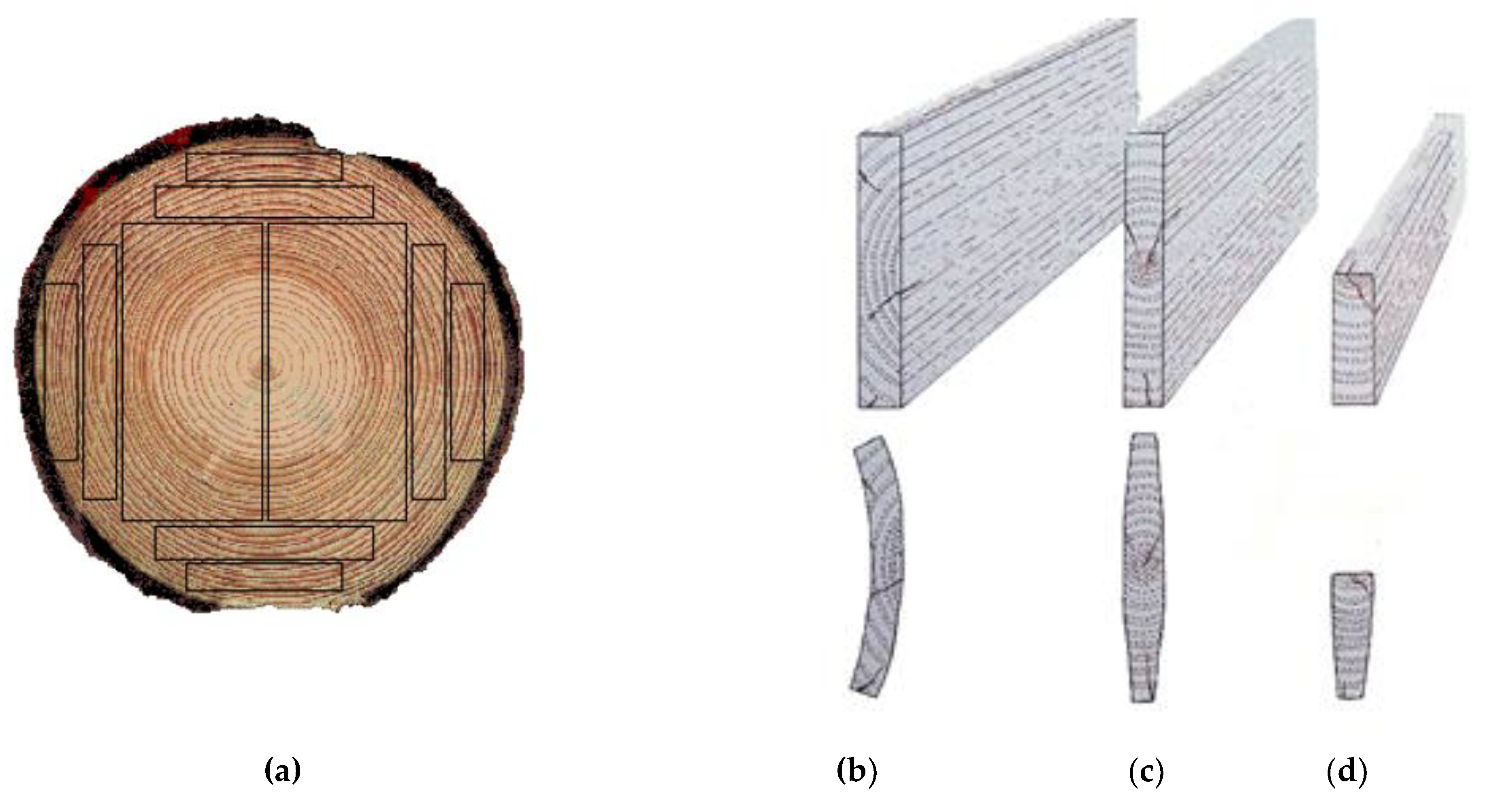

2. Materials and Methods

- mw is the mass of the moisture sample [grams];

- mo is the mass of the absolute dry sample [grams].

- Us is the constant voltage generated by power supply [9.45 V];

- Rm is the internal resistance of the multimeter, [10 MΩ];

- Um is the voltage indicated by multimeter [V];

- Uw is the voltage of wood samples [V] and

- Rw is the resistance of the pine wood [MΩ].

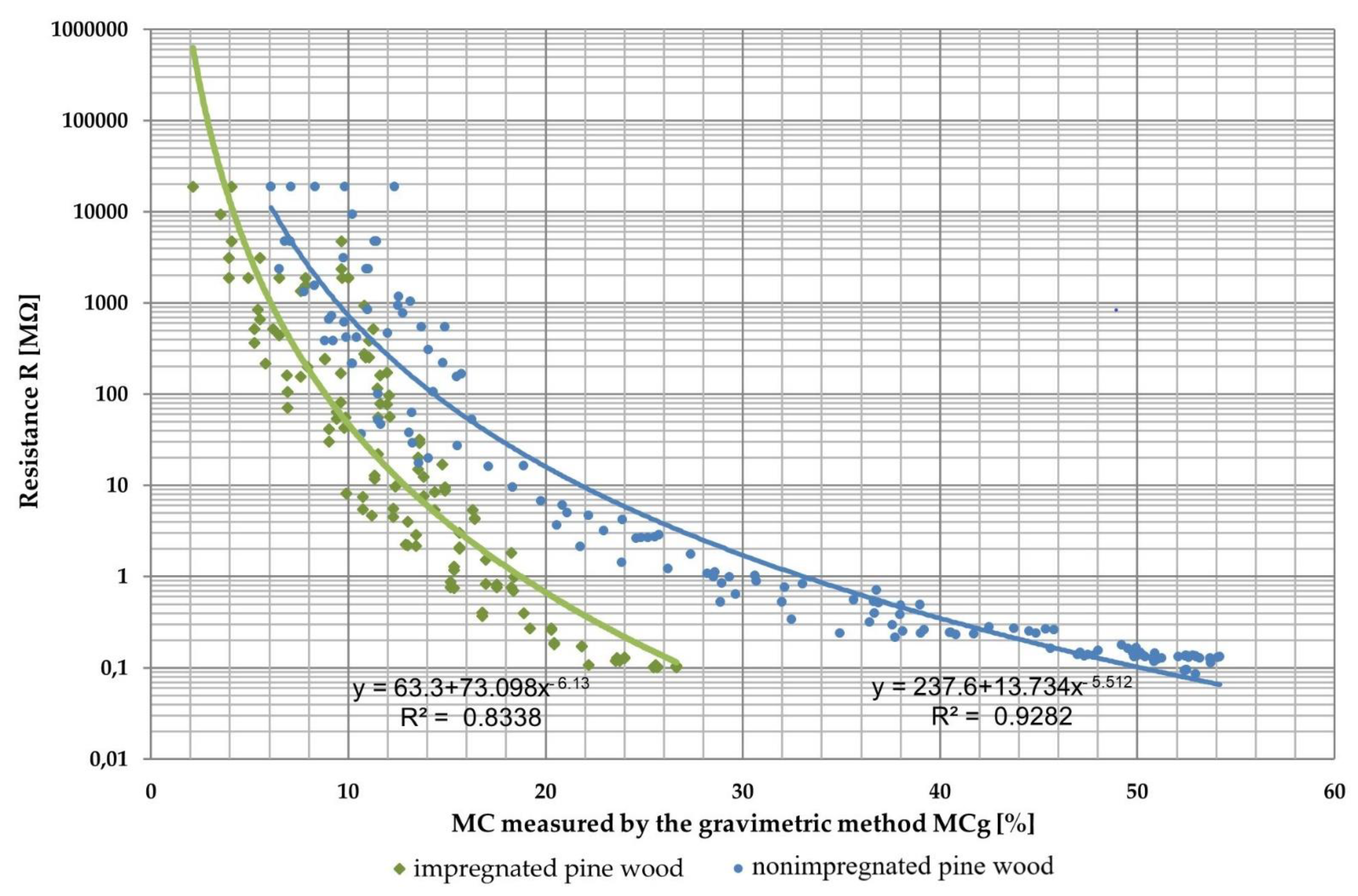

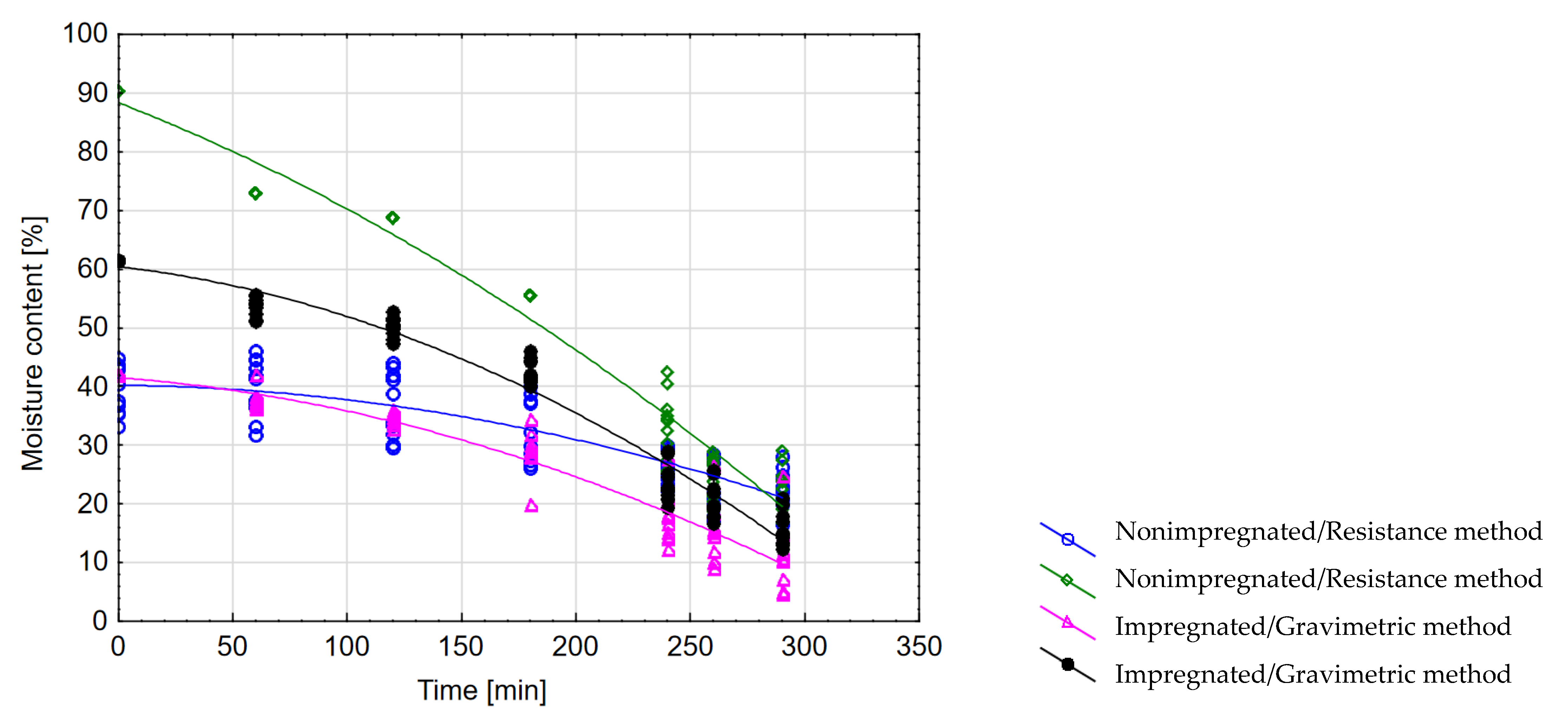

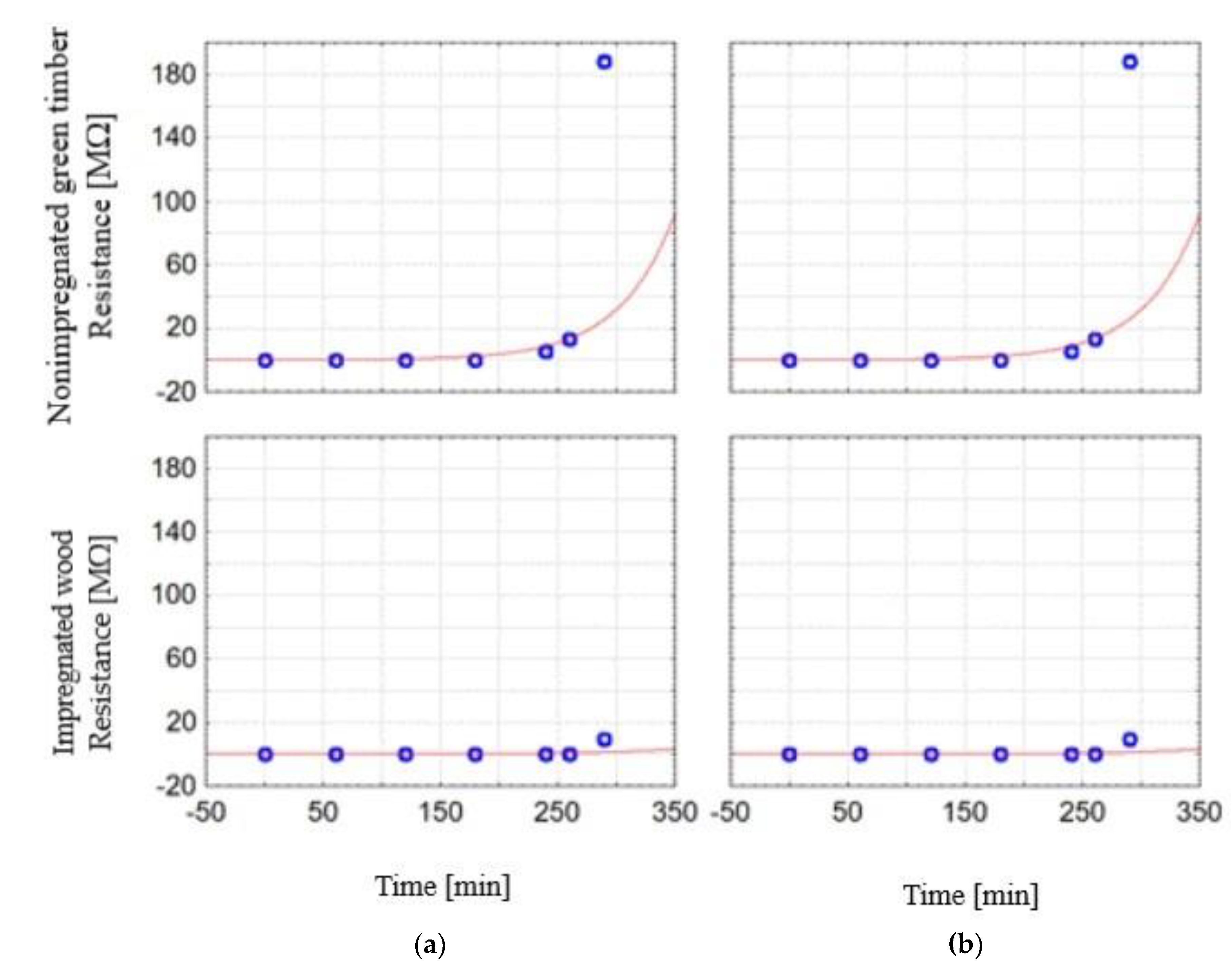

3. Results and Discussion

- MCg is the wood MC using gravimetric method [%];

- MCr is the wood MC using resistance meter, [%].

| Nonimpregnated Wood | Impregnated Wood | |||||

|---|---|---|---|---|---|---|

| Wood Samples’ Resistance | Gravimetric Method | Resistance Meter Method | Wood Samples’ Resistance | Gravimetric Method | Resistance Meter Method | |

| MC | MC | MC | MC | |||

| [MΩ] | [%] | [%] | [MΩ] | [%] | [%] | |

| 1. | 0.190 | 41.99 | 39.70 | 0.030 | 61.40 | 90.30 |

| 2. | 0.208 | 37.53 | 39.80 | 0.045 | 53.70 | 72.90 |

| 3. | 0.241 | 34.44 | 36.90 | 0.052 | 50.20 | 68.60 |

| 4. | 0.399 | 28.60 | 32.90 | 0.072 | 42.60 | 55.40 |

| 5. | 5.101 | 17.45 | 20.30 | 0.511 | 23.40 | 33.00 |

| 6. | 13.158 | 14.63 | 17.80 | 1.196 | 20.50 | 26.90 |

| 7. | 188.380 | 10.47 | 12.90 | 9.632 | 15.80 | 20.50 |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Esping, B.; Salin, J.G.; Brander, P. Fukt i trä för byggindustrin; Trätek: Stockholm, Sweden, 2005. (In Swedish) [Google Scholar]

- Esping, B. Test av kommersiella fuktkvotsmätare in-line; Trätek rapport Trätek: Stockholm, Sweden, 2003. (In Swedish) [Google Scholar]

- Nilsson, M. Evaluation of Three in-Line Wood Moisture Content Meters. Master’s thesis, Luleå University of Technology, Skellefteå, Sweden, 2010. [Google Scholar]

- Vikberg, T. Fuktkvotsmätare för träindustrin: En kartläggning av metoder för mätning av fuktkvoter i intervallet 7–18 fuktkvotsprocent; Technical report; Luleå University of Technology: Skellefteå, Sweden, 2010. (In Swedish) [Google Scholar]

- Dai, G. Ahmet, K. Long-term monitoring of timber moisture content below the fiber saturation point using wood resistance sensors. For. Prod. J. 2001, 51, 52–58. [Google Scholar]

- Tamme, V.; Muiste, P.; Tamme, H. Experimental study of resistance type wood moisture sensors for monitoring wood drying process above fibre saturation point. For. Stud. 2013, 59, 28–44. [Google Scholar]

- Brischke, C. Lampen, S.C. Resistance based moisture content measurements on native, modified and preservative treated wood. Eur. J. Wood Wood Prod. 2014, 72, 289–292. [Google Scholar] [CrossRef]

- Brashaw, B.K.; Wang, X.; Ross, R.J.; Pellerin, R.F. Relationship between stress wave velocities of green and dry veneer. For. Prod. J. 2004, 54, 85–89. [Google Scholar]

- Chan, J.M.; Walker, J.C.; Raymond, A.A. Effects of moisture content and temperature on acoustic velocity and dynamic MOE of radiata pine sapwood boards. Wood Sci. Technol. 2011, 45, 609–626. [Google Scholar] [CrossRef]

- Lundgren, N.; Hagman, O.; Johansson, J. Predicting moisture content and density distribution of Scots pine by microwave scanning of sawn timber II: Evaluation of models generated on a pixel level. J. Wood Sci. 2006, 52, 39–43. [Google Scholar] [CrossRef]

- Moschler, W.W.; Hanson, G.R.; Gee, T.F.; Killough, S.M.; Wilgen, J.B. Microwave moisture measurement system for lumber drying. For. Prod. J. 2007, 57, 69–74. [Google Scholar] [CrossRef]

- Jones, P.D.; Schimleck, L.R.; Peter, G.F.; Daniels, R.F.; Clark, A. Nondestructive estimation of Pinus taeda L. wood properties for samples from a wide range of sites in Georgia. Can. J. For. Res. 2005, 35, 85–92. [Google Scholar] [CrossRef] [Green Version]

- Schimleck, L.R.; Evans, R.; Matheson, A.C. Estimation of Pinus radiata D. Don clear wood properties by near-infrared spectroscopy. J. Wood Sci. 2009, 48, 132–137. [Google Scholar] [CrossRef]

- Tomppo, L.; Tiitta, M.; Laakso, T.; Harju, A.; Venalainen, M.; Lappalainen, R. Dielectric spectroscopy of Scots pine. Wood Sci. Technol. 2009, 43, 653–667. [Google Scholar] [CrossRef]

- Wullschleger, S.D.; Hanson, P.J.; Todd, D.E. Measuring stem water content in four deciduous hardwoods with a time-domain reflectometer. Tree Physiol. 1996, 16, 809–815. [Google Scholar] [CrossRef] [PubMed]

- Woodhead, I.M.; Buchan, G.D.; Christie, J.H.; Irie, K. A general dielectric model for time domain reflectometry. Biosyst. Eng. 2003, 86, 207–216. [Google Scholar] [CrossRef]

- Jazayeri, S.; Ahmet, K. Detection of transverse moisture gradients in timber by measurements of capacitance using a multiple-electrode arrangement. For. Prod. J. 2000, 50, 27–32. [Google Scholar]

- Xinguang, L.; Mingying, X. Applied research on moisture content measurement: One sided capacitance sensors. Meas. Control. 2009, 42, 84–86. [Google Scholar] [CrossRef]

- Jensen, P.D.; Hartmann, H.; Böhm, T.; Temmerman, M.; Rabier, F.; Morsing, M. Moisture content determination in solid biofuels by dielectric and NIR reflection methods. Biomass Bioenergy 2006, 30, 935–943. [Google Scholar] [CrossRef]

- Stamm, A.J. The electrical resistance of wood as a measure of its moisture content. Ind. Eng. Chem. 1927, 19, 1021–1025. [Google Scholar] [CrossRef]

- Skaar, C. Wood-Water Relations; Springer-Verlag: Berlin/Heidelberg, Germany, 1988. [Google Scholar]

- Stamm, A.J. The fiber-saturation point of wood as obtained from electrical conductivity measurements. Ind. Eng. Chem. Anal. Ed. 1929, 1, 94–97. [Google Scholar] [CrossRef]

- Flotaker, S.; Tronstad, S. Description and Initial Test of 8 Principles for in-Kiln Measuring and End-Point Control of Wood Moisture Content. 2000. Available online: http://www.treteknisk.no/resources/filer/publikasjoner/rapporter/Rapport-47.pdf (accessed on 6 June 2021).

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Rowell, R.M. Structure and function of wood. In Handbook of Wood Chemistry and Wood Composites, 2nd ed; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2013. [Google Scholar]

- Forsén, H.; Tarvainen, V. Accuracy and Functionality of Hand-Held Wood Moisture Content Meters, Revised ed.; VTT Publications, VTT Technical Research Centre of Finland: Espoo, Finland, 2000. [Google Scholar]

- Hill, C.A. Wood Modification: Chemical; Thermal and Other Processes: Wiley, Chichester, UK, 2006. [Google Scholar]

- Militz, H. Treatment of timber with water soluble dimethylol resins to improve their dimensional stability and durability. Wood Sci. Technol. 1993, 27, 347–355. [Google Scholar] [CrossRef]

- Schneider, M.H. New cell wall and cell lumen wood polymer composites. Wood Sci. Technol. 1995, 29, 121–127. [Google Scholar] [CrossRef]

- Keplinger, T.; Cabane, E.; Chanana, M.; Hass, P.; Merk, V.; Gierlinger, N.; Burgert, I. A versatile starategy for grafting polymers to wood cell walls. Acta Biomater. 2015, 11, 256–263. [Google Scholar] [CrossRef] [PubMed]

- Rowell, R.M.; Konkol, P. Treatments That Enhance Physical Properties of Wood. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1987. [Google Scholar]

- Lande, S.; Westin, M.; Schneider, M. Properties of furfurylated wood. Scand. J. For. Res. 2004, 19, 22–30. [Google Scholar] [CrossRef]

- Marney, D.; Russell, L. Combined fire retardant and wood preservative treatments for outdoor wood applications–A review of the literature. Fire Technol. 2008, 44, 1–14. [Google Scholar] [CrossRef]

- Krzysik, F. Nauka o Drewnie (The science about the wood); Ed. PWN: Warszawa, Polska, 1978; p. 653. ISBN 2909. (In Polish) [Google Scholar]

- Babiński, L.K. Impregnacja drewna metodą próżniową. Ochr. Zabyt. 1992, 45, 179. [Google Scholar]

- EN 1995-1-1:2004. Eurocode 5: Design of Timber Structures—Part 1-1: General—Common Rules and Rules for Buildings; European Committee for Standardization CEN: Brussels, Belgium, 2004. [Google Scholar]

- EN 13183-1:2002. Moisture Content of a Piece of Sawn Timber—part 1: Determination by Oven Dry Method; European Committee for Standardization CEN: Brussels, Belgium, 2002. [Google Scholar]

- EN 13183-2:2002. Moisture Content of a Piece of Sawn Timber—Part 2: Estimation by Electrical Resistance Method; European Committee for Standardization CEN: Brussels, Belgium, 2002. [Google Scholar]

- EN 13183-3:2005. Moisture Content of a Piece of Sawn Timber—Part 3: Estimation by Capacitance Method; European Committee for Standardization CEN: Brussels, Belgium, 2005. [Google Scholar]

- ISO 13061-1: 2014. Physical and mechanical properties of wood-Test methods for small clear wood specimens-Part 1: Determination of Moisture Content for Physical and Mechanical Tests. Available online: https://www.iso.org/standard/60063.html (accessed on 20 June 2021).

- Gann Mess-, u. Regeltechnik GmbH, Gerlingen, Germany, RTU 600 an Electronic Wood Moisture Meter Data. Available online: http://www.gann.de/Produkte/ElektronischeFeuchtigkeitsmessgeräte/ClassicSerie/HydrometteRTU600/tabid/104/lang (accessed on 20 June 2021).

- Slandi Ltd. Co. Michalowice, Poland, MUC 2000 Digital Multimeter Data. Available online: http://polskiemultimetry.prv.pl (accessed on 20 June 2021).

| Impregnated Wood | Nonimpregnated Sawnwood | |||

|---|---|---|---|---|

| 1. | Average initial MC | MCi [%] | 27 | 55 |

| 2. | Average final MC | MCf [%] | 6.5 | 8.6 |

| 3. | Average initial density | ρi [kg/m3] | 640 | 520 |

| 4. | Average final density | ρf [kg/m3] | 530 | 480 |

| Nonimpregnated Boards | Impregnated Boards | |||||||

|---|---|---|---|---|---|---|---|---|

| Wood Samples’ Resistance | Gravimertic Method | Resistance Meter Method | Moisture-Content Difference | Wood Samples’ Resistance | Gravimetric Method | Resistance Meter Method | Moisture-Content Difference | |

| Moisture Content | Moisture Content | Moisture Content | Moisture Content | |||||

| [MΩ] | [%] | [%] | [%] | [MΩ] | [%] | [%] | [%] | |

| 1. | 0.190 | 41.99 | 39.70 | 0.297 | 0.030 | 61.40 | 90.30 | 22.154 |

| 2. | 0.208 | 37.53 | 39.80 | 0.365 | 0.045 | 53.70 | 72.90 | 12.783 |

| 3. | 0.241 | 34.44 | 36.90 | 0.510 | 0.052 | 50.20 | 68.60 | 13.434 |

| 4. | 0.399 | 28.60 | 32.90 | 2.260 | 0.072 | 42.60 | 55.40 | 9.028 |

| 5. | 5.101 | 17.45 | 20.30 | 2.667 | 0.511 | 23.40 | 33.00 | 16.831 |

| 6. | 13.158 | 14.63 | 17.80 | 4.695 | 1.196 | 20.50 | 26.90 | 9.746 |

| 7. | 188.380 | 10.47 | 12.90 | 5.386 | 9.632 | 15.80 | 20.50 | 8.848 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barański, J.; Suchta, A.; Barańska, S.; Klement, I.; Vilkovská, T.; Vilkovský, P. Wood Moisture-Content Measurement Accuracy of Impregnated and Nonimpregnated Wood. Sensors 2021, 21, 7033. https://doi.org/10.3390/s21217033

Barański J, Suchta A, Barańska S, Klement I, Vilkovská T, Vilkovský P. Wood Moisture-Content Measurement Accuracy of Impregnated and Nonimpregnated Wood. Sensors. 2021; 21(21):7033. https://doi.org/10.3390/s21217033

Chicago/Turabian StyleBarański, Jacek, Aleksandra Suchta, Sylwia Barańska, Ivan Klement, Tatiana Vilkovská, and Peter Vilkovský. 2021. "Wood Moisture-Content Measurement Accuracy of Impregnated and Nonimpregnated Wood" Sensors 21, no. 21: 7033. https://doi.org/10.3390/s21217033

APA StyleBarański, J., Suchta, A., Barańska, S., Klement, I., Vilkovská, T., & Vilkovský, P. (2021). Wood Moisture-Content Measurement Accuracy of Impregnated and Nonimpregnated Wood. Sensors, 21(21), 7033. https://doi.org/10.3390/s21217033