Standardized Extraction Techniques for Meat Analysis with the Electronic Tongue: A Case Study of Poultry and Red Meat Adulteration

Abstract

1. Introduction

2. Materials and Methods

2.1. Determination of Optimal Dilution

2.2. Determination of Optimal Extraction Method

2.2.1. Raw Meat Extraction with Distilled Water

2.2.2. Meat Extraction by Cooking with Distilled Water

2.2.3. Frozen Meat Extraction with Distilled Water

2.3. Electronic Tongue Measurements

2.4. Data Analysis

2.4.1. Classification of Meat Mixtures with Linear Discriminant Analysis

2.4.2. Partial Least Squares Regression

3. Results

3.1. Determination of Optimal Dilution

3.1.1. Linear Discriminant Analysis (LDA) Models Developed for the Determination of Optimal Dilution

3.1.2. Partial Least Squares (PLS) Regression Models Developed for the Determination of Optimal Dilution

3.2. Optimal Extraction Method

3.2.1. Results of Sensor Optimization for LDA Analysis in the Optimal Extraction Method

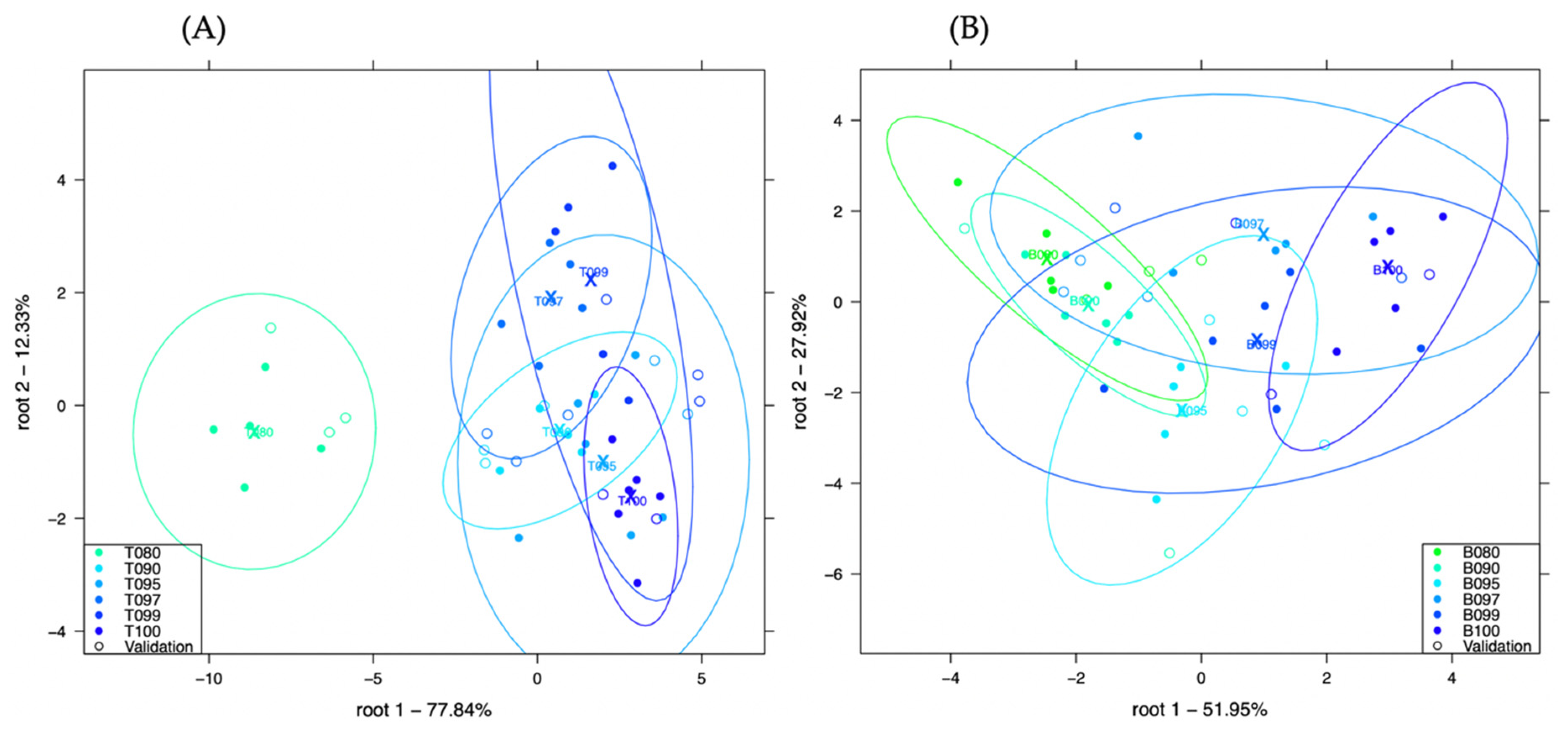

3.2.2. LDA Analysis for Raw Meat Extraction with Distilled Water in the Determination of Optimal Extraction

3.2.3. LDA Analysis for Meat Extraction by Cooking with Distilled Water for the Determination of Optimal Extraction

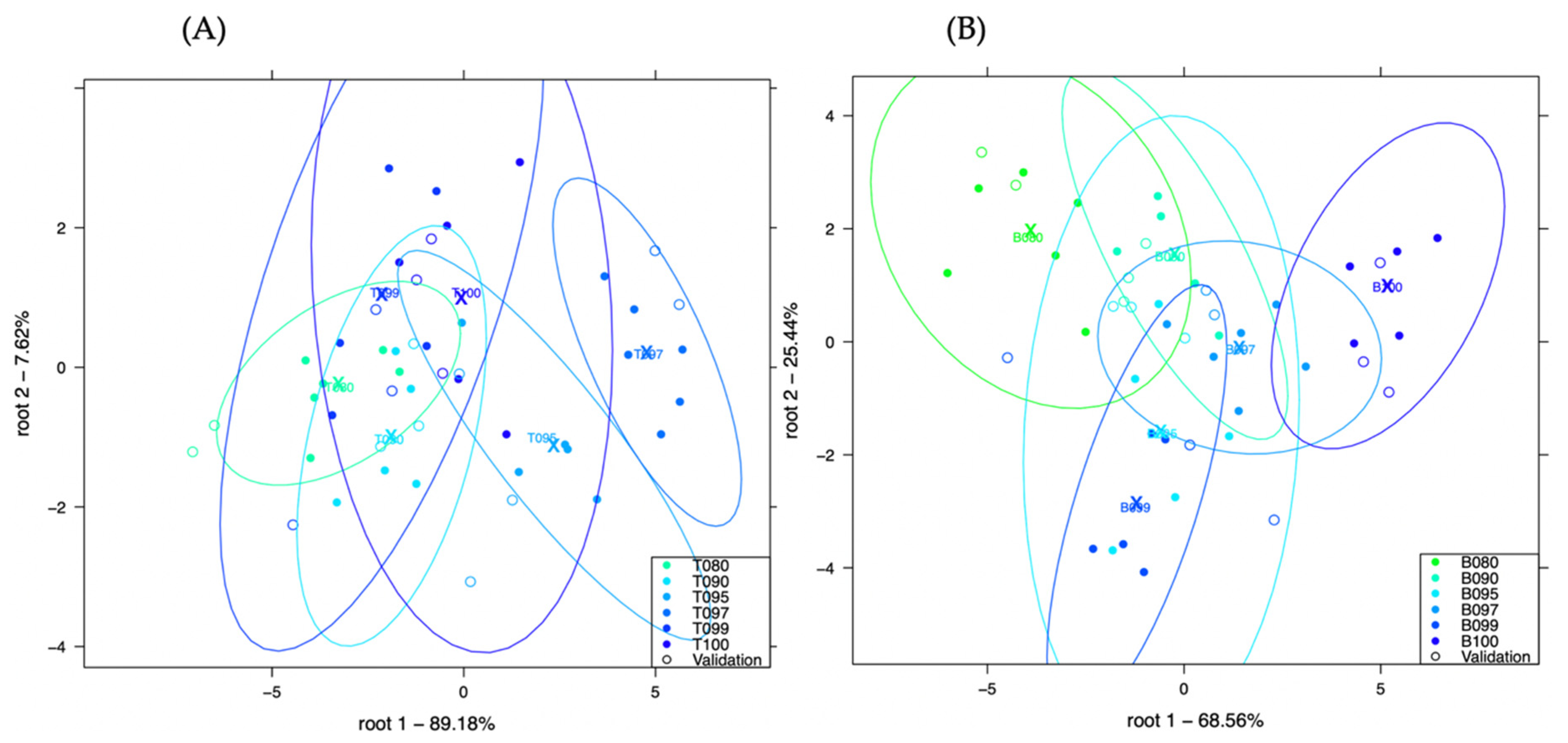

3.2.4. LDA Analysis for Frozen Meat Extraction with Distilled Water for the Determination of Optimal Extraction

3.2.5. Partial Least Squares (PLS) Models to Regress on the Concentrations of Adulterated Poultry and Red Meat for the Determination of Optimal Extraction

3.2.6. PLS Models to Regress on the Concentrations of Chicken in Turkey Using all the Extraction Methods

3.2.7. PLS Models to Regress on the Concentrations of Pork in Beef Using all the Extraction Methods

4. Discussion

4.1. Determination of Optimal Optimal Dilution

4.2. Determination of Optimal Extraction Method

4.2.1. LDA Sensor Optimization for the Determination of Optimal Extraction Method

4.2.2. Raw Meat Extraction with Distilled Water

4.2.3. Meat Extraction by Cooking with Distilled Water

4.2.4. Frozen Meat Extraction with Distilled Water

4.2.5. PLS Sensor Optimization for the Determination of Optimal Extraction Method

4.2.6. PLS Regression Models for Predicting Concentrations of Chicken in Turkey and Pork in Beef Using all the Three Extraction Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Milford, A.B.; Le Mouël, C.; Bodirsky, B.L.; Rolinski, S. Drivers of meat consumption. Appetite 2019, 141, 104313. [Google Scholar] [CrossRef] [PubMed]

- Bonnet, C.; Bouamra-Mechemache, Z.; Réquillart, V.; Treich, N. Viewpoint: Regulating meat consumption to improve health, the environment and animal welfare. Food Policy 2020, 97, 101847. [Google Scholar] [CrossRef]

- Wu, G. Dietary protein intake and human health. Food Funct. 2016, 7, 1251–1265. [Google Scholar] [CrossRef] [PubMed]

- Woodvine, A. The Health Consequences of Consuming Chicken, Turkey, Duck and Goose Meat; York Court: York, UK, 2009. [Google Scholar]

- Zaukuu, J.L.Z.; Bazar, G.; Gillay, Z.; Kovacs, Z. Emerging trends of advanced sensor based instruments for meat, poultry and fish quality—A review. Crit. Rev. Food Sci. Nutr. 2019, 60, 3443–3460. [Google Scholar] [CrossRef]

- Jiang, H.; Cheng, F.; Shi, M. Rapid identification and visualization of jowl meat adulteration in pork using hyperspectral imaging. Foods 2020, 9, 154. [Google Scholar] [CrossRef]

- Alamprese, C.; Casale, M.; Sinelli, N.; Lanteri, S.; Casiraghi, E. Detection of minced beef adulteration with turkey meat by UV e vis, NIR and MIR spectroscopy. LWT Food Sci. Technol. 2013, 53, 225–232. [Google Scholar] [CrossRef]

- Sarno, R.; Sabilla, S.I.; Wijaya, D.R.; Sunaryono, D.; Fatichah, C. Electronic nose dataset for pork adulteration in beef. Data Br. 2020, 32, 106139. [Google Scholar] [CrossRef]

- Han, F.; Huang, X.; Aheto, J.H.; Zhang, D.; Feng, F. Detection of beef adulterated with pork using a low-cost electronic nose based on colorimetric sensors. Foods 2020, 9, 193. [Google Scholar] [CrossRef]

- Black, C.; Chevallier, O.P.; Elliott, C.T. The current and potential applications of Ambient Mass Spectrometry in detecting food fraud. TrAC Trends Anal. Chem. 2016, 82, 268–278. [Google Scholar] [CrossRef]

- Lin, C.C.; Fung, L.L.; Chan, P.K.; Lee, C.M.; Chow, K.F.; Cheng, S.H. A rapid low-cost high-density DNA-based multi-detection test for routine inspection of meat species. Meat Sci. 2014, 96, 922–929. [Google Scholar] [CrossRef]

- Karabasanavar, N.; Girish, P.S.; Kumar, D.; Singh, S.P. Detection of beef adulteration by mitochondrial D-loop based species-specific polymerase chain reaction. Int. J. Food Prop. 2017, 20, 2264–2271. [Google Scholar] [CrossRef]

- Thienes, C.P.; Masiri, J.; Benoit, L.A.; Barrios-Lopez, B.; Samuel, S.A.; Krebs, R.A.; Cox, D.P.; Dobritsa, A.P.; Nadala, C.; Samadpour, M. Quantitative detection of beef contamination in cooked meat products by ELISA. J. AOAC Int. 2019, 102, 898–902. [Google Scholar] [CrossRef] [PubMed]

- Mamani-linares, L.W.; Gallo, C.; Alomar, D. Identification of cattle, llama and horse meat by near infrared reflectance or transflectance spectroscopy. Meat Sci. 2012, 90, 378–385. [Google Scholar] [CrossRef] [PubMed]

- Alamprese, C.; Manuel, J.; Casiraghi, E.; Balling, S. Identification and quantification of turkey meat adulteration in fresh, frozen-thawed and cooked minced beef by FT-NIR spectroscopy and chemometrics. Meat Sci. 2016, 121, 175–181. [Google Scholar] [CrossRef]

- Zhao, Z.; Yu, H.; Zhang, S.; Du, Y.; Sheng, Z.; Chu, Y.; Zhang, D.; Guo, L.; Deng, L. Visualization accuracy improvement of spectral quantitative analysis for meat adulteration using Gaussian distribution of regression coefficients in hyperspectral imaging. Optik 2020, 212, 164737. [Google Scholar] [CrossRef]

- Leng, T.; Li, F.; Xiong, L.; Xiong, Q.; Zhu, M.; Chen, Y. Quantitative detection of binary and ternary adulteration of minced beef meat with pork and duck meat by NIR combined with chemometrics. Food Control 2020, 113, 107203. [Google Scholar] [CrossRef]

- Ha, N.; Xu, K.; Ren, G.; Mitchell, A.; Ou, J.Z. Machine Learning-Enabled Smart Sensor Systems. Adv. Intell. Syst. 2020, 2, 2000063. [Google Scholar] [CrossRef]

- Bratov, A.; Abramova, N.; Ipatov, A. Recent trends in potentiometric sensor arrays—A review. Anal. Chim. Acta 2010, 678, 149–159. [Google Scholar] [CrossRef]

- Aouadi, B.; Zaukuu, J.L.Z.; Vitális, F.; Bodor, Z.; Fehér, O.; Gillay, Z.; Bazar, G.; Kovacs, Z. Historical evolution and food control achievements of near infrared spectroscopy, electronic nose, and electronic tongue—Critical overview. Sensors 2020, 20, 1–42. [Google Scholar]

- Winquist, F. Voltammetric electronic tongues—Basic principles and applications. Microchim. Acta 2008, 163, 3–10. [Google Scholar] [CrossRef]

- Krantz-Rülcker, C.; Stenberg, M.; Winquist, F.; Lundström, I. Electronic tongues for environmental monitoring based on sensor arrays and pattern recognition: A review. Anal. Chim. Acta 2001, 426, 217–226. [Google Scholar] [CrossRef]

- Wasilewski, T.; Migoń, D.; Gębicki, J.; Kamysz, W. Critical review of electronic nose and tongue instruments prospects in pharmaceutical analysis. Anal. Chim. Acta 2019, 1077, 14–29. [Google Scholar] [CrossRef] [PubMed]

- Haddi, Z.; Mabrouk, S.; Bougrini, M.; Tahri, K.; Sghaier, K.; Barhoumi, H.; El Bari, N.; Maaref, A.; Jaffrezic-Renault, N.; Bouchikhi, B. E-Nose and e-Tongue combination for improved recognition of fruit juice samples. Food Chem. 2014, 150, 246–253. [Google Scholar] [CrossRef] [PubMed]

- Oliveri, P.; Baldo, M.A.; Daniele, S.; Forina, M. Development of a voltammetric electronic tongue for discrimination of edible oils. Anal. Bioanal. Chem. 2009, 395, 1135–1143. [Google Scholar] [CrossRef]

- Röck, F.; Barsan, N.; Weimar, U. Electronic Nose: Current Status and Future Trends. Chem. Rev. 2008, 108, 705–725. [Google Scholar] [CrossRef]

- Arrieta, A.A.; Nuñez, Y.E.; Mendoza, J.M. Mini-electronic Tongue Used to Discriminate between Coffee Samples of Different Geographical Origin. Int. J. Technol. 2020, 11, 288. [Google Scholar] [CrossRef]

- Kovacs, Z.; Szöllősi, D.; Zaukuu, J.-L.Z.; Bodor, Z.; Vitális, F.; Aouadi, B.; Zsom-Muha, V.; Gillay, Z. Factors Influencing the Long-Term Stability of Electronic Tongue and Application of Improved Drift. Biosensors 2020, 10, 74. [Google Scholar] [CrossRef]

- Rudnitskaya, A. Calibration update and drift correction for electronic noses and tongues. Front. Chem. 2018, 6, 433. [Google Scholar] [CrossRef]

- Semenov, V.; Volkov, S.; Khaydukova, M.; Fedorov, A.; Lisitsyna, I.; Kirsanov, D.; Legin, A. Determination of three quality parameters in vegetable oils using potentiometric e-tongue. J. Food Compos. Anal. 2019, 75, 75–80. [Google Scholar] [CrossRef]

- Apetrei, I.M.; Apetrei, C. Detection of virgin olive oil adulteration using a voltammetric e-tongue. Comput. Electron. Agric. 2014, 108, 148–154. [Google Scholar] [CrossRef]

- Banerjee, M.B.; Roy, R.B.; Tudu, B.; Bandyopadhyay, R.; Bhattacharyya, N. Black tea classification employing feature fusion of E-Nose and E-Tongue responses. J. Food Eng. 2019, 244, 55–63. [Google Scholar] [CrossRef]

- Vitalis, F.; Zaukuu, J.L.Z.; Bodor, Z.; Aouadi, B.; Hitka, G.; Kaszab, T.; Zsom-Muha, V.; Gillay, Z.; Kovacs, Z. Detection and quantification of tomato paste adulteration using conventional and rapid analytical methods. Sensors 2020, 20, 1–21. [Google Scholar]

- Panchuk, V.; Lvova, L.; Kirsanov, D.; Gonçalves, C.G.; Di Natale, C.; Paolesse, R.; Legin, A. Extending electronic tongue calibration lifetime through mathematical drift correction: Case study of microcystin toxicity analysis in waters. Sens. Actuators B Chem. 2016, 237, 962–968. [Google Scholar] [CrossRef]

- Gil, L.; Barat, J.M.; Baigts, D.; Martínez-máñez, R.; Soto, J.; Garcia-breijo, E.; Aristoy, M.; Toldrá, F.; Llobet, E. Monitoring of physical—Chemical and microbiological changes in fresh pork meat under cold storage by means of a potentiometric electronic tongue. Food Chem. 2011, 126, 1261–1268. [Google Scholar] [CrossRef]

- Gil, L.; Soto, J.; Campos, I.; Masot, R.; Alca, M.; García-breijo, E. Chemical Accurate concentration determination of anions nitrate, nitrite and chloride in minced meat using a voltammetric electronic tongue. Sens. Actuators B 2010, 149, 71–78. [Google Scholar]

- Apetrei, I.M.; Apetrei, C. Application of voltammetric e-tongue for the detection of ammonia and putrescine in beef products. Sens. Actuators B Chem. 2016, 234, 371–379. [Google Scholar] [CrossRef]

- Németh, D.; Balazs, G.; Daood, H.G.; Kovacs, Z.; Bodor, Z.; Zaukuu, J.L.Z.; Szentpeteri, V.; Kokai, Z.; Kappel, N. Standard analytical methods, sensory evaluation, nirs and electronic tongue for sensing taste attributes of different melon varieties. Sensors 2019, 19, 5010. [Google Scholar] [CrossRef]

- Magdalena, S.; Wardencki, W. Food Analysis Using Arti fi cial Senses. J. Agric. Food Chem. 2015, 6, 80–233. [Google Scholar]

- Guo, M.; Nowakowska-Grunt, J.; Gorbanyov, V.; Egorova, M. Green technology and sustainable development: Assessment and green growth frameworks. Sustainability 2020, 12, 6571. [Google Scholar] [CrossRef]

- AlphaM. OS. αAstree Electronic Tongue User Manual; Alpha MOS Toulouse: Toulouse, France, 2003. [Google Scholar]

- Ciosek, P. Potentiometric Electronic Tongues for Foodstuff and Biosample Recognition—An Overview. Sensors 2011, 11, 4688–4701. [Google Scholar] [CrossRef]

- Nagy, A.; Kovács, Z.; Szöllösi, D.; Fekete, A. Temperature correction of electronic tongue measurement results. Acta Aliment. 2013, 42, 37–44. [Google Scholar] [CrossRef]

- Granato, D.; Putnik, P.; Kovačević, D.B.; Santos, J.S.; Calado, V.; Rocha, R.S.; Da Cruz, A.G.; Jarvis, B.; Rodionova, O.Y.; Pomerantsev, A. Trends in Chemometrics: Food Authentication, Microbiology, and Effects of Processing. Compr. Rev. Food Sci. Food Saf. 2018, 17, 663–677. [Google Scholar] [CrossRef] [PubMed]

- Soós, J.; Várvölgyi, E.; Bázár, G.; Felföldi, J.; Magyar, I.; Kovács, Z. Electronic tongue in botrytized wine authentication. In Proceedings of the 16th International Symposium on Olfaction and Electronic Nose, Dijon, France, 28 June–1 July 2015; pp. 75–76. [Google Scholar]

- Chung, N.; Ameer, K.; Jo, Y.; Kwon, J.-H. Comparison of electronic sensing techniques for screening dried shrimps irradiated using three types of approved radiation with standard analytical methods. Food Chem. 2019, 286, 395–404. [Google Scholar] [CrossRef] [PubMed]

- Koncz, F.A.; Bodor, Z.; Kaszab, T.; Kertész, I.; Zaukuu, J.L.Z.; Benedek, C.; Gillay, Z.; Kovacs, Z. Prediction of main analytical and physical parameters of honey with electronic tongue. Hungarian Agric. Eng. 2017, 7410, 38–43. [Google Scholar] [CrossRef]

- Hewavitharana, G.G.; Perera, D.N.; Navaratne, S.B.; Wickramasinghe, I. Extraction methods of fat from food samples and preparation of fatty acid methyl esters for gas chromatography: A review. Arab. J. Chem. 2020, 13, 6865–6875. [Google Scholar] [CrossRef]

- Malva, A.D.; Albenzio, M.; Santillo, A.; Russo, D.; Figliola, L.; Caroprese, M.; Marino, R. Methods for Extraction of Muscle Proteins from Meat and Fish Using Denaturing and Nondenaturing Solutions. J. Food Qual. 2018, 2018, 8478471. [Google Scholar] [CrossRef]

- Putnik, P.; Lorenzo, J.M.; Barba, F.J.; Roohinejad, S.; Jambrak, A.R.; Granato, D.; Montesano, D.; Kovačević, D.B. Novel food processing and extraction technologies of high-added value compounds from plant materials. Foods 2018, 7, 1–16. [Google Scholar]

- Khan, S.A.; Aslam, R.; Makroo, H.A. High pressure extraction and its application in the extraction of bio-active compounds: A review. J. Food Process Eng. 2019, 42, 1–15. [Google Scholar] [CrossRef]

- Kumoro, A.C.; Sofiah, S.; Aini, N.; Retnowati, D.S.; Budiyati, C.S. Effect of Temperature and Particle Size on the Alkaline Extraction of Protein From Chicken Bone Waste. Reaktor 2010, 13, 124. [Google Scholar] [CrossRef]

- Daszkiewicz, T.; Kubiak, D.; Panfil, A. The effect of long-term frozen storage on the quality of meat (Longissimus thoracis et Lumborum) from female roe deer (Capreolus capreolus L.). J. Food Qual. 2018, 2018, 4691542. [Google Scholar] [CrossRef]

- Leygonie, C.; Britz, T.J.; Hoffman, L.C. Impact of freezing and thawing on the quality of meat: Review. Meat Sci. 2012, 91, 93–98. [Google Scholar] [CrossRef] [PubMed]

| Sample ID | Turkey (% w/w) | Chicken (% w/w) | Turkey (g) | Chicken (g) | % w/v of Meat Mixture |

|---|---|---|---|---|---|

| 05_100 | 100 | 0 | 20.00 | 0.00 | 0.50 |

| 05_097 | 97 | 3 | 19.40 | 0.60 | 0.50 |

| 05_095 | 95 | 5 | 19.00 | 1.00 | 0.50 |

| 05_090 | 90 | 10 | 18.00 | 2.00 | 0.50 |

| 10_100 | 100 | 0 | 20.00 | 0.00 | 1.00 |

| 10_097 | 97 | 3 | 19.40 | 0.60 | 1.00 |

| 10_095 | 95 | 5 | 19.00 | 1.00 | 1.00 |

| 10_090 | 90 | 10 | 18.00 | 2.00 | 1.00 |

| 20_100 | 100 | 0 | 20.00 | 0.00 | 2.00 |

| 20_097 | 97 | 3 | 19.40 | 0.60 | 2.00 |

| 20_095 | 95 | 5 | 19.00 | 1.00 | 2.00 |

| 20_090 | 90 | 10 | 18.00 | 2.00 | 2.00 |

| Sample ID | Turkey (%) | Chicken (%) | Turkey (g) | Chicken (g) |

|---|---|---|---|---|

| T100 | 100 | 0 | 20.00 | 0.00 |

| T099 | 99 | 1 | 19.80 | 0.20 |

| T097 | 97 | 3 | 19.40 | 0.60 |

| T095 | 95 | 5 | 19.00 | 1.00 |

| T090 | 90 | 10 | 18.00 | 2.00 |

| T080 | 80 | 20 | 16.00 | 4.00 |

| Sample ID | Beef (%) | Pork (%) | Beef (g) | Pork (g) |

|---|---|---|---|---|

| B100 | 100 | 0 | 20.00 | 0.00 |

| B099 | 99 | 1 | 19.80 | 0.20 |

| B097 | 97 | 3 | 19.40 | 0.60 |

| B095 | 95 | 5 | 19.00 | 1.00 |

| B090 | 90 | 10 | 18.00 | 2.00 |

| B080 | 80 | 20 | 16.00 | 4.00 |

| Dilution Level | LV | R2 | RMSEC (w/v Meat Mixture) | R2CV | RMSECV (w/v Meat Mixture) |

|---|---|---|---|---|---|

| Dilution level 1 (2% w/v turkey) | 3 | 0.88 | 1.26 | 0.81 | 1.57 |

| Dilution level 2 (1% w/v turkey) | 3 | 0.97 | 0.59 | 0.95 | 0.80 |

| Dilution level 3 (0.5% w/v turkey) | 1 | 0.71 | 1.96 | 0.65 | 2.14 |

| Meat Combination | Sample Preparation | Selected Sensors | Omitted Sensors | Initial Cross-Validation Accuracies (%) | Optimized Cross-Validation Accuracies (%) |

|---|---|---|---|---|---|

| Chicken and turkey adulteration | Raw meat extraction with distilled water | HA, BB, ZZ, GA | JE, CA, JB | 47.99 | 58.35 |

| Meat extraction by cooking with distilled water | BB, ZZ, GA, JB | HA, JE, CA | 54.14 | 64.72 | |

| Frozen meat extraction with distilled water | All: HA, BB, ZZ, GA, JE, JB, CA | None | 62.55 | 62.55 | |

| Pork and beef adulteration | Raw meat extraction with distilled water | HA, ZZ, GA, JB | BB, CA, JE | 45.90 | 54.25 |

| Meat extraction by cooking with distilled water | HA, ZZ, GA CA, JE, JB | BB | 58.37 | 68.77 | |

| Frozen meat extraction with distilled water | HA, ZZ, BB, GA, JE, JB | CA | 52.11 | 56.41 |

| Average Accuracies | T080 | T090 | T095 | T097 | T099 | T100 | |

|---|---|---|---|---|---|---|---|

| Recognition 81.28% | T080 | 100 | 0 | 0 | 0 | 0 | 0 |

| T090 | 0 | 93.81 | 18.73 | 24.95 | 0 | 0 | |

| T095 | 0 | 0 | 56.18 | 0 | 12.57 | 6.19 | |

| T097 | 0 | 6.19 | 0 | 68.86 | 6.19 | 0 | |

| T099 | 0 | 0 | 12.55 | 6.19 | 75.05 | 0 | |

| T100 | 0 | 0 | 12.55 | 0 | 6.19 | 93.81 | |

| Cross-validation 58.35% | T080 | 100 | 0 | 0 | 0 | 0 | 0 |

| T090 | 0 | 87.59 | 0 | 49.81 | 0 | 0 | |

| T095 | 0 | 0 | 37.45 | 0 | 25.09 | 12.41 | |

| T097 | 0 | 12.41 | 12.36 | 25.09 | 37.45 | 0 | |

| T099 | 0 | 0 | 25.09 | 25.09 | 12.36 | 0 | |

| T100 | 0 | 0 | 25.09 | 0 | 25.09 | 87.59 |

| Average Accuracies | B080 | B090 | B095 | B097 | B099 | B100 | |

|---|---|---|---|---|---|---|---|

| Recognition 67.73% | B080 | 75.05 | 6.19 | 0 | 24.95 | 12.57 | 0 |

| B090 | 6.19 | 75.05 | 0 | 0 | 0 | 0 | |

| B095 | 0 | 12.57 | 75.05 | 0 | 18.76 | 0 | |

| B097 | 18.76 | 6.19 | 6.19 | 56.29 | 6.19 | 0 | |

| B099 | 0 | 0 | 18.76 | 12.57 | 43.71 | 18.76 | |

| B100 | 0 | 0 | 0 | 6.19 | 18.76 | 81.24 | |

| Cross-validation 54.25% | B080 | 62.78 | 12.41 | 0 | 25.19 | 25.09 | 0 |

| B090 | 12.41 | 62.78 | 0 | 12.41 | 0 | 0 | |

| B095 | 0 | 12.41 | 50 | 0 | 12.36 | 0 | |

| B097 | 12.41 | 12.41 | 12.41 | 50 | 0 | 0 | |

| B099 | 12.41 | 0 | 37.59 | 0 | 37.45 | 37.45 | |

| B100 | 0 | 0 | 0 | 12.41 | 25.09 | 62.55 |

| Average Accuracies | T080 | T090 | T095 | T097 | T099 | T100 | |

|---|---|---|---|---|---|---|---|

| Recognition 78.13% | T080 | 74.91 | 0 | 0 | 0 | 6.19 | 0 |

| T090 | 12.55 | 87.62 | 0 | 0 | 6.19 | 12.55 | |

| T095 | 0 | 0 | 75.05 | 0 | 0 | 12.55 | |

| T097 | 0 | 0 | 0 | 100 | 0 | 0 | |

| T099 | 12.55 | 6.19 | 0 | 0 | 68.86 | 12.55 | |

| T100 | 0 | 6.19 | 24.95 | 0 | 18.76 | 62.36 | |

| Cross-validation 64.72% | T080 | 75.19 | 0 | 0 | 0 | 12.36 | 0 |

| T090 | 12.41 | 75.19 | 0 | 0 | 25.09 | 12.41 | |

| T095 | 0 | 0 | 62.55 | 12.41 | 0 | 12.41 | |

| T097 | 0 | 0 | 12.36 | 87.59 | 0 | 0 | |

| T099 | 12.41 | 12.41 | 0 | 0 | 25.09 | 12.41 | |

| T100 | 0 | 12.41 | 25.09 | 0 | 37.45 | 62.78 |

| Average Accuracies | B080 | B090 | B095 | B097 | B099 | B100 | |

|---|---|---|---|---|---|---|---|

| Recognition 89.62% | B080 | 100 | 0 | 0 | 0 | 0 | 0 |

| B090 | 0 | 87.62 | 18.73 | 6.19 | 0 | 0 | |

| B095 | 0 | 6.19 | 68.73 | 6.19 | 6.19 | 0 | |

| B097 | 0 | 6.19 | 0 | 87.62 | 0 | 0 | |

| B099 | 0 | 0 | 12.55 | 0 | 93.81 | 0 | |

| B100 | 0 | 0 | 0 | 0 | 0 | 100 | |

| Cross-validation 68.77% | B080 | 87.59 | 0 | 0 | 0 | 12.41 | 0 |

| B090 | 12.41 | 87.59 | 25.09 | 12.41 | 0 | 0 | |

| B095 | 0 | 12.41 | 37.45 | 25.19 | 25.19 | 0 | |

| B097 | 0 | 0 | 0 | 50 | 12.41 | 0 | |

| B099 | 0 | 0 | 37.45 | 12.41 | 50 | 0 | |

| B100 | 0 | 0 | 0 | 0 | 0 | 100 |

| Average Accuracies | T080 | T090 | T095 | T097 | T099 | T100 | |

|---|---|---|---|---|---|---|---|

| Recognition 80.52% | T080 | 100 | 0 | 0 | 0 | 0 | 0 |

| T090 | 0 | 81.39 | 6.19 | 6.19 | 0 | 0 | |

| T095 | 0 | 6.2 | 87.62 | 0 | 18.76 | 0 | |

| T097 | 0 | 6.2 | 0 | 93.81 | 0 | 0 | |

| T099 | 0 | 6.2 | 6.19 | 0 | 81.24 | 12.55 | |

| T100 | 0 | 0 | 0 | 0 | 0 | 87.45 | |

| Cross-validation 62.55% | T080 | 100 | 0 | 0 | 0 | 0 | 0 |

| T090 | 0 | 37.45 | 0 | 25.09 | 0 | 0 | |

| T095 | 0 | 25.09 | 62.55 | 12.36 | 50 | 12.41 | |

| T097 | 0 | 25.09 | 0 | 62.55 | 12.41 | 0 | |

| T099 | 0 | 12.36 | 25.09 | 0 | 37.59 | 12.41 | |

| T100 | 0 | 0 | 12.36 | 0 | 0 | 75.19 |

| Average Accuracies | B080 | B090 | B095 | B097 | B099 | B100 | |

|---|---|---|---|---|---|---|---|

| Recognition 85.51% | B080 | 100 | 0 | 0 | 0 | 0 | 0 |

| B090 | 0 | 93.81 | 12.55 | 0 | 6.19 | 0 | |

| B095 | 0 | 0 | 68.73 | 0 | 6.19 | 12.55 | |

| B097 | 0 | 0 | 6.18 | 100 | 0 | 0 | |

| B099 | 0 | 6.19 | 12.55 | 0 | 75.05 | 12.55 | |

| B100 | 0 | 0 | 0 | 0 | 12.57 | 74.91 | |

| Cross-validation 56.41% | B080 | 50 | 0 | 0 | 0 | 0 | 0 |

| B090 | 37.59 | 100 | 12.41 | 0 | 12.41 | 0 | |

| B095 | 12.41 | 0 | 62.78 | 12.41 | 25.19 | 37.45 | |

| B097 | 0 | 0 | 0 | 87.59 | 0 | 0 | |

| B099 | 0 | 0 | 12.41 | 0 | 12.41 | 37.45 | |

| B100 | 0 | 0 | 12.41 | 0 | 50 | 25.09 |

| Meat Combination | Sample Preparation | Selected Sensors | Omitted Sensors | Initial RMSECV (% w/v Meat Mixture) | Optimized RMSECV (% w/v Meat Mixture) |

|---|---|---|---|---|---|

| Turkey and chicken adulteration | Raw meat extraction with distilled water | HA, BB, ZZ, GA, | JE, JB, CA | 3.68 | 3.34 |

| Meat extraction by cooking with distilled water | HA, BB, ZZ, CA, JB | JE, GA | 5.19 | 4.93 | |

| Frozen meat extraction with distilled water | HA, BB, ZZ, GA, JE | JB, CA | 3.04 | 2.89 | |

| Beef and beef pork adulteration | Raw meat extraction with distilled water | HA, BB, CA, GA | JE, JB, ZZ | 5.91 | 5.51 |

| Meat extraction by cooking with distilled water | HA, ZZ, JB | JE, GA, BB, CA | 4.44 | 3.83 | |

| Frozen meat extraction with distilled water | HA, BB, ZZ JB, JE | GA, CA | 5.81 | 5.16 |

| Sample Preparation Method | LV | R2 | RMSEC (w/v Meat Mixture) | R2CV | RMSECV (w/v Meat Mixture) |

|---|---|---|---|---|---|

| Raw meat extraction with distilled water | 3 | 0.82 | 2.91 | 0.76 | 3.34 |

| Meat extraction by cooking with distilled water | 5 | 0.67 | 3.92 | 0.47 | 4.93 |

| Frozen meat extraction with distilled water | 4 | 0.86 | 2.57 | 0.81 | 2.89 |

| Sample Preparation Method | LV | R2 | RMSEC (w/v Meat Mixture) | R2CV | RMSECV (w/v Meat Mixture) |

|---|---|---|---|---|---|

| Raw meat extraction with distilled water | 4 | 0.51 | 4.78 | 0.34 | 5.51 |

| Meat extraction by cooking with distilled water | 3 | 0.76 | 3.35 | 0.72 | 3.83 |

| Frozen meat extraction with distilled water | 4 | 0.65 | 4.05 | 0.43 | 5.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaukuu, J.-L.Z.; Gillay, Z.; Kovacs, Z. Standardized Extraction Techniques for Meat Analysis with the Electronic Tongue: A Case Study of Poultry and Red Meat Adulteration. Sensors 2021, 21, 481. https://doi.org/10.3390/s21020481

Zaukuu J-LZ, Gillay Z, Kovacs Z. Standardized Extraction Techniques for Meat Analysis with the Electronic Tongue: A Case Study of Poultry and Red Meat Adulteration. Sensors. 2021; 21(2):481. https://doi.org/10.3390/s21020481

Chicago/Turabian StyleZaukuu, John-Lewis Zinia, Zoltan Gillay, and Zoltan Kovacs. 2021. "Standardized Extraction Techniques for Meat Analysis with the Electronic Tongue: A Case Study of Poultry and Red Meat Adulteration" Sensors 21, no. 2: 481. https://doi.org/10.3390/s21020481

APA StyleZaukuu, J.-L. Z., Gillay, Z., & Kovacs, Z. (2021). Standardized Extraction Techniques for Meat Analysis with the Electronic Tongue: A Case Study of Poultry and Red Meat Adulteration. Sensors, 21(2), 481. https://doi.org/10.3390/s21020481