Diffractive Sensor Elements for Registration of Long-Term Instability at Writing of Computer-Generated Holograms

Abstract

:1. Introduction

- Drift of various mechanical units of the system (change of air bearings gaps, thermal expansion) due to changes in their temperatures [15];

- Focused laser beam drift (due to instability of beam pointing diagram and optical axis of focusing lens moved by the electrodynamic or piezoelectric actuator of the autofocus system);

- A change in the wavelength of a laser interferometer that controls linear displacements, which can be not fully compensated when using the formula for dependence of refractive index on the temperature, pressure and humidity of the ambient air [16];

- Displacement of the hologram substrate on the spindle faceplate or linear displacement table due to sharp acceleration or vibration at insufficient mechanical fixation.

2. Materials and Methods

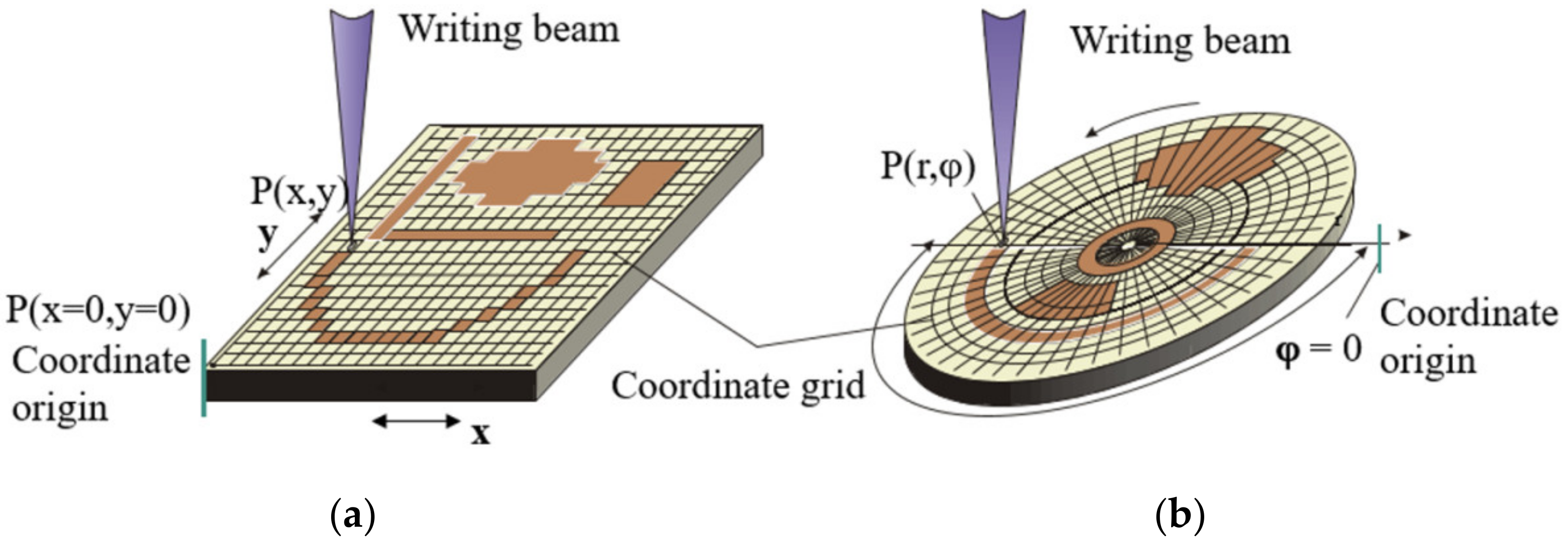

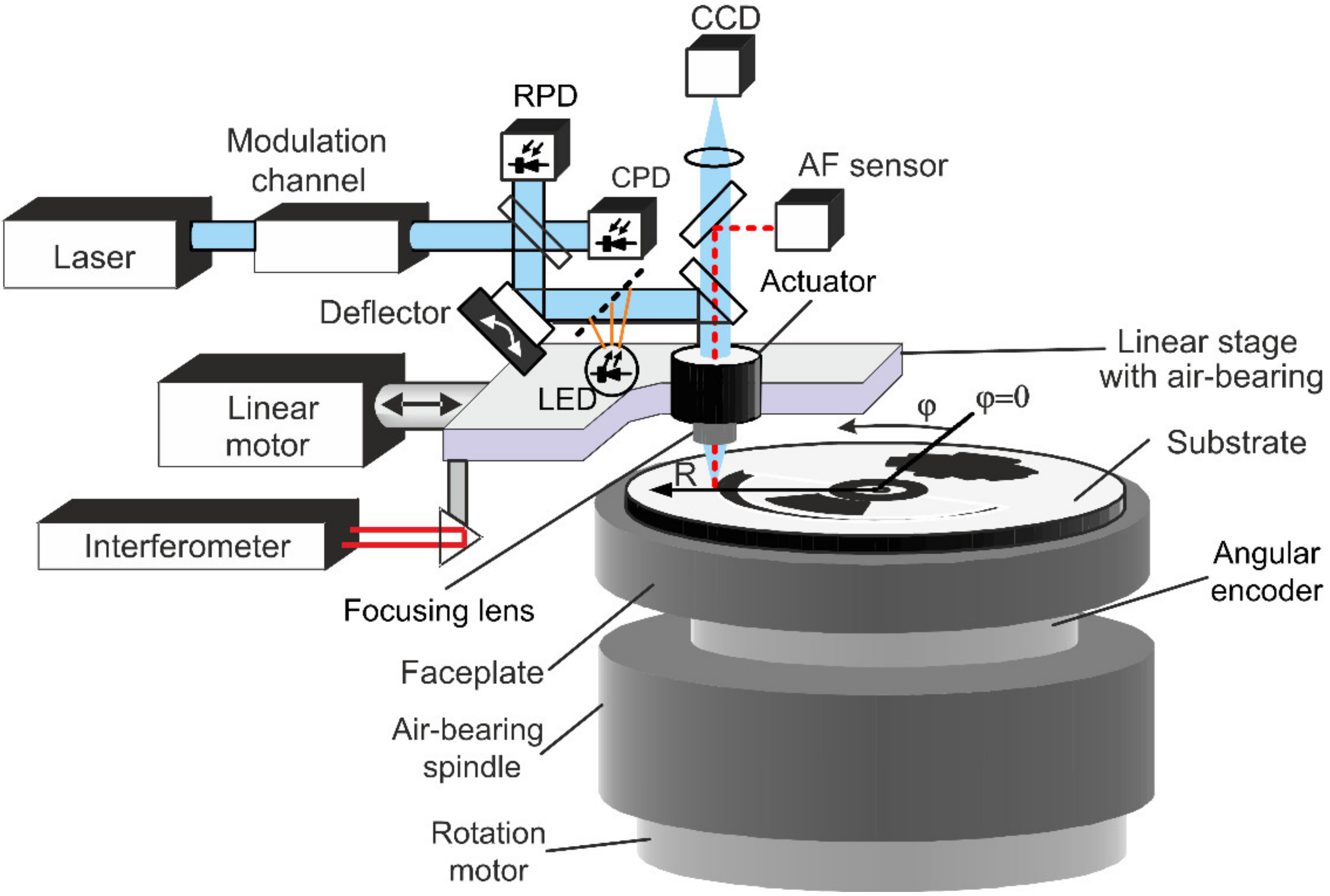

2.1. Laser Writing Systems: Specificity and Errors at Writing of CGHs

- The difference between the assumed and real coordinates of the center of the elementary cell of the CGH pattern;

- Differences in the shape and size of the calculated and actually written elementary cell (size error).

- Low requirements for the quality of the focusing optics and the presence of scattered light in the optical channel;

- A slight increase in the power required for writing, with an increase in scanning speed;

- The nature of the action of the laser beam on the recording material is close to the threshold one and makes it possible to obtain the width of the written track much less than the diameter of the writing spot.

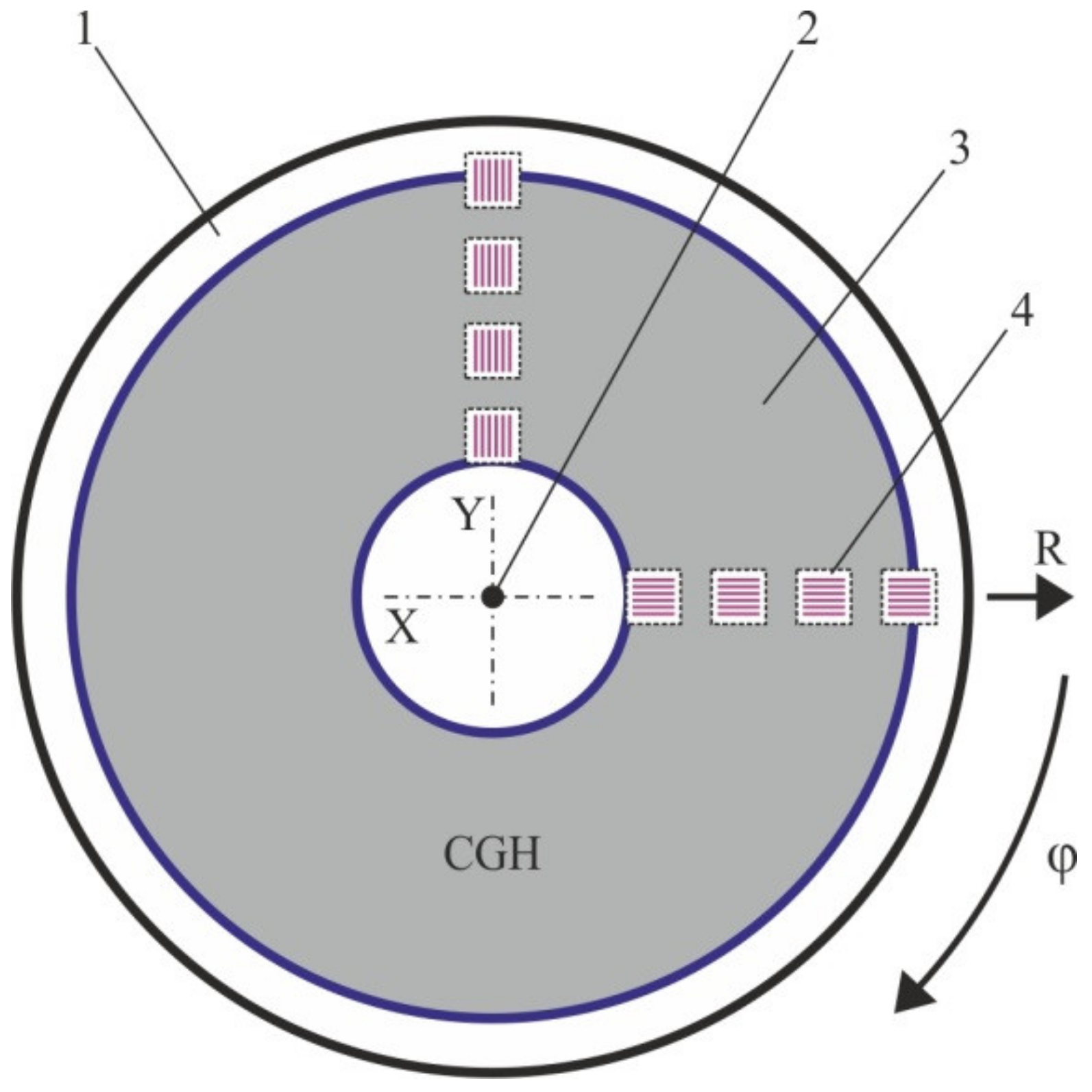

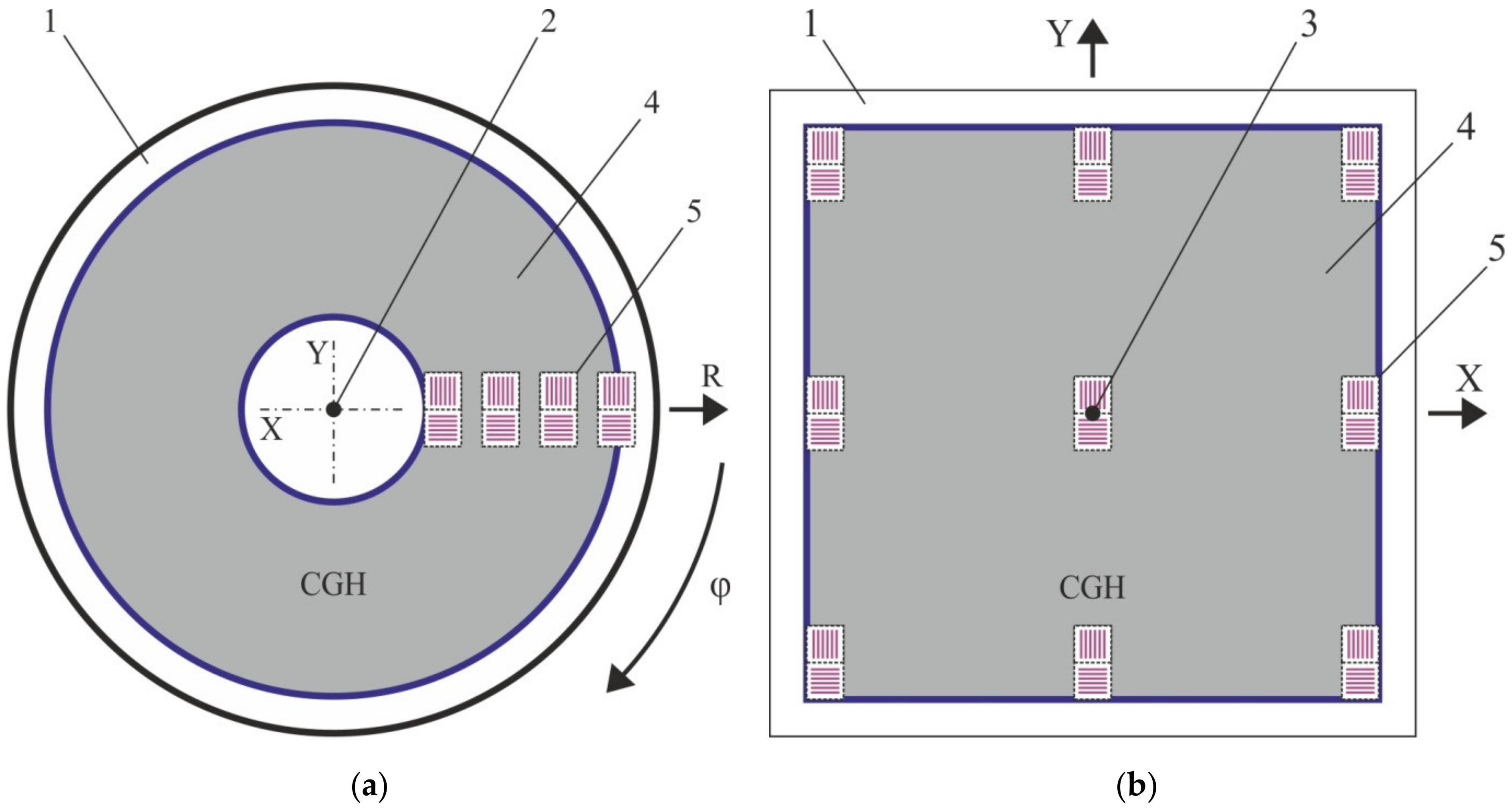

2.2. Method of Built-In Marks (Sensor Elements) for Manufactured CGH Certification

- Techniques used before writing to minimize errors due to design features of positioning subsystems, beam power control, fixing an optical blank on a spindle, etc.;

- Techniques used during CGH writing for dynamic control and correction of the errors arising, for example, with a change in the laser wavelength of the interferometer controlling the radial coordinate;

- Final error inspection after finishing the CGH writing.

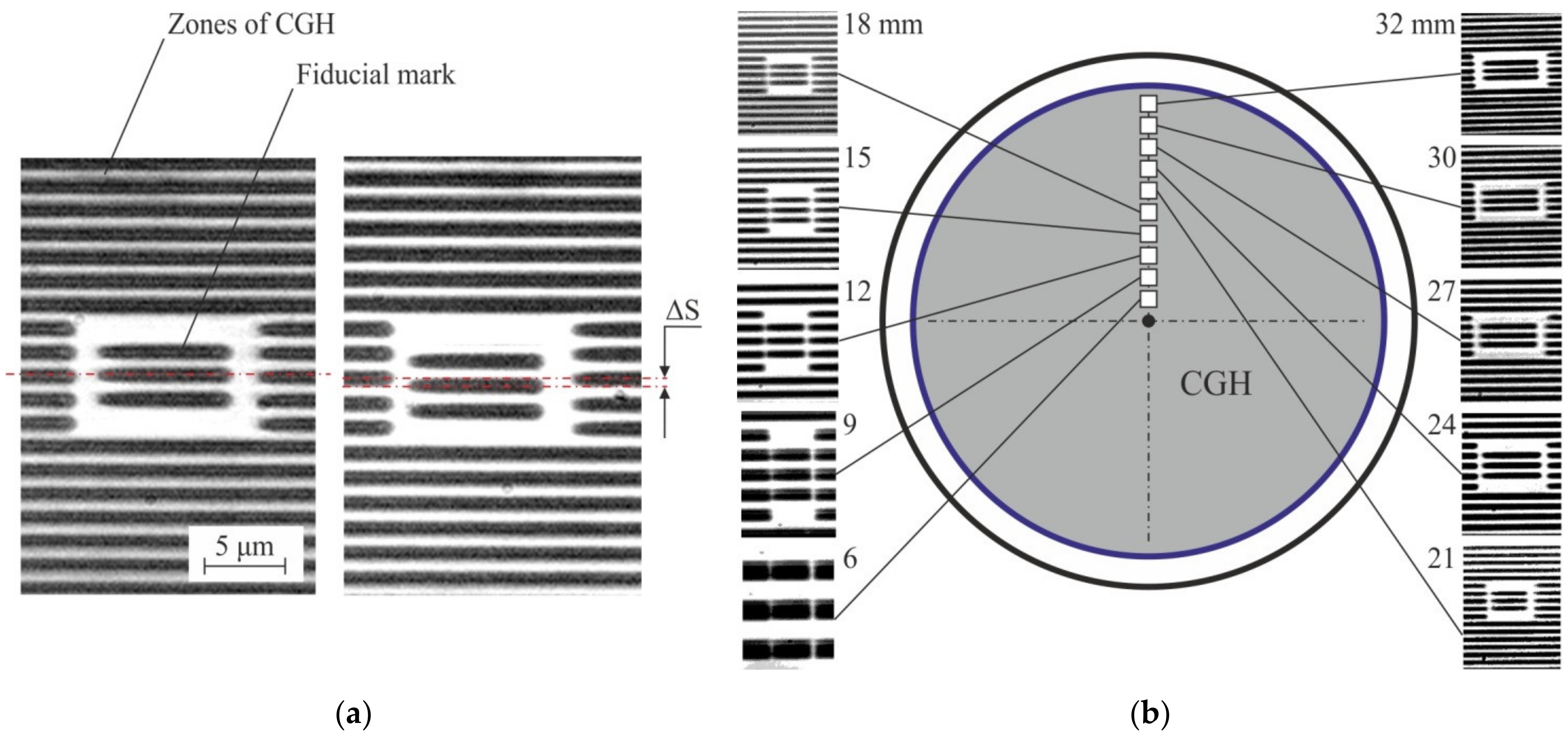

2.2.1. Built-In Marks (Sensors Elements) Based on Image Analysis

- They can only be effectively used for axisymmetric CGHs.

- Quite large size of the window of a built-in mark depends on its position on the CGH pattern;

- With an increase in the size of the zones, the accuracy of estimating the shift of the mark relative to the main structure of the CGH decreases significantly;

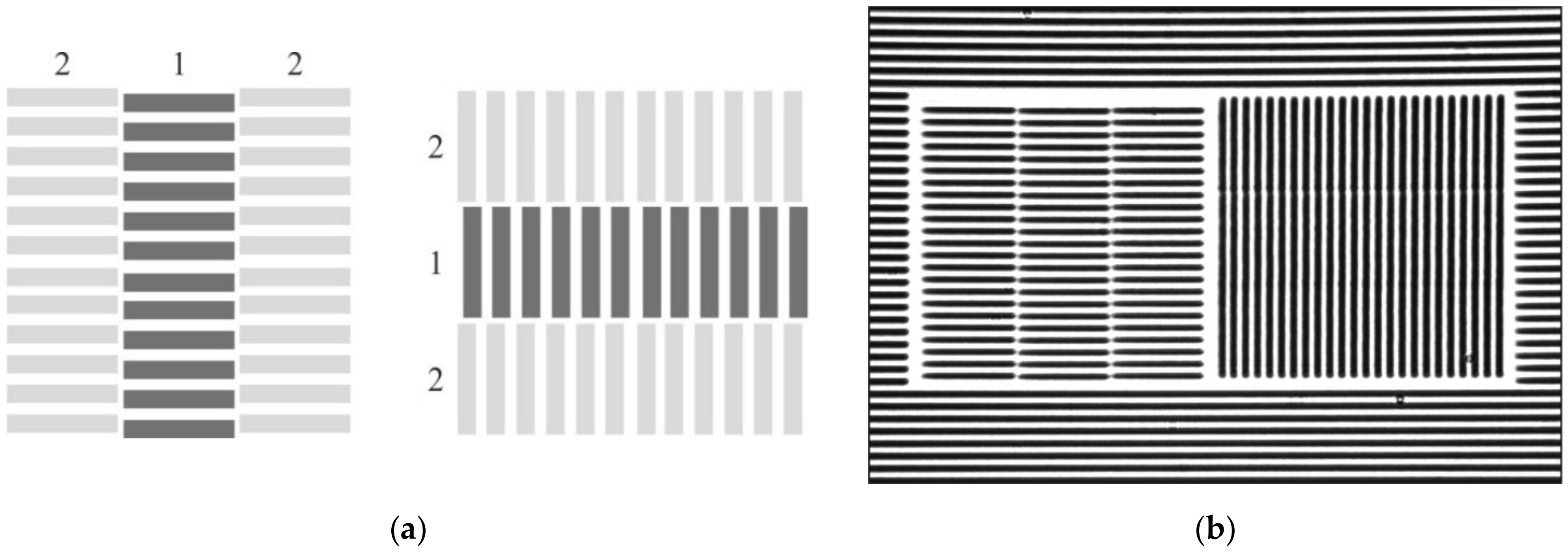

- Based on these built-in marks, one can fairly accurately determine the error on the radial coordinate. However, the estimation of the error for the Y coordinate is difficult, since this error manifests itself on them as a shift of the structure inside the mark window along the diffractive zones (for example, Figure 3a).

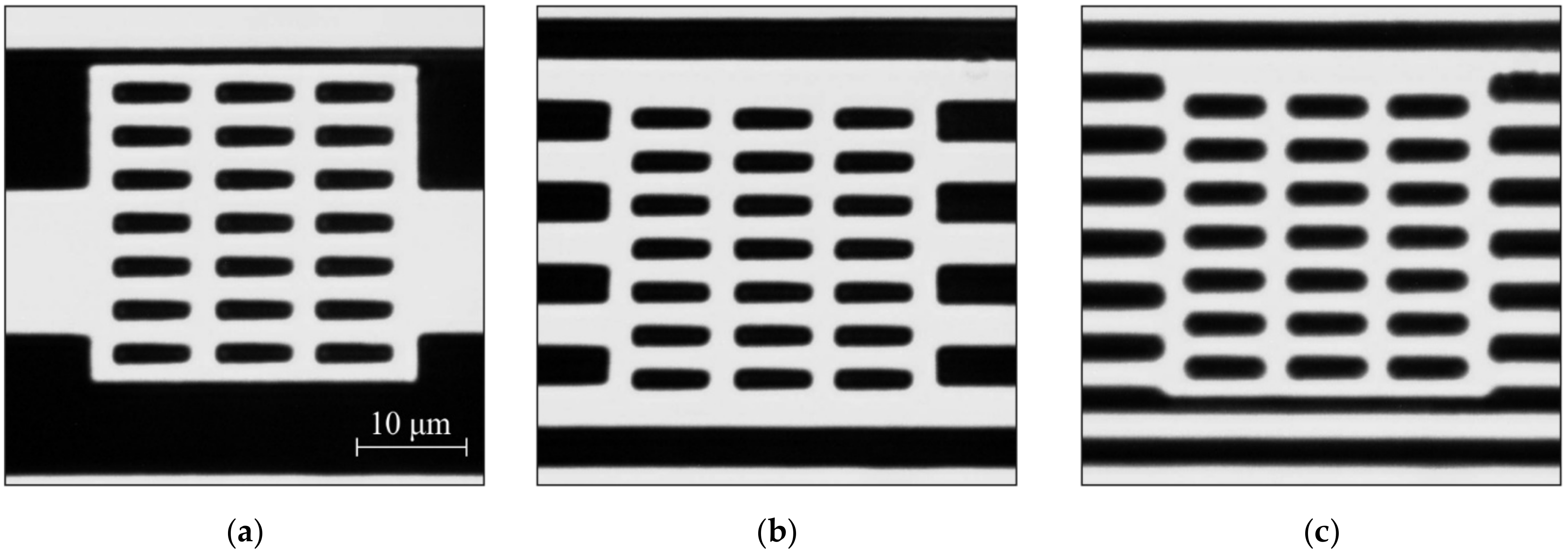

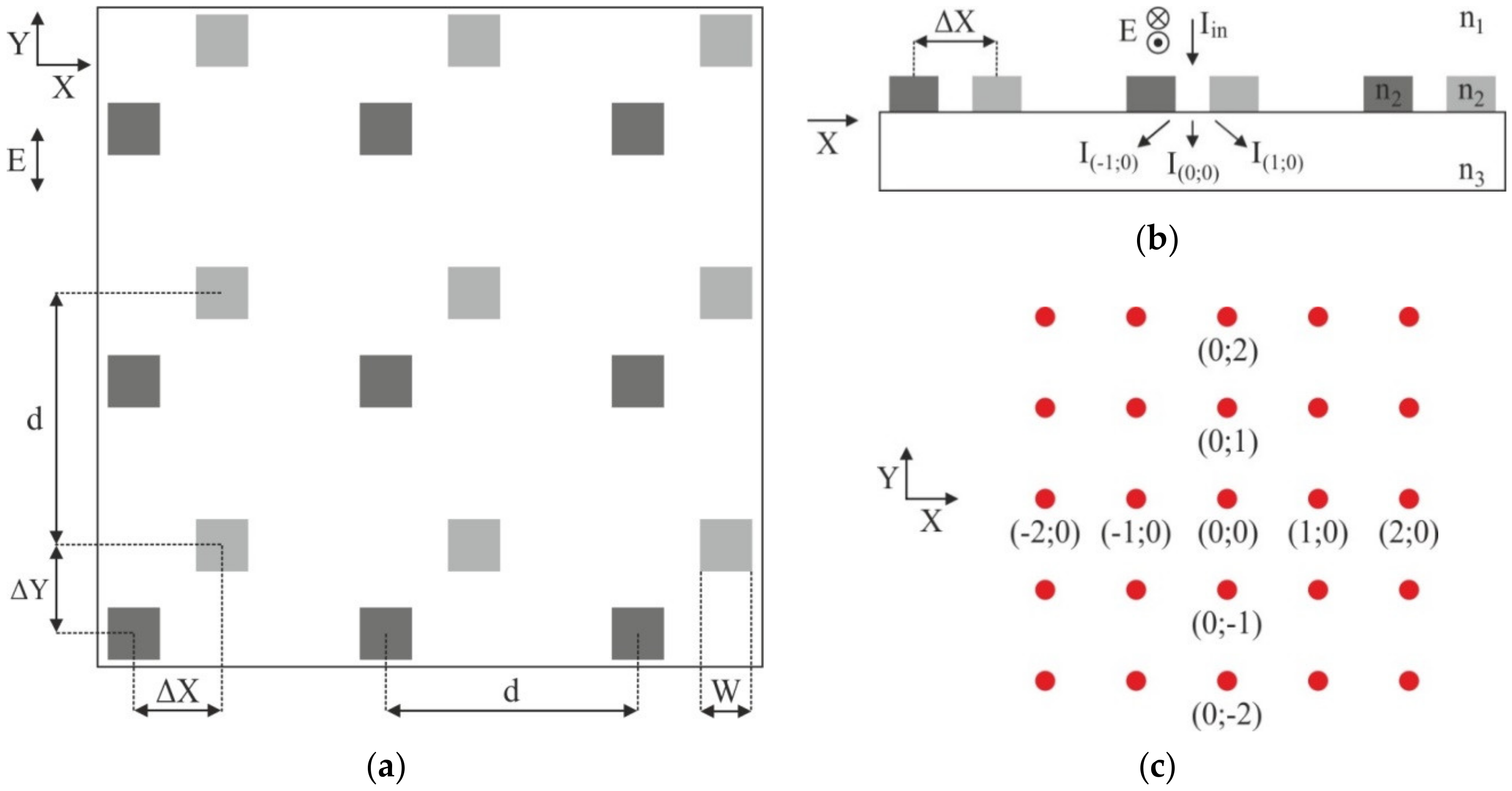

2.2.2. Diffractive Sensor Elements

2.2.3. Mathematical Modeling of the Diffractive Sensors

3. Results

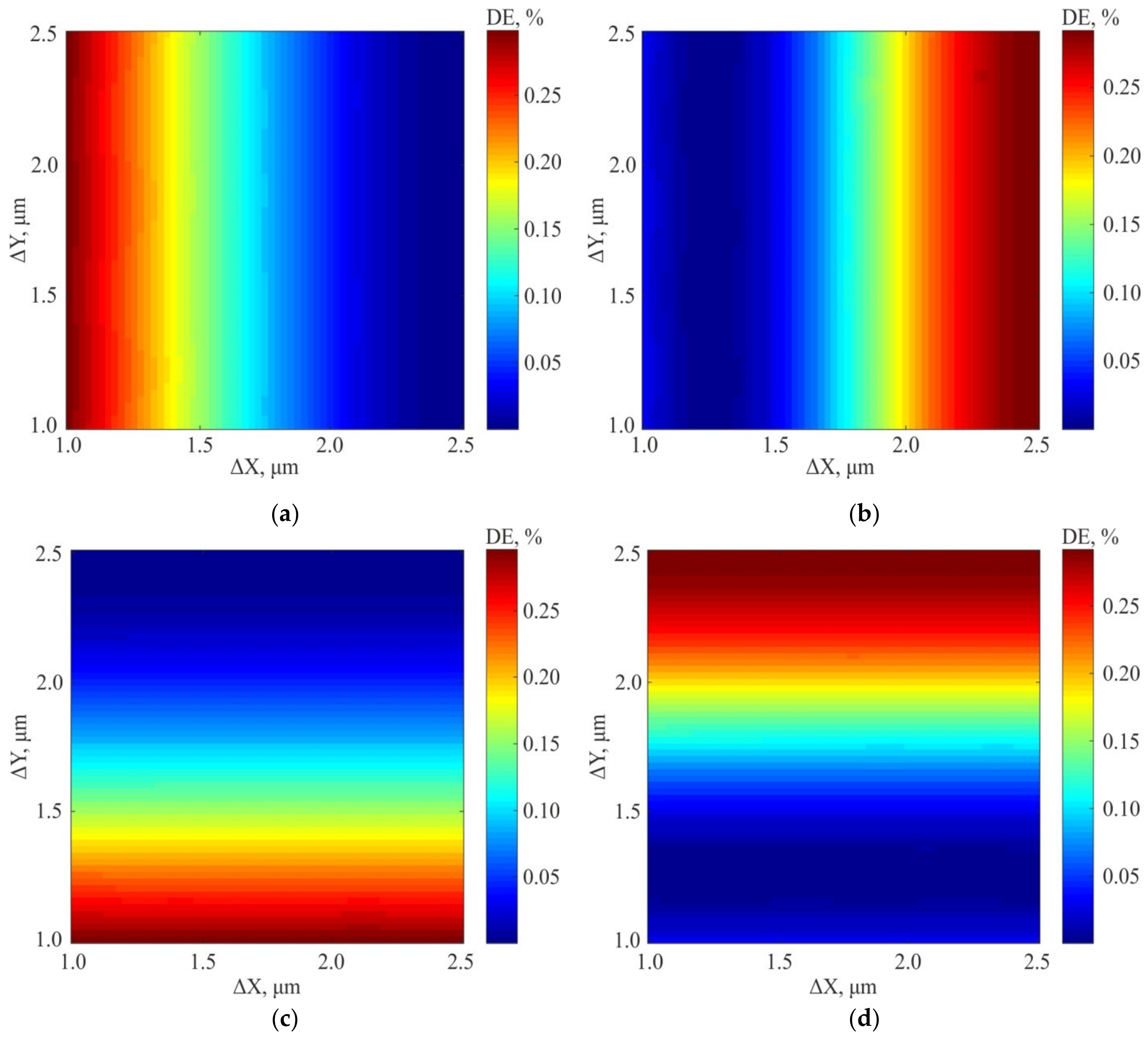

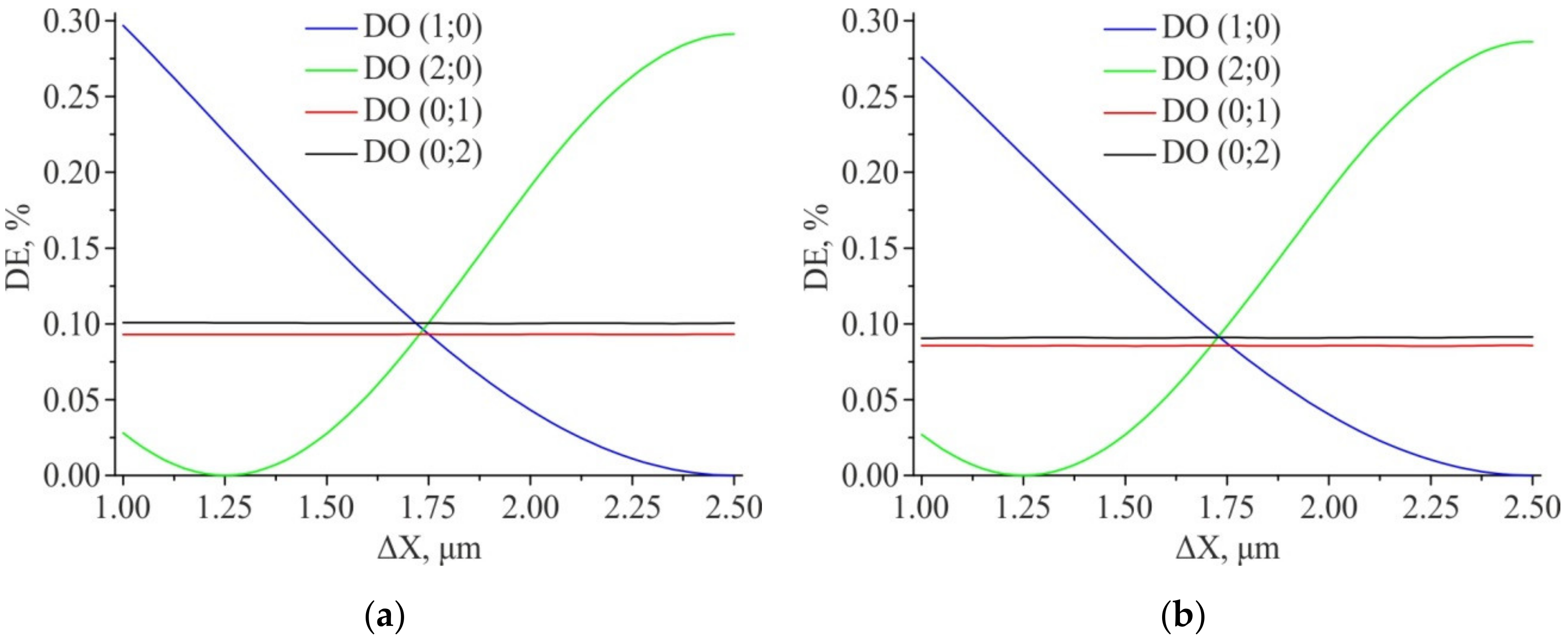

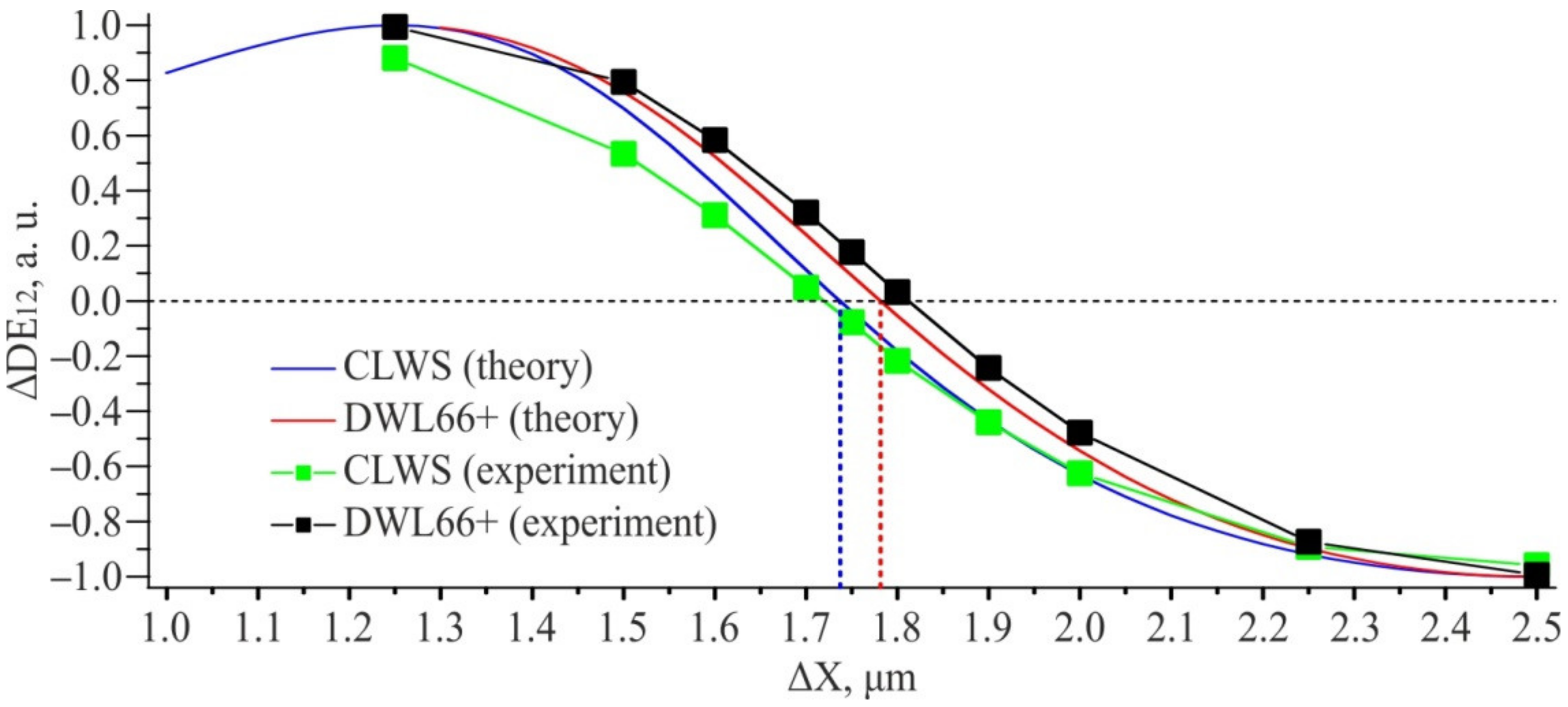

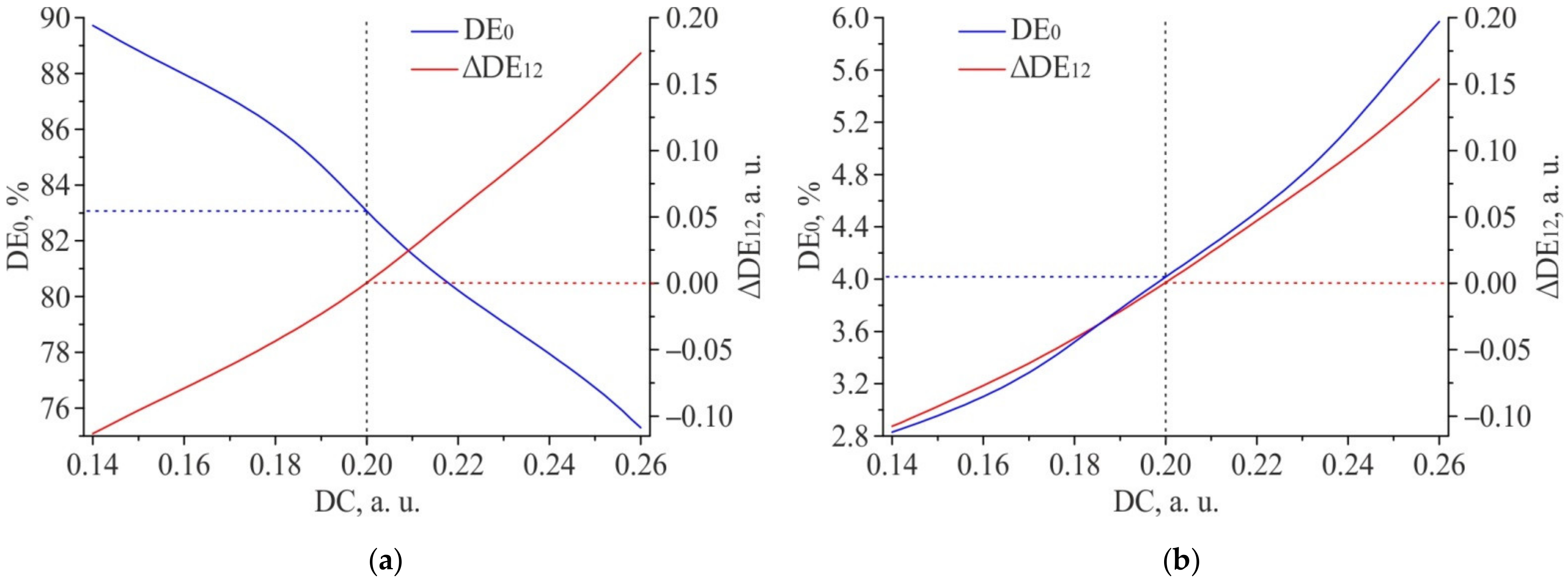

3.1. Results of Numerical Simulation of 2D Diffractive Sensors

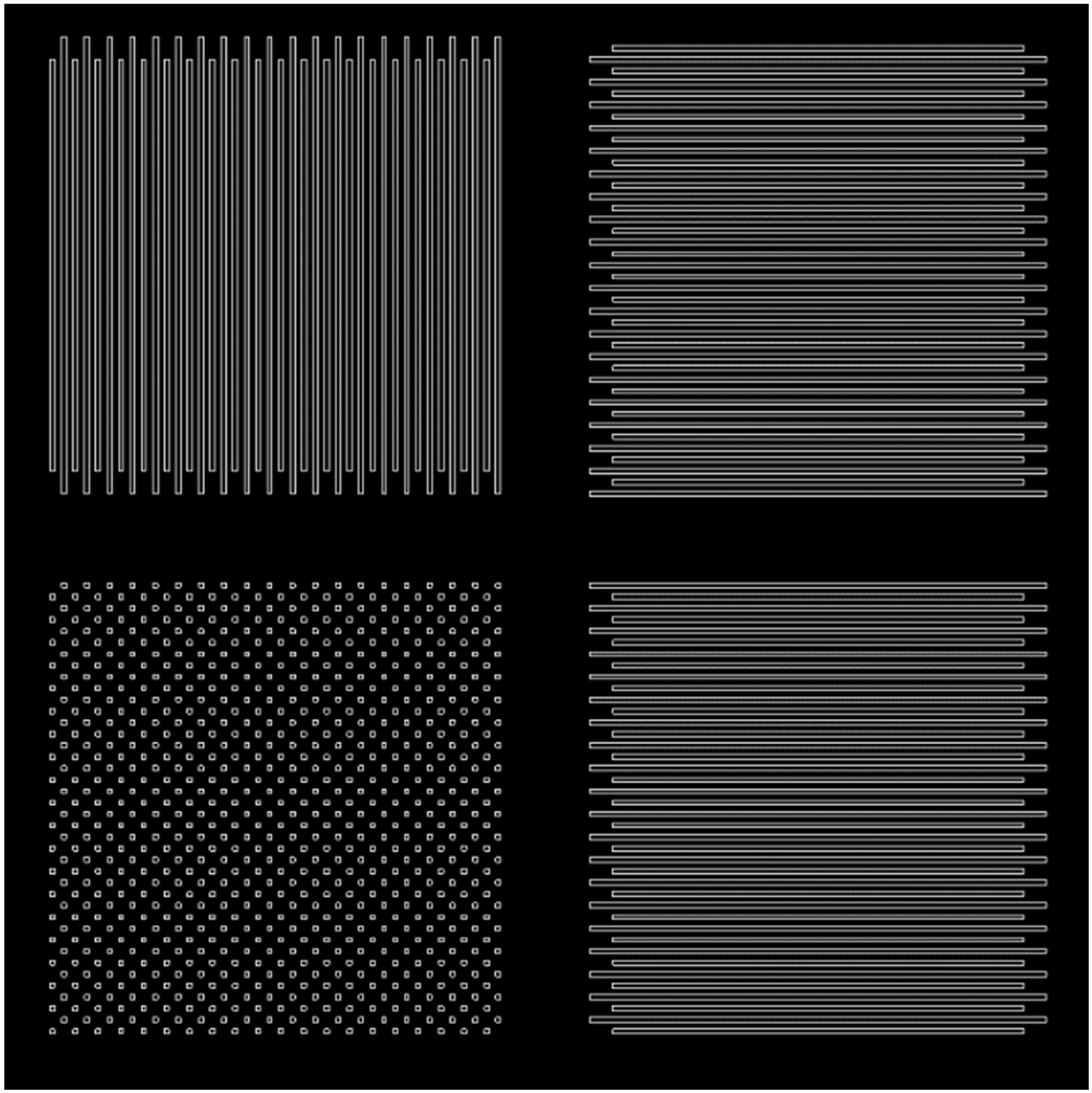

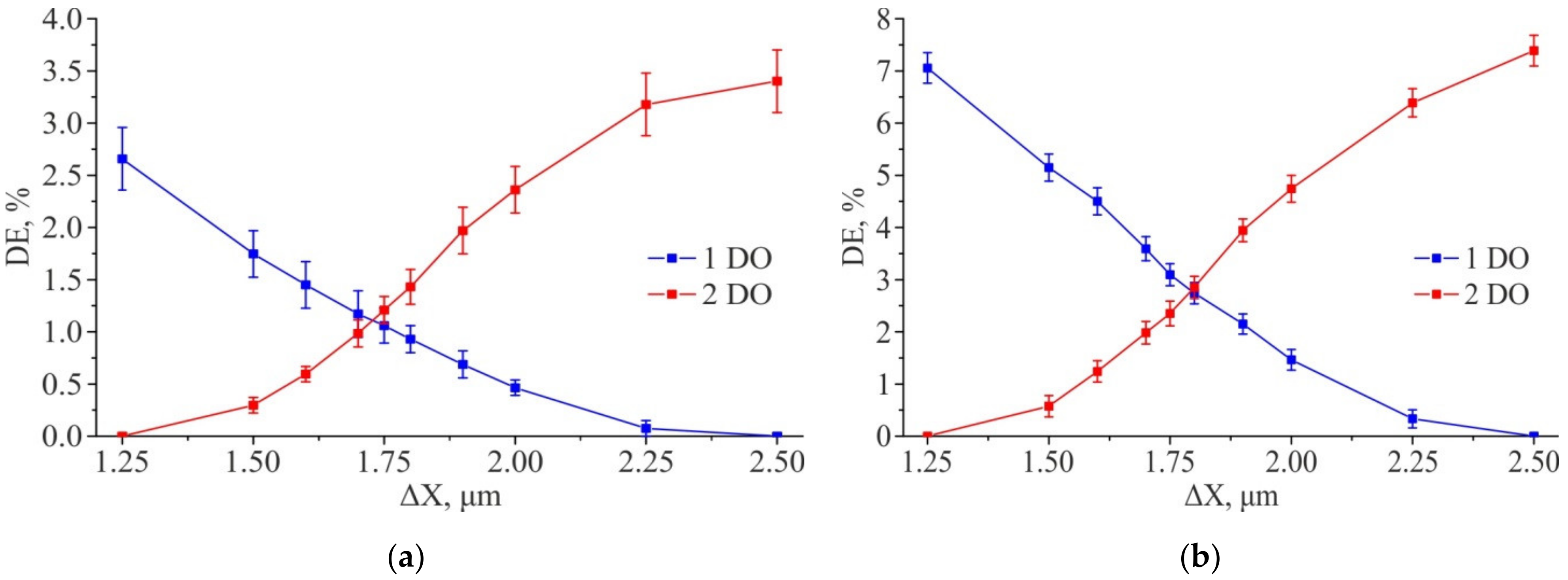

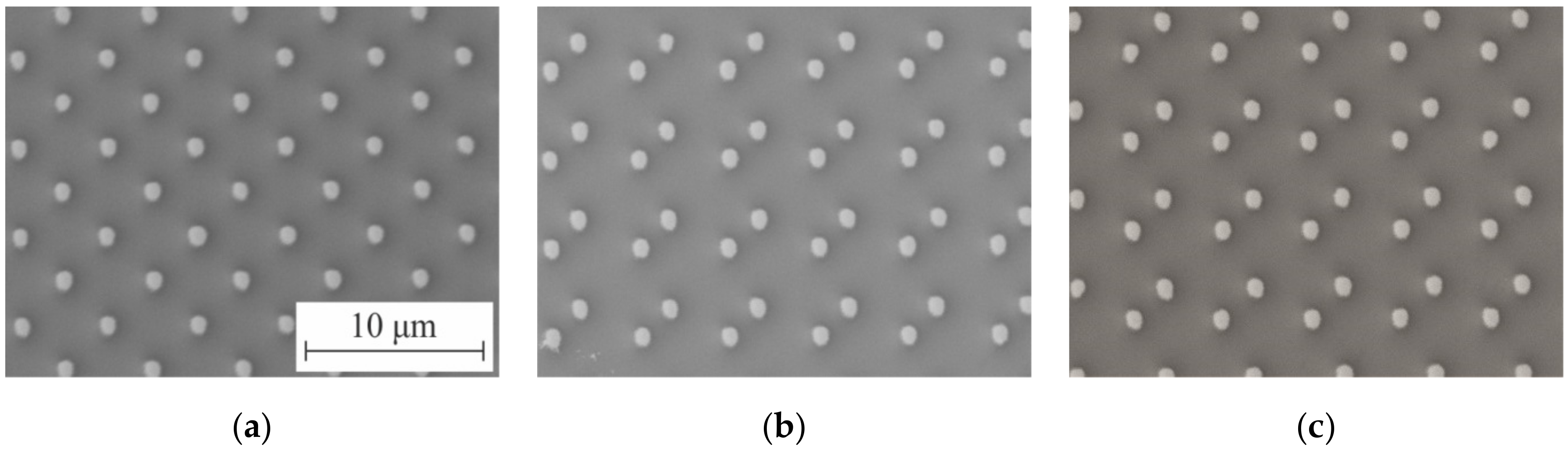

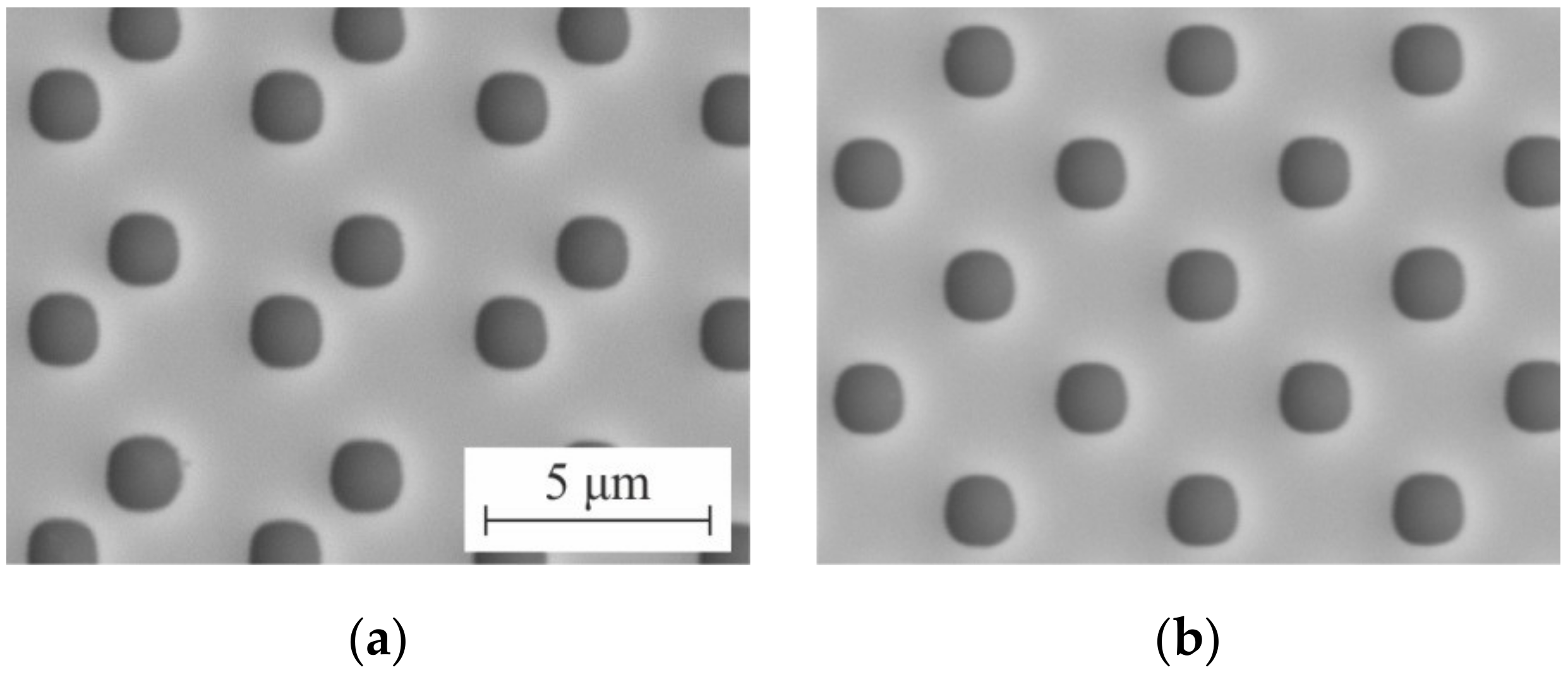

3.2. Experimental Writing of DSEs

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gale, M. Direct writing of continuous-relief micro-optics. In Micro-Optics: Elements, Systems and Applications, 1st ed.; Herzig, H., Ed.; Taylor & Francis: London, UK; CRC Press: Boca Raton, FL, USA, 1997; Chapter 2; p. 40. [Google Scholar]

- Krackhardt, U.W.; Schwider, J.; Schrader, M.; Streibl, N. Synthetic holograms written by a laser pattern generator. Opt. Eng. 1993, 32, 781–785. [Google Scholar] [CrossRef]

- Rensch, C.; Hell, S.; Schickfus, M.V.; Hunklinger, S. Laser scanner for direct writing lithography. Appl. Opt. 1989, 28, 3754–3758. [Google Scholar] [CrossRef]

- Koronkevich, V.P.; Kiriynov, V.P.; Kokoulin, V.P.; Poleschuk, A.G. Fabrication of kinoform optical elements. Optik 1984, 67, 257–266. [Google Scholar]

- Schwider, J.; Burov, R. Testing of aspherics by means of rotational-symmetric synthetic holograms. Opt. Appl. 1976, 6, 83–88. [Google Scholar]

- Nomura, T.; Kamiya, K.; Miyashiro, H.; Yoshikawa, K.; Tashiro, H.; Suzuki, M.; Ozono, S.; Kobayashi, F.; Usuki, M. An instrument for manufacturing zone-plates by using a lathe. Precis. Eng. 1994, 16, 290–295. [Google Scholar] [CrossRef]

- Bowen, J.P.; Michaels, R.L.; Blough, C.G. Generation of large-diameter diffractive elements with laser pattern generation. Appl. Opt. 1997, 36, 8970–8975. [Google Scholar] [CrossRef] [PubMed]

- Burge, J.H. Measurement of large convex aspheres. In Optical Telescopes of Today and Tomorrow; International Society for Optics and Photonics: Bellingham, WA, USA, 1997; Volume 2871, pp. 362–373. [Google Scholar]

- Jun, A.; Eiichi, F. Ultraviolet laser writing system based on polar scanning strategy to produce subwavelength metal gratings for surface plasmon resonance. Opt. Eng. 2013, 52, 063403. [Google Scholar]

- Rhee, H.G.; Song, J.B.; Kim, D.I.; Lee, Y.W. Diffractive Optics Fabrication System for Large Aspheric Surface Testing. J. Korean Phys. Soc. 2007, 50, 1032–1036. [Google Scholar] [CrossRef]

- Khonina, S.N.; Tukmakov, K.N.; Degtyarev, S.A.; Reshetnikov, A.S.; Pavelyev, V.S.; Knyazev, B.A.; Choporova, Y.Y. Design, fabrication and investigation of a subwavelength axicon for terahertz beam polarization transforming. Comput. Opt. 2019, 43, 756–764. [Google Scholar] [CrossRef]

- Lu, Z.; Liu, H.; Wang, R.; Li, F.; Liu, Y. Diffractive axicons fabricated by laser direct writer on curved surface. J. Opt. A. Pure Appl. Opt. 2007, 9, 160–164. [Google Scholar] [CrossRef]

- Pruss, C.; Reichelt, S.; Tiziani, H.J.; Korolkov, V.P. Metrological features of diffractive high-efficiency objectives for laser interferometry. In Seventh International Symposium on Laser Metrology Applied to Science, Industry, and Everyday Life; International Society for Optics and Photonics: Bellingham, WA, USA, 2002; Volume 4900, pp. 873–884. [Google Scholar]

- Xie, Y.; Lu, Z.; Li, F. Lithographic fabrication of large curved hologram by laser writer. Opt. Express 2004, 12, 1810–1814. [Google Scholar] [CrossRef] [PubMed]

- Poleshchuk, A.G.; Korolkov, V.P.; Cherkashin, V.V.; Reichelt, S.; Burge, J. Methods for minimizing the errors in direct laser writing of diffractive optical elements. Optoelectron. Instrum. Proc. 2002, 38, 3–15. [Google Scholar]

- Chen, Q.; Liu, J.; He, Y.; Luo, H.; Luo, J.; Wang, F. Humidity coefficient correction in the calculation equations of air refractive index by He–Ne laser based on phase step interferometry. Appl. Opt. 2015, 54, 1109–1113. [Google Scholar] [CrossRef] [PubMed]

- Shimanskii, R.V.; Poleshchuk, A.G.; Korolkov, V.P.; Cherkashin, V.V. Alignment of the writing beam with the diffractive structure rotation axis in synthesis of diffractive optical elements in a polar coordinate system. Optoelectron. Instrum. Proc. 2017, 53, 123–130. [Google Scholar] [CrossRef]

- Poleshchuk, A.G.; Korolkov, V.P. Fabrication and certification of high-quality and large-aperture CGHs for optical testing. In Proceedings of the EOS Topical Meeting on Diffractive Optics, Rochester, NY, USA, 9–11 October 2006; pp. 20–23. [Google Scholar] [CrossRef]

- Nasyrov, R.K.; Poleshchuk, A.G.; Korolkov, V.P.; Pruss, K.; Reichelt, S. Certification of diffractive optical elements for aspherical optics testing. Optoelectron. Instrum. Proc. 2005, 41, 100–108. [Google Scholar]

- Korolkov, V.P. Measurement and correction of the laser beam trajectory in circular writing systems. Optoelectron. Instrum. Proc. 2003, 39, 12–22. [Google Scholar]

- Korolkov, V.P.; Pruss, C.; Reichelt, S.; Osten, W.; Tiziani, H.J. Performance improvement of CGHs for optical testing. In Optical Measurement Systems for Industrial Inspection III; International Society for Optics and Photonics: Bellingham, WA, USA, 2003; Volume 5144, pp. 460–471. [Google Scholar]

- Korolkov, V.P.; Poleshchuk, A.G.; Cherkashin, V.V.; Burge, J. Methods for certification of CGH fabrication. In Proceedings of the OSA Topical Meeting “DOMO-2002”, Trends in Optics and Photonics, Tucson, AZ, USA, 3–6 June 2002; Volume 75, pp. 438–440. [Google Scholar] [CrossRef]

- Poleshchuk, A.G.; Koronkevich, V.P.; Korolkov, V.P.; Kharisov, A.A.; Cherkashin, V.V. Generation of diffractive optical elements in the polar coordinate system: Fabrication errors and their measurement. Optoelectron. Instrum. Proc. 1997, 6, 42–56. [Google Scholar]

- Becker, H.; Caspary, R.; Toepfer, C.; Schickfus, M.V.; Hunklinger, S. Low-cost direct writing lithography system for the sub-micron range. J. Mod. Opt. 1997, 44, 1715–1723. [Google Scholar] [CrossRef]

- Burge, J.; Chang, Y.R. Error analysis for CGH optical testing. In Optical Manufacturing and Testing III; International Society for Optics and Photonics: Bellingham, WA, USA, 1999; Volume 3782, pp. 358–366. [Google Scholar]

- Cherkashin, V.V.; Churin, E.G.; Korolkov, V.P.; Koronkevich, V.P.; Kharissov, A.A.; Poleshchuk, A.G.; Burge, J.H. Processing parameter optimization for thermochemical writing of DOEs on chromium films. In Diffractive and Holographic Device Technologies and Applications IV; International Society for Optics and Photonics: Bellingham, WA, USA, 1997; Volume 3010, pp. 168–179. [Google Scholar] [CrossRef]

- Veiko, V.P.; Korol’kov, V.P.; Poleshchuk, A.G.; Sametov, A.R.; Shakhno, E.A.; Yarchuk, M.V. Study of the spatial resolution of laser thermochemical technology for recording diffraction microstructures. Quantum Elec. 2011, 41, 631–636. [Google Scholar] [CrossRef]

- Gotchiyaev, V.Z.; Korolkov, V.P.; Sokolov, A.P.; Chernukhin, V.P. High resolution optical recording on a-Si films. J. Non-Cryst. Solids 1991, 137, 1297–1300. [Google Scholar] [CrossRef]

- Nasyrov, R.K.; Poleshchuk, A.G. Manufacturing and certification of a diffraction corrector for controlling the surface shape of the six-meter main mirror of the Big Azimuthal Telescope of the Russian Academy of Sciences. Optoelectron. Instrum. Proc. 2017, 53, 517–523. [Google Scholar] [CrossRef]

- Shimansky, R.V. Error measurement method in the fabrication of precision synthesized holograms on circular laser writing systems. Optoelectron. Instrum. Proc. 2019, 55, 303–308. [Google Scholar] [CrossRef]

- Shimansky, R.V.; Nasyrov, R.K.; Belousov, D.A. Measuring fabrication errors of computer-generated holograms using embedded microgratings. In Holography, Diffractive Optics, and Applications X; International Society for Optics and Photonics: Bellingham, WA, USA, 2020; Volume 11551, p. 115510L. [Google Scholar] [CrossRef]

- Xu, B.; Wu, Q.; Dong, L.; Wei, Y. Selection of DBO measurement wavelength for bottom mark asymmetry based on FDTD method. J. Semicond. 2019, 40, 122403. [Google Scholar] [CrossRef]

- Chen, X.; Gu, H.; Jiang, H.; Zhang, C.; Liu, S. Robust overlay metrology with differential Mueller matrix calculus. Opt. Express 2017, 25, 8491–8510. [Google Scholar] [CrossRef] [Green Version]

- Levinson, H.J. Publication guidelines for metrology and masks. J. Micro/Nanopatterning Mater. Metrol. 2021, 20, 020101. [Google Scholar]

- Shimansky, R.V.; Belousov, D.A.; Kuts, R.I.; Korolkov, V.P. Controlling the accuracy of fabricating computer-generated holograms on circular and X-Y laser writing systems. In Optical Design and Engineering VIII; International Society for Optics and Photonics: Bellingham, WA, USA, 2021; Volume 11871, p. 118710I. [Google Scholar] [CrossRef]

- Diffraction Optics Simulation and Design from KJ Innovation. Available online: https://kjinnovation.com (accessed on 8 September 2021).

- MATLAB—MathWorks—MATLAB & Simulink. Available online: https://www.mathworks.com/products/matlab.html (accessed on 8 September 2021).

- DWL66+. Available online: https://heidelberg-instruments.com/product/dwl-66-laser-lithography-system/ (accessed on 28 September 2021).

- Belousov, D.A.; Poleshchuk, A.G.; Khomutov, V.N. Device for Characterization of the Diffraction Pattern of Computer-Generated Holograms in a Wide Angular Range. Optoelectron. Instrum. Proc. 2018, 54, 139–145. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shimansky, R.V.; Belousov, D.A.; Korolkov, V.P.; Kuts, R.I. Diffractive Sensor Elements for Registration of Long-Term Instability at Writing of Computer-Generated Holograms. Sensors 2021, 21, 6635. https://doi.org/10.3390/s21196635

Shimansky RV, Belousov DA, Korolkov VP, Kuts RI. Diffractive Sensor Elements for Registration of Long-Term Instability at Writing of Computer-Generated Holograms. Sensors. 2021; 21(19):6635. https://doi.org/10.3390/s21196635

Chicago/Turabian StyleShimansky, Ruslan V., Dmitrij A. Belousov, Victor P. Korolkov, and Roman I. Kuts. 2021. "Diffractive Sensor Elements for Registration of Long-Term Instability at Writing of Computer-Generated Holograms" Sensors 21, no. 19: 6635. https://doi.org/10.3390/s21196635

APA StyleShimansky, R. V., Belousov, D. A., Korolkov, V. P., & Kuts, R. I. (2021). Diffractive Sensor Elements for Registration of Long-Term Instability at Writing of Computer-Generated Holograms. Sensors, 21(19), 6635. https://doi.org/10.3390/s21196635