Investigation of the Impact of Neutron Irradiation on SiC Power MOSFETs Lifetime by Reliability Tests

Abstract

:1. Introduction

2. Experimental

2.1. Electrical Characterization

2.2. HTGB and HTRB Tests

- HTRB = 0 V, = 1200 V

- HTGB1 = +22 V, = 0 V

- HTGB2 = −10 V, = 0 V

3. Results

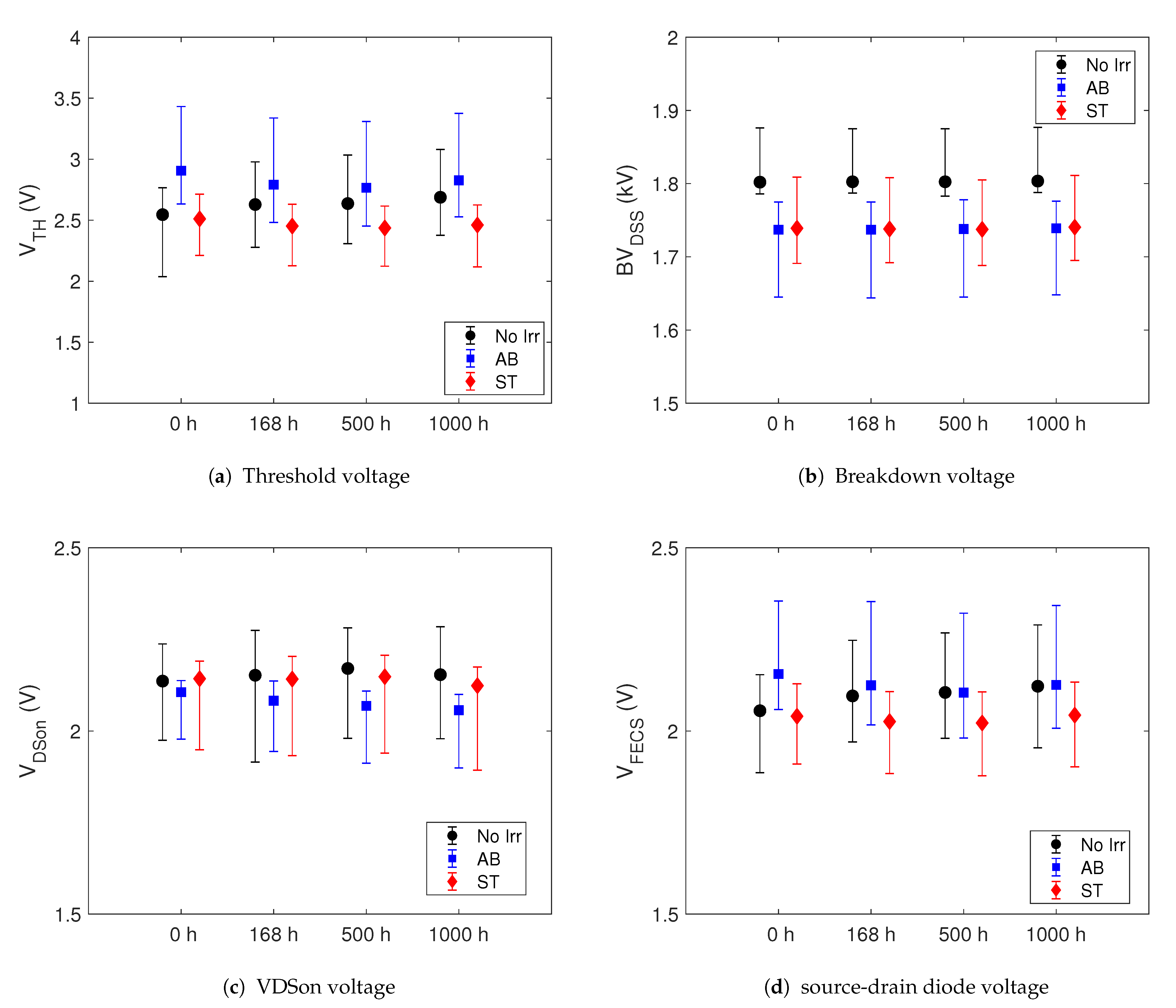

3.1. Electrical Characterization of the Survived Samples

3.2. Weibull Analysis of the Irradiation Failures

3.3. HTGB and HTRB Tests on Survived GEN3 SiC MOSFETs

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Davidson, C.; Blackmore, E.; Hess, J. Failures of MOSFETs in terrestrial power electronics due to single event burnout. In Proceedings of the 26th Annual International Telecommunications Energy Conference (INTELEC 2004), Chicago, IL, USA, 19–23 September 2004; pp. 503–507. [Google Scholar]

- Consentino, G.; Laudani, M.; Privitera, G.; Pace, C.; Giordano, C.; Hernandez, J.; Mazzeo, M. Effects on power transistors of Terrestrial Cosmic Rays: Study, experimental results and analysis. In Proceedings of the 2014 IEEE Applied Power Electronics Conference and Exposition (APEC 2014), Fort Worth, TX, USA, 16–20 March 2014; pp. 2582–2587. [Google Scholar]

- Titus, J.L. An Updated Perspective of Single Event Gate Rupture and Single Event Burnout in Power MOSFETs. IEEE Trans. Nucl. Sci. 2013, 60, 1912–1928. [Google Scholar] [CrossRef]

- Akturk, A.; McGarrity, J.M.; Goldsman, N.; Lichtenwalner, D.; Hull, B.; Grider, D.; Wilkins, R. Terrestrial Neutron-Induced Failures in Silicon Carbide Power MOSFETs and Diodes. IEEE Trans. Nucl. Sci. 2018, 65, 1248–1254. [Google Scholar] [CrossRef]

- Ball, D.R.; Sierawski, B.D.; Galloway, K.F.; Johnson, R.A.; Alles, M.L.; Sternberg, A.L.; Witulski, A.F.; Reed, R.A.; Schrimpf, R.D.; Javanainen, A.; et al. Estimating Terrestrial Neutron-Induced SEB Cross Sections and FIT Rates for High-Voltage SiC Power MOSFETs. IEEE Trans. Nucl. Sci. 2019, 66, 337–343. [Google Scholar] [CrossRef] [Green Version]

- Asai, H.; Nashiyama, I.; Sugimoto, K.; Shiba, K.; Sakaide, Y.; Ishimaru, Y.; Okazaki, Y.; Noguchi, K.; Morimura, T. Tolerance Against Terrestrial Neutron-Induced Single-Event Burnout in SiC MOSFETs. IEEE Trans. Nucl. Sci. 2014, 61, 3109–3114. [Google Scholar] [CrossRef]

- Martinella, C.; Alia, R.G.; Stark, R.; Coronetti, A.; Cazzaniga, C.; Kastriotou, M.; Kadi, Y.; Gaillard, R.; Grossner, U.; Javanainen, A. Impact of Terrestrial Neutrons on the Reliability of SiC VD-MOSFET Technologies. IEEE Trans. Nucl. Sci. 2021, 68, 634–641. [Google Scholar] [CrossRef]

- Principato, F.; Altieri, S.; Abbene, L.; Pintacuda, F. Accelerated Tests on Si and SiC Power Transistors with Thermal, Fast and Ultra-Fast Neutrons. Sensors 2020, 20, 3021. [Google Scholar] [CrossRef] [PubMed]

- Akturk, A.; McGarrity, J.M.; Goldsman, N.; Lichtenwalner, D.J.; Hull, B.; Grider, D.; Wilkins, R. Predicting Cosmic Ray-Induced Failures in Silicon Carbide Power Devices. IEEE Trans. Nucl. Sci. 2019, 66, 1828–1832. [Google Scholar] [CrossRef]

- Lichtenwalner, D.J.; Akturk, A.; McGarrity, J.; Richmond, J.; Barbieri, T.; Hull, B.; Grider, D.; Allen, S.; Palmour, J.W. Reliability of SiC Power Devices against Cosmic Ray Neutron Single-Event Burnout. In Silicon Carbide and Related Materials 2017; Materials Science Forum; Trans Tech Publications Ltd.: Washington, DC, USA, 2017; Volume 924, pp. 559–562. [Google Scholar]

- Yazdi, M.B.; Schmeidl, M.; Wu, X.; Neyer, T. A concise study of neutron irradiation effects on power MOSFETs and IGBTs. Microelectron. Reliab. 2016, 62, 74–78. [Google Scholar] [CrossRef]

- Process Management for Avionics–Atmospheric Radiation Effects. Accommodation of Atmospheric Radiation Effects via Single Event Effects within Avionics Electronic Equipment; IEC Standard 62396-1; International Electrotechnical Commission: Geneva, Switzerland, 2016; Available online: https://webstore.iec.ch/publication/24053 (accessed on 13 August 2021).

- Bolotnikov, A.; Losee, P.; Permuy, A.; Dunne, G.; Kennerly, S.; Rowden, B.; Nasadoski, J.; Harfman-Todorovic, M.; Raju, R.; Tao, F.; et al. Overview of 1.2 kV–2.2 kV SiC MOSFETs targeted for industrial power conversion applications. In Proceedings of the 2015 IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015; pp. 2445–2452. [Google Scholar]

- Akturk, A.; Wilkins, R.; McGarrity, J. Terrestrial Neutron Induced Failures in Commercial SiC Power MOSFETs at 27C and 150C. In Proceedings of the 2015 IEEE Radiation Effects Data Workshop (REDW), Boston, MA, USA, 13–17 July 2015; pp. 1–5. [Google Scholar]

- Marshall, P.; Marshall, C. Proton effects and test issues for satellite designers. Presented at the Short Course at the IEEE Nuclear and Space Radiation Effects Conference (NSREC), Norfolk, VA, USA, 12–16 July 1999. [Google Scholar]

- Oldham, T.R.; Whitney, C.M.; Griffiths, B.J.; van Vonno, N. Summary and Analysis of Neutron Displacement Damage Results. In Proceedings of the 2018 IEEE Radiation Effects Data Workshop (REDW), Waikoloa, HI, USA, 16–20 July 2018; pp. 1–4. [Google Scholar]

- Faccio, F.; Allongue, B.; Blanchot, G.; Fuentes, C.; Michelis, S.; Orlandi, S.; Sorge, R. TID and Displacement Damage Effects in Vertical and Lateral Power MOSFETs for Integrated DC-DC Converters. IEEE Trans. Nucl. Sci. 2010, 57, 1790–1797. [Google Scholar] [CrossRef] [Green Version]

- Test Procedure for the Measurement of Terrestrial Cosmic Ray Induced Destructive Effects in Power Semiconductor Devices; JEDEC Standard JEP151; JEDEC Solid State Technology Association: Arlington, VA, USA, 2015.

- Lelis, A.J.; Green, R.; Habersat, D.B.; El, M. Basic Mechanisms of Threshold-Voltage Instability and Implications for Reliability Testing of SiC MOSFETs. IEEE Trans. Electron Devices 2015, 62, 316–323. [Google Scholar] [CrossRef]

- Aichinger, T.; Rescher, G.; Pobegen, G. Threshold voltage peculiarities and bias temperature instabilities of SiC MOSFETs. Microelectron. Reliab. 2018, 80, 68–78. [Google Scholar] [CrossRef]

- Failure Mechanisms Based Stress Test Qualification for Discrete Semiconductors in Automotive Applications. Aec-q101-rev–d1, Automotive Electronics Council, Component Technical Committee, 6 September 2013. Available online: http://www.aecouncil.com/ (accessed on 13 August 2021).

- Pintacuda, F.; Cantarella, V.; Muschitiello, M.; Massetti, S. Prototyping and characterization of radiation hardened SiC MOS structures. In Proceedings of the 2019 European Space Power Conference (ESPC), Juan-les-Pins, France, 30 September–4 October 2019; pp. 1–8. [Google Scholar]

- Fernandez, A.; Vazquez, M. Improved Estimation of Weibull Parameters Considering Unreliability Uncertainties. IEEE Trans. Reliab. 2012, 61, 32–40. [Google Scholar] [CrossRef] [Green Version]

- Patrick, D.T.; O′Connor. Practical Reliability and Lifetime Data; Wiley: London, UK, 1981. [Google Scholar]

- Khalili, A.; Kromp, K. Statistical properties of Weibull estimators. J. Mater. Sci. 1991, 26, 6741–6752. [Google Scholar] [CrossRef]

- Pritts, J.M.; Wender, S.A.; George, J.S.; Fairbanks, T.D.; O’Donnell, J.M. Energy-Dependent Single-Event Effects in Power MOSFETs from a Broad-Spectrum Neutron Beam. In Proceedings of the 2020 IEEE Radiation Effects Data Workshop (in Conjunction with 2020 NSREC), Santa Fe, NM, USA, 29 November–30 December 2020; pp. 1–8. [Google Scholar]

- Akturk, A.; Wilkins, R.; McGarrity, J.; Gersey, B. Single Event Effects in Si and SiC Power MOSFETs Due to Terrestrial Neutrons. IEEE Trans. Nucl. Sci. 2017, 64, 529–535. [Google Scholar] [CrossRef]

| (V) under Irradiation (V) | FIT Sea Level [95% CI Bounds] | FIT 12 km [95% CI Bounds] |

|---|---|---|

| 800 | 0.01 | 4.6 |

| 850 | 0.09 | 42 |

| Symbol | Unit | Parameter | Condition at = 25 °C |

|---|---|---|---|

| nA | gate leakage current | 10 V, 0 V | |

| nA | gate leakage current | 22 V, 0 V | |

| V | gate-source threshold voltage | 1 mA, | |

| A | drain leakage current | 1.2 kV, = 0 V | |

| V | drain-source breakdown voltage | 1 mA, = 0 V | |

| V | drain-source on-state voltage | 120 A, = 18 V | |

| V | source-drain diode voltage | 10 A, = 0 V |

| Power Device | (V) | (V) (under Irradiation) | Lower 95% CI | Upper 95% CI | |

|---|---|---|---|---|---|

| SiC-SCT35N65G2V | 650 | 480 | 1.1 | 0.86 | 1.50 |

| SiC-SCT130N120G3 | 950 | 1200 | 1.2 | 0.87 | 1.50 |

| Si-STB45N40DM2AG | 325 | 400 | 0.95 | 0.70 | 1.30 |

| IGBT-STGW8M120DF3 | 850 | 1200 | 1.20 | 0.79 | 1.80 |

| Failures/Samples | |||||||

|---|---|---|---|---|---|---|---|

| Test | Standard Reference | Conditions | n° Samples | Step | No Irr | ST | AB |

| HTRB | MIL-STD-750-1M1038 | = 200 °C, BIAS = 1200 V | 23 | 168 h | 0/10 | 0/6 | 0/7 |

| 500 h | 0/10 | 0/6 | 0/7 | ||||

| 1000 h | 0/10 | 0/6 | 0/7 | ||||

| HTGB1 | JESD22A-108 | = 200 °C, BIAS = +22 V | 17 | 168 h | 0/10 | 0/4 | 0/3 |

| 500 h | 0/10 | 0/4 | 0/3 | ||||

| 1000 h | 0/10 | 0/4 | 0/3 | ||||

| HTGB2 | JESD22A-108 | = 200 °C, BIAS = −10 V | 19 | 168 h | 0/10 | 0/6 | 0/3 |

| 500 h | 0/10 | 0/6 | 0/3 | ||||

| 1000 h | 0/10 | 0/6 | 0/3 | ||||

| HTRB | |||||||

|---|---|---|---|---|---|---|---|

| Parameter | Median | Max Drift | Spec. Drift | Datasheet Limit | |||

| 0 h | 168 h | 500 h | 1000 h | ||||

| @ −10 V | <10 nA | <10 nA | <10 nA | <10 nA | - | 5 times initial value | <100 nA |

| @ +22 V | <10 nA | <10 nA | <10 nA | <10 nA | - | 5 times initial value | <100 nA |

| @ 1 mA | 2.58 V | 2.48 V | 2.47 V | 2.46 V | <5% | <20% | >1 V, <6 V |

| @ 1.2 kV | 0.44 A | 0.40 A | 0.38 A | 0.32 A | - | 5 times initial value | <10 A |

| @ 1 mA | 1.73 kV | 1.73 kV | 1.73 kV | 1.74 kV | <2% | <20% | >1.2 kV, <1.9 kV |

| @ = 120 A 18 V | 2.16 V | 2.14 V | 2.15 V | 2.12 V | <2% | <20% | >1.5 V, <4.14 V |

| @ 6 A | 2.06 V | 2.04 V | 2.04 V | 2.04 V | <1% | <20% | <5 V |

| HTGB1 | |||||||

|---|---|---|---|---|---|---|---|

| Parameter | Median | Max Drift | Spec. Drift | Datasheet Limit | |||

| 0 h | 168 h | 500 h | 1000 h | ||||

| @ −10 V | <10 nA | <10 nA | <10 nA | <10 nA | - | 5 times initial value | <100 nA |

| @ +22 V | <10 nA | <10 nA | <10 nA | <10 nA | - | 5 times initial value | <100 nA |

| @ 1 mA | 2.76 V | 2.92 V | 3.02 V | 3.02 V | <5% | <20% | >1 V, <6 V |

| @ 1.2 kV | 0.30 A | 0.29 A | 0.29 A | 0.06 A | - | 5 times initial value | <10 A |

| @ 1 mA | 1.78 kV | 1.78 kV | 1.78 kV | 1.74 kV | <2% | <20% | >1.2 kV, <1.9 kV |

| @ = 120 A 18 V | 2.32 V | 2.29 V | 2.35 V | 2.47 V | <2% | <20% | >1.5 V, <4.14 V |

| @ 6 A | 2.16 V | 2.20 V | 2.23 V | 2.08 V | <1% | <20% | <5V |

| HTGB2 | |||||||

|---|---|---|---|---|---|---|---|

| Parameter | Median | Max Drift | Spec. Drift | Datasheet Limit | |||

| 0 h | 168 h | 500 h | 1000 h | ||||

| @ −10 V | <10 nA | <10 nA | <10 nA | <10 nA | - | 5 times initial value | <100 nA |

| @ +22 V | <10 nA | <10 nA | <10 nA | <10 nA | - | 5 times initial value | <100 nA |

| @ 1 mA | 2.94 V | 3.20 V | 3.22 V | 3.21 V | <5% | <20% | >1 V, <6 V |

| @ 1.2 kV | 0.40 A | 0.41 A | 0.41 A | 0.42 A | - | 5 times initial value | <10 A |

| @ 1 mA | 1.76 kV | 1.76 kV | 1.76 kV | 1.76 kV | <2% | <20% | >1.2 kV, <1.9 kV |

| @ = 120 A 18 V | 2.27 V | 2.36 V | 2.40 V | 2.40 V | <2% | <20% | >1.5 V, <4.14 V |

| @ 6 A | 2.20 V | 2.30 V | 2.31 V | 2.30 V | <1% | <20% | <5V |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Principato, F.; Allegra, G.; Cappello, C.; Crepel, O.; Nicosia, N.; D′Arrigo, S.; Cantarella, V.; Di Mauro, A.; Abbene, L.; Mirabello, M.; et al. Investigation of the Impact of Neutron Irradiation on SiC Power MOSFETs Lifetime by Reliability Tests. Sensors 2021, 21, 5627. https://doi.org/10.3390/s21165627

Principato F, Allegra G, Cappello C, Crepel O, Nicosia N, D′Arrigo S, Cantarella V, Di Mauro A, Abbene L, Mirabello M, et al. Investigation of the Impact of Neutron Irradiation on SiC Power MOSFETs Lifetime by Reliability Tests. Sensors. 2021; 21(16):5627. https://doi.org/10.3390/s21165627

Chicago/Turabian StylePrincipato, Fabio, Giuseppe Allegra, Corrado Cappello, Olivier Crepel, Nicola Nicosia, Salvatore D′Arrigo, Vincenzo Cantarella, Alessandro Di Mauro, Leonardo Abbene, Marcello Mirabello, and et al. 2021. "Investigation of the Impact of Neutron Irradiation on SiC Power MOSFETs Lifetime by Reliability Tests" Sensors 21, no. 16: 5627. https://doi.org/10.3390/s21165627

APA StylePrincipato, F., Allegra, G., Cappello, C., Crepel, O., Nicosia, N., D′Arrigo, S., Cantarella, V., Di Mauro, A., Abbene, L., Mirabello, M., & Pintacuda, F. (2021). Investigation of the Impact of Neutron Irradiation on SiC Power MOSFETs Lifetime by Reliability Tests. Sensors, 21(16), 5627. https://doi.org/10.3390/s21165627