Use of Long Short-Term Memory for Remaining Useful Life and Degradation Assessment Prediction of Dental Air Turbine Handpiece in Milling Process

Abstract

:1. Introduction

2. Method

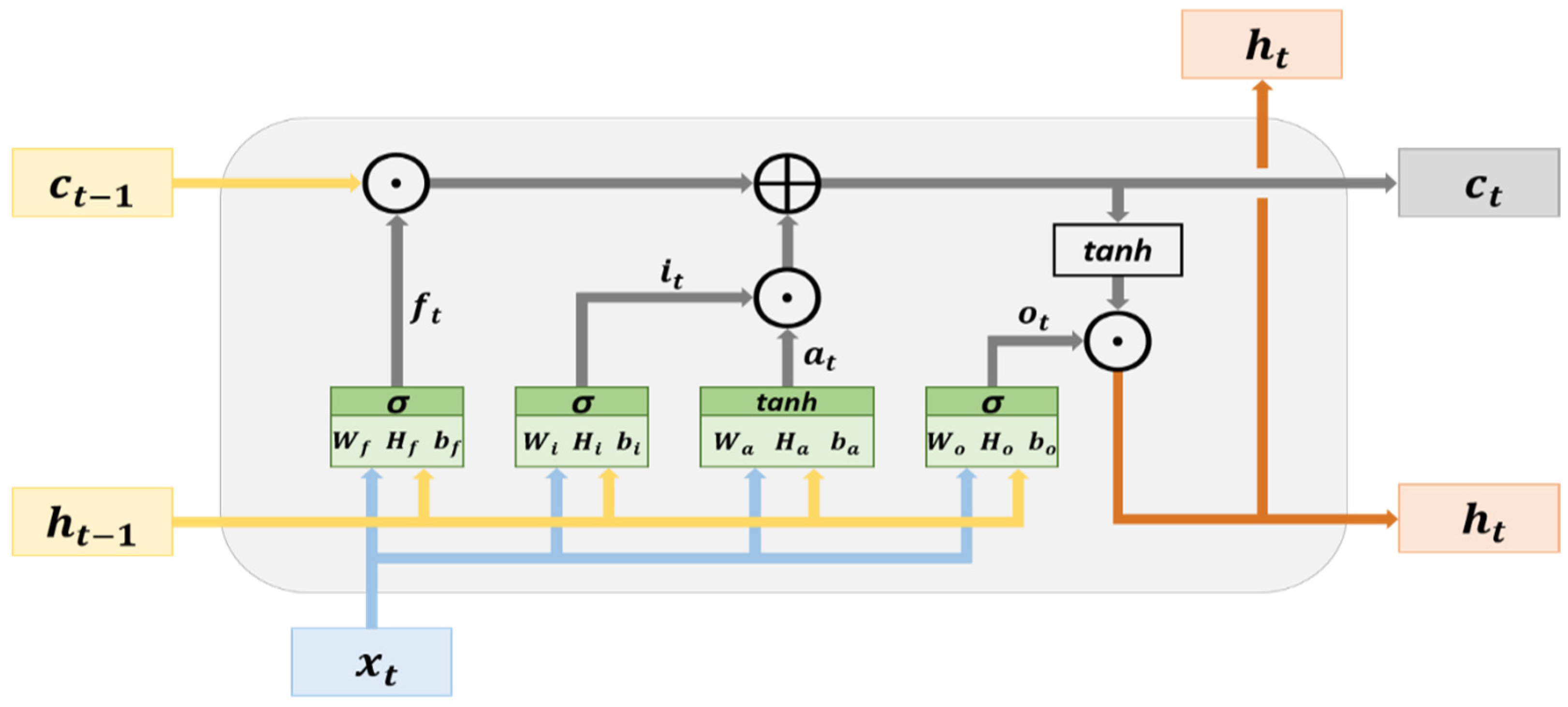

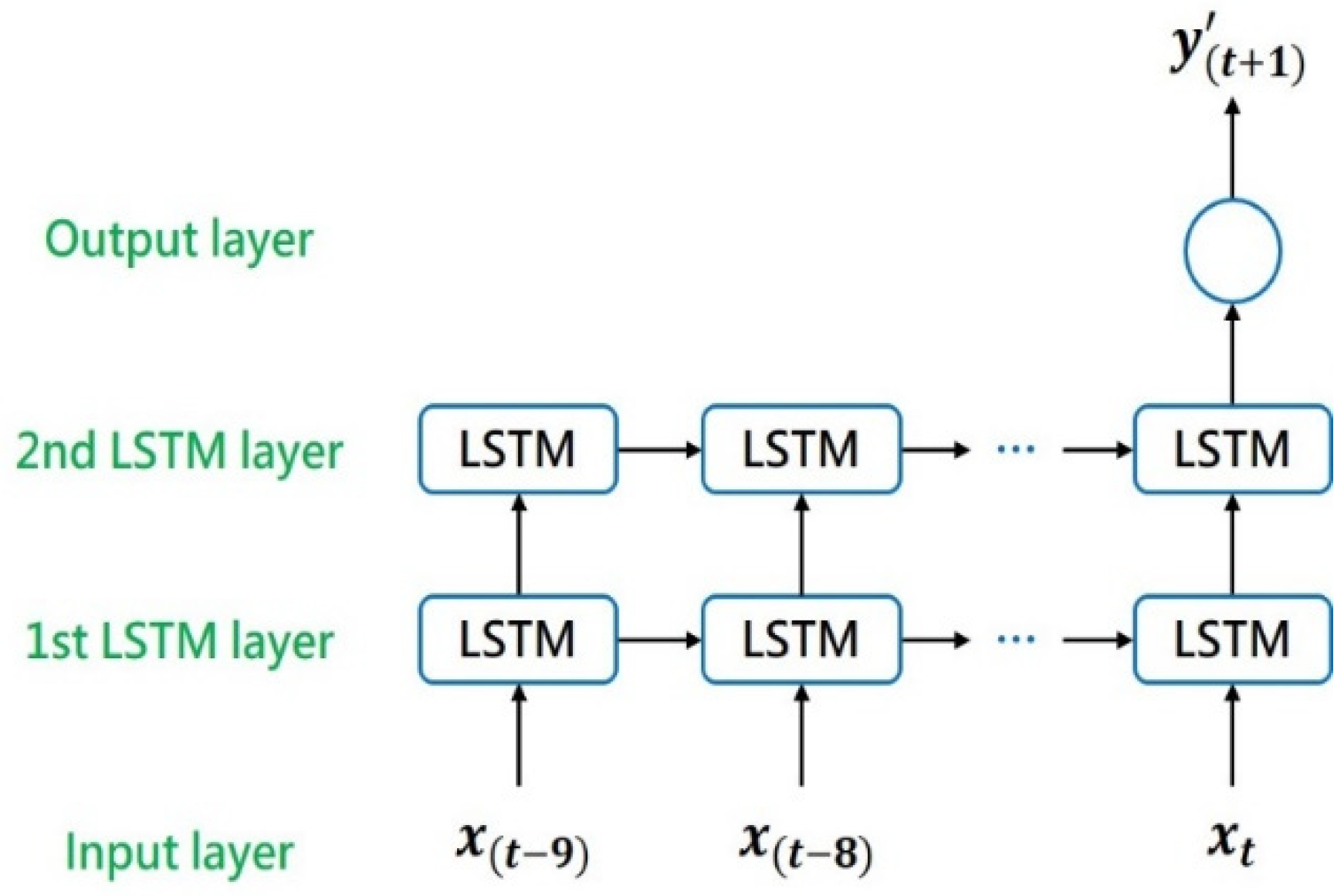

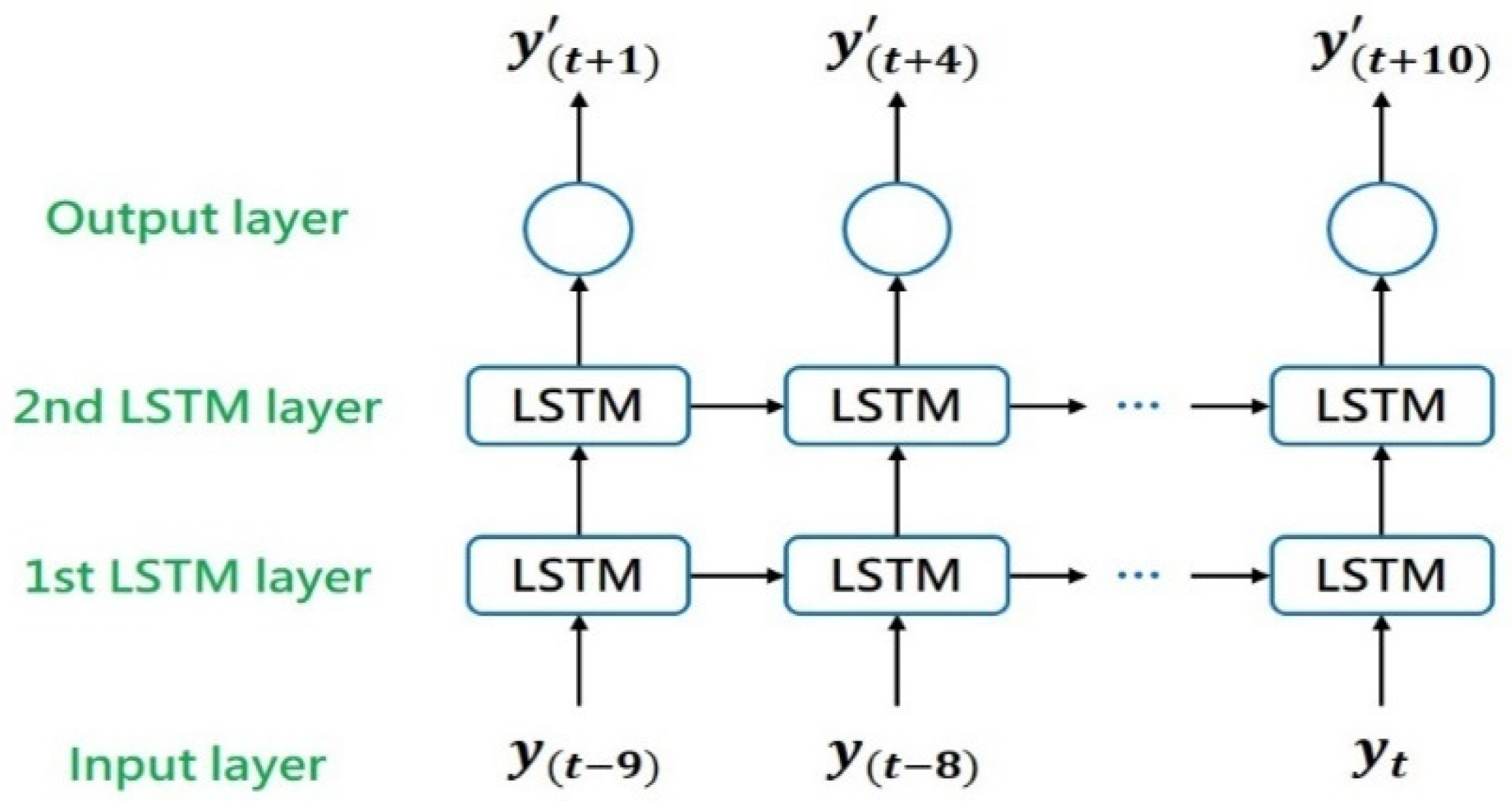

2.1. Many to One and Many to Many LSTM Structures for RUL and Degradation Assessment

2.2. Logistic Regression Prediction Model for Many to One Structure

2.3. Kalman Filter

- I.

- Prediction

- II.

- Correction

3. Experiments

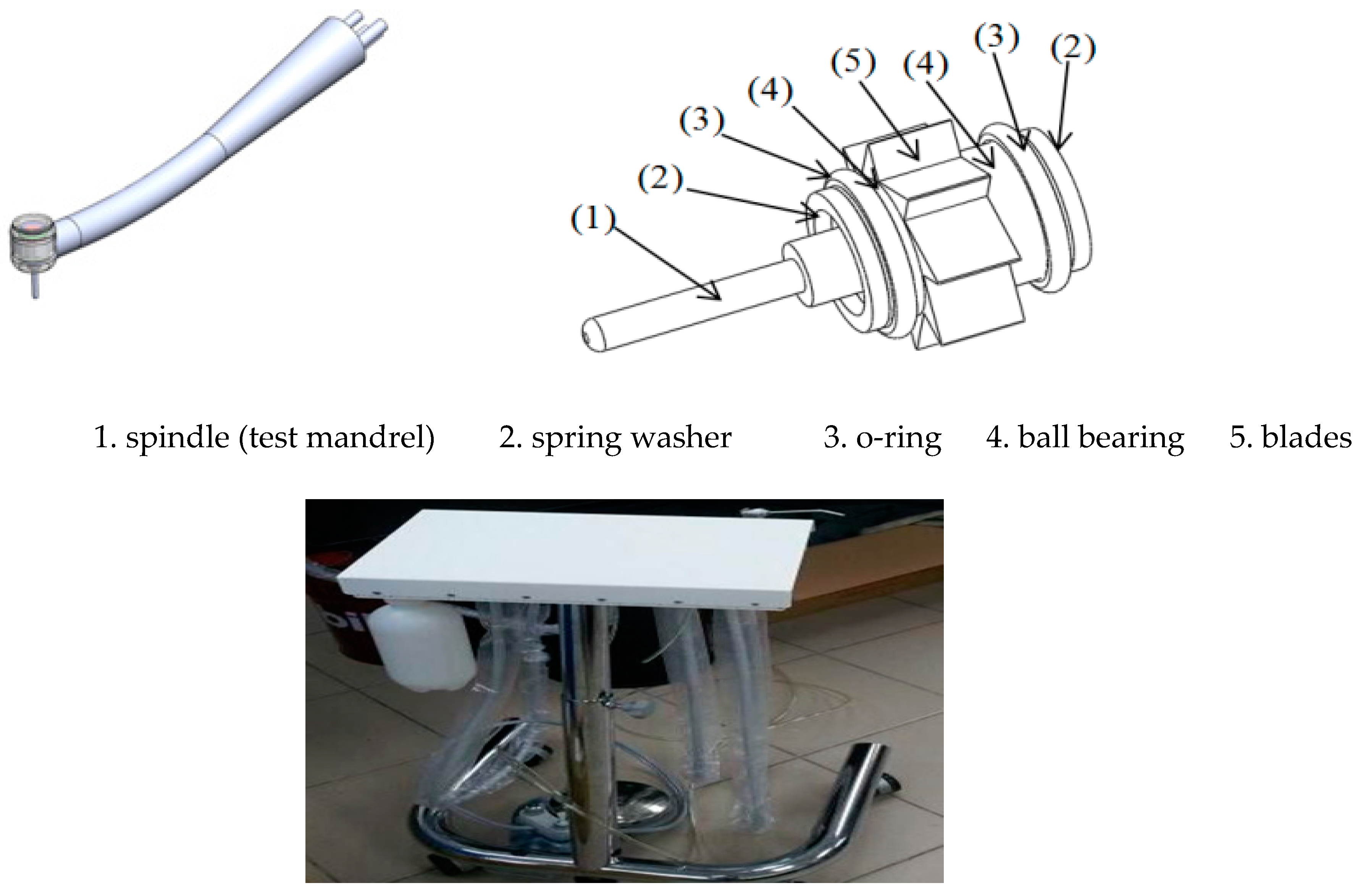

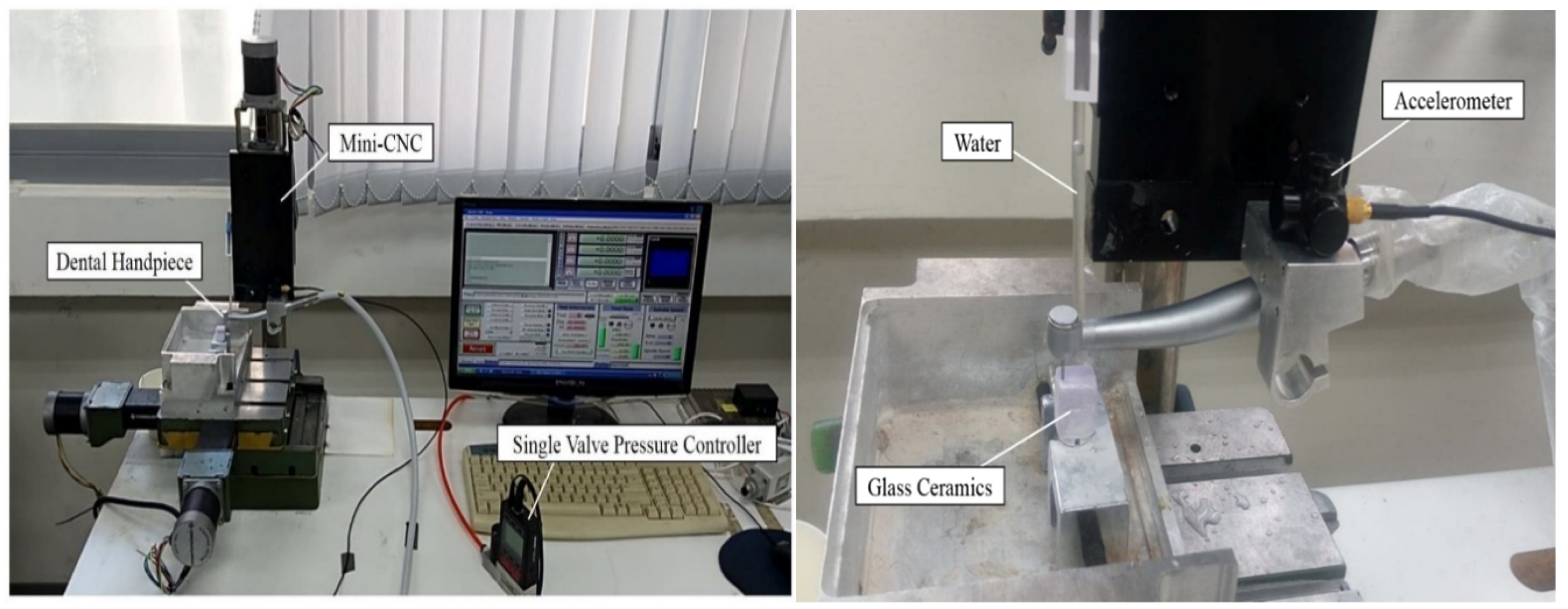

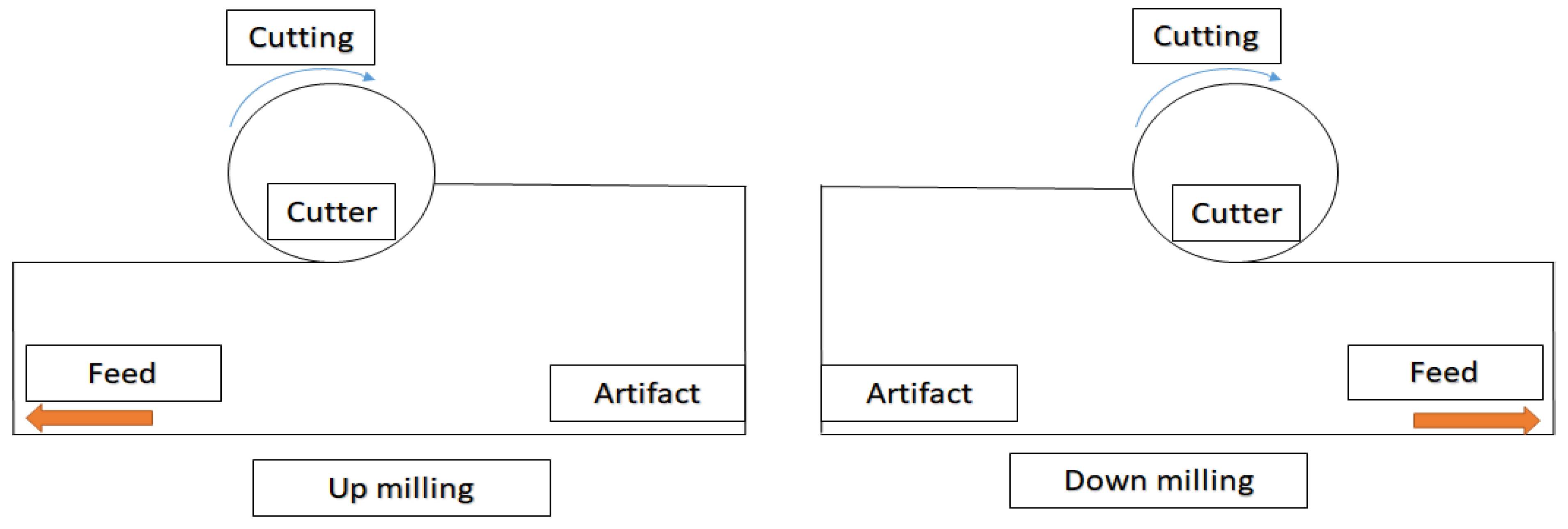

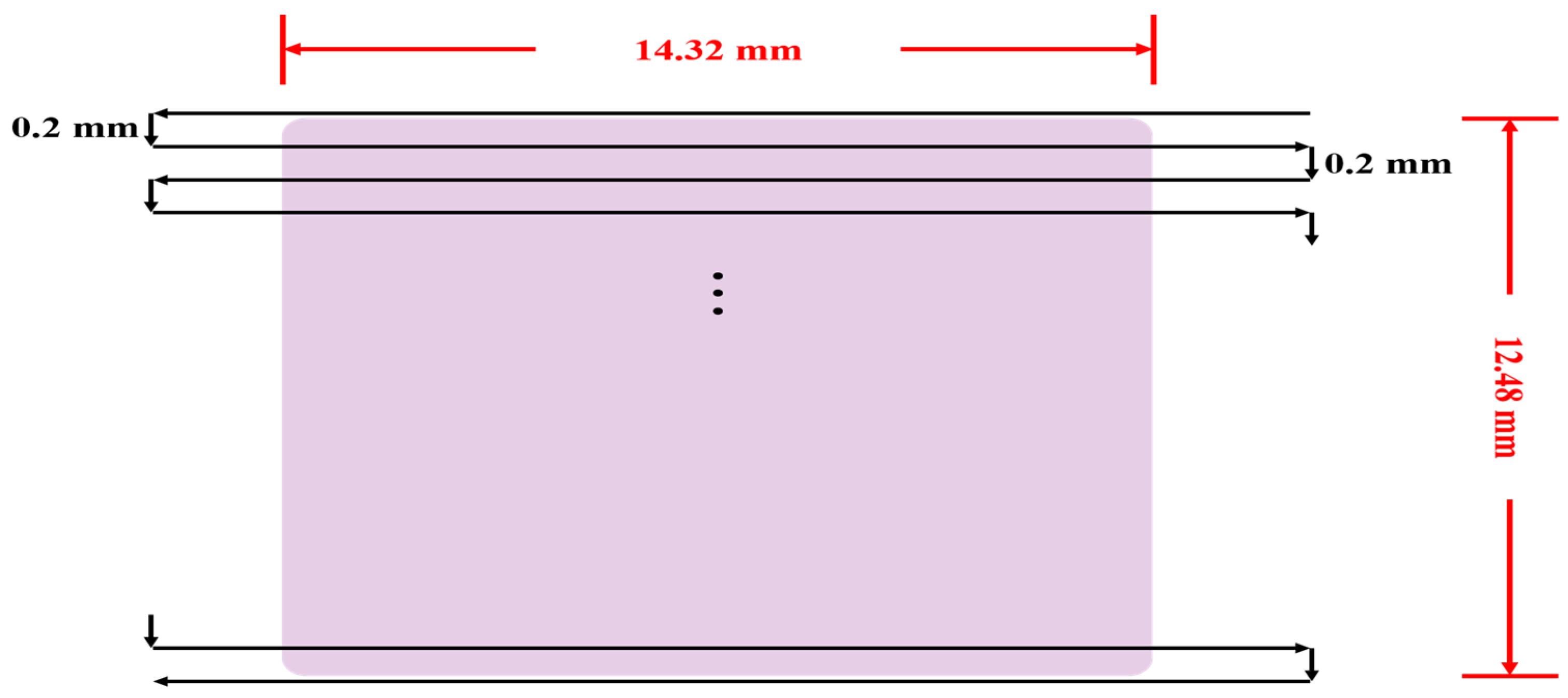

3.1. Experimental Setup and Milling

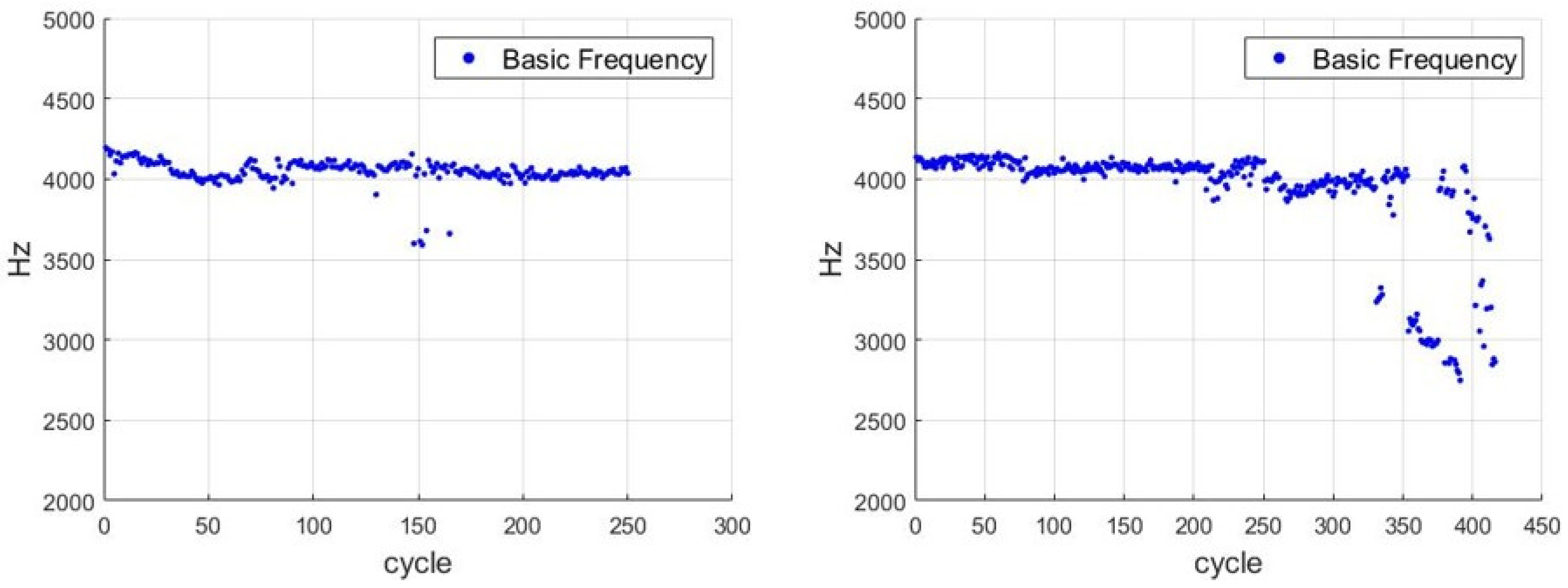

3.2. Free-Running Vibration Signals

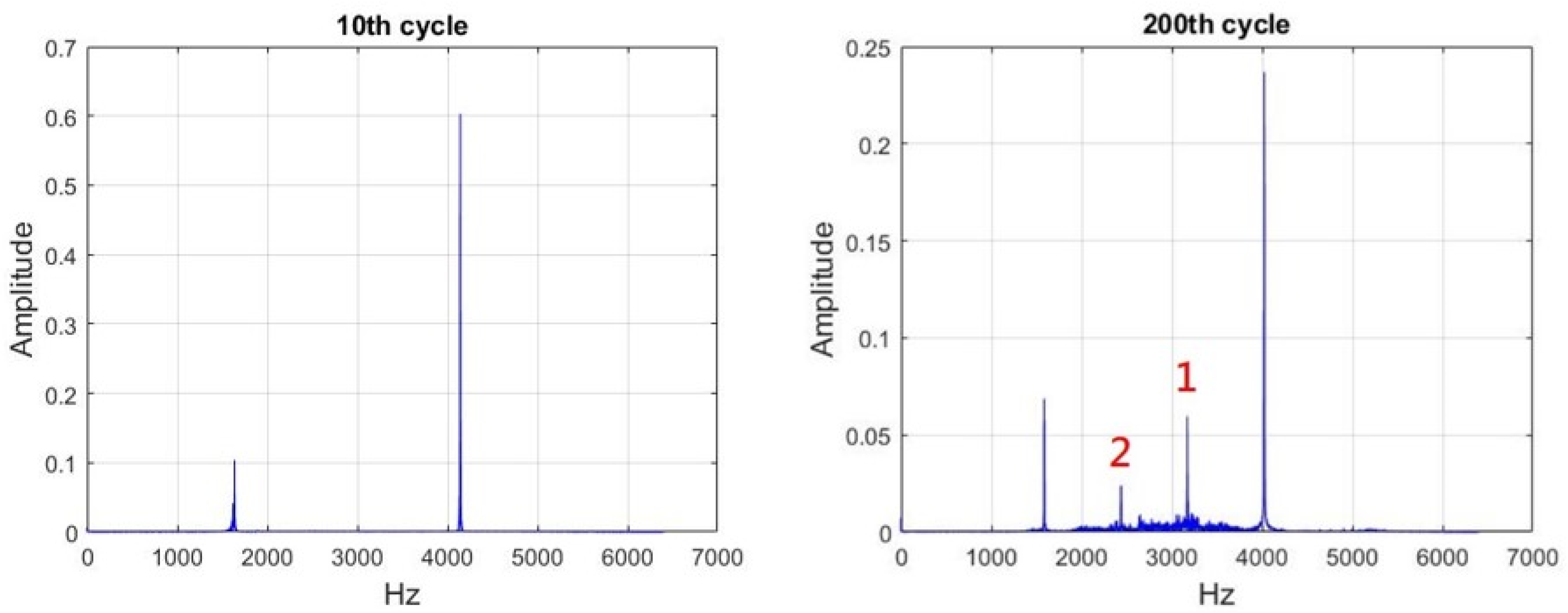

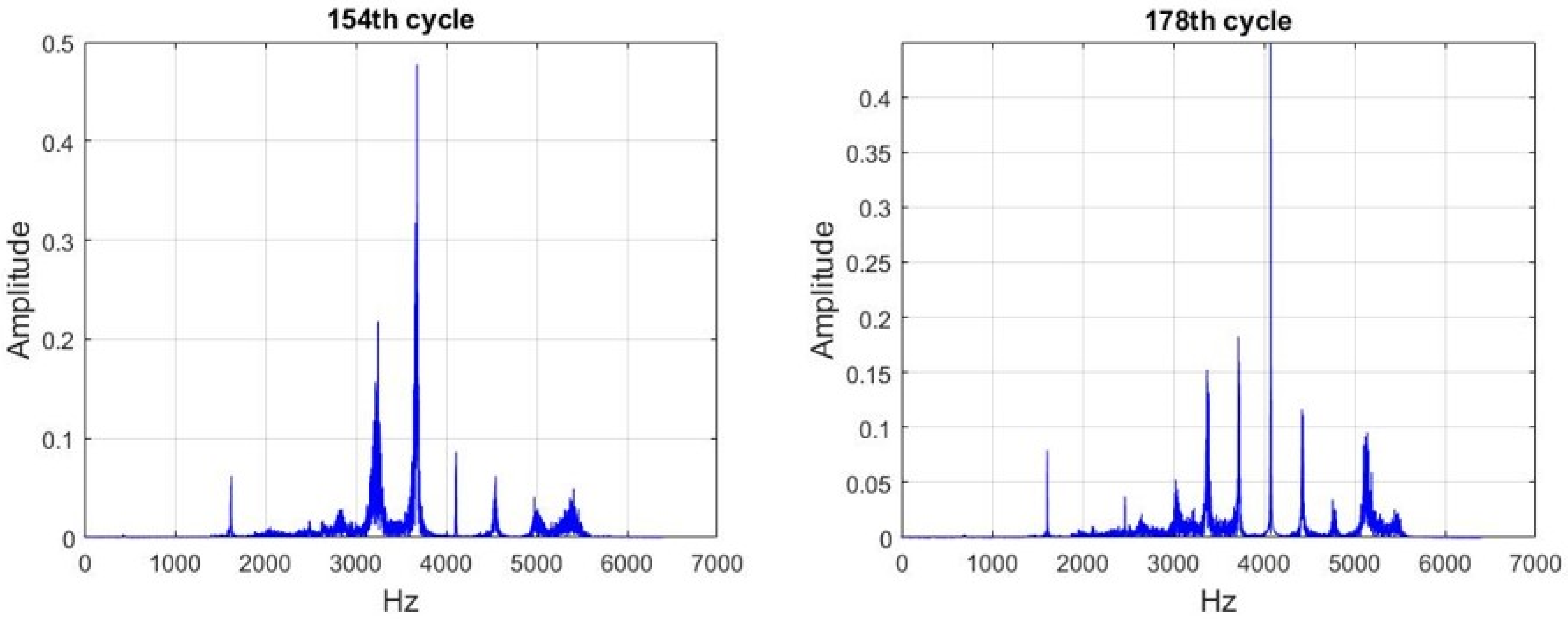

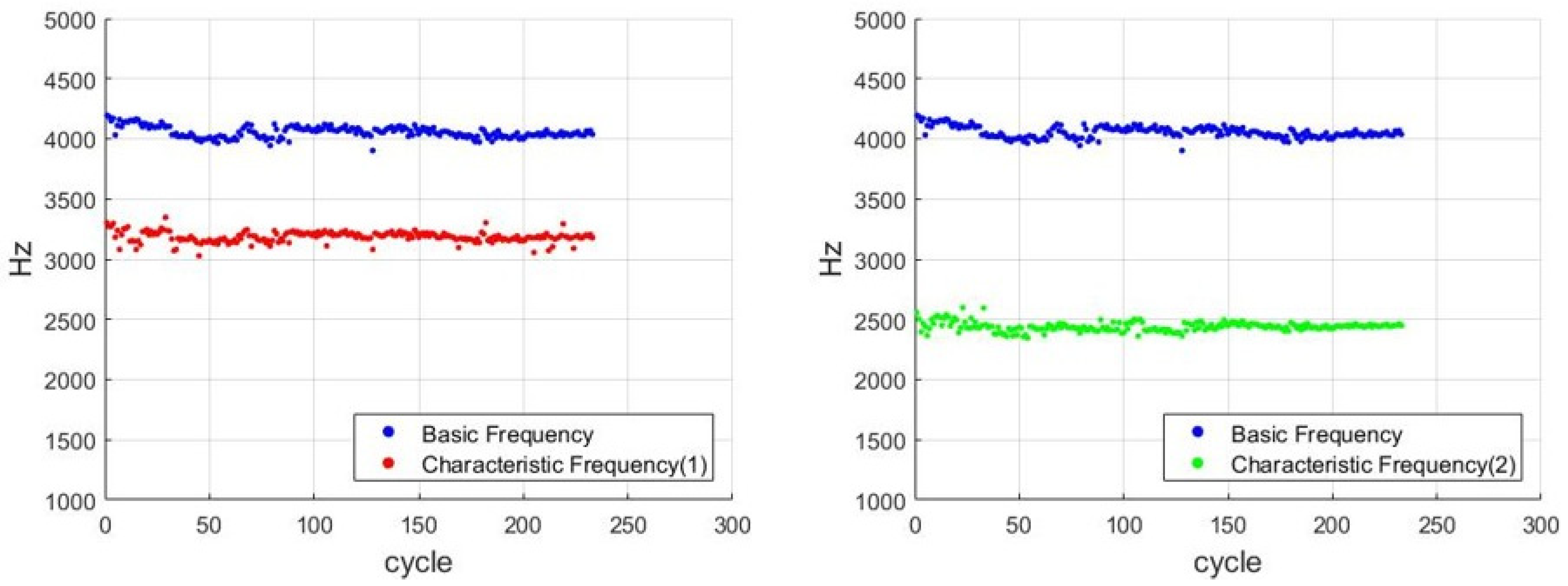

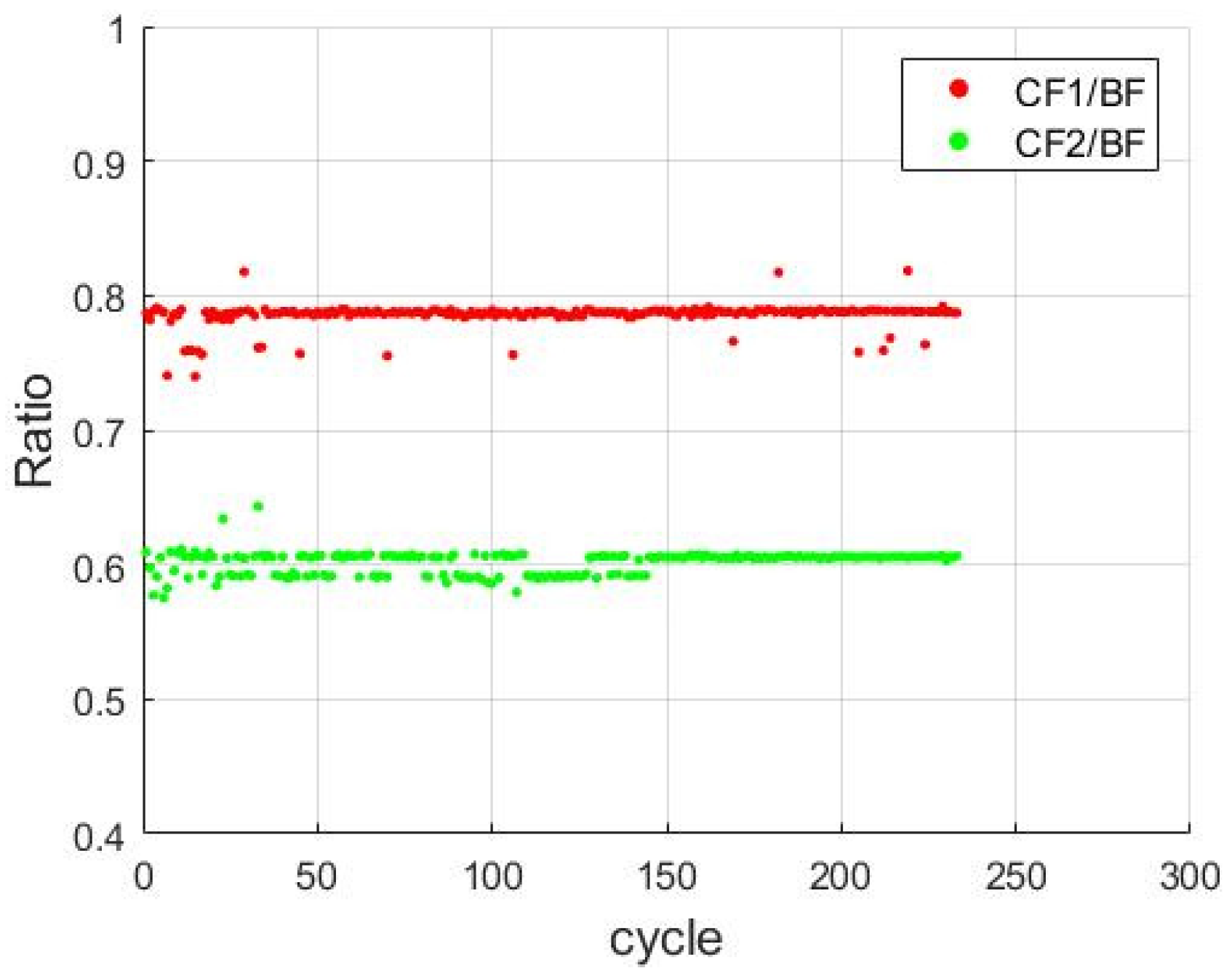

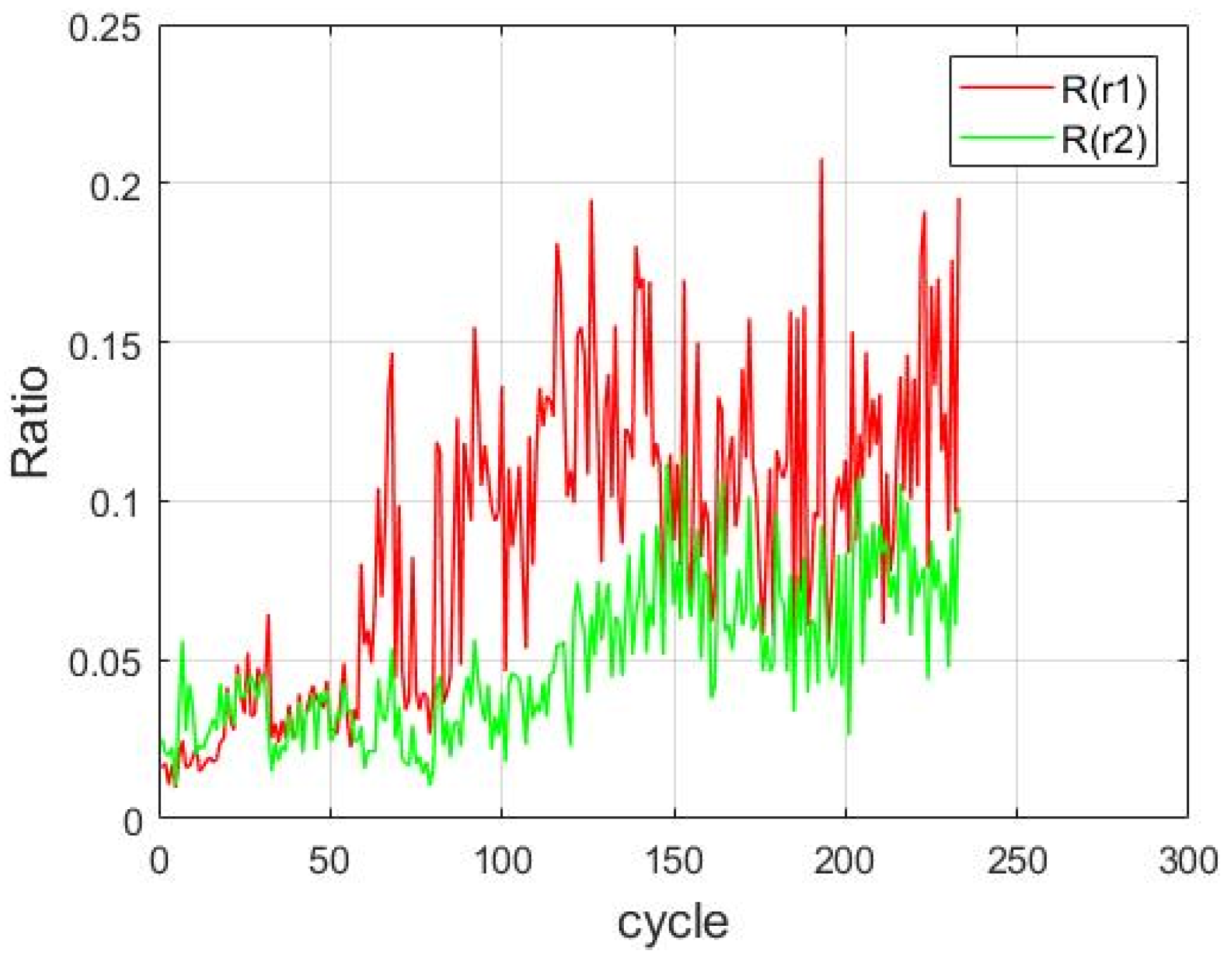

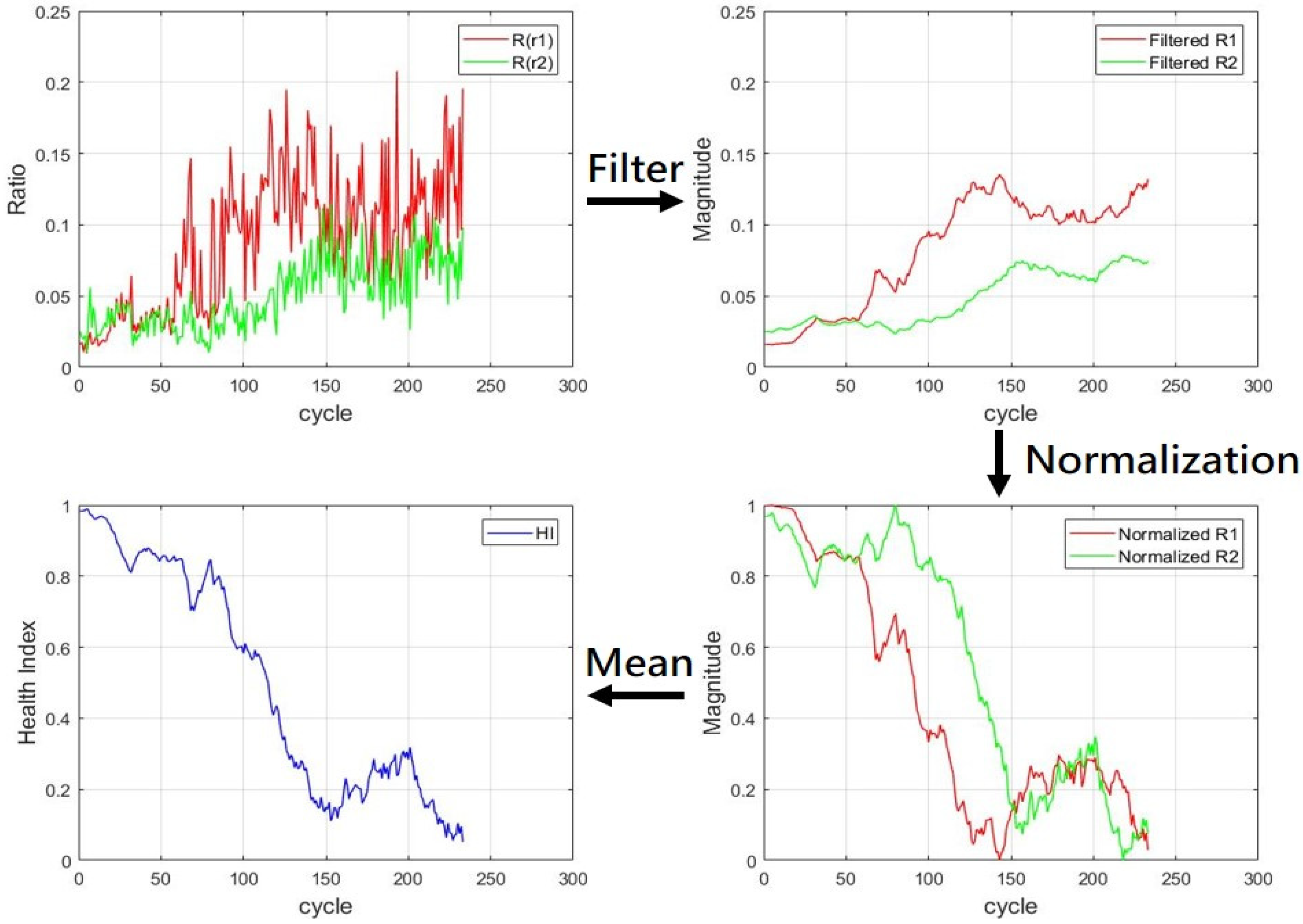

3.3. Building Health Index

4. Remaining Useful Life Prediction and Degradation Assessment

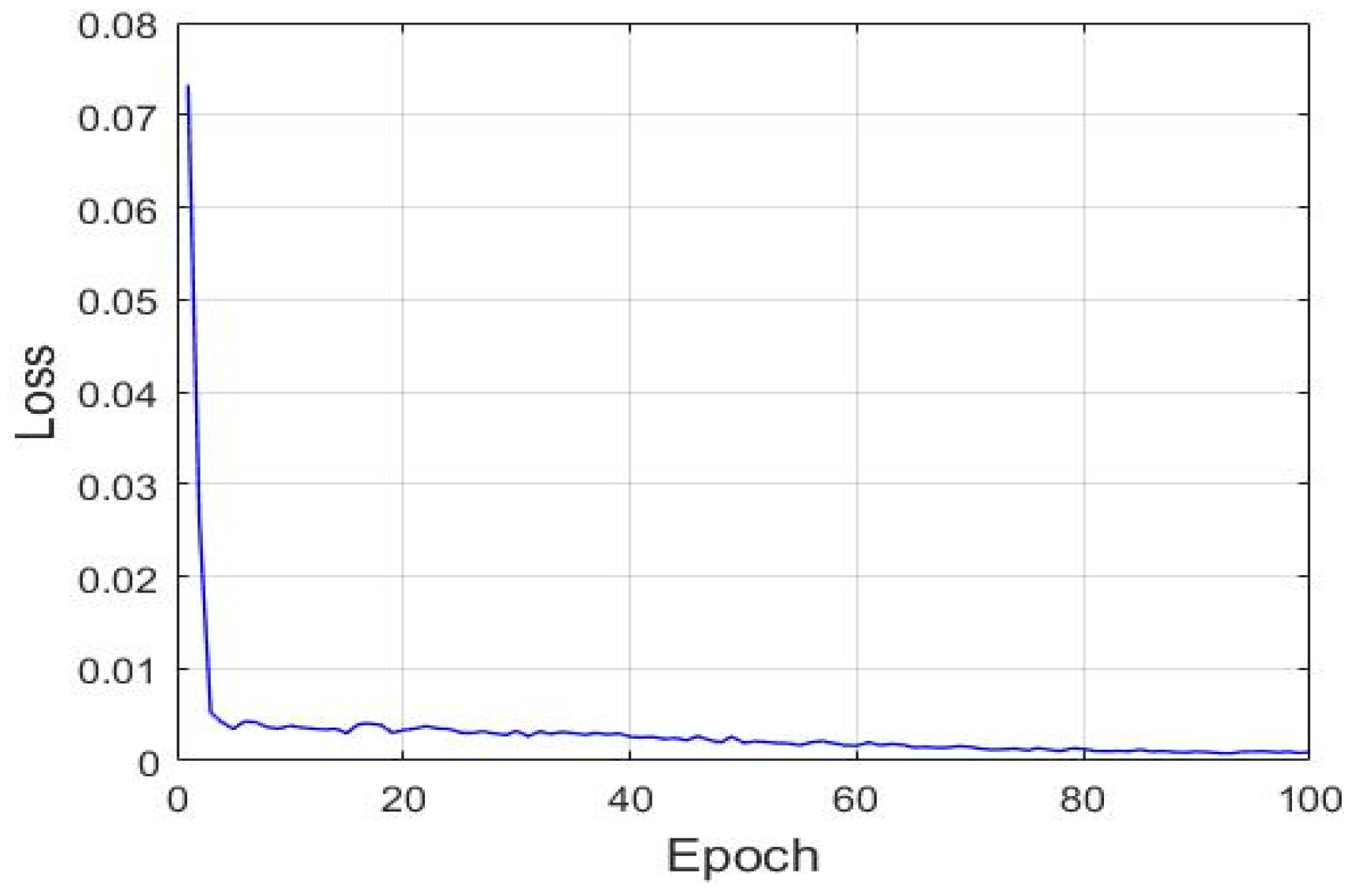

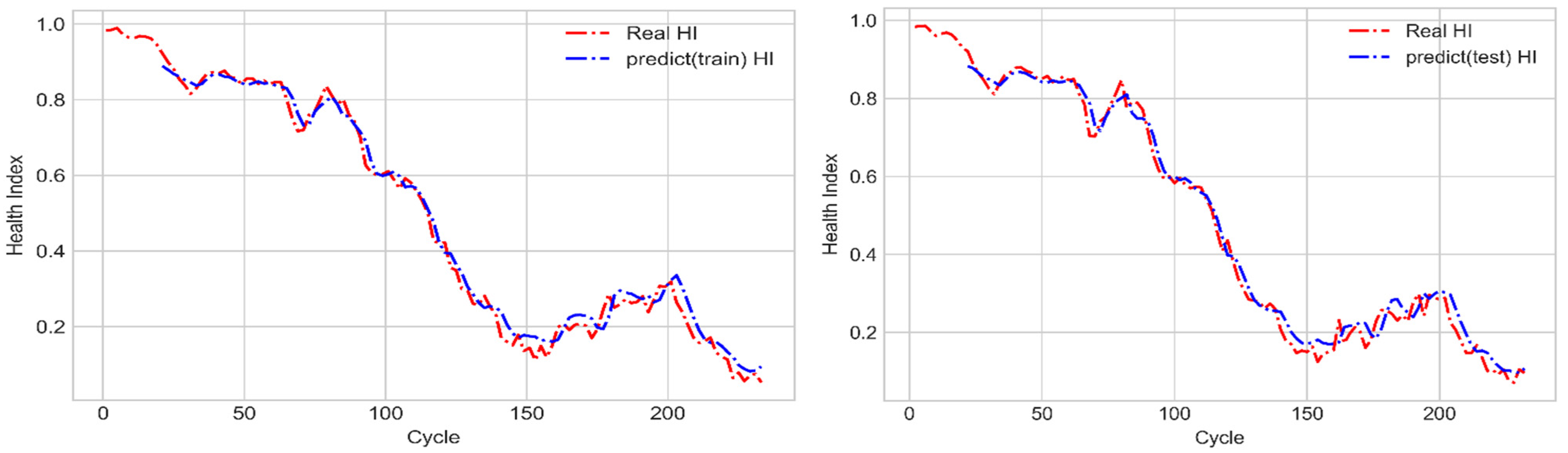

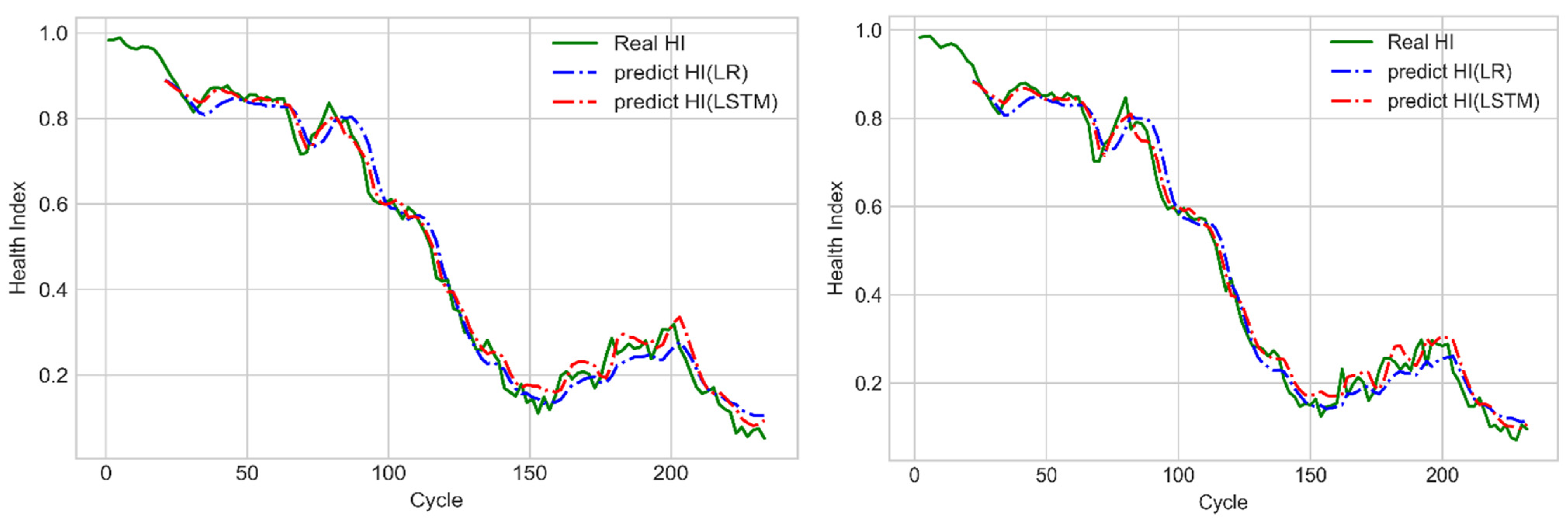

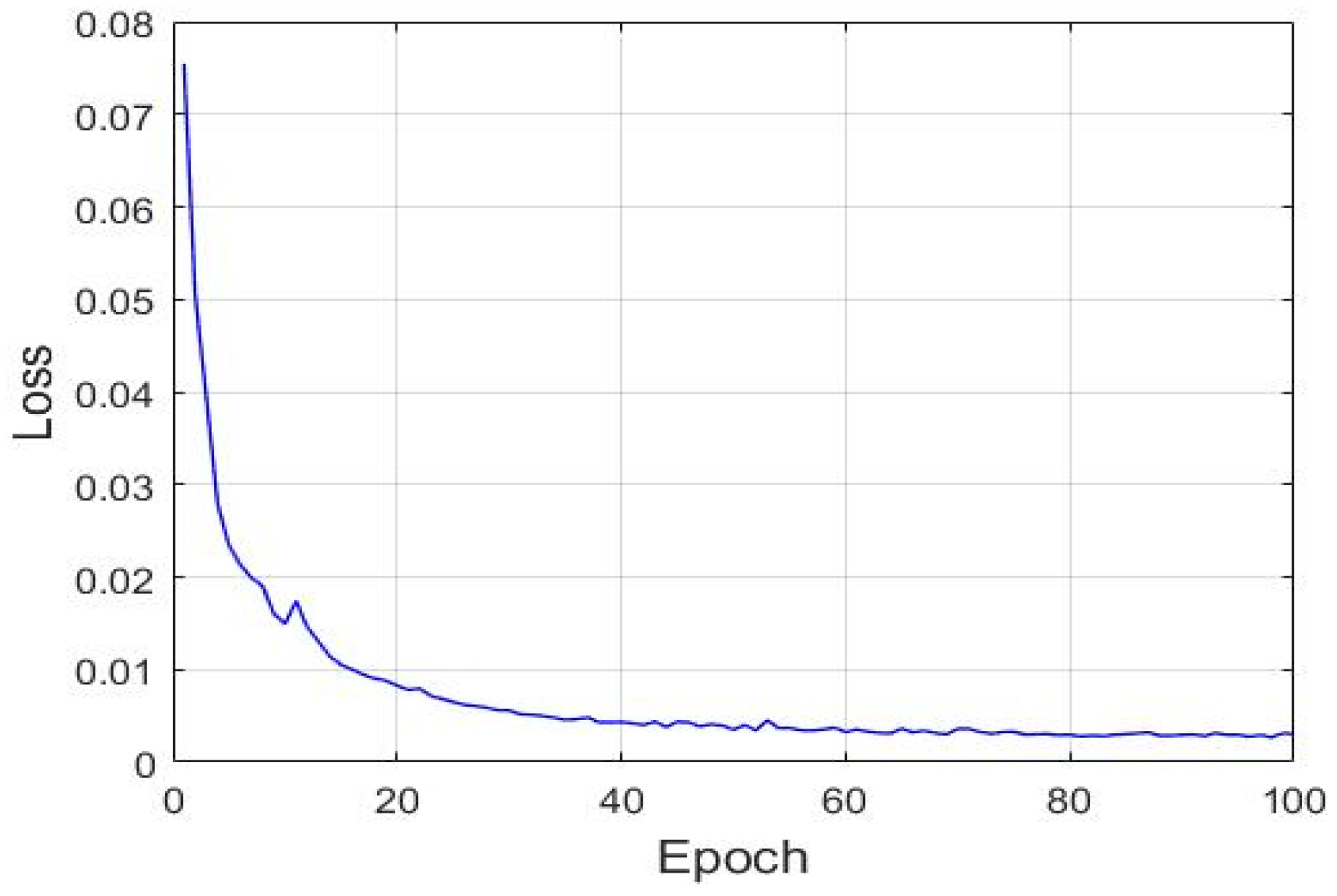

4.1. RUL Based on LSTM Many-to-One Structure

4.2. LR Prediction Model

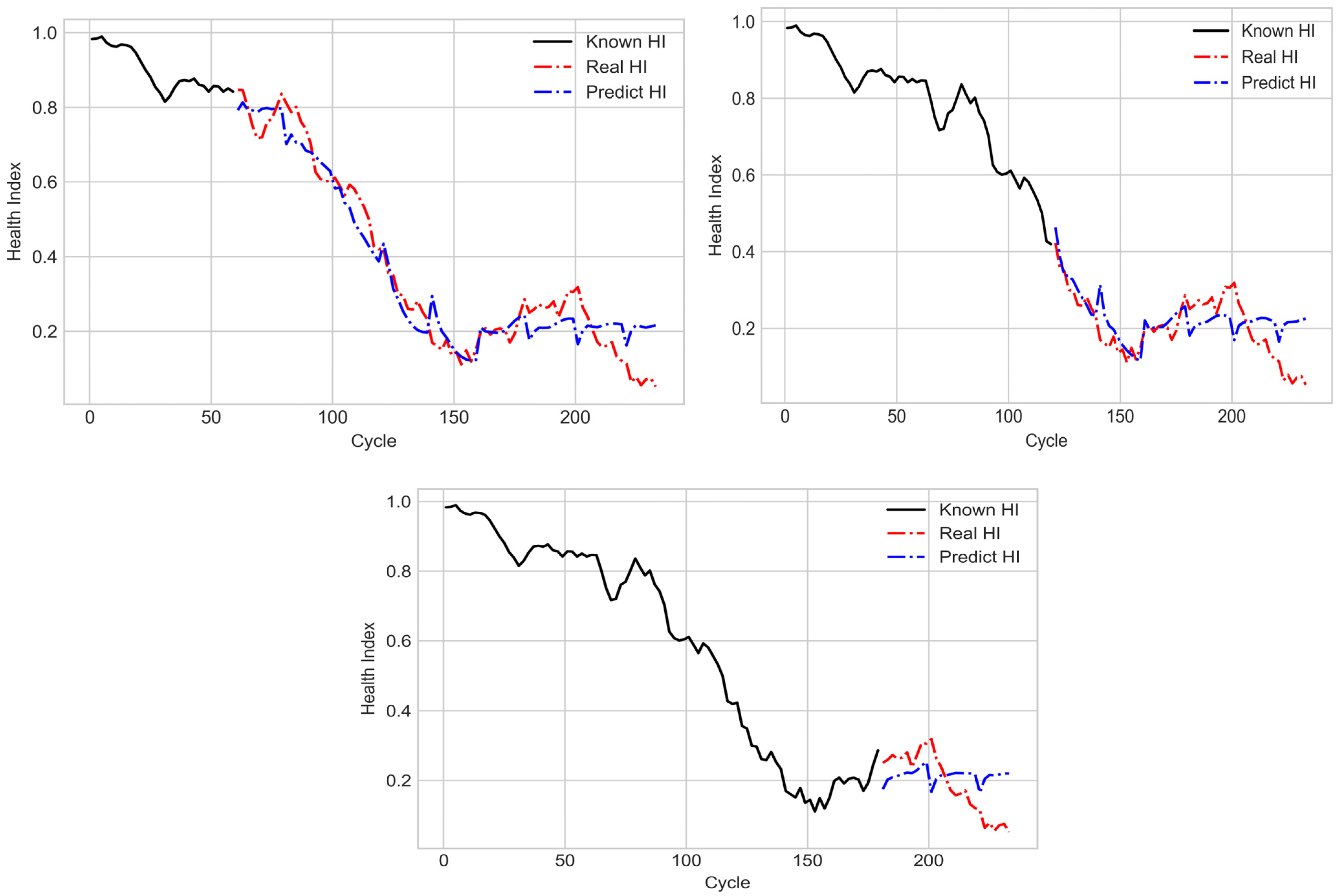

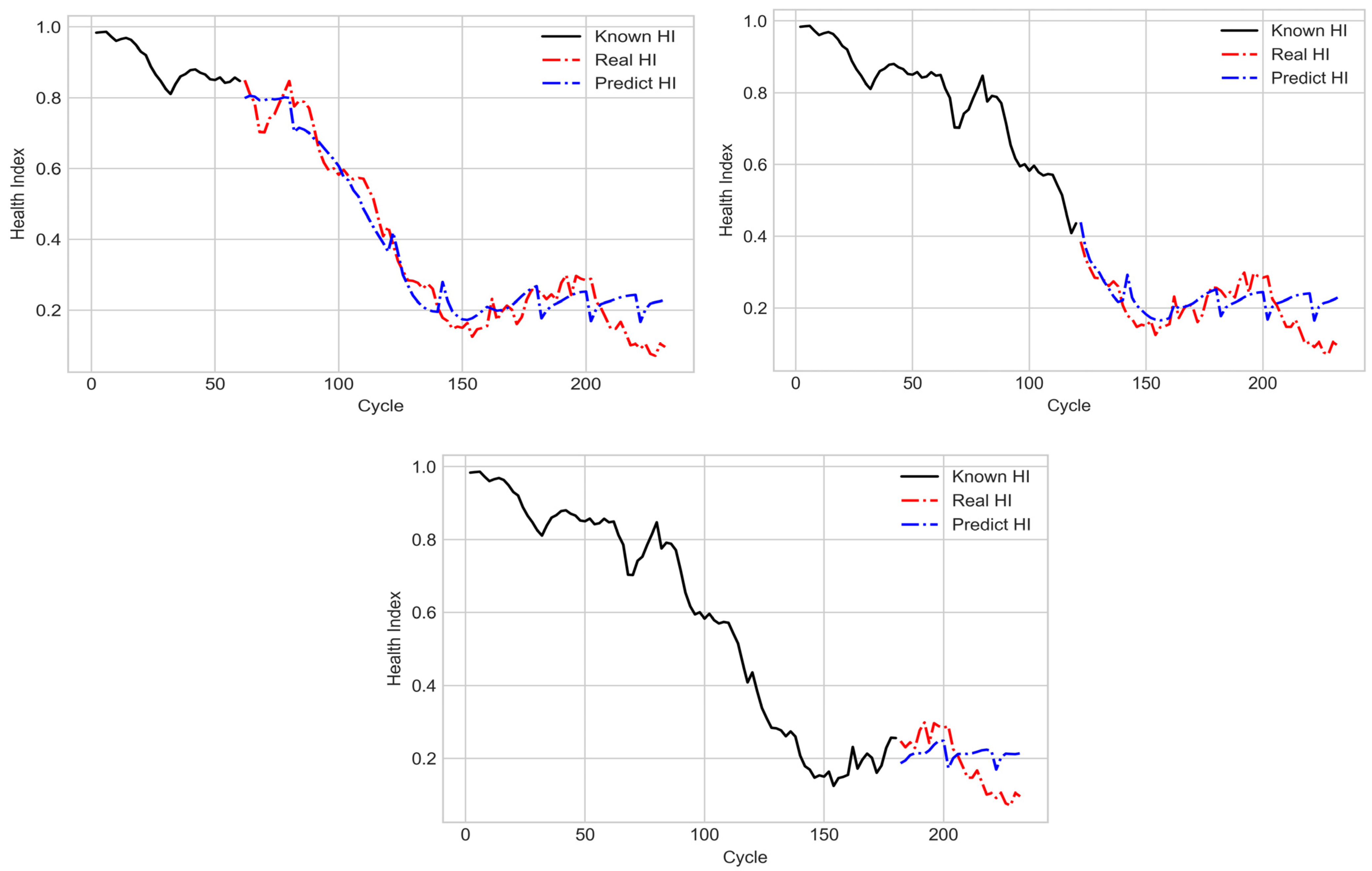

4.3. LSTM Many-to-Many Structure

5. Conclusions

- This study used a triaxial accelerometer to measure the vibration signals of dental handpieces under the free-running condition. The collected data were subjected to the FFT, after which the frequency spectrum of the rotation speed was plotted. Subsequently, the amplitudes of CFs and the main rotation speed frequency were identified in the frequency domain and compared to obtain two critical CFs related to the SOHs of the dental handpieces. These CFs were used as indices for predicting the RUL and assessing the degradation of the handpiece.

- This study established an LSTM model with the many-to-one structure that can store and transfer memories and an LR prediction model that cannot store memories to predict the SOHs of the dental handpieces. These models exhibited favorable prediction results. However, the LSTM model had a lower mean square error than the LR model did, which indicates that the LSTM model could monitor the SOH for a long time. The aforementioned LSTM model can be used to predict the RULs of clinical dental handpieces with high accuracy.

- An LSTM model with the many-to-many structure was used to predict the SOHs of unknown cycles. The obtained output was then used as the input for the next unknown cycle; thus, iterations were executed. Although the aforementioned LSTM model did not provide highly accurate results for the later cycles (with respect to the real HI), the model could favorably reveal the gradual degradation of the dental handpieces in the middle cycles.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Saghlatoon, H.; Soleimani, M.; Moghimi, S.; Talebi, M. An Experimental Investigation about the Heat Transfer Phenomenon in Human Teeth; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2012; pp. 1598–1601. [Google Scholar]

- Zakeri, V.; Arzanpour, S. Measurement and Analysis of Dental Handpiece Vibration for Real-Time Discrimination of Tooth Layers. J. Sel. Areas Bioeng. 2010, 8, 13–18. [Google Scholar]

- Wei, M.; Dyson, J.E.; Darvell, B.W. Factors Affecting Dental Air-Turbine Handpiece Bearing Failure. Oper. Dent. 2012, 37, E1–E12. [Google Scholar] [CrossRef]

- Wei, M.; Dyson, J.E.; Darvell, B.W. Failure analysis of the ball bearings of dental air turbine handpieces. Aust. Dent. J. 2013, 58, 514–521. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.-C.; Liu, C.-C.; Chuo, P.-C. Prognostic Diagnosis of the Health Status of an Air-Turbine Dental Handpiece Rotor by Using Sound and Vibration Signals. J. Vibroeng. 2016, 18, 1514–1524. [Google Scholar]

- Xu, L.; Pennacchi, P.; Chatterton, S. A new method for the estimation of bearing health state and remaining useful life based on the moving average cross-correlation of power spectral density. Mech. Syst. Signal Process. 2020, 139, 106617. [Google Scholar] [CrossRef] [Green Version]

- Ren, L.; Sun, Y.; Cui, J.; Zhang, L. Bearing remaining useful life prediction based on deep autoencoder and deep neural networks. J. Manuf. Syst. 2018, 48, 71–77. [Google Scholar] [CrossRef]

- Beganovic, N.; Söffker, D. Remaining lifetime modeling using State-of-Health estimation. Mech. Syst. Signal Process. 2017, 92, 107–123. [Google Scholar] [CrossRef]

- Yan, J.; Lee, J. Degradation Assessment and Fault Modes Classification Using Logistic Regression. J. Manuf. Sci. Eng. 2004, 127, 912–914. [Google Scholar] [CrossRef]

- Zhang, S.; Zhai, B.; Guo, X.; Wang, K.; Peng, N.; Zhang, X. Synchronous estimation of state of health and remaining useful lifetime for lithium-ion battery using the incremental capacity and artificial neural networks. J. Energy Storage 2019, 26, 100951. [Google Scholar] [CrossRef]

- Weng, C.; Sun, J.; Peng, H. A unified open-circuit-voltage model of lithium-ion batteries for state-of-charge estimation and state-of-health monitoring. J. Power Sources 2014, 258, 228–237. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, T.; Chu, F. Deep convolutional neural network based planet bearing fault classification. Comput. Ind. 2019, 107, 59–66. [Google Scholar] [CrossRef]

- Zocca, V.; Spacagna, G.; Slater, D.; Roelants, P. Python Deep Learning; Packt Publishing: Birmingham, UK, 2017; Chapter 6. [Google Scholar]

- Cen, Z.; Wang, J. Crude oil price prediction model with long short term memory deep learning based on prior knowledge data transfer. Energy 2019, 169, 160–171. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, P.; Yan, R.; Gao, R.X. Long short-term memory for machine remaining life prediction. J. Manuf. Syst. 2018, 48, 78–86. [Google Scholar] [CrossRef]

- Elsheikh, A.; Yacout, S.; Ouali, M.-S. Bidirectional handshaking LSTM for remaining useful life prediction. Neurocomputing 2019, 323, 148–156. [Google Scholar] [CrossRef]

- Heimes, F.O. Recurrent neural networks for remaining useful life estimation. In Proceedings of the 2008 International Conference on Prognostics and Health Management, Denver, CO, USA, 6–9 October 2008; pp. 1–6. [Google Scholar]

- Kovvali, N.; Banavar, M.; Spanias, A. An Introduction to Kalman Filtering with MATLAB Examples. Synth. Lect. Signal Process. 2013, 6, 1–81. [Google Scholar] [CrossRef]

| LSTM | LR | |

|---|---|---|

| Training dataset | 0.000769 | 0.001359 |

| Testing dataset | 0.000820 | 0.001360 |

| 30 Known Cycles | 60 Known Cycles | 90 Known Cycles | |

|---|---|---|---|

| Training dataset | 0.006889 | 0.005170 | 0.009435 |

| Testing dataset | 0.005132 | 0.004260 | 0.007701 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.-C.; Chen, Y.-H. Use of Long Short-Term Memory for Remaining Useful Life and Degradation Assessment Prediction of Dental Air Turbine Handpiece in Milling Process. Sensors 2021, 21, 4978. https://doi.org/10.3390/s21154978

Huang Y-C, Chen Y-H. Use of Long Short-Term Memory for Remaining Useful Life and Degradation Assessment Prediction of Dental Air Turbine Handpiece in Milling Process. Sensors. 2021; 21(15):4978. https://doi.org/10.3390/s21154978

Chicago/Turabian StyleHuang, Yi-Cheng, and Yu-Hsien Chen. 2021. "Use of Long Short-Term Memory for Remaining Useful Life and Degradation Assessment Prediction of Dental Air Turbine Handpiece in Milling Process" Sensors 21, no. 15: 4978. https://doi.org/10.3390/s21154978

APA StyleHuang, Y.-C., & Chen, Y.-H. (2021). Use of Long Short-Term Memory for Remaining Useful Life and Degradation Assessment Prediction of Dental Air Turbine Handpiece in Milling Process. Sensors, 21(15), 4978. https://doi.org/10.3390/s21154978