New Fiber Bragg Grating Three-Dimensional Accelerometer Based on Composite Flexure Hinges

Abstract

:1. Introduction

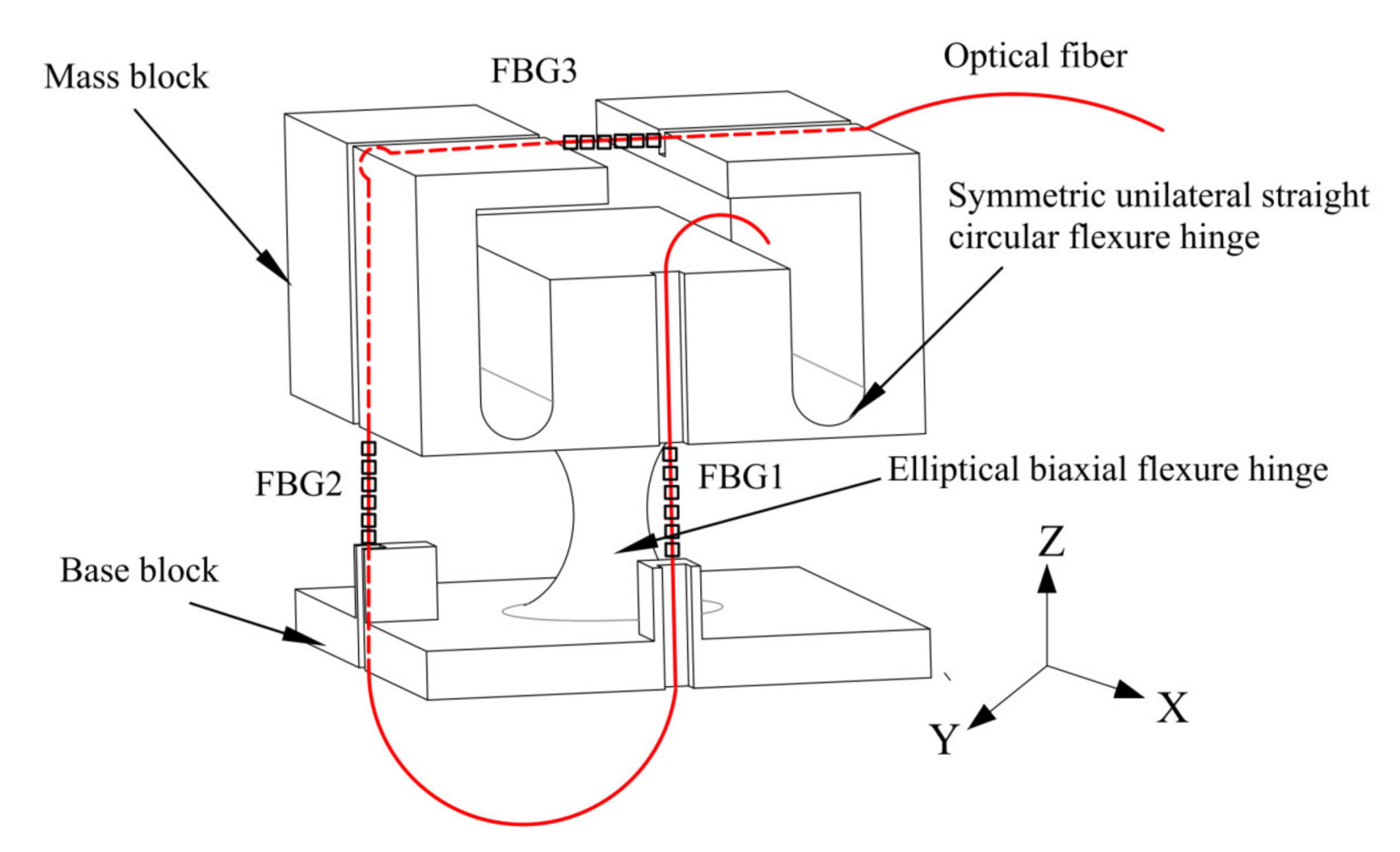

2. Materials and Methods

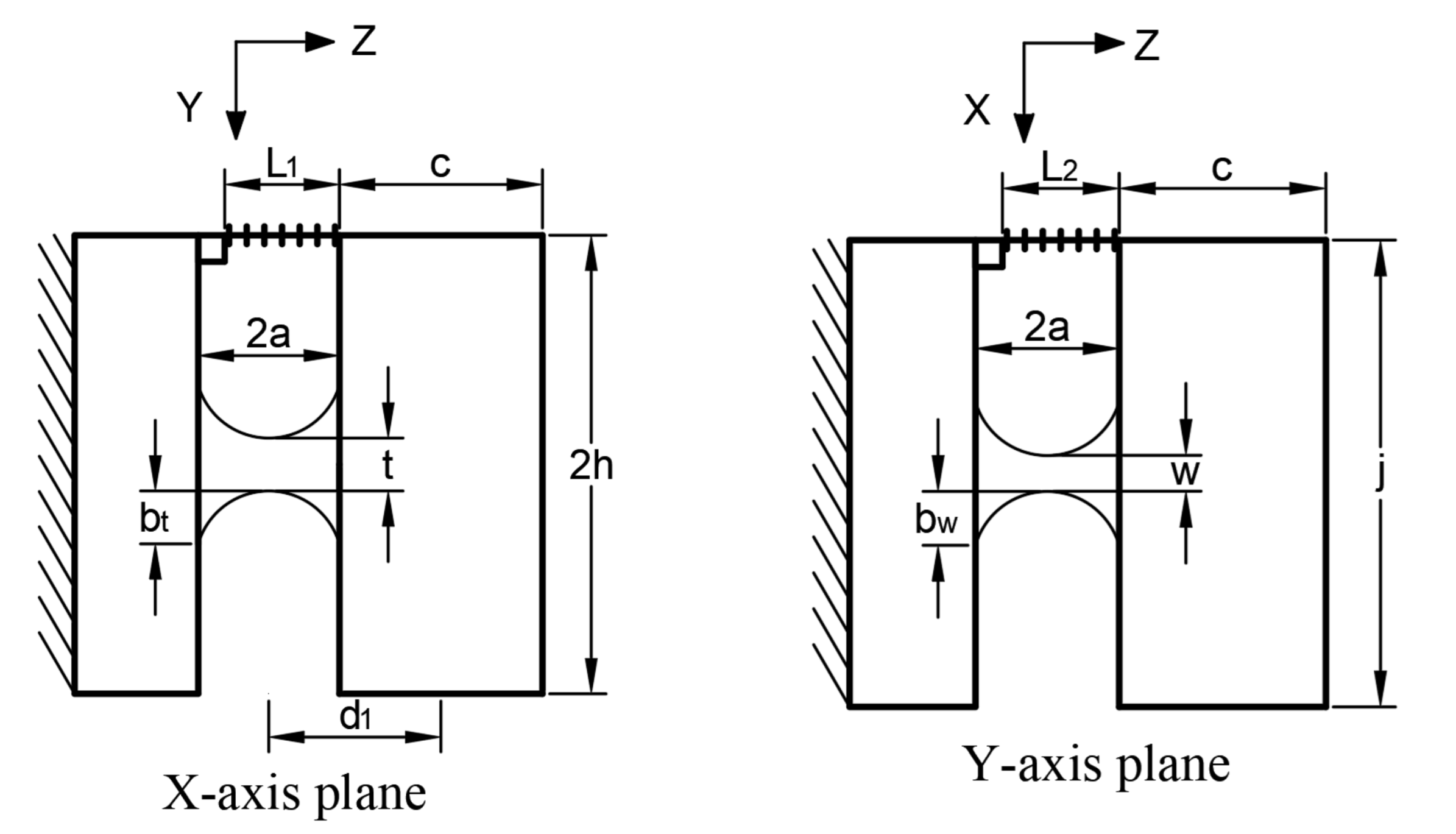

2.1. Structural Design and Theoretical Derivation

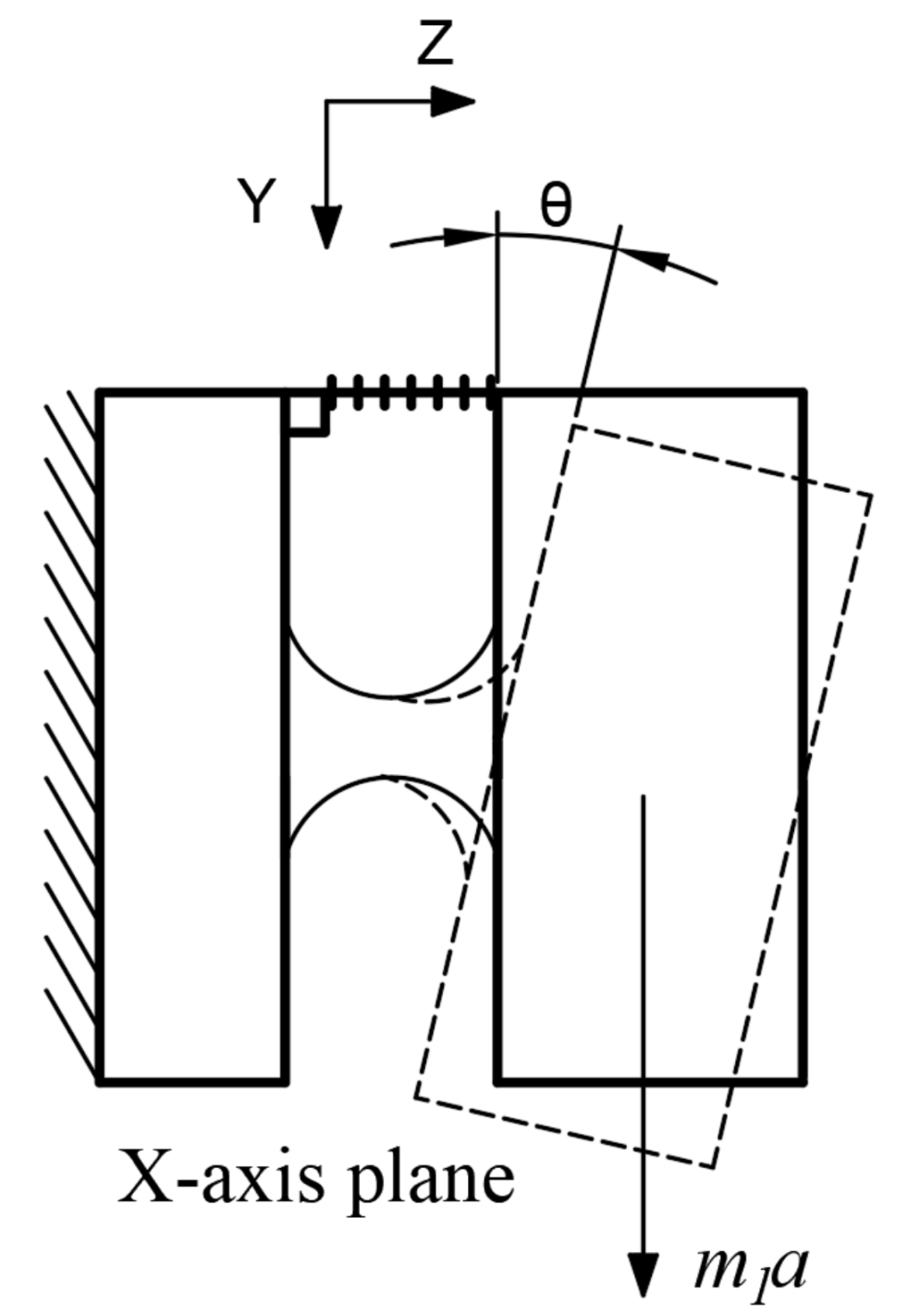

2.1.1. X- and Y-Directional Theoretical Formulas

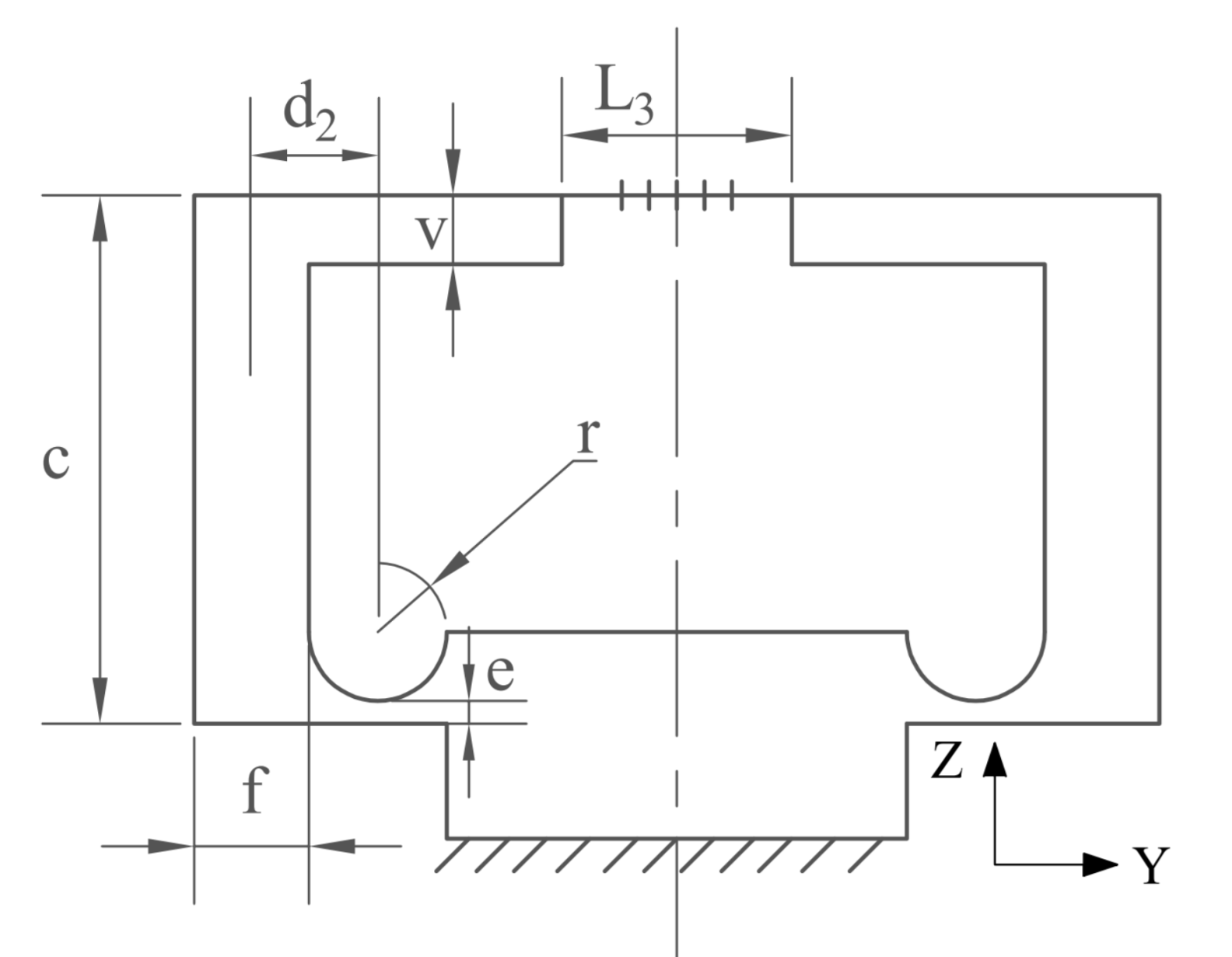

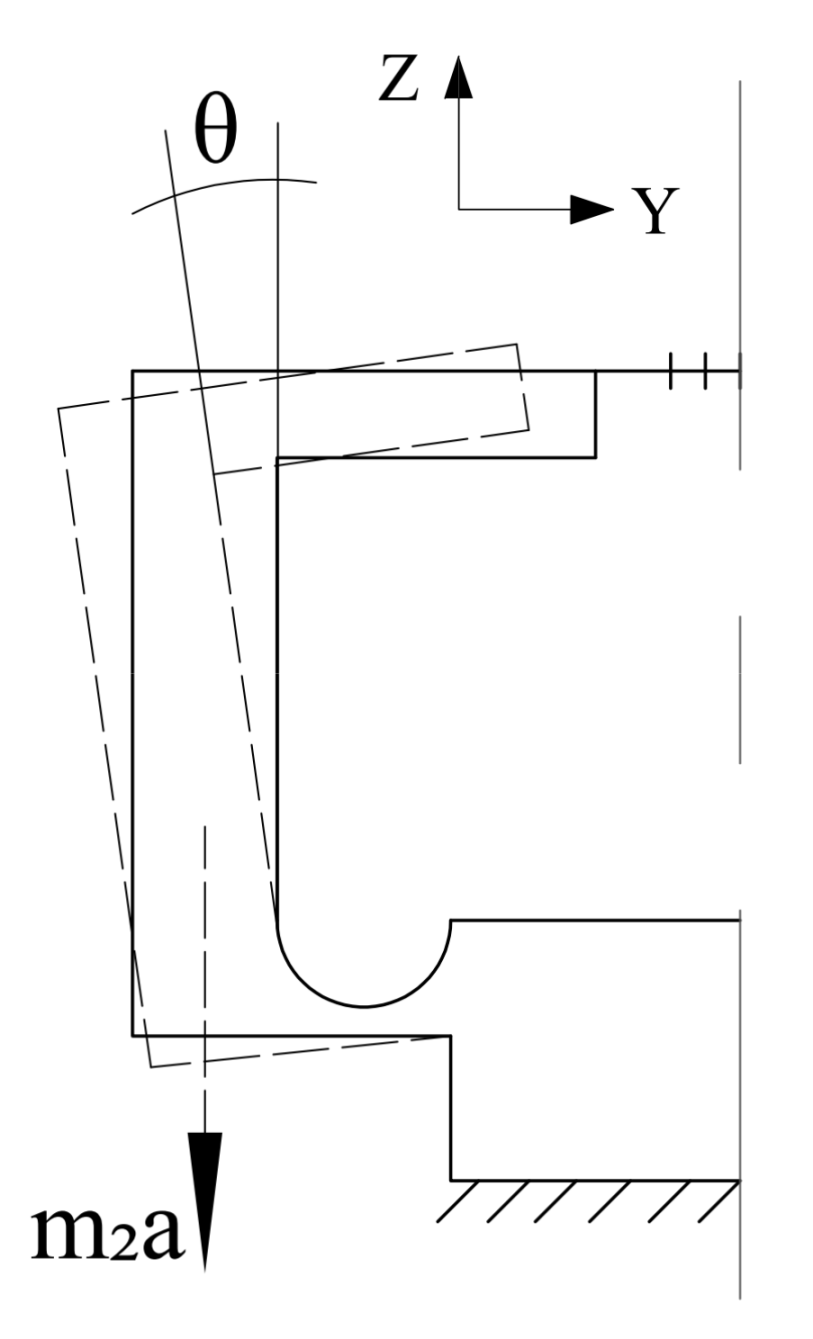

2.1.2. Z-Direction Theoretical Formula

2.2. Dimensional Parameter Optimization

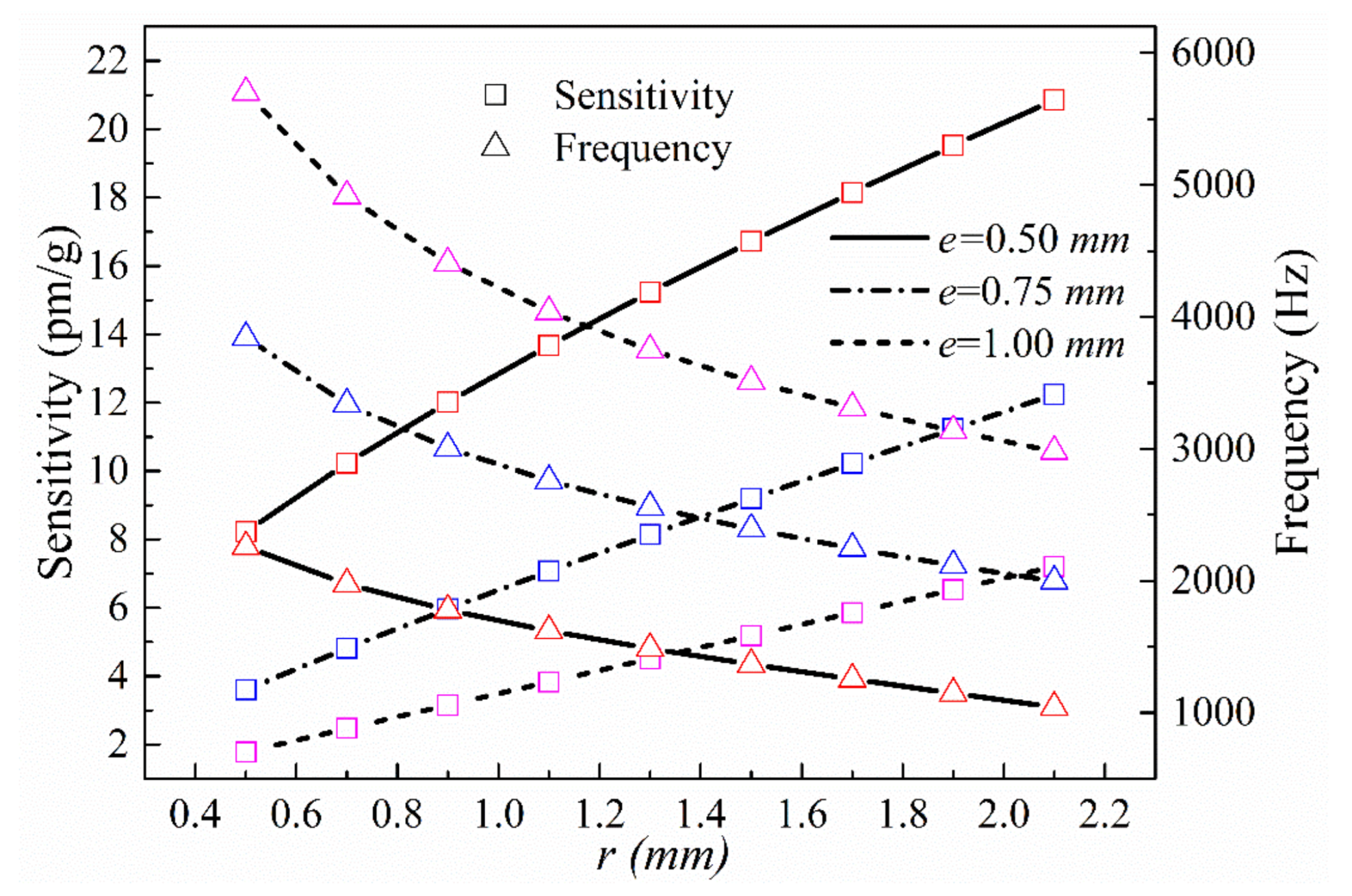

2.2.1. Z-Axis Dimensional Optimization

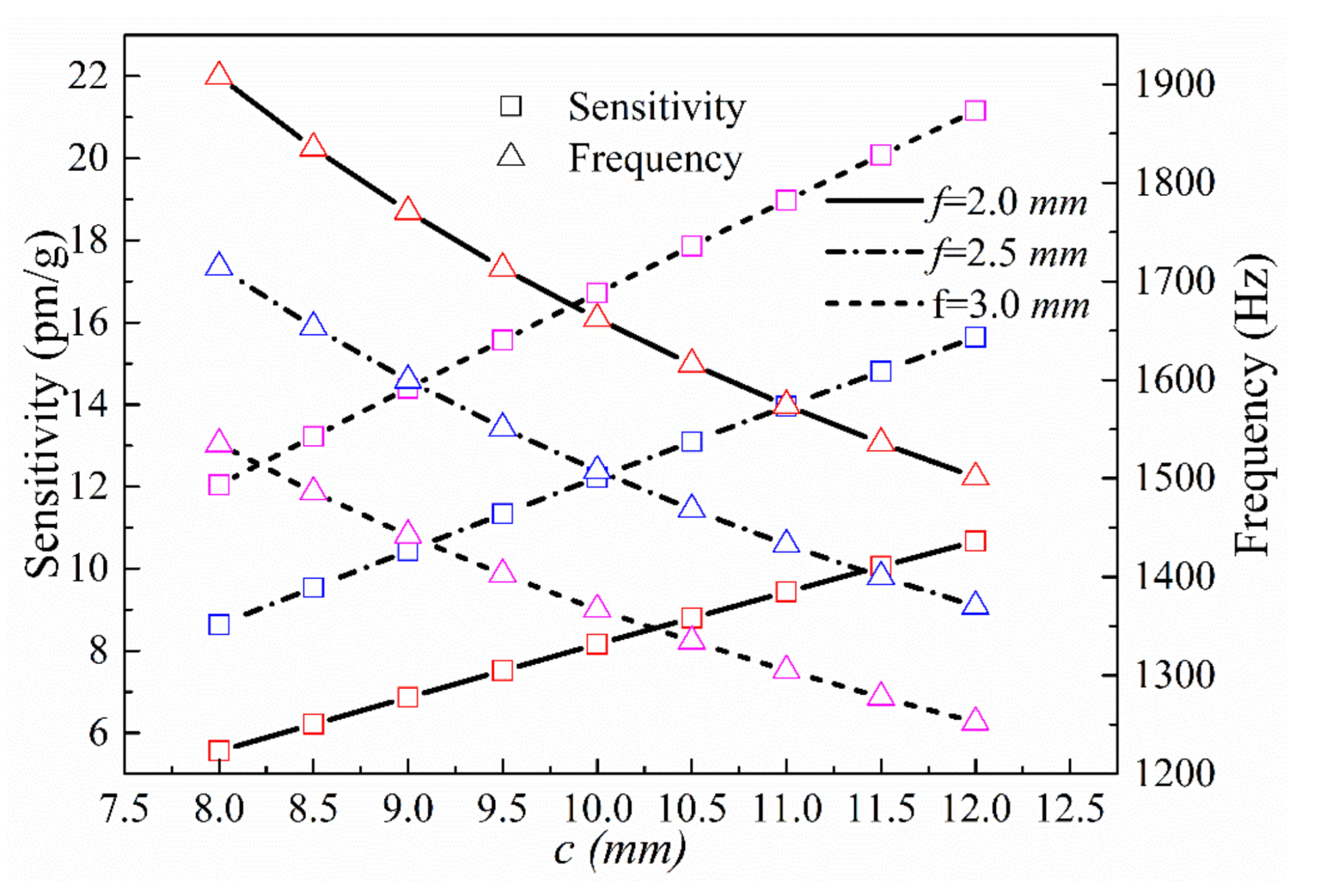

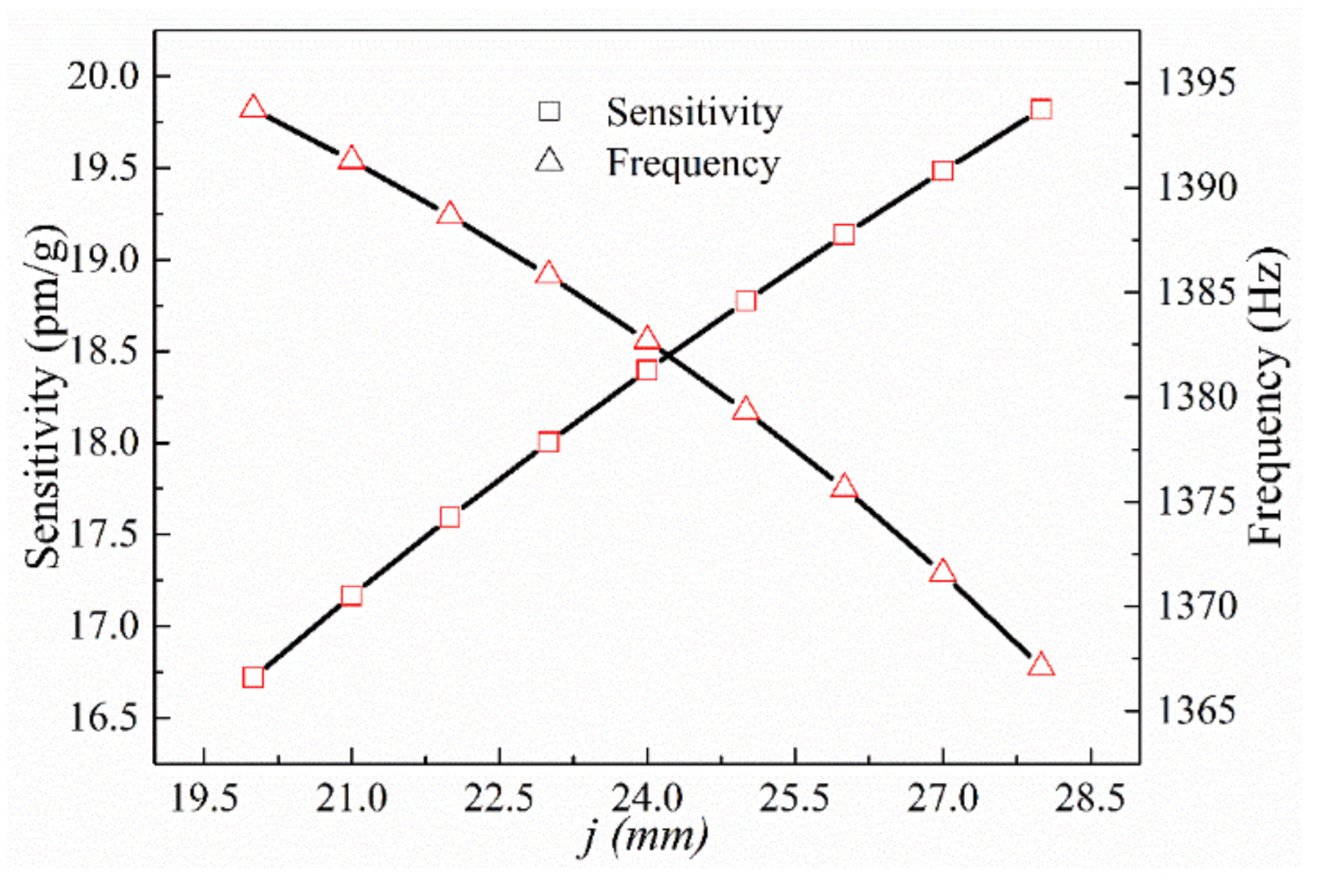

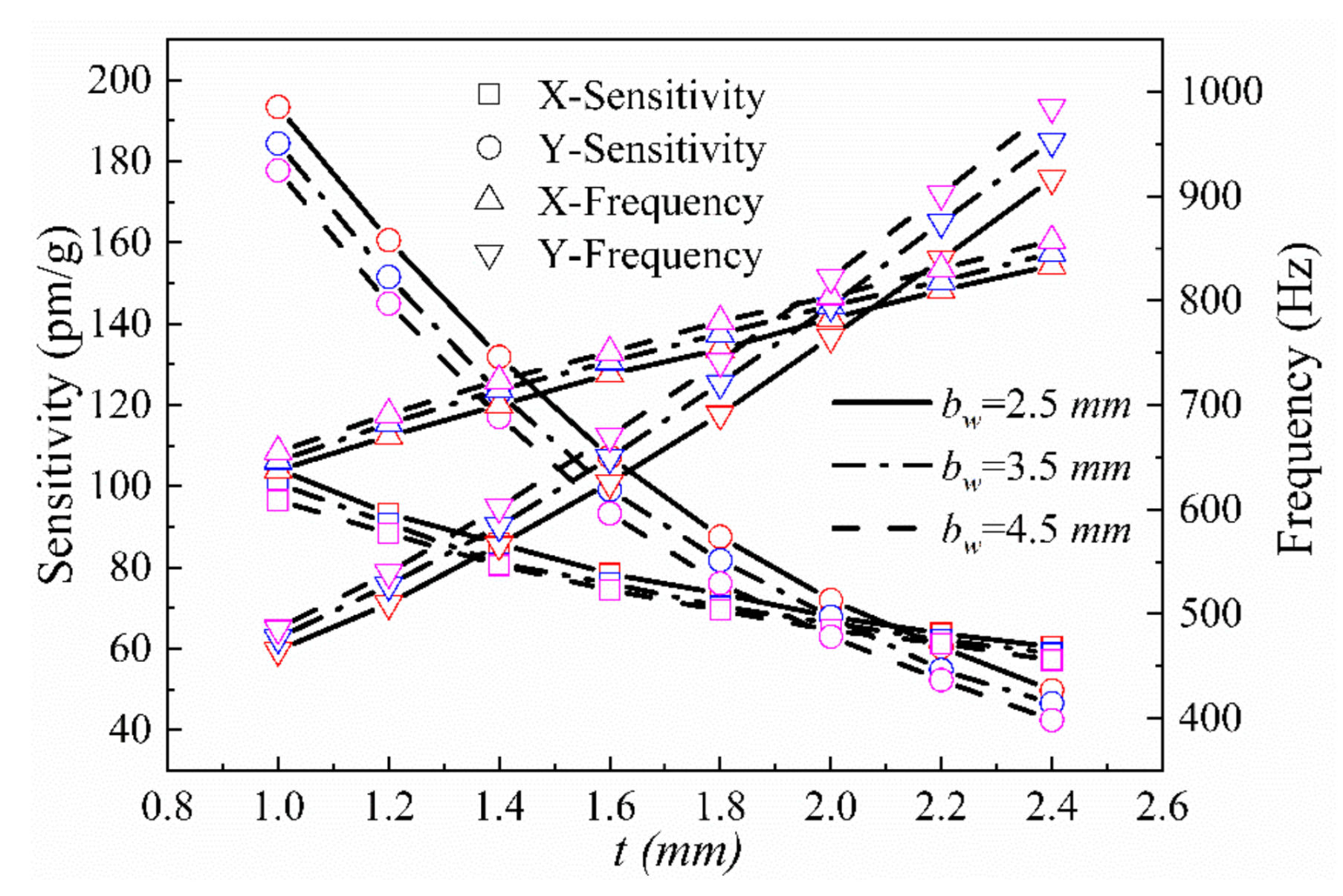

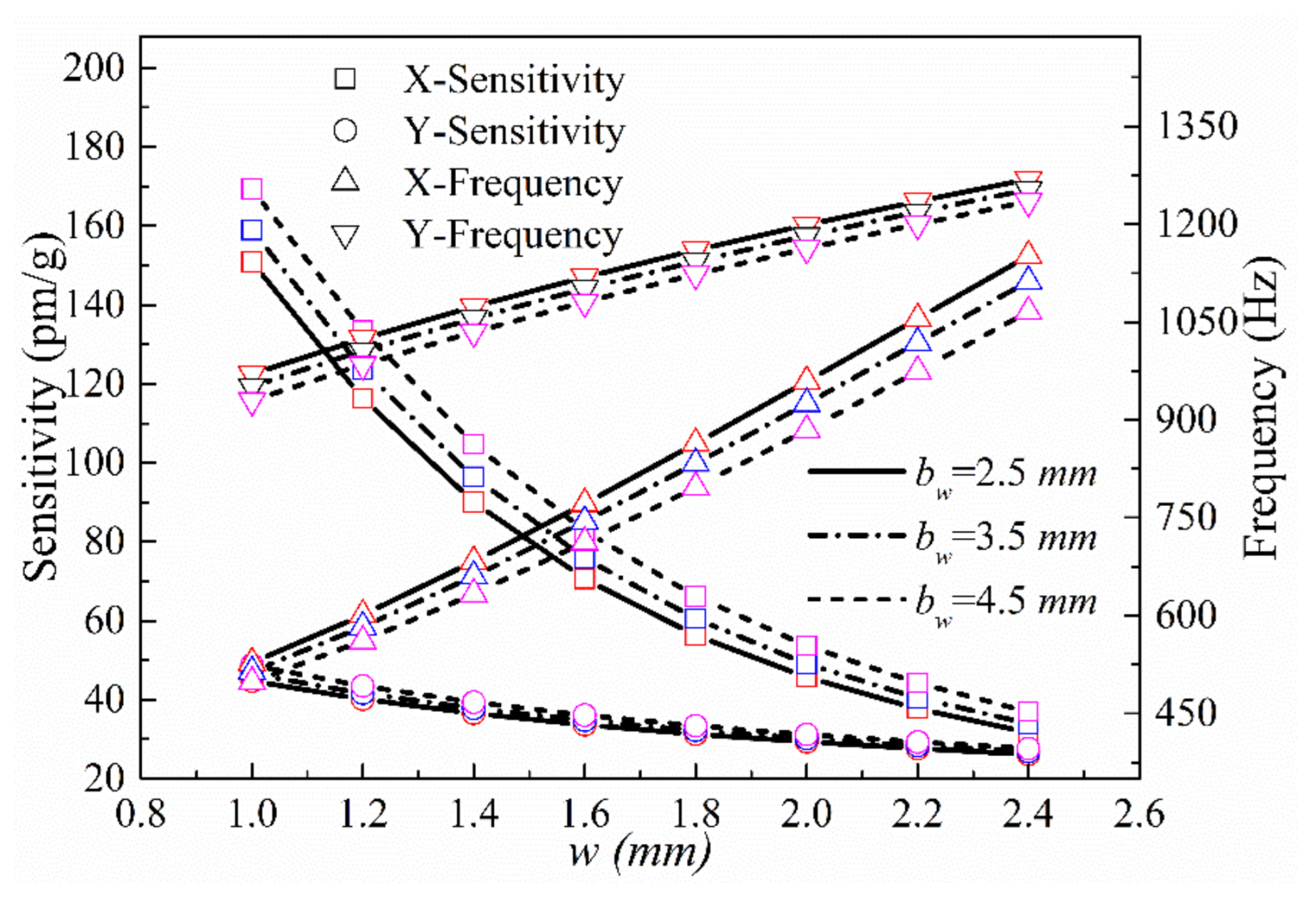

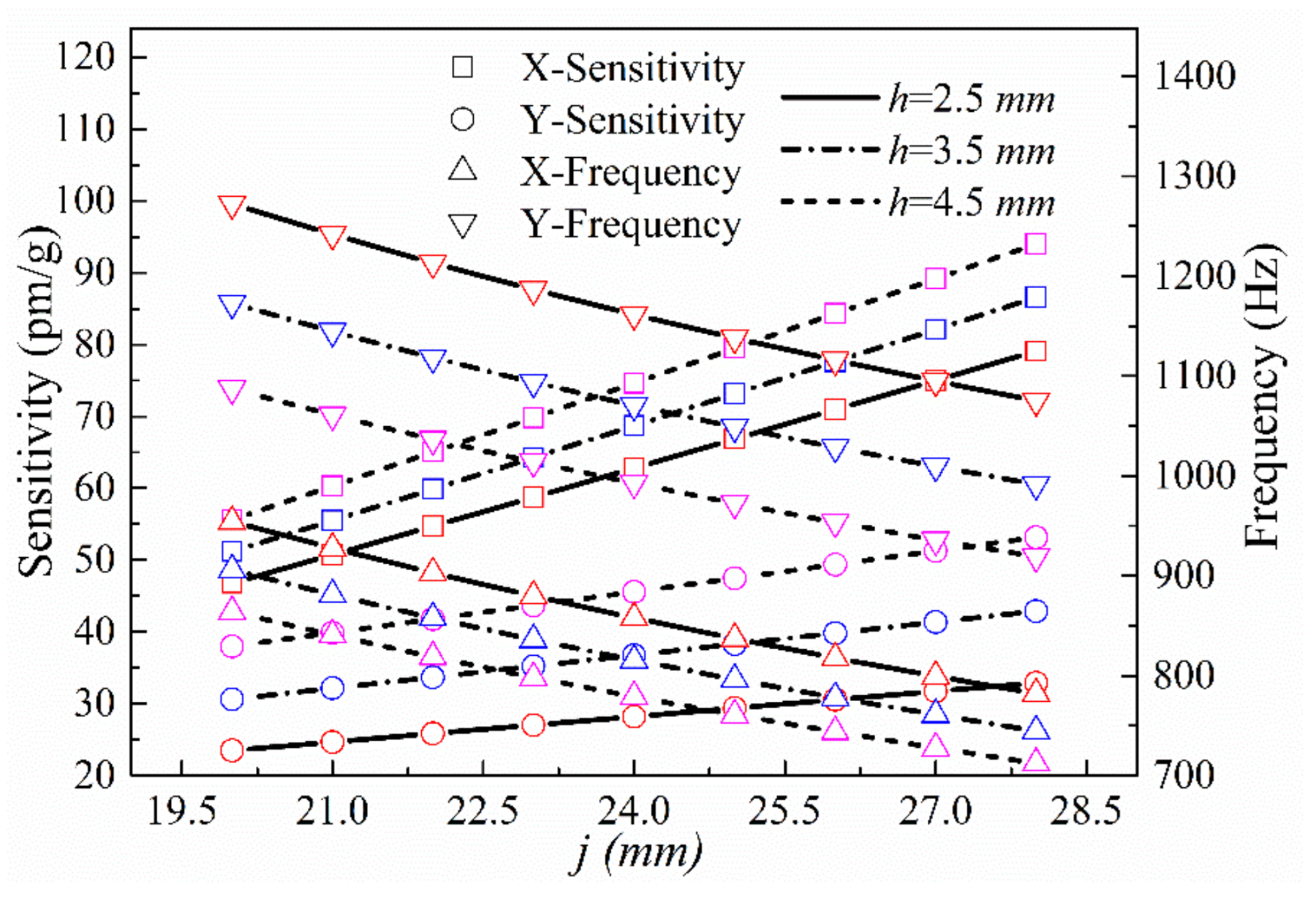

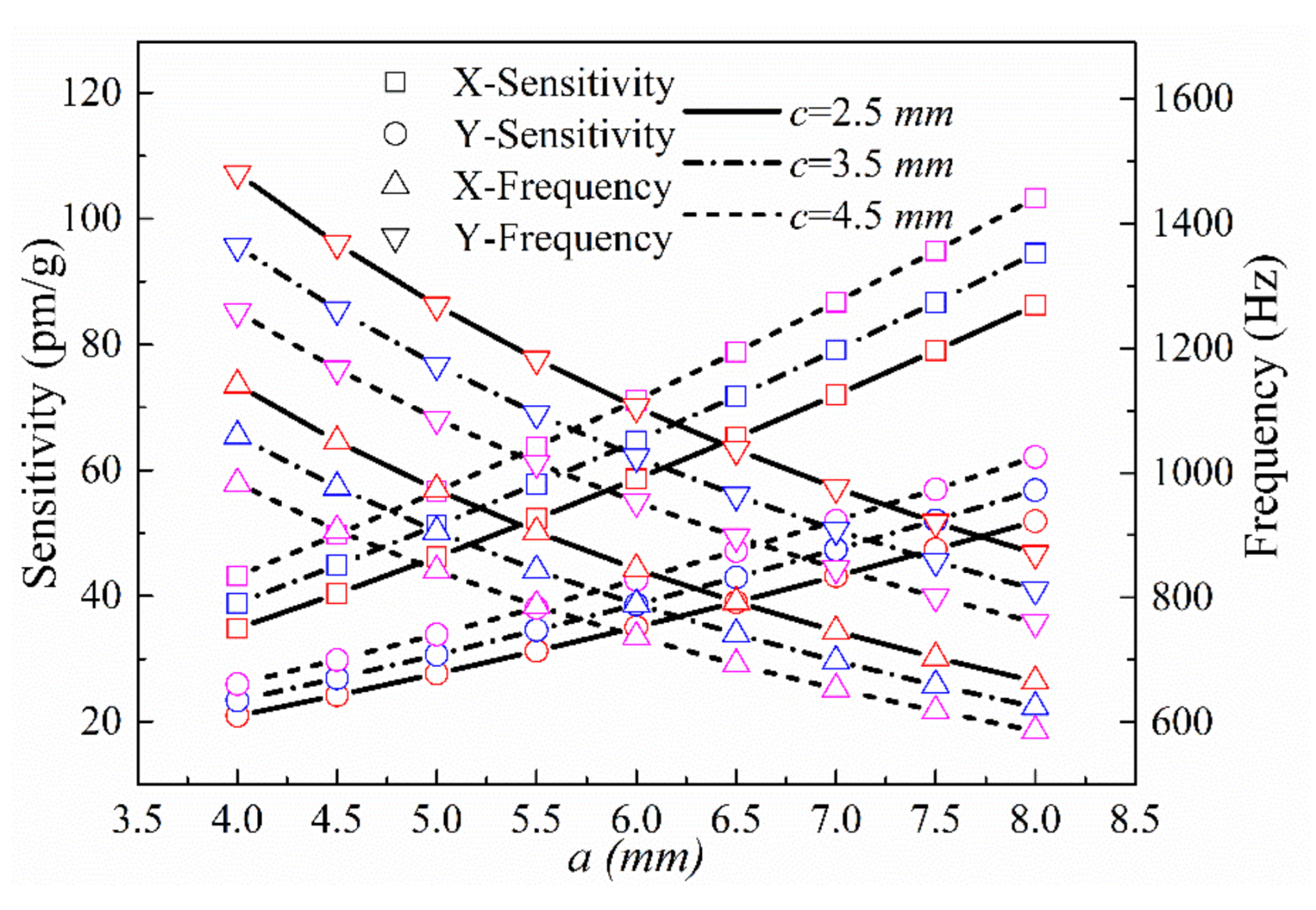

2.2.2. X and Y-Axis Dimensional Optimizations

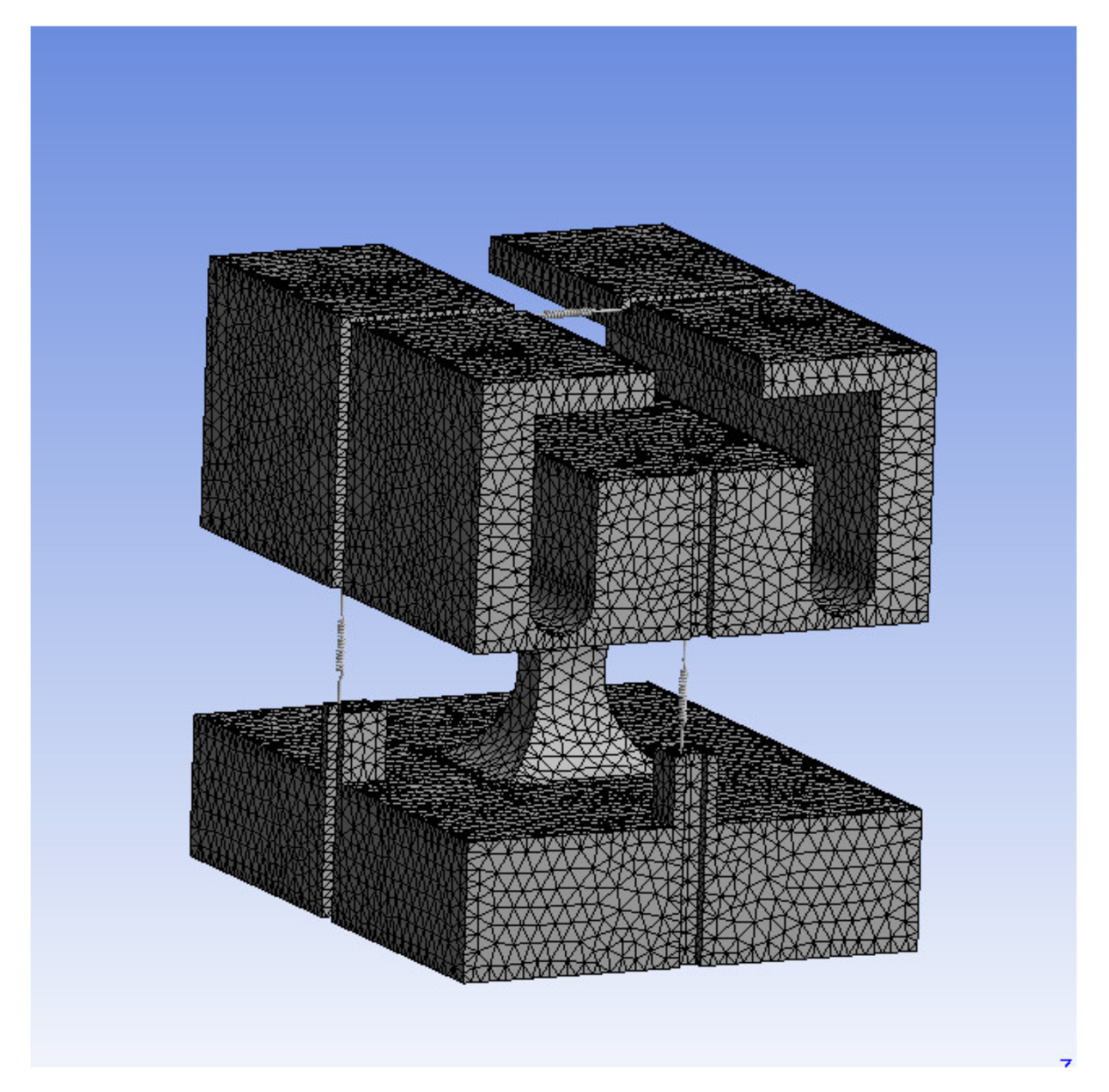

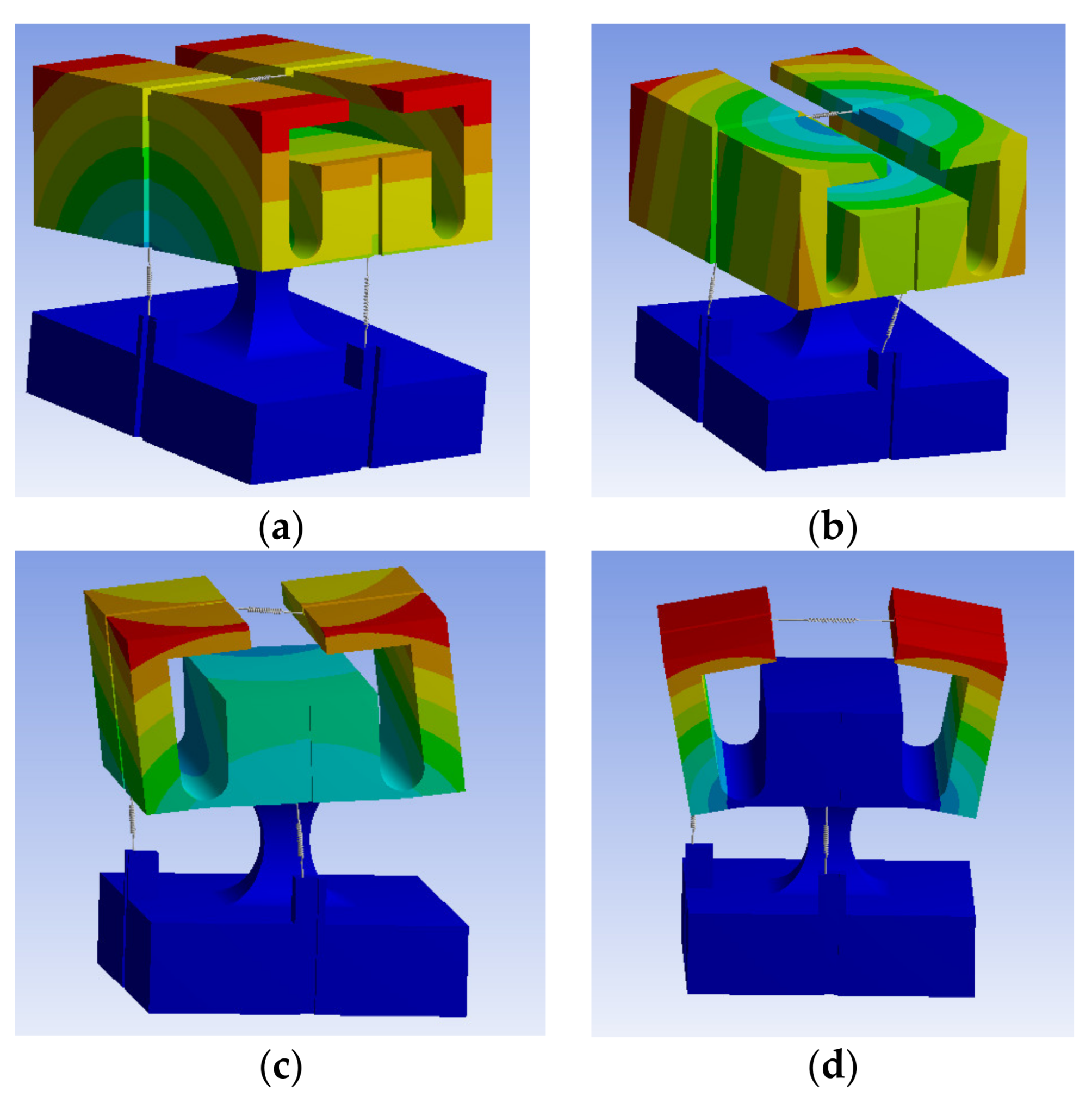

3. Finite Element Simulation

3.1. Natural Frequency

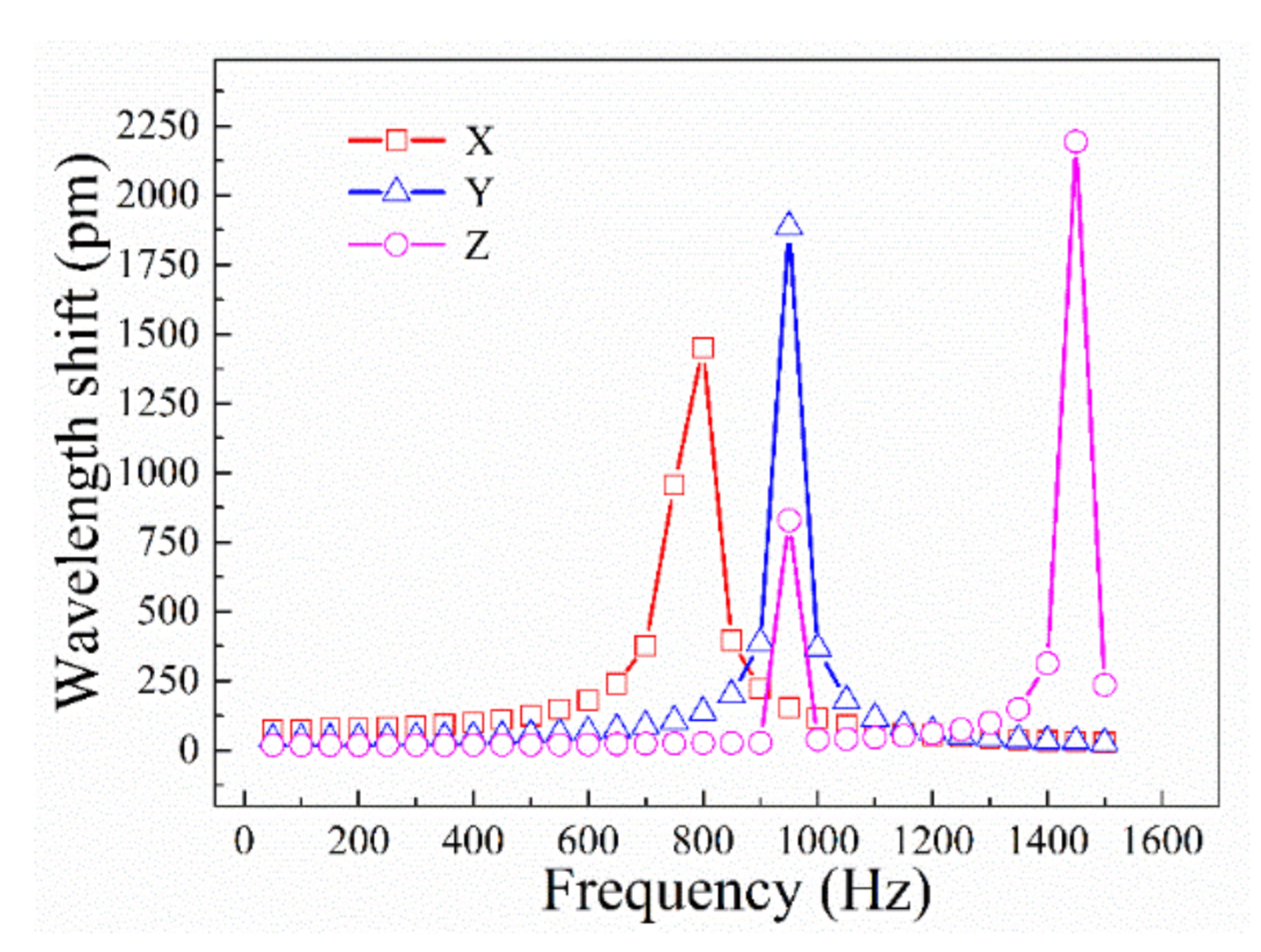

3.2. Harmonic Response

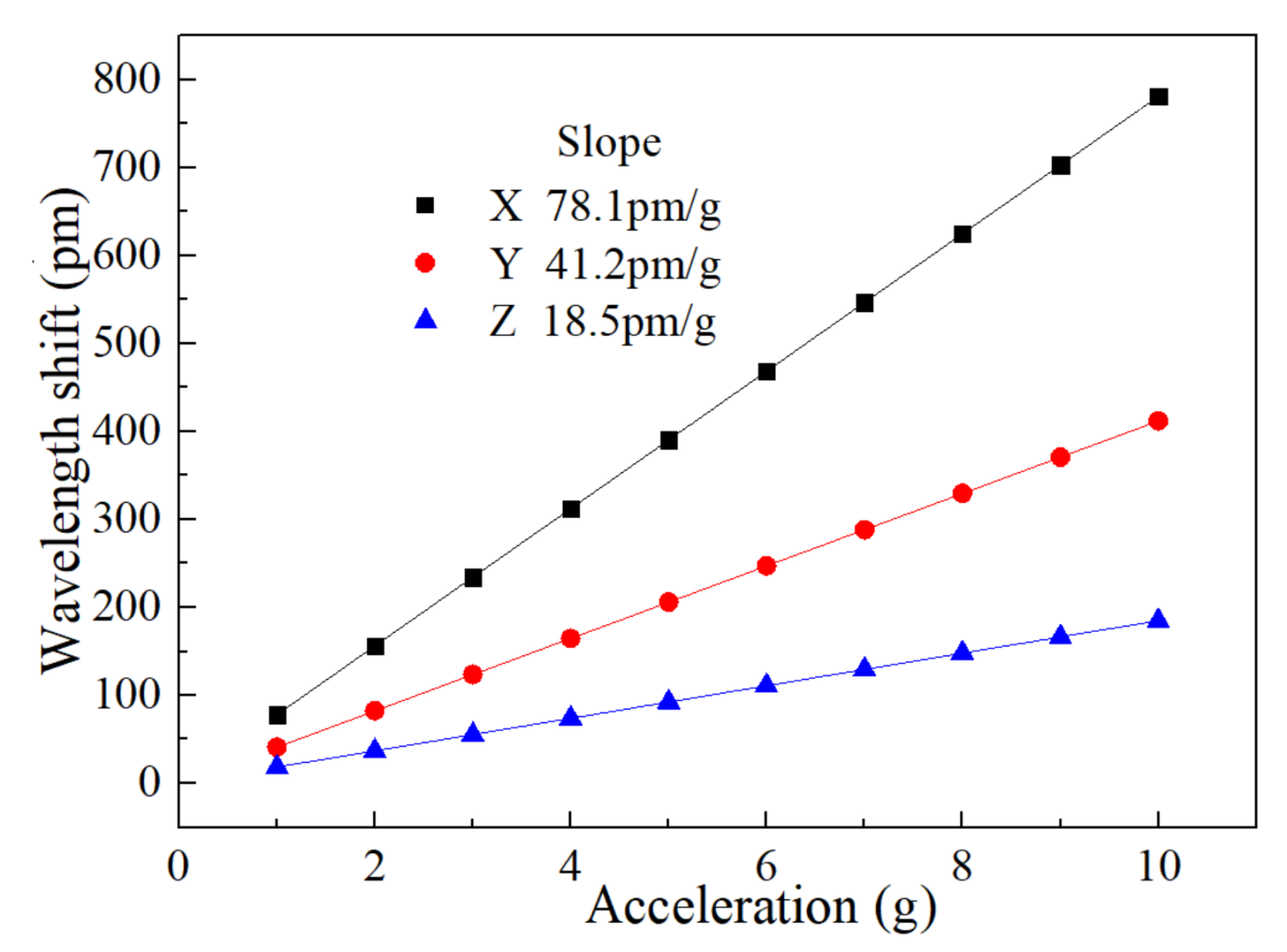

3.3. Sensitivity

4. Testing and Discussion

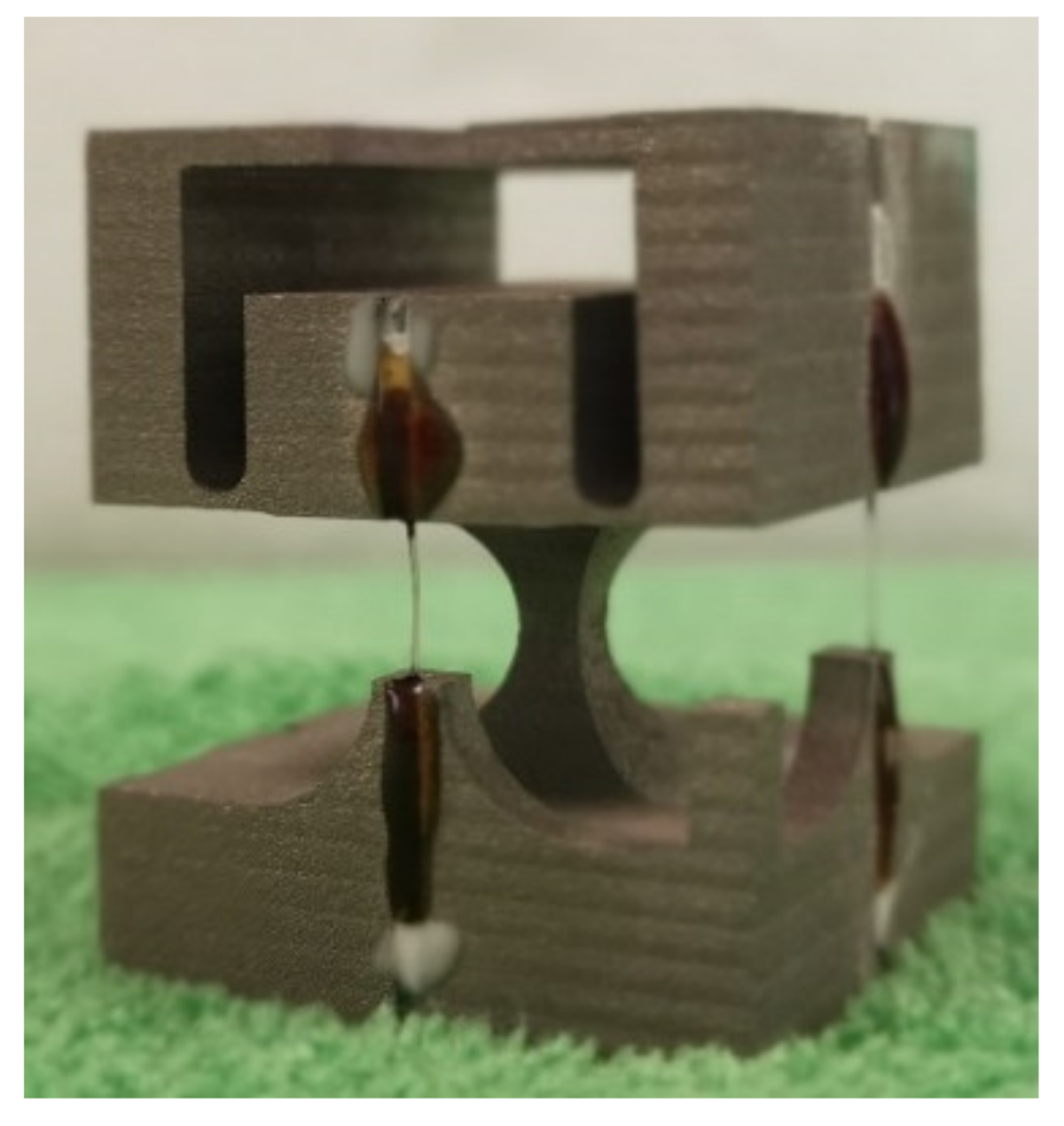

4.1. Installation of FBGs

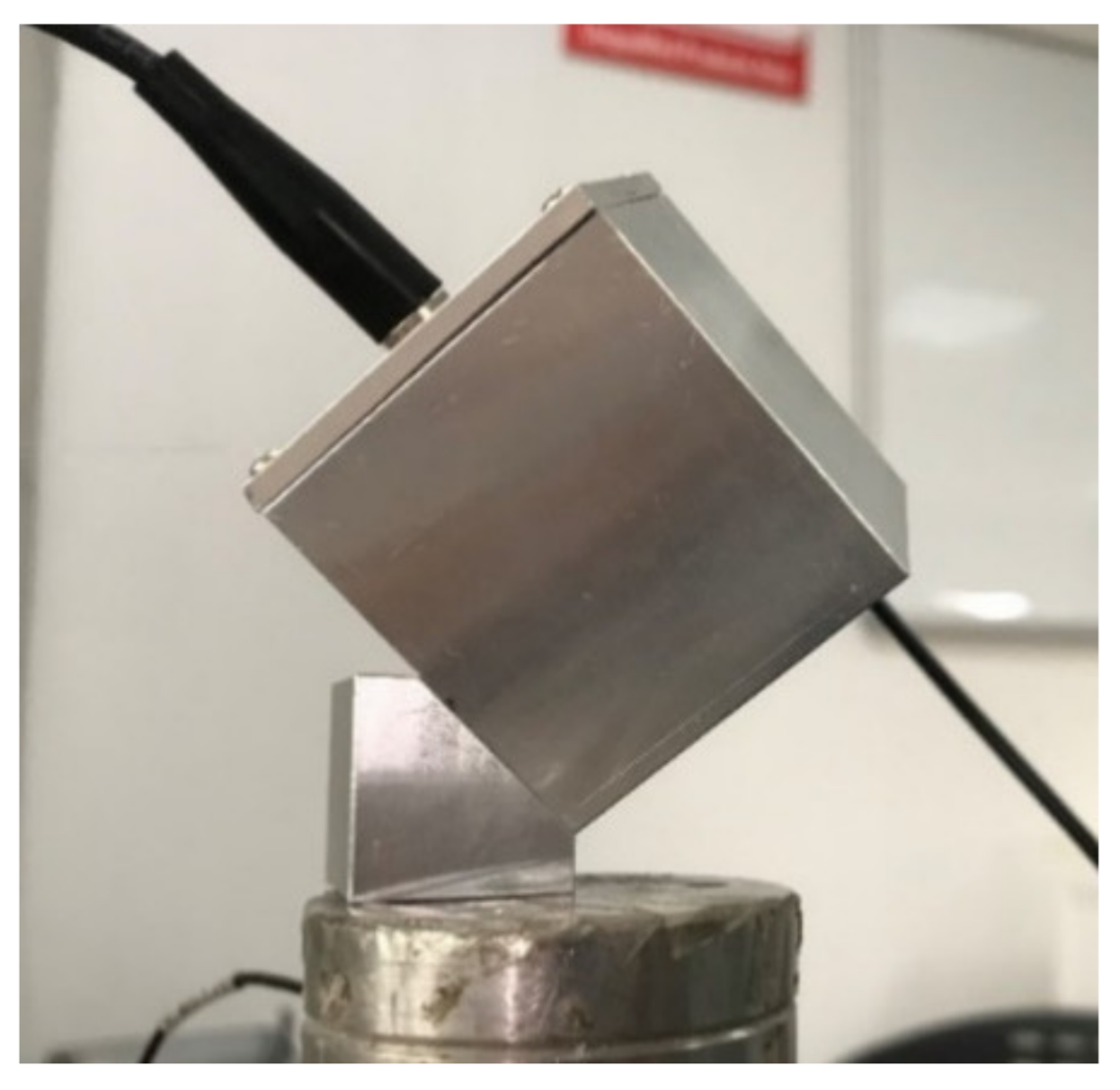

4.2. Performance Testing

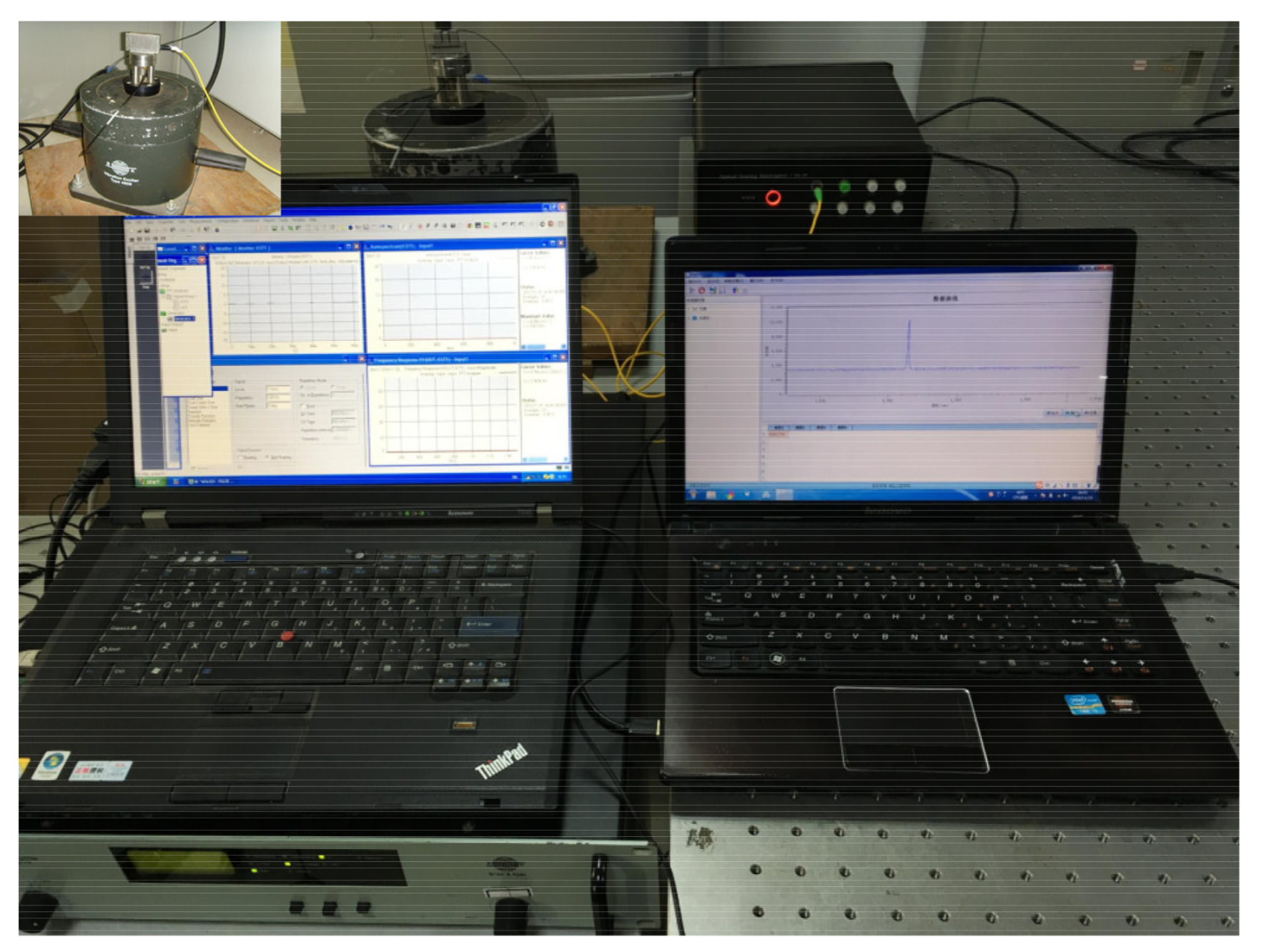

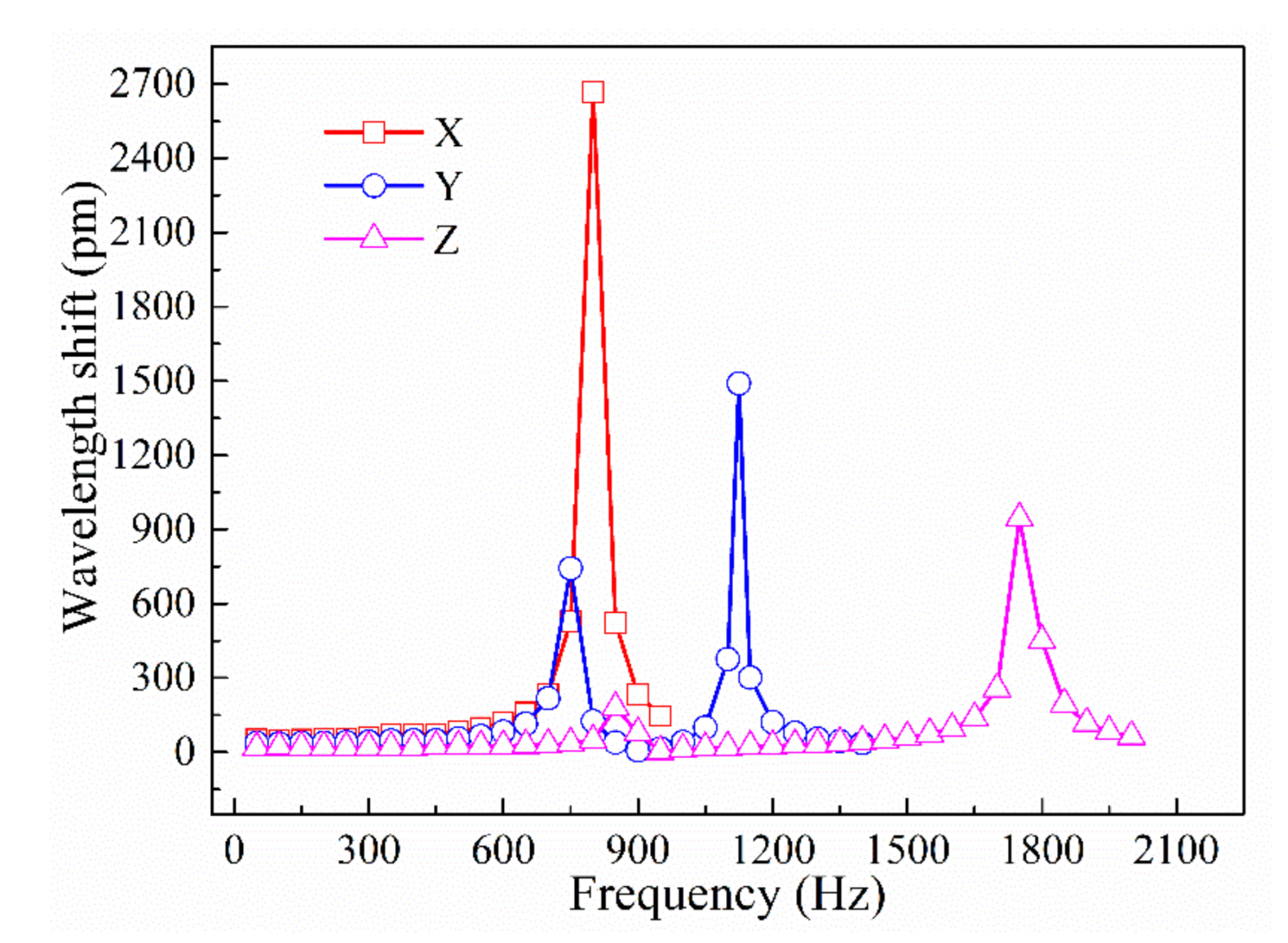

4.2.1. Natural Frequency Testing

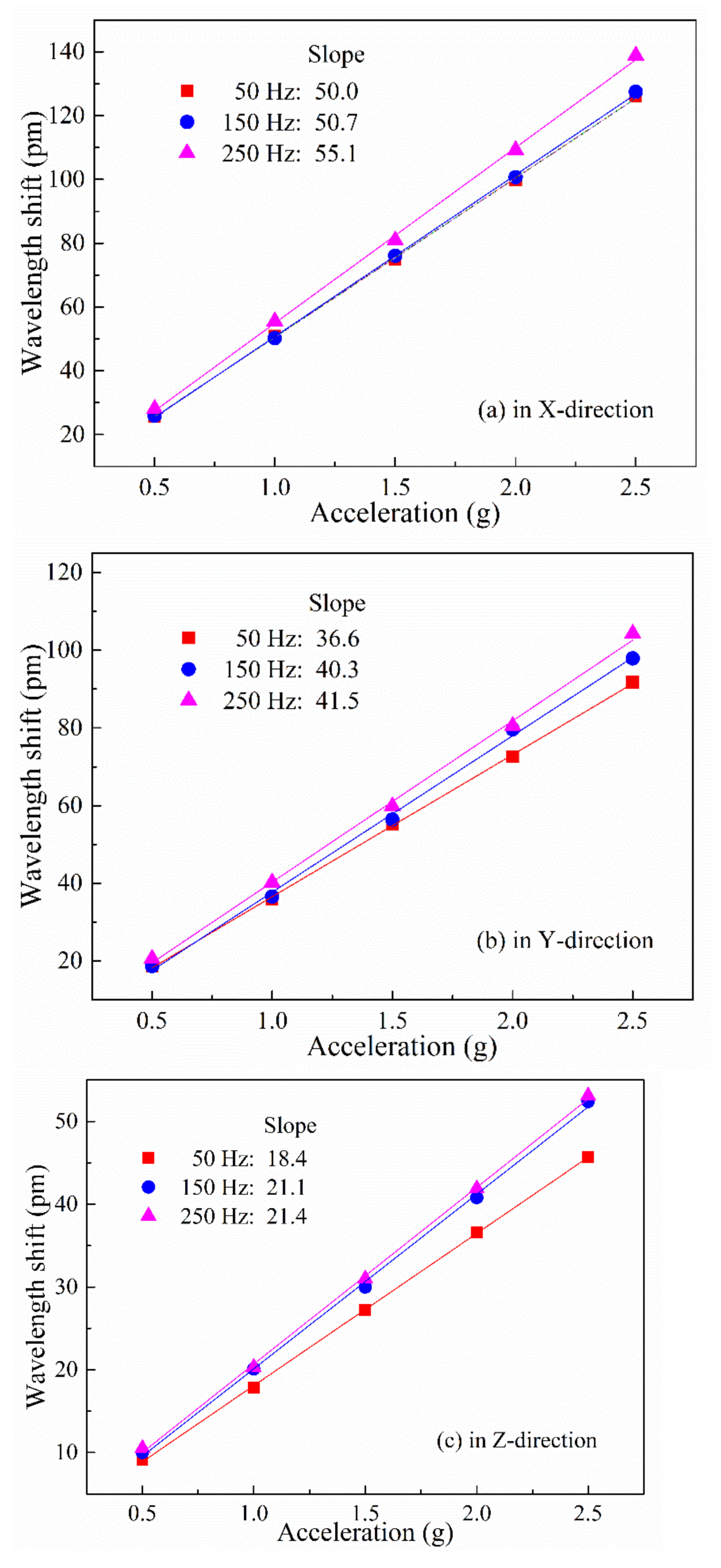

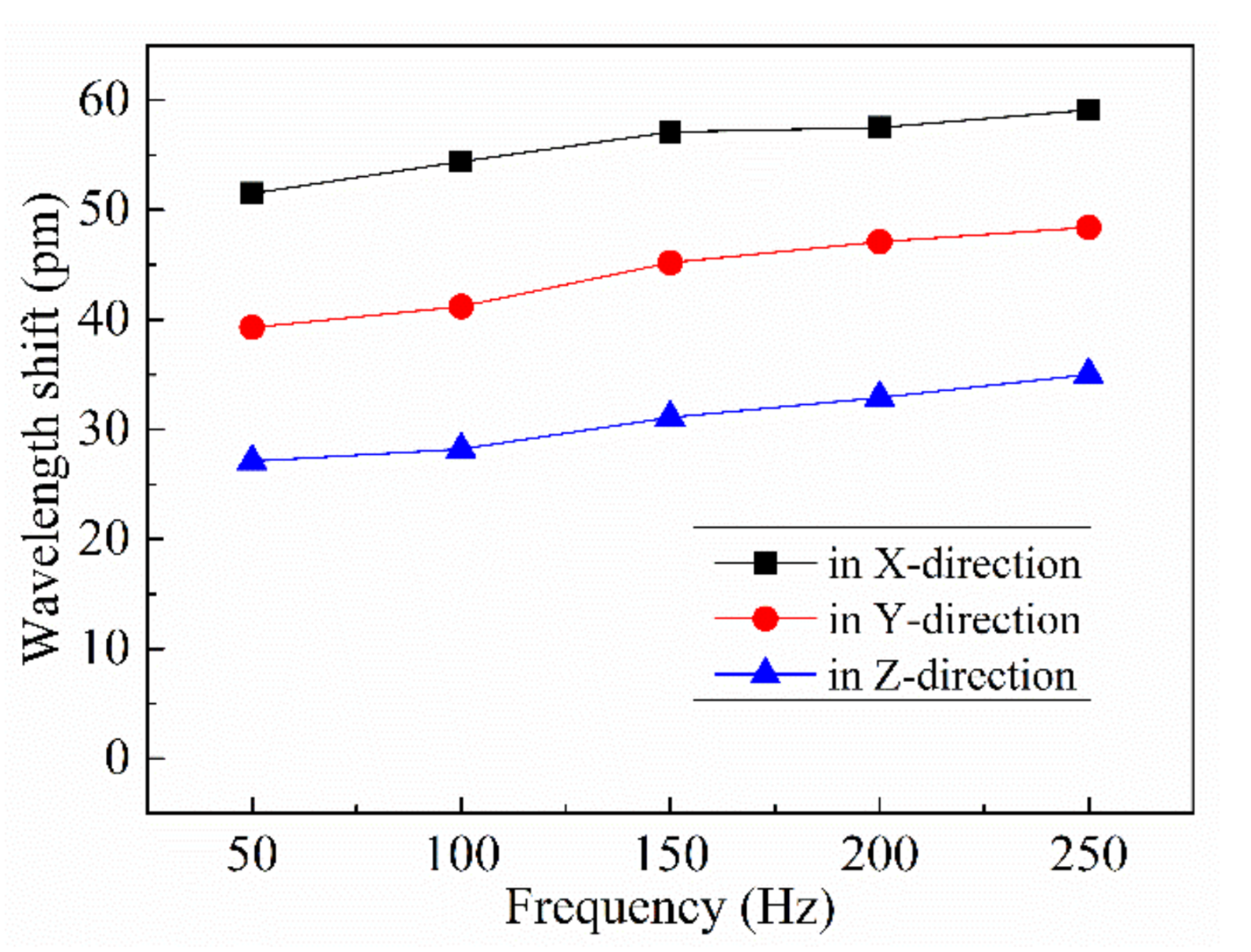

4.2.2. Sensitivity Testing

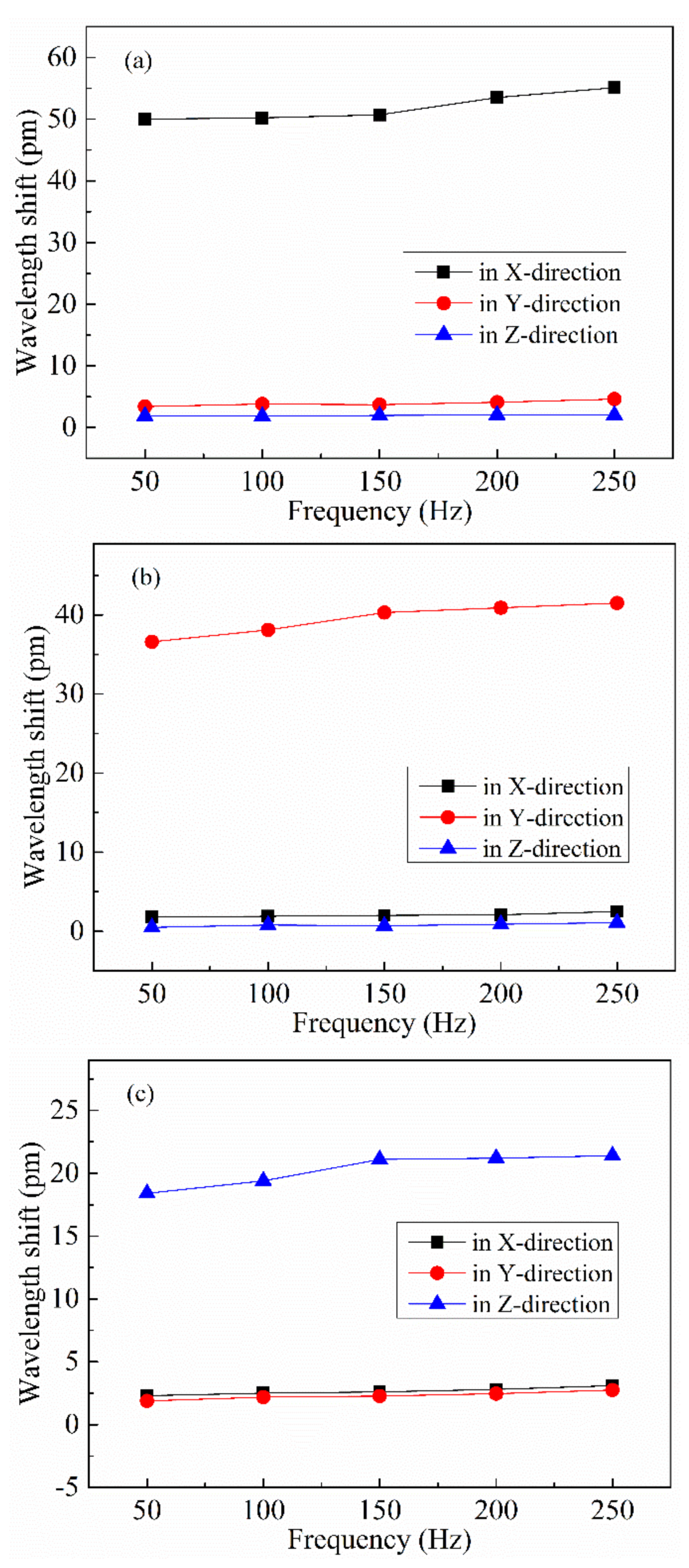

4.2.3. Anti-Interference Testing

4.3. Dynamic Response Testing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dong, L.; Wang, H.; Wang, G.; Qiu, W. A wireless multifunctional monitoring system of tower body running state based on MEMS acceleration sensor. In Proceedings of the 2018 19th International Symposium on Quality Electronic Design (ISQED), Santa Clara, CA, USA, 13–14 March 2018; pp. 357–363. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, M.; Xiong, L.; Zhou, X.; Li, C. Fiber Bragg grating based acceleration sensors: A review. Sens. Rev. 2021, 41, 101–122. [Google Scholar] [CrossRef]

- Morikawa, S.; Ribeiro, A.; Regazzi, R.; Valente, L.; Braga, A. Triaxial Bragg grating accelerometer. In Proceedings of the 2002 15th Optical Fiber Sensors Conference Technical Digest, OFS 2002 (Cat. No.02EX533), Portland, OR, USA, 10–10 May 2002; pp. 95–98. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Li, Z. Study on triaxial accelerometer based on FBG. Chin. J. Sci. Instrum. 2006, S1, 299–301. [Google Scholar]

- Ai, C.; Sun, Z.; Wu, S.; Zhang, J.; Yang, Y. Research on 3D optical fiber and grating microseismic acceleration sensor. Min. RD 2014, 6, 64–67. [Google Scholar]

- Feng, D.; Qiao, X.; Yang, H.; Rong, Q.; Wang, R.; Du, Y.; Hu, M.; Feng, Z. A Fiber Bragg Grating Accelerometer Based on a Hybridization of Cantilever Beam. IEEE Sens. J. 2014, 15, 1532–1537. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, D.; Li, J.; Zhu, F. Two dimensional fiber bragg grating accelerometer. Chin. J. Lasers 2012, 39, 198–204. [Google Scholar]

- Antunes, P.; Marques, C.; Varum, H.; Andre, P.S. Biaxial Optical Accelerometer and High-Angle Inclinometer with Temperature and Cross-Axis Insensitivity. IEEE Sens. J. 2012, 12, 2399–2406. [Google Scholar] [CrossRef]

- Wei, L.; Yu, L.; Wang, J.; Jiang, D.; Liu, Q.; Liu, Z. An FBG-Sensing Two-Dimensional Vibration Sensor Based on Multi-Axis Flexure Hinge. IEEE Sens. J. 2019, 19, 3698–3710. [Google Scholar] [CrossRef]

- Wei, L.; Jiang, D.; Yu, L.; Li, H.; Liu, Z. A Novel Miniaturized Fiber Bragg Grating Vibration Sensor. IEEE Sens. J. 2019, 19, 11932–11940. [Google Scholar] [CrossRef]

- Umesh, S.; Kumar, R.R.; Pant, S.; Asokan, S. Fiber Bragg Grating based two-dimensional Accelerometer. In Proceedings of the 2015 International Conference on Smart Sensors and Systems (IC-SSS), Bangalore, India, 21–23 December 2015; pp. 1–4. [Google Scholar]

- Wang, J.; Wei, L.; Li, R.; Liu, Q.; Yu, L.; Li, T.; Tan, Y. An FBG-Based 2-D Vibration Sensor with Adjustable Sensitivity. IEEE Sens. J. 2017, 17, 4716–4724. [Google Scholar] [CrossRef]

- Wang, Y.; Dai, Y.; Wei, Y.; Liu, W.M. Optimization design of fiber Bragg grating two-dimensional accelerometer based on flexure hinge. Acta. Phys. Sin. 2019, 48, 1–7. [Google Scholar]

- Cui, J.; Liu, Z.; Gunawardena, D.S.; Zhao, Z.; Tam, H.Y. Two-dimensional vector accelerometer based on Bragg gratings inscribed in a multi-core fiber. Opt. Express 2019, 27, 20848–20856. [Google Scholar] [CrossRef]

- Song, H.; Wang, Q.; Liu, M.; Cai, Q. A Novel Fiber Bragg Grating Vibration Sensor Based on Orthogonal Flexure Hinge Structure. IEEE Sens. J. 2020, 20, 5277–5285. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, T.; Li, Y.; Qiao, X. Highly Sensitive FBG Seismometer With a 3D-Printed Hexagonal Configuration. J. Light. Technol. 2020, 38, 4588–4595. [Google Scholar] [CrossRef]

- Liu, F.; Yi, D.; Chen, Y.; Xu, P.; Zhang, M.; Zhu, X.; He, X.; Zhou, X.; Long, K. Common-mode noise self-suppressed 3-component fiber optic accelerometer based on low-reflectivity Bragg gratings. Opt. Lett. 2021, 46, 1596–1599. [Google Scholar] [CrossRef]

- Zhou, R.; Chen, F.; Li, S.; Wang, R.; Qiao, X. Three-Dimensional Vector Accelerometer Using a Multicore Fiber Inscribed With Three FBGs. J. Light. Technol. 2021, 39, 3244–3250. [Google Scholar] [CrossRef]

- Chen, F.; Li, X.; Wang, R.; Qiao, X. Two-dimensional vector accelerometer based on orthogonal Bragg gratings inscribed in a standard single-mode fiber cladding. Opt. Lett. 2021, 46, 2992–2995. [Google Scholar] [CrossRef]

- Li, Y.; Li, K.; Liu, G.; Tian, J.; Wang, Y. A pre-relaxed FBG accelerometer using transverse forces with high sensitivity and improved resonant frequency. Photonics Lett. Pol. 2020, 12, 4–6. [Google Scholar] [CrossRef]

- Wu, H.; Lin, Q.; Han, F.; Zhao, L.; Jiang, Z. Design and analysis of high-frequency fiber Bragg grating vibration sensor. Meas. Sci. Technol. 2021, 32, 025108. [Google Scholar] [CrossRef]

- Hong, L.; Zhang, Y.; Mu, R.; Teng, Y.; Qiu, Z.; Zhang, R. Temperature-insensitive FBG acceleration sensor based on strain chirp effect. Meas. Control 2021, 1–10. [Google Scholar] [CrossRef]

- Yan, B.; Liang, L. A Novel Fiber Bragg Grating Accelerometer Based on Parallel Double Flexible Hinges. IEEE Sens. J. 2019, 20, 4713–4718. [Google Scholar] [CrossRef]

- Li, T.; Guo, J.; Tan, Y.; Zhou, Z. Recent Advances and Tendency in Fiber Bragg Grating-Based Vibration Sensor: A Review. IEEE Sens. J. 2020, 20, 12074–12087. [Google Scholar] [CrossRef]

- Li, K.; Liu, G.; Li, Y.; Yang, J.; Ma, W. Ultra-Small Fiber Bragg Grating Accelerometer. Appl. Sci. 2019, 9, 2707. [Google Scholar] [CrossRef] [Green Version]

- Jing, Z.; Wang, J.; Peng, G.; Hu, Z.; Hu, Y. Design and analysis of a novel dual fbg accelerometer based on lantern shape metallic shells. IEEE Sens. J. 2017, 16, 1–7. [Google Scholar]

- Antunes, P.; Varum, H.; André, P. Uniaxial fiber Bragg grating accelerometer system with temperature and cross axis insensitivity. Measurement 2011, 44, 55–59. [Google Scholar] [CrossRef]

- Cao, F.; Jiao, Z. Design of double-axis elliptical flexure hinges. J. Eng. Mech. 2007, 24, 178–182. [Google Scholar]

- Yingfei, W.; Zhaoying, Z. Deduction of design equation of flexure hinge. Chin. Sci. Instrum. 2004, 1, 125–128. [Google Scholar]

| Parameter | Numerical Value (mm) |

|---|---|

| a | 4 |

| t | 3 |

| w | 2 |

| bt | 3 |

| bw | 3 |

| n | 5 |

| i | 7 |

| r | 1.5 |

| e | 0.5 |

| c | 11.5 |

| f | 2.5 |

| v | 1.5 |

| j | 26 |

| Axial | Parameter | Numerical Value |

|---|---|---|

| X | central wavelength | 1544.3482 nm |

| period | 0.1 um | |

| reflectivity | >70% | |

| grid length | 5 mm | |

| Y | central wavelength | 1533.4438 nm |

| period | 0.1 um | |

| reflectivity | >70% | |

| grid length | 5 mm | |

| Z | central wavelength | 1558.2875 nm |

| period | 0.1 um | |

| reflectivity | >70% | |

| grid length | 5 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Liang, L.; Zhou, X.; Tu, B. New Fiber Bragg Grating Three-Dimensional Accelerometer Based on Composite Flexure Hinges. Sensors 2021, 21, 4715. https://doi.org/10.3390/s21144715

Wang H, Liang L, Zhou X, Tu B. New Fiber Bragg Grating Three-Dimensional Accelerometer Based on Composite Flexure Hinges. Sensors. 2021; 21(14):4715. https://doi.org/10.3390/s21144715

Chicago/Turabian StyleWang, Hui, Lei Liang, Xiongbing Zhou, and Bin Tu. 2021. "New Fiber Bragg Grating Three-Dimensional Accelerometer Based on Composite Flexure Hinges" Sensors 21, no. 14: 4715. https://doi.org/10.3390/s21144715

APA StyleWang, H., Liang, L., Zhou, X., & Tu, B. (2021). New Fiber Bragg Grating Three-Dimensional Accelerometer Based on Composite Flexure Hinges. Sensors, 21(14), 4715. https://doi.org/10.3390/s21144715