4.1. Evaluation Setting

The performance of the proposed smart-collaborative plastic-waste management system has been simulated in the city of Quezon, Philippines. The Philippines as a country has not completely managed the plastic-waste problem yet. The country is plagued with drainage blockages due to plastics that usually occur during floods [

32], posing a serious hazard to the population. Quezon City is the largest and most populous city in the Philippines, producing 262 tons of plastic waste per day. With 3,085,227 people and an area of 161.126 km

, multiple waste management plans have been tried and tested until today with different results [

33], showing that there is still a need for ideas and projects to improve waste management.

With the aim of assisting the management of plastics through household smart bins for people with disabilities, senior citizens and COVID-19 affected residents, we have focused on data mainly about these profiles in the neighborhoods of Quezon City. In an Ecological Profile report made by the government office of Quezon City in 2015 [

34], 34.92% of the total population are people with mental, speech, orthopedic, visual or hearing disabilities, among others. According to the report, the senior citizens are also included in this vulnerable group. In 2015, the estimated total number of people over 60 years old was 162,158.

In this study, three neighborhoods (known as

barangays) of three different districts in Quezon are involved for a simulation scenario: Don Manuel under districts Galas, Commonwealth under the district with the same name and Mariana in New Manila. These neighborhoods represent a 0.13%, 6.75%, and 0.38% of the total population, respectively (

https://www.philatlas.com/luzon/ncr/quezon-city.htmlsectionBrgys (accessed on 15 June 2021)). We have used this setting to allocate the different households simulated in the study and thus calculate the real distances for the route-planning algorithm described in

Section 3.8.

In terms of socio-demographic profile of each neighborhood, in Don Manuel the computed age dependency ratio is 22 youth dependents to every 100 working age population. Commonwealth’s ratio is 43 and in Mariana it is 17 to every 100 working age population, respectively. Regarding the old-age-dependency ratio in these 3 neighborhoods, Mariana has the highest ratio of 11 to every 100. In terms of COVID-19, the city with the highest cases is Quezon City as of May 2021, with more than 150 active COVID-19 cases only in Barangay Commonwealth (

https://quezoncity.gov.ph/covid19counts/qc-covid-19-update-as-of-may-11-2021-8am/(accessed on 15 June 2021)).

4.5. Prediction Results

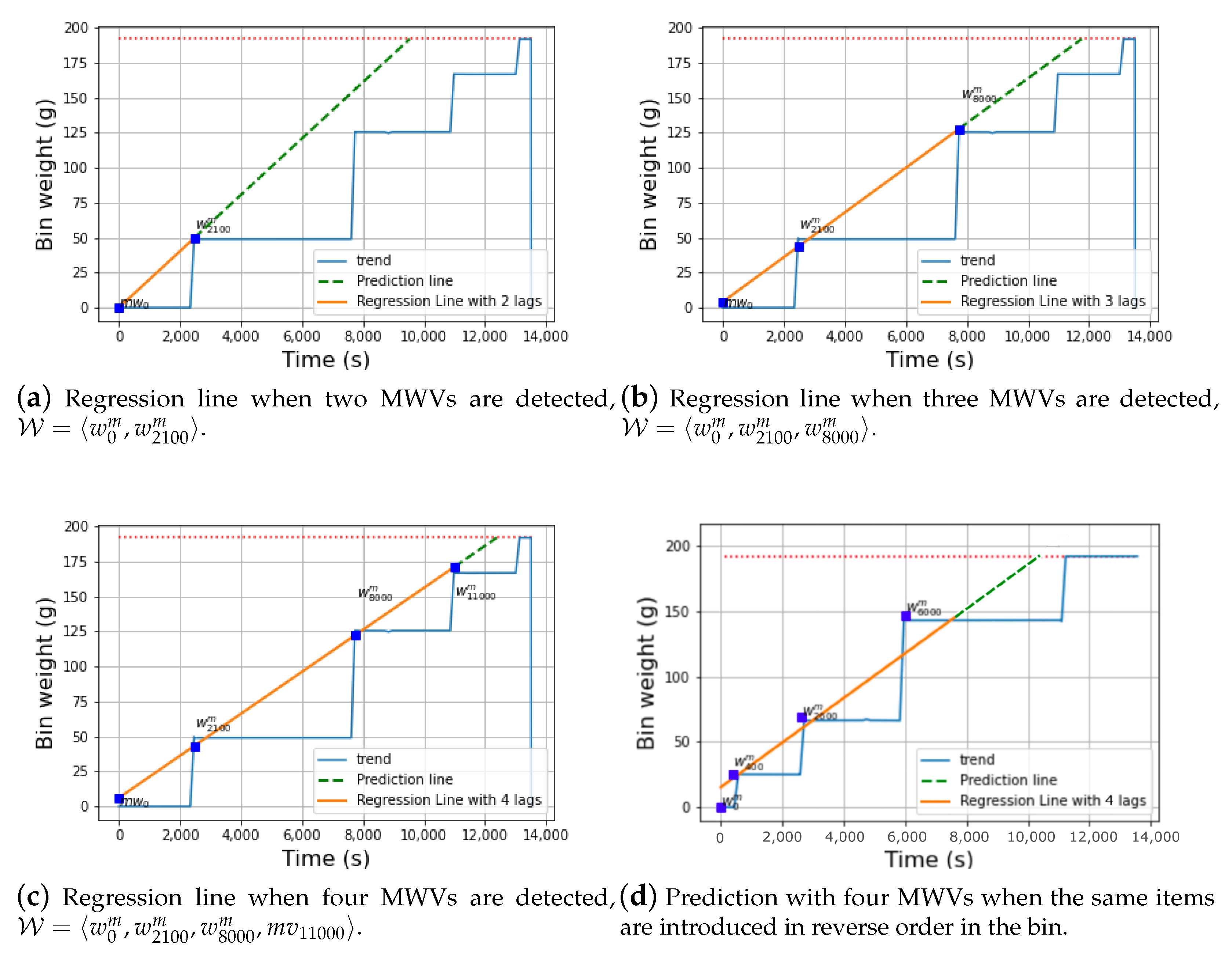

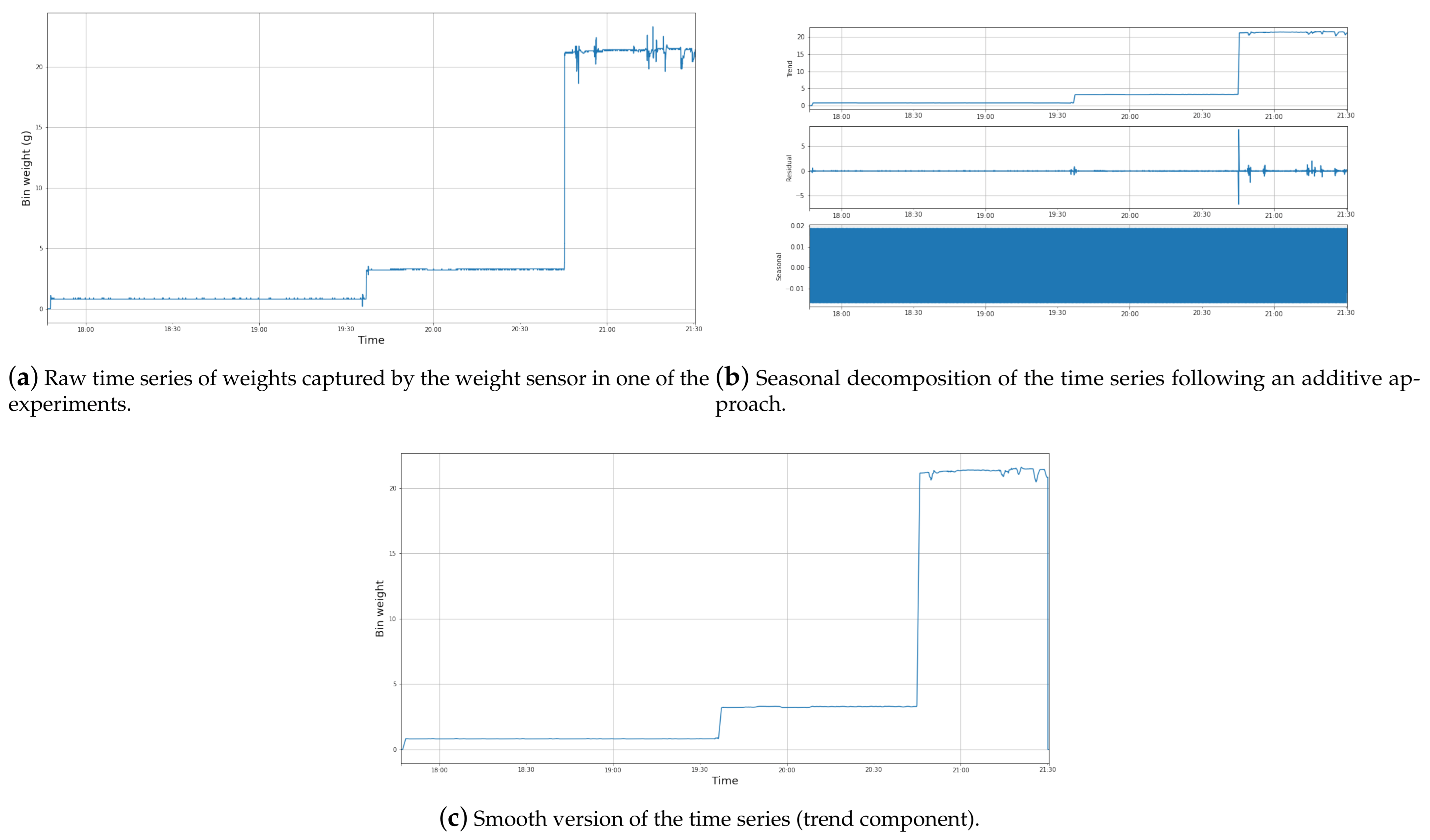

Given the predictor model in

Section 3.7 aimed at forecasting the time when a bin is likely to be completely filled, we set

to 5 g and

to 200 s. This configuration was calculated by means of a grid search in the input space of both parameters. For this configuration, the solution had an average residual error of 2167 s (∼36 min) ±1390 s (∼23 min).

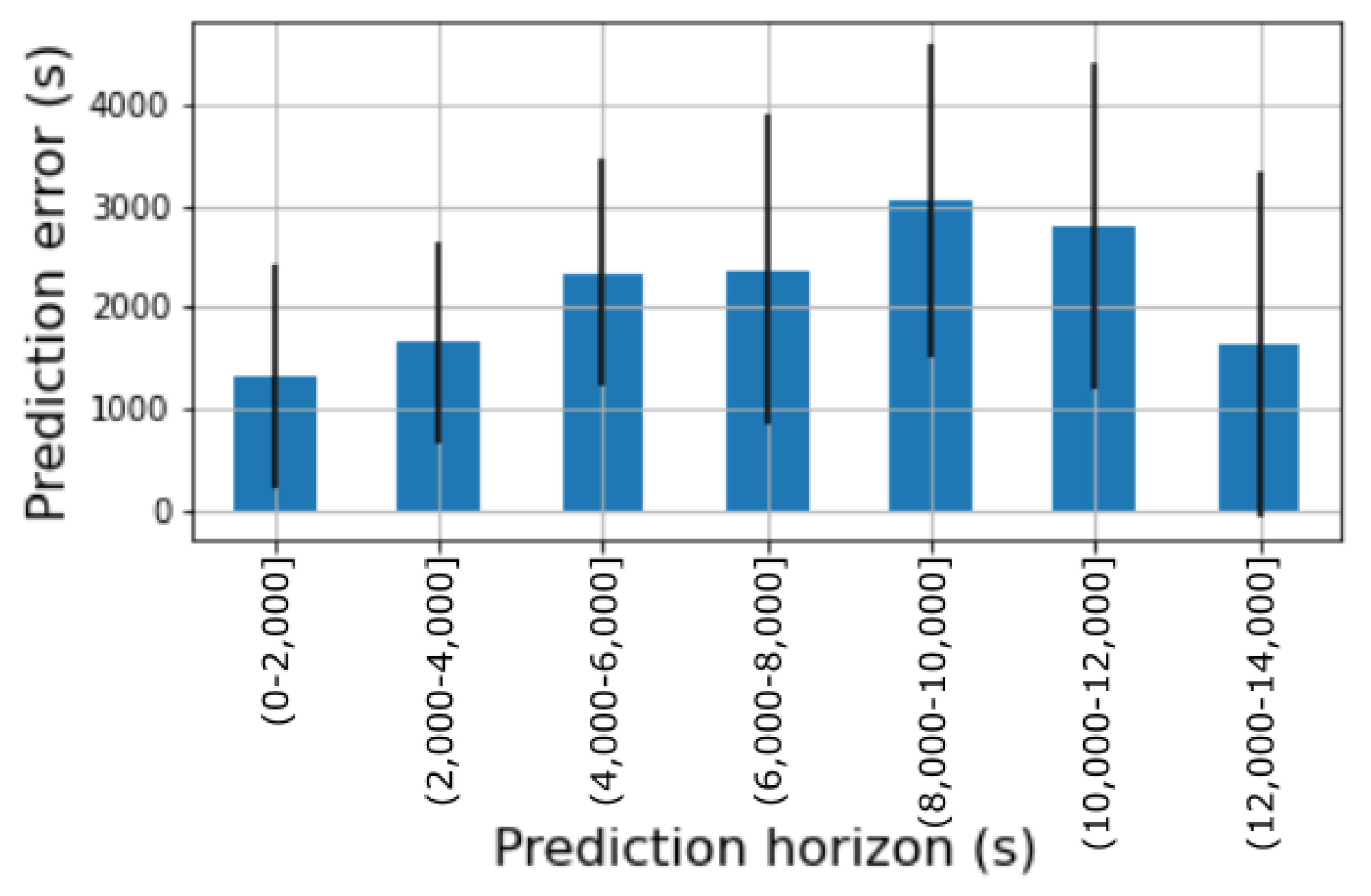

Figure 8 shows the residual error (

) of this model for different time horizons. For instance, for a time horizon below 2000 s (∼33 min) the error of the model was 1320 s (∼22 min) on average. It is observed that the accuracy of the model degrades as long as the prediction horizon increases.

However, a meaningful drop in the residual error occurs for very long time horizons between 12,000 and 14,000 s. The predictions for such horizons are provided by models fitted with sets comprising the very first meaningful variations of an experiment (that is, the very first plastic items place inside the bin). This might suggest that the initial set of plastic items inserted in a bin might actually define the whole waste behavior of the target users at a high degree.

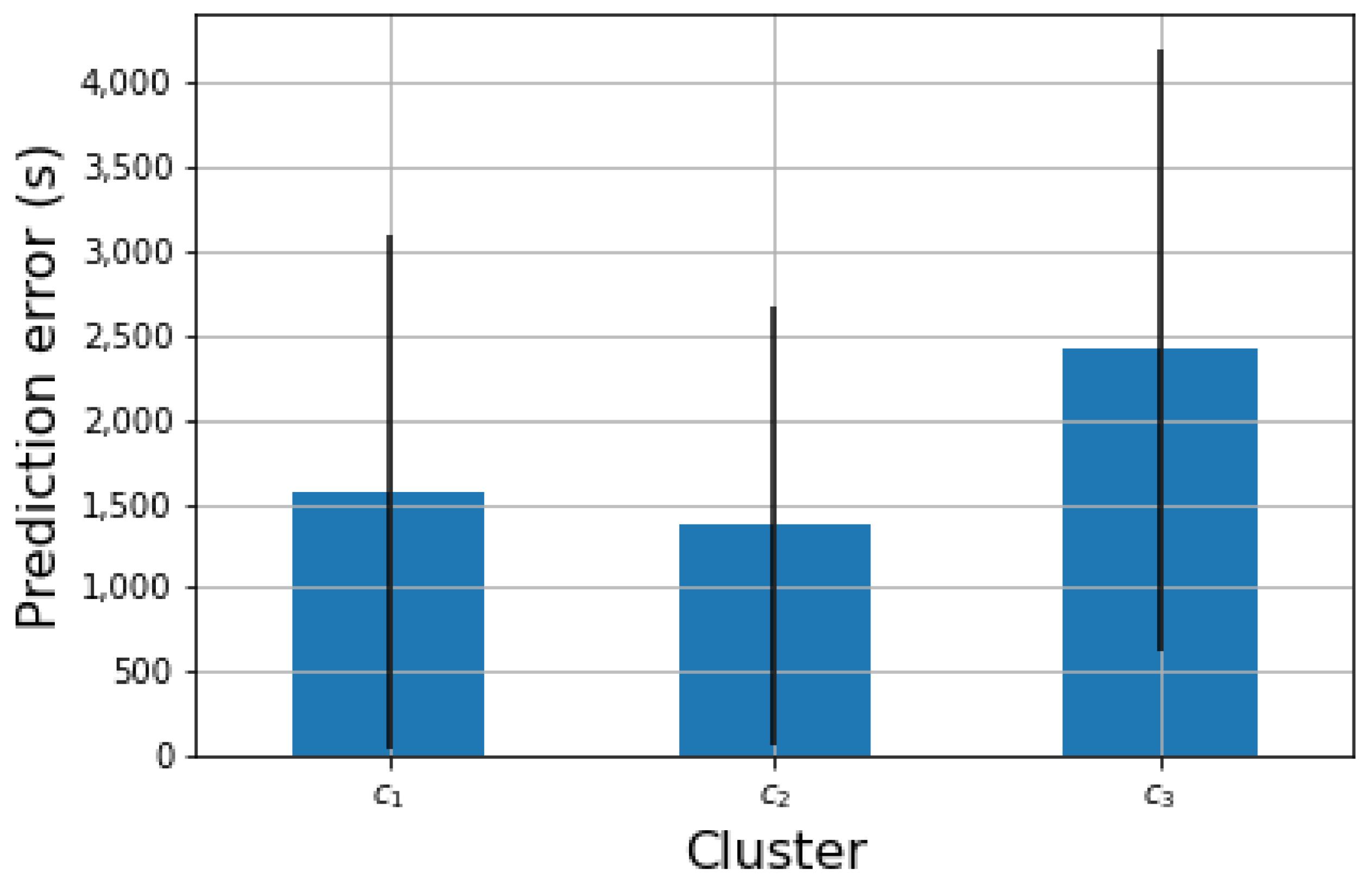

Figure 9 shows the distribution of the residual error for each of the user profiles defined in

Section 4.4. It is observed that the accuracy of the predictor was lower for the experiments with cluster

, with a residual error of 3352 s (∼55 min) on average. For the other two clusters, the error was around 2000 s (∼33 min.).

From

Figure 8 and

Figure 9 it is observed that the predictor error ranges between 1200 and 4600 s (20 and 76 min). These predictions are used by the route generation algorithm to compute the pick-up hour for each bin as stated in

Section 3.8. We believe that this error range is small enough to generate a pick-up hour close enough to the actual moment when the bin is full. In the worst case, users will have their bin completely full for around 76 min before a waste-picker arrives at their home. This seems a sensible time period to wait given the benefit that the system would bring to the user.

Finally, the web application included in our proposal (

Section 3.6) displays the time series of each experiment along with its associated prediction as shown in

Figure 10. This allows the timely control and validation of the state of each bin in a real-world deployment.

4.6. Composition of the Collection Routes

The evaluation of the route generation algorithm explained in

Section 3.8 has been performed in a simulated test-bed scenario within Quezon City for the clusters defined in

Section 4.4.

To run the simulation, eight household smart bins and two waste-picker locations were defined within the city area. Then, each bin location was linked to a particular cluster for plastic-waste behavior. As shown in

Figure 11, six smart bin locations in the south of the city were assigned to clusters

(locations

,

,

) and

(

,

,

), respectively, and two more in the north to

(

,

). The set of waste-pickers was defined as

. Furthermore, we also considered the location of three municipal dumpsites at Quezon City. They are depicted as green dots in

Figure 11a. Please note that these dumpsites are an important contextual factor to be considered. This is because waste-pickers need to deposit the plastic waste from the target houses in any of these dumpsites during their collection routes.

Once the scenario was set, each smart bin location

was associated with a subset

of the data collection experiments (out of 176) by considering its cluster (

Section 4.2). For example,

comprised experiments related to cluster

. In this manner we simulate a real-time behavior of the use of the household smart bins by means of an iterative approach. For each day in the study period (from 19 October 2019 to 30 January 2021 according to

Section 4.2), we extracted a particular experiment related to that day, if any, from each set

. Next, for each experiment we kept its weight evolution of its first

k items. A particular experiment gave rise to as many

sub-experiments as its total number of items (see

Table 4). Then, a prediction for the target

sub-experiment of each location was generated giving rise to a set or pick-up points

(

). Moreover, the two waste-pickers had the following range of available hours,

= (16:00, 23:00),

= (20:00, 02:00). Consequently, the simulated real-time behavior can be regarded as a two-level loop, one moving across the days and a nested one moving across the number of items of the experiments.

The set of pick-up points along with the range hours of the waste-pickers fed the ILOG solver to compose the required collecting routes. To do so, we made use of the implementation provided by the

OR-tools suite [

40], open-source software for optimization.

This suite requires the time distances among the target locations to compose the final routes. To study the impact of the means of transport used by the waste-pickers to cover the routes, we defined distance matrices based on three means of transport, namely bike, car and on foot. The travel times were calculated by means of the

Google Maps web service (

https://www.google.com/maps (accessed on 24 May 2021)). For completeness,

Appendix A shows the travel time matrices for each means of transport (see

Table A1 for bike,

Table A2 for on foot and

Table A3 for car). Furthermore, we also considered that the number of plastic-waste bags that a waste-picker can carry at the same time depends on the specific means of transport. It was assumed that a waste-picker can carry only two bags at the same time when moving on foot or by bike and eight when moving by car. This was done by forcing the route composer to include a visit to the closest dumpsite when such several bags are reached.

For each route, its collection rate was calculated. This metric indicates the percentage of bins included in the route that would have been eventually collected by the waste-picker before they were filled. This is possible to calculate because each route comprises the collection hour for each bin and the actual filling hour of the bin, which is available through the original experiment.

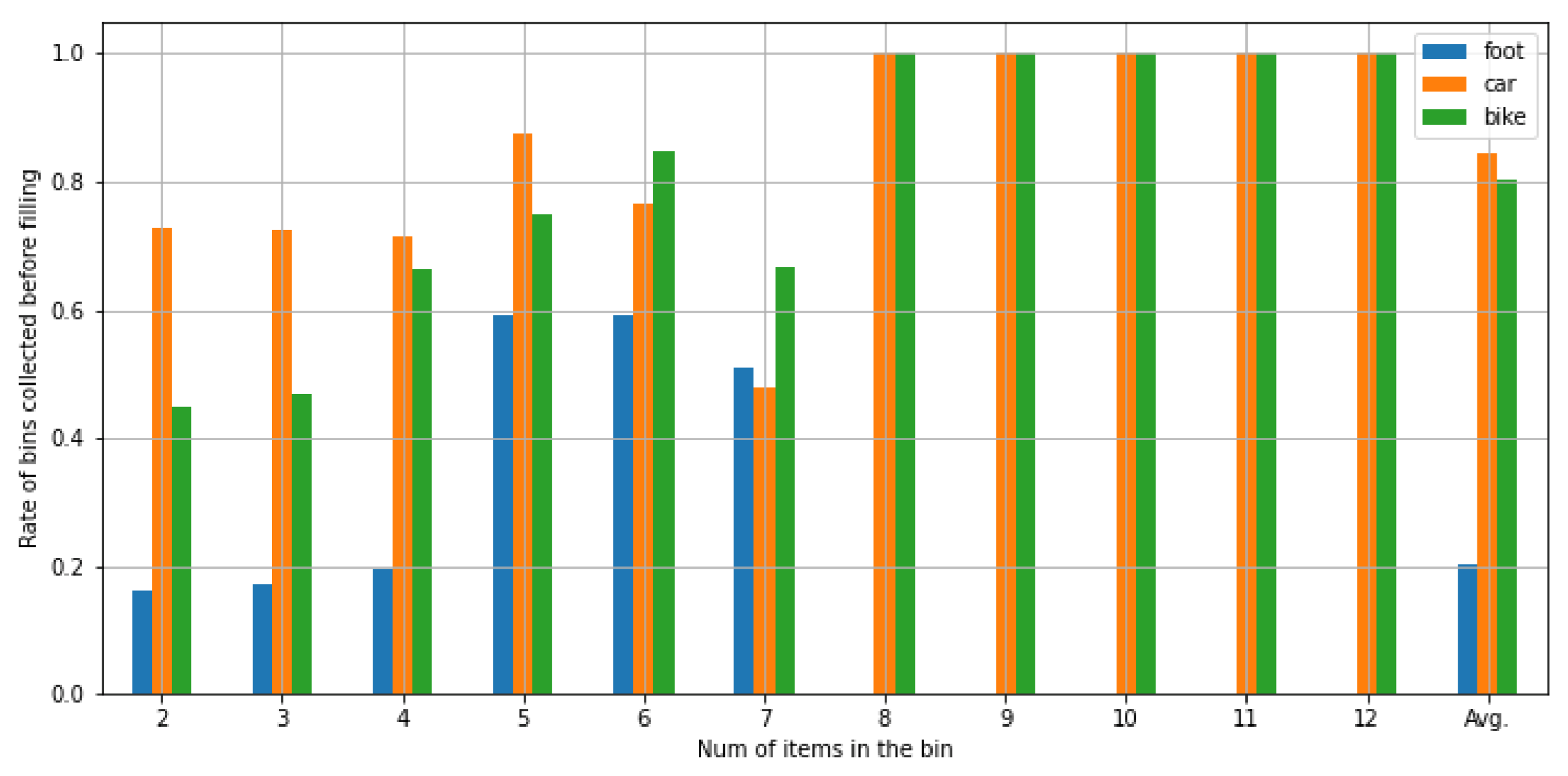

Figure 12 shows the collection rate for the three means of transport. This rate is shown taking into account the number of items that were already inserted in the bin when the route composition algorithm was performed. For example, the leftmost blue column shows that the average collection rate for routes based on predictions generated when there were two plastic items in the bin and the waste-pickers moved on foot was 0.18 (i.e., 18% of the bins were collected before they were filled).

According to

Figure 12, the solution achieved a collection rate around 0.8 on average when bikes or cars were used as means of transport. However, this rate remarkably dropped when waste-pickers moved on foot (see the last

Avg. column in

Figure 12). This is because this means of transport required very long walks to the dumpsites, requiring an extra time with respect to the other means of transport.

Another interesting finding is that the collection rate when using bikes and cars increases as long as the predictions are based on a larger number of items. As a matter of fact, their rate equals to 1 (i.e., all the bins are collected before they are actually filled) when the predictions used by the ILOG solver rely on 8 or more items regardless of the means of transport. The reason of this behavior is that the predictions based on a low number of items have a larger variability than those based on a high number. This high variability makes the route composer to receive as input pick-up points with very different filling hours, and therefore it is not able to find a suitable route covering all the locations in most situations. However, if the estimated filling hours rely on predictions based on a larger number of items, they tend to be more homogeneous covering a smaller range of hours within a day. This makes it easier for the solver to find a feasible pick-up sequence. Regarding the predictions based on a lower number of items, the rate is usually higher when the waste-pickers use car or bikes.

Regarding the results when waste-pickers move on foot, it is observed a different behavior than for the other two means of transport. Although the system achieved collection rates from 0.18 to 0.59 when predictions were based on seven or less items (see

Figure 12), it was not able to compose collection routes when a larger number of items were included in the prediction step. This is strongly related to the homogeneity of the predictions explained in the previous paragraph. Since the range of hours is smaller in this case, the route composer is not able to find a route that covers all the houses along with the required visits to the dumpsites.

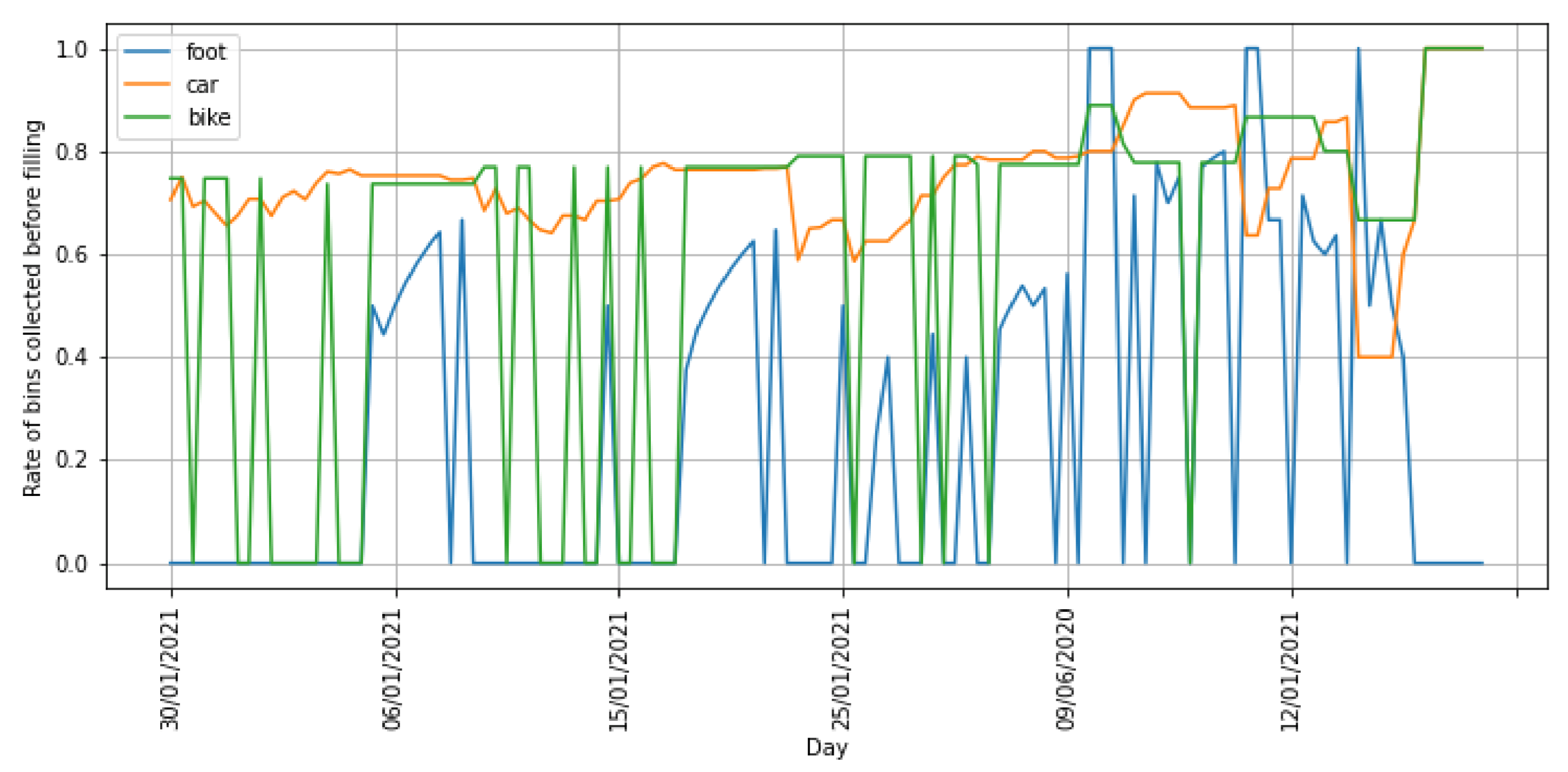

Furthermore,

Figure 13 shows the collection rate for each of the days under study. As observed, the rate fluctuations for the routes covered on foot and by bike were higher than for the routes covered by car. Those walking and biking routes had a rate of 0 in several days indicating that it was not possible to compose a route able to visit any of the bins’ houses before the filling hour. However, the car-based routes exhibited a higher stability with rates above 0.7 in most of the days.

As an illustrative example of a specific route, given the following pick-up points , the route solver is able to compose the following route for when she moves by bike,

As a result, the waste-picker would be able to reach bins at

and

and leave their bags at dumpsite

during the same hour range, since it only takes 4 min to go from

to

and 15 min to go from

to

according to the time matrix for bike routes (

Table A1). The same occurs for

and

because it takes 49 min to move from one location to the other.