Sensor Integrated Load-Bearing Structures: Measuring Axis Extension with DIC-Based Transducers

Abstract

1. Introduction

Fundamentals of DIC

2. Methods

2.1. Background of Sensor Integrated Load-Bearing Structures

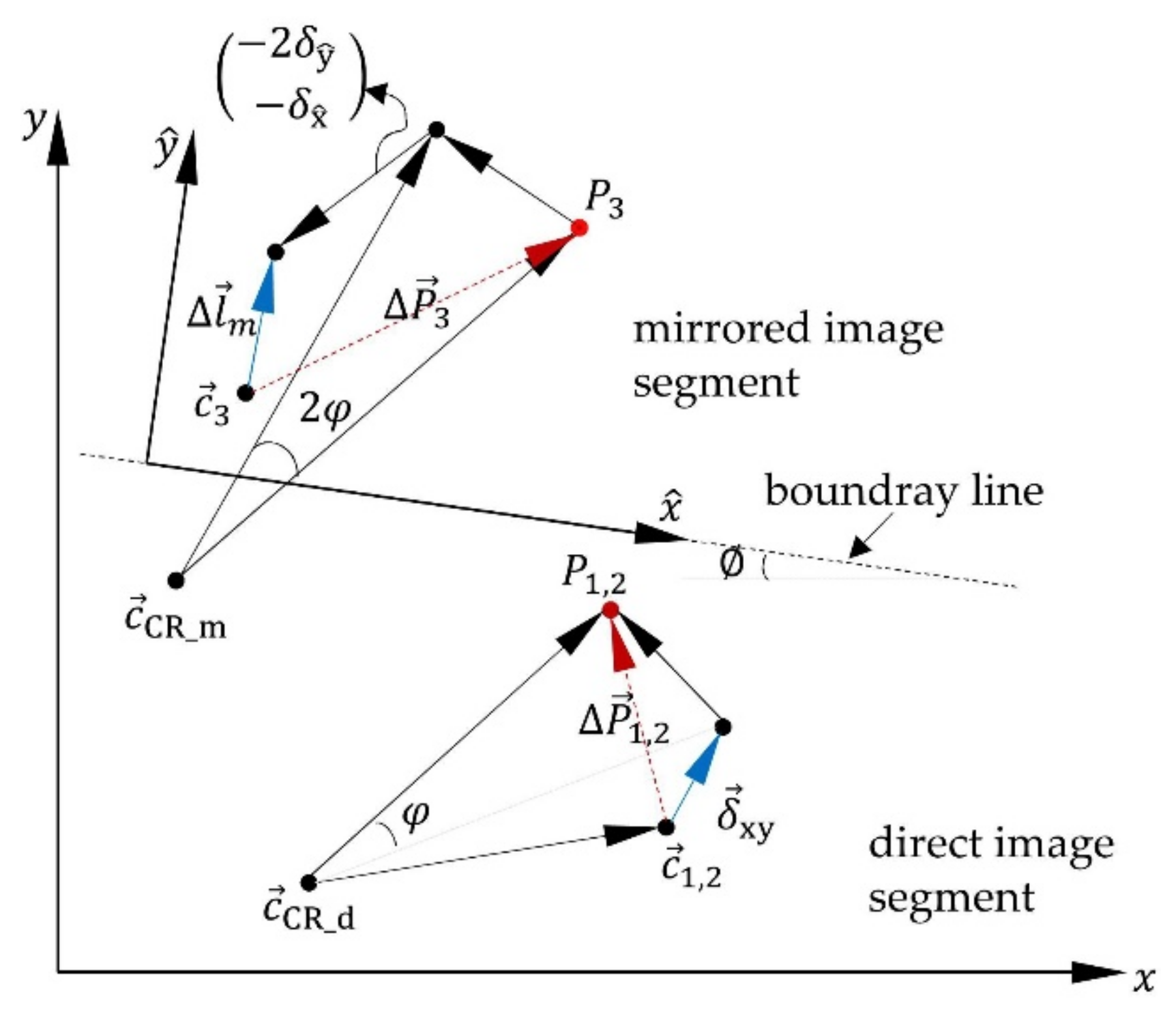

2.2. The DIC-Based Force/Torque Sensor

2.2.1. Sensor Design

2.2.2. Determination of the System Behavior

3. Evaluation and Results

3.1. Design of the Prototype

3.2. Results

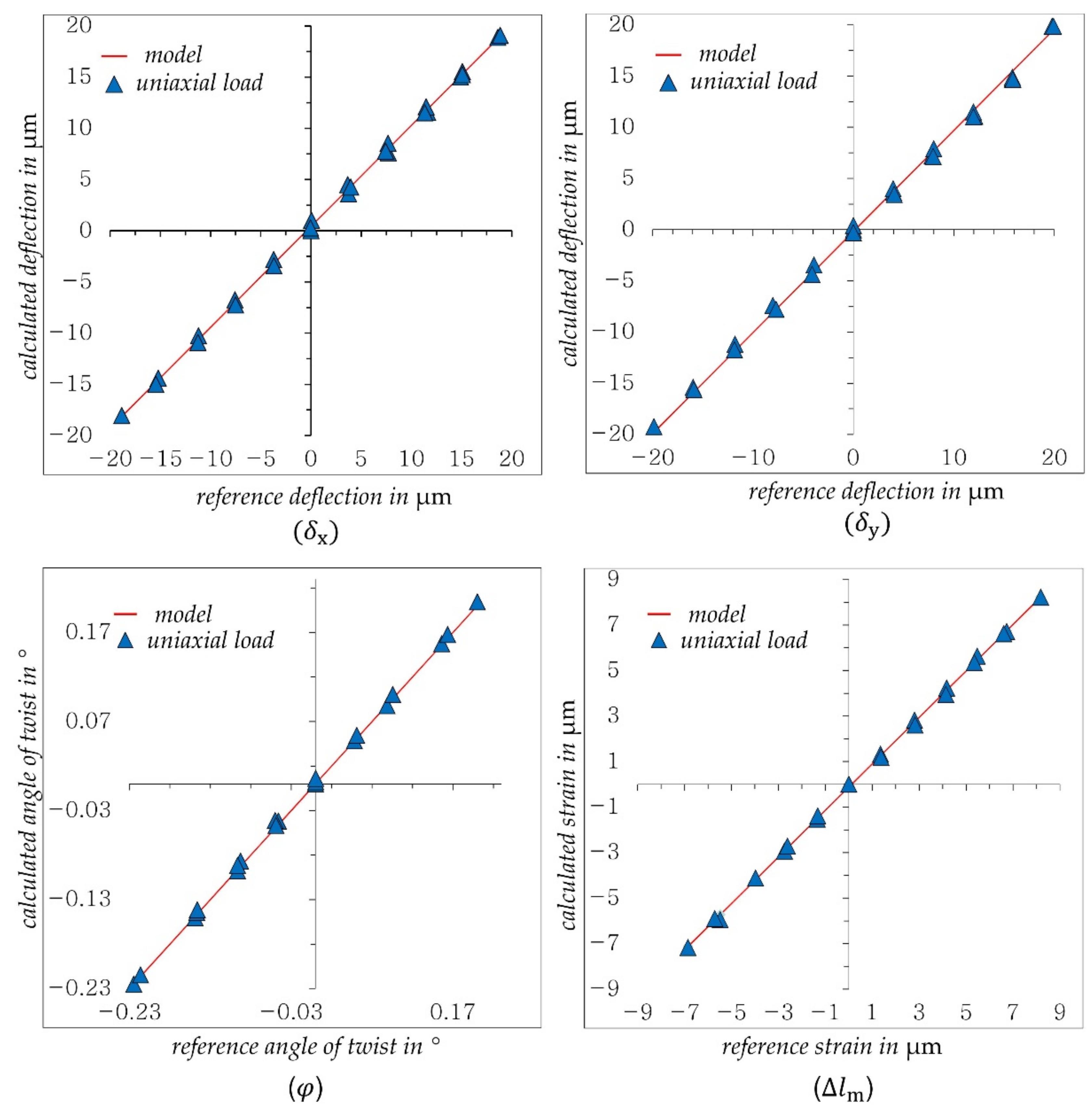

3.2.1. Results of Uniaxial Loading

3.2.2. Determining the Crosstalk Behavior

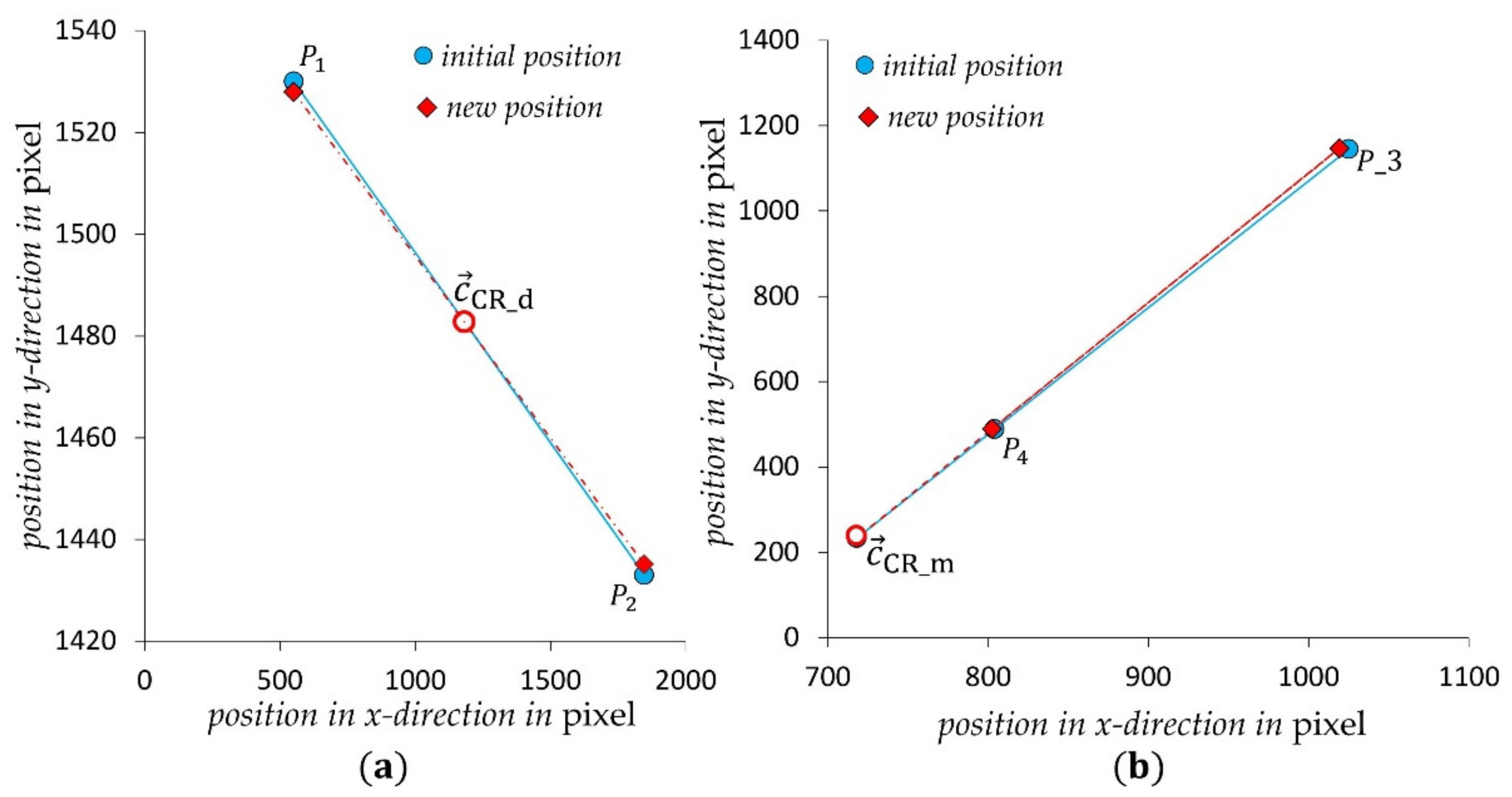

3.2.3. Determining of Centers of Rotation

3.2.4. Results of Multiaxial Loads ( + + )

3.2.5. Results of Multiaxial Loads ()

3.2.6. Sources of the Measurement Errors

4. Conclusion and Outlook

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiong, L.; Jiang, G.; Guo, Y.; Liu, H. A Three-Dimensional Fiber Bragg Grating Force Sensor for Robot. IEEE Sens. J. 2018, 18, 3632–3639. [Google Scholar] [CrossRef]

- Kang, M.-K.; Lee, S.; Kim, J.-H. Shape optimization of a mechanically decoupled six-axis force/torque sensor. Sens. Actuators A Phys. 2014, 209, 41–51. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Ahmad, A.R.; Kebede, G.A. Novel Mechanically Fully Decoupled Six-Axis Force-Moment Sensor. Sensors 2020, 20, 395. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.; Wang, H.; Wang, Y.; Liu, Z. Design of a Novel Six-Axis Wrist Force Sensor. Sensors 2018, 18, 3120. [Google Scholar] [CrossRef]

- Lv, C.; Wang, S.; Shi, C. A High-Precision and Miniature Fiber Bragg Grating-Based Force Sensor for Tissue Palpation During Minimally Invasive Surgery. Ann. Biomed. Eng. 2019, 48, 669–681. [Google Scholar] [CrossRef]

- Hong, D.-H.; Kim, Y.-G.; Kwak, J.-H.; Jeong, C.-P.; An, J. Miniature force-torque sensor using semiconductor strain gage sensor frame design and analysis for development. In Proceedings of the 2012 9th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Daejeon, Korea, 26–28 November 2012; pp. 627–628. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, Y.; Wang, C.; Liang, S.; Cheng, R.; Qin, Y.; Wang, P.; Li, Y.; Li, X.; Hu, T. Design and development of a cutting force sensor based on semi-conductive strain gauge. Sens. Actuators A Phys. 2016, 237, 119–127. [Google Scholar] [CrossRef]

- Lee, D.-H.; Kim, U.; Jung, H.; Choi, H.R. A Capacitive-Type Novel Six-Axis Force/Torque Sensor for Robotic Applications. IEEE Sens. J. 2016, 16, 2290–2299. [Google Scholar] [CrossRef]

- Groche, P.; Türk, M. Smart structures assembly through incremental forming. CIRP Ann. 2011, 60, 21–24. [Google Scholar] [CrossRef]

- Krech, M.; Groche, P. Robust force and torque measurements by integrated sensors in hollow shafts. In Proceedings of the 18th International Conference on Sensors and Measurement Technology (SENSOR 2017), Nürnberg, Germany, 30 May–1 June 2017; pp. 511–515. [Google Scholar] [CrossRef]

- Billeschou, P.; Albertsen, C.; Larsen, J.C.; Manoonpong, P. A Low-Cost, Compact, Sealed, Three-Axis Force/Torque Sensor for Walking Robots. IEEE Sens. J. 2021, 21, 8916–8926. [Google Scholar] [CrossRef]

- Kim, U.; Jeong, H.; Do, H.; Park, J.; Park, C. Six-Axis Force/Torque Fingertip Sensor for an Anthropomorphic Robot Hand. IEEE Robot. Autom. Lett. 2020, 5, 5566–5572. [Google Scholar] [CrossRef]

- Tar, Á.; Cserey, G. Development of a low cost 3D optical compliant tactile force sensor. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Budapest, Hungary, 3–7 July 2011. [Google Scholar] [CrossRef]

- Noh, Y.; Bimbo, J.; Sareh, S.; Wurdemann, H.; Fraś, J.; Chathuranga, D.S.; Liu, H.; Housden, J.; Althoefer, K.; Rhode, K. Multi-Axis Force/Torque Sensor Based on Simply-Supported Beam and Optoelectronics. Sensors 2016, 16, 1936. [Google Scholar] [CrossRef]

- Al-Mai, O.; Ahmadi, M.; Albert, J. A Compliant 3-Axis Fiber-Optic Force Sensor for Biomechanical Measurement. IEEE Sens. J. 2017, 17, 6549–6557. [Google Scholar] [CrossRef]

- Al-Mai, O.; Ahmadi, M.; Albert, J. Design, Development and Calibration of a Lightweight, Compliant Six-Axis Optical Force/Torque Sensor. IEEE Sens. J. 2018, 18, 7005–7014. [Google Scholar] [CrossRef]

- Xie, H.; Jiang, A.; Seneviratne, L.; Althoefer, K. Pixel-based optical fiber tactile force sensor for robot manipulation. In Proceedings of the 2012 IEEE Sensors, Taipei, Taiwan, 28–31 October 2012. [Google Scholar] [CrossRef]

- Díez, J.A.; Catalán, J.M.; Blanco, A.; García-Perez, J.V.; Badesa, F.J.; Gacía-Aracil, N. Customizable Optical Force Sensor for Fast Prototyping and Cost-Effective Applications. Sensors 2018, 18, 493. [Google Scholar] [CrossRef] [PubMed]

- Berkovic, G.; Shafir, E. Optical methods for distance and displacement measurements. Adv. Opt. Photonics 2012, 4, 441–471. [Google Scholar] [CrossRef]

- Sirkis, J.S.; Lim, T.J. Displacement and strain measurement with automated grid methods. Exp. Mech. 1991, 31, 382–388. [Google Scholar] [CrossRef]

- Goldrein, H.; Palmer, S.; Huntley, J. Automated fine grid technique for measurement of large-strain deformation maps. Opt. Lasers Eng. 1995, 23, 305–318. [Google Scholar] [CrossRef]

- Pan, B.; Qian, K.; Xie, H.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas. Sci. Technol. 2009, 20, 062001. [Google Scholar] [CrossRef]

- Sutton, M.A. Digital Image Correlation for Shape and Deformation Measurements. In Springer Handbook of Experimental Solid Mechanics; Sharpe, W., Ed.; Springer Handbooks; Springer: Boston, MA, USA, 2008; pp. 565–600. [Google Scholar] [CrossRef]

- Dong, Y.; Pan, B. A Review of Speckle Pattern Fabrication and Assessment for Digital Image Correlation. Exp. Mech. 2017, 57, 1161–1181. [Google Scholar] [CrossRef]

- Malesa, M.; Szczepanek, D.; Kujawińska, M.; Świercz, A.; Kołakowski, P. Monitoring of civil engineering structures using Digital Image Correlation technique. In Proceedings of the 14th International Conference on Experimental Mechanics, Poitiers, France, 4–9 July 2010. [Google Scholar] [CrossRef]

- Ya’Akobovitz, A.; Krylov, S.; Hanein, Y. Nanoscale displacement measurement of electrostatically actuated micro-devices using optical microscopy and digital image correlation. Sens. Actuators A Phys. 2010, 162, 1–7. [Google Scholar] [CrossRef]

- Berfield, T.A.; Patel, J.K.; Shimmin, R.G.; Braun, P.V.; Lambros, J.; Sottos, N.R. Micro- and Nanoscale Deformation Measurement of Surface and Internal Planes via Digital Image Correlation. Exp. Mech. 2007, 47, 51–62. [Google Scholar] [CrossRef]

- Baizeau, T.; Campocasso, S.; Rossi, F.; Poulachon, G.; Hild, F. Cutting force sensor based on digital image correlation for segmented chip formation analysis. J. Mater. Process. Technol. 2016, 238, 466–473. [Google Scholar] [CrossRef][Green Version]

- Huang, Y.; Liu, L.; Yeung, T.; Hung, Y. Real-time monitoring of clamping force of a bolted joint by use of automatic digital image correlation. Opt. Laser Technol. 2009, 41, 408–414. [Google Scholar] [CrossRef]

- Reu, P. All about speckles: Aliasing. Exp. Tech. 2014, 38, 1–3. [Google Scholar] [CrossRef]

- Yaofeng, S.; Pang, J.H. Study of optimal subset size in digital image correlation of speckle pattern images. Opt. Lasers Eng. 2007, 45, 967–974. [Google Scholar] [CrossRef]

- Bing, P.; Hui-Min, X.; Bo-Qin, X.; Fu-Long, D. Performance of sub-pixel registration algorithms in digital image correlation. Meas. Sci. Technol. 2006, 17, 1615–1621. [Google Scholar] [CrossRef]

- Yang, F.; He, X.; Quan, C. Characterization of dynamic microgyroscopes by use of temporal digital image correlation. Appl. Opt. 2006, 45, 7785–7790. [Google Scholar] [CrossRef]

- Kokorian, J.; Buja, F.; Van Spengen, W.M. In-Plane Displacement Detection With Picometer Accuracy on a Conventional Microscope. J. Microelectromech. Syst. 2015, 24, 618–625. [Google Scholar] [CrossRef]

- Luo, P.F.; Chao, Y.J.; Sutton, M.A.; Peters, W.H. Accurate measurement of three-dimensional deformations in deformable and rigid bodies using computer vision. Exp. Mech. 1993, 33, 123–132. [Google Scholar] [CrossRef]

- Pan, B.; Yu, L.P.; Zhang, Q.B. Review of single-camera stereo-digital image correlation techniques for full-field 3D shape and deformation measurement. Sci. China Technol. Sci. 2018, 61, 2–20. [Google Scholar] [CrossRef]

- Pan, B.; Wu, D.; Xia, Y. An active imaging digital image correlation method for deformation measurement insensitive to ambient light. Opt. Laser Technol. 2012, 44, 204–209. [Google Scholar] [CrossRef]

- Schwankl, M.; Rubner, M.F.; Singer, R.; Korner, C. Integration of PZT-Ceramic Modules using Hybrid Structures in High Pressure Die Casting. Procedia Mater. Sci. 2013, 2, 166–172. [Google Scholar] [CrossRef][Green Version]

- Stein, S.; Wedler, J.; Rhein, S.; Schmidt, M.; Körner, C.; Michaelis, A.; Gebhardt, S. A process chain for integrating piezoelectric transducers into aluminum die castings to generate smart lightweight structures. Results Phys. 2017, 7, 2534–2539. [Google Scholar] [CrossRef]

- Lee, C.; Tarbutton, J.A. Electric poling-assisted additive manufacturing process for PVDF polymer-based piezoelectric device applications. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Stoffregen, H.; Fischer, J.; Flaschenträger, D.; Rauschenbach, M.; Nuffer, J.; Melz, T.; Abele, E. Additive Manufacturing of Adaptive Components by Selective Laser Melting. In Proceedings of the Adaptronic Congress, Darmstadt, Germany, 7–8 September 2011; pp. 82–89. [Google Scholar]

- Al-Baradoni, N.; Krech, M.; Groche, P. In-process calibration of smart structures produced by incremental forming. Prod. Eng. 2021, 15, 79–87. [Google Scholar] [CrossRef]

- Groche, P.; Krech, M. Efficient production of sensory machine elements by a two-stage rotary swaging process—Relevant phenomena and numerical modelling. J. Mater. Process. Technol. 2017, 242, 205–217. [Google Scholar] [CrossRef]

- Krech, M.; Trunk, A.; Groche, P. Controlling the sensor properties of smart structures produced by metal forming. J. Mater. Process. Technol. 2018, 262, 541–550. [Google Scholar] [CrossRef]

- Groche, P.; Wohletz, S.; Mann, A.; Krech, M.; Monnerjahn, V. Conjoint forming—Technologies for simultaneous forming and joining. IOP Conf. Ser. Mater. Sci. Eng. 2016, 119, 012025. [Google Scholar] [CrossRef]

- Groche, P.; Brenneis, M. Manufacturing and use of novel sensoric fasteners for monitoring forming processes. Meas. J. Int. Meas. Confed. 2014, 53, 136–144. [Google Scholar] [CrossRef]

- Niessen, B.; Siegel, M.; Groche, P. Investigations on Shock Waves during Collision Welding. In Proceedings of the 8th International Conference on High Speed Forming (ICHSF 2018), Columbus, OH, USA, 14–15 May 2018. [Google Scholar] [CrossRef]

- Platz, R.; Ondoua, S.; Habermehl, K.; Bedarff, T.; Hauer, T.; Schmitt, S.; Hanselka, H. Approach to validate the influences of uncertainties in manufacturing on using load-carrying structures. In Proceedings of the International Conference on Noise and Vibration Engineering (ISMA 2010), Including USD 2010, Leuven, Belgium, 20–22 September 2010; pp. 5319–5333. [Google Scholar]

- Giachetti, A. Matching techniques to compute image motion. Image Vis. Comput. 2000, 18, 247–260. [Google Scholar] [CrossRef]

- Simončič, S.; Kompolšek, M.; Podržaj, P. An advanced coarse-fine search approach for digital image correlation applications. Facta Univ. Series Mech. Eng. 2016, 14, 63–73. [Google Scholar] [CrossRef][Green Version]

| Direct Image Segment | Mirrored Image Segment | |||||||

|---|---|---|---|---|---|---|---|---|

| x | y | x | y | x | y | x | y | |

| initial positions | 552 | 1530 | 1847 | 1433 | 804 | 489 | 1025 | 1145 |

| linear equations | y = −0.0749 x + 1571.3 | y = 2.9683 x − 1897.5 | ||||||

| calculated displacement | 0.32 | −2.12 | −1.8 | 2.2 | −1.66 | 0.55 | −5.9 | 1.97 |

| new position | 554.22 | 1533.47 | 1432.59 | 1852.91 | 802.34 | 488.45 | 1019.1 | 1146.97 |

| linear equations | y = −0.0716 x + 1567.4 | y = 3.0331 x − 1944.1 | ||||||

| intersection points | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Baradoni, N.; Groche, P. Sensor Integrated Load-Bearing Structures: Measuring Axis Extension with DIC-Based Transducers. Sensors 2021, 21, 4104. https://doi.org/10.3390/s21124104

Al-Baradoni N, Groche P. Sensor Integrated Load-Bearing Structures: Measuring Axis Extension with DIC-Based Transducers. Sensors. 2021; 21(12):4104. https://doi.org/10.3390/s21124104

Chicago/Turabian StyleAl-Baradoni, Nassr, and Peter Groche. 2021. "Sensor Integrated Load-Bearing Structures: Measuring Axis Extension with DIC-Based Transducers" Sensors 21, no. 12: 4104. https://doi.org/10.3390/s21124104

APA StyleAl-Baradoni, N., & Groche, P. (2021). Sensor Integrated Load-Bearing Structures: Measuring Axis Extension with DIC-Based Transducers. Sensors, 21(12), 4104. https://doi.org/10.3390/s21124104