Monitoring Strain Response of Epoxy Resin during Curing and Cooling Using an Embedded Strain Gauge

Abstract

1. Introduction

2. Materials and Methods

2.1. Cryogenic-Grade Epoxy Resin

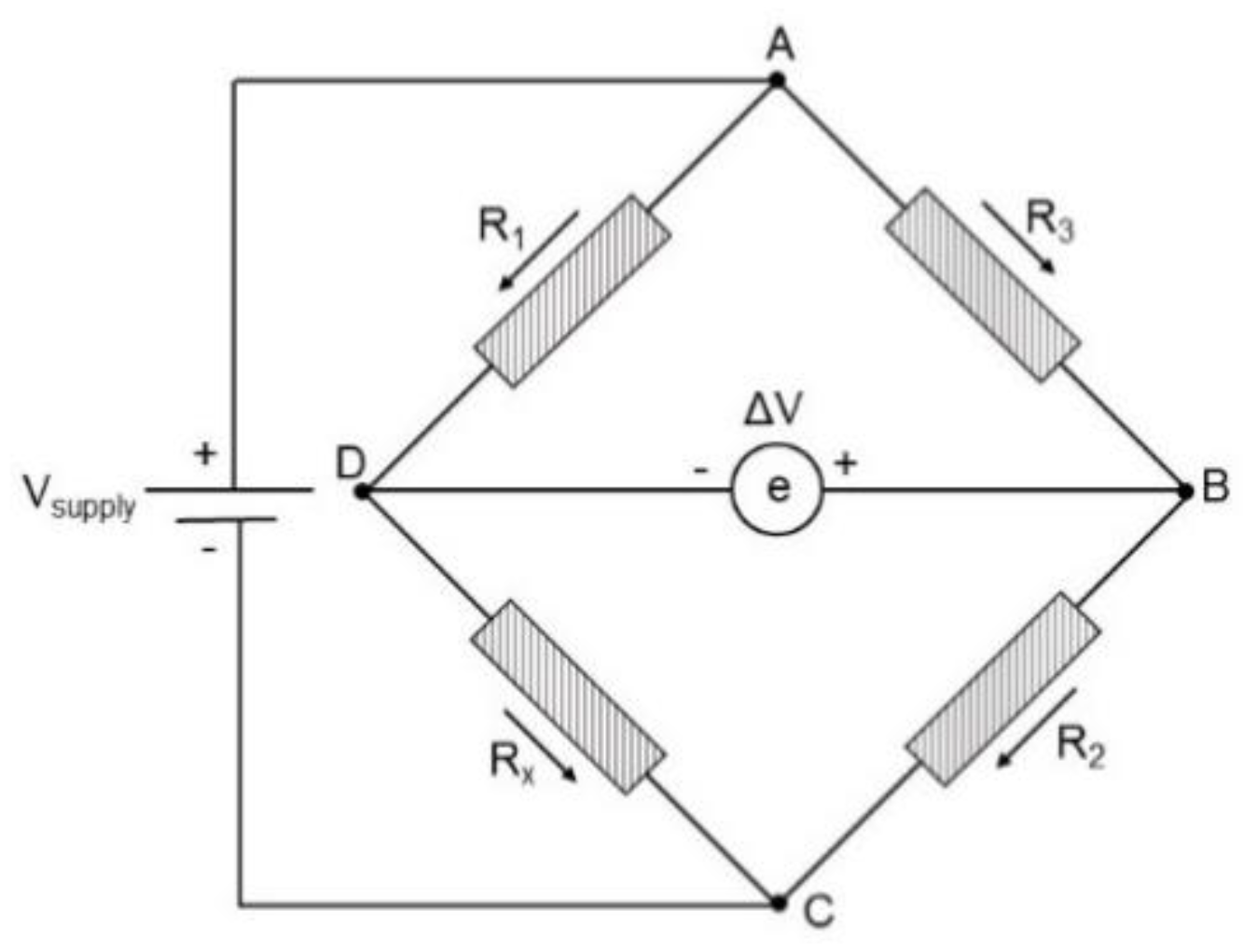

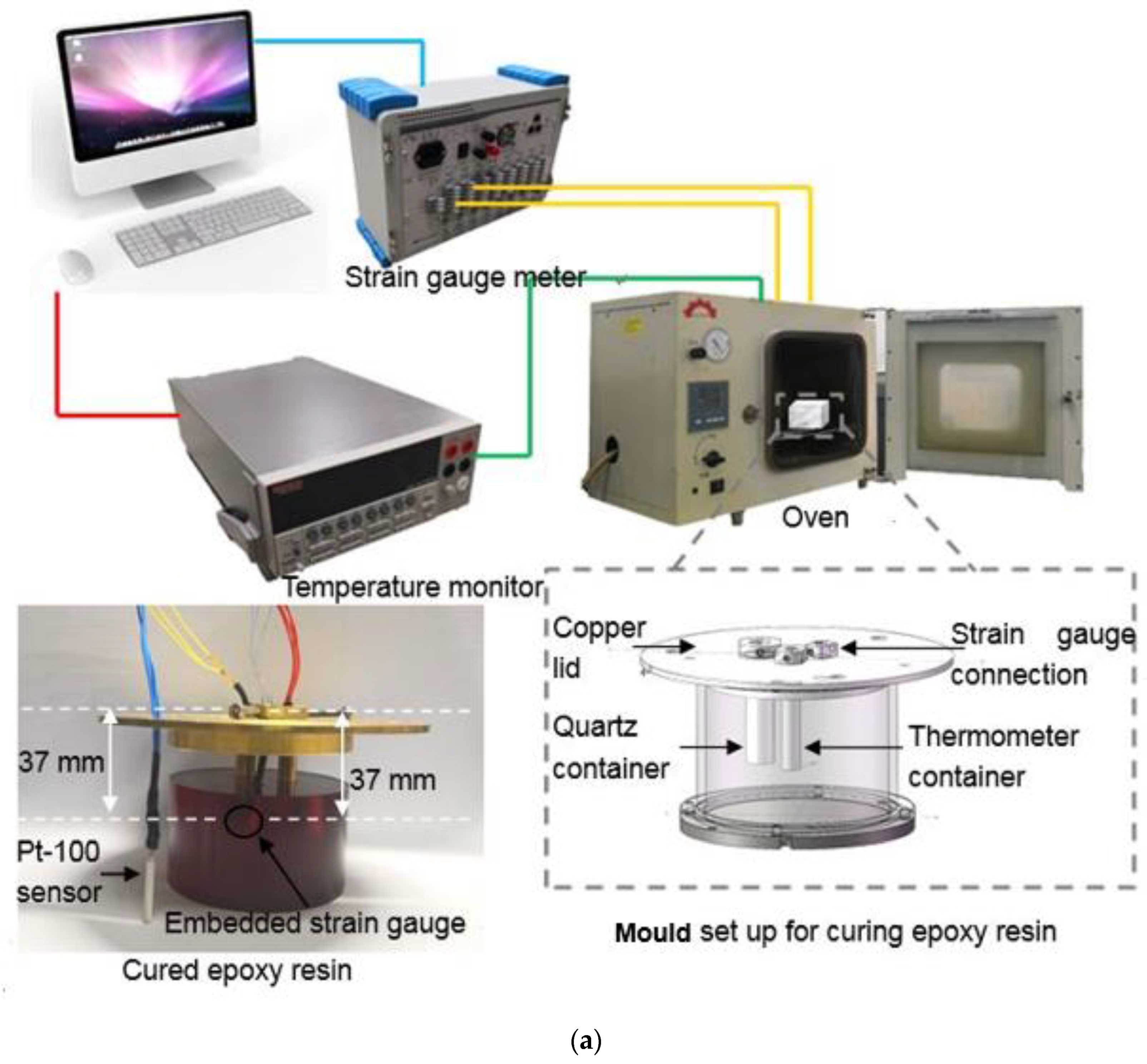

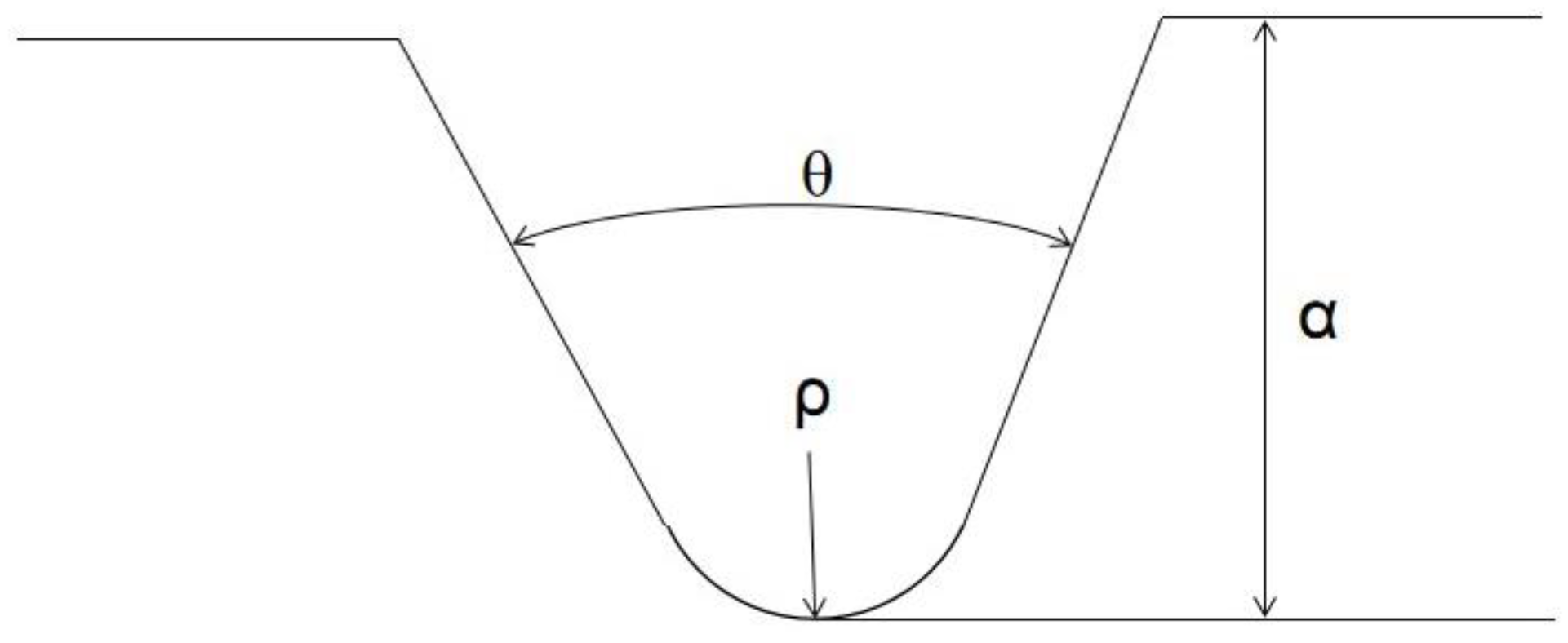

2.2. Cryogenic-Grade Strain Gauge

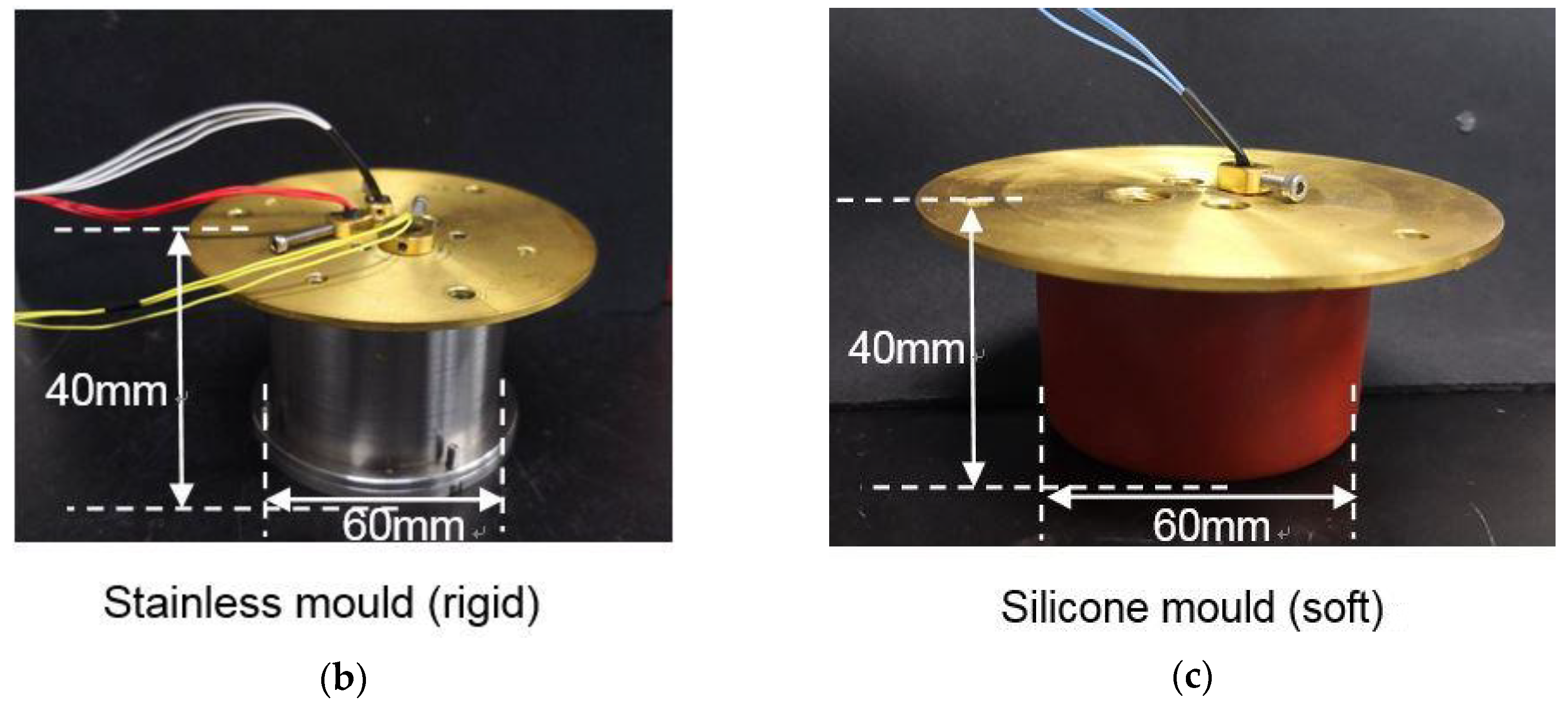

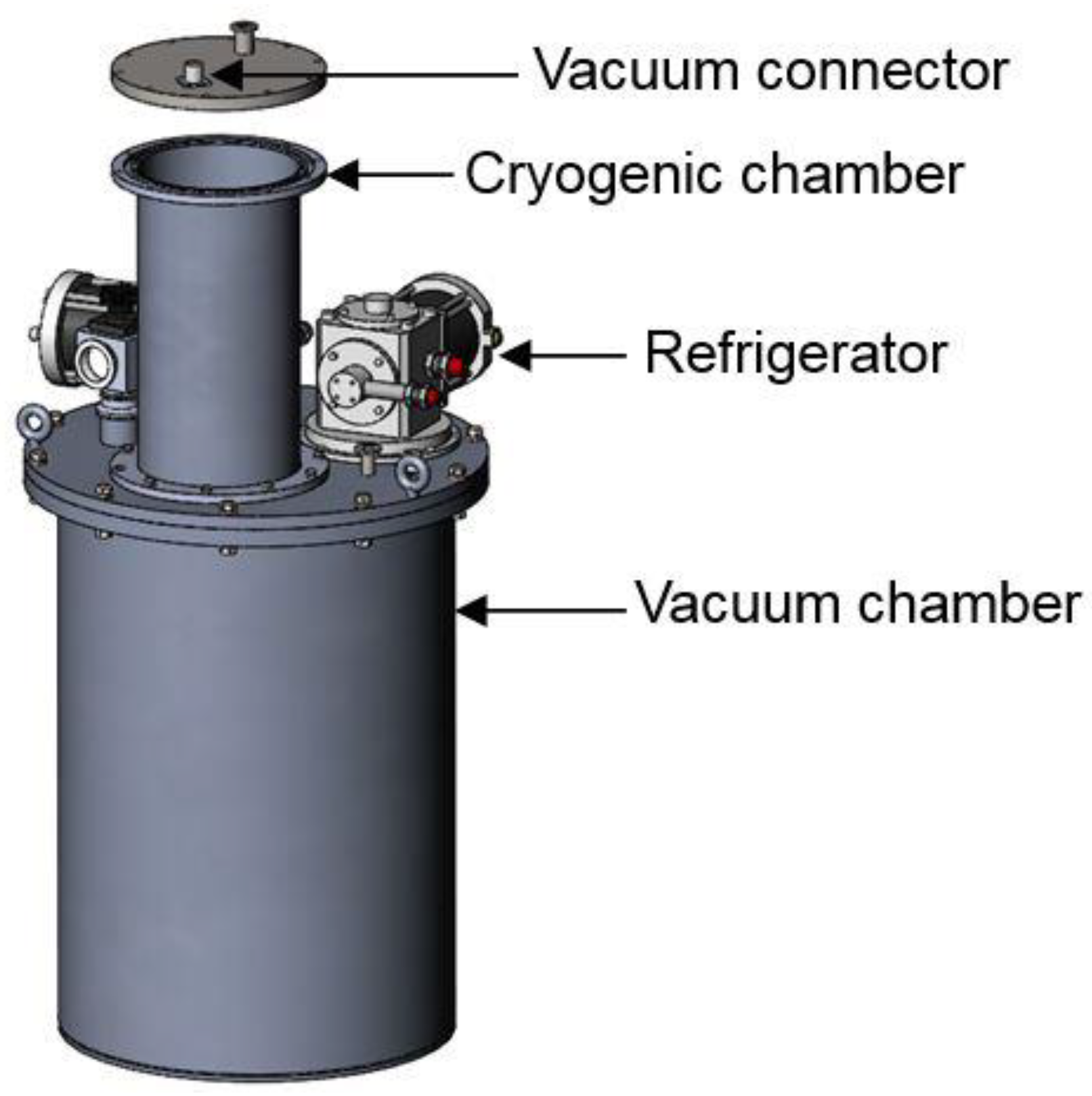

2.3. Experimental Method

3. Results and Discussion

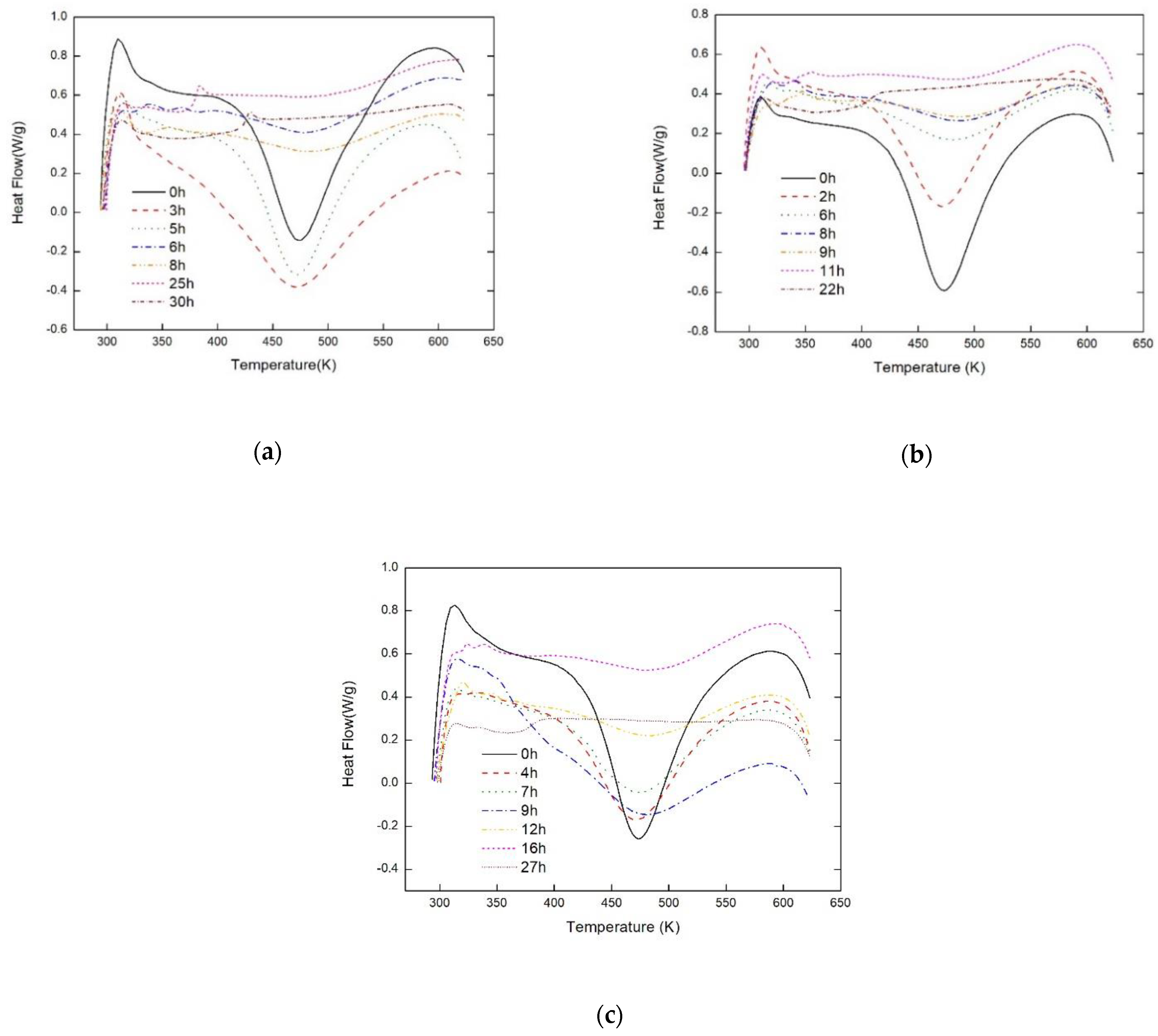

3.1. DSC Curve and Strain Response of Epoxy Resin during Curing Process

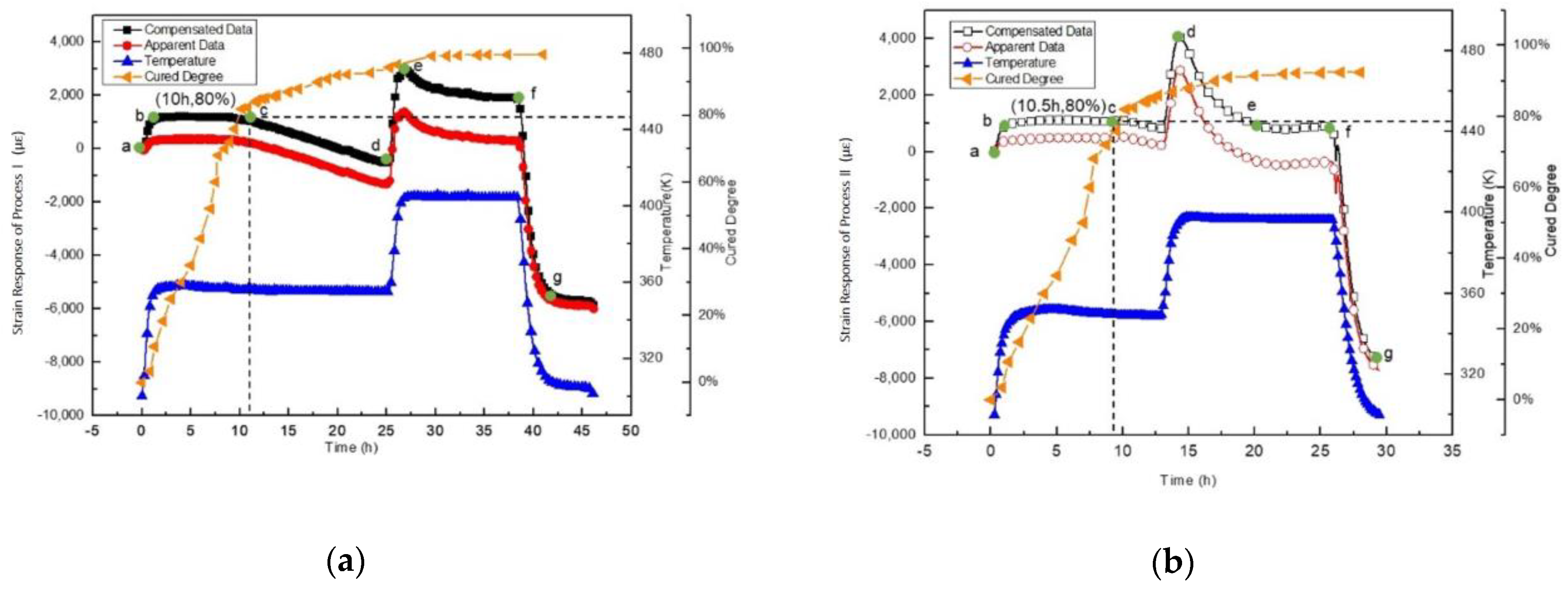

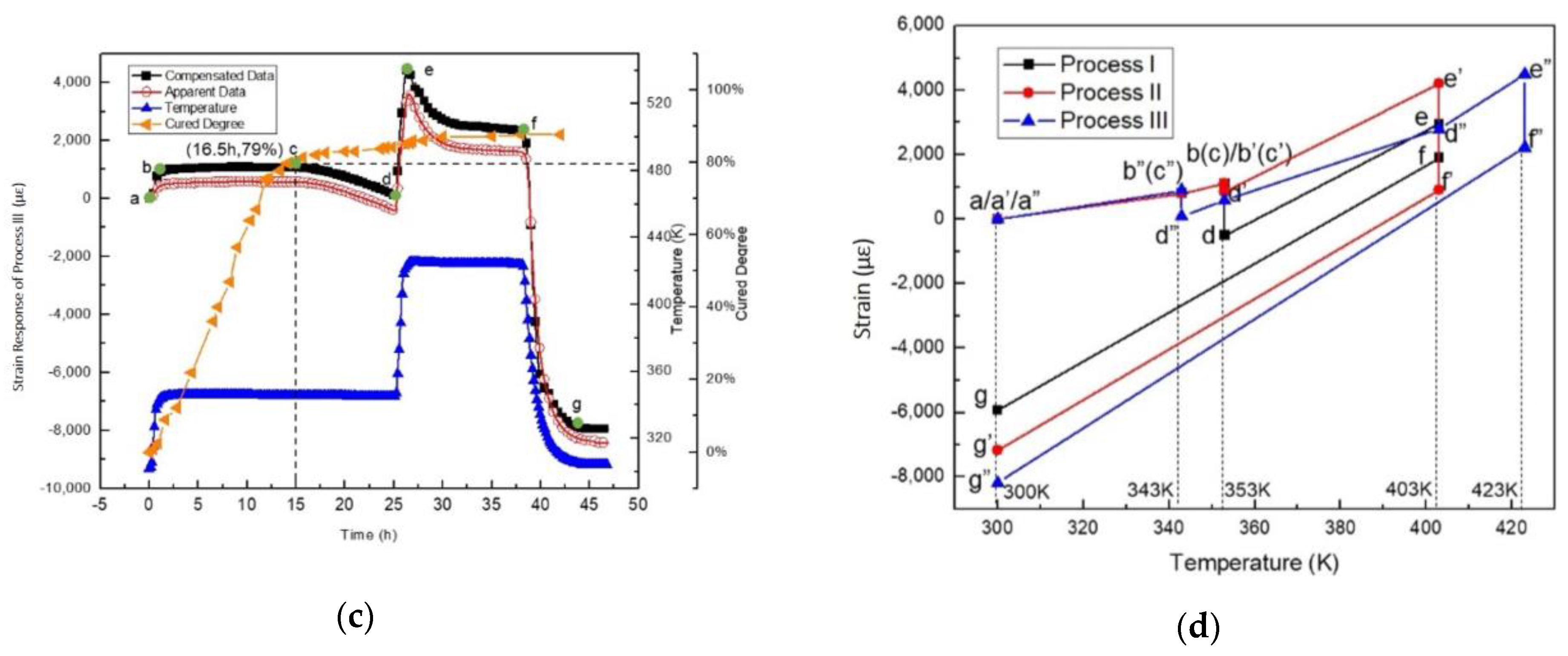

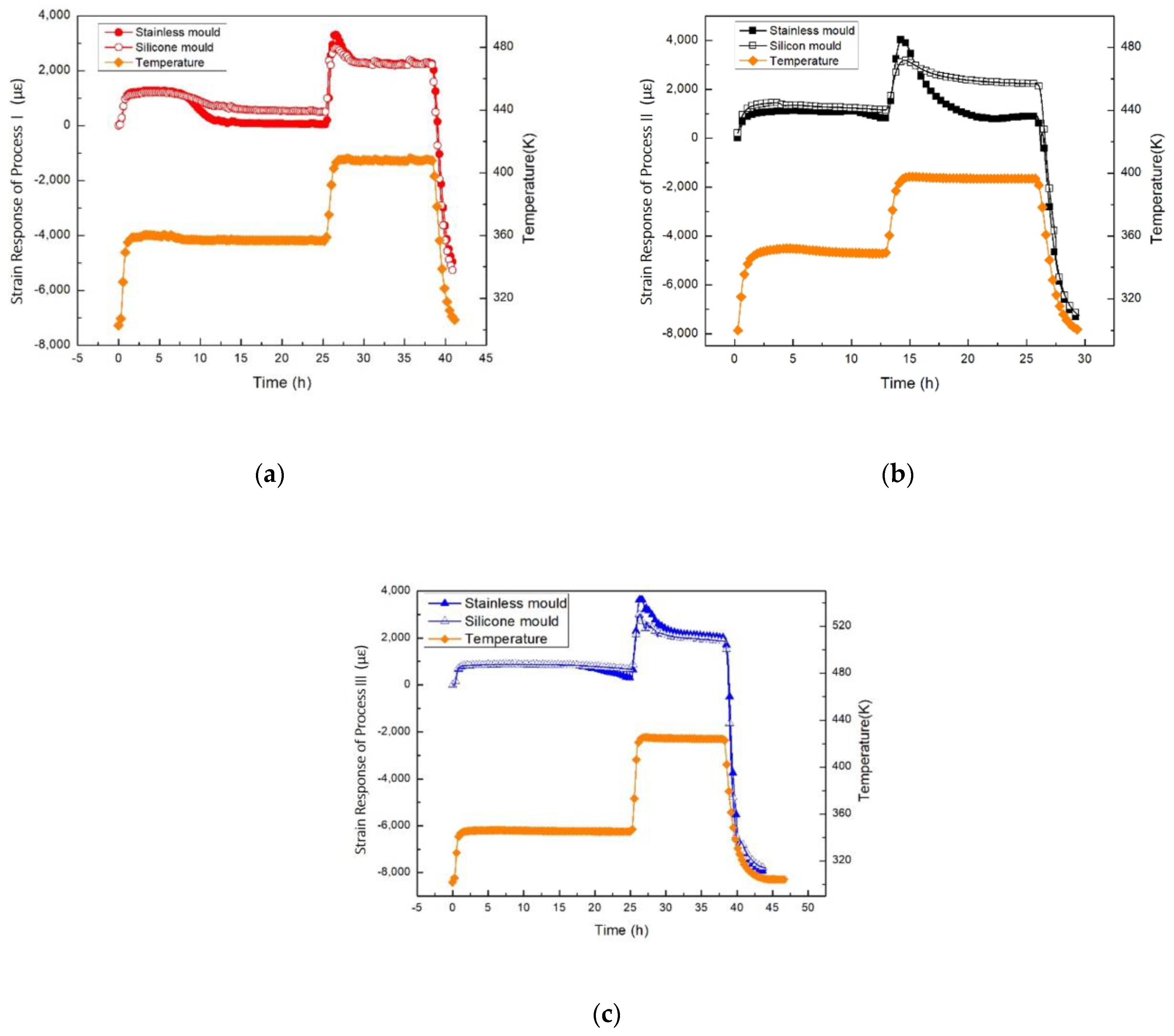

3.2. Strain Response of the Epoxy Resin Curing with Different Boundary Conditions

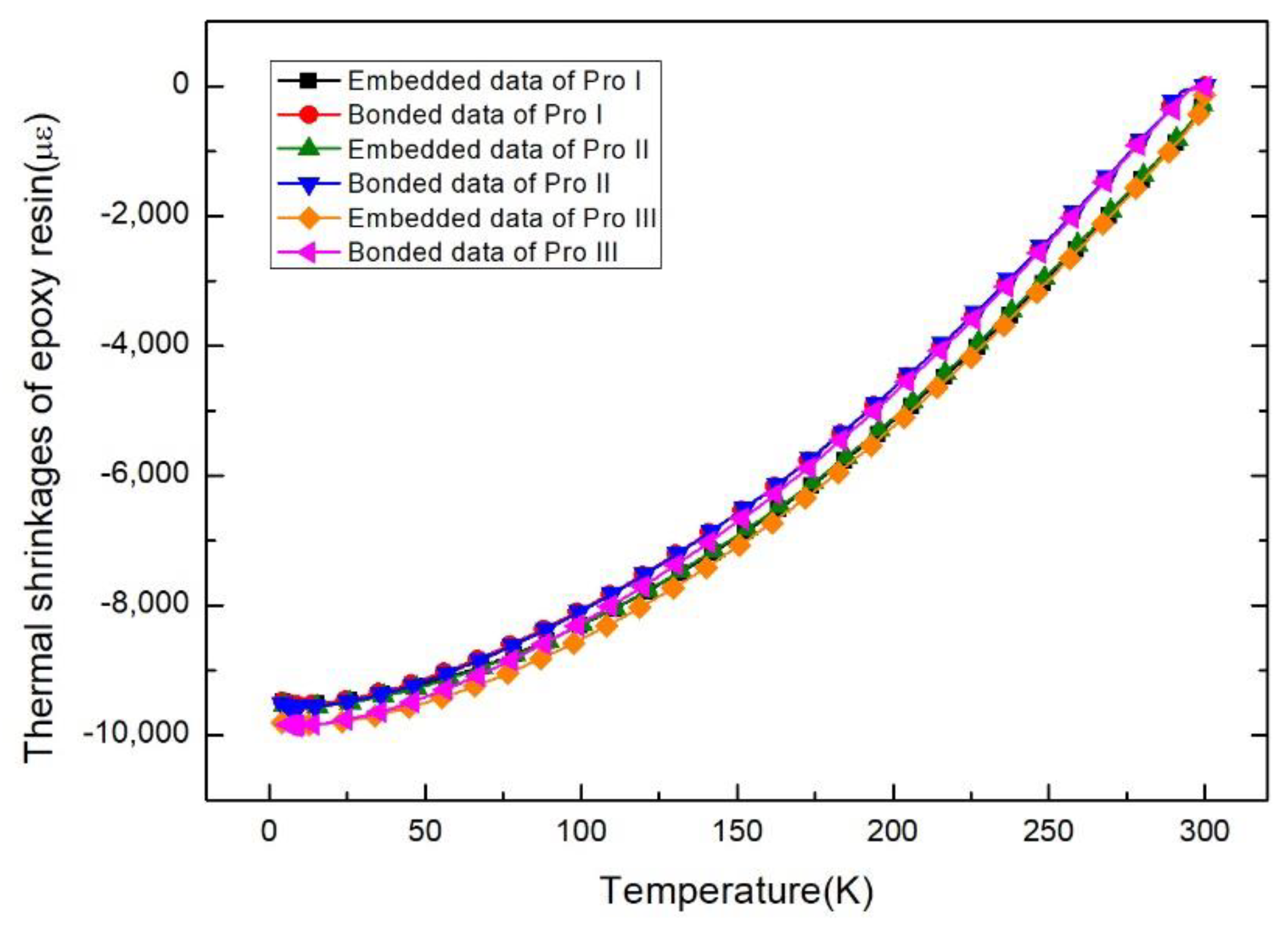

3.3. Strain Response of Epoxy Resin during Cooling down Process

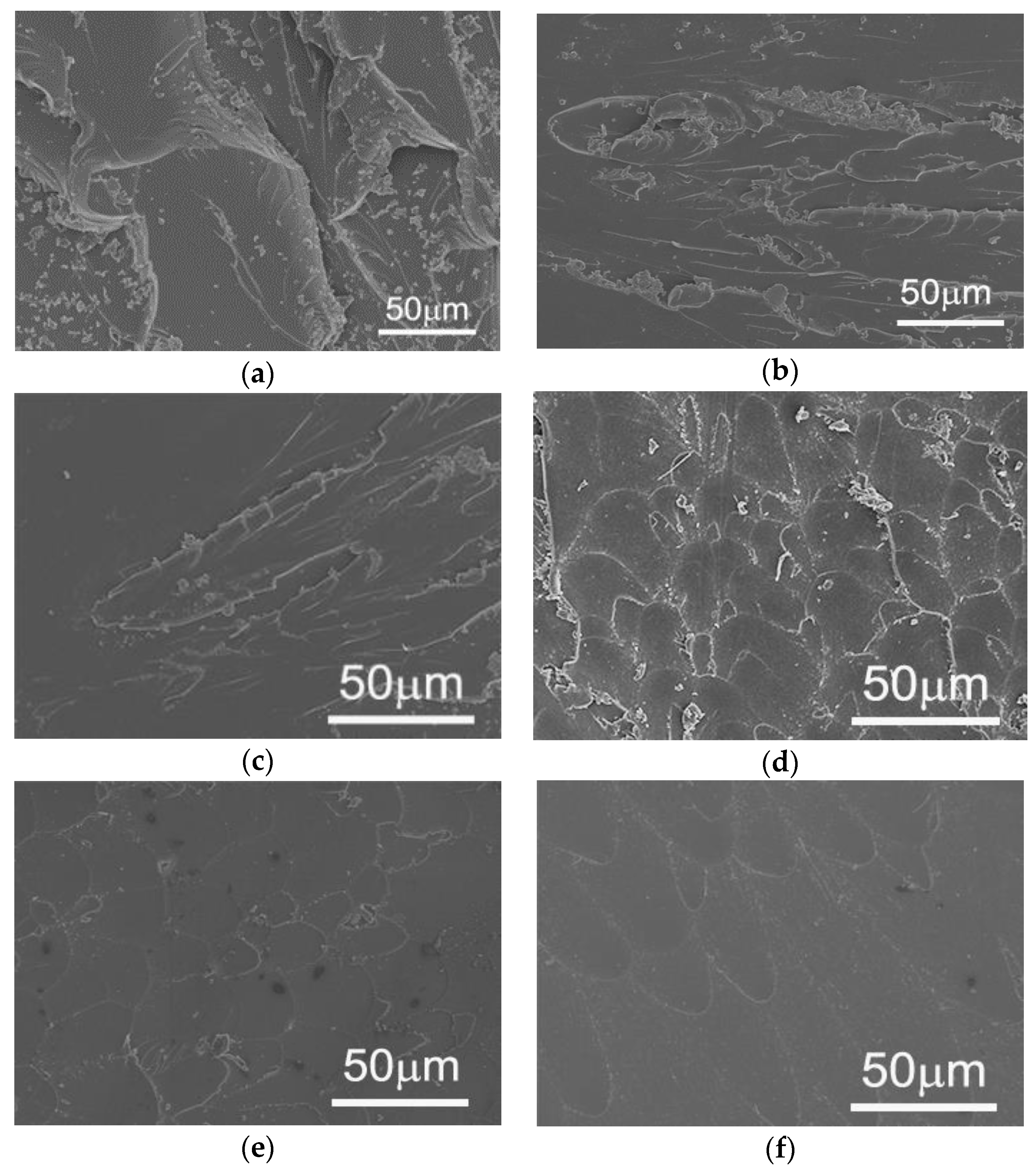

3.4. Mechanical Property and Fracture Morphologies of Epoxy Resin Curing with Different Process

3.5. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Attin, T.; Buchalla, W.; Kielbassa, A.M.; Helwig, E. Curing shrinkage and volumetric changes of resin--modified glass ionomer restorative materials. Dent. Mater. 1995, 11, 359–362. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Thrusabanjong, E.; Williams, J.G. Fracture at bimaterial interfaces: The role of residual stresses. J. Mater. Sci. 1991, 26, 6260–6270. [Google Scholar] [CrossRef]

- Pärnänen, T.; Alderliesten, R.C.; Rans, C.; Brander, T.; Saarela, O. Applicability of AZ31B--H24 magnesium in Fibre Metal Laminates—An experimental impact research. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1578–1586. [Google Scholar] [CrossRef]

- Talagani, M.R.; Dormohammadi, S.; Dutton, R.; Godines, C.; Baid, H.; Abdi, F.; Kunc, V.; Compton, B.; Simunovic, S.; Duty, C.; et al. Numerical simulation of big area additive manufacturing (3D printing) of a full size car. SAMPE J. 2015, 51, 27–36. [Google Scholar]

- Shah, D.U.; Schubel, P.J. Evaluation of cure shrinkage measurement techniques for thermosetting resins. Polym. Test. 2010, 29, 629–639. [Google Scholar] [CrossRef]

- Hill, R.R.; Muzumdar, S.V.; Lee, L.J. Analysis of volumetric changes of unsaturated polyester resins during curing. Polym. Eng. Sci. 1995, 35, 852–859. [Google Scholar] [CrossRef]

- Khoun, L.; Hubert, P. Cure shrinkage characterization of an epoxy resin system by two in situ measurement methods. Polym. Compos. 2010, 31, 1603–1610. [Google Scholar] [CrossRef]

- Holst, M.; Schänzlin, K.; Wenzel, M.; Xu, J.; Lellinger, D.; Alig, I. Time--resolved method for the measurement of volume changes during polymerization. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 2314–2325. [Google Scholar] [CrossRef]

- Yu, H.; Mhaisalkar, S.G.; Wong, E.H. Cure shrinkage measurement of nonconductive adhesives by means of a thermomechanical analyzer. J. Electron. Mater. 2005, 34, 1177–1182. [Google Scholar] [CrossRef]

- Ventura, G.; Perfetti, M. Thermal Properties of Solids at Room and Cryogenic Temperatures; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar]

- Kanagaraj, S.; Pattanayak, S. Measurement of the thermal expansion of metal and FRPs. Cryogenics 2003, 43, 399–424. [Google Scholar] [CrossRef]

- Yang, C.G.; Xu, L.; Chen, N. Thermal expansion of polyurethane foam at low temperature. Energy Conv. Manag. 2007, 48, 481–485. [Google Scholar] [CrossRef]

- Bing, P.; Hui-min, X.; Tao, H.; Asundi, A. Measurement of coefficient of thermal expansion of films using digital image correlation method. Polym. Test. 2009, 28, 75–83. [Google Scholar] [CrossRef]

- Ackerman, D.; Anderson, A. Dilatometry at low temperatures. Rev. Sci. Instrum. 1982, 53, 1657–1660. [Google Scholar] [CrossRef]

- Barron, T.; White, G. Heat Capacity and Thermal Expansion at Low Temperatures; Springer: Boston, MA, USA, 1999. [Google Scholar]

- Ekin, J.; Zimmerman, G. Experimental Techniques for Low--Temperature Measurements: Cryostat Design, Material Properties, and Superconductor Critical--Current Testing. Phys. Today 2007, 60, 67. [Google Scholar]

- Chung, D. Thermal analysis of carbon fiber polymer--matrix composites by electrical resistance measurement. Thermochim. Acta 2000, 364, 121–132. [Google Scholar] [CrossRef]

- Wang, X.; Chung, D. Residual stress in carbon fiber embedded in epoxy, studied by simultaneous measurement of applied stress and electrical resistance. Compos. Interfaces 1997, 5, 277–281. [Google Scholar] [CrossRef]

- Chung, D. Fibrous Composite Interfaces Studied by Electrical Resistance Measurement. Adv. Eng. Mater. 2000, 2, 788–796. [Google Scholar] [CrossRef]

- Wang, X.; Chung, D. Piezoresistive Behavior of Carbon Fiber in Epoxy. Carbon 1997, 35, 1649–1651. [Google Scholar] [CrossRef]

- Tzounis, L.; Liebscher, M.; Petinakis, E.; Paipetis, A.; Mäder, E.; Stamm, M. CNT-grafted glass fibers as a smart tool for the epoxy cure monitoring, UV-sensing and thermal energy harvesting in model composites. RSC Adv. 2016, 6, 55514–55525. [Google Scholar] [CrossRef]

- Rodríguez-Uicab, O.; Abot, J.; Avilés, F. Electrical Resistance Sensing of Epoxy Curing Using an Embedded Carbon Nanotube Yarn. Sensors 2020, 20, 3230. [Google Scholar] [CrossRef]

- Huang, Y.; Young, R.J. Interfacial behaviour in high temperature cured carbon fibre/epoxy resin model composite. Compos 1995, 26, 541–550. [Google Scholar] [CrossRef]

- Epelle, O.B. Measurement of strains in plain and perforated epoxy models by means of embedded strain gauges. Strain 1975, 11, 17–22. [Google Scholar] [CrossRef]

- Hillery, M.T.; Griffin, S. An embedded-strain-gauge technique of stress analysis in rod drawing. J. Mater. Process. Technol. 1994, 47, 1–12. [Google Scholar] [CrossRef]

- Schnack, E.; Prinz, B.; Dimitrov, S. Interlaminar Stress Determination in Carbon Fibre Epoxy Composites with the Embedded Strain Gauge Technique. Strain 2004, 40, 113–118. [Google Scholar] [CrossRef]

- Kanerva, M.; Antunes, P.; Sarlin, E.; Orell, O.; Jokinen, J.; Wallin, M.; Brander, T.; Vuorinen, J. Direct measurement of residual strains in CFRP-tungsten hybrids using embedded strain gauges. Mater. Des. 2017, 127, 352–363. [Google Scholar] [CrossRef]

- ISO. ISO 8130–6:1992: Coating Powders, Part 6: Determination of Gel Time of Thermosetting Coating Powders at a Given Temperature; ISO: Geneva, Switzerland, 1992. [Google Scholar]

- Schweinsberg, D.P.; George, G. A chemiluminescence study of the properties and degradation of epoxy resins as coatings. Corrosion Sci. 1986, 26, 331–340. [Google Scholar] [CrossRef]

- Tung, C.Y.; Dynes, P. Relationship between viscoelastic properties and gelation in thermosetting systems. J. Appl. Polym. Sci. 1982, 27, 569–574. [Google Scholar] [CrossRef]

- ASTM. ASTM D 4217–02: Standard Test Method for Gel Time of Thermosetting Coating Powder; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ASTM. ASTM A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- George, G.A.; Cole-Clarke, P.; St John, N.; Friend, G. Real-time monitoring of the cure reaction of a TGDDM/DDS epoxy resin using fiber optic FT-IR. J. Appl. Polym. Sci 1991, 42, 643–657. [Google Scholar] [CrossRef]

- Gupta, S.; Fan, G.; Loh, K.J. Noninvasive Monitoring of Epoxy Curing. IEEE Sens. Lett. 2017, 1, 1–4. [Google Scholar] [CrossRef]

| Curing Process | Cured Percentage/% | Residual Strain/με |

|---|---|---|

| Pro. I: 353 K/24 h + 403 K/12 h | 98.25 | 5945 |

| Pro. II: 353 K/12 h + 403 K/12 h | 92.44 | 17,169 |

| Pro. III: 343 K/24 h + 423 K/12 h | 87.65 | 8183 |

| Curing Process | Impact Strength at RT kJ/m2 | Impact Strength at 77 K kJ/m2 |

|---|---|---|

| Pro. I | 31.0 ± 2.3 | 15.4 ± 1.6 |

| Pro. II | 20.1 ± 1.6 | 11.8 ± 1.1 |

| Pro. III | 19.7 ± 2.4 | 11.5 ± 1.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, H.; Liu, H.; Nishimura, A.; Wu, Z.; Zhang, H.; Han, Y.; Wang, T.; Wang, Y.; Huang, C.; Li, L. Monitoring Strain Response of Epoxy Resin during Curing and Cooling Using an Embedded Strain Gauge. Sensors 2021, 21, 172. https://doi.org/10.3390/s21010172

Dong H, Liu H, Nishimura A, Wu Z, Zhang H, Han Y, Wang T, Wang Y, Huang C, Li L. Monitoring Strain Response of Epoxy Resin during Curing and Cooling Using an Embedded Strain Gauge. Sensors. 2021; 21(1):172. https://doi.org/10.3390/s21010172

Chicago/Turabian StyleDong, Hongyu, Huiming Liu, Arata Nishimura, Zhixiong Wu, Hengcheng Zhang, Yemao Han, Tao Wang, Yongguang Wang, Chuanjun Huang, and Laifeng Li. 2021. "Monitoring Strain Response of Epoxy Resin during Curing and Cooling Using an Embedded Strain Gauge" Sensors 21, no. 1: 172. https://doi.org/10.3390/s21010172

APA StyleDong, H., Liu, H., Nishimura, A., Wu, Z., Zhang, H., Han, Y., Wang, T., Wang, Y., Huang, C., & Li, L. (2021). Monitoring Strain Response of Epoxy Resin during Curing and Cooling Using an Embedded Strain Gauge. Sensors, 21(1), 172. https://doi.org/10.3390/s21010172