Thin Film Protected Flexible Nanoparticle Strain Sensors: Experiments and Modeling

Abstract

1. Introduction

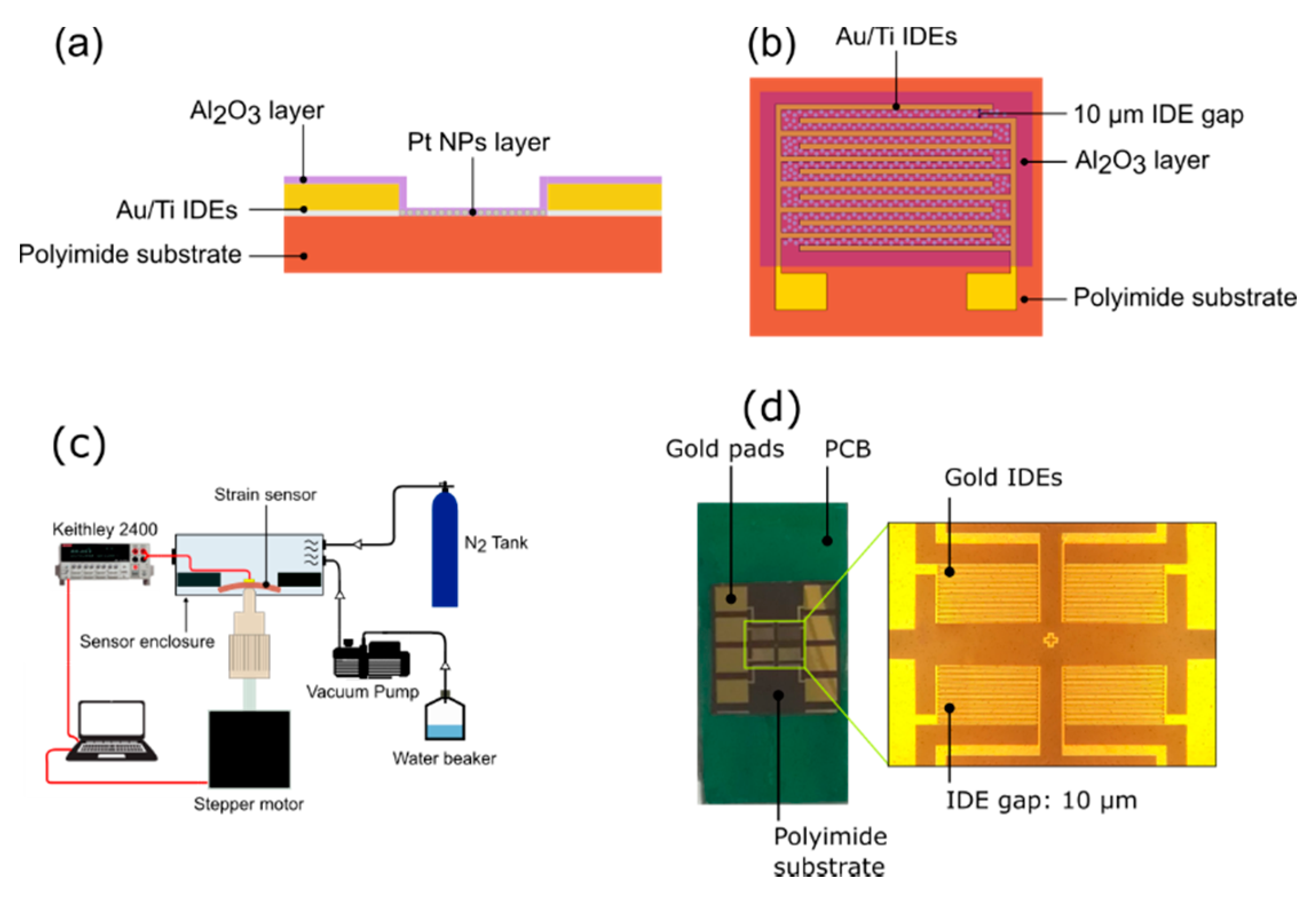

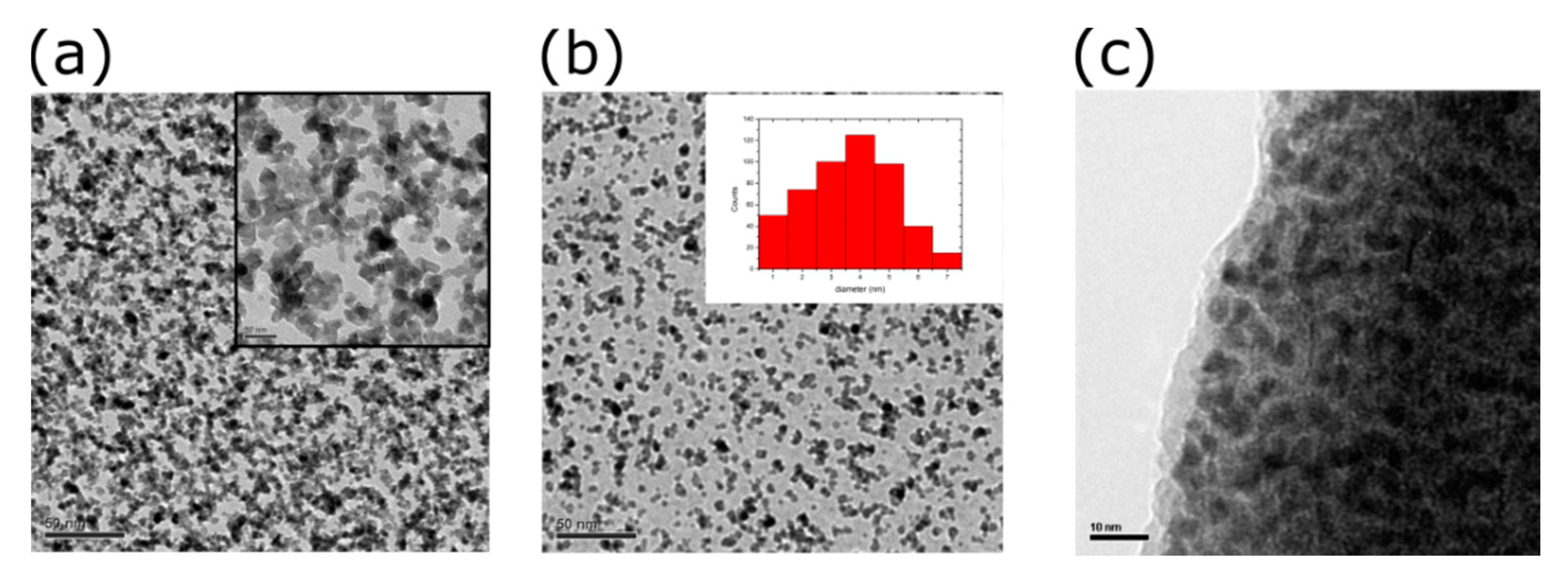

2. Materials and Methods

3. Results and Discussion

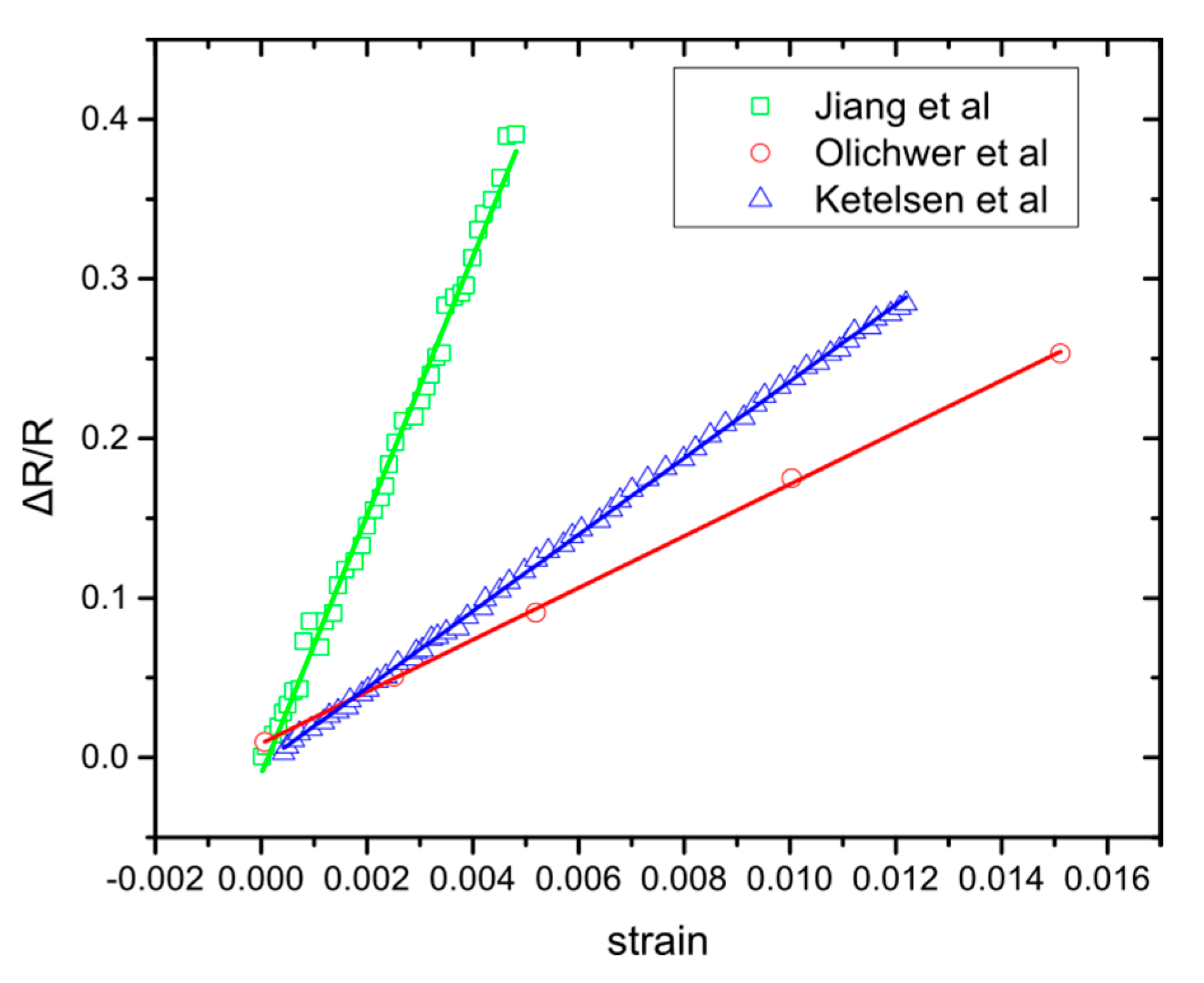

3.1. Sensor Response Using Cross-Linked NPs

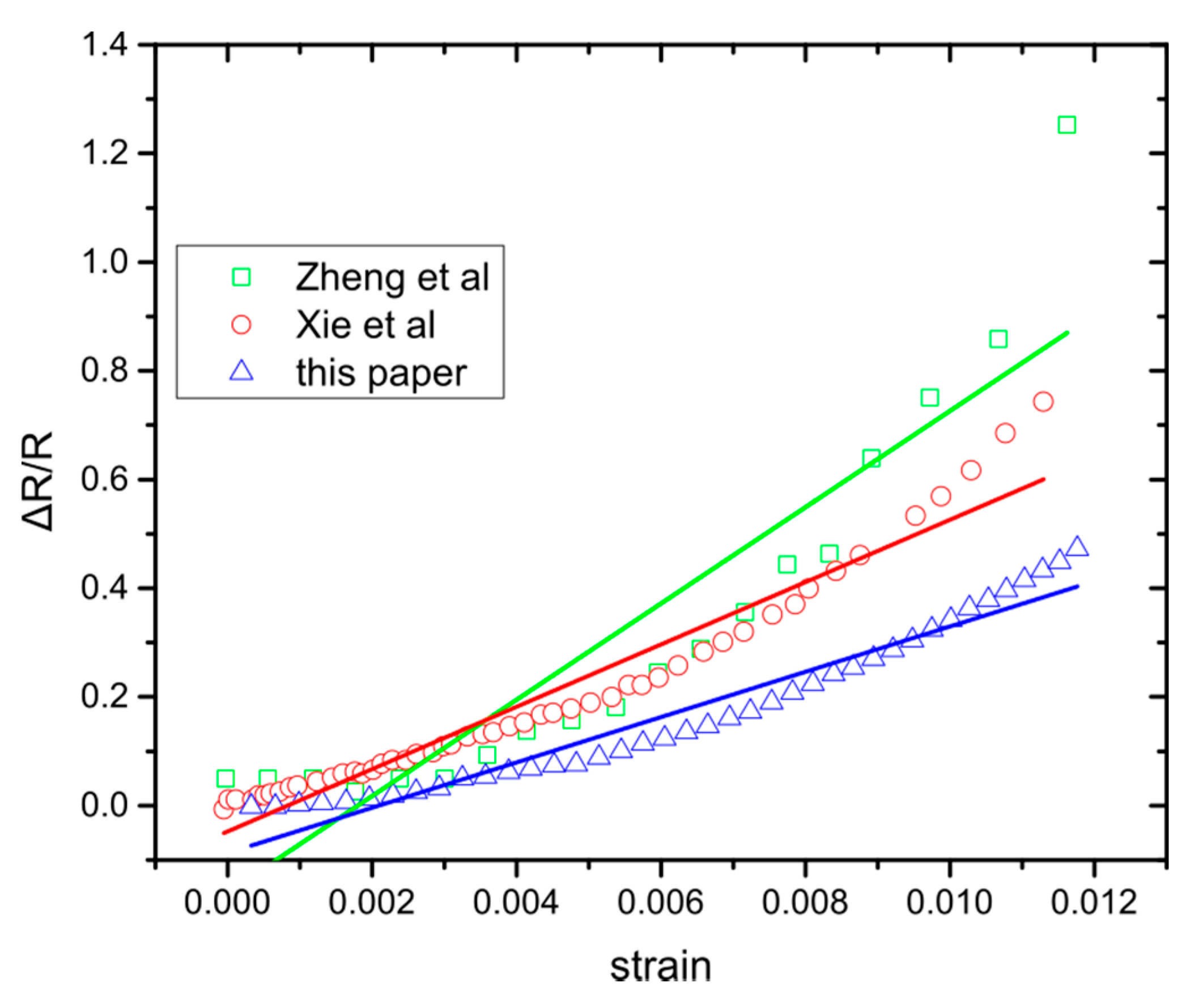

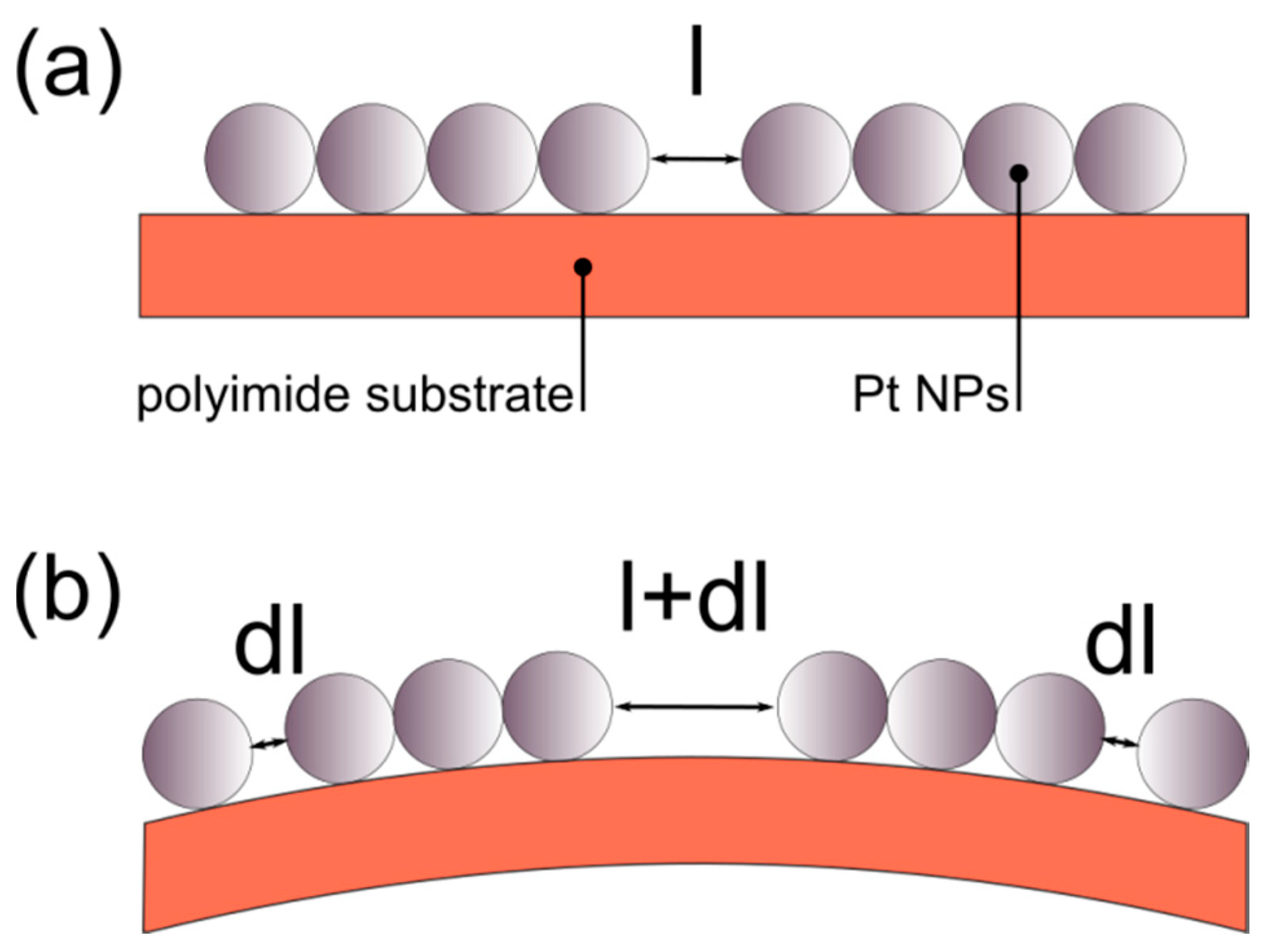

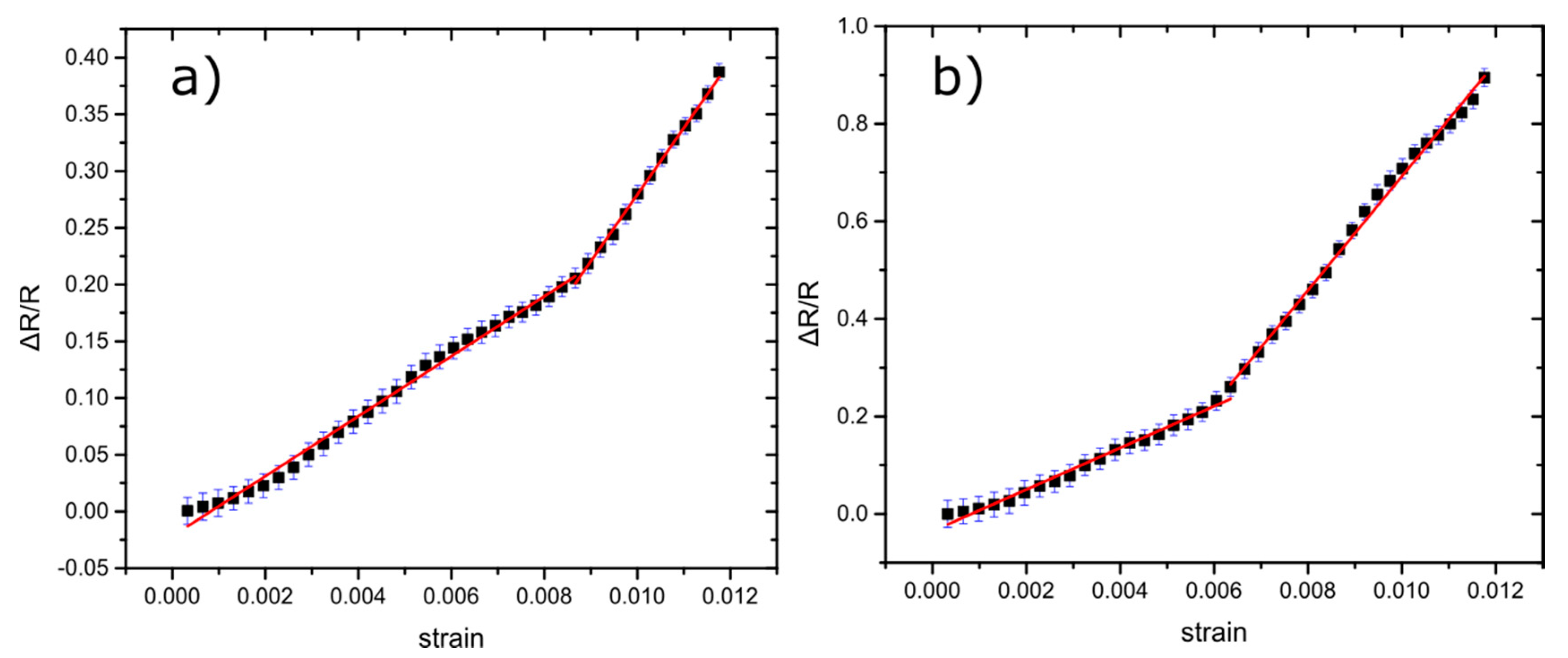

3.2. Sensor Response Using Solvent-Free NPs and Modeling

3.3. Model Effectiveness and Exposure in Adverse Conditions

3.3.1. Fatigue Experiments

3.3.2. Protection of the Sensor against Humidity and Model Effectiveness

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kang, M.S.; Joh, H.; Kim, H.; Yun, H.W.; Kim, D.; Woo, H.K.; Lee, W.S.; Hong, S.H.; Oh, S.J. Synergetic effects of ligand exchange and reduction process enhancing both electrical and optical properties of Ag nanocrystals for multifunctional transparent electrodes. Nanoscale 2018, 10, 18415–18422. [Google Scholar] [CrossRef]

- Russo, S.; Ranzani, T.; Liu, H.; Nefti-Meziani, S.; Althoefer, K.; Menciassi, A. Soft and stretchable sensor using biocompatible electrodes and liquid for medical applications. Soft Rob. 2015, 2, 146–154. [Google Scholar] [CrossRef]

- Ha, M.; Lim, S.; Ko, H. Wearable and flexible sensors for user-interactive health-monitoring devices. J. Mater. Chem. B 2018, 6, 4043–4064. [Google Scholar] [CrossRef]

- Lee, W.S.; Jeon, S.; Oh, S.J. Wearable sensors based on colloidal nanocrystals. Nano Converg. 2019, 6, 10. [Google Scholar] [CrossRef]

- Shengbo, S.; Lihua, L.; Aoqun, J.; Qianqian, D.; Jianlong, J.; Qiang, Z.; Wendong, Z. Highly sensitive wearable strain sensor based on silver nanowires and nanoparticles. Nanotechnology 2018, 29, 255202. [Google Scholar] [CrossRef]

- Joh, H.; Lee, S.W.; Seong, M.; Lee, W.S.; Oh, S.J. Engineering the Charge Transport of Ag Nanocrystals for Highly Accurate, Wearable Temperature Sensors through All-Solution Processes. Small 2017, 13, 1700247. [Google Scholar] [CrossRef] [PubMed]

- Laflamme, S.; Kollosche, M.; Connor, J.J.; Kofod, G. Robust flexible capacitive surface sensor for structural health monitoring applications. J. Eng. Mech. 2013, 139, 879–885. [Google Scholar] [CrossRef]

- Yi, Y.; Wang, B.; Bermak, A. A Low-Cost Strain Gauge Displacement Sensor Fabricated via Shadow Mask Printing. Sensors 2019, 19, 4713. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Anderson, N.; Bland, S.; Nutt, S.; Jursich, G.; Joshi, S. All-printed strain sensors: Building blocks of the aircraft structural health monitoring system. Sens. Actuators A Phys. 2017, 253, 165–172. [Google Scholar] [CrossRef]

- Takei, K.; Yu, Z.; Zheng, M.; Ota, H.; Takahashi, T.; Javey, A. Highly sensitive electronic whiskers based on patterned carbon nanotube and silver nanoparticle composite films. Proc. Natl. Acad. Sci. USA 2014, 111, 1703–1707. [Google Scholar] [CrossRef]

- Fang, X.; Tan, J.; Gao, Y.; Lu, Y.; Xuan, F. High-performance wearable strain sensors based on fragmented carbonized melamine sponges for human motion detection. Nanoscale 2017, 9, 17948–17956. [Google Scholar] [CrossRef]

- Li, Q.; Li, J.; Tran, D.; Luo, C.; Gao, Y.; Yu, C.; Xuan, F. Engineering of carbon nanotube/polydimethylsiloxane nanocomposites with enhanced sensitivity for wearable motion sensors. J. Mater. Chem. C 2017, 5, 11092–11099. [Google Scholar] [CrossRef]

- Guo, X.; Huang, Y.; Zhao, Y.; Mao, L.; Gao, L.; Pan, W.; Zhang, Y.; Liu, P. Highly stretchable strain sensor based on SWCNTs/CB synergistic conductive network for wearable human-activity monitoring and recognition. Smart Mater. Struct. 2017, 26, 095017. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly stretchable and sensitive strain sensor based on silver nanowire–elastomer nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.J.; Park, K.H.; Han, C.J.; Oh, M.S.; You, B.; Kim, Y.S.; Kim, J.W. Crack-induced Ag nanowire networks for transparent, stretchable, and highly sensitive strain sensors. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Park, M.; Park, Y.J.; Chen, X.; Park, Y.K.; Kim, M.S.; Ahn, J.H. MoS2-based tactile sensor for electronic skin applications. Adv. Mater. 2016, 28, 2556–2562. [Google Scholar] [CrossRef]

- Khalil, I.; Rahmati, S.; Julkapli, N.M.; Yehye, W.A. Graphene metal nanocomposites—Recent progress in electrochemical biosensing applications. J. Ind. Eng. Chem. 2018, 59, 425–439. [Google Scholar] [CrossRef]

- Hossain, M.A.; Jeon, S.; Ahn, J.; Joh, H.; Bang, J.; Oh, S.J. Control of tunneling gap between nanocrystals by introduction of solution processed interfacial layers for wearable sensor applications. J. Ind. Eng. Chem. 2019, 73, 214–220. [Google Scholar] [CrossRef]

- Lee, W.S.; Lee, S.W.; Joh, H.; Seong, M.; Kim, H.; Kang, M.S.; Cho, K.H.; Sung, Y.M.; Oh, S.J. Designing metallic and insulating nanocrystal heterostructures to fabricate highly sensitive and solution processed strain gauges for wearable sensors. Small 2017, 13, 1702534. [Google Scholar] [CrossRef]

- Lee, W.S.; Kim, D.; Park, B.; Joh, H.; Woo, H.K.; Hong, Y.K.; Kim, T.I.; Ha, D.H.; Oh, S.J. Multiaxial and Transparent Strain Sensors Based on Synergetically Reinforced and Orthogonally Cracked Hetero-Nanocrystal Solids. Adv. Funct. Mater. 2019, 29, 1806714. [Google Scholar] [CrossRef]

- Zhang, S.; Cai, L.; Li, W.; Miao, J.; Wang, T.; Yeom, J.; Sepúlveda, N.; Wang, C. Fully Printed Silver-Nanoparticle-Based Strain Gauges with Record High Sensitivity. Adv. Electron. Mater. 2017, 3, 1700067. [Google Scholar] [CrossRef]

- Zhao, X.; Guo, J.; Xiao, T.; Zhang, Y.; Yan, Y.; Grzybowski, B.A. Charged Metal Nanoparticles for Chemoelectronic Circuits. Adv. Mater. 2019, 31, 1804864. [Google Scholar] [CrossRef] [PubMed]

- Wilson, J.S. (Ed.) Sensor Technology Handbook; Elsevier: Oxford, UK, 2005. [Google Scholar]

- Segev-Bar, M.; Haick, H. Flexible sensors based on nanoparticles. ACS Nano 2013, 7, 8366–8378. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Oh, J.Y.; Xu, J.; Tran, H.; Bao, Z. Skin-inspired electronics: An emerging paradigm. Acc. Chem. Res. 2018, 51, 1033–1045. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.; Yin, F.; Xia, D.; Peng, H.; Yang, J.; Yuan, W. A highly flexible and multifunctional strain sensor based on a network-structured MXene/polyurethane mat with ultra-high sensitivity and a broad sensing range. Nanoscale 2019, 11, 9949–9957. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Liu, Q.; Chen, P. Flexible strain sensor based on carbon black/silver nanoparticles composite for human motion detection. Materials 2018, 11, 1836. [Google Scholar] [CrossRef]

- Herrmann, J.; Müller, K.H.; Reda, T.; Baxter, G.R.; Raguse, B.D.; De Groot, G.J.; Chai, R.; Roberts, M.; Wieczorek, L. Nanoparticle films as sensitive strain gauges. Appl. Phys. Lett. 2007, 91, 183105. [Google Scholar] [CrossRef]

- Zhang, P.; Bousack, H.; Dai, Y.; Offenhäusser, A.; Mayer, D. Shell-binary nanoparticle materials with variable electrical and electro-mechanical properties. Nanoscale 2018, 10, 992–1003. [Google Scholar] [CrossRef]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.Y.; Kim, T.I.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222. [Google Scholar] [CrossRef]

- Han, Z.; Liu, L.; Zhang, J.; Han, Q.; Wang, K.; Song, H.; Wang, Z.; Jiao, Z.; Niu, S.; Ren, L. High-performance flexible strain sensor with bio-inspired crack arrays. Nanoscale 2018, 10, 15178–15186. [Google Scholar] [CrossRef]

- Jung, H.; Park, C.; Lee, H.; Hong, S.; Kim, H.; Cho, S.J. Nano-Cracked Strain Sensor with High Sensitivity and Linearity by Controlling the Crack Arrangement. Sensors 2019, 19, 2834. [Google Scholar] [CrossRef]

- Tanner, J.L.; Mousadakos, D.; Giannakopoulos, K.; Skotadis, E.; Tsoukalas, D. High strain sensitivity controlled by the surface density of platinum nanoparticles. Nanotechnology 2012, 23, 285501. [Google Scholar] [CrossRef] [PubMed]

- Patsiouras, L.; Skotadis, E.; Gialama, N.; Drivas, C.; Kennou, S.; Giannakopoulos, K.; Tsoukalas, D. Atomic layer deposited Al2O3 thin films as humidity barrier coatings for nanoparticle-based strain sensors. Nanotechnology 2018, 29, 465706. [Google Scholar] [CrossRef] [PubMed]

- Zheng, M.; Li, W.; Xu, M.; Xu, N.; Chen, P.; Han, M.; Xie, B. Strain sensors based on chromium nanoparticle arrays. Nanoscale 2014, 6, 3930–3933. [Google Scholar] [CrossRef] [PubMed]

- Xie, B.; Mao, P.; Chen, M.; Li, Z.; Liu, C.; Qin, Y.; Yang, L.; Wei, M.; Liu, M.; Wang, X.; et al. A tunable palladium nanoparticle film-based strain sensor in a Mott variable-range hopping regime. Sens. Actuators A Phys. 2018, 272, 161–169. [Google Scholar] [CrossRef]

- Lee, G.Y.; Kim, M.S.; Min, S.H.; Kim, H.S.; Kim, H.J.; Keller, R.; Ihn, J.B.; Ahn, S.H. Highly Sensitive Solvent-free Silver Nanoparticle Strain Sensors with Tunable Sensitivity Created Using an Aerodynamically Focused Nanoparticle Printer. ACS Appl. Mater. Interfaces 2019, 11, 26421–26432. [Google Scholar] [CrossRef]

- Zhang, P.; Dai, Y.; Viktorova, J.; Offenhäusser, A.; Mayer, D. Electronic Responses to Humidity in Monolayer and Multilayer AuNP Stripes Fabricated by Convective Self-Assembly. Phys. Status Solidi A 2018, 215, 1700950. [Google Scholar] [CrossRef]

- Ketelsen, B.; Yesilmen, M.; Schlicke, H.; Noei, H.; Su, C.H.; Liao, Y.C.; Vossmeyer, T. Fabrication of Strain Gauges via Contact Printing: A Simple Route to Healthcare Sensors Based on Cross-Linked Gold Nanoparticles. ACS Appl. Mater. Interfaces 2018, 10, 37374–37385. [Google Scholar] [CrossRef]

- Digianantonio, L.; Gauvin, M.; Alnasser, T.; Babonneau, D.; Viallet, B.; Grisolia, J.; Viau, G.; Coati, A.; Garreau, Y.; Ressier, L. Influence of the humidity on nanoparticle-based resistive strain gauges. J. Phys. Chem. C 2016, 120, 5848–5854. [Google Scholar] [CrossRef]

- Jiang, C.W.; Ni, I.C.; Tzeng, S.D.; Kuo, W. Nearly isotropic piezoresistive response due to charge detour conduction in nanoparticle thin films. Sci. Rep. 2015, 5, 1–9. [Google Scholar] [CrossRef]

- Olichwer, N.; Leib, E.W.; Halfar, A.H.; Petrov, A.; Vossmeyer, T. Cross-linked gold nanoparticles on polyethylene: Resistive responses to tensile strain and vapors. ACS Appl. Mater. Interfaces 2012, 4, 6151–6161. [Google Scholar] [CrossRef]

- Kano, S.; Kim, K.; Fujii, M. Fast-response and flexible nanocrystal-based humidity sensor for monitoring human respiration and water evaporation on skin. ACS Sens. 2017, 2, 828–833. [Google Scholar] [CrossRef] [PubMed]

- Nehm, F.; Klumbies, H.; Richter, C.; Singh, A.; Schroeder, U.; Mikolajick, T.; Mönch, T.; Hoßbach, C.; Albert, M.; Bartha, J.W.; et al. Breakdown and protection of ALD moisture barrier thin films. ACS Appl. Mater. Interfaces 2015, 7, 22121–22127. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Hu, P.; Luo, J.; Wang, L.; Cohen, M.F.; Zhong, C.J. Molecularly mediated thin film assembly of nanoparticles on flexible devices: Electrical conductivity versus device strains in different gas/vapor environment. ACS Nano 2011, 5, 6516–6526. [Google Scholar] [CrossRef] [PubMed]

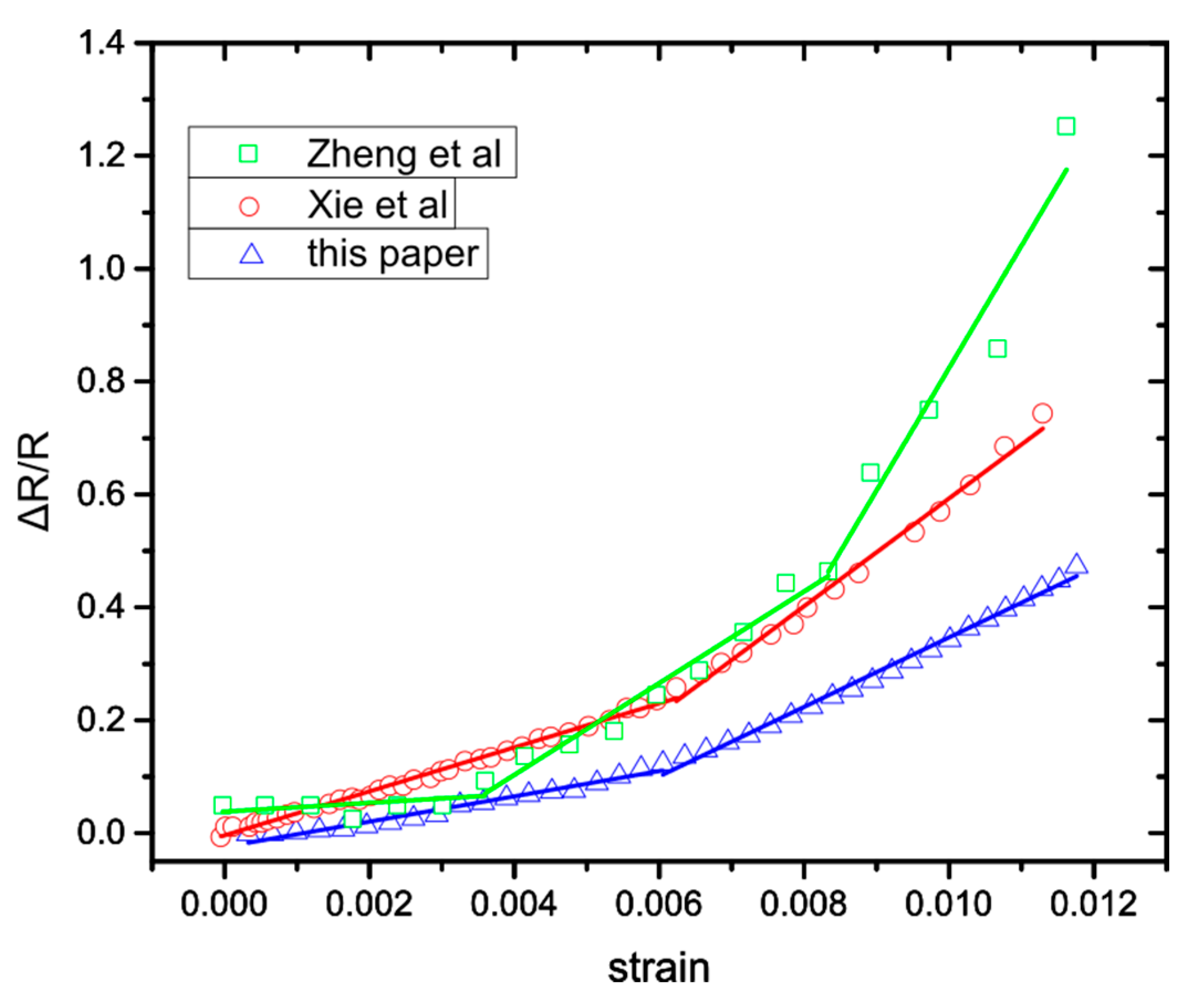

| Materials | Substrate | Fabrication Method | Herrmann’s Model Pearson’s r | This Paper’s Model Pearson’s r | |||

|---|---|---|---|---|---|---|---|

| First Line | Second Line | Third Line | |||||

| Zheng et al. [35] | Cr NPs | PET | sputtering | 0.91238 | 0.99059 | 0.96269 | 0.92329 |

| Xie et al. [36] | Pd NPs | PET | sputtering | 0.9711 | 0.99548 | 0.99491 | - |

| this paper | Pt NPs | polyimide | sputtering | 0.97147 | 0.98129 | 0.99651 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aslanidis, E.; Skotadis, E.; Moutoulas, E.; Tsoukalas, D. Thin Film Protected Flexible Nanoparticle Strain Sensors: Experiments and Modeling. Sensors 2020, 20, 2584. https://doi.org/10.3390/s20092584

Aslanidis E, Skotadis E, Moutoulas E, Tsoukalas D. Thin Film Protected Flexible Nanoparticle Strain Sensors: Experiments and Modeling. Sensors. 2020; 20(9):2584. https://doi.org/10.3390/s20092584

Chicago/Turabian StyleAslanidis, Evangelos, Evangelos Skotadis, Evangelos Moutoulas, and Dimitris Tsoukalas. 2020. "Thin Film Protected Flexible Nanoparticle Strain Sensors: Experiments and Modeling" Sensors 20, no. 9: 2584. https://doi.org/10.3390/s20092584

APA StyleAslanidis, E., Skotadis, E., Moutoulas, E., & Tsoukalas, D. (2020). Thin Film Protected Flexible Nanoparticle Strain Sensors: Experiments and Modeling. Sensors, 20(9), 2584. https://doi.org/10.3390/s20092584