Effect of the Elastomer Matrix on Thermoplastic Elastomer-Based Strain Sensor Fiber Composites

Abstract

1. Introduction

2. Materials and Methods

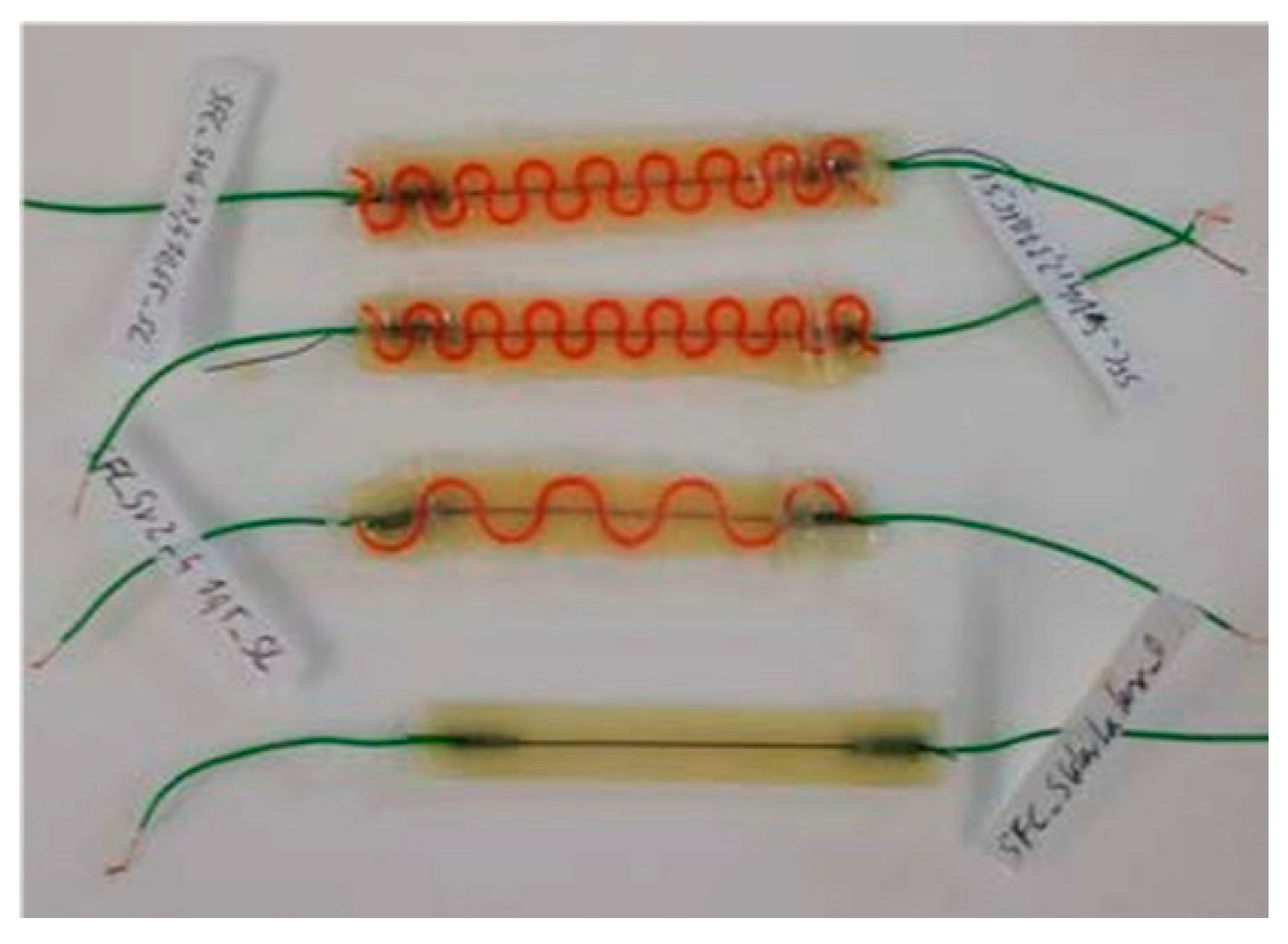

2.1. Sensor Fiber Composite Preparation

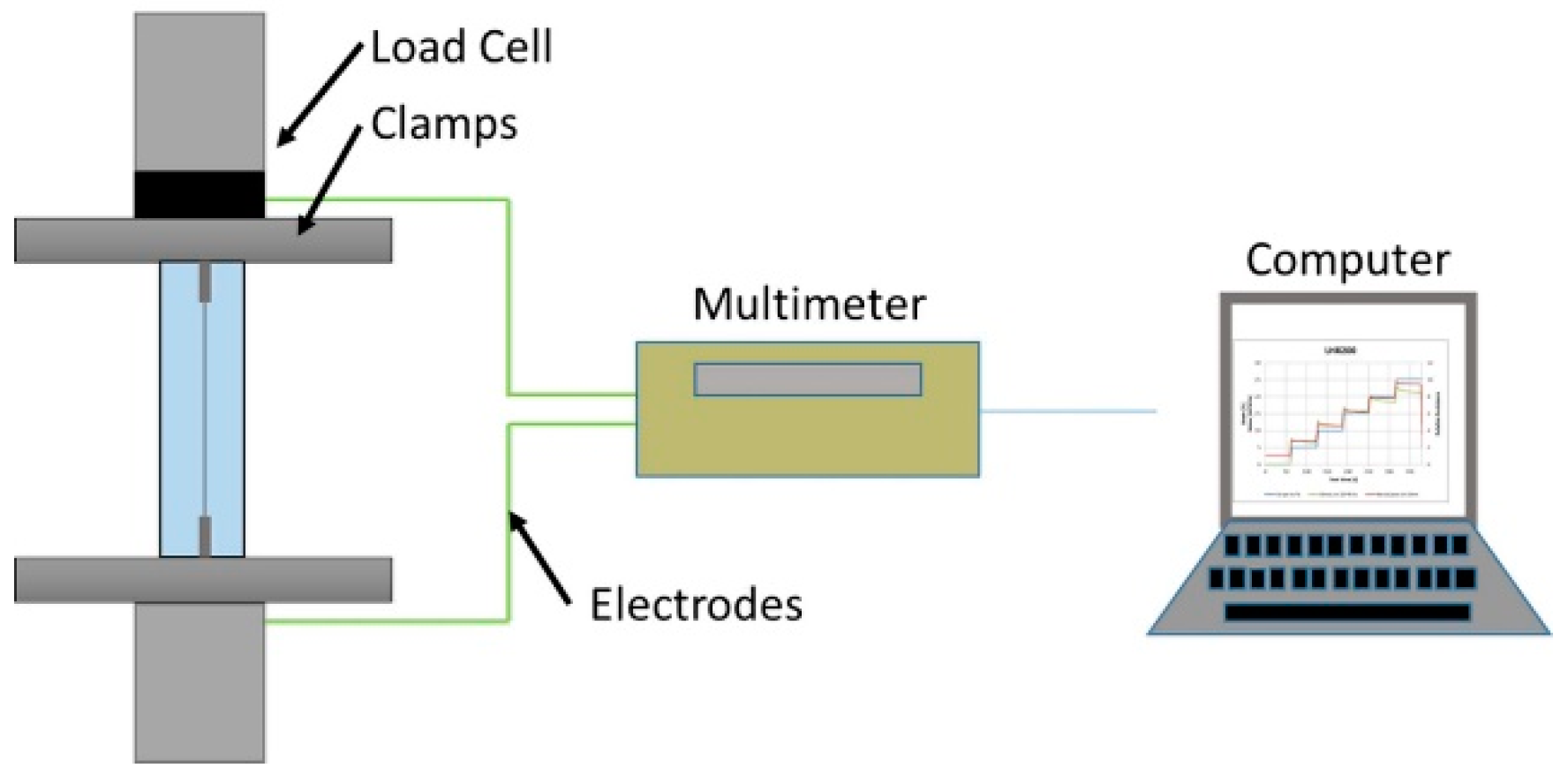

2.2. Tensile Testing

3. Results and Discussion

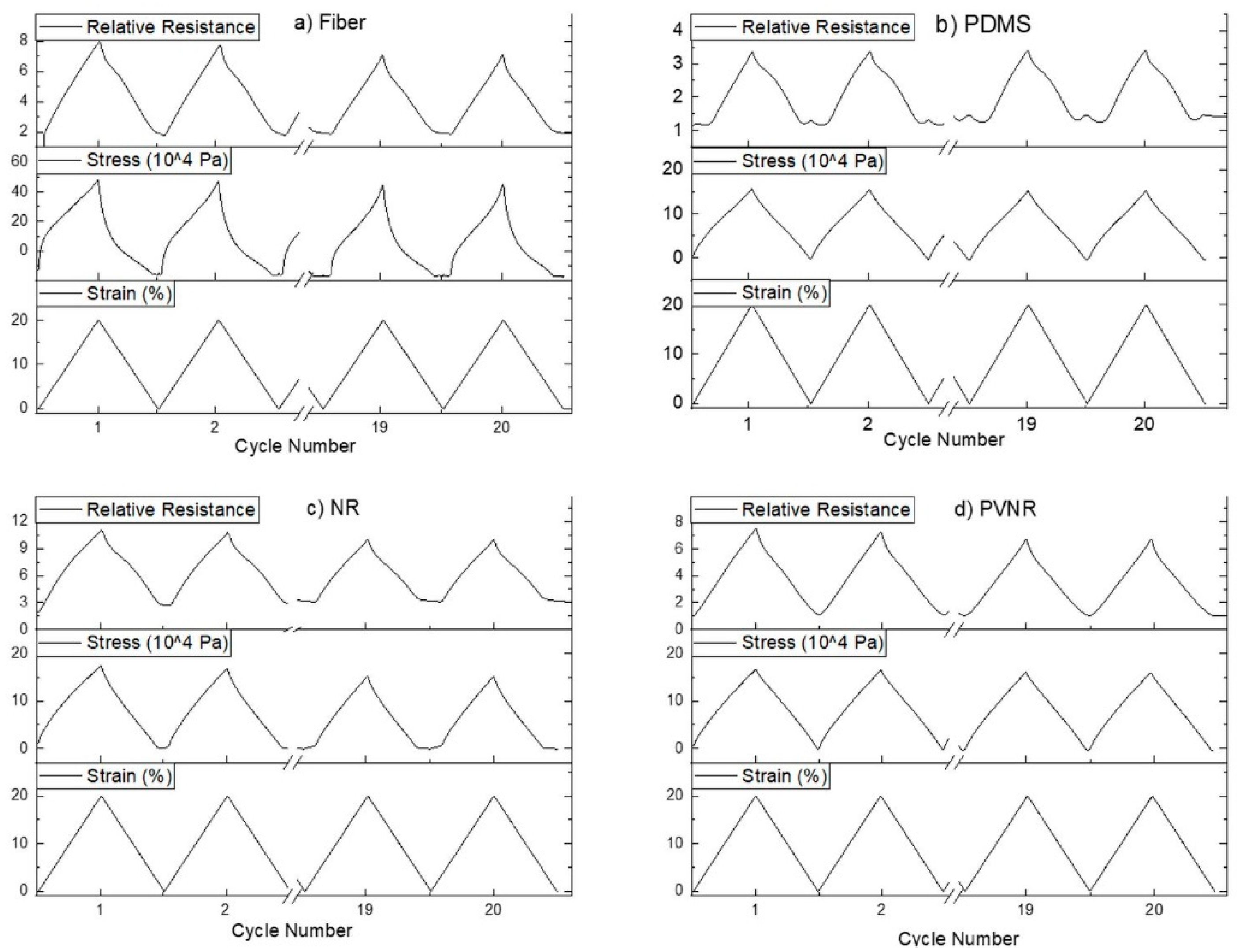

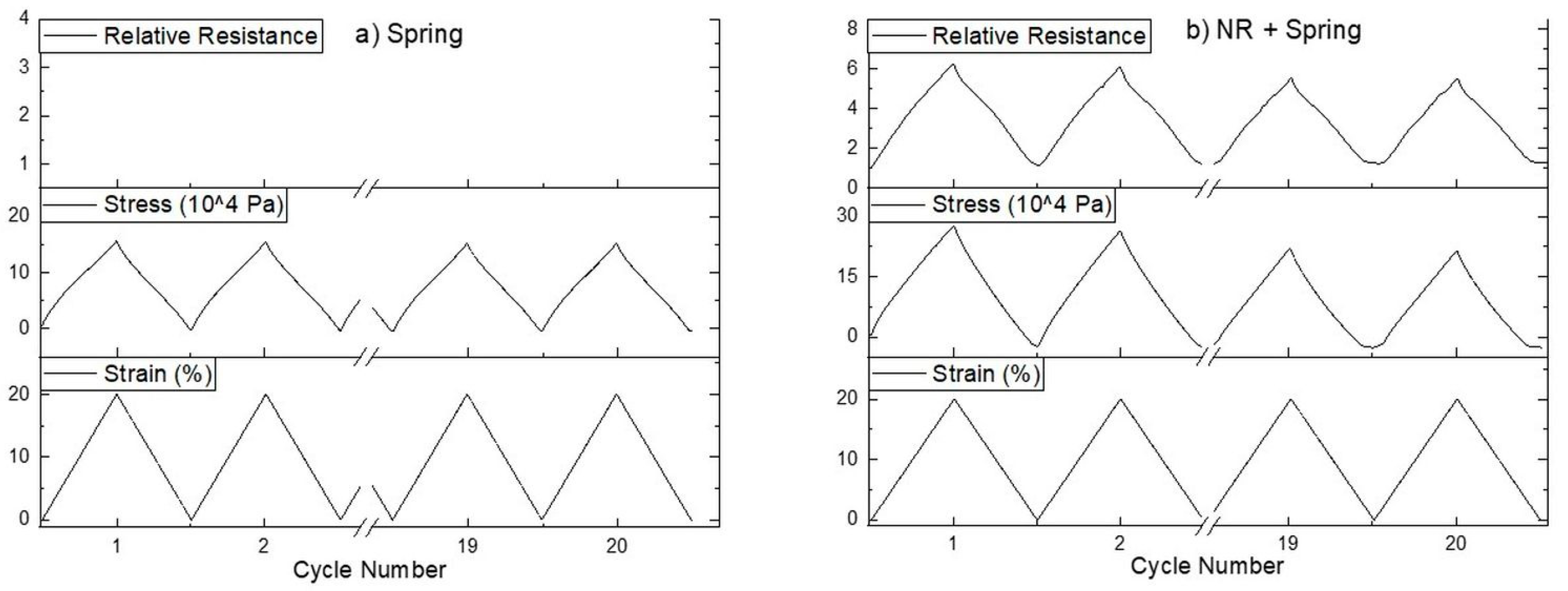

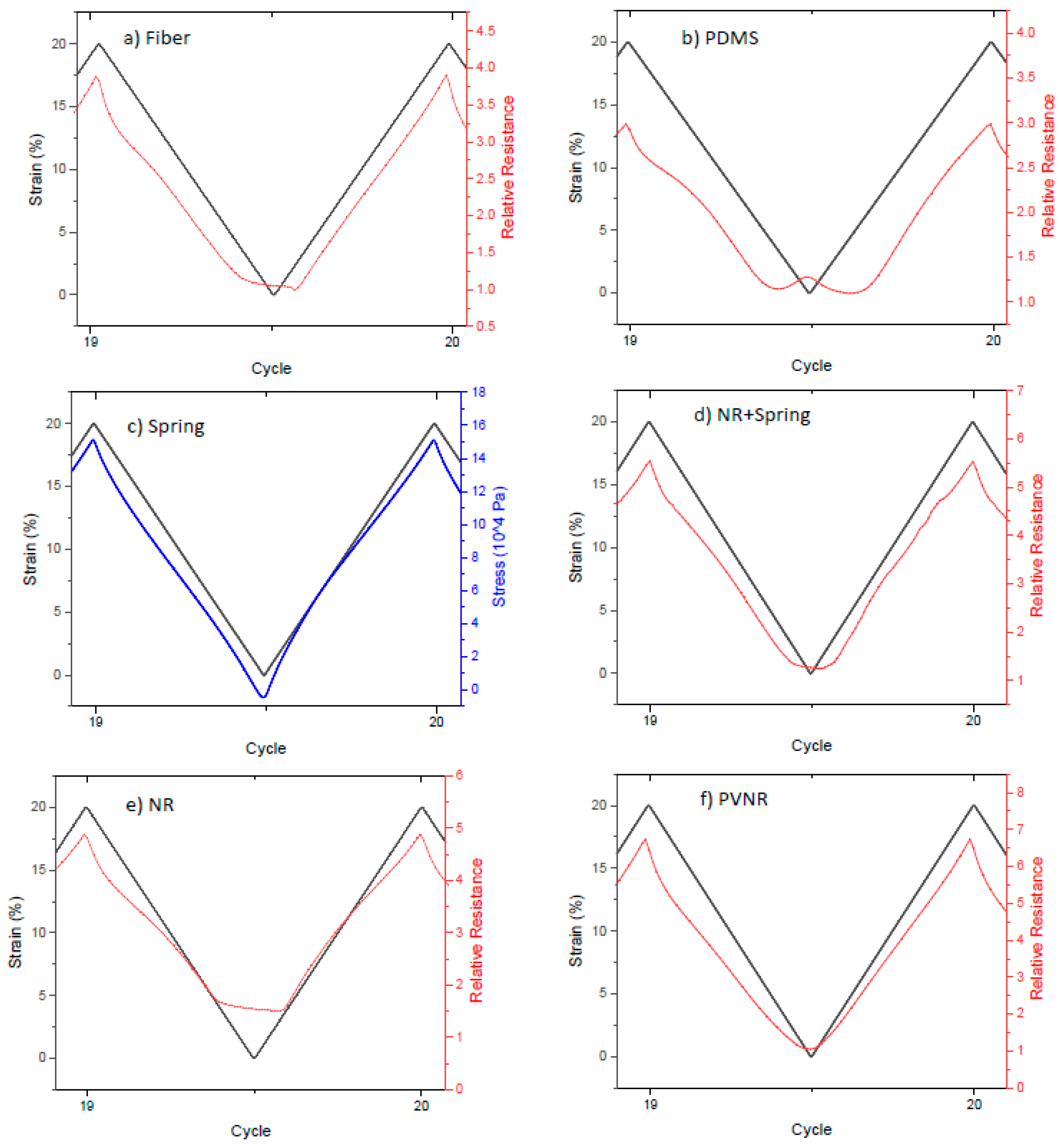

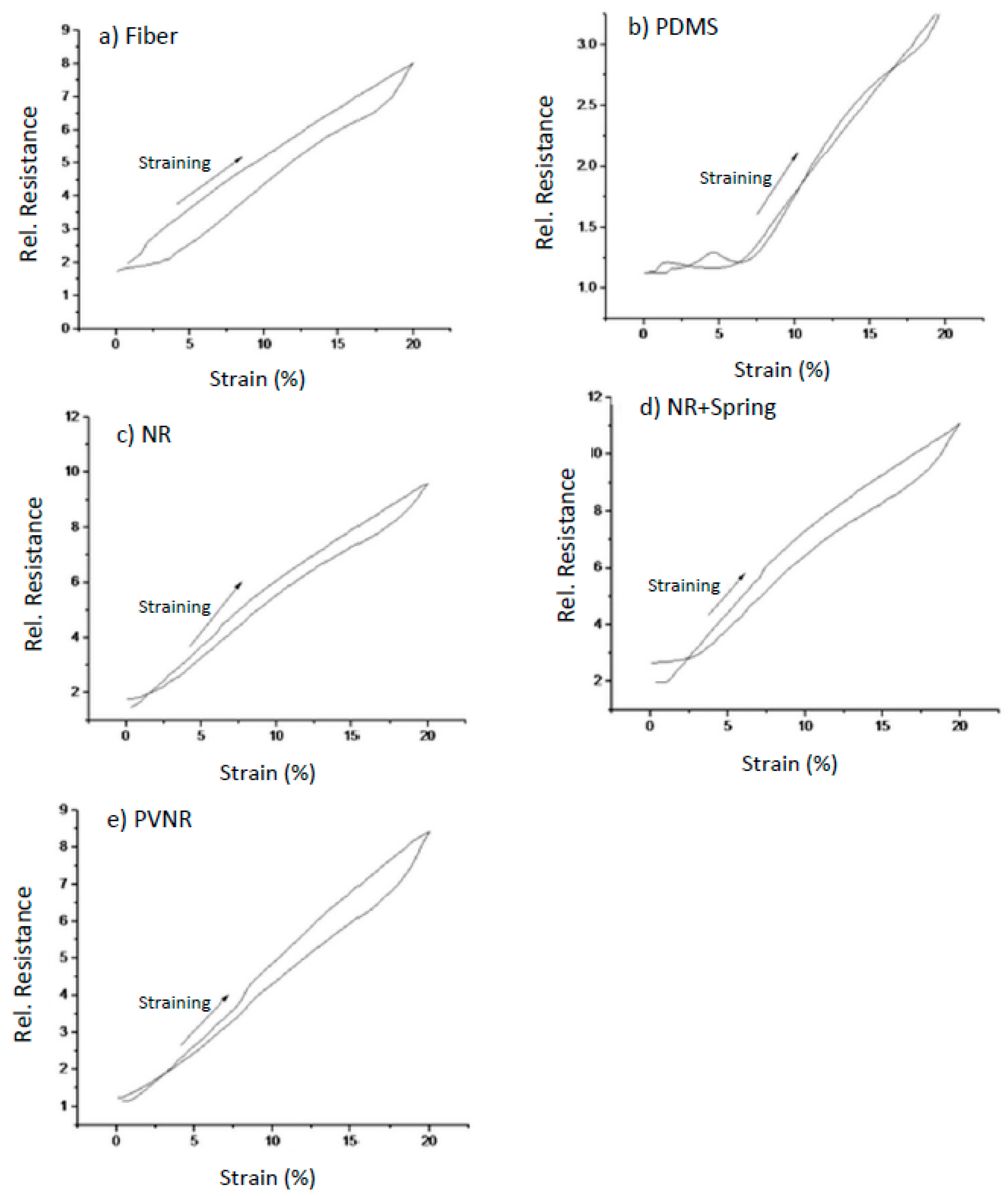

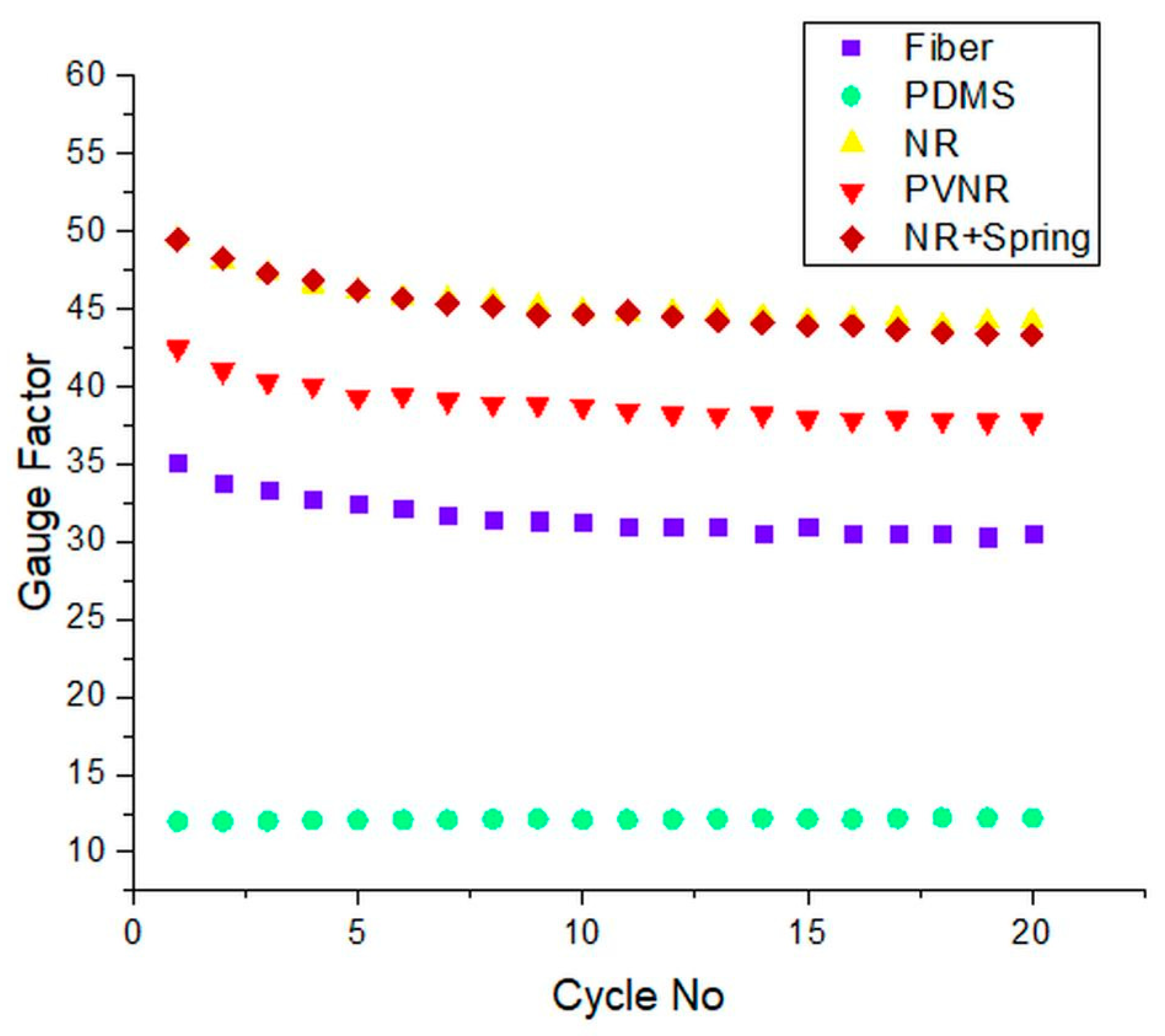

3.1. Dynamic Testing

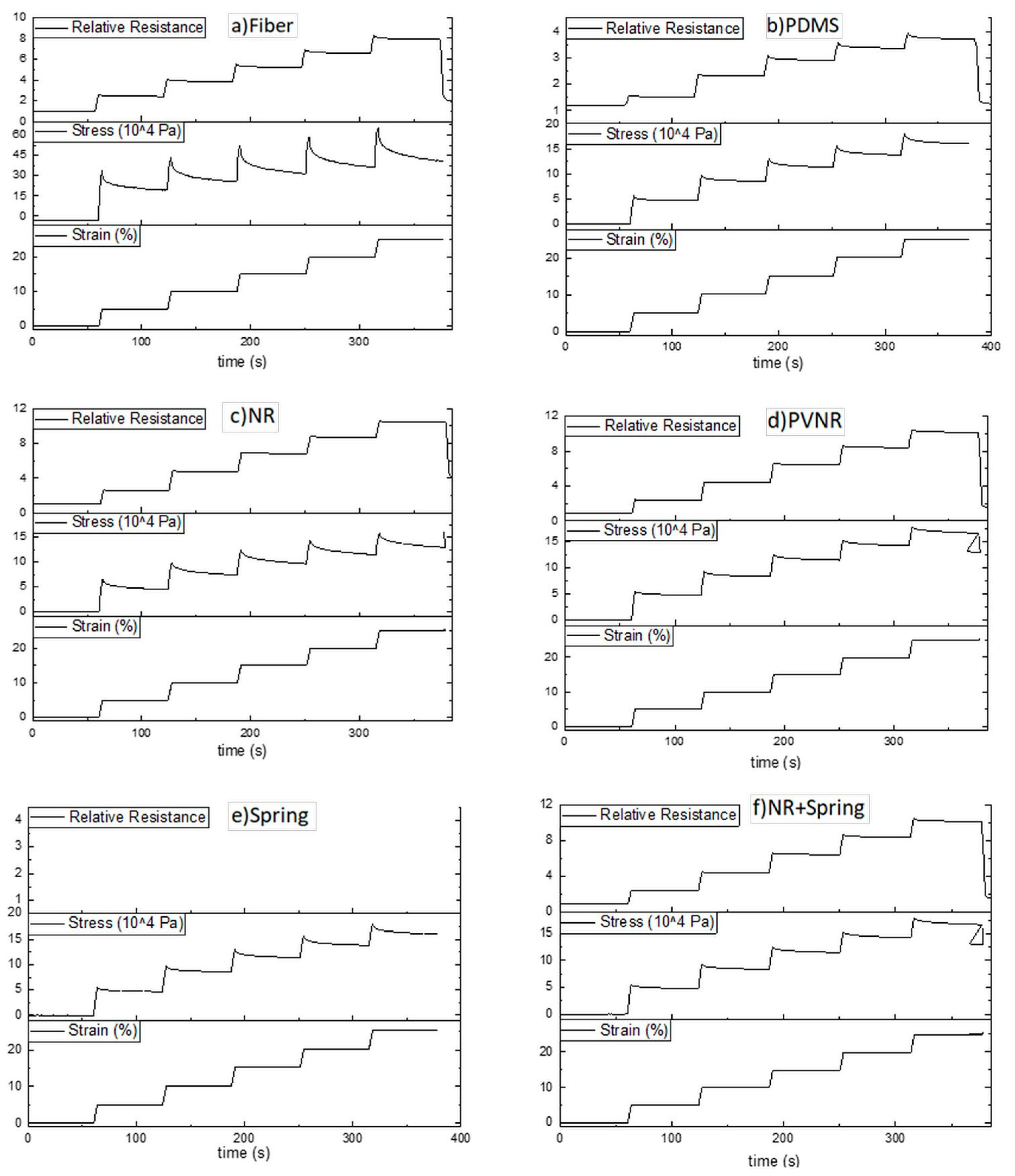

3.2. Quasi-Static Test and the Effect of Relaxation

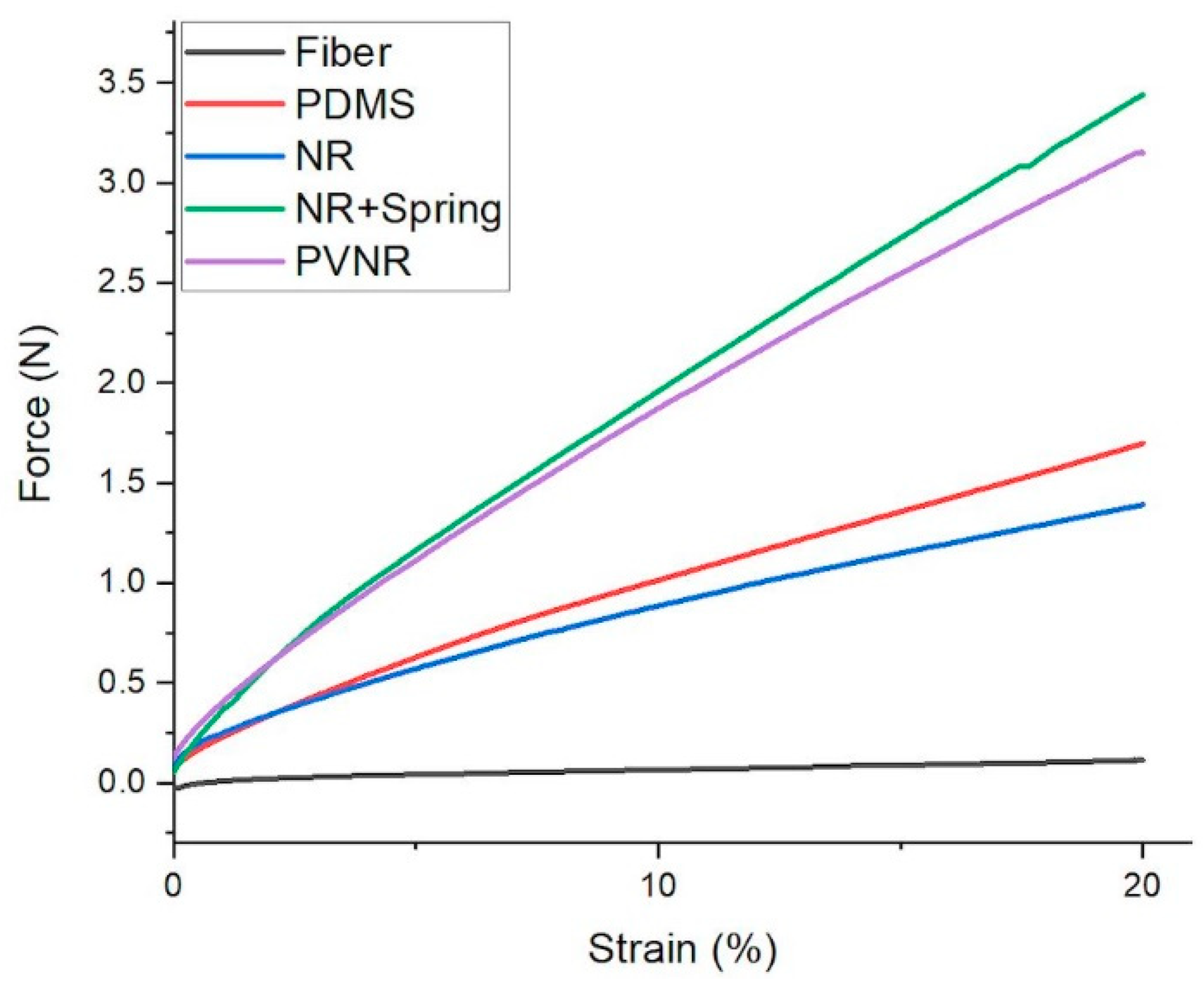

3.3. Calculation of Stiffness

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lehmann, T.; Stockmann, M.; Ihlemann, J.; Menger, T. Applications of electrical strain gages in the fields of monitoring and material mechanics. GAMM-Mitteilungen 2018, 41, e201800006. [Google Scholar] [CrossRef]

- Yamada, T. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 6. [Google Scholar] [CrossRef] [PubMed]

- Lu, N.; Lu, C.; Yang, S.; Rogers, J. Highly Sensitive Skin-Mountable Strain Gauges Based Entirely on Elastomers. Adv. Funct. Mater. 2012, 22, 4044–4050. [Google Scholar] [CrossRef]

- Melnykowycz, M.; Tschudin, M.; Clemens, F. Piezoresistive Soft Condensed Matter Sensor for Body-Mounted Vital Function Applications. Sensors 2016, 16, 326. [Google Scholar] [CrossRef]

- Melnykowycz, M.; Tschudin, M.; Clemens, F. Piezoresistive Carbon-based Hybrid Sensor for Body-Mounted Biomedical Applications. IOP Conf. Ser. Mater. Sci. Eng. 2017, 175, 012006. [Google Scholar] [CrossRef]

- Mattmann, C.; Clemens, F.; Troester, G. Sensor for measuring strain in textile. Sensors 2008, 8, 3719–3732. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Din, S.; Xu, W.; Cheng, L.K.; Dirven, S. A Stretchable Multimodal Sensor for Soft Robotic Applications. IEEE Sens. J. 2017, 17, 5678–5686. [Google Scholar] [CrossRef]

- Flandin, L.; Hiltner, A.; Baer, E. Interrelationships between electrical and mechanical properties of a carbon black-filled ethylene-octene elastomer. Polymer 2001, 42, 827–838. [Google Scholar] [CrossRef]

- Hempel, M.; Nezich, D.; Kong, J.; Hofmann, M. A Novel Class of Strain Gauges Based on Layered Percolative Films of 2D Materials. Nano Lett. 2012, 12, 5714–5718. [Google Scholar] [CrossRef]

- Gao, Y.; Fang, X.; Tan, J.; Lu, T.; Pan, L.; Xuan, F. Highly sensitive strain sensors based on fragmentized carbon nanotube/polydimethylsiloxane composites. Nanotechnology 2018, 29, 235501. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Shu, Y.; Cui, Y.-L.; Mi, W.-T.; Yang, Y.; Xie, D.; Ren, T.-L. Scalable fabrication of high-performance and flexible graphene strain sensors. Nanoscale 2014, 6, 699–705. [Google Scholar] [CrossRef] [PubMed]

- Fan, Q.; Qin, Z.; Gao, S.; Wu, Y.; Pionteck, J.; Mäder, E.; Zhu, M. The use of a carbon nanotube layer on a polyurethane multifilament substrate for monitoring strains as large as 400%. Carbon 2012, 50, 4085–4092. [Google Scholar] [CrossRef]

- Kanoun, O.; Mueller, C.; Benchirouf, A.; Sanli, A.; Dinh, T.N.; Al-Hamry, A.; Bu, L.; Gerlach, C.; Bouhamed, A. Flexible Carbon Nanotube Films for High Performance Strain Sensors. Sensors 2014, 14, 10042–10071. [Google Scholar] [CrossRef] [PubMed]

- Stassi, S.; Cauda, V.; Canavese, G.; Pirri, C.F. Flexible Tactile Sensing Based on Piezoresistive Composites: A Review. Sensors 2014, 14, 5296–5332. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, Z.; Pan, Z.-J. Flexible strain sensors fabricated using carbon-based nanomaterials: A review. Curr. Opin. Solid State Mater. Sci. 2018, 22, 213–228. [Google Scholar]

- Melnykowycz, M.; Koll, B.; Scharf, D.; Clemens, F. Comparison of Piezoresistive Monofilament Polymer Sensors. Sensors 2014, 14, 1278–1294. [Google Scholar] [CrossRef]

- Culha, U.; Nurzaman, S.G.; Clemens, F.; Iida, F. SVAS(3): Strain Vector Aided Sensorization of Soft Structures. Sensors 2014, 14, 12748–12770. [Google Scholar] [CrossRef]

- Ajovalasit, A.; D’Acquisto, L.; Fragapane, S.; Zuccarello, B. Stiffness and reinforcement effect of electrical resistance strain gauges. Strain 2007, 43, 299–305. [Google Scholar] [CrossRef]

- Clemens, F.J.; Koll, B.; Graule, T.; Watras, T.; Binkowski, M.; Mattmann, C.; Silveira, I. Development of Piezoresistive Fiber Sensors, Based on Carbon Black Filled Thermoplastic Elastomer Compounds, for Textile Application. In Advances in Science and Technology; Trans Tech Publications Ltd.: Baech, Switzerland, 2013; p. 7. [Google Scholar]

- Abshirini, M.; Charara, M.; Liu, Y.; Saha, M.; Altan, M.C. 3D Printing of Highly Stretchable Strain Sensors Based on Carbon Nanotube Nanocomposites. Adv. Eng. Mater. 2018, 20, 1800425. [Google Scholar] [CrossRef]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Menguec, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D Printing of Strain Sensors within Highly Stretchable Elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef] [PubMed]

- Hosono, M.; Noda, K.; Matsumoto, K.; Shimoyama, I. Dynamic performance analysis of a micro cantilever embedded in elastomer. J. Micromch. Microeng. 2015, 25, 075006. [Google Scholar] [CrossRef]

- Cho, C.; Ryuh, Y. Fabrication of flexible tactile force sensor using conductive ink and silicon elastomer. Sens. Actuators -Phys. 2016, 237, 72–80. [Google Scholar] [CrossRef]

- Park, Y.-L.; Majidi, C.; Kramer, R.; Berard, P.; Wood, R.J. Hyperelastic pressure sensing with a liquid-embedded elastomer. J. Micromch. Microeng. 2010, 20, 125029. [Google Scholar] [CrossRef]

- Sriring, M.; Nimpaiboon, A.; Kumarn, S.; Sirisinha, C.; Sakdapipanich, J.; Toki, S. Viscoelastic and mechanical properties of large- and small-particle natural rubber before and after vulcanization. Polym. Test. 2018, 70, 127–134. [Google Scholar] [CrossRef]

- Davies, B. Natural rubber—Its engineering characteristics. Mater. Des. 1986, 7, 68–74. [Google Scholar] [CrossRef]

- Ruellan, B.; Le Cam, J.-B.; Jeanneau, I.; Canévet, F.; Mortier, F.; Robin, E. Fatigue of natural rubber under different temperatures. Int. J. Fatigue 2019, 124, 544–557. [Google Scholar] [CrossRef]

- Röthmeyer, F.; Sommer, F. Kautsuk-Technologie Werkstoffe-Verarbeitung; Hanser: Münich, Germany, 2013. [Google Scholar]

- Natarajan, T.S.; Eshwaran, S.B.; Stöckelhuber, K.W.; Wießner, S.; Pötschke, P.; Heinrich, G.; Das, A. Strong Strain Sensing Performance of Natural Rubber Nanocomposites. ACS Appl. Mater. Interfaces 2017, 9, 4860–4872. [Google Scholar] [CrossRef] [PubMed]

- Averett, R.D.; Realff, M.L.; Jacob, K.; Cakmak, M.; Yalcin, B. The mechanical behavior of poly(lactic acid) unreinforced and nanocomposite films subjected to monotonic and fatigue loading conditions. J. Compos. Mater. 2011, 45, 2717–2726. [Google Scholar] [CrossRef]

- Iwatake, A.; Nogi, M.; Yano, H. Cellulose nanofiber-reinforced polylactic acid. Compos. Sci. Technol. 2008, 68, 2103–2106. [Google Scholar] [CrossRef]

- Clemens, F.J.; Wallquist, V.; Buchser, W.; Wegmann, M.; Graule, T. Silicon carbide fiber-shaped microtools by extrusion and sintering SiC with and without carbon powder sintering additive. Ceram. Int. 2007, 33, 491–496. [Google Scholar] [CrossRef]

- Wolf, M.P.; Salieb-Beugelaar, G.B.; Hunziker, P. PDMS with designer functionalities—Properties, modifications strategies, and applications. Prog. Polym. Sci. 2018, 83, 97–134. [Google Scholar] [CrossRef]

- Duan, L.; D’hooge, D.R.; Spoerk, M.; Cornillie, P.; Cardon, L. Facile and Low-Cost Route for Sensitive Stretchable Sensors by Controlling Kinetic and Thermodynamic Conductive Network Regulating Strategies. ACS Appl. Mater. Interfaces 2018, 10, 22678–22691. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Kong, S.; Li, Y.; Lu, M.; Kong, D. Soft elastomeric composite materials with skin-inspired mechanical properties for stretchable electronic circuits. Lab. Chip 2019, 19, 2709–2717. [Google Scholar] [CrossRef]

- Imbernon, L.; Norvez, S.; Leibler, L. Stress Relaxation and Self-Adhesion of Rubbers with Exchangeable Links. Macromolecules 2016, 49, 2172–2178. [Google Scholar] [CrossRef]

| Sensor | Initial Resistance (kΩ) |

|---|---|

| Single Fiber | 10 |

| PDMS | 16 |

| NR | 4 |

| PVNR | 4 |

| NR+Spring | 4 |

| Dynamic Properties | ||||||||

|---|---|---|---|---|---|---|---|---|

| Mechanical Drift | Electrical Drift | Gauge Factor | ||||||

| Max | Min | Hysteresis at 10% | Max | Min | Hysteresis at 10% | First Cycle | Last Cycle | |

| Single Fiber | 0.2% | 6.4% | 6.0% | 11.9% | 3.4% | 15.5% | 35.1 | 30.6 |

| PDMS | 4.1% | 85.7% | 8.6% | 1.3% | 22.3% | 1.2% | 15.0 | 12.2 |

| NR | 13.2% | 72.0% | 0.6% | 10.2% | 16.0% | 1.4% | 49.5 | 44.2 |

| PVNR | 4% | 61.3% | 11.2% | 10.4% | 8.8% | 2.3% | 42.3 | 37.6 |

| NR+ Spring | 24.3% | 24.0% | 50.2% | 11.4% | 8.4% | 16.0% | 49.5 | 43.3 |

| Quasi-Static Properties | ||||||

|---|---|---|---|---|---|---|

| Mechanical Relaxation % | Electrical Relaxation % | Gauge Factor | ||||

| 5% strain | 20% strain | 5% strain | 20% strain | 5% strain | 20% strain | |

| Single Fiber | 42% | 39% | 9% | 5.0% | 32.7 | 29.4 |

| PDMS | 15% | 11% | 2.5% | 4.2% | 6.3 | 9.72 |

| NR | 28% | 13% | 4% | 2.5% | 32.9 | 38.6 |

| PVNR | 14% | 7% | 4% | 2.0% | 36.8 | 44.9 |

| NR+Spring | 26% | 21% | 3.5% | 3.5% | 36.6 | 42.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Georgopoulou, A.; Kummerlöwe, C.; Clemens, F. Effect of the Elastomer Matrix on Thermoplastic Elastomer-Based Strain Sensor Fiber Composites. Sensors 2020, 20, 2399. https://doi.org/10.3390/s20082399

Georgopoulou A, Kummerlöwe C, Clemens F. Effect of the Elastomer Matrix on Thermoplastic Elastomer-Based Strain Sensor Fiber Composites. Sensors. 2020; 20(8):2399. https://doi.org/10.3390/s20082399

Chicago/Turabian StyleGeorgopoulou, Antonia, Claudia Kummerlöwe, and Frank Clemens. 2020. "Effect of the Elastomer Matrix on Thermoplastic Elastomer-Based Strain Sensor Fiber Composites" Sensors 20, no. 8: 2399. https://doi.org/10.3390/s20082399

APA StyleGeorgopoulou, A., Kummerlöwe, C., & Clemens, F. (2020). Effect of the Elastomer Matrix on Thermoplastic Elastomer-Based Strain Sensor Fiber Composites. Sensors, 20(8), 2399. https://doi.org/10.3390/s20082399