Optical Thickness Monitoring as a Strategic Element for the Development of SPR Sensing Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Theoretical Simulation Using the Fresnel Equations and the Matrix Method

2.2. Evaporation of Cr/Au Thin Films

2.3. SPR Measurements

3. Results and Discussions

3.1. Characterization of the Gold and Chrome Thin Film

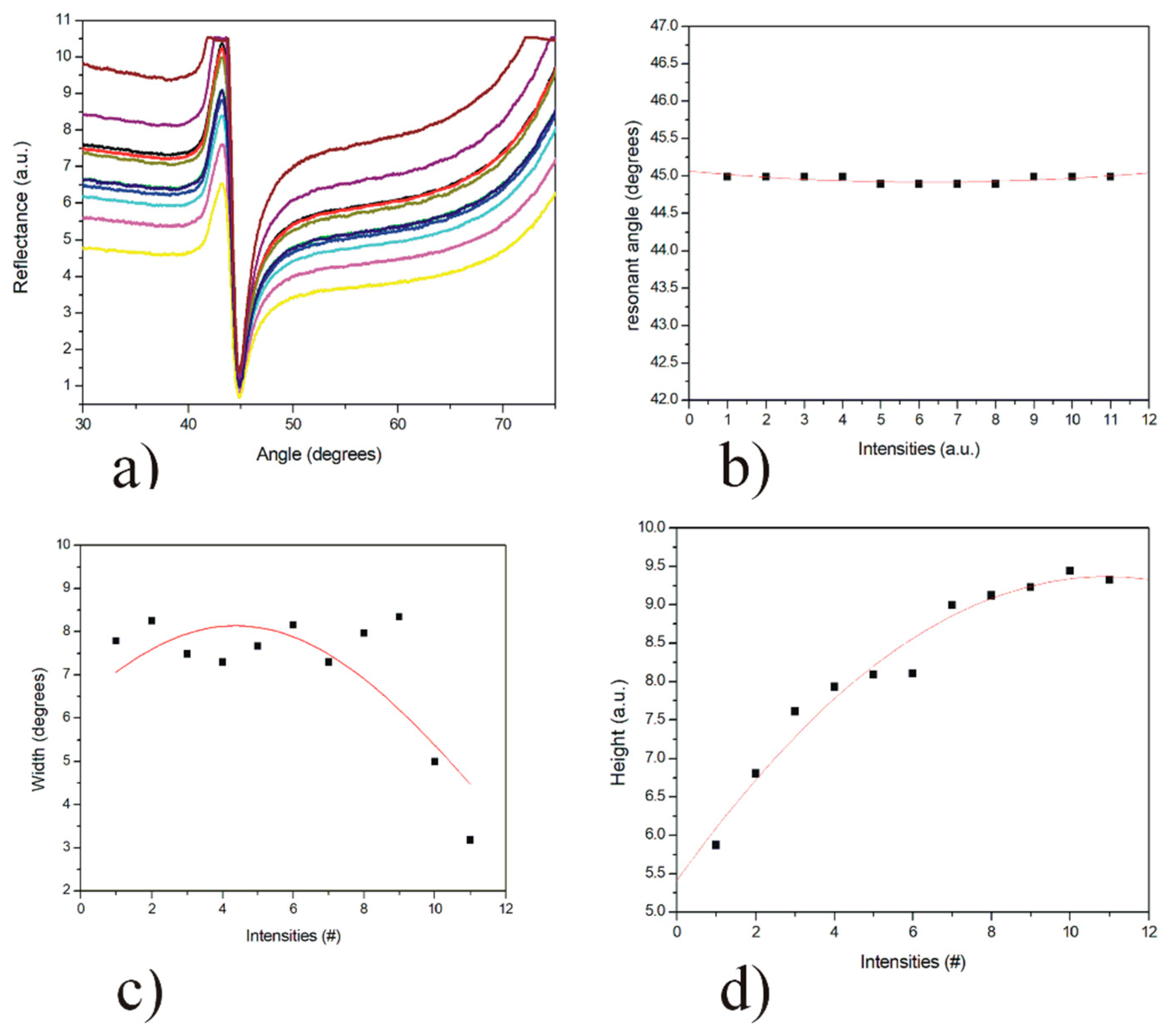

3.2. Effect of the Intensity of the Incident Light in the SPR System

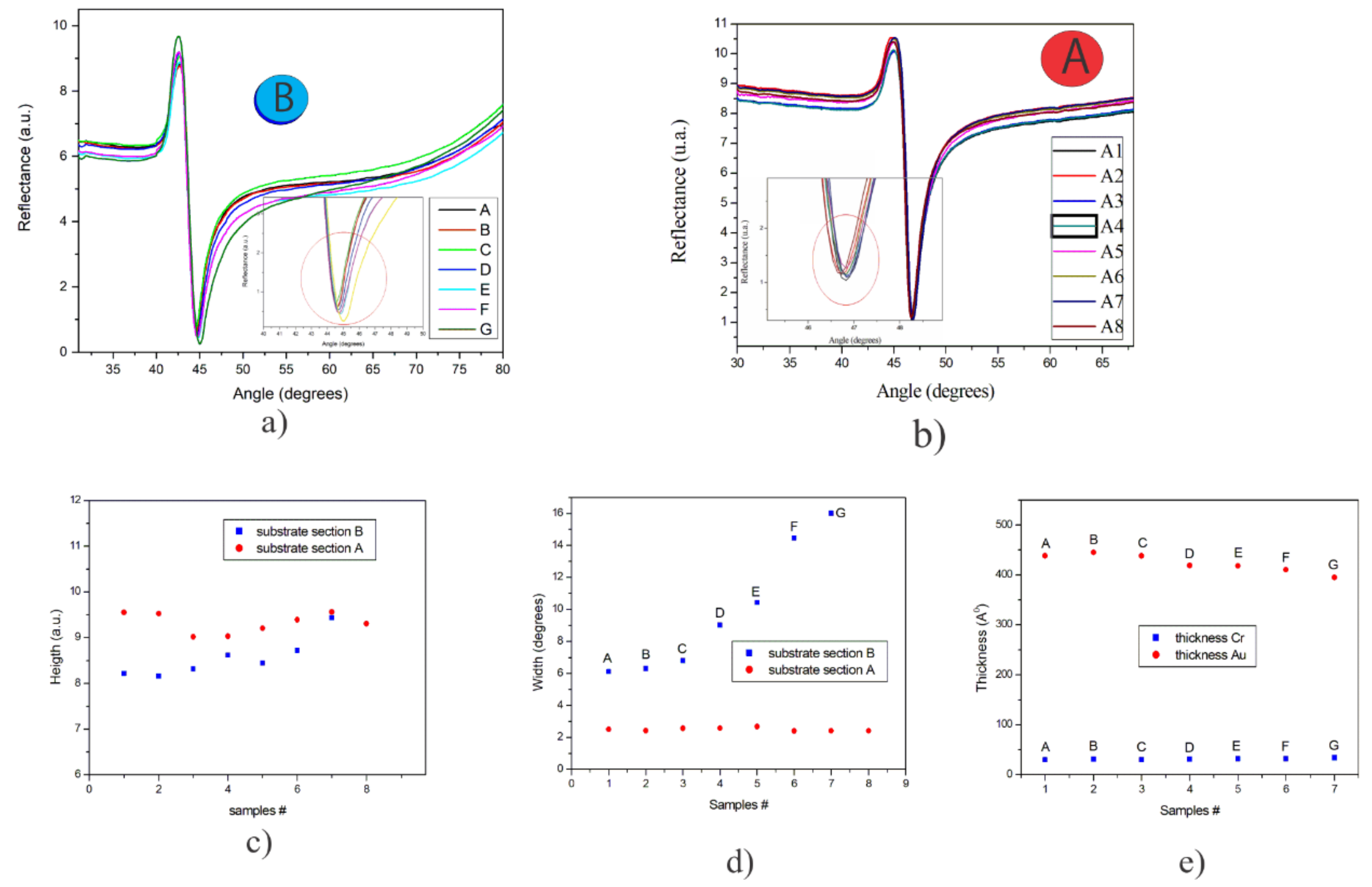

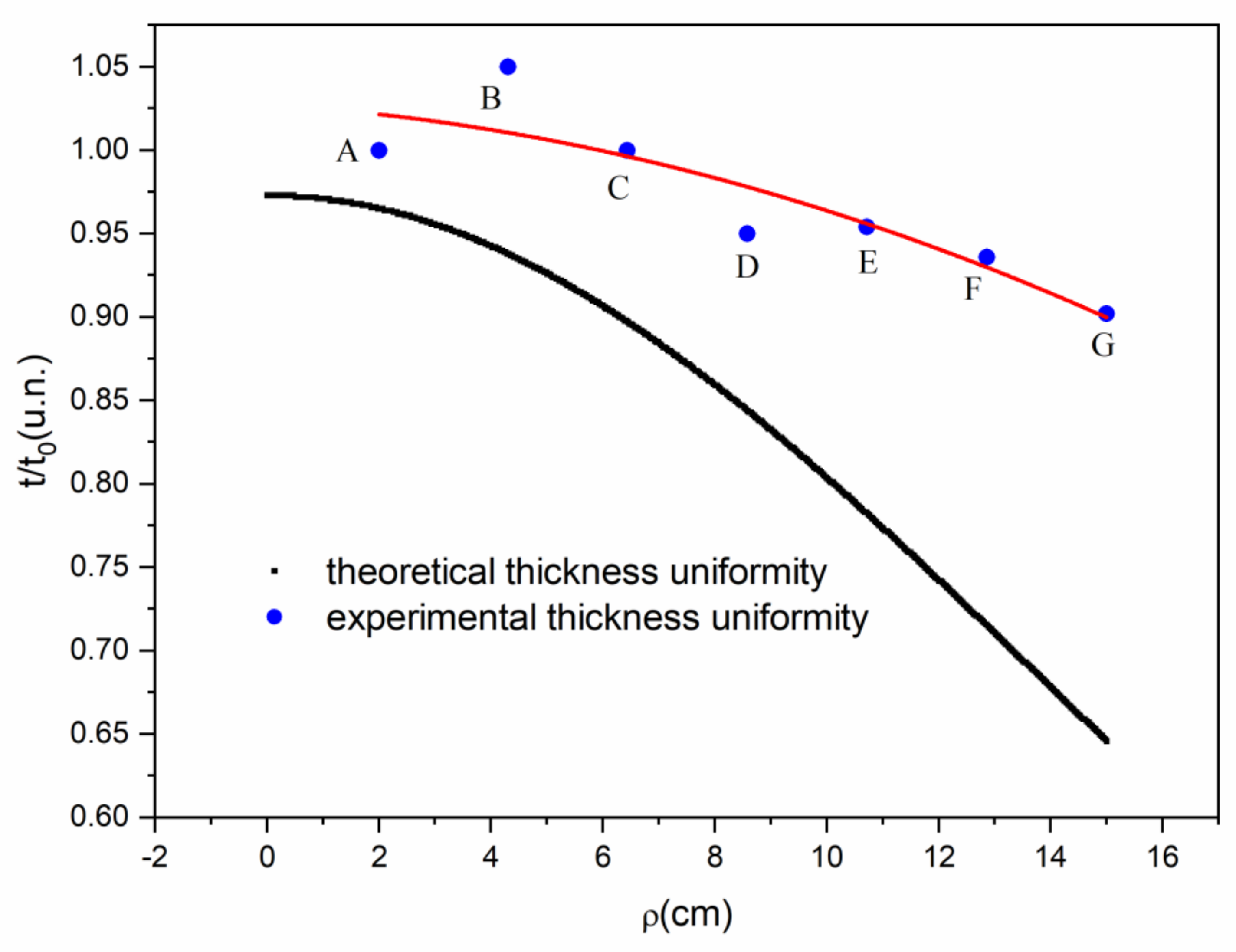

3.3. Evaporation of Cr/Au with no-Rotation System

3.4. Evaporation of Cr/Au with Rotation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- West, P.; Ishii, S.; Naik, G.; Emani, N.; Shalaev, V.; Boltasseva, A. Searching for better plasmonic materials. Laser Photon- Rev. 2010, 4, 795–808. [Google Scholar] [CrossRef] [Green Version]

- Kolomenskii, A.A.; Gershon, P.D.; Schuessler, H.A. Sensitivity and detection limit of concentration and adsorption measurements by laser-induced surface-plasmon resonance. Appl. Opt. 1997, 36, 6539–6547. [Google Scholar] [CrossRef]

- Moreno, D.L.; Sánchez, Y.E.; De León, Y.P.; Arias, E.N.; Campos, G.G. Virtual instrumentation in LabVIEW for multiple optical characterizations on the same opto-mechanical system. Opt. 2015, 126, 1923–1929. [Google Scholar]

- Homola, J.; Koudela, I.; Yee, S.S. Surface plasmon resonance sensors based on diffraction gratings and prism couplers: Sensitivity comparison. Sensors Actuators B: Chem. 1999, 54, 16–24. [Google Scholar] [CrossRef]

- Barnes, W.L. Comparing experiment and theory in plasmonics. J. Opt. A: Pure Appl. Opt. 2009, 11, 114002. [Google Scholar] [CrossRef]

- McPeak, K.M.; Jayanti, S.V.; Kress, S.J.P.; Meyer, S.; Iotti, S.; Rossinelli, A.; Norris, D.J. Plasmonic Films Can Easily Be Better: Rules and Recipes. ACS Photon- 2015, 2, 326–333. [Google Scholar] [CrossRef] [PubMed]

- Sennett, R.S.; Scott, G.D. The Structure of Evaporated Metal Films and Their Optical Properties. J. Opt. Soc. Am. 1950, 40, 203. [Google Scholar] [CrossRef]

- Yang, Z.; Gu, D.; Gao, Y. An improved dispersion law of thin metal film and application to the study of surface plasmon resonance phenomenon. Opt. Commun. 2014, 329, 180–183. [Google Scholar] [CrossRef]

- Villa, F.; Pompa, O. Emission pattern of real vapor sources in high vacuum: An overview. Appl. Opt. 1999, 38, 695–703. [Google Scholar] [CrossRef]

- Sun, J.S.J.; Zhang, W.; Yi, K.Y.K.; Shao, J.S.J. Optimization of thickness uniformity of coatings on spherical substrates using shadow masks in a planetary rotation system. Chin. Opt. Lett. 2014, 12, 53101–53104. [Google Scholar]

- Liu, C.; Kong, M.; Guo, C.; Gao, W.; Li, B. Theoretical design of shadowing masks for uniform coatings on spherical substrates in planetary rotation systems. Opt. Express 2012, 20, 23790–23797. [Google Scholar] [CrossRef] [PubMed]

- Layer uniformity and thickness monitoring. Available online: https://www.semanticscholar.org/paper/Layer-uniformity-and-thickness-monitoring-Macleod/bf2e2c6b58135bf6256a03e63cfa8f24008f6818 (accessed on 25 March 2020).

- Luna-Moreno, D.; Monzón-Hernández, D.; Calixto, S.; Espinosa-Luna, R. Tailored Pd–Au layer produced by conventional evaporation process for hydrogen sensing. Opt. Lasers Eng. 2011, 49, 693–697. [Google Scholar] [CrossRef]

- Luna-Moreno, D.; Monzón-Hernández, D. Effect of the Pd–Au thin film thickness uniformity on the performance of an optical fiber hydrogen sensor. Appl. Surf. Sci. 2007, 253, 8615–8619. [Google Scholar] [CrossRef]

- Hu, J.; Jiang, M.; Lin, Z. Novel technology for depositing a Pd–Ag alloy film on a tapered optical fibre for hydrogen sensing. J. Opt. A: Pure Appl. Opt. 2005, 7, 593–598. [Google Scholar] [CrossRef]

- Hosoki, A.; Nishiyama, M.; Igawa, H.; Seki, A.; Watanabe, K. Multi-point hydrogen detection system using hetero-core structured optical fiber hydrogen tip sensor based on surface plasmon resonance and pseudorandom noise code correlation reflectometry. In Proceedings of the Asia Pacific Optical Sensors Conference, Jeju Island, Korea, 20—22 May 2015. [Google Scholar]

- Espinosa-Sánchez, Y.; Luna-Moreno, D.; Rodriguez, M.; Sánchez-Álvarez, A. Determination of optical parameters of organic and inorganic thin films using both surface plasmon resonance and Abelès-Brewster methods. Opt. 2017, 142, 426–435. [Google Scholar] [CrossRef]

- Macleod, H.A. Thin Film Optical Filters, 3rd ed.; Academic Press: Cambridge, MA, USA, 2001; Volume 4, p. 1967. [Google Scholar]

- Schott Glass Inc. Available online: https://www.us.schott.com/advanced_optics/english/knowledge-center/technical-articles-and-tools/abbe-diagramm.html?us-origin=en-US# (accessed on 11 February 2019).

- Alvarez, A.S.; Luna-Moreno, D.; Hernández-Morales, J.; Zaragoza-Zambrano, J.; Castillo-Guerrero, D. Control of Stepper Motor Rotary Stages applied to optical sensing technique using LabView. Opt. 2018, 164, 65–71. [Google Scholar]

- Espinosa-Sánchez, Y.M.; Luna-Moreno, D.; Monzón-Hernández, D. Detection of aromatic compounds in tequila through the use of surface plasmon resonance. Appl. Opt. 2015, 54, 4439–4446. [Google Scholar] [CrossRef]

- Luna-Moreno, D.; Sanchez-Alvarez, A.; Islas-Flores, I.; Canché, B.C.; Carrillo-Pech, M.; Villarreal-Chiu, J.F.; Rodriguez, M. Early Detection of the Fungal Banana Black Sigatoka Pathogen Pseudocercospora fijiensis by an SPR Immunosensor Method. Sensors 2019, 19, 465. [Google Scholar] [CrossRef] [Green Version]

- Horn, N.; Kreiter, M. Plasmon Spectroscopy: Methods, Pitfalls and How to Avoid Them. Plasmon. 2010, 5, 331–345. [Google Scholar] [CrossRef]

- Arndt, D.P.; Azzam, R.M.A.; Bennett, J.M.; Borgogno, J.P.; Carniglia, C.K.; Case, W.E.; Dobrowolski, J.A.; Gibson, U.J.; Hart, T.T.; Ho, F.C.; et al. Multiple determination of the optical constants of thin-film coating materials. Appl. Opt. 1984, 23, 3571–3596. [Google Scholar] [CrossRef]

- Weast, R.C. HANDBOOK OF CHEMISTRY AND PHYSICS, 49th ed. Am. J. Med Sci. 1969, 257, 423. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luna-Moreno, D.; Sánchez-Álvarez, A.; Rodríguez-Delgado, M. Optical Thickness Monitoring as a Strategic Element for the Development of SPR Sensing Applications. Sensors 2020, 20, 1807. https://doi.org/10.3390/s20071807

Luna-Moreno D, Sánchez-Álvarez A, Rodríguez-Delgado M. Optical Thickness Monitoring as a Strategic Element for the Development of SPR Sensing Applications. Sensors. 2020; 20(7):1807. https://doi.org/10.3390/s20071807

Chicago/Turabian StyleLuna-Moreno, Donato, Araceli Sánchez-Álvarez, and Melissa Rodríguez-Delgado. 2020. "Optical Thickness Monitoring as a Strategic Element for the Development of SPR Sensing Applications" Sensors 20, no. 7: 1807. https://doi.org/10.3390/s20071807

APA StyleLuna-Moreno, D., Sánchez-Álvarez, A., & Rodríguez-Delgado, M. (2020). Optical Thickness Monitoring as a Strategic Element for the Development of SPR Sensing Applications. Sensors, 20(7), 1807. https://doi.org/10.3390/s20071807