Arc Tracking Control in Insulation Systems for Aeronautic Applications: Challenges, Opportunities, and Research Needs

Abstract

1. Introduction

2. Factors Affecting Arc Tracking

3. Wet- and Dry-Wire Arc Tracking

4. Wire Types for Aircraft Applications

5. Comparative Tracking Index (CTI)

6. Arc Tracking Detection Methods

7. Identified Research Needs

- (1)

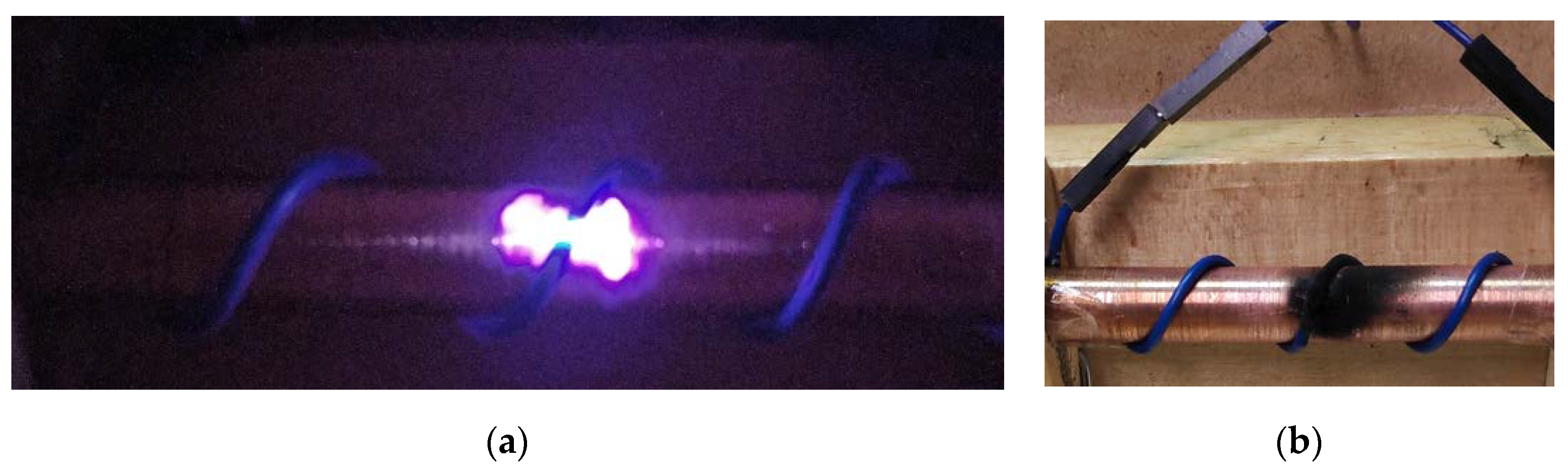

- Arc tracking occurrence depends upon diverse factors such as applied voltage, materials involved and age, environmental conditions (temperature, humidity and pressure), debris type and quantity, and geometry. Changes of such factors will impact the outcome of arc tracking tests, thus making the control of the experiments difficult, and also drawing meaningful conclusions from a reduced number of experimental tests. It is a difficult task to recreate the arc tracking phenomenon under laboratory conditions, since it requires gathering residues and dust in the locations and amounts needed to recreate natural arc tracking conditions, which can be an arduous and non-repeatable task. Generating natural arc tracking conditions at laboratory level is a complex and time-consuming task, often being not cost-effective [40]. Moreover, aeronautic wires can be used under low pressure conditions, typically between 1 bar (sea level conditions) and 0.125 bar (flight altitude in non-pressurized circuits). Specific research and extensive test plans must be carried out to determine wire behavior under arc tracking occurrences in these singular conditions, with a special emphasis on evaluating the transfer of energy from the arc to the material in order to predict the potential damage. Therefore, it is required to develop realistic and standardized arc tracking tests based on extensive test plans to take into account all the abovementioned factors influencing arc tracking occurrence and the effects accounting for aeronautic conditions, specifically reproducing pressure and temperature conditions found in such environments as they have a deep impact on arc tracking occurrence.

- (2)

- As a consequence of point (1), there is a shortage of technical works analyzing in detail the arc tracking phenomenon, and more specifically focused on aeronautic environments. This lack of data is due to the difficulty in characterizing the arc phenomenon due to its irregular behavior [18].

- (3)

- It is known that the shape of the applied voltage waveform (different frequencies, AC, DC, positive and negative polarity, pulsed, impulsive, etc.) has a deep impact on discharge occurrence in insulation systems. There is a lack of studies in this area, and specifically regarding aeronautic environmental conditions. This fact requires a deep research in order to improve the knowledge and to set the baseline for improving or developing new standard test methods accounting for the particularities of aeronautic environments and electrical systems.

- (4)

- Different standards support the design of high voltage systems for aeronautic applications, although standards do not totally cover all high voltage design aspects for aeronautic environments, so there is a growing need in this area in the coming years [71]. For example, the IEC 60664 standard [92] related to insulation coordination for low voltage applications is limited to equipment operating below to 2000 m above sea level, analyzing AC, DC and lightning voltages. It also guides how to calculate creepage distances to avoid tracking based on empirical data, which cannot be applied to equipment operating under low-pressure aeronautic environments [71].

- (5)

- There is the need to develop fast and simple inspection procedures to evaluate wiring system health status. For example, the inclined plane standard test method [74] is commonly used to measure erosion and tracking resistance of insulation materials, since it emulates the thermal degradation by electric arcing under AC supply. However, it is a complex and time-consuming method, being very difficult to perform in field inspection [76], specifically in aeronautic environments. There is also the need to develop an equivalent standard test method for DC supply [75].

- (6)

- Existing AFCB protections actuate when the arc occurs, but not before, so they must be improved to minimize the damage level and shorten the reaction time. There is a need to develop specific electrical protections to detect PD and/or corona activity well before arc tracking occurrence, thus safeguarding electrical wiring systems and aircraft integrity. For this purpose, it is necessary to develop fast response, small-size and cost-effective sensors, as well as specific signal processing techniques specially conceived to operate under aeronautic environmental conditions.

- (7)

- Research on erosion and tracking resistance of insulation materials is a key point to ensure the long-term reliability and safety of electrical insulation systems. For example, such characteristics can be improved by using polymeric nanocomposites. However, studies to analyze the relationship between the role of interfacial strength and the electrical properties of nanocomposites [23] are still scarce, and there are fewer studies analyzing the behavior of such insulation materials under aeronautic environmental conditions.

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

Acronyms

| AC | Alternating current |

| AEA | All electric aircraft |

| AFCB | Arc fault circuit breakers |

| CIV | Corona inception voltage |

| CTI | Comparative tracking index |

| DBD | Dry band discharge |

| DC | Direct current |

| ETFE | Ethylene tetrafluoroethylene |

| FAA | Federal Aviation Administration |

| Kapton® | Aromatic polyimide |

| MEA | More electric aircraft |

| PD | Partial discharge |

| PI | Polyimide |

| PVC | Polyvinyl chloride |

| PTFE (Teflon®) | Polytetrafluoroethylene |

| SAE | Society of Automotive Engineers |

| SiR | Silicon rubber |

| TFE | Tetrafluoroethylene |

| TKT | Teflon®-Kapton®-Teflon® |

| UV | Ultraviolet |

| XL | Cross-link |

| XLPE | Cross-linked polyethylene |

References

- Riba, J.-R.; Gómez-Pau, Á.; Moreno-Eguilaz, M. Experimental study of visual corona under aeronautic pressure conditions using low-cost imaging sensors. Sensors 2020, 20, 411. [Google Scholar] [CrossRef] [PubMed]

- Rui, R.; Cotton, I. Impact of low pressure aerospace environment on machine winding insulation. In Proceedings of the 2010 IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 6–9 June 2010; pp. 1–5. [Google Scholar]

- Degardin, V.; Kone, L.; Valensi, F.; Laly, P.; Lienard, M.; Degauque, P. Characterization of the high-frequency conducted electromagnetic noise generated by an arc tracking between dc wires. IEEE Trans. Electromagn. Compat. 2016, 58, 1228–1235. [Google Scholar] [CrossRef]

- El Bayda, H.; Valensi, F.; Masquere, M.; Gleizes, A. Energy losses from an arc tracking in aeronautic cables in DC circuits. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 19–27. [Google Scholar] [CrossRef]

- Mermigkas, A.C.; Clark, D.; Manu Haddad, A. Investigation of high altitude/tropospheric correction factors for electric aircraft applications. In Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2020; Volume 598, pp. 308–315. [Google Scholar]

- Belijar, G.; Chanaud, G.; Hermette, L.; Risacher, A. Study of Electric Arc Ignition, Behavior and Extinction in Aeronautical Environment, in Presence of FOD; HAL: Lyon, France, 2017; pp. 1–8. [Google Scholar]

- Capineri, L.; Dainelli, G.; Materassi, M.; Dunn, B.D. Partial discharge testing of solder fillets on PCBs in a partial vacuum: New experimental results. IEEE Trans. Electron. Packag. Manuf. 2003, 26, 294–304. [Google Scholar] [CrossRef]

- CleanSky. CleanSky 9th Call for Proposals (CFP09)—List and Full Description of Topics; Clean Sky: Brussels, Belgium, 2018; pp. 1–354. [Google Scholar]

- Esfahani, A.N.; Shahabi, S.; Stone, G.; Kordi, B. Investigation of corona partial discharge characteristics under variable frequency and air pressure. In Proceedings of the 2018 IEEE Electrical Insulation Conference (EIC), San Antonio, TX, USA, 17–20 June 2018; pp. 31–34. [Google Scholar]

- Du, B.; Liu, H. Effects of atmospheric pressure on tracking failure of gamma-ray irradiated polymer insulating materials. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 541–547. [Google Scholar] [CrossRef]

- IEEE. IEEE Std 100–2000. In The Authoritative Dictionary of IEEE Standards Terms, 7th ed.; IEEE: Piscataway, NJ, USA, 2000; pp. 1–1362. [Google Scholar]

- Cella, B. On-Line Partial Discharges Detection in Conversion Systems used in Aeronautics; Université de Toulouse: Toulouse, France, 2015. [Google Scholar]

- Du, B.X.; Liu, Y.; Liu, H.J. Effects of low pressure on tracking failure of printed circuit boards. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1379–1384. [Google Scholar] [CrossRef]

- Douar, M.A.; Beroual, A.; Souche, X. Assessment of the resistance to tracking of polymers in clean and salt fogs due to flashover arcs and partial discharges degrading conditions on one insulator model. IET Gener. Transm. Distrib. 2016, 10, 986–994. [Google Scholar] [CrossRef]

- Meng, D.; Zhang, B.Y.; Chen, J.; Lee, S.C.; Lim, J.Y. Tracking and Erosion Properties Evaluation of Polymeric Insulating Materials. In Proceedings of the ICHVE 2016—2016 IEEE International Conference on High Voltage Engineering and Application, Chengdu, China, 19–22 September 2016; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2016. [Google Scholar]

- Dricot, F.; Reher, H.J. Survey of arc tracking on aerospace cables and wires. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 896–903. [Google Scholar] [CrossRef]

- Babrauskas, V. Research on electrical fires: The state of the art. Fire Saf. Sci. 2008, 9, 3–18. [Google Scholar] [CrossRef]

- André, T.; Valensi, F.; Teulet, P.; Cressault, Y.; Zink, T.; Caussé, R. Arc tracking energy balance for copper and aluminum aeronautic cables. J. Phys. Conf. Ser. 2017, 825. [Google Scholar] [CrossRef]

- Rajini, V.; Kanchana, K.; Gowrishree, V.; Udayakumar, K. Comparison of surface tracking in polymeric insulating materials. In Proceedings of the 2004 International Conference on Power System Technology, PowerCon 2004, Singapore, Singapore, 21–24 November 2004; Volume 2, pp. 1513–1517. [Google Scholar]

- Piah, M.A.M.; Darus, A.; Hassan, A. Leakage current and surface discharge phenomena: Effect on tracking and morphological properties of LLDPE-natural rubber compounds. In Proceedings of the 7th International Conference on Properties and Applications of Dielectric Materials (Cat. No.03CH37417), Nagoya, Japan, 1–5 June 2003; Volume 1, pp. 347–350. [Google Scholar]

- Pinnangudi, B.; Gorur, R.; Poweleit, C. Degradation dynamics of polymeric housing materials used for hv line and station apparatus. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 1215–1223. [Google Scholar] [CrossRef]

- Du, B.X. Effects of atmospheric pressure on DC resistance to tracking of polymer insulating materials. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 1162–1171. [Google Scholar] [CrossRef]

- Suchitra, M.; Renukappa, N.M.; Ranganathaiah, C.; Rajan, J.S. Correlation of free space length and surface energy of epoxy nanocomposites to surface tracking. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2129–2138. [Google Scholar] [CrossRef]

- Raetzke, S.; Kindersberger, J. Role of interphase on the resistance to high-voltage arcing, on tracking and erosion of silicone/SiO2 nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 607–614. [Google Scholar] [CrossRef]

- An, Z.; Shen, R.; Gao, W.; Gu, X.; Chen, W.; Yang, L.; Yang, W.; Zhang, Z. Improved flashover performance and tracking resistance of silicone rubber by direct fluorination. J. Appl. Polym. Sci. 2019, 48556. [Google Scholar] [CrossRef]

- Siguier, J.-M.; Inguimbert, V.; Murat, G.; Payan, D.; Balcon, N. Study on secondary arcing occurrence on solar panel backside wires with cracks. IEEE Trans. Plasma Sci. 2015, 43, 2980–2984. [Google Scholar] [CrossRef]

- Junian, S.; Makmud, M.Z.H.; Sahari, J. Natural rubber as electrical insulator: A review. J. Adv. Rev. Sci. Res. 2015, 6, 28–42. [Google Scholar]

- Khan, H.; Amin, M.; Ahmad, A.; Yasin, M. Investigation of electrical, tracking/erosion, and water absorption resistance properties of ATH-SiO2- reinforced RTV-SiR composites for high-voltage insulations. J. Elastomers Plast. 2018, 50, 501–519. [Google Scholar] [CrossRef]

- Muhamedin, F.L.; Piah, M.; Othman, N.A. Modelling on tracking test condition of polymer nanocomposite using finite element simulation. Telkomnika 2015, 13, 1194–1203. [Google Scholar] [CrossRef][Green Version]

- Jeon, Y.; Hong, S.-K.; Kim, M. Effect of filler concentration on tracking resistance of ATH-filled silicone rubber nanocomposites. Energies 2019, 12, 2401. [Google Scholar] [CrossRef]

- FAA. Aircraft Electrical Wiring Interconnect System (EWIS) Best Practices; FAA: Atlantic City, NJ, USA, 2020.

- NFPA. NFPA 921: Guide for Fire and Explosion Investigations; National Fire Protection Agency: Quincy, MA, USA, 2017. [Google Scholar]

- Parrot, K.D.; Stahl, D.R.; Parrott, K.D.; Stahl, D.R. Electrical Arcs and Sparks: A Literature Review of Definitions and Their Implications in the Analysis of 12 Volt Direct Current Electrical System Fires; Stahl-Engineering: Fort Wayne, Indiana, 2020. [Google Scholar]

- Babrauskas, V.; Society of Fire Protection Engineers. Ignition Handbook: Principles and Applications to Fire Safety Engineering, Fire Investigation, Risk Management and Forensic Science; Fire Science Publishers: Issaquah, WA, USA, 2003. [Google Scholar]

- Slama, M.E.A.; Beroual, A.; Hadi, H. Influence of pollution constituents on DC flashover of high voltage insulators. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 401–408. [Google Scholar] [CrossRef]

- Boukadoum, R.; Barbet, A.; Dessante, P.; Landfried, R.; Leblanc, T.; Teste, P. Simple 1D model of a short gap DC electric arc in in aeronautical pressure conditions. In Proceedings of the 2016 IEEE 62nd Holm Conference on Electrical Contacts (Holm), Clearwater Beach, FL, USA, 9–12 October 2016; pp. 179–186. [Google Scholar]

- Klimenta, D.; Radosavljević, J.; Jevtić, M.; Raičević, V.; Tasić, D.; Pajković, B. An improved non-adiabatic FEM model of a line-to-earth fault in buried power cables. Int. J. Heat Mass Transf. 2011, 54, 3514–3522. [Google Scholar] [CrossRef]

- Hoertz, F.; Koenig, D.; Hanson, J.; van Eesbeek, M. Ranking of wire insulation for spacecraft use. High Perform. Polym. 2001, 13, S517–S524. [Google Scholar] [CrossRef]

- IEC. IEC 60587:2007 Electrical Insulating Materials Used under Severe Ambient Conditions—Test Methods for Evaluating Resistance to Tracking and Erosion; IEC: Geneva, Switzerland, 2007; pp. 1–28. [Google Scholar]

- Martens, J.; Johnson, G.; So, P. Design considerations for consumer products utilizing high voltage. In Proceedings of the 2006 IEEE Symposium on Product Safety Engineering, Irvine, CA, USA, 23–24 October 2006; pp. 1–6. [Google Scholar]

- Lu, F.K.; Phonharath, L.; Mitchell, R.R.; Bigdeli, B. Flame suppression technique in arc tracking of circuit boards. In Volume 5: Electronics and Photonics; ASMEDC: Seattle, WA, USA, 2007; pp. 215–222. [Google Scholar]

- NASA. Arc-Tracking and Wire Insulation Pyrolization-EPB of NASA GRC. Available online: https://www.grc.nasa.gov/WWW/epbranch/SpaceEnvSim/arc2.htm (accessed on 7 January 2020).

- Paterson, A. Aircraft Electrical Wire Types Associated with Aircraft Electrical Fires. Available online: http://www.vision.net.au/~apaterson/aviation/wire_types.htm (accessed on 9 January 2020).

- What Are the Disadvantages of Kapton Insulated Wire?—InterConnect Wiring. Available online: https://www.interconnect-wiring.com/blog/disadvantages-kapton-insulated-wire/ (accessed on 10 January 2020).

- Hanson, J.; Koenig, D. Fault arcs effects in cable bundles for space applications in vacuum. IEEE Trans. Dielectr. Electr. Insul. 1997, 4, 394–399. [Google Scholar] [CrossRef]

- Ignition > Electrical > Arc Tracking. Available online: https://depts.washington.edu/vehfire/ignition/electrical/carbontrack.html (accessed on 7 January 2020).

- Kumagai, S.; Yoshimura, N. Tracking and erosion of HTV silicone rubber and suppression mechanism of ATH. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 203–211. [Google Scholar] [CrossRef]

- Degardin, V.; Kone, L.; Laly, P.; Lienard, M.; Degauque, P.; Valensi, F. Measurement and analysis of arc tracking characteristics in the high frequency band. In Autotestcon (Proceedings); Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2016; Volume 2016, pp. 1–6. [Google Scholar]

- Slama, M.E.A.; Albano, M.; Haddad, A.; Waters, R.T. Dry-band discharges dynamic at the surface of sir textured insulator during ac inclined plane test. In ISH 2019: Proceedings of the 21st International Symposium on High Voltage Engineering; Springer: Cham, Switzerland, 2020; pp. 504–517. [Google Scholar]

- Ashitha, P.N.; Ganga, S. A study on the effect of UV radiations on silicone rubber insulators under polluted conditions using inclined plane tracking and erosion test. In Proceedings of the 2017 3rd International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Rupnagar, India, 16–18 November 2017; pp. 259–264. [Google Scholar]

- Du, B.X.; Gu, L. Effects of interfacial pressure on tracking failure between XLPE and silicon rubber. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1922–1930. [Google Scholar] [CrossRef]

- Gu, L.; Zhang, T. Effect of pressure on tracking failure at XLPE-SIR interface based on image processing. In Proceedings of the 2019 IEEE 3rd Information Technology, Networking, Electronic and Automation Control Conference, ITNEC 2019, Chengdu, China, 15–17 March 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; pp. 523–526. [Google Scholar]

- Du, B.X.; Gu, L. Effects of interfacial pressure on tracking failure at XLPE cable joint by analyzing discharge light distribution. In Proceedings of the 2010 10th IEEE International Conference on Solid Dielectrics, Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Robert, I. Ochs Electric Wire Insulation Study: Flammable Properties and Testing Methods; FAA: Atlantic City, NJ, USA, 2006. [Google Scholar]

- Cahill, P.L.; Dailey, J.H. Aircraft Electrical Wet-Wire Arc Tracking; FAA: Atlantic City, NJ, USA, 1988. [Google Scholar]

- Which Aircraft Have Kapton Insulated Wire?—InterConnect Wiring. Available online: https://www.interconnect-wiring.com/blog/aircraft-kaptontm-insulated-wire/ (accessed on 14 January 2020).

- Babrauskas, V. Mechanisms and modes for ignition of low-voltage, PVC-insulated electrotechnical products. Fire Mater. 2006, 30, 151–174. [Google Scholar] [CrossRef]

- Jamail, N.A.M.; Piah, M.A.M.; Muhamedin, F.L.; Kasri, N.F.; Muhamad, N.A.; Kamarudin, Q.E. Electrical tracking characterization of LLDPE-natural rubber blends filled with nanofillers. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013; pp. 695–698. [Google Scholar]

- Nazir, M.T.; Phung, B.T.; Li, S.; Yu, S. Comparative AC tracking and erosion resistance of micro-A1N and BN filled silicone rubber composites. In Proceedings of the ICEMPE 2017—1st International Conference on Electrical Materials and Power Equipment, Xi’an, China, 14–17 May 2017; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017; pp. 603–606. [Google Scholar]

- Prabakar, K.; Karady, G.G. Experimental investigation of dry band arcing on ADSS cables when spiral vibration dampers are installed. In Proceedings of the 2011 Electrical Insulation Conference, EIC 2011, Annapolis, MD, USA, 5–8 June 2011; pp. 226–230. [Google Scholar]

- Liu, C.; Li, Y. Development of aircraft used wires for general purpose and a study on the application. Appl. Mech. Mater. 2014, 551, 214–220. [Google Scholar] [CrossRef]

- Lisnyak, M. Theoretical, Numerical and Experimental Study of DC and AC Electric Arcs; Université d’Orléans: Orléans, France, 2018. [Google Scholar]

- Wiring Installation—Wire Types. Available online: http://www.flight-mechanic.com/wiring-installation-wire-types/ (accessed on 14 January 2020).

- FAA. Acceptable Methods, Techniques, and Practices—Aircraft Inspection and Repair; Oklahoma, FAA: Atlantic City, NJ, USA, 1998.

- SAE. Standards SAE AS 4373: Test Methods for Insulated Electric Wire—SAE International; SAE: Warrendale, PA, USA, 1995; pp. 1–67. [Google Scholar]

- SAE. Standards SAE AS 4372: Performance Requirements for Wire, Electric, Insulated Copper or Copper Alloy; SAE International: Warrendale, PA, USA, 1990; pp. 1–21. [Google Scholar]

- Vetter, B. Smooth surface composite insulation wiring. SAE Int. J. Aerosp. 2012, 5, 590–594. [Google Scholar] [CrossRef]

- Chisca, S.; Sava, I.; Musteata, V.-E.; Bruma, M. Dielectric and conduction properties of polyimide films. In Proceedings of the CAS 2011 Proceedings (2011 International Semiconductor Conference), Sinaia, Romania, 17–19 October 2011; pp. 253–256. [Google Scholar]

- Hammoud, A.N.; Stavnes, M.W.; Dickman, J.E.; Burkhardt, L.A.; Woodford, L.M. Evaluation of wiring constructions for space applications. In Proceedings of the Conference Record of IEEE International Symposium on Electrical Insulation, Indianapolis, IN, USA, 19–22 September 1994; pp. 592–595. [Google Scholar]

- SAE. AS50881: Wiring, Aerospace Vehicle; SAE International: Warrendale, PA, USA, 1998; pp. 1–91. [Google Scholar]

- Zhang, L. Electrical Tracking over Solid Insulating Materials for Aerospace Applications; University of Manchester: Manchester, UK, 2011. [Google Scholar]

- IEC. 60112:2003+AMD1:2009 CSV Method for the Determination of the Proof and the Comparative Tracking Indices of Solid Insulating Materials; IEC Stand: Geneva, Switzerland, 2009; pp. 1–40. [Google Scholar]

- ASTM. ASTM D3638—12 Standard Test Method for Comparative Tracking Index of Electrical Insulating Materials; ASTM: West Conshohocken, PA, USA, 2012; pp. 1–5. [Google Scholar]

- ASTM. ASTM D2303—13 Standard Test Methods for Liquid-Contaminant, Inclined-Plane Tracking and Erosion of Insulating Materials; ASTM: West Conshohocken, PA, USA, 2013; pp. 1–11. [Google Scholar]

- Ghunem, R.; Jayaram, S.; Cherney, E. The DC inclined-plane tracking and erosion test and the role of inorganic fillers in silicone rubber for DC insulation. IEEE Electr. Insul. Mag. 2015, 31, 12–21. [Google Scholar] [CrossRef]

- Chen, P.; Wang, X.; Li, X.; Lyu, Q.; Wang, N.; Jia, Z. A quick classifying method for tracking and erosion resistance of htv silicone rubber material via laser-induced breakdown spectroscopy. Sensors 2019, 19, 1087. [Google Scholar] [CrossRef] [PubMed]

- SAE. AS6019: ARC Fault Circuit Breaker (AFCB), Aircraft, Trip-Free 28 VDC; SAE International: Warrendale, PA, USA, 2012; pp. 1–60. [Google Scholar]

- Riba, J.-R.; Morosini, A.; Capelli, F.; Riba, J.-R.; Morosini, A.; Capelli, F. Comparative study of ac and positive and negative dc visual corona for sphere-plane gaps in atmospheric air. Energies 2018, 11, 2671. [Google Scholar] [CrossRef]

- Abomailek, C.; Riba, J.-R.; Casals-Torrens, P. Feasibility analysis of reduced-scale visual corona tests in high voltage laboratories. IET Gener. Transm. Distrib. 2019. [Google Scholar] [CrossRef]

- Karady, G.G.; Sirkis, M.D.; Oliva, J.R. Degrading effect of high-altitude corona on electronic circuit boards. IEEE Trans. Electr. Insul. 1991, 26, 1216–1219. [Google Scholar] [CrossRef]

- Robledo-Martinez, A.; Sobral, H.; Ruiz-Meza, A. Effect of pressure in fast-front lightning discharges in air. IEEE Trans. Plasma Sci. 2008, 36, 948–949. [Google Scholar] [CrossRef]

- McMahon, E.J. The chemistry of corona degradation of organic insulating materials in high-voltage fields and under mechanical strain. IEEE Trans. Electr. Insul. 1968, EI-3, 3–10. [Google Scholar] [CrossRef]

- Refaat, S.S.; Shams, M.A. A Review of Partial Discharge Detection, Diagnosis Techniques in High Voltage Power Cables. In Proceedings of the 2018 IEEE 12th International Conference on Compatibility, Power Electronics and Power Engineering, CPE-POWERENG 2018, Doha, Qatar, 10–12 April 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018; pp. 1–5. [Google Scholar]

- Chai, H.; Phung, B.T.; Mitchell, S. Application of UHF sensors in power system equipment for partial discharge detection: A review. Sensors 2019, 19, 1029. [Google Scholar] [CrossRef]

- Souza, A.L.; Lopes, I.J.S. Experimental investigation of corona onset in contaminated polymer surfaces. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1321–1331. [Google Scholar] [CrossRef]

- Kozioł, M.; Nagi, Ł.; Kunicki, M.; Urbaniec, I. Radiation in the optical and UHF range emitted by partial discharges. Energies 2019, 12, 4334. [Google Scholar] [CrossRef]

- Moore, A.J.; Schubert, M.; Rymer, N. Technologies and operations for high voltage corona detection with UAVs. In Proceedings of the IEEE Power and Energy Society General Meeting, IEEE Computer Society, Portland, OR, USA, 5–10 August 2018; Volume 2018. [Google Scholar]

- Maistry, N.; Schutz, R.A.; Cox, E. The Quantification of Corona Discharges on High Voltage Electrical Equipment in the UV Spectrum Using a Corona Camera. In Proceedings of the 2018 International Conference on Diagnostics in Electrical Engineering, Diagnostika 2018, Pilsen, Czech Republic, 4–7 September 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018. [Google Scholar]

- Stranges, M.K.W.; Ul Haq, S.; Dunn, D.G. Black-Out test versus UV camera for corona inspection of HV motor stator endwindings. IEEE Trans. Ind. Appl. 2014, 50, 3135–3140. [Google Scholar] [CrossRef]

- Prasad, D.S.; Reddy, B.S. Understanding Corona Discharges using Digital Imaging. In Proceedings of the 2018 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Athens, Greece, 10–13 September 2018; pp. 1–4. [Google Scholar]

- Miao, W.; Liu, X.; Lam, K.H.; Pong, P.W.T. DC-arcing detection by noise measurement with magnetic sensing by TMR sensors. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- IEC. IEC 60664:2020 Insulation Coordination for Equipment within low-Voltage Systems; IEC: Geneva, Switzerland, 2020; pp. 1–504. [Google Scholar]

| Designation | Insulation Material |

|---|---|

| M5086/1,2 | PVC/Nylon |

| M81381 | Aromatic Polyimide (Kapton®) |

| M22759/34 | Cross-Linked ETFE |

| M22759/80-92 | PTFE/Polyimide/PTFE composite (TKT) |

| M22759/11 | Teflon® (PTFE) |

| M22759/18 | Tezfel® (ETFE) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riba, J.-R.; Gómez-Pau, Á.; Moreno-Eguilaz, M.; Bogarra, S. Arc Tracking Control in Insulation Systems for Aeronautic Applications: Challenges, Opportunities, and Research Needs. Sensors 2020, 20, 1654. https://doi.org/10.3390/s20061654

Riba J-R, Gómez-Pau Á, Moreno-Eguilaz M, Bogarra S. Arc Tracking Control in Insulation Systems for Aeronautic Applications: Challenges, Opportunities, and Research Needs. Sensors. 2020; 20(6):1654. https://doi.org/10.3390/s20061654

Chicago/Turabian StyleRiba, Jordi-Roger, Álvaro Gómez-Pau, Manuel Moreno-Eguilaz, and Santiago Bogarra. 2020. "Arc Tracking Control in Insulation Systems for Aeronautic Applications: Challenges, Opportunities, and Research Needs" Sensors 20, no. 6: 1654. https://doi.org/10.3390/s20061654

APA StyleRiba, J.-R., Gómez-Pau, Á., Moreno-Eguilaz, M., & Bogarra, S. (2020). Arc Tracking Control in Insulation Systems for Aeronautic Applications: Challenges, Opportunities, and Research Needs. Sensors, 20(6), 1654. https://doi.org/10.3390/s20061654