ADAPTS: An Intelligent Sustainable Conceptual Framework for Engineering Projects

Abstract

1. Introduction

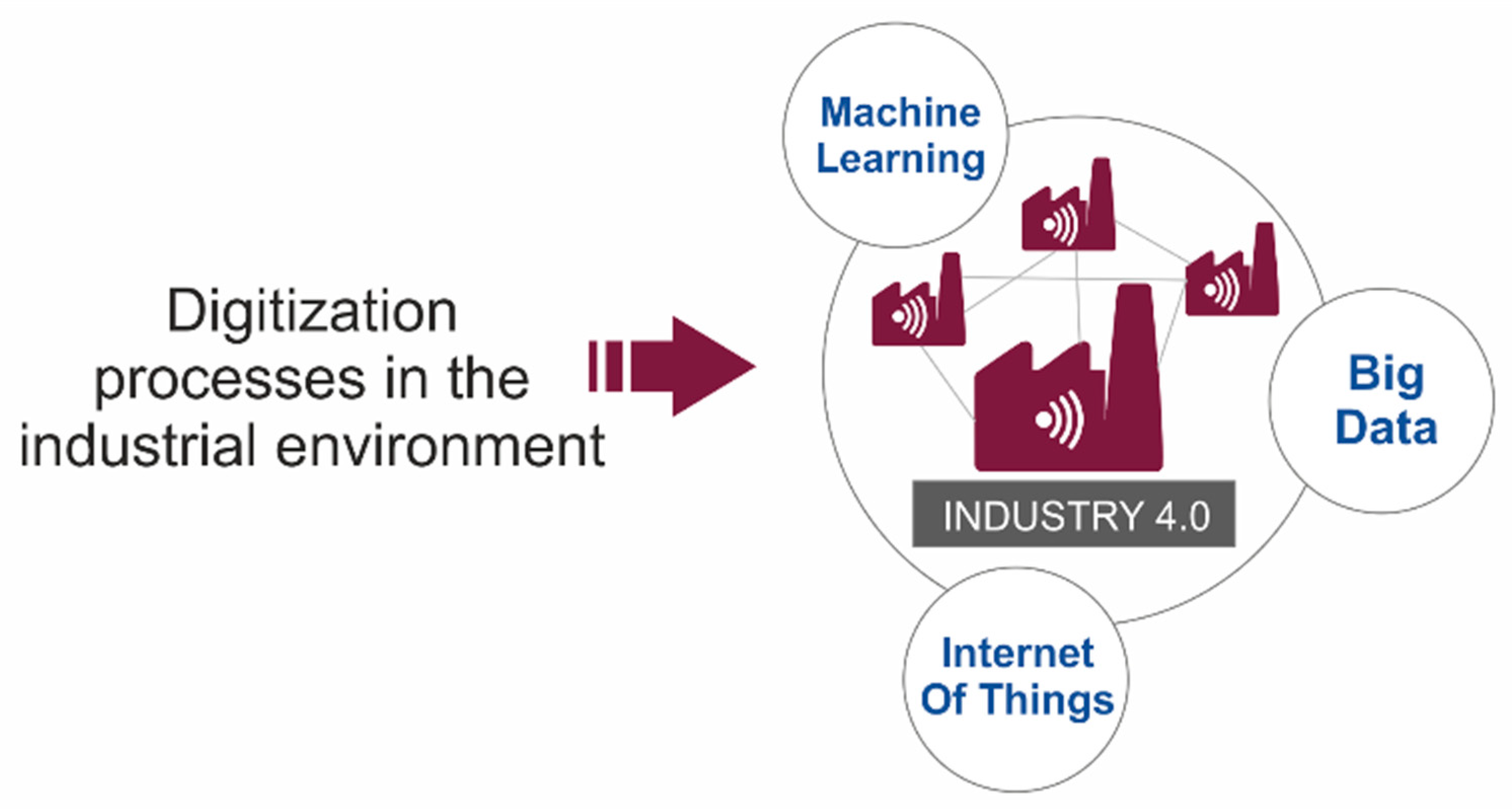

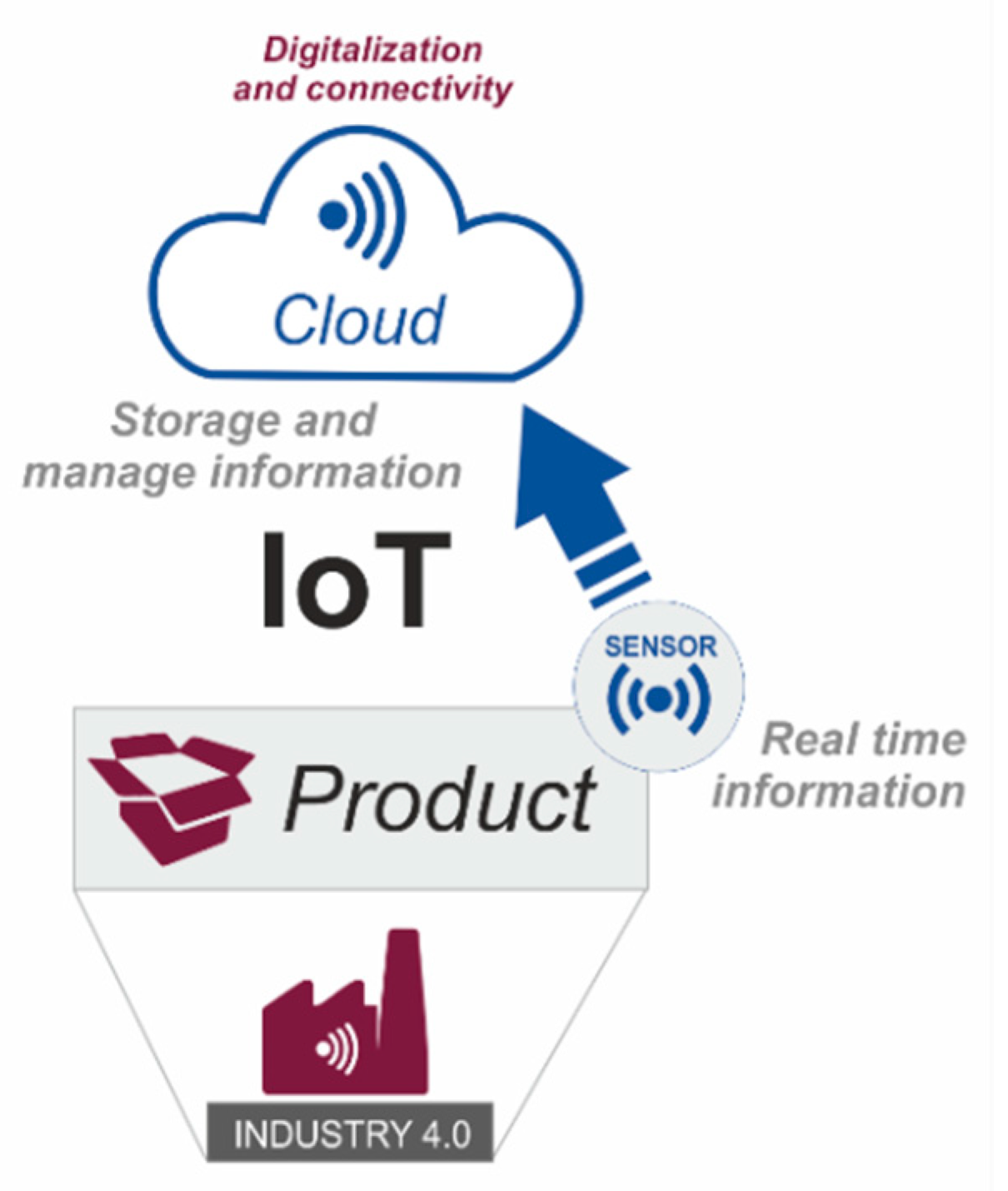

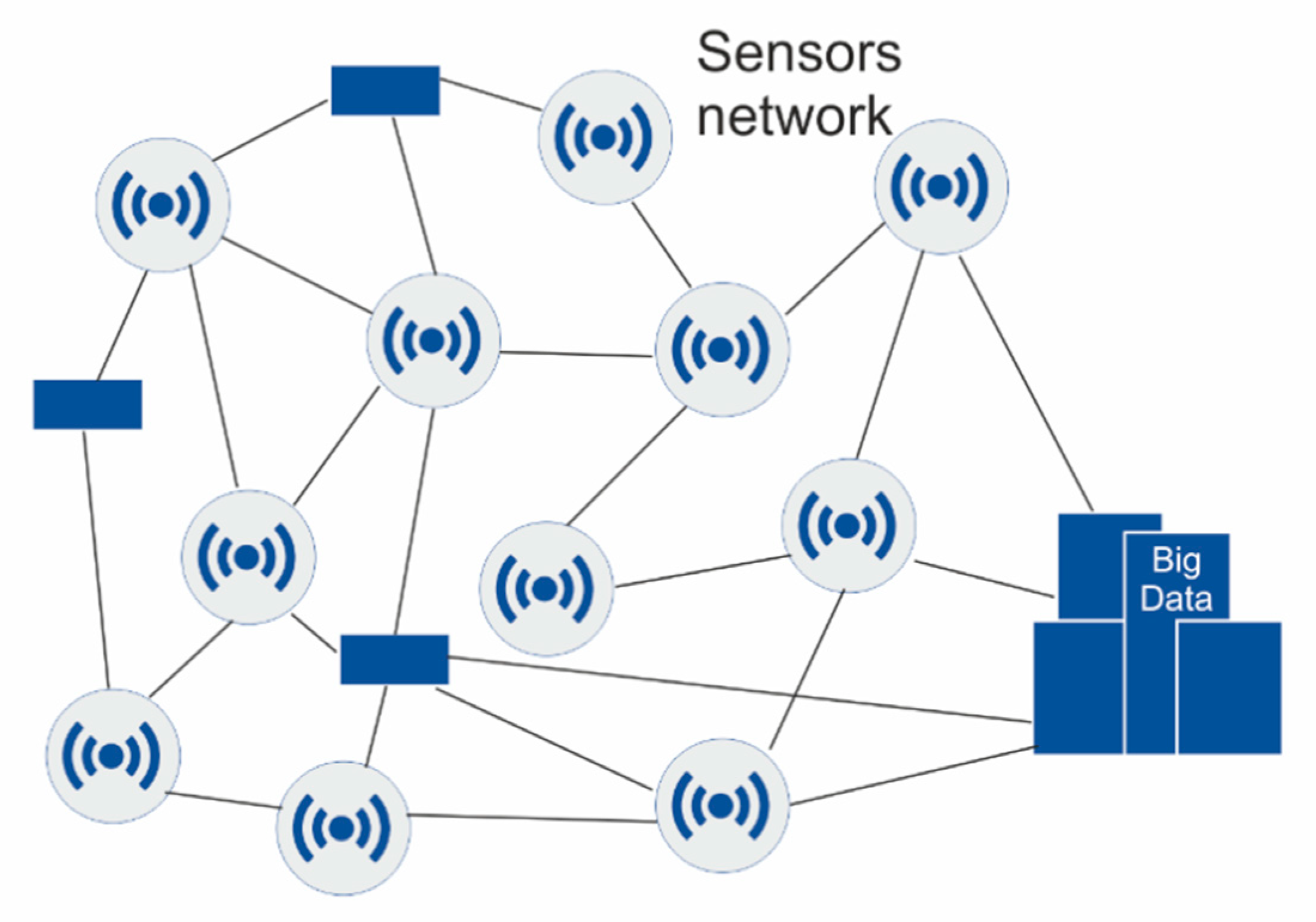

- Collection of data from machines, warehouses and articles, achieved through the Internet of Things (IoT).

- Analysis and exploitation of this huge amount of data through big data and business intelligence (BI) techniques.

- Predictive analytics based on data through machine learning.

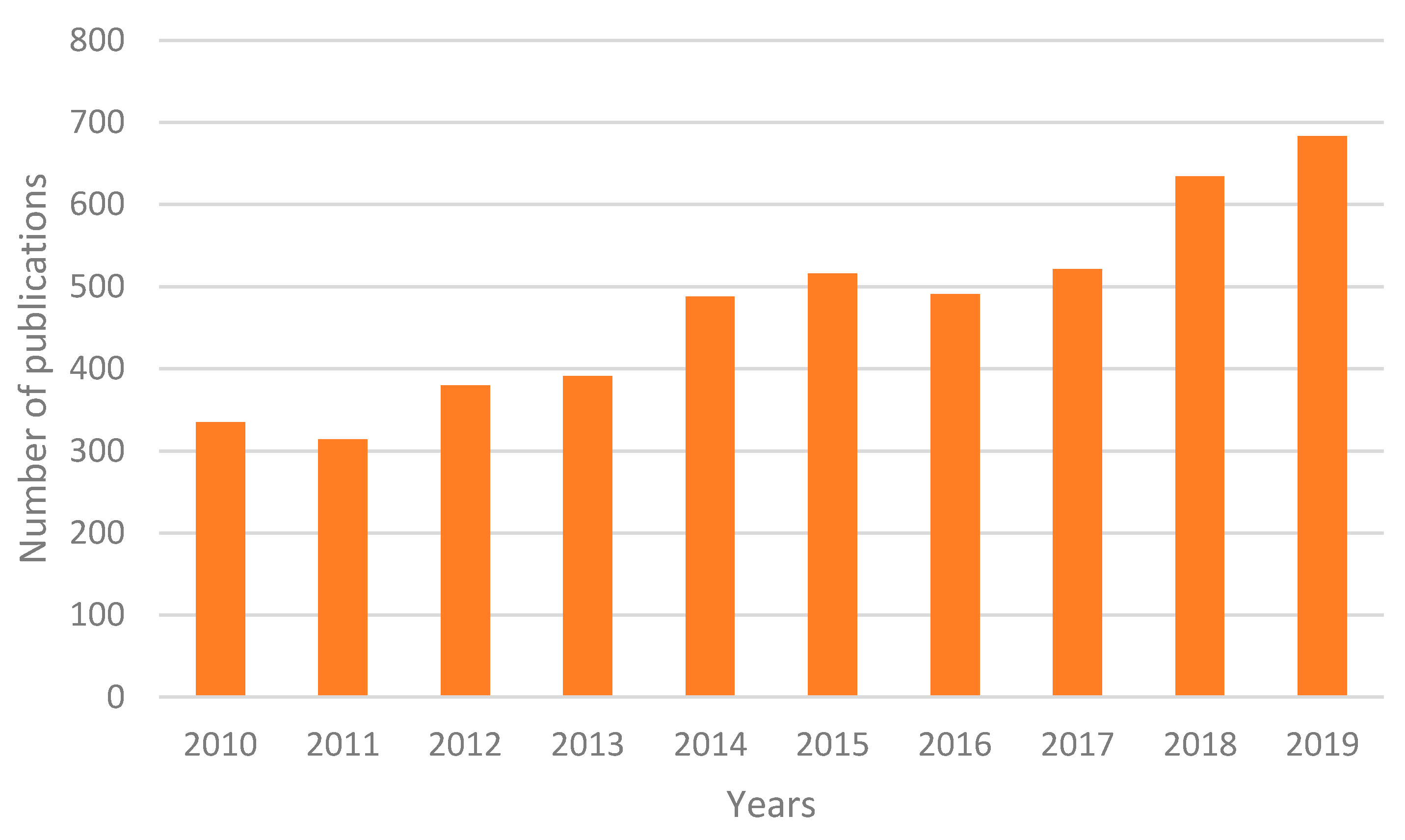

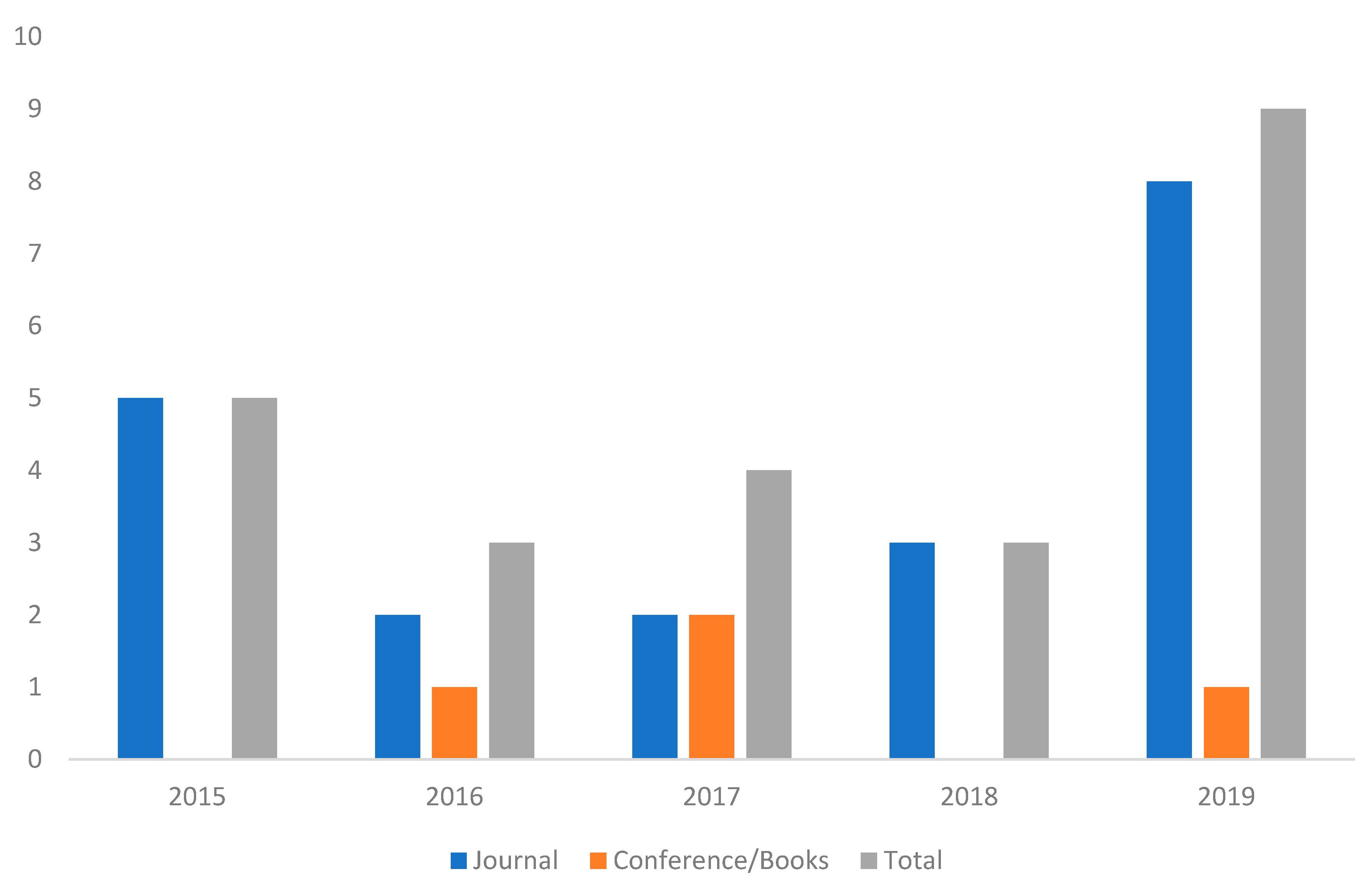

2. Methodology

3. Results

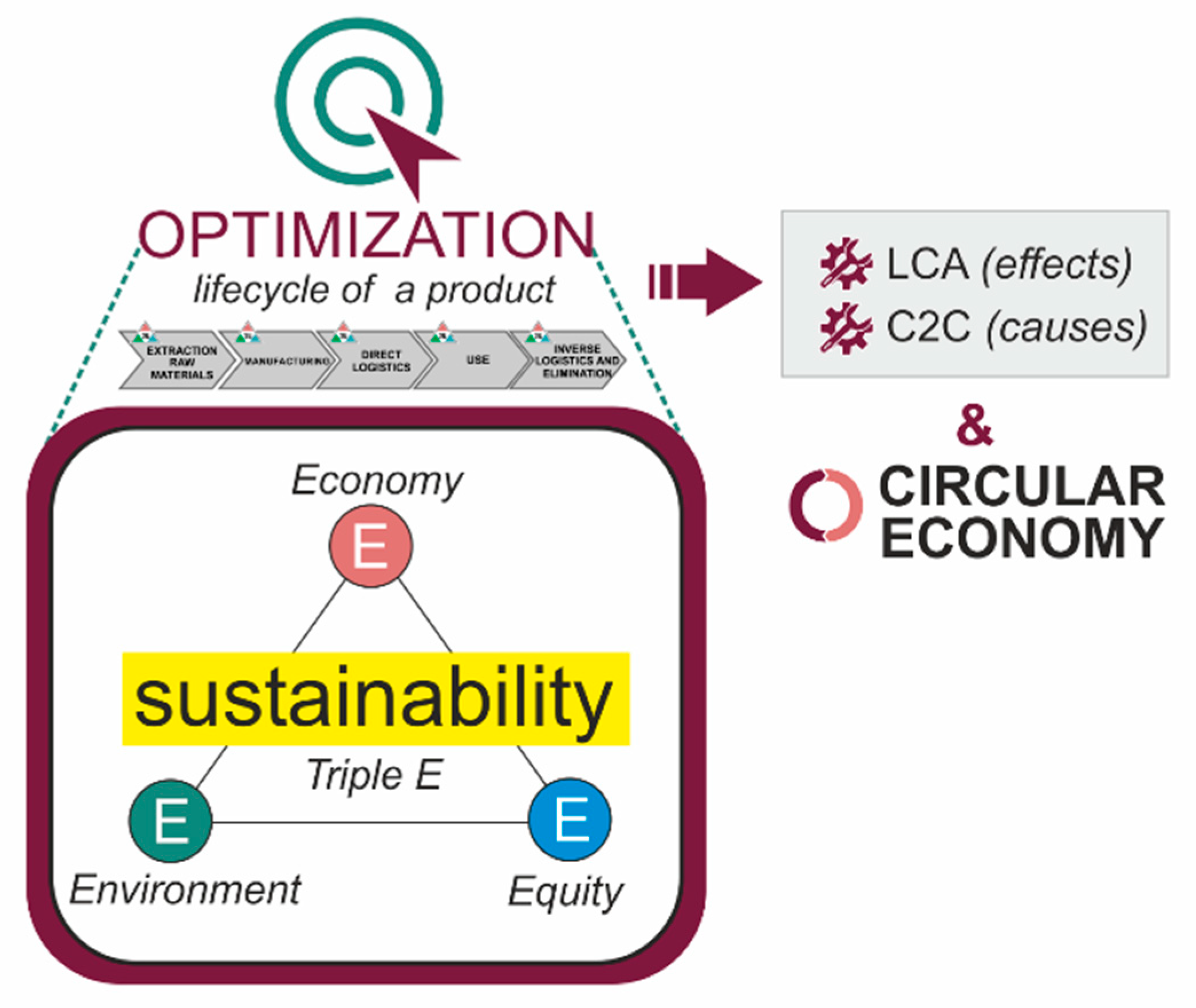

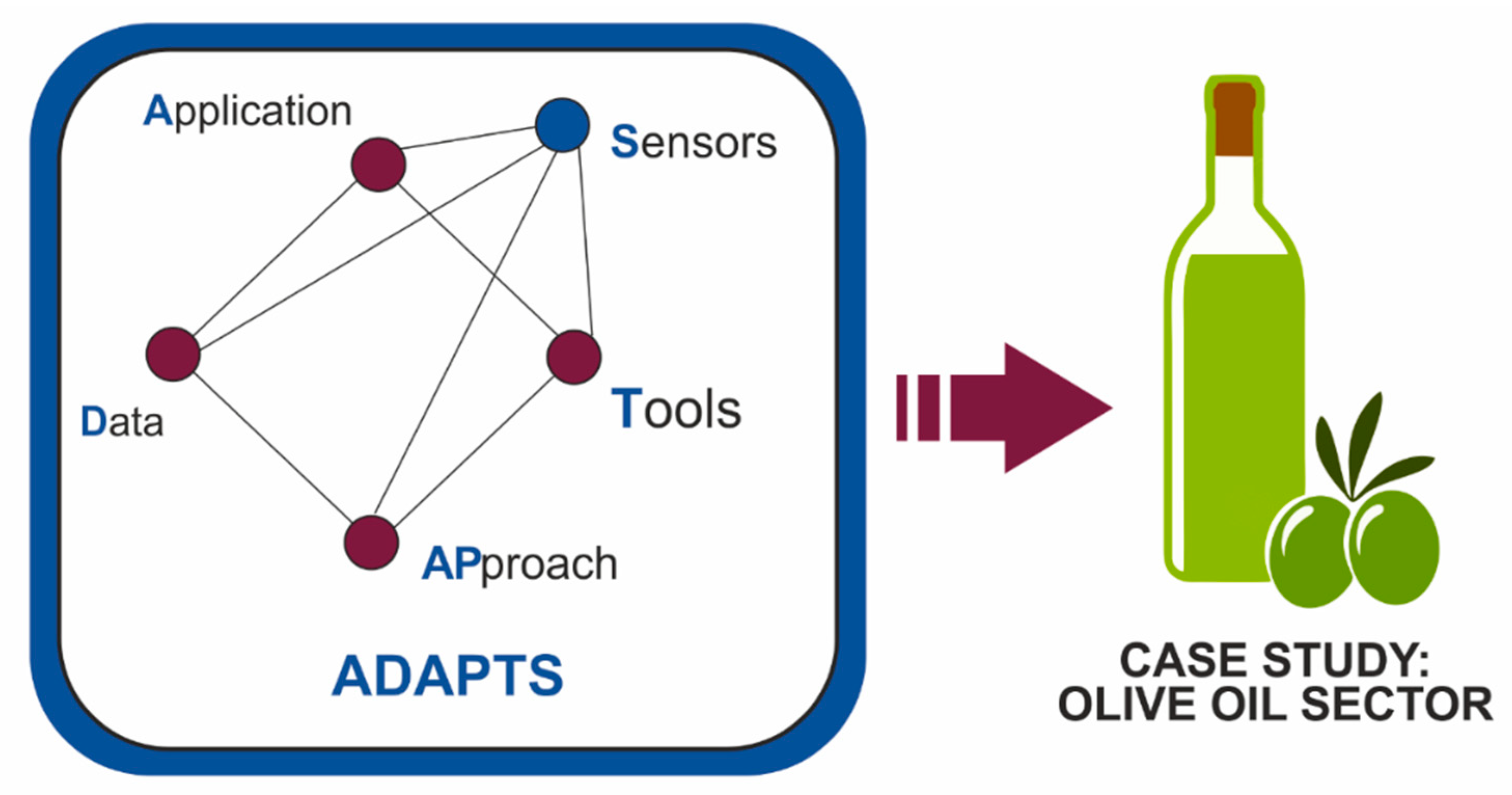

3.1. ADAPTS: A Proposal of Conceptual Framework for Engineering Projects

3.1.1. Applications

3.1.2. Data

3.1.3. Approaches

3.1.4. Tools

3.1.5. Sensors

3.2. Case Study

- (1)

- (2)

- Does it provide a common language from which to describe the situation under scrutiny and to report the findings about it [79].

- (3)

- Does it develop a set of guiding principles against which judgments and predictions might be made?

- (4)

- Does it act as a series of reference points from which to locate the research questions within contemporary theorizing?Does it provided a structure within which to organize the content of the research and to frame conclusions within the context? [78].

- (5)

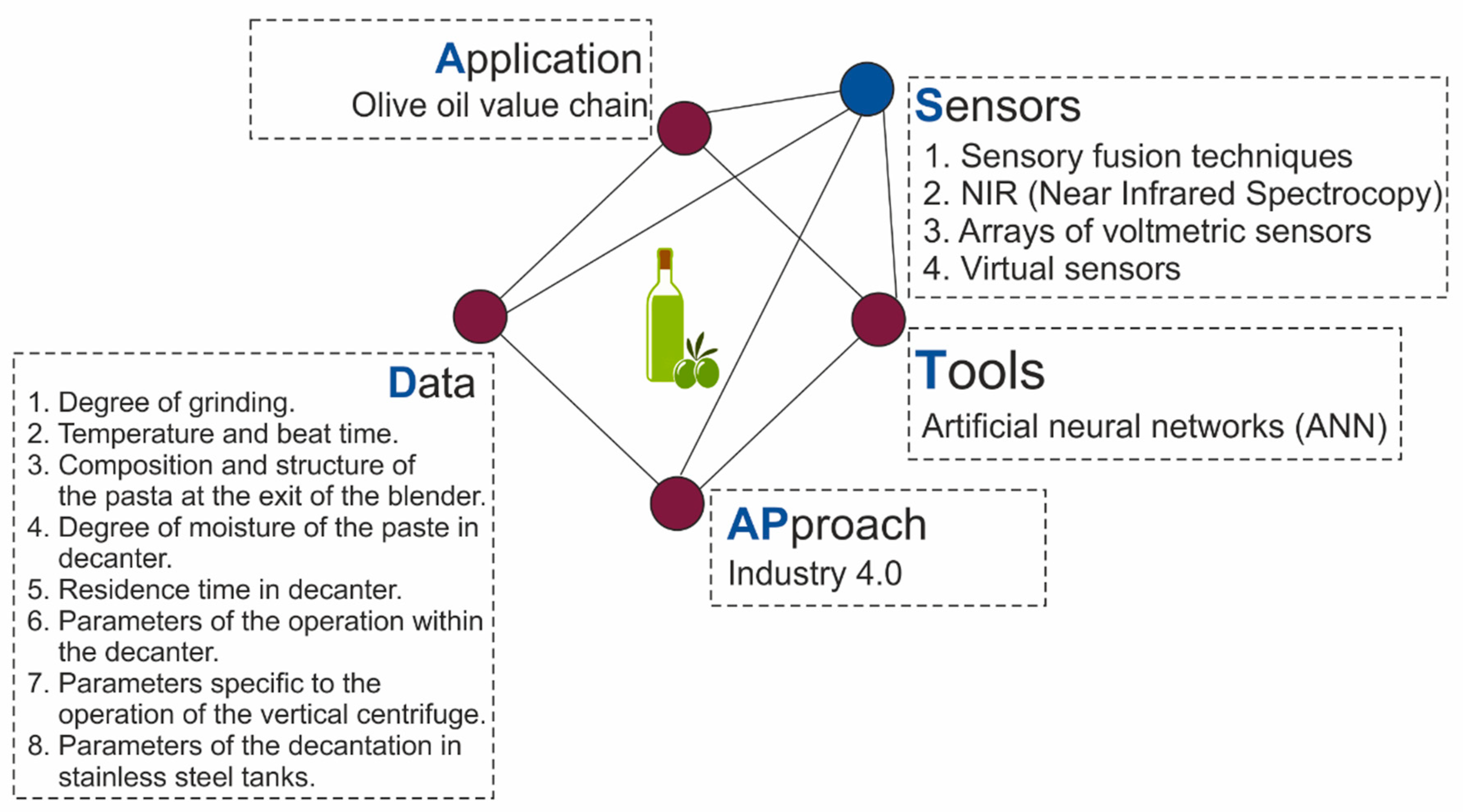

- Below is an application of the proposed conceptual framework to a specific case study, the olive oil sector. Each of the dimensions of the ADAPTS pyramid will be discussed in this example (Figure 10).

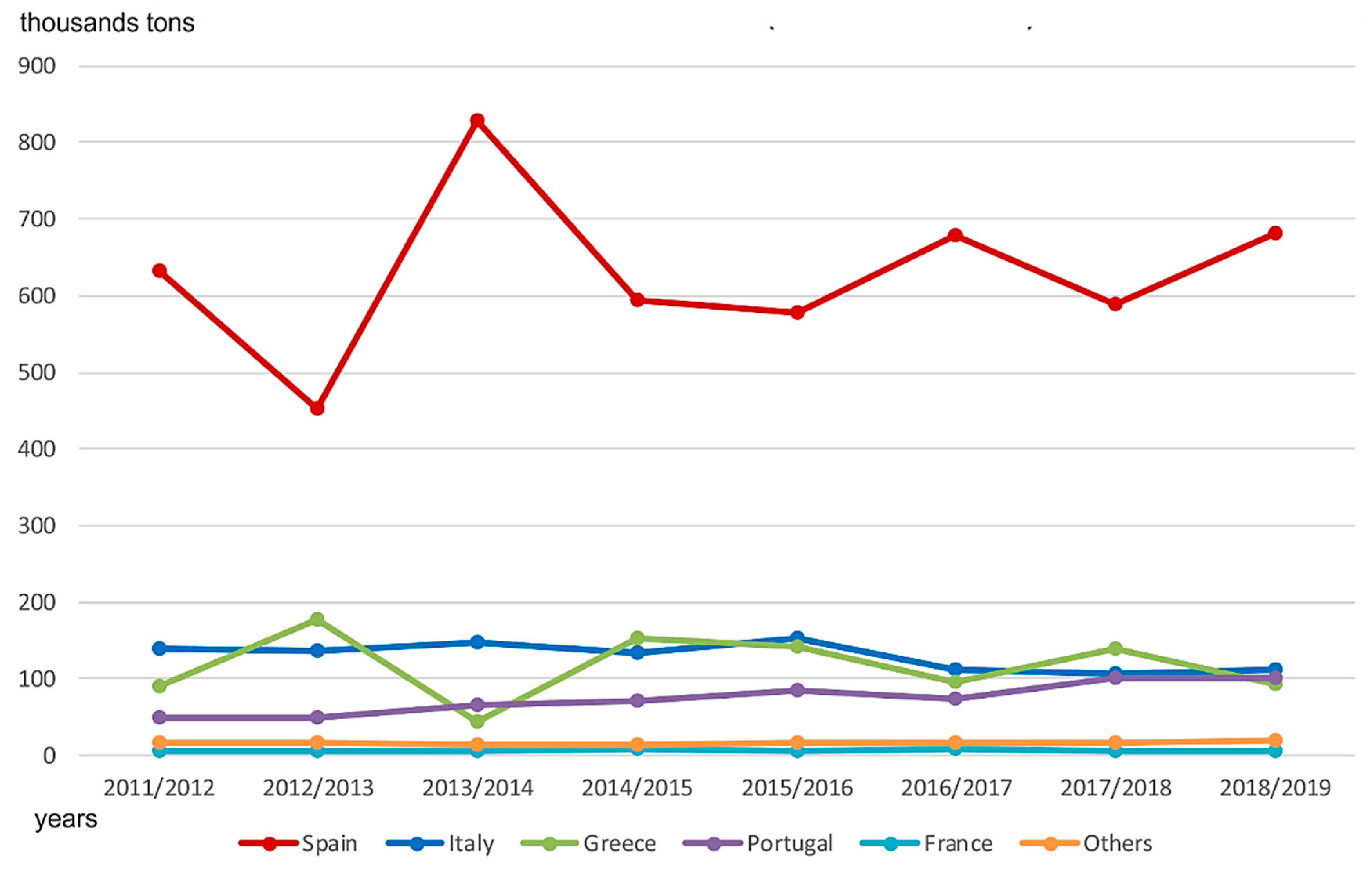

3.2.1. Application

3.2.2. Data

- (1)

- Degree of grinding. The degree of grinding indicates the average size in which the hardest parts of the paste remain. Grinding too thick means a weak breakage of the tissues that leads to a decrease in exhaustion. On the other hand, too fine grinding causes a greater increase in the temperature of the paste that has a negative impact on the quality of the oil, and can generate more emulsions in the pasta that deplete exhaustion. Additionally, too fine grinding causes problems of bindings in the mill and increases energy consumption [85].

- (2)

- Temperature and beat time. These parameters are, perhaps, the most decisive in the quality of the oil to be obtained. The increase in the temperature of the pasta in the blender reduces its viscosity, which favors the aggregation of the drops of oil and therefore improves extraction performance. On the other hand, the increase in shaking time also favors the change in the structure of the paste that allows increasing the depletion of the pomace. However, both parameters have a negative impact on the quality of the oil obtained, since the increase in temperature accelerates the speed of the reactions that take place in the blender and favors the loss of volatile components.

- (3)

- Composition and structure of the pasta at the exit of the blender. In the shaking of the so-called difficult pastes, which are those pastes that present difficulties in extracting the oil, it is necessary to use adjuvants (natural microtalco and, where appropriate, water) to improve their behavior. A repair of the deficient pulp entails substantial increases in the oil contained in the pomace, while the addition of adjuvants has no influence on the quality of the oils obtained [86].

- (4)

- Degree of moisture of the paste in decanter. This parameter has great relevance in depletion, since it will determine the thickness of the rings inside the decanter and, therefore, the operating conditions of the machine.

- (5)

- Residence time in decanter. The residence time in the decanter is determined by the established production rate, which is generally imposed by the olive oil entering the mill and the capacity of the installation. Operating the decanter at higher rates than recommended implies a significant loss of fat in the pomace.

- (6)

- Parameters of the operation within the decanter. The differential screw-bowl speed and the discharge height of the oil phase determine the width of the different rings within the decanter [87]. A correct choice of these parameters makes it possible to improve depletion without influencing the quality of the oil obtained.

- (7)

- Parameters specific to the operation of the vertical centrifuge. The temperature of the addition water must be adjusted to the temperature of the oil so as not to affect its organoleptic properties and avoid the formation of emulsions that induce the loss of oil with the wash waters. Likewise, the water flow must be adjusted to that of oil for the proper functioning of the machine in terms of losses. Finally, the discharge frequency of the cumulative strips is an important parameter since it influences the quality of the oil obtained and the oil losses in the operation.

- (8)

- Parameters of the decantation in stainless steel tanks. The main parameter is the residence time of the oil in the tanks and the frequency of the purges of the erasures. A short residence time means that the oil remains with a high level of moisture and impurities, while a residence time that is too high and a poor purge frequency can be supposed to damage its organoleptic characteristics [88].

3.2.3. Approach

3.2.4. Tools

3.2.5. Sensors

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kuhlman, T.; Farrington, J. What is Sustainability? Sustainability 2010, 2, 3436–3448. [Google Scholar] [CrossRef]

- Mebratu, D. Sustainability and sustainable development: Historical and conceptual review. Environ. Impact Assess. Rev. 1998, 18, 493–520. [Google Scholar] [CrossRef]

- Lélé, S.M. Sustainable development: A critical review. World Dev. 1991, 19, 607–621. [Google Scholar] [CrossRef]

- Baker, S.; Kousis, M.; Young, S.; Richardson, D. The Politics of Sustainable Development: Theory, Policy and Practice within the European Union; Psychology Press: London, UK, 1997. [Google Scholar]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?-Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Elkington, J. Accounting for the Triple Bottom Line. Meas. Bus. Excell. 1998, 2, 18–22. [Google Scholar] [CrossRef]

- Chong, H.Y.; Lee, C.Y.; Wang, X. A mixed review of the adoption of Building Information Modelling (BIM) for sustainability. J. Clean. Prod. 2017, 142, 4114–4126. [Google Scholar] [CrossRef]

- Eleftheriadis, S. BIM Integrated Optimisation Framework for Environmentally Responsible and Structurally Efficient Design Systems: A Holistic Cloud Based Approach BIM Integrated Optimisation Framework for Environmentally Responsible and Structurally Efficient Design Syste. Ph.D. Thesis, University College London, London, UK, 2014. [Google Scholar]

- Shi, J.; Liu, Z.; Zhang, H.; Jiang, Q.; Li, T. Life Cycle Assessment: State of the Art and Future Perspectives. Recent Patents Mech. Eng. 2015, 8, 211–221. [Google Scholar] [CrossRef]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things, 1st ed.; North Point Press: New York, NY, USA, 2002; ISBN 9780865475878. [Google Scholar]

- Aguayo González, F.; Peralta Álvarez, M.E.; Lama Ruiz, J.; Soltero Sánchez, V. Ecodiseño: Ingeniería Sostenible de la Cuna a la Cuna (C2C); RC Libros: Madrid, Spain, 2011; ISBN 9788493831264. [Google Scholar]

- Prieto-Sandoval, V.; Jaca, C.; Ormazabal, M. Towards a consensus on the circular economy. J. Clean. Prod. 2018, 179, 605–615. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Bjørn, A.; Hauschild, M.Z. Cradle to Cradle and LCA–is there a Conflict. In Glocalized Solutions for Sustainability in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 599–604. [Google Scholar]

- Peralta-Álvarez, M.E.; Aguayo-Gonzálezz, F.; Lama-Ruiz, J.R.; Ávila-Gutiérrez, M.J. MGE2: Un marco de referencia para el diseño de la cuna a la cuna. DYNA 2015, 82, 137–146. [Google Scholar]

- Chang, D.; Lee, C.K.M.; Chen, C.H. Review of life cycle assessment towards sustainable product development. J. Clean. Prod. 2014, 83, 48–60. [Google Scholar] [CrossRef]

- Jacquemin, L.; Pontalier, P.Y.; Sablayrolles, C. Life cycle assessment (LCA) applied to the process industry: A review. Int. J. Life Cycle Assess. 2012, 17, 1028–1041. [Google Scholar] [CrossRef]

- Del Val Román, J.L. Industria 4.0: La transformación digital de la industria. In Proceedings of the Conferencia de Directores y Decanos de Ingeniería Informática, Informes CODDII, Valencia, Spain, 18 March 2016; p. 10. [Google Scholar]

- Schweer, D.; Sahl, J.C. The Digital Transformation of Industry—The Benefit for Germany. In The Drivers of Digital Transformation; Springer: Cham, Switzerland, 2017; pp. 23–31. ISBN 978-3-319-31823-3. [Google Scholar]

- Kagermann, H. Change through digitization—Value creation in the age of industry 4.0. In Management of Permanent Change; Springer Science + Business Media: Norwell, MA, USA, 2015; pp. 23–45. ISBN 9783658050146. [Google Scholar]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Networks 2016, 2016, 3159805. [Google Scholar] [CrossRef]

- Al-Jarrah, O.Y.; Yoo, P.D.; Muhaidat, S.; Karagiannidis, G.K.; Taha, K. Efficient Machine Learning for Big Data: A Review. Big Data Res. 2015, 2, 87–93. [Google Scholar] [CrossRef]

- Palaniappan, R.; Sundaraj, K.; Ahamed, N.U. Machine learning in lung sound analysis: A systematic review. Biocybern. Biomed. Eng. 2013, 33, 129–135. [Google Scholar] [CrossRef]

- Madabhushi, A.; Lee, G. Image analysis and machine learning in digital pathology: Challenges and opportunities. Med. Image Anal. 2016, 33, 170–175. [Google Scholar] [CrossRef]

- Komura, D.; Ishikawa, S. Machine Learning Methods for Histopathological Image Analysis. Comput. Struct. Biotechnol. J. 2018, 16, 34–42. [Google Scholar] [CrossRef]

- Arano, K.A.G.; Sun, S.; Ordieres-Mere, J.; Gong, B. The use of the internet of things for estimating personal pollution exposure. Int. J. Environ. Res. Public Health 2019, 16, 3130. [Google Scholar] [CrossRef]

- Steyerberg, E.W.; van der Ploeg, T.; Van Calster, B. Risk prediction with machine learning and regression methods. Biom. J. 2014, 56, 601–606. [Google Scholar] [CrossRef]

- Gholami, B.; Phan, T.S.; Haddad, W.M.; Cason, A.; Mullis, J.; Price, L.; Bailey, J.M. Replicating human expertise of mechanical ventilation waveform analysis in detecting patient-ventilator cycling asynchrony using machine learning. Comput. Biol. Med. 2018, 97, 137–144. [Google Scholar] [CrossRef] [PubMed]

- Kashnikov, A.V.; Levin, L. Applying machine learning techniques to mine ventilation control systems. In Proceedings of the 2017 20th IEEE International Conference on Soft Computing and Measurements, SCM 2017, St. Petersburg, Russia, 24–26 May 2017; Institute of Electrical and Electronics Engineers Inc.: Interlaken, Switzerland, 2017; pp. 391–393. [Google Scholar]

- Van Peteghem, V.; Vanhoucke, M. A genetic algorithm for the preemptive and non-preemptive multi-mode resource-constrained project scheduling problem. Eur. J. Oper. Res. 2010, 201, 409–418. [Google Scholar] [CrossRef]

- Vanhoucke, M.; Coelho, J.; Debels, D.; Maenhout, B.; Tavares, L.V. An evaluation of the adequacy of project network generators with systematically sampled networks. Eur. J. Oper. Res. 2008, 187, 511–524. [Google Scholar] [CrossRef]

- Cai, H.; Xu, B.; Jiang, L.; Vasilakos, A.V. IoT-Based Big Data Storage Systems in Cloud Computing: Perspectives and Challenges. IEEE Internet Things J. 2017, 4, 75–87. [Google Scholar] [CrossRef]

- Adamson, G.; Wang, L.; Holm, M.; Moore, P. Cloud manufacturing—A critical review of recent development and future trends. Int. J. Comput. Integr. Manuf. 2017, 30, 347–380. [Google Scholar] [CrossRef]

- De Carolis, A.; Macchi, M.; Kulvatunyou, B.; Brundage, M.P.; Terzi, S. Maturity Models and tools for enabling smart manufacturing systems: Comparison and reflections for future developments. In IFIP Advances in Information and Communication Technology; Springer New York LLC: New York, NY, USA, 2017; Volume 517, pp. 23–35. [Google Scholar]

- Kost, G.J. Connectivity: The millennium challenge for point-of-care testing. Arch. Pathol. Lab. Med. 2000, 124, 1108–1110. [Google Scholar] [PubMed]

- Puyol Moreno, J. Una aproximación a Big Data. RDUNED. Rev. Derecho UNED 2014, 14, 471–506. [Google Scholar]

- Diez-Olivan, A.; Del Ser, J.; Galar, D.; Sierra, B. Data fusion and machine learning for industrial prognosis: Trends and perspectives towards Industry 4.0. Inf. Fusion 2019, 50, 92–111. [Google Scholar] [CrossRef]

- Sarvari, P.A.; Ustundag, A.; Cevikcan, E.; Kaya, I.; Cebi, S. Technology Roadmap for Industry 4.0. In Industry 4.0: Managing the Digital Transformation; Springer Series in Advanced Manufacturing; Springer: Cham, Switzerland, 2018; Volume 95, 103, ISBN 978-3-319-57869-9. [Google Scholar]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef]

- Nalepa, G.J.; Kutt, K.; Zycka, B.G.; Jemioło, P.; Bobek, S. Analysis and use of the emotional context with wearable devices for games and intelligent assistants. Sensors 2019, 19, 2509. [Google Scholar] [CrossRef]

- Zupančič, E.; Žalik, B. Data trustworthiness evaluation in mobile crowdsensing systems with users’ trust dispositions’ consideration. Sensors 2019, 19, 1326. [Google Scholar] [CrossRef] [PubMed]

- Mordecai, Y.; Dori, D. Minding the cyber-physical gap: Model-based analysis and mitigation of systemic perception-induced failure. Sensors 2017, 17, 1644. [Google Scholar] [CrossRef] [PubMed]

- González, I.; Calderón, A.J.; Barragán, A.J.; Andújar, J.M. Integration of sensors, controllers and instruments using a novel OPC architecture. Sensors 2017, 17, 1512. [Google Scholar] [CrossRef] [PubMed]

- Yoo, M.J.; Grozel, C.; Kiritsis, D. Closed-loop lifecycle management of service and product in the internet of things: Semantic framework for knowledge integration. Sensors 2016, 16, 1053. [Google Scholar] [CrossRef]

- Varela, G.; Paz-Lopez, A.; Becerra, J.A.; Vazquez-Rodriguez, S.; Duro, R.J. UniDA: Uniform device access framework for human interaction environments. Sensors 2011, 11, 9361–9392. [Google Scholar] [CrossRef]

- Succar, B. Building information modelling framework: A research and delivery foundation for industry stakeholders. Autom. Constr. 2009, 18, 357–375. [Google Scholar] [CrossRef]

- Zamora-Polo, F. Conceptual Framework for the Use of Building Information Modeling in Engineering Education. Int. J. Eng. Educ. 2019, 35, 744–755. [Google Scholar]

- Borsotti, C.A. Temas de Metodología de la Investigación; Argentina: Miño y Dávila: Buenos Aires, Argentina, 2006. [Google Scholar]

- Zamora-Polo, F.; Sánchez-Martín, J. Teaching for a better world. Sustainability and Sustainable Development Goals in the construction of a change-maker university. Sustainability 2019, 11, 4224. [Google Scholar] [CrossRef]

- Heidegger, M. Sein und Zeit (Ser y Tiempo); Trotta S.A.: Madrid, Spain, 2005; ISBN 9788498790474. [Google Scholar]

- Lozano, R.; Merrill, M.; Sammalisto, K.; Ceulemans, K.; Lozano, F. Connecting Competences and Pedagogical Approaches for Sustainable Development in Higher Education: Review and Framework Proposal. Sustainability 2017, 9, 1889. [Google Scholar] [CrossRef]

- Pawson, R.; Greenhalgh, T.; Harvey, G.; Walshe, K. Realist review-a new method of systematic review designed for complex policy interventions. J. Health Serv. Res. Policy 2005, 10, 21–34. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical review of bim-based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. BMJ Case Rep. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Jabareen, Y. Building a Conceptual Framework: Philosophy, Definitions, and Procedure. Int. J. Qual. Methods 2009, 8, 49–62. [Google Scholar] [CrossRef]

- Strauss, A.; Corbin, J. Basics of Qualitative Research; Sage Publications, Inc.: Newbury Park, CA, USA, 1967; ISBN 0-8039-5939-7. [Google Scholar]

- Strauss, A.; Corbin, J. Grounded theory research: Procedures, canons, and evaluative criteria. Qual. Sociol. 1990, 13, 3–21. [Google Scholar]

- El Hamzaoui, Y.; Rodríguez, J.A.; Hernández, J.A.; Salazar, V. Optimization of operating conditions for steam turbine using an artificial neural network inverse. Appl. Therm. Eng. 2015, 75, 648–657. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Omid, M.; Mousazadeh, H.; Shamshirband, S.; Hamid, S.H.A. Developing a fuzzy clustering model for better energy use in farm management systems. Renew. Sustain. Energy Rev. 2015, 48, 27–34. [Google Scholar] [CrossRef]

- Marvuglia, A.; Kanevski, M.; Benetto, E. Machine learning for toxicity characterization of organic chemical emissions using USEtox database: Learning the structure of the input space. Environ. Int. 2015, 83, 72–85. [Google Scholar] [CrossRef]

- Slapnik, M.; Istenič, D.; Pintar, M.; Udovč, A. Extending life cycle assessment normalization factors and use of machine learning—A Slovenian case study. Ecol. Indic. 2015, 50, 161–172. [Google Scholar] [CrossRef]

- Gust, K.A.; Collier, Z.A.; Mayo, M.L.; Stanley, J.K.; Gong, P.; Chappell, M.A. Limitations of toxicity characterization in life cycle assessment: Can adverse outcome pathways provide a new foundation? Integr. Environ. Assess. Manag. 2016, 12, 580–590. [Google Scholar] [CrossRef]

- Wisthoff, A.; Huynh, T.; Ferrero, V.; Dupont, B. Quantifying the impact of sustainable product design decisions in the early design phase through machine learning. In Proceedings of the ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016; Volume 4, pp. 1–10. [Google Scholar]

- Li, Y.; Zhang, H.; Roy, U.; Lee, Y.T. A data-driven approach for improving sustainability assessment in advanced manufacturing. In Proceedings of the 2017 IEEE International Conference on Big Data (Big Data), Boston, MA, USA, 11–14 December 2017; pp. 1736–1745. [Google Scholar]

- DeRousseau, M.A.; Kasprzyk, J.R.; Srubar, W.V. Computational design optimization of concrete mixtures: A review. Cem. Concr. Res. 2018, 109, 42–53. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Rafiee, S.; Mohtasebi, S.S.; Hosseinzadeh-Bandbafha, H.; Chau, K. Wing Integration of artificial intelligence methods and life cycle assessment to predict energy output and environmental impacts of paddy production. Sci. Total Environ. 2018, 631–632, 1279–1294. [Google Scholar] [CrossRef] [PubMed]

- Sharif, S.A.; Hammad, A. Developing surrogate ANN for selecting near-optimal building energy renovation methods considering energy consumption, LCC and LCA. J. Build. Eng. 2019, 25, 100790. [Google Scholar] [CrossRef]

- D’Amico, B.; Myers, R.J.; Sykes, J.; Voss, E.; Cousins-Jenvey, B.; Fawcett, W.; Richardson, S.; Kermani, A.; Pomponi, F. Machine Learning for Sustainable Structures: A Call for Data. Structures 2019, 19, 1–4. [Google Scholar] [CrossRef]

- Ziyadi, M.; Al-Qadi, I.L. Model uncertainty analysis using data analytics for life-cycle assessment (LCA) applications. Int. J. Life Cycle Assess. 2019, 24, 945–959. [Google Scholar] [CrossRef]

- Feng, K.; Lu, W.; Wang, Y. Assessing environmental performance in early building design stage: An integrated parametric design and machine learning method. Sustain. Cities Soc. 2019, 50, 101596. [Google Scholar] [CrossRef]

- Perrotta, F.; Parry, T.; Neves, L.C.; Mesgarpour, M. A machine learning approach for the estimation of fuel consumption related to road pavement rolling resistance for large fleets of trucks. In Life Cycle Analysis and Assessment in Civil Engineering: Towards an Integrated Vision, Proceedings of the Sixth International Symposium on Life-Cycle Civil Engineering (IALCCE 2018), Ghent, Belgium, 28–31 October 2018; CRC Press: Boca Raton, FL, USA, 2019; pp. 2011–2015. [Google Scholar]

- Kaab, A.; Sharifi, M.; Mobli, H.; Nabavi-Pelesaraei, A.; Chau, K. Wing Combined life cycle assessment and artificial intelligence for prediction of output energy and environmental impacts of sugarcane production. Sci. Total Environ. 2019, 664, 1005–1019. [Google Scholar] [CrossRef]

- Huijbregts, M.; Margni, M.; Van de Meent, D.; Jolliet, O.; Rosenbaum, R.; McKone, T.E.; Hauschild, M.Z. USEtoxTM Chemical-Specific Database: Organics. Available online: https://usetox.org/ (accessed on 2 March 2020).

- Walczak, S. Artificial neural networks. In Advanced Methodologies and Technologies in Artificial Intelligence, Computer Simulation, and Human-Computer Interaction; IGI Global: Hershey, PA, USA, 2019; pp. 40–53. [Google Scholar]

- Färber, M.; Jatowt, A. Finding Temporal Trends of Scientific Concepts. In Proceedings of the BIR@ ECIR, Cologne, Germany, 14 April 2019; pp. 132–139. [Google Scholar]

- Smyth, R. Exploring the usefulness of a conceptual framework as a research tool: A researcher’s reflections. Issues Educ. Res. 2004, 14, 167–180. [Google Scholar]

- Minichiello, V.; Sullivan, G. Handbook for Research Methods in Health Sciences.; Pearson Ecuation Australia: Melbourne, Australia, 2004. [Google Scholar]

- Mason, J.; Waywood, A. The Role of Theory in Mathematics Education and Research; Mason, J.; Waywood, A. Springer: Dordrecht, The Netherlands, 1996. [Google Scholar]

- Guarino, F.; Falcone, G.; Stillitano, T.; De Luca, A.I.; Gulisano, G.; Mistretta, M.; Strano, A. Life cycle assessment of olive oil: A case study in southern Italy. J. Environ. Manag. 2019, 238, 396–407. [Google Scholar] [CrossRef]

- Directorate-General for Agriculture and Rural Development. Olive Oil Trade Data. Available online: http://data.europa.eu/88u/dataset/olive-oil-trade-data (accessed on 18 December 2019).

- Espadas-Aldana, G.; Vialle, C.; Belaud, J.P.; Vaca-Garcia, C.; Sablayrolles, C. Analysis and trends for Life Cycle Assessment of olive oil production. Sustain. Prod. Consum. 2019, 19, 216–230. [Google Scholar] [CrossRef]

- Food Price Observatory MARM. Value Chain Study and Olive Oil Price Formation. Available online: https://www.internationaloliveoil.org/wp-content/uploads/2019/12/CADENADEVALOR-ENG.pdf (accessed on 12 January 2020).

- De Latorre, P.; del Pilar, M. Innovación en la Cadena de Valor del Aceite de Oliva: Análisis de una Cadena de Valor Concreta; Tesis doctoral, Universidad de Comillas: Madrid, Spain, 2019. [Google Scholar]

- Civantos, L. El Olivo, el Aceite, la Aceituna, 2nd ed.; Consejo Oleícola Internacional: Madrid, Spain, 1998. [Google Scholar]

- Cert, A.; Moreda, W.; León-Camacho, M.; Pérez-Camino, M.C. Determinación de absorción de luz UV a 232 nm, composición de ácidos grasos, trilinoleína y triglicéridos con numéro equivalente de carbonos igual a 42, en aceites de oliva y de orujo de oliva: Determinación de precisión de los métodos analíticos mediante. Grasas Aceites 1996, 47, 401–410. [Google Scholar] [CrossRef]

- Leung, W.W.F. Torque requirement for high-solids centrifugal sludge dewatering. Filtr. Sep. 1998, 35, 883–887. [Google Scholar] [CrossRef]

- Cano Marchal, P.; Gómez Ortega, J.; Aguilera Puerto, D.; Gámez García, J. Situación actual y perspectivas futuras del control del proceso de elaboración del aceite de oliva virgin. RIAI Rev. Iberoam. Autom. Inform. Ind. 2011, 8, 258–269. [Google Scholar] [CrossRef]

- Ministerio de Agricultura, Pesca y Alimentación. Marco Estratégico para la Industria de Alimentación y Bebidas; Ministerio de Agricultura, Pesca y Alimentación, Federación Española de Industrias de la alimentación y la bebida (FIAB): Madrid, Spain, 2018. [Google Scholar]

- Ciruela-Lorenzo, A.M.; Del Aguila-Obra, A.R.; Padilla-Meléndez, A.; Plaza-Angulo, J.J. Digitalization of Agri-cooperatives in the Smart Agriculture Context. Proposal of a Digital Diagnosis Tool. Sustainability 2020, 12, 1325. [Google Scholar] [CrossRef]

- Guerrero, M.; Luque Sendra, A.; Lama-Ruiz, J.R. Técnicas de predicción mediante minería de datos en la industria alimentaria bajo el paradigma de Industria 4.0. In Avances en la Investigación en Ciencia e Ingeniería; Área de Innovación y Desarrollo, S.L., Ed.; 3Ciencias: Alcoy, Alicante, 2019; pp. 149–157. ISBN 978-84-120057-2-1. [Google Scholar]

- Malekjafarian, A.; Golpayegani, F.; Moloney, C.; Clarke, S. A machine learning approach to bridge-damage detection using responses measured on a passing vehicle. Sensors 2019, 19, 4035. [Google Scholar] [CrossRef] [PubMed]

- Perea, R.G.; García, A.M.; García, I.F.; Poyato, E.C.; Montesinos, P.; Díaz, J.A.R. Middleware to operate smart photovoltaic irrigation systems in real time. Water 2019, 11, 1508. [Google Scholar] [CrossRef]

- Capraro, F.; Tosetti, S.; Rossomando, F.; Mut, V.; Serman, F.V. Web-based system for the remote monitoring and management of precision irrigation: A case study in an arid region of Argentina. Sensors 2018, 18, 3847. [Google Scholar] [CrossRef]

- Sola-Guirado, R.R.; Bayano-Tejero, S.; Rodríguez-Lizana, A.; Gil-Ribes, J.A.; Miranda-Fuentes, A. Assessment of the accuracy of a multi-beam LED scanner sensor for measuring olive canopies. Sensors 2018, 18, 4406. [Google Scholar] [CrossRef]

- Hermoso, M.; Uceda, M.; Frias, L.; Beltrán, G. Maduración. el Cultivo del Olivo; Barranco, D., Fernández-Escobar, D., Rallo, L., Eds.; Junta de Andalucía y Ediciones Mundi-Prensa: Madrid, Spain, 1997. [Google Scholar]

- Marquez, A.J.; Díaz, A.M.; Reguera, M.I.P. Using optical NIR sensor for on-line virgin olive oils characterization. Sens. Actuators B Chem. 2005, 107, 64–68. [Google Scholar] [CrossRef]

- Jiménez, A.; Beltrán, G.; Aguilera, M.P.; Uceda, M. A sensor-software based on artificial neural network for the optimization of olive oil elaboration process. Sens. Actuators B Chem. 2008, 129, 985–990. [Google Scholar] [CrossRef]

- Rodríguez-Méndez, M.L.; Apetrei, C.; de Saja, J.A. Evaluation of the polyphenolic content of extra virgin olive oils using an array of voltammetric sensors. Electrochim. Acta 2008, 53, 5867–5872. [Google Scholar] [CrossRef]

- Sonia, E.; GianFrancesco, M.; Roberto, S.; Ibanez, R.; Agnese, T.; Stefania, U.; Maurizio, S. Monitoring of virgin olive oil volatile compounds evolution during olive malaxation by an array of metal oxide sensors. Food Chem. 2009, 113, 345–350. [Google Scholar] [CrossRef]

- Bordons, C.; Zafra, M.L. Inferential sensor for the olive oil industry. In Proceedings of the European Control Conference, ECC 2003, Cambridge, UK, 1–4 September 2003; Institute of Electrical and Electronics Engineers Inc.: Interlaken, Switzerland, 2003; pp. 1940–1946. [Google Scholar]

- Furferi, R.; Carfagni, M.; Daou, M. Artificial neural network software for real-time estimation of olive oil qualitative parameters during continuous extraction. Comput. Electron. Agric. 2007, 55, 115–131. [Google Scholar] [CrossRef]

- Jiménez Marquez, A.; Aguilera Herrera, M.P.; Uceda Ojeda, M.; Beltrán Maza, G. Neural network as tool for virgin olive oil elaboration process optimization. J. Food Eng. 2009, 95, 135–141. [Google Scholar] [CrossRef]

- Rykiel, E.J. Testing ecological models: The meaning of validation. Ecol. Model. 1996, 90, 229–244. [Google Scholar] [CrossRef]

- Matalas, N.C.; Landwehr, J.M.; Wolman, M.G. Prediction in Water Management, Scientific Basis of Water Management; Scientific basis of water resource management, National Research Council, National Academy Press: Washington, DC, USA, 1982. [Google Scholar]

- Refsgaard, J.C.; Henriksen, H.J. Modelling guidelines—Terminology and guiding principles. Adv. Water Resour. 2004, 27, 71–82. [Google Scholar] [CrossRef]

- Adom, D.; Adu-Gyamfi, S.; Agyekum, K.; Ayarkwa, J.; Dwumah, P.; Abass, K.; Osei-Poku, P. Theoretical and conceptual framework: Mandatory ingredients of a quality research. J. Educ. Hum. Dev. 2016, 5, 158–172. [Google Scholar]

- Pérez, S.G.; Villar, S.G.; Carrillo, Á.G.; López, L.D. Sostenibilidad, energía y gestión urbana: Enfoque integral para el diseño de proyectos de ingeniería en el contexto de formación MDP-UPC. In Proceedings of the XIV International Congress on Project Engineering, Madrid, Spain, 30 June–2 July 2010; pp. 2927–2938. [Google Scholar]

- García-Serna, J.; Pérez-Barrigón, L.; Cocero, M.J. New trends for design towards sustainability in chemical engineering: Green engineering. Chem. Eng. J. 2007, 133, 7–30. [Google Scholar] [CrossRef]

- Vanegas, J.A. Road Map and Principles for Built Environment Sustainability. Environ. Sci. Technol. 2003, 37, 5363–5372. [Google Scholar] [CrossRef]

- Segalàs Coral, J. Engineering Education for a Sustainable Future; Universitat Politècnica de Catalunya: Barcelona, Spain, 2009. [Google Scholar]

- Vezzoli, C.; Sciama, D. Life Cycle Design: From general methods to product type specific guidelines and checklists: A method adopted to develop a set of guidelines/checklist handbook for the eco-efficient design of NECTA vending machines. J. Clean. Prod. 2006, 14, 1319–1325. [Google Scholar] [CrossRef]

- Labuschagne, C.; Brent, A.C.; Van Erck, R.P.G. Assessing the sustainability performances of industries. J. Clean. Prod. 2005, 13, 373–385. [Google Scholar] [CrossRef]

- Fernández-Sánchez, G.; Rodríguez-López, F.; Hruškovič, P. Identificación de factores e indicadores de sostenibilidad genéricos en los proyectos de ingeniería civil. In Proceedings of the XIII Congreso Internacional de Ingeniería de Proyectos, Badajoz, Spain, 8–10 July 2009; pp. 12–25. [Google Scholar]

- Armenia, S.; Dangelico, R.M.; Nonino, F.; Pompei, A. Sustainable project management: A conceptualization-oriented review and a framework proposal for future studies. Sustainability 2019, 11, 2664. [Google Scholar] [CrossRef]

- Reidl, L.M. Marco conceptual en el proceso de investigación. Investig. Educ. Médica 2012, 1, 146–151. [Google Scholar]

| Keywords | Search Criteria |

|---|---|

| “Machine Learning” and “LCA” | I |

| “Machine Learning” and “Life Cycle Assessment” | II |

| “Artificial Intelligence" and “Life Cycle Assessment” | III |

| “Artificial Intelligence” and “LCA” | IV |

| ID [ref] | Tittle | Year | Search Criteria | |||

|---|---|---|---|---|---|---|

| I | II | III | IV | |||

| A [61] | Machine learning for toxicity characterization of organic chemical emissions using USEtox database: Learning the structure of the input space | 2015 | 1 | 1 | ||

| B [62] | Extending life cycle assessment normalization factors and use of machine learning - A Slovenian case study | 2015 | 1 | 1 | ||

| C [63] | Limitations of toxicity characterization in life cycle assessment: Can adverse outcome pathways provide a new foundation? | 2016 | 1 | 1 | ||

| D [64] | Quantifying the impact of sustainable product design decisions in the early design phase trough machine learning | 2016 | 1 | 1 | ||

| E [65] | A Data-Driven Approach for Improving Sustainability Assessment in Advanced Manufacturing | 2017 | 1 | 1 | 1 | |

| F [66] | Computational design optimization of concrete mixtures: A review | 2018 | 1 | |||

| G [67] | Integration of artificial intelligence methods and life cycle assessment to predict energy output and environmental impacts of paddy production | 2018 | 1 | 1 | ||

| H [68] | Developing surrogate ANN for selecting near-optimal building energy renovation methods considering energy consumption, LCC and LCA | 2019 | 1 | 1 | ||

| I [69] | Machine Learning for Sustainable Structures: A Call for Data | 2019 | 1 | 1 | 1 | 1 |

| J [70] | Model uncertainty analysis using data analytics for life-cycle assessment (LCA) applications | 2019 | 1 | 1 | ||

| K [71] | Assessing environmental performance in early building design stage: An integrated parametric design and machine learning method | 2019 | 1 | |||

| L [72] | A machine learning approach for the estimation of fuel consumption related to road pavement rolling resistance for large fleets of trucks | 2019 | 1 | |||

| M [73] | Combined life cycle assessment and artificial intelligence for prediction of output energy and environmental impacts of sugarcane production | 2019 | 1 | 1 | ||

| ID | Application | Data | Approach | Tools | Sensors |

|---|---|---|---|---|---|

| A [61] | Predict energy consumption of buildings | TRNSYS simulation data. Data collected on existing buildings. | Energy. Performance prediction | ANN + SBMO (genetic algorithms) | Literature review |

| B [62] | Reduce the impact of Structures | Geometry, material, building type and other key parameters | A more sustainable built environment | Machine Learning + Artificial Neural Networks | Resource efficient built environment lab |

| C [63] | Predict the sources of uncertainty in the LCA: Chicago Pavement LCA | Traffic data report | Objective uncertainty quantification (UQ) | Various data analytics methods were used to conduct a thorough model uncertainty analysis | Traffic, Speed IRI Collected from 2015 Traffic data report |

| D [64] | Sustainability in manufacture | Manufacture data using simulation models | Data-driven modeling | Data-model-decision network | Cheaper monitoring tools and pervasive wireless technology enables environmental data to be collected. Manufacturing process data is most often proprietary |

| E [65] | To asses biological effects using a tool quantitative outcome pathway (qAOP) | Toxicity data. The emission levels. Data of inventory analysis | Toxicological LCIA models and assumptions | Mechanistic; Probabilistic supervised machine learning models; and Weight of evidence | Experimental toxicity data |

| F [66] | Estimate LCA results from product properties. 37 case study | LCA data. Data generated during conceptual design. | Guidelines, Heuristics, Standards Methods Preferences | Multi-layer perception neural network with back propagation training | Product attributes |

| G [67] | Toxicity characterization of chemical emissions in Life Cycle Assessment (LCA) | Properties of the chemical compounds being assessed (databases) buildings. | Usetox model | Dimensionality reduction techniques. | Environmental properties |

| H [68] | LCA normalization factors | A pesticides properties database PPDB, ReciPe .08 and FURS. | LCA normalization | Linear regression using Java program Package | Environmental indicators |

| I [69] | Estimate LC environmental impacts and output energy of sugarcane production (planted or ratoon farms) | Ecoinvent 2.2 databases | Cradle to grave approach | Artificial neural networks (ANNs) and adaptive neuro fuzzy inference system (ANFIS) model | Used resources emissions, Used electricity |

| J [70] | Estimate LC and energy of paddy production | Agricultural input parameters from 240 paddy producers. | CExD cumulative. Energy Demand | Artificial neural networks (ANNs) and adaptive neuro fuzzy inference system (ANFIS) | Paddy production process |

| K [71] | Evaluate environmental impact in early building design stage | Generated samples | Parametric design | Fuzzy C-means clustering and extreme learning machine | Properties of the building |

| L [72] | Energy consumption of the trucks to evaluate the operation phase of the pavements. | Database of Micrilise Ltd. Road geometry and condition of the road surface for each vehicle in the databases | Enveloping methods (Boruta) | Boruta algorithm and Neural Networks | Standard sensors (SAE International 2016) that keep track of various parameters (including consumption) |

| M [73] | Design and optimization of concrete structures | Literature review | Optimization Decision Making | ANNs, instance-based learning, decision-trees and SVMs. | Concrete mixture parameters |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luque, A.; De Las Heras, A.; Ávila-Gutiérrez, M.J.; Zamora-Polo, F. ADAPTS: An Intelligent Sustainable Conceptual Framework for Engineering Projects. Sensors 2020, 20, 1553. https://doi.org/10.3390/s20061553

Luque A, De Las Heras A, Ávila-Gutiérrez MJ, Zamora-Polo F. ADAPTS: An Intelligent Sustainable Conceptual Framework for Engineering Projects. Sensors. 2020; 20(6):1553. https://doi.org/10.3390/s20061553

Chicago/Turabian StyleLuque, Amalia, Ana De Las Heras, María Jesús Ávila-Gutiérrez, and Francisco Zamora-Polo. 2020. "ADAPTS: An Intelligent Sustainable Conceptual Framework for Engineering Projects" Sensors 20, no. 6: 1553. https://doi.org/10.3390/s20061553

APA StyleLuque, A., De Las Heras, A., Ávila-Gutiérrez, M. J., & Zamora-Polo, F. (2020). ADAPTS: An Intelligent Sustainable Conceptual Framework for Engineering Projects. Sensors, 20(6), 1553. https://doi.org/10.3390/s20061553