An Automatic Bearing Fault Diagnosis Method Based on Characteristics Frequency Ratio

Abstract

1. Introduction

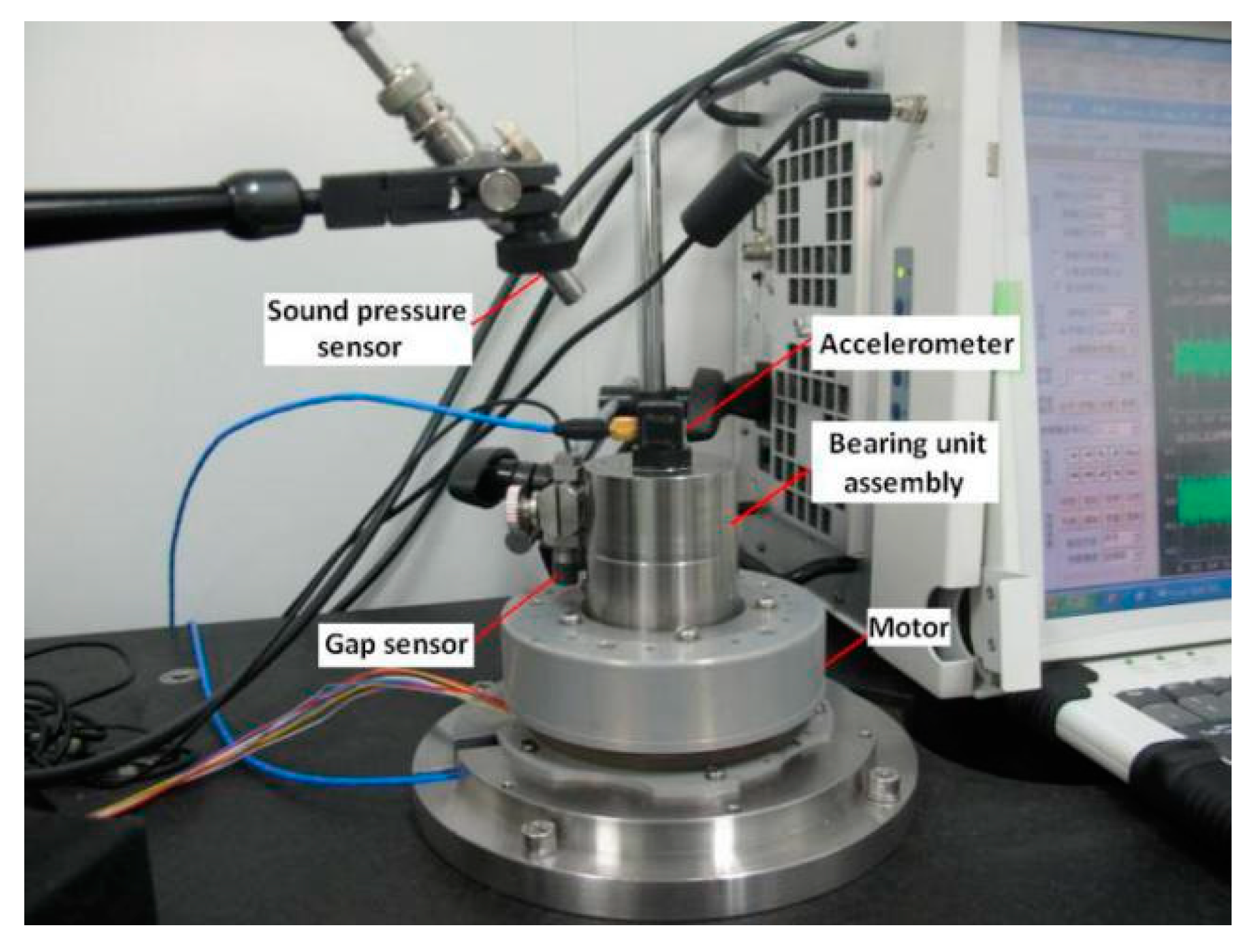

2. Experimental Data Acquisition

3. Fault Feature Extraction Method Based on Improved Envelope Detection method

3.1. The Proposal of the Method

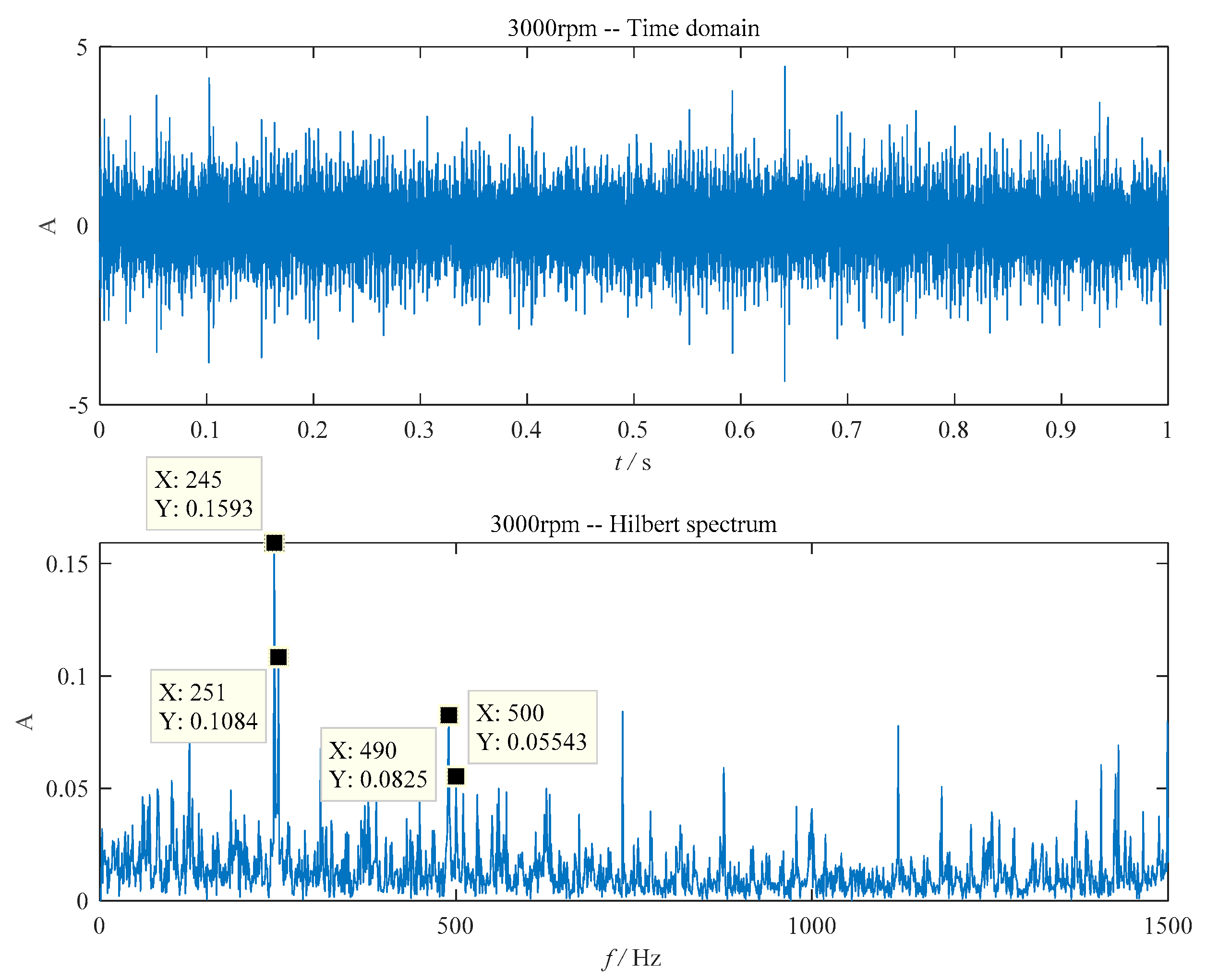

3.2. The Verification of the Method

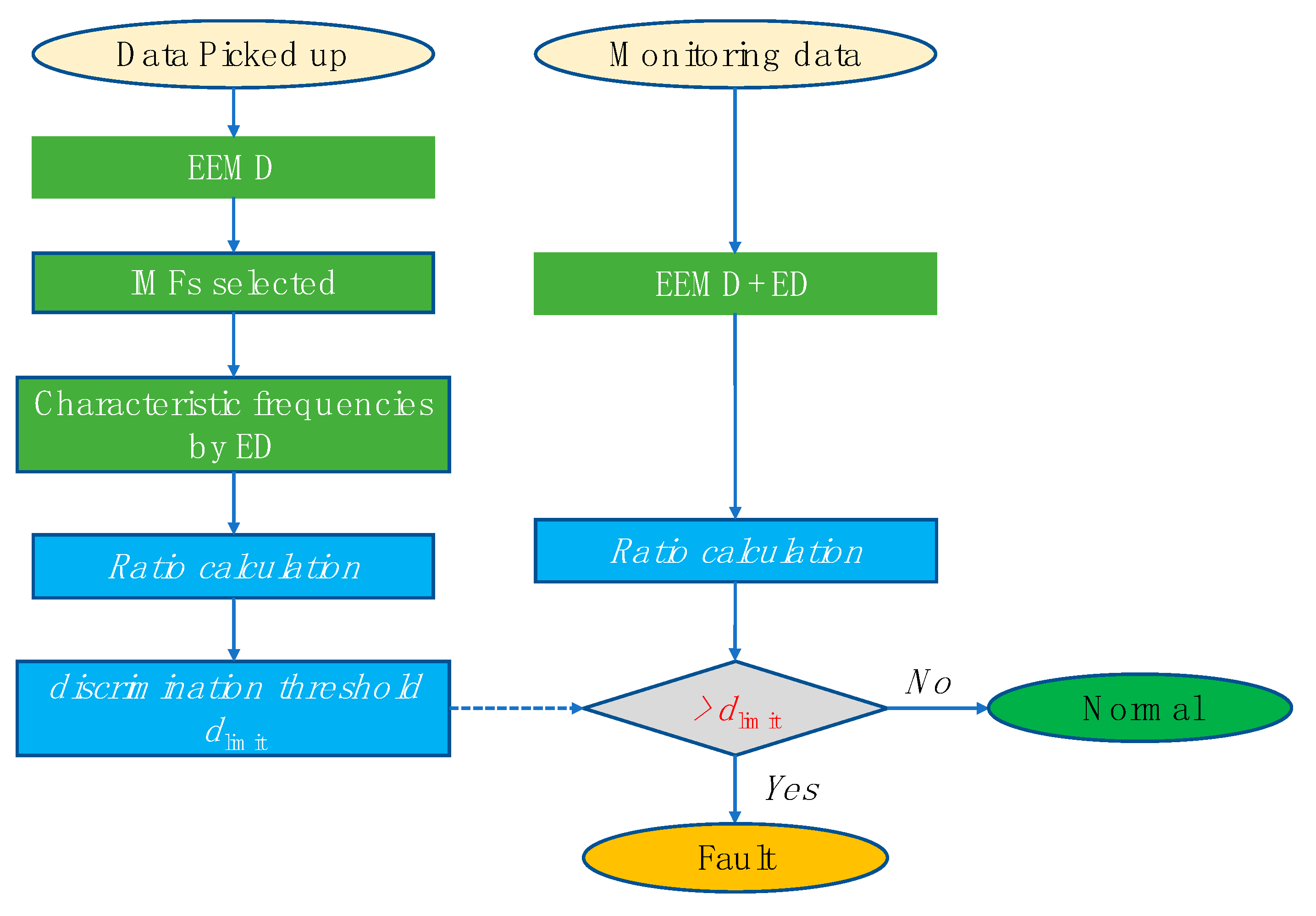

4. The Automatic Fault Diagnosis Method Based on Characteristic Frequency Ratio

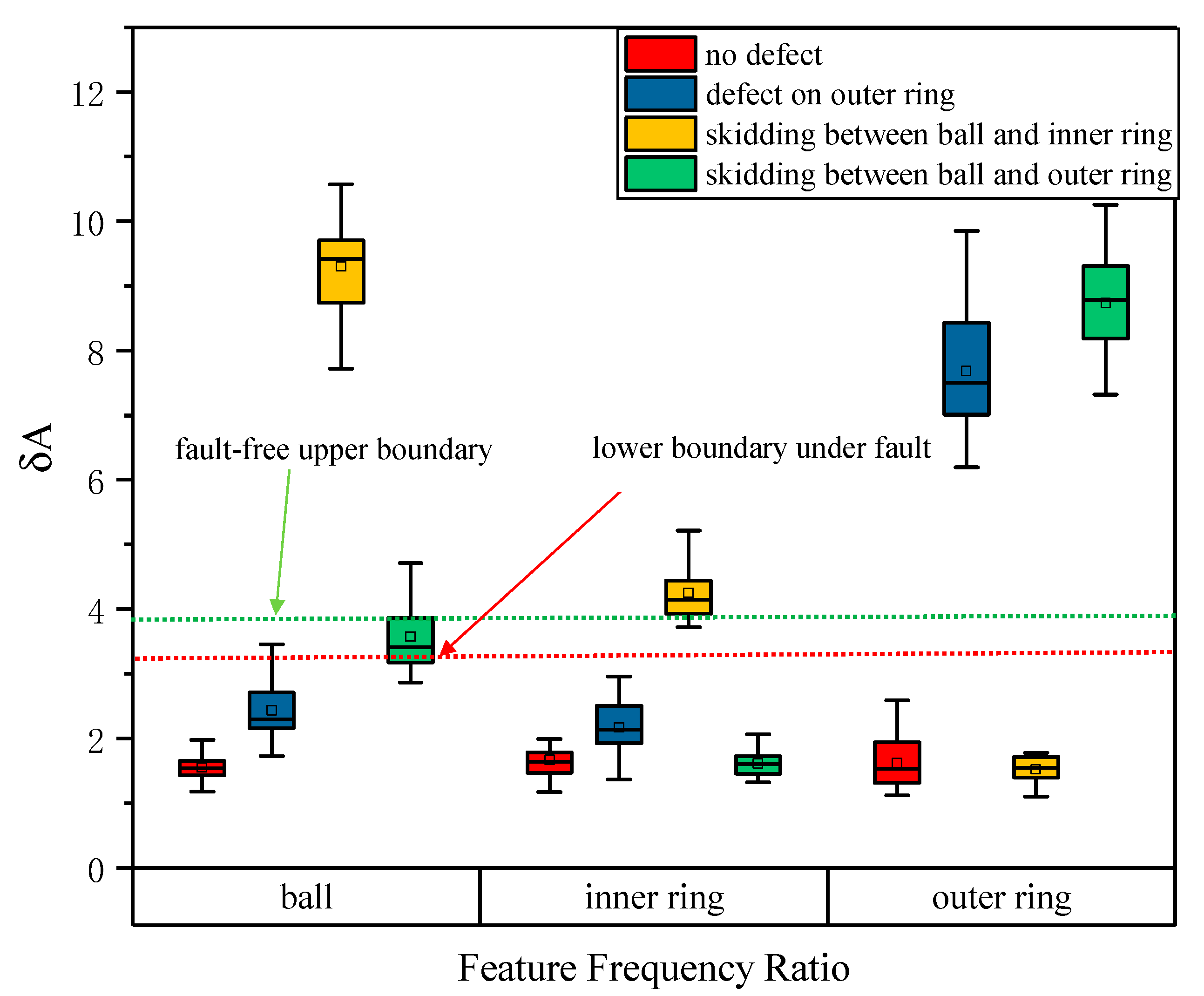

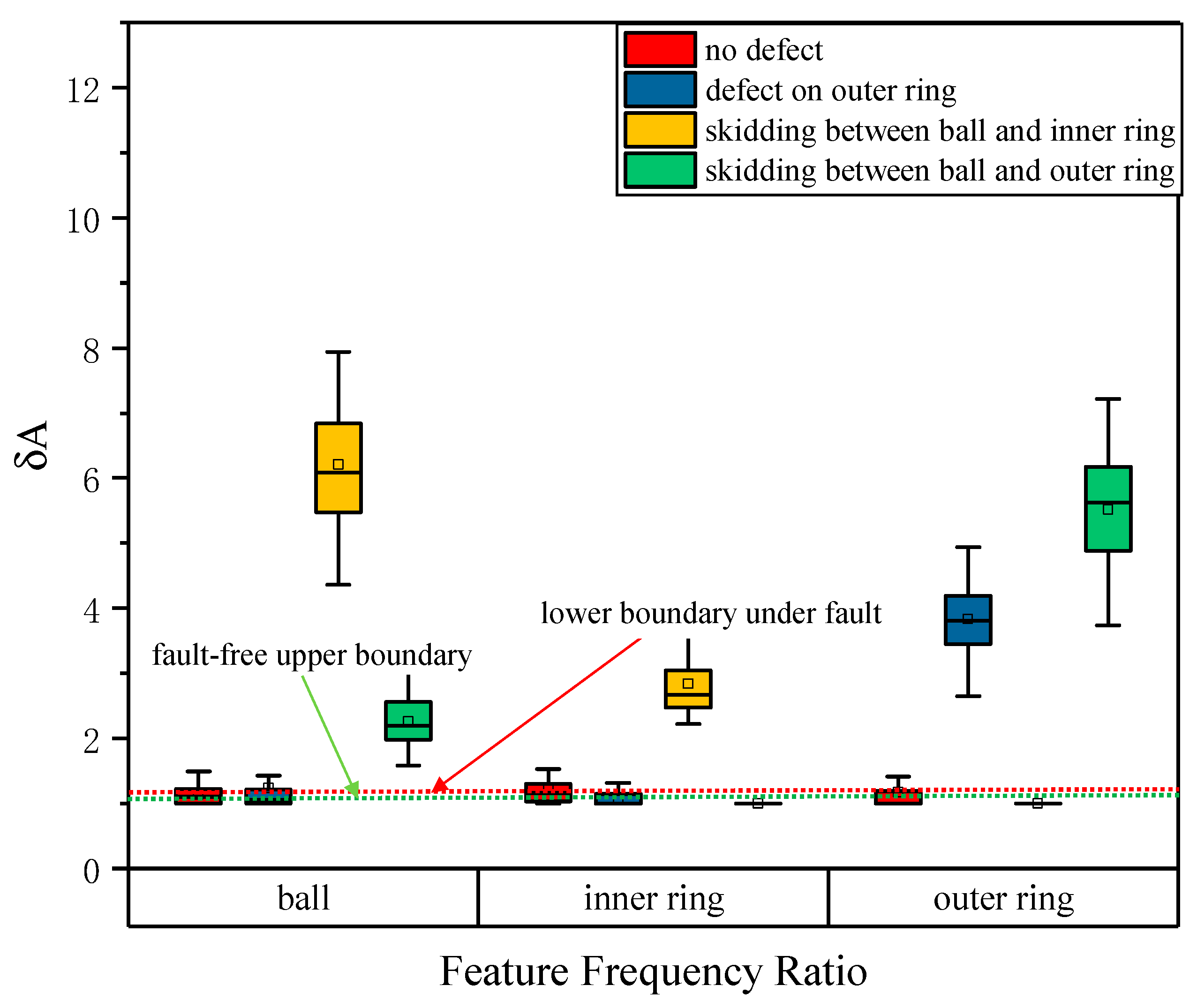

4.1. The Characteristic Frequency Ratio

4.2. Automatic Bearing Fault Diagnosis Process Based on

5. Determination of Automatic Discrimination Threshold

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wu, D.Y.; Wang, H.; Liu, H.X.; He, T.; Xie, T. Health Monitoring on the Spacecraft Bearings in High-Speed Rotating Systems by Using the Clustering Fusion of Normal Acoustic Parameters. Appl. Sci. 2019, 9, 3246. [Google Scholar] [CrossRef]

- Georgoulas, G.; Loutas, T.; Stylios, C.D.; Kostopoulos, V. Bearing fault detection based on hybrid ensemble detector and empirical mode decomposition. Mech. Syst. Sig. Process. 2013, 41, 510–525. [Google Scholar] [CrossRef]

- El-Thalji, I.; Jantunen, E. A summary of fault modeling and predictive health monitoring of rolling element bearings. Mech. Syst. Sig. Process 2015, 60–61, 252–272. [Google Scholar] [CrossRef]

- Zhang, S.; Shi, J.; Wang, J.L. Satellite on-board failure statistics and analysis. Spacecraft Eng. 2010, 19, 41–46. (In Chinese) [Google Scholar]

- Jiang, X.X.; Cheng, X.; Shi, J.J.; Huang, W.G.; Shen, C.Q.; Zhu, Z.K. A new l0-norm embedded MED method for roller element bearing fault diagnosis at early stage of damage. Measurement 2018, 127, 414–424. [Google Scholar] [CrossRef]

- Wang, Y.L.; Wang, W.Z.; Zhang, S.G.; Zhao, Z.Q. Investigation of skidding in angular contact ball bearings under high speed. Tribol. Int. 2015, 92, 404–417. [Google Scholar] [CrossRef]

- Li, J.; Wang, H.; Wang, X.; Zhang, Y. Rolling bearing fault diagnosis based on improved adaptive parameterless empirical wavelet transform and sparse denoising. Measurement 2020, 152, 107392. [Google Scholar] [CrossRef]

- Attoui, I.; Fergani, N.; Boutasseta, N.; Oudjani, B.; Deliou, A. A newtime–frequency method for identification and classification of ball bearing faults. J. Sound Vib. 2017, 397, 241–265. [Google Scholar] [CrossRef]

- Albezzawy, M.N.; Nassef, M.G.; Sawalhi, N. Rolling element bearing fault identification using a novel three-step adaptive and automated filtration scheme based on Gini index. ISA Trans. 2020. [Google Scholar] [CrossRef]

- Had, A.; Sabri, K. A two-stage blind deconvolution strategy for bearing fault vibration signals. Mech. Syst. Sig. Process. 2019, 134, 106307. [Google Scholar] [CrossRef]

- Ai, Y.T.; Guan, J.Y.; Fei, C.W.; Tian, J.; Zhang, F.L. Fusion information entropy method of rolling bearing fault diagnosis based on n-dimensional characteristic parameter distance. Mech. Syst. Sig. Process. 2017, 88, 123–136. [Google Scholar] [CrossRef]

- Chen, H.T.; Jiang, B. A review of fault detection and diagnosis for the traction system in high-speed trains. IEEE Trans. Intell. Transp. Syst. 2020, 21, 450–465. [Google Scholar] [CrossRef]

- Miao, Y.H.; Zhao, M.; Lin, J. Periodicity-impulsiveness spectrum based on singular value negentropy and its application for identification of optimal frequency band. IEEE Trans. Intell. Transp. Syst. 2019, 66, 3127–3138. [Google Scholar] [CrossRef]

- Yu, K.; Lin, T.R.; Tan, J.; Ma, H. An adaptive sensitive frequency band selection method for empirical wavelet transform and its application in bearing fault diagnosis. Measurement 2019, 134, 375–384. [Google Scholar] [CrossRef]

- Tandon, N.; Choudhury, A. A review of vibration and acoustic measurement methods for the detection of defects in rolling element bearings. Tribol. Int. 1999, 32, 469–480. [Google Scholar] [CrossRef]

- Darlow, M.S.; Badgley, R.H.; Hogg, G.W. Applications of High Frequency Resonance Techniques for Bearing Diagnostics in Helicopter Gearboxes; US Army Air Mobility Research and Development Laboratory Technical Report; Mechanical Technology Inc.: Latham, NY, USA, 1974; pp. 74–77. [Google Scholar]

- McFadden, P.D.; Smith, J.D. The vibration monitoring of rolling element bearings by the high-frequency resonance technique—A review. Tribol. Int. 1984, 17, 3–10. [Google Scholar] [CrossRef]

- Randall, R.B.; Antoni, J. Rolling element bearing diagnostics—A tutorial. Mech. Syst. Sig. Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Tyagi, S.; Panigrahi, S.K. An improved envelope detection method using particle swarm optimization for rolling element bearing fault diagnosis. J. Comput. Design Eng. 2017, 4, 305–317. [Google Scholar] [CrossRef]

- Klausen, A.; Robbersmyr, K.G.; Karimi H., R. Autonomous Bearing Fault Diagnosis Method based on Envelope Spectrum. IFAC-PapersOnLine 2017, 50–51, 13378–13383. [Google Scholar] [CrossRef]

- Feng, G.; Zhao, H.; Needham, F.G.; Ball, A.D. Efficient implementation of envelope analysis on resources limited wireless sensor nodes for accurate bearing fault diagnosis. Measurement 2017, 110, 307–318. [Google Scholar] [CrossRef]

- Wang, D.X.; Zhao, J.; Kou, L.L.; Qin, Y.; Zhao, Y.; Tsui, K.L. A simple and fast guideline for generating enhanced/squared envelope spectra from spectral coherence for bearing fault diagnosis. Mech. Syst. Sig. Process. 2019, 122, 754–768. [Google Scholar] [CrossRef]

- Tsao, W.C.; Li, Y.F.; Le, D.D.; Pan, M.C. An insight concept to select appropriate IMFs for envelope analysis of bearing fault diagnosis. Measurement 2012, 45, 1489–1498. [Google Scholar] [CrossRef]

- Li, X.; Ma, J.; Wang, X.; Wu, J.; Li, Z. An improved local mean decomposition method based on improved composite interpolation envelope and its application in bearing fault feature extraction. ISA Trans. 2019, 97, 365–383. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.C.; Chen, J.; Dong, G.M. Feature extraction of rolling bearing’s early weak fault based on EEMD and tunable Q-factor wavelet transform. Mech. Syst. Sig. Process. 2014, 48, 103–119. [Google Scholar] [CrossRef]

| Rotating Speed | 3000 rpm | |

|---|---|---|

| Fault Elements | ||

| 356.1 Hz | ||

| 243.9 Hz | ||

| 124.7 Hz | ||

| 29.7 Hz | ||

| Elements | Inner ring | Outer ring | Ball | |

|---|---|---|---|---|

| Fault Types | ||||

| Normal | 1.667 | 1.617 | 1.553 | |

| Outer ring | 2.173 | 7.682 | 2.438 | |

| ball-inner ring scratching | 4.251 | 1.526 | 9.302 | |

| ball-outer ring scratching | 1.608 | 8.735 | 3.573 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Wang, J.; Wang, H.; Liu, H.; Lai, L.; He, T.; Xie, T. An Automatic Bearing Fault Diagnosis Method Based on Characteristics Frequency Ratio. Sensors 2020, 20, 1519. https://doi.org/10.3390/s20051519

Wu D, Wang J, Wang H, Liu H, Lai L, He T, Xie T. An Automatic Bearing Fault Diagnosis Method Based on Characteristics Frequency Ratio. Sensors. 2020; 20(5):1519. https://doi.org/10.3390/s20051519

Chicago/Turabian StyleWu, Dengyun, Jianwen Wang, Hong Wang, Hongxing Liu, Lin Lai, Tian He, and Tao Xie. 2020. "An Automatic Bearing Fault Diagnosis Method Based on Characteristics Frequency Ratio" Sensors 20, no. 5: 1519. https://doi.org/10.3390/s20051519

APA StyleWu, D., Wang, J., Wang, H., Liu, H., Lai, L., He, T., & Xie, T. (2020). An Automatic Bearing Fault Diagnosis Method Based on Characteristics Frequency Ratio. Sensors, 20(5), 1519. https://doi.org/10.3390/s20051519