Advances in Sensor Technologies in the Era of Smart Factory and Industry 4.0 †

Abstract

1. Introduction

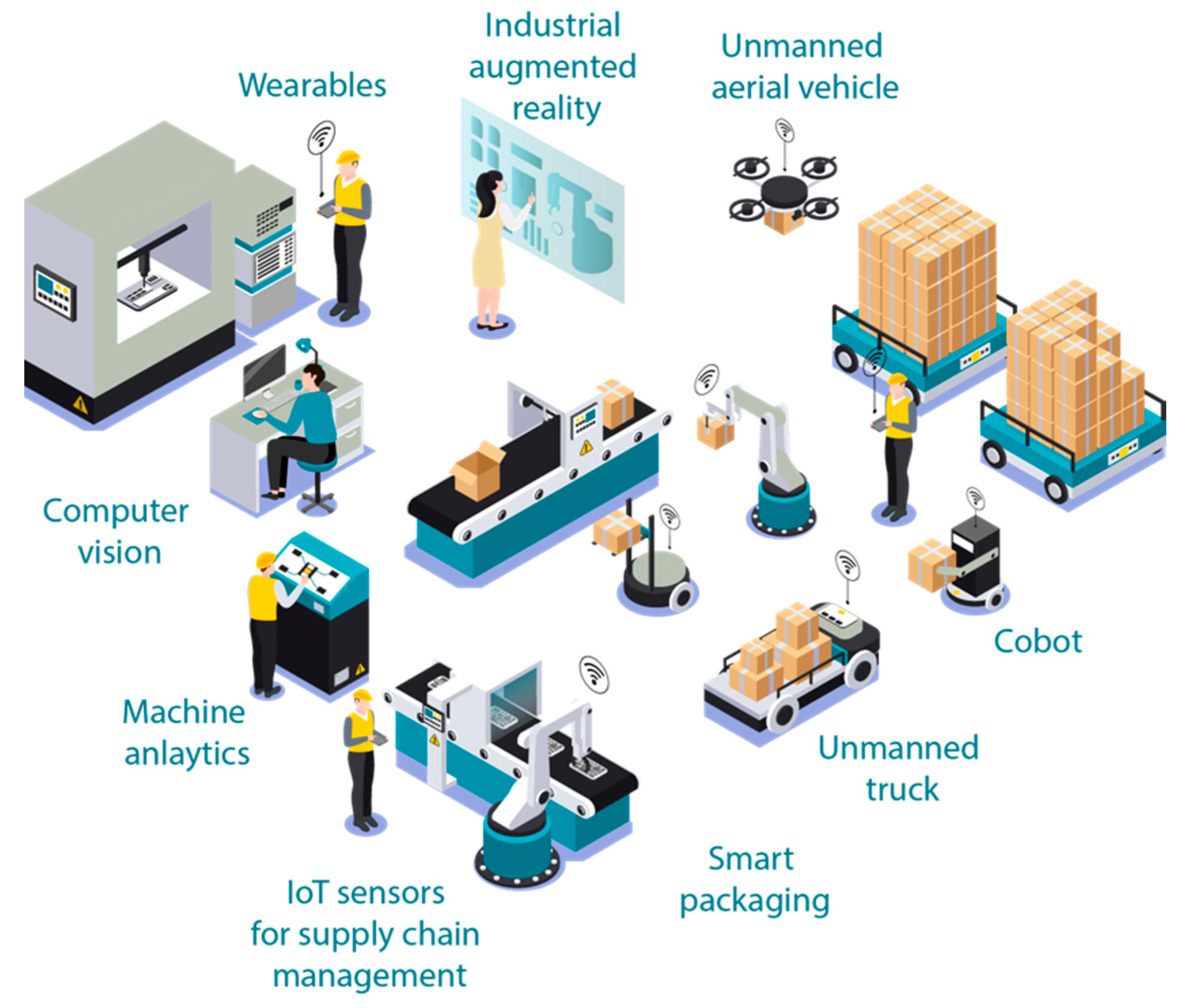

2. Smart Factory

Smart Factory vs. Traditional Factory

- Sensors: these are devices that have the ability to self-organize, learn, and maintain environmental information to analyze behaviors and abilities. Therefore, sensors can make decisions that enable them to adjust to changes in the environment.

- Interoperability: through interconnection between different devices, coordination between them can be enhanced, allowing flexibility in configuration protocols of the production system.

- Integration: robots and artificial intelligence (AI) allow smart factories to have a high level of integration among processes. AI, along with the integration of human intellectual capabilities, enables factories to perform analysis and decision making.

- Virtual reality (VR) techniques: as one of the high-level components of smart factories, VR facilitates human–machine integration by virtualizing manufacturing processes using computers, signal processing, animation technology, intelligent reasoning, prediction, and simulation and multimedia technologies.

3. Key Sensing Technologies in a Smart Factory

3.1. Passive Sensors

3.1.1. Temperature Sensors

3.1.2. Pressure Sensors

3.1.3. Position Sensors

3.1.4. Force Sensors

3.1.5. Flow Sensors

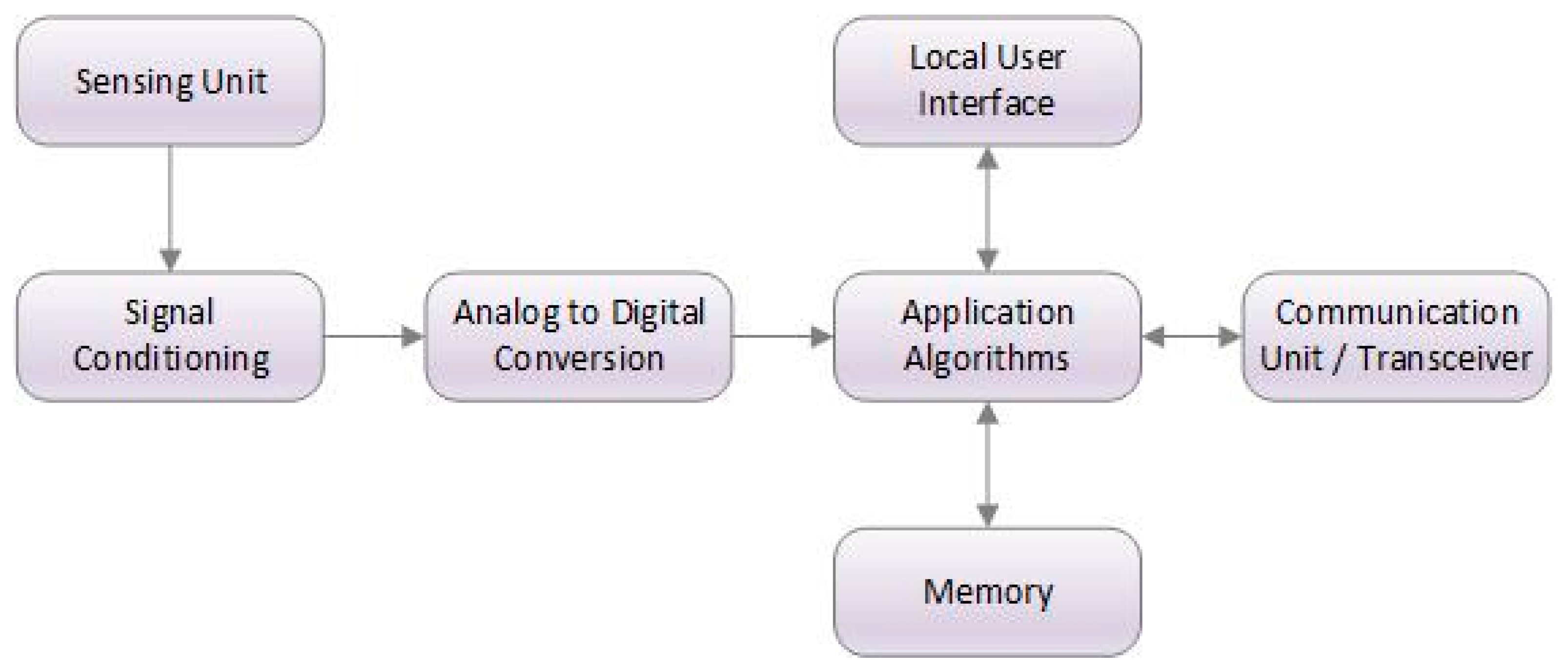

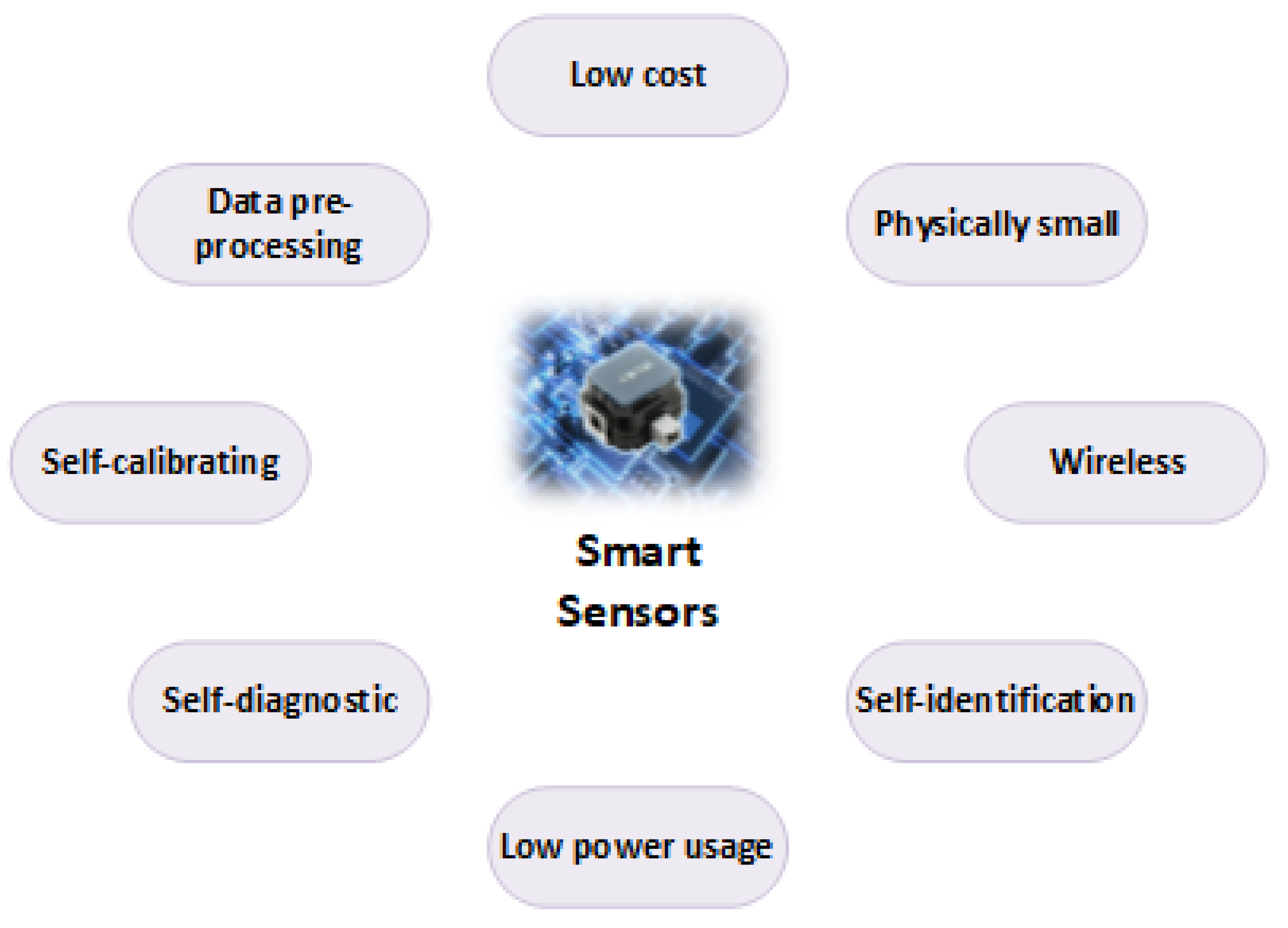

3.2. Smart Sensors

3.2.1. Calibration Capability

- Sensors with an electric output carry out calibration by using a known reference of voltage level.

- Sensors such as load cells used for weighing systems can adjust their output to zero when no force is being applied [27].

- Other sensors can use look-up tables for calibration. However, to carry out calibration using look-up tables, a huge amount of memory capacity must be available to store correction points due to the large volume of data gathered during the process. On the contrary, an interpolation method is preferable in which a small matrix of correction points is required [35].

3.2.2. Self-Diagnosis of Faults

3.3. Nuclear Sensors

3.4. Micro-Sensors (MEMS Sensors)

3.5. Nano-Sensors (NEMS)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chang, W.; Ellinger, A.E.; Kim, K.; Franke, G.R. Supply chain integration and firm financial performance: A meta-analysis of positional advantage mediation and moderating factors. Eur. Manag. J. 2016, 34, 282–295. [Google Scholar] [CrossRef]

- Afzal, B.; Umair, M.; Shah, G.A.; Ahmed, E. Enabling IoT platforms for social IoT applications: Vision, feature mapping, and challenges. Future Gener. Comput. Syst. 2019, 92, 718–731. [Google Scholar] [CrossRef]

- Castelo-Branco, I.; Cruz-Jesus, F.; Oliveira, T. Assessing Industry 4.0 readiness in manufacturing: Evidence for the European Union. Comput. Ind. 2019, 107, 22–32. [Google Scholar] [CrossRef]

- Shi, Z.; Xie, Y.; Xue, W.; Chen, Y.; Fu, L.; Xu, X. Smart factory in Industry 4.0. Syst. Res. Behav. Sci. 2020, 37, 607–617. [Google Scholar] [CrossRef]

- Lass, S.; Gronau, N. A factory operating system for extending existing factories to Industry 4.0. Comput. Ind. 2020, 115, 103128. [Google Scholar] [CrossRef]

- Xie, Y.; Yin, Y.; Xue, W.; Shi, H.; Chong, D. Intelligent supply chain performance measurement in Industry 4.0. Syst. Res. Behav. Sci. 2020, 37, 711–718. [Google Scholar] [CrossRef]

- Ortiz, A.M.; Hussein, D.; Park, S.; Han, S.N.; Crespi, N. The Cluster between Internet of Things and Social Networks: Review and Research Challenges. IEEE Internet Things J. 2014, 1, 206–215. [Google Scholar] [CrossRef]

- Agostini, L.; Filippini, R. Organizational and managerial challenges in the path toward Industry 4.0. Eur. J. Innov. Manag. 2019, 22, 406–421. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Giglio, R.; Van Dun, D.H. Industry 4.0 adoption as a moderator of the impact of lean production practices on operational performance improvement. Int. J. Oper. Prod. Manag. 2019, 39, 860–886. [Google Scholar] [CrossRef]

- Cimini, C.; Pirola, F.; Pinto, R.; Cavalieri, S. A human-in-the-loop manufacturing control architecture for the next generation of production systems. J. Manuf. Syst. 2020, 54, 258–271. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Wilkesmann, M.; Wilkesmann, U. Industry 4.0—organizing routines or innovations? VINE J. Inf. Knowl. Manag. Syst. 2018, 48, 238–254. [Google Scholar] [CrossRef]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart factories in Industry 4.0: A review of the concept and of energy management approached in production based on the Internet of Things paradigm. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Bandar Sunway, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar]

- Kaur, J.; Kaur, K. A fuzzy approach for an IoT-based automated employee performance appraisal. Comput. Mater. Contin. 2017, 53, 24–38. [Google Scholar]

- Zanella, A.; Bui, N.; Castellani, A.; Vangelista, L.; Zorzi, M. Internet of things for smart cities. IEEE Internet Things J. 2014, 1, 22–32. [Google Scholar] [CrossRef]

- Ghasemaghaei, M.; Ebrahimi, S.; Hassanein, K. Data analytics competency for improving firm decision making performance. J. Strat. Inf. Syst. 2018, 27, 101–113. [Google Scholar] [CrossRef]

- Benitez, G.B.; Ayala, N.F.; Frank, A.G. Industry 4.0 innovation ecosystems: An evolutionary perspective on value cocreation. Int. J. Prod. Econ. 2020, 228, 107735. [Google Scholar] [CrossRef]

- Mehami, J.; Nawi, M.; Zhong, R.Y. Smart automated guided vehicles for manufacturing in the context of Industry 4.0. Procedia Manuf. 2018, 26, 1077–1086. [Google Scholar] [CrossRef]

- Aydiner, A.S.; Tatoglu, E.; Bayraktar, E.; Zaim, S. Information system capabilities and firm performance: Opening the black box through decision-making performance and business-process performance. Int. J. Inf. Manag. 2019, 47, 168–182. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Ning, F.; Zhou, W.; Zhang, F.; Yin, Q.; Ni, X. The architecture of cloud maufacturing and its key technologies research. In Proceedings of the 2011 IEEE International Conference on Cloud Computing and Intelligence Systems, Beijing, China, 15–17 September 2011; pp. 259–263. [Google Scholar]

- Xu, M.; Song, C.; Ji, Y.; Shih, M.-W.; Lu, K.; Zheng, C.; Duan, R.; Jang, Y.; Lee, B.; Qian, C.; et al. Toward Engineering a Secure Android Ecosystem. ACM Comput. Surv. 2016, 49, 1–47. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Choy, J.L.C.; Wu, J.; Long, C.; Lin, Y.-B. Ubiquitous and Low Power Vehicles Speed Monitoring for Intelligent Transport Systems. IEEE Sens. J. 2020, 20, 5656–5665. [Google Scholar] [CrossRef]

- Farhangi, H. Smart Grid. Encycl. Sustain. Technol. 2017, 195–203. [Google Scholar]

- Gattullo, M.; Scurati, G.W.; Fiorentino, M.; Uva, A.E.; Ferrise, F.; Bordegoni, M. Towards augmented reality manuals for industry 4.0: A methodology. Robot. Comput. Integr. Manuf. 2019, 56, 276–286. [Google Scholar] [CrossRef]

- Punithavathi, P.; Geetha, S.; Karuppiah, M.; Islam, S.H.; Hassan, M.M.; Choo, K.-K.R. A lightweight machine learning-based authentication framework for smart IoT devices. Inf. Sci. 2019, 484, 255–268. [Google Scholar] [CrossRef]

- Burke, R.; Mussomeli, A.; Laaper, S.; Hartigan, M.; Sniderman, B. The smart Factory. Responsive, adaptive, connected manufacturing. Deloitte 2014, 31, 1–10. [Google Scholar]

- Kimani, K.; Oduol, V.; Langat, K. Cyber security challenges for IoT-based smart grid networks. Int. J. Crit. Infrastruct. Prot. 2019, 25, 36–49. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B.; Werner, F.; Ivanova, M. A dynamic model and an algorithm for short-term supply chain scheduling in the smart factory industry 4.0. Int. J. Prod. Res. 2016, 54, 386–402. [Google Scholar] [CrossRef]

- Agrifoglio, R.; Cannavale, C.; Laurenza, E.; Metallo, C. How emerging digital technologies affect operations management through co-creation. Empirical evidence from the maritime industry. Prod. Plan. Control 2017, 28, 1298–1306. [Google Scholar] [CrossRef]

- Lightfoot, H.; Baines, T.; Smart, P. The servitization of manufacturing: A systematic literature review of interdependent trends. Int. J. Oper. Prod. Manag. 2013, 33, 1408–1434. [Google Scholar] [CrossRef]

- Tanyingyong, V.; Olsson, R.; Cho, J.-W.; Hidell, M.; Sjodin, P. IoT-Grid: IoT Communication for Smart DC Grids. In Proceedings of the 2016 IEEE Global Communications Conference (GLOBECOM), Washington, DC, USA, 4–8 December 2016; pp. 1–7. [Google Scholar]

- Herrojo, C.; Paredes, F.; Mata-Contreras, J.; Martín, F. Chipless-RFID: A review and recent developments. Sensors 2019, 19, 3385. [Google Scholar] [CrossRef]

- Bibby, L.; Dehe, B. Defining and assessing industry 4.0 maturity levels-case of the defence sector. Prod. Plan. Control 2018, 29, 1030–1043. [Google Scholar] [CrossRef]

- Mulloni, V.; Donelli, M. Chipless RFID Sensors for the Internet of Things: Challenges and Opportunities. Sensors 2020, 20, 2135. [Google Scholar] [CrossRef] [PubMed]

- Jeon, B.; Yoon, J.S.; Um, J.; Suh, S.H. The architecture development of Industry 4.0 compliant smart machine tool system (SMTS). J. Intell. Manuf. 2020, 31, 1837–1859. [Google Scholar] [CrossRef]

- Landaluce, H.; Arjona, L.; Perallos, A.; Falcone, F.; Angulo, I.; Muralter, F. A Review of IoT Sensing Applications and Challenges Using RFID and Wireless Sensor Networks. Sensors 2020, 20, 2495. [Google Scholar] [CrossRef]

- Le, D.N.; Le Tuan, L.; Tuan, M.N.D. Smart-building management system: An Internet-of-Things (IoT) application business model in Vietnam. Technol. Forecast. Soc. Chang. 2019, 141, 22–35. [Google Scholar] [CrossRef]

- Kadechkar, A.; Riba, J.-R.; Moreno-Eguilaz, M.; Perez, J. SmartConnector: A Self-Powered IoT Solution to Ease Predictive Maintenance in Substations. IEEE Sens. J. 2020, 20, 11632–11641. [Google Scholar] [CrossRef]

- Sattar, H.; Bajwa, I.S.; Amin, R.U.; Sarwar, N.; Jamil, N.; Malik, M.G.A.; Mahmood, A.; Shafi, U. An IoT-Based Intelligent Wound Monitoring System. IEEE Access 2019, 7, 144500–144515. [Google Scholar] [CrossRef]

- Leal-Junior, A.; Casas, J.; Marques, C.; Pontes, M.J.; Frizera, A. Application of Additive Layer Manufacturing Technique on the Development of High Sensitive Fiber Bragg Grating Temperature Sensors. Sensors 2018, 18, 4120. [Google Scholar] [CrossRef]

- Bentley, J.P. Temperature sensor characteristics and measurement system design. J. Phys. E Sci. Instrum. 1984, 17, 430–439. [Google Scholar] [CrossRef]

- Lewis, G.D.; Merken, P.; Vandewal, M. Enhanced Accuracy of CMOS Smart Temperature Sensors by Nonlinear Curvature Correction. Sensors 2018, 18, 4087. [Google Scholar] [CrossRef]

- Herter, J.; Wunderlich, V.; Janeczka, C.; Zamora, V. Experimental Demonstration of Temperature Sensing with Packaged Glass Bottle Microresonators. Sensors 2018, 18, 4321. [Google Scholar] [CrossRef]

- Tao, W.; Lu, Z.; He, Q.; Lv, P.; Wang, Q.; Zhao, H. Research on the Temperature Characteristics of the Photoacoustic Sensor of Glucose Solution. Sensors 2018, 18, 4323. [Google Scholar] [CrossRef]

- Sakamoto, T.; Kimura, S. Plant temperature sensors. Sensors 2018, 18, 4365. [Google Scholar] [CrossRef]

- Clark, J. Self-Calibration and Performance Control of MEMS with Applications for IoT. Sensors 2018, 18, 4411. [Google Scholar] [CrossRef]

- Zuo, G.; Dou, Y.; Chang, X.; Chen, Y.; Ma, C. Design and Performance Analysis of a Multilayer Sea Ice Temperature Sensor Used in Polar Region. Sensors 2018, 18, 4467. [Google Scholar] [CrossRef]

- Monea, B.F.; Ionete, E.I.; Spiridon, S.I.; Ion-Ebrasu, D.; Petre, A.E. Carbon Nanotubes and Carbon Nanotube Structures Used for Temperature Measurement. Sensors 2019, 19, 2464. [Google Scholar] [CrossRef]

- Eaton, W.P.; Smith, J.H. Micromachined pressure sensors: Review and recent developments. Smart Mater. Struct. 1997, 6, 530–539. [Google Scholar] [CrossRef]

- Mathias, K.A.; Kulkarni, S.M. Investigation on Influence of Geometry on Performance of a Cavity-less Pressure Sensor. IOP Conf. Ser. Mater. Sci. Eng. 2018, 417, 012035. [Google Scholar] [CrossRef]

- Tessarolo, M.; Possanzini, L.; Campari, E.G.; Bonfiglioli, R.; Violante, F.S.; Bonfiglio, A.; Fraboni, B. Adaptable pressure textile sensors based on a conductive polymer. Flex. Print. Electron. 2018, 3, 034001. [Google Scholar] [CrossRef]

- Wang, F.; Zhu, B.; Shu, L.; Tao, X.-M. Flexible pressure sensors for smart protective clothing against impact loading. Smart Mater. Struct. 2013, 23, 015001. [Google Scholar] [CrossRef]

- Islam, M.M.M.; Sohaib, M.; Kim, J.; Kim, J.-M. Crack Classification of a Pressure Vessel Using Feature Selection and Deep Learning Methods. Sensors 2018, 18, 4379. [Google Scholar] [CrossRef]

- Petrov, R.V.; Sokolov, O.V.; Bichurin, M.I.; Petrova, A.R.; Bozhkov, S.; Milenov, I.; Bozhkov, P. Strength of multiferroic layered structures in position sensor structures. IOP Conf. Ser. Mater. Sci. Eng. 2020, 939, 012058. [Google Scholar] [CrossRef]

- Gödecke, M.L.; Bett, C.M.; Buchta, D.; Frenner, K.; Osten, W. Optical sensor design for fast and process-robust position measurements on small diffraction gratings. Opt. Lasers Eng. 2020, 134, 106267. [Google Scholar] [CrossRef]

- Chan, Y.J.; Carr, A.R.; Charkhabi, S.; Furnish, M.; Beierle, A.M.; Reuel, N.F. Wireless position sensing and normalization of embedded resonant sensors using a resonator array. Sens. Actuators A Phys. 2020, 303, 111853. [Google Scholar] [CrossRef]

- Kim, J.-A.; Kim, J.W.; Kang, C.-S.; Lee, J.Y.; Jin, J. On-machine calibration of angular position and runout of a precision rotation stage using two absolute position sensors. Measurement 2020, 153, 107399. [Google Scholar] [CrossRef]

- Helseth, L.E. On the accuracy of an interdigital electrostatic position sensor. J. Electrost. 2020, 107, 103480. [Google Scholar] [CrossRef]

- Xu, L.; Wang, S.; Zheng, P.; Huang, Z.; Luo, X. Investigation into position deviation effect on micro newton force sensor. IOP Conf. Ser. Mater. Sci. Eng. 2020, 799. [Google Scholar] [CrossRef]

- Cherkun, A.; Mishakov, G.; Sharkov, A.; Demikhov, E. The use of a piezoelectric force sensor in the magnetic force microscopy of thin permalloy films. Ultramicroscopy 2020, 217, 113072. [Google Scholar] [CrossRef]

- Nastro, A.; Ferrari, M.; Ferrari, V. Double-actuator position-feedback mechanism for adjustable sensitivity in electrostatic-capacitive MEMS force sensors. Sens. Actuators A Phys. 2020, 312, 112127. [Google Scholar] [CrossRef]

- Templeman, J.O.; Sheil, B.B.; Sun, T. Multi-axis force sensors: A state-of-the-art review. Sens. Actuators A Phys. 2020, 304, 111772. [Google Scholar] [CrossRef]

- Zang, H.; Zhang, X.; Zhu, B.; Fatikow, S. Recent advances in non-contact force sensors used for micro/nano manipulation. Sens. Actuators A Phys. 2019, 296, 155–177. [Google Scholar] [CrossRef]

- Palmer, K.; Kratz, H.; Nguyen, H.; Thornell, G. A highly integratable silicon thermal gas flow sensor. J. Micromech. Microeng. 2012, 22, 65015. [Google Scholar] [CrossRef]

- Garrett, A.; Soler, G.J.; DiLuna, M.L.; Grant, R.A.; Zaveri, H.P.; Hoshino, K. A passive, biocompatible microfluidic flow sensor to assess flows in a cerebral spinal fluid shunt. Sens. Actuators A Phys. 2020, 312, 112110. [Google Scholar] [CrossRef]

- Bekraoui, A.; Hadjadj, A. Thermal flow sensor used for thermal mass flowmeter. Microelectron. J. 2020, 103, 104871. [Google Scholar] [CrossRef]

- Ejeian, F.; Azadi, S.; Razmjou, A.; Orooji, Y.; Kottapalli, A.; Warkiani, M.E.; Asadnia, M. Design and applications of MEMS flow sensors: A review. Sens. Actuators A Phys. 2019, 295, 483–502. [Google Scholar] [CrossRef]

- Kim, J.; Cho, H.; Han, S.-I.; Han, A.; Han, K.-H. A disposable microfluidic flow sensor with a reusable sensing substrate. Sens. Actuators B Chem. 2019, 288, 147–154. [Google Scholar] [CrossRef]

- Dahlin, A.B. Size Matters: Problems and Advantages Associated with Highly Miniaturized Sensors. Sensors 2012, 12, 3018–3036. [Google Scholar] [CrossRef]

- Li, J.; Xing, F.; Chu, D.; Liu, Z. High-Accuracy Self-Calibration for Smart, Optical Orbiting Payloads Integrated with Attitude and Position Determination. Sensors 2016, 16, 1176. [Google Scholar] [CrossRef]

- Shkel, M. Smart MEMS: Micro-structures with error-suppression and self-calibration control capabilities. Proc. Am. Control Conf. 2001, 2, 1208–1213. [Google Scholar]

- Leng, J.; Yan, D.; Liu, Q.; Xu, K.; Zhao, J.L.; Shi, R.; Wei, L.; Zhang, D.; Chen, X. ManuChain: Combining Permissioned Blockchain With a Holistic Optimization Model as Bi-Level Intelligence for Smart Manufacturing. IEEE Trans. Syst. Man Cybern. Syst. 2019, 50, 1–11. [Google Scholar] [CrossRef]

- Leng, J.; Ruan, G.; Jiang, P.; Xu, K.; Liu, Q.; Zhou, X.; Liu, C. Blockchain-empowered sustainable manufacturing and product lifecycle management in industry 4.0: A survey. Renew. Sustain. Energy Rev. 2020, 132, 110112. [Google Scholar] [CrossRef]

| Traditional Factory | Smart Factory |

|---|---|

| Manual and isolated processes, operations; no integration with different systems and tools. | Digitized and integrated processes, operations; complete integration with existing systems, new systems and tools. |

| Legacy systems with frequent machine failures and increased maintenance costs. | Smart systems with improved machine utilization and reduced maintenance costs. |

| Tied to systems or machines for data, therefore zero or limited data for decision making; process-driven decision making. | Update or receive data on the go, therefore complete data for faster decision making; data-driven decision making. |

| Limited technology involvement. | Internet-of-things (IoT), sensor, mobile app, radio frequency identification (RFID) enabled. |

| Zero or limited visibility on operations, productivity data. | Increased transparency, visibility on operations and production data. |

| Limited innovation in production development. | Smart and intelligent products. |

| Inaccurate asset tracking process and poor resource utilization. | Accurate asset tracking using IoT, RFID; improved resource utilization. |

| Poor interoperability. | High interoperability. |

| The production line is fixed unless manually reconfigured by people with system power down. | When switching between different types of products, the needed resources and the route to link these resources should be reconfigured automatically and online. |

| Sensor Types | Characteristics | Material | Uses | Advantages | Disadvantages | Source |

|---|---|---|---|---|---|---|

| Thermistor | Additionally called thermally sensitive resistors, change their physical appearance with changes in temperature. The effective operating range is −50 °C to 250 °C. | Ceramic such as oxides of nickel, manganese or cobalt coated in glass. | Widely used in automobile industry to detect the intake and coolant temperature. | Fast thermal response; lead wire resistance results in small error. | Limited temperature range; low resistance to shock. | [42,43,44,45,46,47,48,49,50] |

| Resistance Thermometer | Have a fixed relationship with temperature, resistance changes as temperature changes. Known for accuracy and stability, these sensors detect temperature changes ranging from −50 °C to 500 °C for thin film, and −200 °C to 850 °C for wide film. | High purity conducting metals such as platinum, copper or nickel wound into a coil. | Most widely used as HVAC, room, duct and refrigerant temperature, motors for overload protection and in automotives for air and oil temperature detection. | High precision and stability; strong output signal and high sensitivity; good stability (can maintain temperatures below 0.1 °C for a long time). | Expensive; easily influenced by lead wire resistance; slow thermal response; low resistance to shock and vibration. | |

| Thermocouple | Temperature changes cause a temperature dependent voltage which is in turn converted into a temperature reading. Detect temperatures as high as 3000 °C and as low as −250 °C. | Two junctions of different materials such as copper and constantan that are welded together. | Most widely used in industrial measurement due to inexpensive, rugged and reliable nature. | Wide temperature range; high temperature measurement; high resistance to shock and vibration; fast thermal response. | Compensating conductors needed when extending lead wires. |

| Sensor Type | Characteristics | Material | Uses | Advantages | Disadvantages | Source |

|---|---|---|---|---|---|---|

| Resonant | Follows the principle of vibrating wire, where a magnetic coil is attached to a diaphragm which vibrates when faced by a magnetic field conducting an electric current. The vibration frequency depends on pressure applied. | Metal resistive element such as silicon and quartz. | Used in industrial gauge and vacuum measurement. | High over-pressure and burst pressure capabilities. | Expensive; limited machining processes of quartz. | [48,52,53,54,55,56] |

| Capacitive | Most commonly used. Display change in capacitance when pressure is applied to the diaphragm creating an oscillator frequency. | Metals such as copper and indium tin oxide. | Ideal for flow applications. | Highly sensitive, can measure high and low changes; measure pressures below 10 mbar; withstand large overloads. | Material constraints and joining and sealing requirements restrict applications. | |

| Piezoelectric | Use the properties of piezoelectric materials such as quartz to create a charge which is proportional to the force applied on the surface when pressure is applied. | Piezoelectric materials such as quartz, rochelle salt, barium titanium, and tourmaline. | Widely used for dynamic pressure measurement in turbulence, blast and engine combustion, also used in some medical applications such as monitoring arterial pulse. | Measures fast changing dynamic pressures. | Need high impedance circuit; susceptible to noise; unable to measure solid state pressure due to dynamic nature. | |

| Optical | Use interferometry to detect changes in pressure in optical fiber. Can be created using tiny components or micro-electromechanical systems (MEMS) technology. | Use a Fabry-Perot interferometer, with two partially reflecting mirrors made of glass or quartz. | Most widely used in radiography equipment. | Not disturbed by electromagnetic interference, allowing use in noisy conditions; highly sensitive, small size, and long life span; medically safe for implantation. | Costly; susceptible to interference from environmental effects and physical damage. |

| Sensor Type | Characteristics | Material | Uses | Advantages | Disadvantages | Source |

|---|---|---|---|---|---|---|

| Potentiometric | Resistance-based sensors, use a resistive track with a wiper which moves with the movement of the object. | Carbon film. | Commonly used in computer game joysticks, steering wheels, industrial and robot applications. | Inexpensive and easy to use. | Wear easily due to moving parts; low accuracy, repeatability and limited frequency response; limited detection range due to small size of the wiper. | [57,59,60,61,62] |

| Capacitive | Consist of two plates separated by a dielectric material. Rely on detecting change in capacitance to measure the position of an object either by changing the dielectric constant or overlapping area. | Metallic electrodes used as plates, with a dielectric material between them. | Widely used in accelerometers, ice detection, spacing and thickness of materials. | Non-contact measurement; high resolution; can detect motion in both linear and angular directions; different material detection such as skin, plastic, metal, liquid, etc. | Sensitive to environmental changes such as humidity, temperature etc. | |

| Magnetostrictive Linear Position | Material changes its size or shape when in the presence of a magnetic field to detect the position of an object. | Ferromagnetic materials such as iron, nickel, and cobalt. | Used in the controlling of gaps between rollers, hydraulic or pneumatic cylinders, in automotive industry and electric actuators. | Non-contact; ability to detect position in the presence of a barrier between magnet and sensing rod; ability to measure multiple magnets with a single sensing rod. | Dead band on each side of the sensor cannot be reduced to zero. | |

| Eddy Current based | Work with induced currents that occur in a conductive material in the presence of a changing magnetic field using Faraday’s law of induction. | Conductive material such as copper, aluminum, titanium alloy etc. | Widely used in automation applications, machine tool mounting, final assembly of delicate machinery and monitoring drive shafts. | Functional in dirty environments; less expensive; unaffected by most contaminants. | Omnidirectional, can only determine the distance of the object not the direction of the object from the sensor. | |

| Optical | Work two ways: (1) light is transmitted from an emitter and sent to a receiver at the other end of the sensor; (2) emitted light signal is reflected from the monitored object towards the light source. Change in light characteristics are used to determine the position. | Glass or plastic disc used as an encoder, with LED used as a light source, and a photodetector as light receiver. | Widely used in deadbeat galvanometers, induction motors, induction furnaces, electric brakes, and speedometers. | Both linear and rotational movement can be detected. | Large amount of heat is produced in the soft core of transformers, induction coil, electric motors, etc., reducing the efficiency of these machines. |

| Sensor Type | Characteristics | Material | Uses | Advantages | Disadvantages | Source |

|---|---|---|---|---|---|---|

| Load cells | Convert applied force into an output signal measuring force such as compressive forces. Include pneumatic, hydraulic, piezoelectric crystal, inductive, capacitive, and magnetostrictive load cells. | Materials such as ferromagnetic, metal resistive elements, metallic electrodes etc. | Commonly used in truck scales. | Performance is affected by no-axial force; requires temperature network; excessive force may damage the load cells permanently. | Small and compact in size; good accuracy; less expensive; good sensitivity. | [58,63,64,65,66] |

| Strain gauges | Sensors whose electrical resistance changes with applied force. | An insulating substrate with a conductive metallic foil. | Widely used in load measuring applications, from truck scales to bolt tensioning devices. | High resolution; small size; measures both static and rapidly changing stress; low price. | Low accuracy; need to be calibrated after installation. | |

| Force Sensing Resistors (FSR) | Use a type of piezoresistive technology consisting of a semi-conductor material or ink sandwiched between substrates separated by a separator. A conductive film is formed with applied force and presses against a conductive ink printed on the substrate. | Electronic and electronic components; PCB, conductive foam. | Used in foot pronation systems, automobiles like car sensors, resistive touch pads, etc. | Thin and flexible; available in variety of sizes and shapes; low power consumption; low cost. | Low in precision and repeatability, repeated measurements vary by 10% or more. |

| Sensor Types | Characteristics | Material | Uses | Advantages | Disadvantages | Source |

|---|---|---|---|---|---|---|

| Positive displacement | Perform direct measurement of volume of the fluid passing through the device. A known volume of fluid is trapped and moved through the sensor using rotating parts that effectively pass the fluid along sequentially before allowing more fluid to enter the device. | Stainless steel. | Used in measuring oils, gasoline, hydraulic fluids, and home installed metering of water and gas. | Function over a wide range of fluid viscosities; high accuracy; low maintenance requirements; provide mechanical or electronic interface. | Extremely expensive to install and maintain due to moving parts. | [46,67,68,69,70,71] |

| Mass flow | Detect energy transfer from a heated surface to a flowing fluid following different ways: (1) introducing thermal energy and measuring change in temperature; (2) maintaining constant temperature and measuring the amount of energy needed to do so; (3) introducing electric current to a resistive wire and measuring the current needed to maintain temperature. | Special alloys to cope with aggressive gases. | Widely used in automotive applications. | Directly measure liquid flow with high accuracy; wide range of measurable fluids, including highly viscous liquids; bidirectional flow measurement. | Poor zero stability; cannot measure liquids with low density; highly sensitive to vibration interference. | |

| Velocity flow | Sensors detect flow rate by measuring the velocity of fluid flowing through the sensor. | |||||

| Mechanical: Fluid flow measured by the movement of a paddle wheel detected by a magnetic coil or infrared sensor. | Stainless steel. | Commonly used in water/waste treatment plants. | Cost effective; compact; need very little energy to operate; detect a wide variety of fluids. | Moving parts are subject to wear; build-up of contamination due to flow of dirty fluids; a minimum amount of fluid needed to move the paddle wheel. | ||

| Electromagnetic: Operate on Faraday’s law of induction. A coil induces a magnetic field in the fluid being measured and uses a set of electrodes to measure the induced voltage. | Hastelloy, tantalum 90% platinum 10%, iridium and titanium for electrodes. | Widely used in chemical manufacturing, petrochemical industries. | Can measure liquids with some degree of contamination; pressure drop is not induced in the pipe. | Do not function with non-conductive fluids; not suitable for vacuum conditions; require fluids to have some level of minimum conductivity. | ||

| Ultrasonic: A pair of ultrasonic transducers generate a signal directed into the fluid flow, each signal is directed back to the receiver using a set of mirrors. | Stainless steel pipe wall. | Used in facilities management, aquafarms, pulp and paper manufacturing. | Used for both conductive and non-conductive fluids; handle high temperatures and pressures; can be non-wetted. | Fluids with air bubbles cannot pass through ultrasonic energy; high vibrations cause difficulty in reading; high cost. |

| Sensor Type | Characteristics | Material | Uses | Advantages | Disadvantages | Source |

|---|---|---|---|---|---|---|

| Nuclear sensor | Operate following the principles of optical sensors, where a medium facilitates the transmission of radiation between a source and a detector; and the magnitude of transmission is attenuated according to the measured variable. | Cesium 137—as gamma ray source; sodium diode device as gamma ray detector. | Mass flow measurement and medical scanning applications. | Zero carbon emission; energy independence. | Very expensive; are prone to contamination by background radiation. | [74,75] |

| Micro-sensors | An element with some sort of mechanical functionality is integrated with microelectronics. The typical sizes of these sensors range between 0.01 mm or 10–5 m to 5 mm. | Silicon semiconductor material; sometimes fabricated with metals, plastics, polymers, gasses, and ceramics deposited on the silicon base. | Largely used in the automotive industry and medical equipment, such as blood pressure measurement. | Smaller size; improved performance; better reliability; lower production costs. | Have low capacitance; output signals prone to noise contamination; produce output signals of very low magnitude. | [74,75] |

| Nano-sensors | Vary in size from 1 to 1000 mm, using nanotechnology. | Thin layers of metal films or semiconductors; more advance than MEMS using special forms of etching, optical lithography or electron beam lithography. | Used as accelerometers, biological sensors and sensors for airborne chemicals. | Lower production costs; reduced power consumption; smaller size. | Complicate to handle; short-term noise issues. | [72,74] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalsoom, T.; Ramzan, N.; Ahmed, S.; Ur-Rehman, M. Advances in Sensor Technologies in the Era of Smart Factory and Industry 4.0. Sensors 2020, 20, 6783. https://doi.org/10.3390/s20236783

Kalsoom T, Ramzan N, Ahmed S, Ur-Rehman M. Advances in Sensor Technologies in the Era of Smart Factory and Industry 4.0. Sensors. 2020; 20(23):6783. https://doi.org/10.3390/s20236783

Chicago/Turabian StyleKalsoom, Tahera, Naeem Ramzan, Shehzad Ahmed, and Masood Ur-Rehman. 2020. "Advances in Sensor Technologies in the Era of Smart Factory and Industry 4.0" Sensors 20, no. 23: 6783. https://doi.org/10.3390/s20236783

APA StyleKalsoom, T., Ramzan, N., Ahmed, S., & Ur-Rehman, M. (2020). Advances in Sensor Technologies in the Era of Smart Factory and Industry 4.0. Sensors, 20(23), 6783. https://doi.org/10.3390/s20236783