1. Introduction

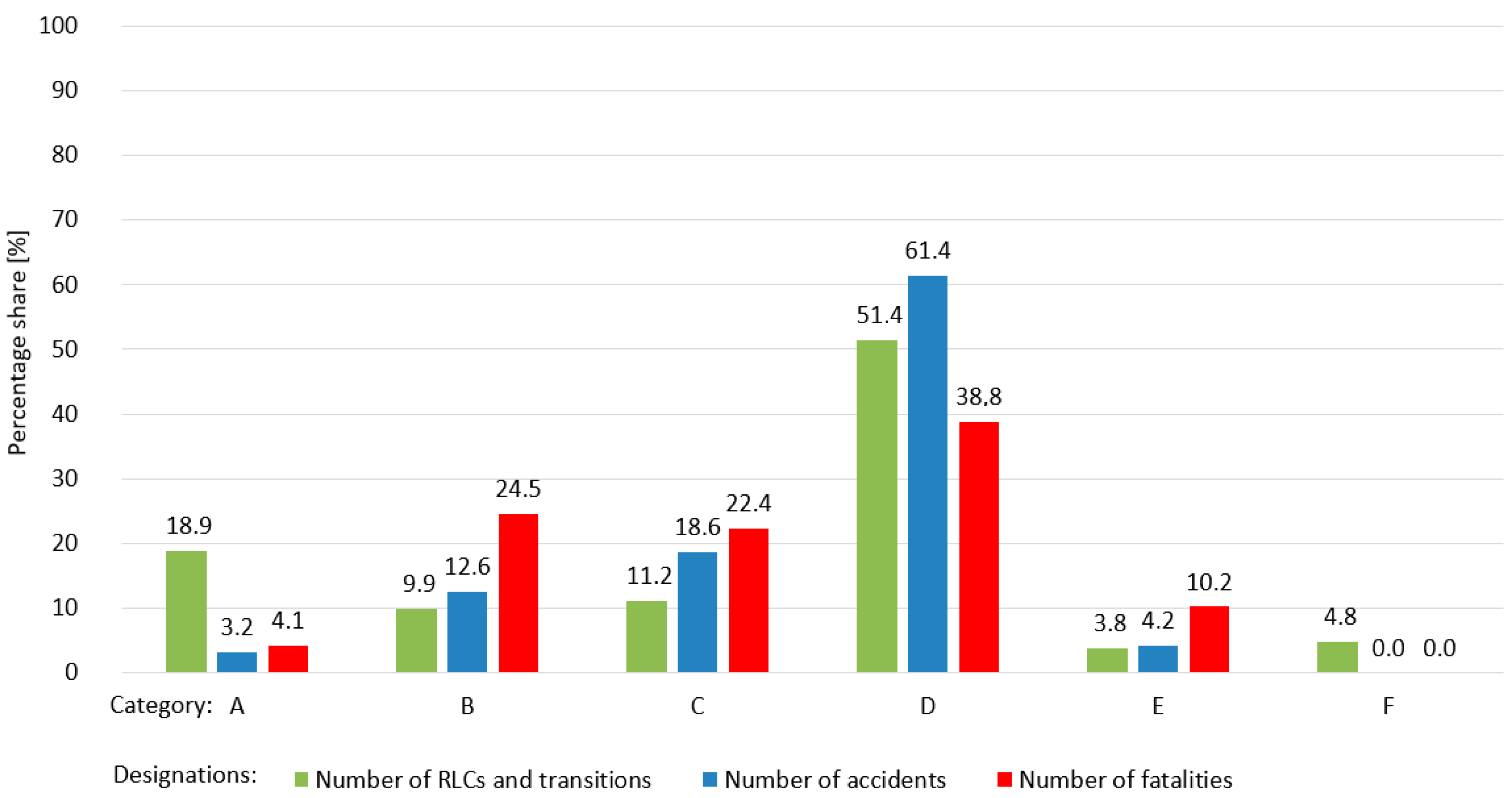

Railway level crossings (RLCs) are intersections of railway lines with roadways, other than pedestrian crossings (i.e., crossings, cross-walks, or transitions), on one level. A pedestrian crossing comprises a crossroads on one level intended exclusively for pedestrian and/or bicycle traffic [

1]. RLCs and pedestrian crossings in Poland are divided into the categories A–F as follows [

1,

2,

3,

4]:

A—RLC on which the road traffic is directed by an authorized employee;

B—RLC on which the road traffic is directed by means of an automatic crossing system (ACS) equipped with traffic signals (roadside signals) and barriers;

C—RLC on which the road traffic is directed by means of an ACS equipped only with traffic signals;

D—RLC that is not equipped with motion protection systems and devices;

E—a pedestrian crossing equipped with:

semi-automatic or automatic crossing system;

reels, barriers, or mazes;

F—RLC or pedestrian crossing located on an internal road, equipped:

with barriers, permanently closed, and opened by users as needed;

in accordance with the technical conditions specified for category A or B.

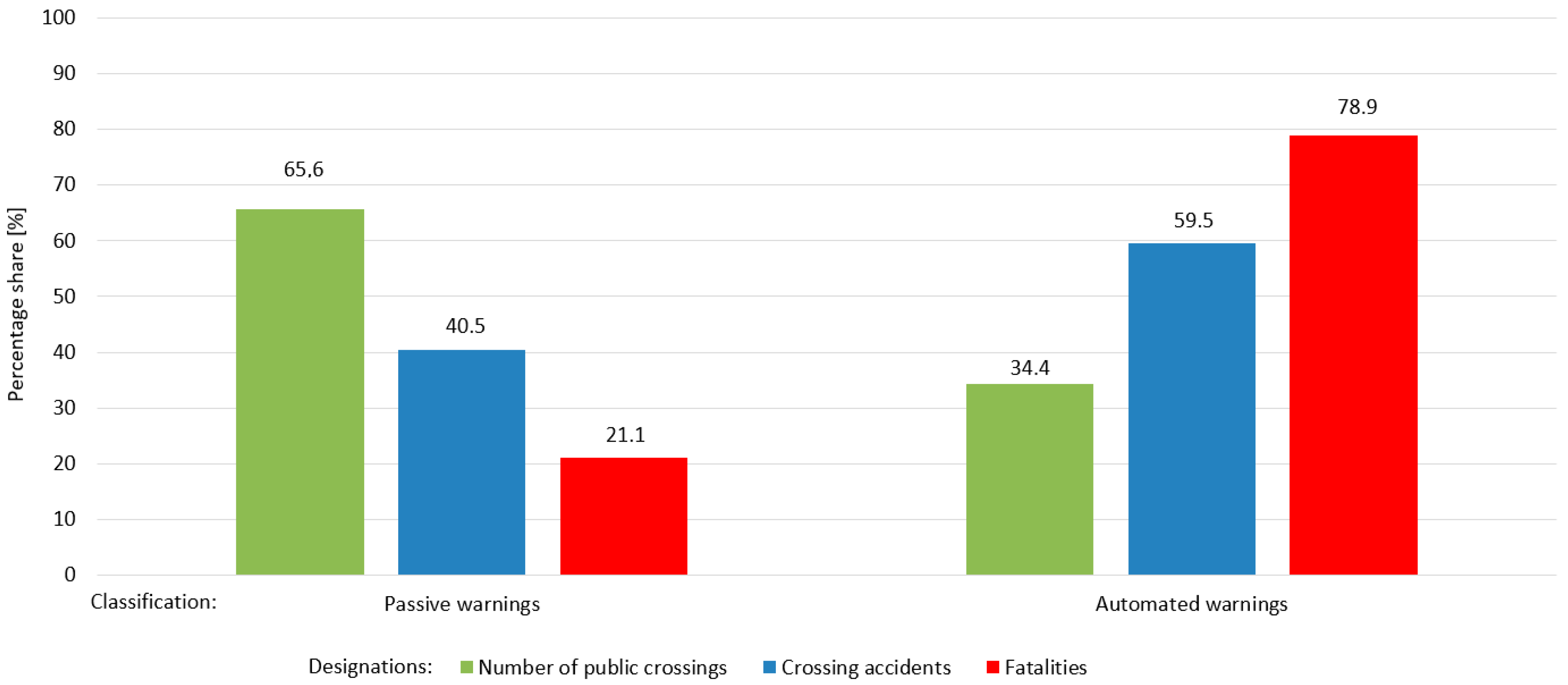

The basic classification of railway level crossing protection systems is divided into passive and active [

5,

6]. In passive systems, the road user is solely responsible for observing the traffic situation (e.g., an approaching train). Road traffic signs used for passive level crossings (i.e., traffic signs “Stop” and “St. Andrews Cross”) are unchanged and users must understand their meaning, look/listen for trains, and then respond according to the observed traffic situation. By comparison, an active protection system changes its state to warn road users of an approaching train (i.e., via flashing lights and sound and/or full or half barriers) [

5,

6].

RLCs pose a significant safety challenge due to complex social and technical systems that involve interactions between many different types of road users (pedestrians, cyclists, motor vehicle drivers) and rail operators (drivers, signaling operators) and infrastructure (protective systems) [

5,

7].

Abnormalities at railway level crossings are a global problem. Nedeliaková et al. [

8] emphasize that the safety of railway level crossings is a global concern. Because individual railway level crossings have specific conditions, it is necessary to monitor each of them individually. Tjahjono et al. [

9] recognize that accidents between road and rail traffic at railway level crossings are an important problem in developing countries. Although accidents are a major problem for railway companies globally, compared to road accidents, the number of accidents at railway level crossings is very small [

10]. Ambros et al. [

11] and Tey et al. [

12] state that railway level crossings are a critical and complex element of both rail and road networks, at which accidents in most cases lead to serious and fatal injuries. The results in [

11] confirmed the influence of traffic flows on safety, in addition to speeding and individual viewing distances. Evans et al. [

13] referred to the relationship between railway level crossings, delays, and fatalities for road users at railway level crossings in the United Kingdom. The choice between automatic or rail-controlled RLCs on public roads was considered. Liang et al. [

14] confirm that safety is a key issue in railway operations. In particular, safety at RLCs is one of the most critical points on railways.

RLCs are critical points with a high number of accidents per year due to the intersection of rail and road infrastructure, and improving their safety is of key importance globally [

5,

7,

15,

16,

17]. Together with tunnels and specific road black spots, railway level crossings have been identified as a particularly weak point in road infrastructure which seriously threatens road safety [

18,

19,

20,

21].

Żakowska [

22] states that one of the dominant causes of loss of life and health of people around the world is road traffic. In the group of European Union countries, Poland has for years been a leader in terms of fatal road accidents. The statistics present the importance of the road transport safety problem as an important social problem. The state of transport safety includes two types of safety:

objective—defined by objective parameters of the traffic environment and the behavior of its participants;

subjective—assessed in accordance with the feeling and perception of safety perceived by individuals and groups of people.

According to Żakowska [

22] and Olejnik et al. [

23], an unconscious danger may cause a subjective feeling of safety. With regard to traffic participants, we observe behaviors that they think are safe. In fact, their feeling is subjective, but they do not realize it. Żakowska in [

22] and Reason in [

24] emphasize that a safe society is an informed society, one that is always aware of where the dangerous edge is, without having to cross it. The edge lies between relative, subjective security and not an acceptable threat. Moving in this area requires special skills and social culture.

Żakowska states in [

22] that a change in a driver’s behavior occurs as a result of changes in perceived risk. Subjective perceived risk, depending on the perception processes, is the basis for a driver’s safe behavior. The difficulty of determining the state of subjective security is still controversial. While some scientists claim that drivers in most cases are not aware of the risk they are taking, then exposing other users to danger, other experts express the opinion that normal drivers always make decisions that are not dangerous in their opinion [

22,

25]. It is also suggested that normal road users accept a certain level of risk, regardless of the existing situation on the road [

22,

26]. Wilde in [

27] states that risk homeostasis as the degree of risk-taking behavior and the magnitude of loss due to accidents and lifestyle-dependent disease is maintained over time, unless there is a change in the target level of risk.

Transport safety issues, especially the theory of driver behavior in the traffic environment, have been referred to in [

28], the theory of behavioral adaptation [

29], the theory of homeostasis [

26,

27,

30,

31], and the theory of risk compensation [

32]. In [

33], reference is made to how homeostasis drives behavioral adaptation. Ward et al. [

34] relate how drivers approach behavior at an unprotected railway crossing before and after enhancement of lateral sight distances as an experimental investigation of a risk perception and behavioral compensation hypothesis. They note that common sense dictates that railway crossings with restricted lateral visibility should be more hazardous than sites with unrestricted visibility. However, evidence of any relationship between lateral sight distance and accident history has not been consistently demonstrated. Based on the tenets of risk homeostasis theory, this relates to disassociation in terms of motorist compensatory behavior (e.g., speed reduction) in response to the perceived risk associated with restricted visibility. The expectation of this regulatory mechanism is to sustain a more-or-less constant safety margin. In this study, we examine the effect of enhancing lateral sight distances at an unprotected crossing. Parallel observations were made at an untreated site to control for secular confounding. Improvement of lateral sight distances resulted in an upstream shift toward longer search durations and a tendency toward faster approach speeds, but it failed to produce a calculated net safety benefit. A survey of local residents suggests that the enhancement treatment reduced perceived risk [

34].

In the paper [

22,

35], it is also noted that a high level of subjective risk, i.e., lack of safety, according to the Klebersberg risk model is often undesirable from the perspective of traffic safety.

Safety in the traffic environment depends on the interaction between an objective threat and a subjective risk. If the impression of risk on the road remains high for an extended period of time, then the driver acts in a state of above-average danger, which can cause objectively dangerous reactions and behavior. Maintaining the driver’s average state of arousal should therefore be considered in the process of designing a safe road environment [

22].

Ishak et al. [

36] refer to the development of the RLC safety assessment model for evaluating the performance and reliability of RLC locations using stochastic Petri nets. They draw attention to the interconnection of elements in the RLC system, such as signaling control and train and traffic characteristics. The use of a geographic information system (GIS) in the spatial representation of an RLC combines model output with the visualization of the surrounding land use environment and aims at increasing the understanding of RLC accident phenomena.

Pen et al. [

37] investigate RLCs by measuring the deflection of railway tracks during a train’s passage using geophones, cameras, and digital image correlation (DIC). Special emphasis is placed on the measurements of track movement during the approach to a railway level crossing before and after tamping.

The impatience and frustration of road users has been identified as a factor underlying non-compliance and can be characterized as a specific risk factor [

38,

39]. Subjective data showed that participants do not comply with railway level crossing rules due to factors such as time pressure, impatience/frustration, and low perceived risk [

38]. Jonsson et al. [

40] also state that the safety devices, road type, train traffic, and number of people living near a railway level crossing each have a significant impact on the probability of an accident.

Djordjević et al. [

15] proposed a new approach to RLC security assessment using a non-radial data envelopment analysis (DEA) model. The proposed model is used to assess the effectiveness of railways in European countries in relation to the RLC safety level.

Magyari et al. [

41] conducted a visibility study at railway level crossings by comparing point clouds from terrestrial laser scanning (TLS) and an unmanned aerial vehicle (UAV). It was found that the compared methods could produce contradicting results because the drone elevation model did not capture high and narrow columns, such as sign poles, and that the two survey methods could work effectively together.

Amaral et al. [

21] studied laser-based obstacle detection at railway level crossings. They noted that detecting small obstacles (e.g., rocks ≈10 dm

3) on an RLC is an open problem. They presented a system for obstacle detection on railway level crossings from 3D point clouds acquired with tilting 2D laser scanners. By allowing the detection of large and small obstacles (≥10 dm

3) despite lighting conditions, they stated the system contributes to reducing the number of casualties in level crossings without reducing traffic flow.

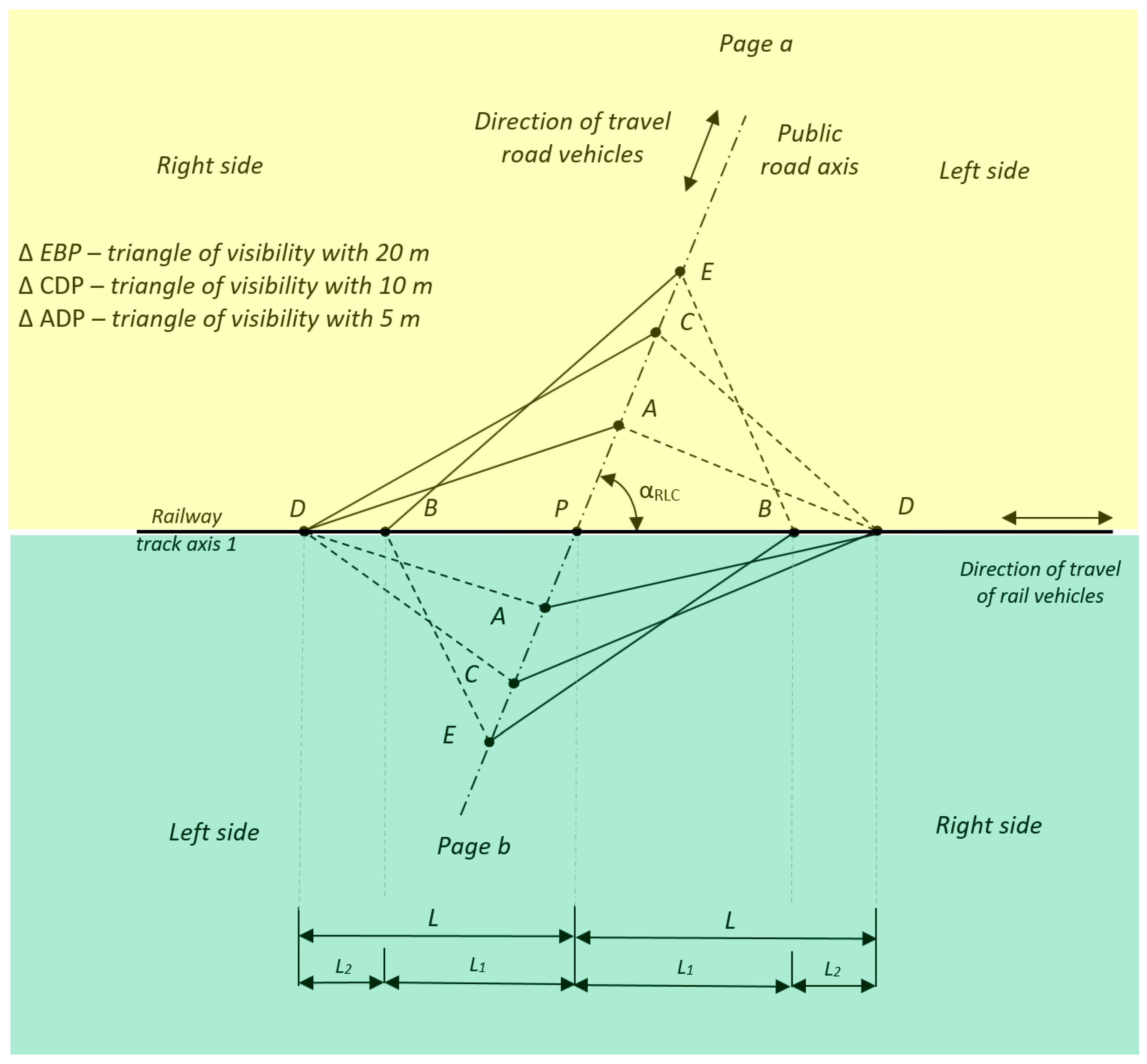

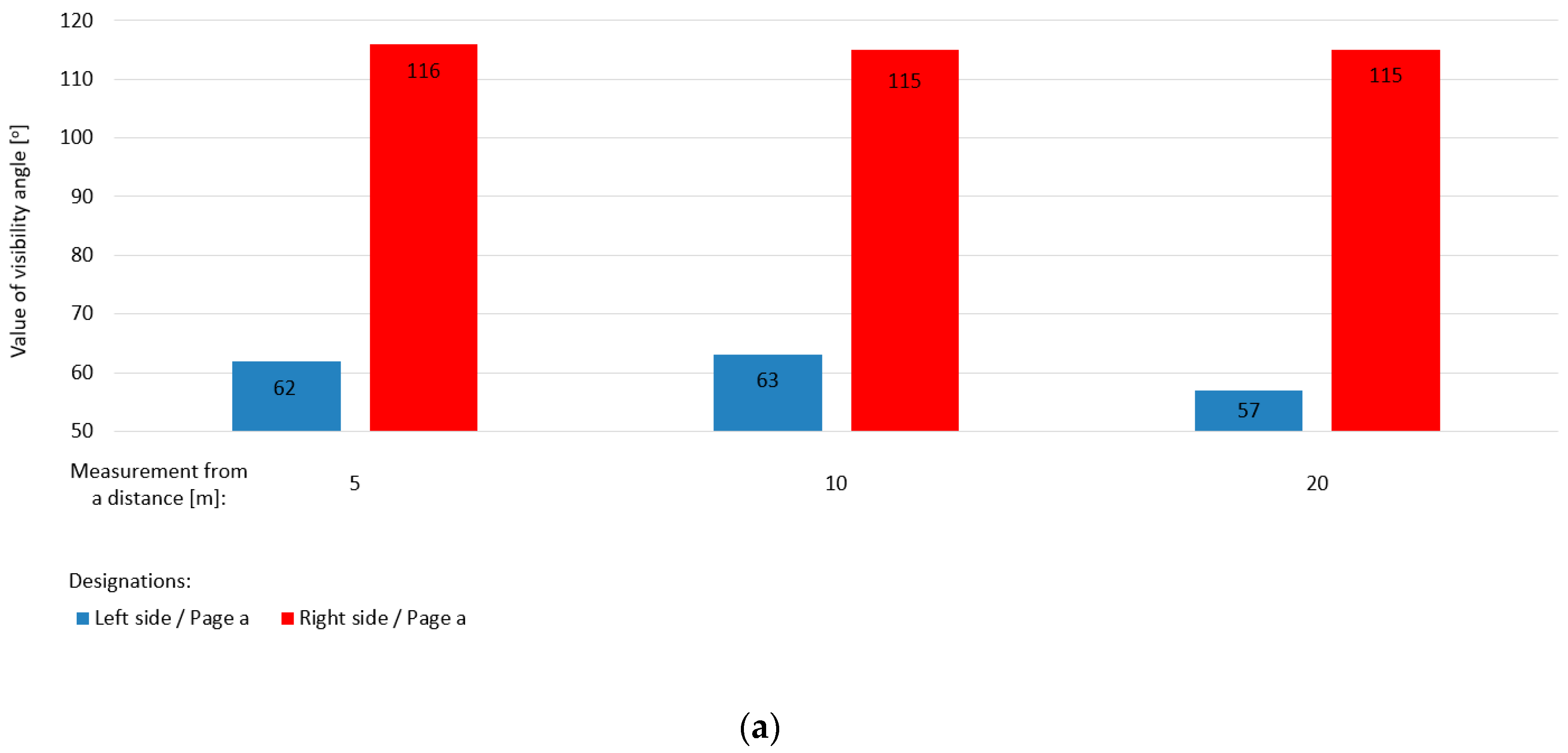

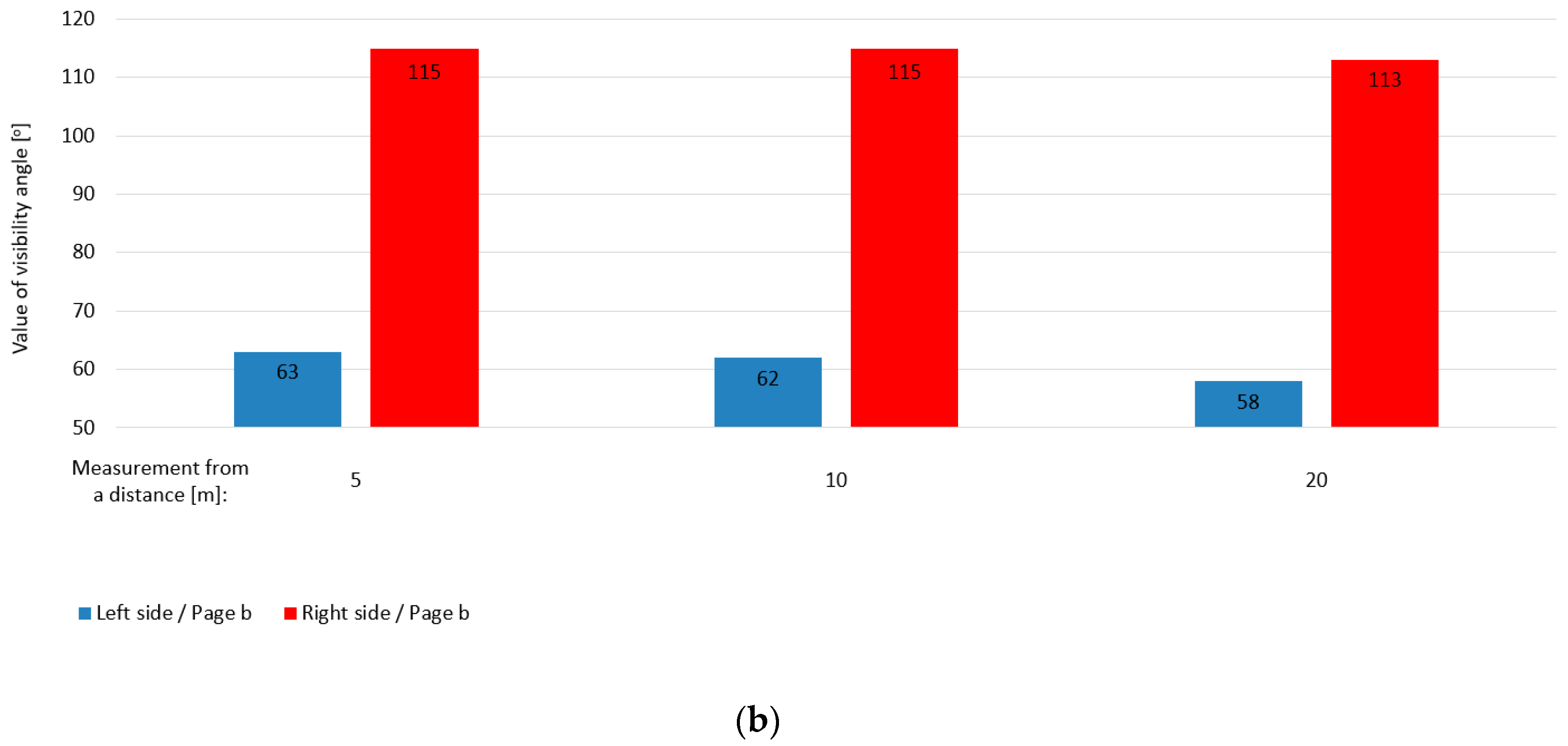

This article concerns the safety status of railway level crossings in Poland. It contains the results of tests of the geometry of visibility triangles and assesses the impact on the safety of anomalies and non-compliance with regulations. The article draws attention to the need to implement measures that increase safety, with particular emphasis on surveying and diagnostic measurements to eliminate accidents and incidents on RLCs. The main objective of the research is to draw attention to a new approach to monitoring the geometry of visibility triangles of RLCs using an electronic total station and magnetic measuring square (MMS). The visibility is demonstrated, taking into account the angles of intersection of the road axis with the track axis of the line, including additional attributes to help analyze and evaluate the overall visibility conditions. The object of measurement is a railway level crossing of category D (passive) situated on a continuous welded rail. A case study examines the single-track railway line no. 144 Tarnowskie Góry—Opole Główne at 7.581 km, track no. 1, of the Silesian Voivodship (in Polish: Śląskie), Poland, characterized by the individual number: 144 007 581. At this location, the railway line is single-track, on which two-way traffic takes place.

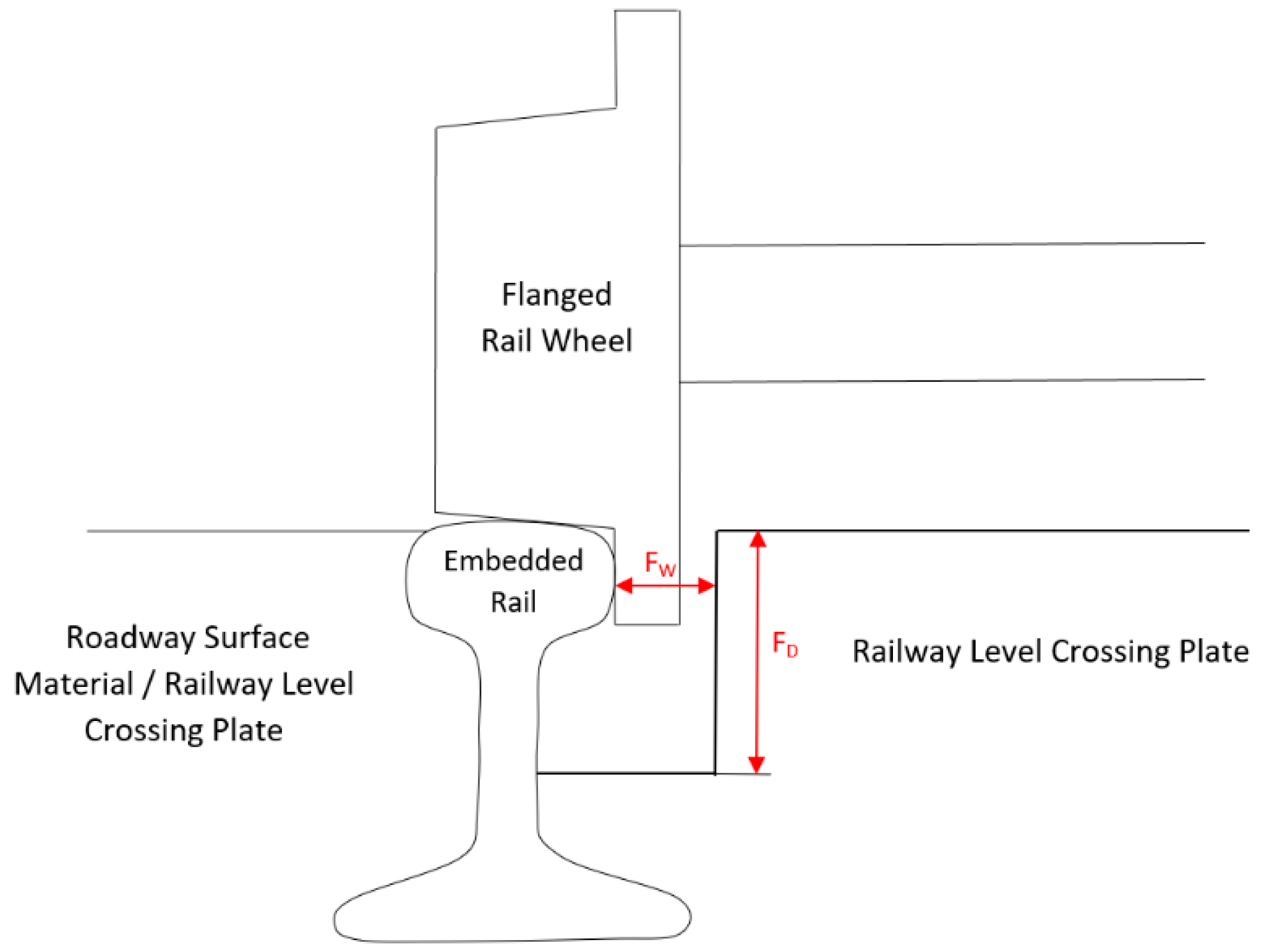

In this work, the author’s research also highlights several controversies regarding particular factors:

The threshold values of the angle of intersection of the road axis with the track axis of the line are different in different countries;

There are differences in the permissible width and depth values of RLC flangeways in different countries;

There are no uniform rules for measuring the location of road signs;

The angle of intersection varies according to the location of the RLC in each type of conventional railway;

Lack of uniform regulations and technical standards for monitoring RLC geometry and pedestrian crossings within the European Union.

The presented methodology, which is based on the integration of surveying prisms with MMS, confirmed the validity of their correct placement on the rail and the determination of characteristic measurement points for monitoring the geometry of visibility triangles of RLCs in conjunction with additional attributes. The measurement solution is tailored and closely related to the elements of the specific construction of the railway infrastructure, achieving a balance of safety and accessibility.

The introduced methodology for monitoring the geometry of RLC visibility triangles significantly improves the supervision of rail and road transport.

2. Related Work

Moayedfar et al. [

20] investigate the calculation of sight triangle dimensions and unobstructed areas at railway level crossings in Iran. They draw attention to three categories:

Approach area: Drivers should recognize the existence of a crossing in front of them, look for other trains or signs, and make appropriate decisions;

Irreversible area: The area in which drivers decide to stop according to train distance and initial speed. If a correct decision to stop is not made in time, an accident will occur;

Hazard zone: The area in which a stopped or moving vehicle may have collision with a stopped or moving train.

Tey at al. [

42] applied VISSIM (in German: Verkehr in Städten—SIMulationsmodell) traffic microsimulation modeling based on data from field video recording. In addition, Młyńczak and Celiński in [

43] used measurements based on an eye tracking device and an accelerometer (smartphone) installed onboard a test vehicle to monitor drivers of vehicles transporting dangerous and sensitive goods in the area of railway level crossings. The measuring system made it possible to study the characteristics of the driver’s process of perception of the external environment in the area of railway level crossings. For comparison purposes, an analogy was made to the measurement of train drivers’ behavior in the area of railway level crossings due to interaction of both road and rail traffic flows.

Bureika et al. [

16] suggest assessing the safety of railway level crossings as a binary logical regression. Solving this regression results in an equation which consists of several variables and expresses the dependence of traffic safety at level crossings on several quantitative indicators, i.e., it estimates how a binary variable

Y (safety at level crossings) depends on one or several variables. Variable

Y is called the dependent (regressand) variable, and variables

X1,

X2,

X3 are called independent variables (regressors). In the case of research [

16], the dependent variable is safety level at level crossing

Y and the independent variables are safety assessment criteria at level crossings,

X1–

X7.

Khan et al. [

44] state that safety at highway rail grade crossings (HRCs) continues to be a serious concern despite improved safety practices. The authors developed a binary logit regression model to predict accident likelihood at HRCs by incorporating various contributory factors in addition to population within five miles of crossings.

Salmon et al. [

45] noted that resolving the tension between efficiency and safety at rail level crossings is a key line of further inquiry.

Gikas [

46] referred to surveying techniques for checking basic parameters of railway track geometry. To apply a geodetic mini prism (surveying mini prism) with a stylus tip as a standard solution for the measuring point below the top surface of the rail head, a special iron part was used to set the mini prism. Klug et al. [

47] used the Leica Geodetic Mini Prism GMP111 with a surveying pole tip as a standard solution, which was placed in a special rail clamp drilling hole.

Urbančič et al. [

48] suggested an improved approach for the control measurements of a ski-flying hill run in a case study of Planica. They presented a specially designed platform containing three measuring prisms to control the position of pipes (a metal tube is located on each side of the track to guide the trolley that mills tracks into the ice).

Marjetič et al. [

49] and Kregar et al. [

50] presented an alternative approach to controlling measurements of crane rails by applying a special platform on which two precise surveying prisms were fixed.

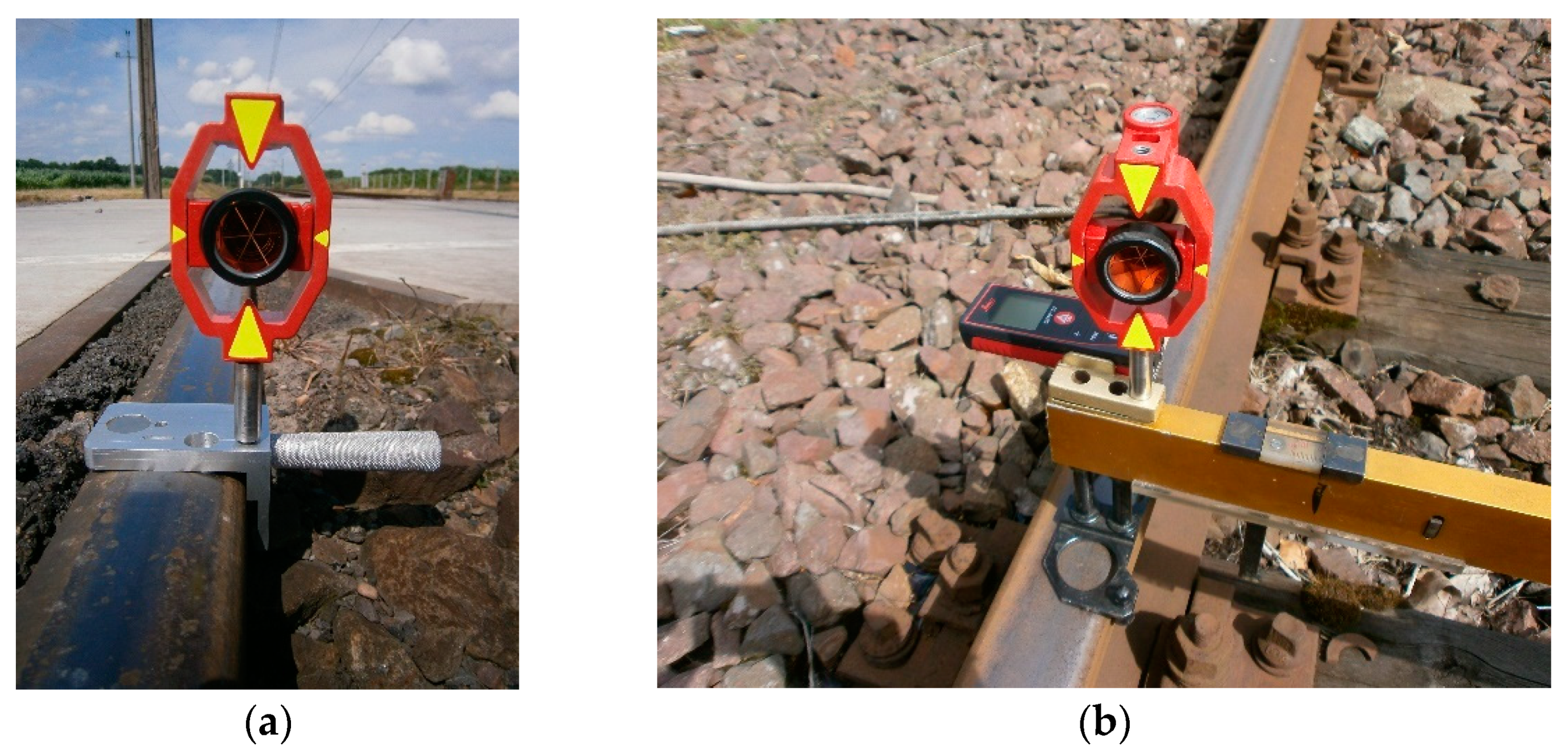

This article is a continuation of previous research [

2,

3,

51,

52]. The works [

2,

3] include studies of the geometry of category D railway level crossings located on a double track line. In [

2], the MMS device for monitoring the geometry of visibility triangles was used in measurements (

Figure 1a), while in [

3], a gauge measure (for measuring railway track and turnout parameters; GM) with adapters and Leica Geodetic Mini Prisms Type 111 (GMP111) and laser distance meter (LDM) (

Figure 1b) were used.

The main vertical axis of the GMP111 mini prisms mounted on the GM coincides with the inner edge at a point 14 mm below the top running surface of the rail head (crown of the rail). The device is also compatible with other surveying prisms. The rear housing of the LDM mounted on the adapter coincides with the inner edge of the rail profile at a height of 14 mm below the top rolling surface of the rail head (

Figure 1).

In [

51], application of the magnetic measuring square in the measurement of the circular curve of rail transport tracks is presented, with particular reference to the measurement of versines and difference in rail length (rail shortenings). The study also focuses on the multifunctionality of its application, via integration with terrestrial laser scanning reference signals, a laser distance meter, surveying measuring disk (with a millimeter scale with concentric rings), and GMP111 [

51,

52].

Each measuring process assumes an object of measurement. However, each object must be localized in space; in general, there can be no space without objects [

53]. Thus, regardless of the results and their mutual arrangement, it should be remembered that in the case of surveying measurements and continuous or periodic surveying monitoring, the choice of the measurement method and data processing method depends on the nature of the object and specific field conditions [

54]. Dybeł [

55,

56] states that the nature of surveying work depends to a large extent on the type of the structure (construction) being studied and the accompanying phenomena. In addition, the interpretation of the acquired data is an important activity, and the possibility of taking cyclic measurements from the same points at a given time (in different time horizons) is highly important.

5. Conclusions

It is necessary to conduct research to improve safety at railway level crossings and pedestrian crossings. However, the public is also obliged to comply with the applicable road user rules. Modern technology also contributes to improving safety at railway level crossings and pedestrian crossings, thus providing better protection.

This article examines the control measurements of the geometry of visibility triangles using an electronic total station and MMS with additional attributes. The research confirmed the usefulness of the presented measurement methodology, particularly in terms of the importance of geometry control. To achieve the highest level of efficiency, an optimal control measurement methodology should be applied. The described method simplifies the process of control measurements of the geometry of visibility triangles and ensures its accuracy.

The detail and impartiality of the specification of characteristic points is the main advantage of the proposed solution. The integrated Leica GMP111 surveying mini prism with MMS or gauge measure ensures that the point is correctly related to the transverse profile of the crown of the rail. The classic method used to date, which is based on the use of a surveying mini prism with a ranging pole and a surveying pole tip, combined with the polar method, suffers from the problems during measurement of repeatability and determination of the characteristic point. The use of the Leica GMP111 integrated surveying mini prism with MMS or with a GM as a physical stabilization of a characteristic measuring point ensures that it can be correctly determined, measured, and repeated at the same point. The proposed methodology prevents defects that occur in the use of geodetic prisms with a ranging pole and surveying pole tip in the range of characteristic points located on elements of the metal structures of railway infrastructure. The proposed methodology for control measurements can also be used to monitor the geometry of other infrastructures to ensure good quality, analysis, and evaluation.

In future work, I intend to analyze the state of permissible values of crossing angles contained in legal regulations in other countries and investigate the state of RLC geometry at intersections of railway lines with roads with more than two directions of travel.