A Review of Solar Energy Harvesting Electronic Textiles

Abstract

:1. Introduction

2. Energy Storage Textiles

3. Textile Energy Harvesting

3.1. Thermal Energy Harvesting for Powering Wearables

3.2. Piezoelectric Generators for Powering Wearables

3.3. Triboelectric Generators for Powering Wearables

3.4. Electromagnetic Induction-Based Energy Harvesters for Powering Wearables

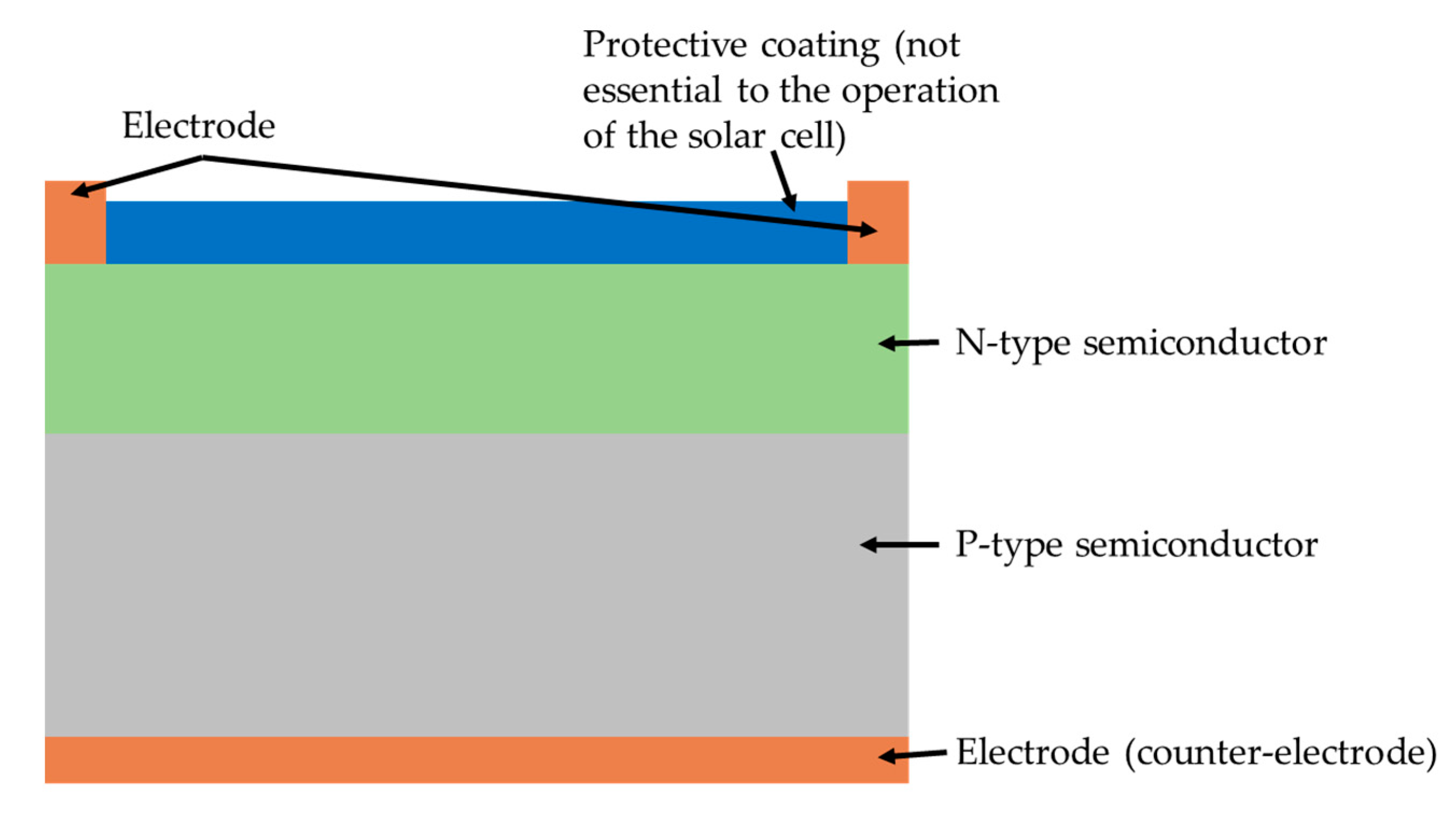

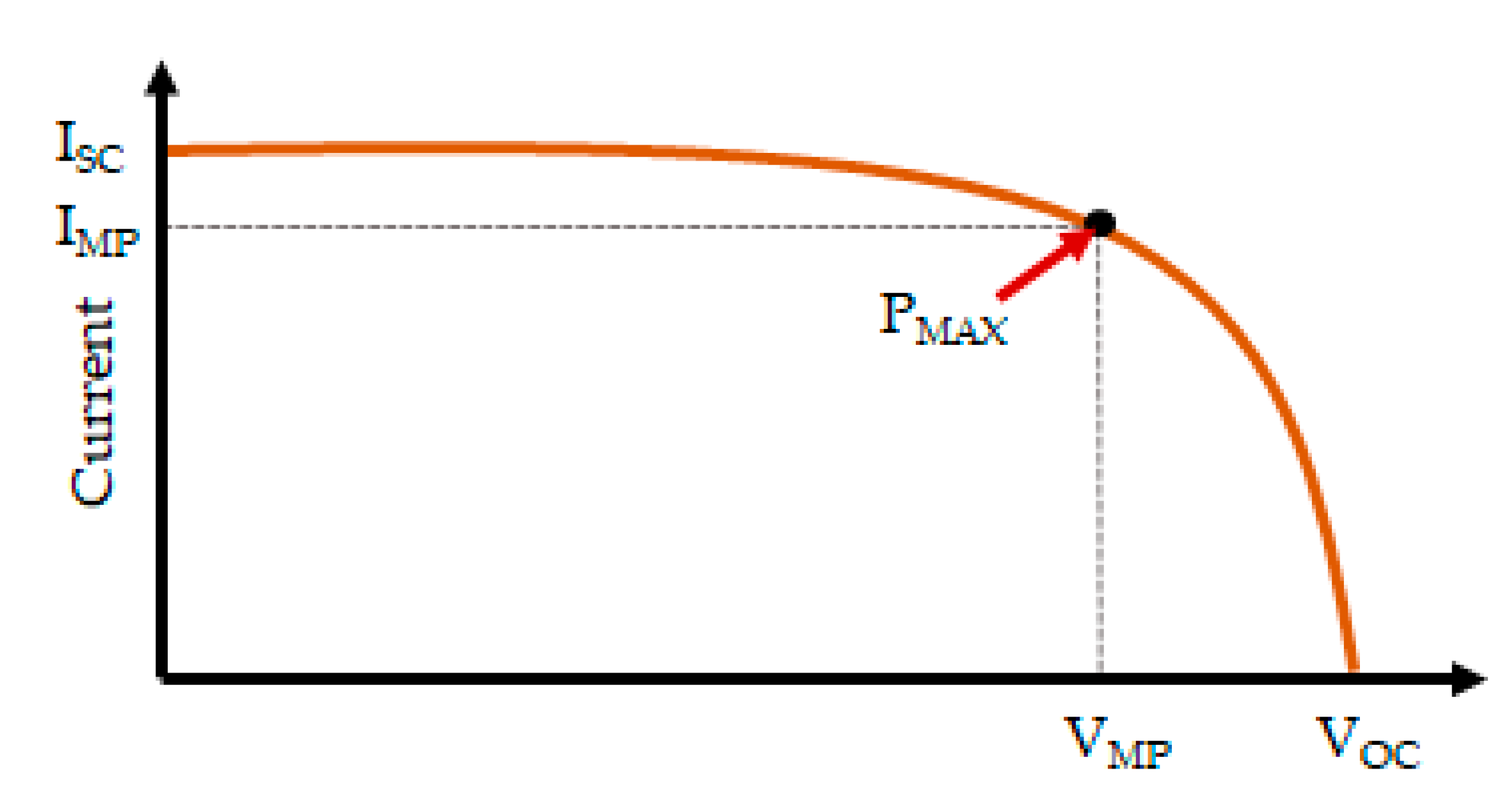

4. Solar Energy Harvesting

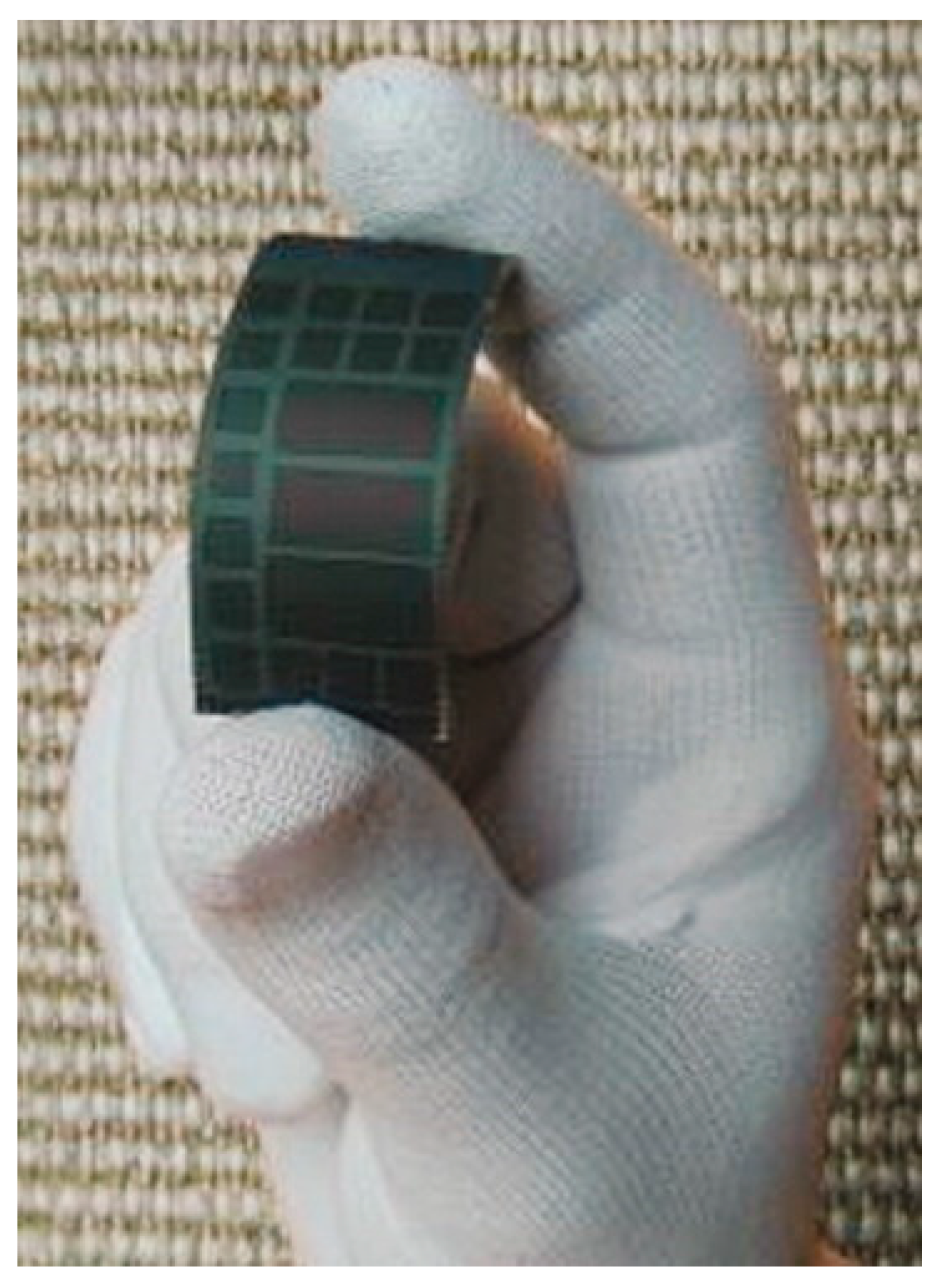

5. Integrating Flexible Solar Panels with Textiles

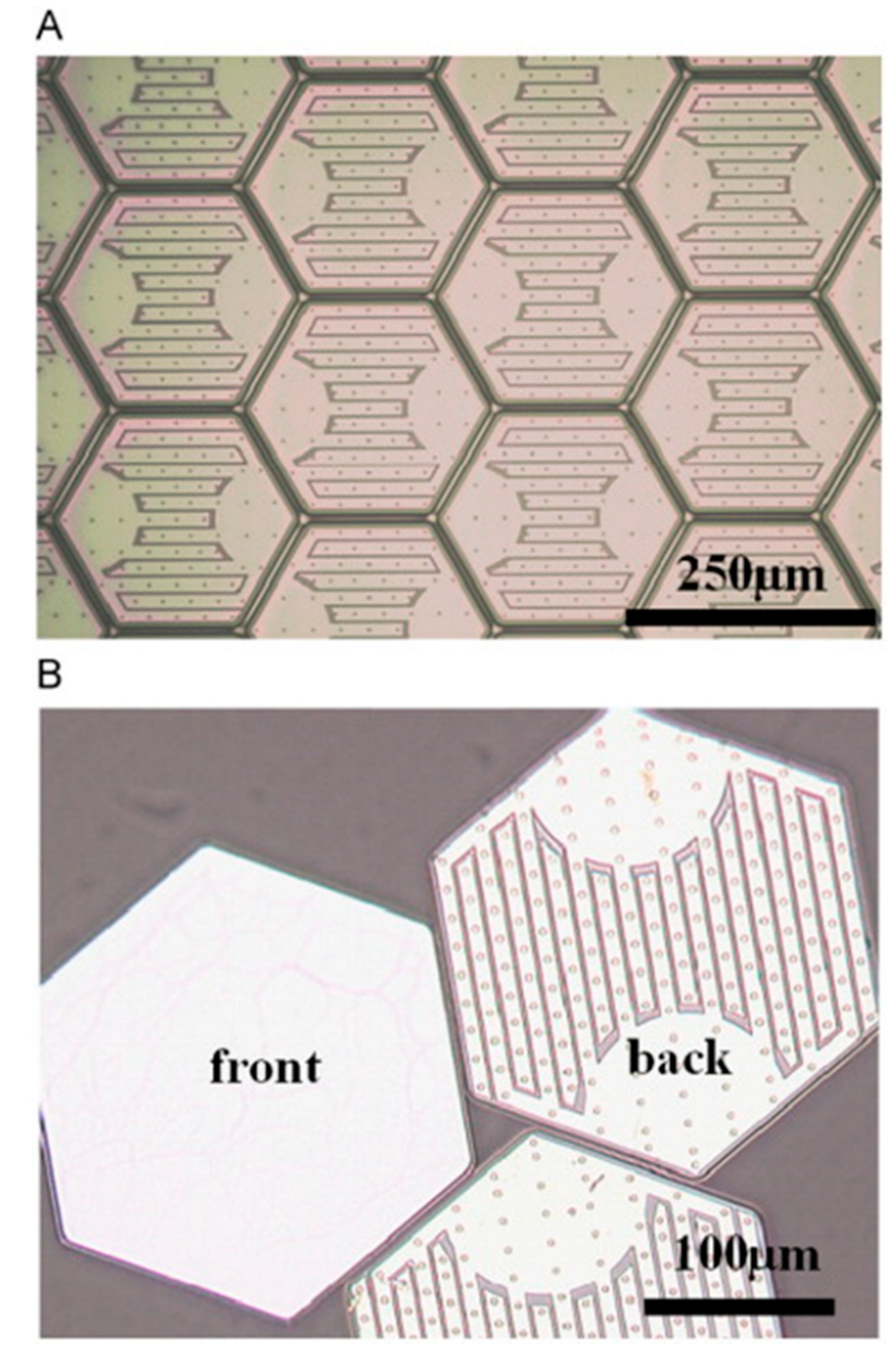

6. Solar Cell Arrays

7. Applying Flexible Photovoltaic Films and Coatings onto Planar Textiles

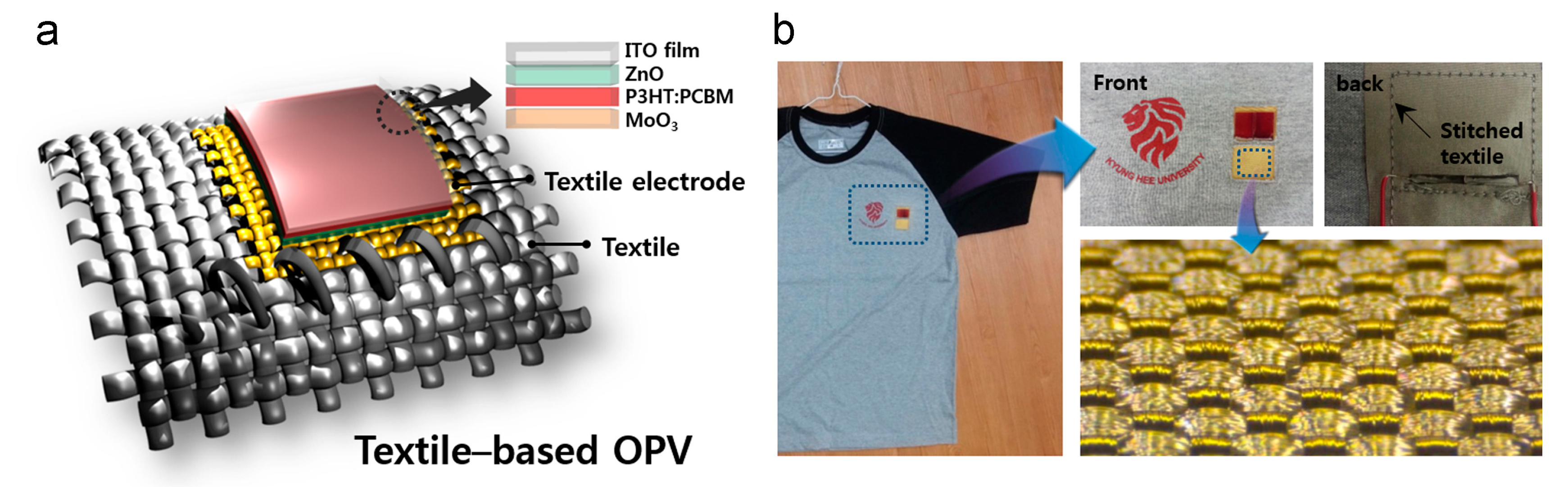

7.1. Organic Photovoltaic Films and Coatings

7.2. Dye Sensitized Solar Cell Films and Coatings

7.3. Other Types of Solar Cell Films and Coatings

7.4. Discussion of PV Films and Coating Applied to Textiles

8. Photovoltaic Wires, Fibers, and Yarns

8.1. 1D Photovoltaics Devices Using Non-Polymeric Fibers or Wires as a Core

8.1.1. 1D DSSCs Using Non-Polymeric Fibers or Wires as a Core

8.1.2. 1D Perovskite Solar Cells Using Non-Polymeric Fibers or Wires as a Core

8.1.3. 1D Coaxial Devices Using Non-Polymeric Fibers or Wires as a Core

8.2. 1D Photovoltatic Devices Conducted Using Polymeric Fibers as a Core

8.3. Discussion on Photovoltaic Wires, Fibers, and Yarns

9. Textiles Woven from Photovoltatic Fibers

9.1. Using Interlacing Points to Complete the Photovoltatic Device

9.2. Weaving Photovoltaic Ribbons or Tapes

9.3. Discussion on Textiles Woven from PV Fibers, Ribbons or Tapes

10. Non-Woven Photovoltaic Textiles

11. Discussion about Solar Energy Harvesting Textiles

11.1. Textile Properties of Photovoltaic Textiles

11.2. Suitability for Powering E-Textile Sensing Systems

11.3. Future Perspectives for Solar Energy Harvesting Textiles for Wearable Applications

Author Contributions

Funding

Conflicts of Interest

References

- Weng, W.; Chen, P.; He, S.; Sun, X.; Peng, H. Smart electronic textiles. Angew. Chem. Int. Ed. 2016, 55, 6140–6169. [Google Scholar] [CrossRef] [PubMed]

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X. Fiber-based wearable electronics: A review of materials, fabrication, devices, and applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef] [PubMed]

- Hughes-Riley, T.; Dias, T.; Cork, C. A Historical Review of the Development of Electronic Textiles. Fibers 2018, 6, 34. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Fu, X.; He, J.; Shi, X.; Chen, T.; Chen, P.; Wang, B.; Peng, H. Application challenges in fiber and textile electronics. Adv. Mater. 2020, 32, 1901971. [Google Scholar] [CrossRef]

- Magno, M.; Boyle, D. Wearable energy harvesting: From body to battery. In Proceedings of the 2017 12th International Conference on Design & Technology of Integrated Systems In Nanoscale Era (DTIS), Palma de Mallorca, Spain, 4 April 2017; pp. 1–6. [Google Scholar]

- Adapa, A.; Nah, F.F.; Hall, R.H.; Siau, K.; Smith, S.N. Factors influencing the adoption of smart wearable devices. Int. J. Hum. Comput. Interact. 2018, 34, 399–409. [Google Scholar] [CrossRef]

- Zhai, S.; Karahan, H.E.; Wei, L.; Qian, Q.; Harris, A.T.; Minett, A.I.; Ramakrishna, S.; Ng, A.K.; Chen, Y. Textile energy storage: Structural design concepts, material selection and future perspectives. Energy Storage Mater. 2016, 3, 123–139. [Google Scholar] [CrossRef]

- Jost, K.; Dion, G.; Gogotsi, Y. Garment devices: Integrating energy storage into textiles. In Fundamentals of Wearable Computers and Augmented Reality; CRC Press: Boca Raton, FL, USA, 2015; pp. 656–677. [Google Scholar]

- Torah, R.; Lawrie-Ashton, J.; Li, Y.; Arumugam, S.; Sodano, H.A.; Beeby, S. Energy-harvesting materials for smart fabrics and textiles. MRS Bull. 2018, 43, 214–219. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Zhang, Y.; Zhang, J.; Sun, X.; Peng, H. Energy harvesting and storage in 1D devices. Nat. Rev. Mater. 2017, 2, 1–12. [Google Scholar] [CrossRef]

- Conibeer, G.; Willoughby, A. Solar Cell Materials; John Wiley & Sons, Ltd.: Chichester, UK, 2014. [Google Scholar]

- Schubert, M.B.; Werner, J.H. Flexible solar cells for clothing. Mater. Today 2006, 9, 42–50. [Google Scholar] [CrossRef]

- Mather, R.R.; Wilson, J.I. Fabrication of photovoltaic textiles. Coatings 2017, 7, 63. [Google Scholar] [CrossRef] [Green Version]

- Singh, M.K. Flexible photovoltaic textiles for smart applications. Sol. Cells New Asp. Solut. 2011, 43–68. [Google Scholar] [CrossRef] [Green Version]

- Hatamvand, M.; Kamrani, E.; Lira-Cantú, M.; Madsen, M.; Patil, B.R.; Vivo, P.; Mehmood, M.S.; Numan, A.; Ahmed, I.; Zhan, Y. Recent Advances in Fiber-Shaped and Planar-Shaped Textile Solar Cells. Nano Energy 2020, 104609. [Google Scholar] [CrossRef]

- Ehrmann, A.; Blachowicz, T. Recent coating materials for textile-based solar cells. Aims Mater. Sci. 2019, 6, 234–251. [Google Scholar] [CrossRef]

- Powering Wearables: Battery Types, Current Challenges, and Energy Harvesting. Available online: https://www.powerelectronicsnews.com/powering-wearables-battery-types-current-challenges-and-energy-harvesting/ (accessed on 27 March 2020).

- Jost, K.; Dion, G.; Gogotsi, Y. Textile energy storage in perspective. J. Mater. Chem. A 2014, 2, 10776–10787. [Google Scholar] [CrossRef]

- Kaushik, V.; Lee, J.; Hong, J.; Lee, S.; Lee, S.; Seo, J.; Mahata, C.; Lee, T. Textile-based electronic components for energy applications: Principles, problems, and perspective. Nanomaterials 2015, 5, 1493–1531. [Google Scholar] [CrossRef] [Green Version]

- Hu, L.; Pasta, M.; La Mantia, F.; Cui, L.; Jeong, S.; Deshazer, H.D.; Choi, J.W.; Han, S.M.; Cui, Y. Stretchable, porous, and conductive energy textiles. Nano Lett. 2010, 10, 708–714. [Google Scholar] [CrossRef] [Green Version]

- Jost, K.; Perez, C.R.; McDonough, J.K.; Presser, V.; Heon, M.; Dion, G.; Gogotsi, Y. Carbon coated textiles for flexible energy storage. Energy Environ. Sci. 2011, 4, 5060–5067. [Google Scholar] [CrossRef]

- Bae, J.; Song, M.K.; Park, Y.J.; Kim, J.M.; Liu, M.; Wang, Z.L. Fiber supercapacitors made of nanowire-fiber hybrid structures for wearable/flexible energy storage. Angew. Chem. Int. Ed. 2011, 50, 1683–1687. [Google Scholar] [CrossRef]

- Lau, D.; Song, N.; Hall, C.; Jiang, Y.; Lim, S.; Perez-Wurfl, I.; Ouyang, Z.; Lennon, A. Hybrid solar energy harvesting and storage devices: The promises and challenges. Mater. Today Energy 2019, 13, 22–44. [Google Scholar] [CrossRef]

- Fu, Y.; Wu, H.; Ye, S.; Cai, X.; Yu, X.; Hou, S.; Kafafy, H.; Zou, D. Integrated power fiber for energy conversion and storage. Energy Environ. Sci. 2013, 6, 805–812. [Google Scholar] [CrossRef]

- Li, C.; Islam, M.M.; Moore, J.; Sleppy, J.; Morrison, C.; Konstantinov, K.; Dou, S.X.; Renduchintala, C.; Thomas, J. Wearable energy-smart ribbons for synchronous energy harvest and storage. Nat. Commun. 2016, 7, 13319. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Beeby, S.P.; Cao, Z.; Almussallam, A. Kinetic, thermoelectric and solar energy harvesting technologies for smart textiles. In Multidisciplinary Know-How for Smart-Textiles Developers; Elsevier: Amsterdam, The Netherlands, 2013; pp. 306–328. [Google Scholar]

- Stark, I. Integrating thermoelectric technology into clothing for generating usable energy to power wireless devices. In Proceedings of the Conference on Wireless Health; Association for Computing Machinery: New York, NY, USA, 2012; pp. 1–2. [Google Scholar]

- Du, Y.; Cai, K.; Chen, S.; Wang, H.; Shen, S.Z.; Donelson, R.; Lin, T. Thermoelectric fabrics: Toward power generating clothing. Sci. Rep. 2015, 5, 6411. [Google Scholar] [CrossRef]

- Cao, Z.; Tudor, M.J.; Torah, R.N.; Beeby, S.P. Screen printable flexible BiTe–SbTe-based composite thermoelectric materials on textiles for wearable applications. IEEE Trans. Electron. Devices 2016, 63, 4024–4030. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.A.; Aliev, A.E.; Bykova, J.S.; de Andrade, M.J.; Kim, D.; Sim, H.J.; Lepró, X.; Zakhidov, A.A.; Lee, J.; Spinks, G.M. Woven-yarn thermoelectric textiles. Adv. Mater. 2016, 28, 5038–5044. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Guo, Y.; Mu, J.; Wang, H.; Zhang, Q.; Li, Y. Single-walled carbon nanotubes/polyaniline-coated polyester thermoelectric textile with good interface stability prepared by ultrasonic induction. RSC Adv. 2016, 6, 90347–90353. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, H.; Mao, C.; Li, C.M. Silk fabric-based wearable thermoelectric generator for energy harvesting from the human body. Appl. Energy 2016, 164, 57–63. [Google Scholar] [CrossRef]

- Wu, Q.; Hu, J. Waterborne polyurethane based thermoelectric composites and their application potential in wearable thermoelectric textiles. Compos. Part B Eng. 2016, 107, 59–66. [Google Scholar] [CrossRef]

- Leonov, V. Thermoelectric energy harvesting of human body heat for wearable sensors. IEEE Sens. J. 2013, 13, 2284–2291. [Google Scholar] [CrossRef]

- Seeberg, T.M.; Røyset, A.; Jahren, S.; Strisland, F. Printed organic conductive polymers thermocouples in textile and smart clothing applications. In Proceedings of the 2011 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Boston, MA, USA, 30 August–3 September 2011; pp. 3278–3281. [Google Scholar]

- Kim, S.J.; We, J.H.; Cho, B.J. A wearable thermoelectric generator fabricated on a glass fabric. Energy Environ. Sci. 2014, 7, 1959–1965. [Google Scholar] [CrossRef]

- Sebald, G.; Guyomar, D.; Agbossou, A. On thermoelectric and pyroelectric energy harvesting. Smart Mater. Struct. 2009, 18, 125006. [Google Scholar] [CrossRef]

- Yang, B.; Yun, K. Piezoelectric shell structures as wearable energy harvesters for effective power generation at low-frequency movement. Sens. Actuators A Phys. 2012, 188, 427–433. [Google Scholar] [CrossRef]

- Chang, J.; Dommer, M.; Chang, C.; Lin, L. Piezoelectric nanofibers for energy scavenging applications. Nano Energy 2012, 1, 356–371. [Google Scholar] [CrossRef]

- Zeng, W.; Tao, X.; Chen, S.; Shang, S.; Chan, H.L.W.; Choy, S.H. Highly durable all-fiber nanogenerator for mechanical energy harvesting. Energy Environ. Sci. 2013, 6, 2631–2638. [Google Scholar] [CrossRef]

- Åkerfeldt, M.; Nilsson, E.; Gillgard, P.; Walkenström, P. Textile piezoelectric sensors-melt spun bi-component poly (vinylidene fluoride) fibres with conductive cores and poly (3, 4-ethylene dioxythiophene)-poly (styrene sulfonate) coating as the outer electrode. Fash. Text. 2014, 1, 13. [Google Scholar] [CrossRef] [Green Version]

- Yun, D.; Park, J.; Yun, K. Highly stretchable energy harvester using piezoelectric helical structure for wearable applications. Electron. Lett. 2015, 51, 284–285. [Google Scholar] [CrossRef]

- Zhang, M.; Gao, T.; Wang, J.; Liao, J.; Qiu, Y.; Yang, Q.; Xue, H.; Shi, Z.; Zhao, Y.; Xiong, Z. A hybrid fibers based wearable fabric piezoelectric nanogenerator for energy harvesting application. Nano Energy 2015, 13, 298–305. [Google Scholar] [CrossRef]

- Song, S.; Ahn, Y.; Yun, K. Scalable textile energy harvester in woven piezoelectric structures. In Proceedings of the 2015 Transducers-2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; pp. 708–709. [Google Scholar]

- Anand, S.; Soin, N.; Shah, T.H.; Siores, E. Energy harvesting “3-D knitted spacer” based piezoelectric textiles. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; p. 012001. [Google Scholar]

- Zhao, J.; You, Z. Models for 31-mode PVDF energy harvester for wearable applications. Sci. World J. 2014, 2014, 1–11. [Google Scholar] [CrossRef]

- Soin, N.; Shah, T.H.; Anand, S.C.; Geng, J.; Pornwannachai, W.; Mandal, P.; Reid, D.; Sharma, S.; Hadimani, R.L.; Bayramol, D.V. Novel “3-D spacer” all fibre piezoelectric textiles for energy harvesting applications. Energy Environ. Sci. 2014, 7, 1670–1679. [Google Scholar] [CrossRef]

- Waqar, S.; Wang, L.; John, S. Piezoelectric energy harvesting from intelligent textiles. In Electronic Textiles; Elsevier: Amsterdam, The Netherlands, 2015; pp. 173–197. [Google Scholar]

- Qin, Y.; Wang, X.; Wang, Z.L. Microfibre-nanowire hybrid structure for energy scavenging. Nature 2008, 451, 809–813. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology for self-powered systems and as active mechanical and chemical sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef] [PubMed]

- Ha, M.; Park, J.; Lee, Y.; Ko, H. Triboelectric generators and sensors for self-powered wearable electronics. ACS Nano 2015, 9, 3421–3427. [Google Scholar] [CrossRef]

- Cheng, X.; Meng, B.; Zhang, X.; Han, M.; Su, Z.; Zhang, H. Wearable electrode-free triboelectric generator for harvesting biomechanical energy. Nano Energy 2015, 12, 19–25. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, T.; Zhang, C.; Fan, F.R.; Han, C.B.; Wang, Z.L. A power-transformed-and-managed triboelectric nanogenerator and its applications in a self-powered wireless sensing node. Nanotechnology 2014, 25, 225402. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Ko, W.; Oh, Y.; Lee, J.; Baek, G.; Lee, Y.; Sohn, J.; Cha, S.; Kim, J.; Park, J. Triboelectric energy harvester based on wearable textile platforms employing various surface morphologies. Nano Energy 2015, 12, 410–418. [Google Scholar] [CrossRef]

- Pu, X.; Li, L.; Song, H.; Du, C.; Zhao, Z.; Jiang, C.; Cao, G.; Hu, W.; Wang, Z.L. A self-charging power unit by integration of a textile triboelectric nanogenerator and a flexible lithium-ion battery for wearable electronics. Adv. Mater. 2015, 27, 2472–2478. [Google Scholar] [CrossRef]

- Liu, L.; Pan, J.; Chen, P.; Zhang, J.; Yu, X.; Ding, X.; Wang, B.; Sun, X.; Peng, H. A triboelectric textile templated by a three-dimensionally penetrated fabric. J. Mater. Chem. A 2016, 4, 6077–6083. [Google Scholar] [CrossRef]

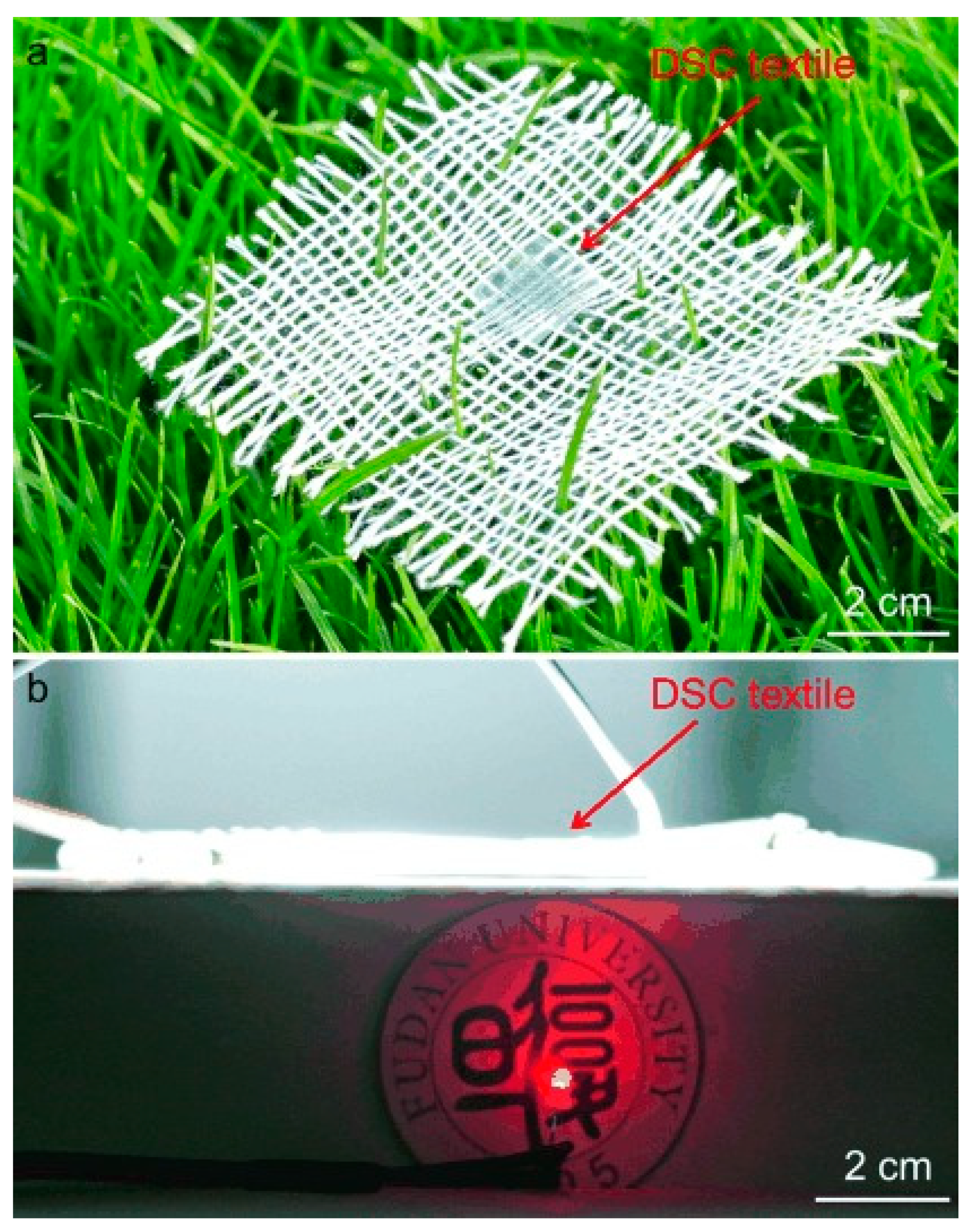

- Pu, X.; Song, W.; Liu, M.; Sun, C.; Du, C.; Jiang, C.; Huang, X.; Zou, D.; Hu, W.; Wang, Z.L. Wearable power-textiles by integrating fabric triboelectric nanogenerators and fiber-shaped dye-sensitized solar cells. Adv. Energy Mater. 2016, 6, 1601048. [Google Scholar] [CrossRef]

- Zhao, Z.; Yan, C.; Liu, Z.; Fu, X.; Peng, L.; Hu, Y.; Zheng, Z. Machine-washable textile triboelectric nanogenerators for effective human respiratory monitoring through loom weaving of metallic yarns. Adv. Mater. 2016, 28, 10267–10274. [Google Scholar] [CrossRef]

- Zhu, M.; Huang, Y.; Ng, W.S.; Liu, J.; Wang, Z.; Wang, Z.; Hu, H.; Zhi, C. 3D spacer fabric based multifunctional triboelectric nanogenerator with great feasibility for mechanized large-scale production. Nano Energy 2016, 27, 439–446. [Google Scholar] [CrossRef]

- Zhu, G.; Zhou, Y.S.; Bai, P.; Meng, X.S.; Jing, Q.; Chen, J.; Wang, Z.L. A shape-adaptive thin-film-based approach for 50% high-efficiency energy generation through micro-grating sliding electrification. Adv. Mater. 2014, 26, 3788–3796. [Google Scholar] [CrossRef] [PubMed]

- Niu, S.; Wang, Z.L. Theoretical systems of triboelectric nanogenerators. Nano Energy 2015, 14, 161–192. [Google Scholar] [CrossRef] [Green Version]

- Zhao, K.; Wang, Y.; Han, L.; Wang, Y.; Luo, X.; Zhang, Z.; Yang, Y. Nanogenerator-based self-charging energy storage devices. Nano Micro Lett. 2019, 11, 19. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Ylli, K.; Hoffmann, D.; Folkmer, B.; Manoli, Y. Design, fabrication and characterization of an inductive human motion energy harvester for application in shoes. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2013; p. 012012. [Google Scholar]

- Teichmann, D.; Kuhn, A.; Leonhardt, S.; Walter, M. The MAIN shirt: A textile-integrated magnetic induction sensor array. Sensors 2014, 14, 1039–1056. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Q.; Wang, Y.; Kim, E.S. Electromagnetic energy harvester with flexible coils and magnetic spring for 1-10 Hz resonance. J. Microelectromech. Syst. 2015, 24, 1193–1206. [Google Scholar] [CrossRef]

- Cho, H.; Yang, J.; Park, S.; Yun, K.; Kim, Y.; Lee, J. An exploratory study on the feasibility of a foot gear type energy harvester using a textile coil inductor. J. Electr. Eng. Technol. 2016, 11, 1210–1215. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Roh, J. Wearable electromagnetic energy-harvesting textiles based on human walking. Text. Res. J. 2019, 89, 2532–2541. [Google Scholar] [CrossRef]

- Becquerel, M.E. Mémoire sur les effets électriques produits sous l’influence des rayons solaires. Comptes Rendus De L’Academie Des Sci. 1839, 9, 561–567. [Google Scholar]

- McEvoy, A.; Markvart, T. Solar cells: Materials, Manufacture and Operation; Academic Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Green, M.A.; Dunlop, E.D.; Levi, D.H.; Hohl-Ebinger, J.; Yoshita, M.; Ho-Baillie, A.W. Solar cell efficiency tables (version 54). Prog. Photovolt. Res. Appl. 2019, 27, 565–575. [Google Scholar] [CrossRef]

- Nocito, C.; Koncar, V. Flexible photovoltaic cells embedded into textile structures. In Smart Textiles and Their Applications; Elsevier: Amsterdam, The Netherlands, 2016; pp. 401–422. [Google Scholar]

- Beam Backpack-The Most Advanced Solar Power Backpack. Available online: https://www.kickstarter.com/projects/1265473734/beam-backpack-the-most-advanced-solar-power-backpa (accessed on 16 October 2020).

- Kingsons Beam Backpack-The Most Advanced Solar Power Backpack-Waterproof, Anti-Theft Laptop Bag. Available online: https://www.amazon.co.uk/Kingsons-Beam-Backpack-Waterproof-Anti-Theft/dp/B07L9R76W3/ref=cm_cr_arp_d_product_top?ie=UTF8 (accessed on 16 October 2020).

- Zenith-Solar Backpack. Available online: https://www.sunslice-solar.com/products/zenith (accessed on 16 October 2020).

- Tommy Hilfiger’s Solar-Powered Jacket-Wearable Tech in Review. Available online: https://www.forbes.com/sites/rachelarthur/2014/11/20/tommy-hilfigers-solar-powered-jacket-wearable-tech-in-review/ (accessed on 1 April 2020).

- Tommy Hilfiger Solar Clothing. Available online: http://www.pvilion.com/solar-clothing (accessed on 16 October 2020).

- Wearable Solar Shirt. Available online: http://www.paulinevandongen.nl/project/wearable-solar-shirt/ (accessed on 1 April 2020).

- Wearable Solar Dress. Available online: http://www.paulinevandongen.nl/project/wearable-solar/ (accessed on 1 April 2020).

- Smelik, A.; Toussaint, L.; Van Dongen, P. Solar fashion: An embodied approach to wearable technology. Int. J. Fash. Stud. 2016, 3, 287–303. [Google Scholar] [CrossRef]

- Haugen, A.E. Sun-Powered Vest. U.S. Patent 4,827,534, 9 May 1989. [Google Scholar]

- Jaynes, S. Solar Powered Survival Suit. U.S. Patent Application US 2007/0151593 A1, 5 July 2007. [Google Scholar]

- Orandi, K. Solar Powered Motorcycle Jacket. U.S. Patent Application US 2009/0144887 A1, 11 June 2009. [Google Scholar]

- Energy Conversion Devices, Inc. Retractable Power Supply. U.S. Patent 4,636,579, 13 January 1987. [Google Scholar]

- Ma, J. Power Generation Umbrella. U.S. Patent Application US 2011/0290288 A1, 1 December 2011. [Google Scholar]

- ILAND Green Technologies SA. Photovoltaic Blind. U.S. Patent Application US 2014/0027069 A1, 30 January 2014. [Google Scholar]

- Heidenreich, D.C. Photovoltaic Awning Structures. U.S. Patent Application US 2009/0014130 A1, 15 January 2009. [Google Scholar]

- Lambey, J. Blind or Awning Photo-Generator. U.S. Patent Application US 2008/0163984 A1, 10 July 2008. [Google Scholar]

- Dickson Constant. Awning Type Solar Protection Device Equipped with an Electrical Power Production System. U.S. Patent 9,133,662 B2, 15 September 2015. [Google Scholar]

- Palo Alto Research Center Incorporated. Photovoltaic Modules on a Textile Substrate. U.S. Patent Application US 2011/0290304 A1, 1 December 2011. [Google Scholar]

- Pvilion, Inc. Systems and Methods for Applying Flexible Solar Panels to Flexible Underlying Membranes. U.S. Patent Application US 2019/0288639 A1, 19 September 2019. [Google Scholar]

- Fuchi Textile Co., Ltd. Flexible Photovoltaic Apparatus. U.S. Patent Application US 2015/0059825 A1, 5 March 2015. [Google Scholar]

- Ascent Solar Technologies, Inc. Photovoltaic Assembly and Associated Methods. U.S. Patent Application US 2014/0083485 A1, 27 March 2014. [Google Scholar]

- Infineon Technologies Americas Corp. Flexible Fabric Support Structure for Photovoltaic Cells. U.S. Patent 3,255,047, 7 June 1966. [Google Scholar]

- SOLANNEX Inc. Collector Grid and Interconnect Structures for Photovoltaic Arrays and Modules. U.S. Patent 8,138,413 B2, 20 March 2012. [Google Scholar]

- Forster Rohner AG Method for Attaching Flat Electronic Components Onto a Flexible Surface Structure. U.S. Patent Application US 2011/0240091 A1, 6 October 2011.

- Cruz-Campa, J.L.; Okandan, M.; Resnick, P.J.; Clews, P.; Pluym, T.; Grubbs, R.K.; Gupta, V.P.; Zubia, D.; Nielson, G.N. Microsystems enabled photovoltaics: 14.9% efficient 14 μm thick crystalline silicon solar cell. Sol. Energy Mater. Sol. Cells 2011, 95, 551–558. [Google Scholar] [CrossRef]

- Gu, T.; Agrawal, G.; Vessey, A.; Sweatt, W.C.; Jared, B.H.; Cruz-Campa, J.L.; Goeke, R.; Miller, W.K.; Zamora, D.L.; Langlois, E. Micro-concentrator module for Microsystems-Enabled Photovoltaics: Optical performance characterization, modelling and analysis. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015; pp. 1–5. [Google Scholar]

- Sandia’s Solar Glitter Closer to Market with New Licensing Agreement. Available online: https://phys.org/news/2017-02-sandia-solar-glitter-closer-agreement.html (accessed on 3 April 2020).

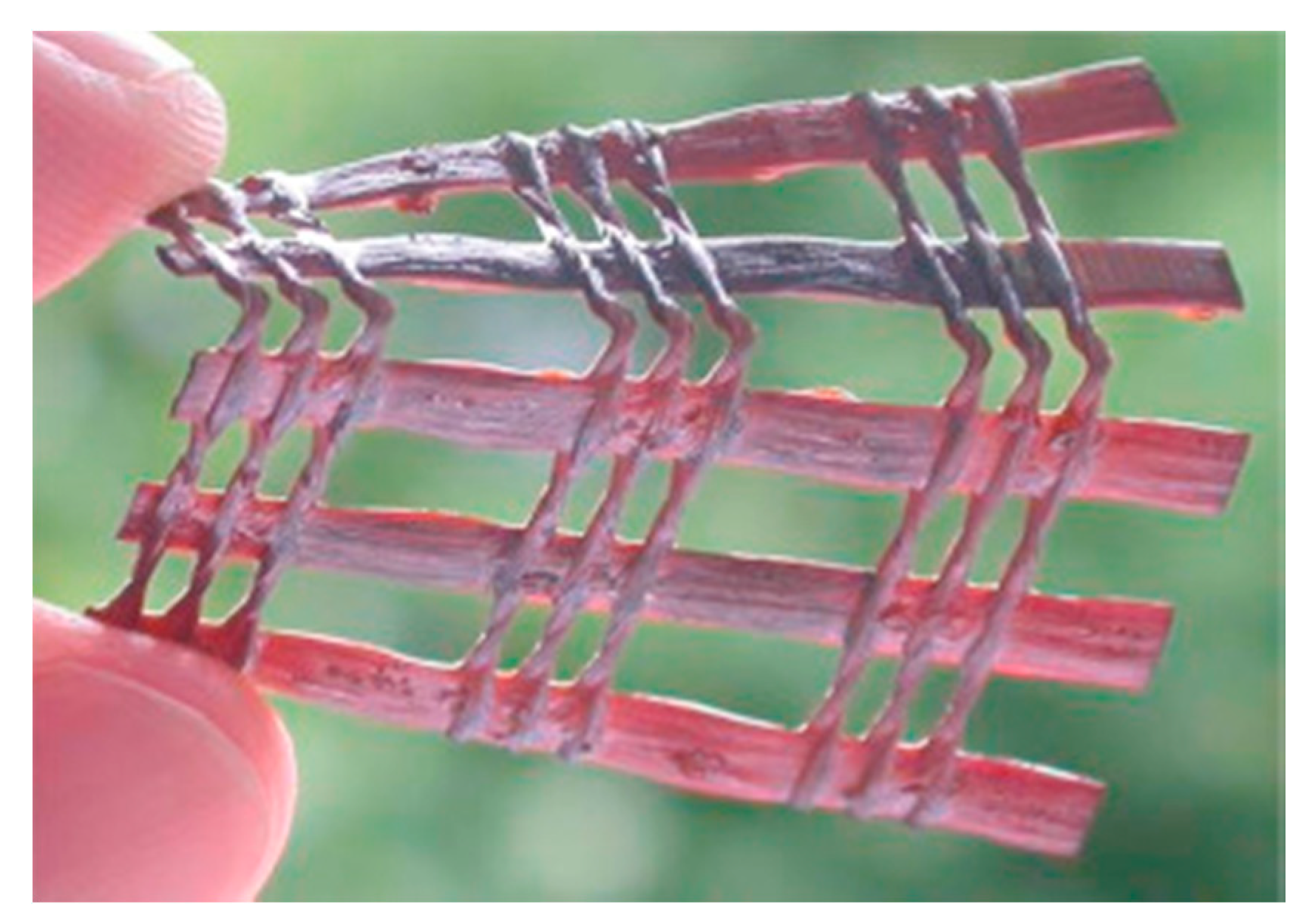

- Satharasinghe, A.; Hughes-Riley, T.; Dias, T. An investigation of a wash durable solar energy harvesting textile. Prog. Photovolt. Res. Appl. 2019, 28, 578–592. [Google Scholar] [CrossRef]

- Du, P.; Song, L.; Xiong, J.; Wang, L.; Li, N. A photovoltaic smart textile and a photocatalytic functional textile based on co-electrospun TiO2/MgO core-sheath nanorods: Novel textiles of integrating energy and environmental science with textile research. Text. Res. J. 2013, 83, 1690–1702. [Google Scholar] [CrossRef]

- Krebs, F.C.; Biancardo, M.; Winther-Jensen, B.; Spanggard, H.; Alstrup, J. Strategies for incorporation of polymer photovoltaics into garments and textiles. Sol. Energy Mater. Sol. Cells 2006, 90, 1058–1067. [Google Scholar] [CrossRef]

- Jinno, H.; Fukuda, K.; Xu, X.; Park, S.; Suzuki, Y.; Koizumi, M.; Yokota, T.; Osaka, I.; Takimiya, K.; Someya, T. Stretchable and waterproof elastomer-coated organic photovoltaics for washable electronic textile applications. Nat. Energy 2017, 2, 780–785. [Google Scholar] [CrossRef]

- Lee, S.; Lee, Y.; Park, J.; Choi, D. Stitchable organic photovoltaic cells with textile electrodes. Nano Energy 2014, 9, 88–93. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Arumugam, S.; Tudor, J.; Beeby, S. Screen printed dye-sensitized solar cells (DSSCs) on woven polyester cotton fabric for wearable energy harvesting applications. Mater. Today Proc. 2018, 5, 13753–13758. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Yong, S.; Arumugam, S.; Beeby, S. Flexible printed monolithic-structured solid-state dye sensitized solar cells on woven glass fibre textile for wearable energy harvesting applications. Sci. Rep. 2019, 9, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Lam, J.; Chen, J.; Tsai, P.; Hsieh, Y.; Chueh, C.; Tung, S.; Chen, W. A stable, efficient textile-based flexible perovskite solar cell with improved washable and deployable capabilities for wearable device applications. RSC Adv. 2017, 7, 54361–54368. [Google Scholar] [CrossRef] [Green Version]

- Jung, J.W.; Bae, J.H.; Ko, J.H.; Lee, W. Fully solution-processed indium tin oxide-free textile-based flexible solar cells made of an organic-inorganic perovskite absorber: Toward a wearable power source. J. Power Sources 2018, 402, 327–332. [Google Scholar] [CrossRef]

- Bedeloglu, A.; Demir, A.; Bozkurt, Y.; Sariciftci, N.S. A flexible textile structure based on polymeric photovoltaics using transparent cathode. Synth. Met. 2009, 159, 2043–2048. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Tee, B.C.; Vosgueritchian, M.; Bao, Z. Stretchable organic solar cells. Adv. Mater. 2011, 23, 1771–1775. [Google Scholar] [CrossRef] [PubMed]

- Kaltenbrunner, M.; White, M.S.; GÅowacki, E.D.; Sekitani, T.; Someya, T.; Sariciftci, N.S.; Bauer, S. Ultrathin and lightweight organic solar cells with high flexibility. Nat. Commun. 2012, 3, 770. [Google Scholar] [CrossRef] [Green Version]

- Kylberg, W.; De Castro, F.A.; Chabrecek, P.; Sonderegger, U.; Chu, B.T.; Nüesch, F.; Hany, R. Woven electrodes for flexible organic photovoltaic cells. Adv. Mater. 2011, 23, 1015–1019. [Google Scholar] [CrossRef]

- Arumugam, S.; Li, Y.; Senthilarasu, S.; Torah, R.; Kanibolotsky, A.L.; Inigo, A.R.; Skabara, P.J.; Beeby, S.P. Fully spray-coated organic solar cells on woven polyester cotton fabrics for wearable energy harvesting applications. J. Mater. Chem. A 2016, 4, 5561–5568. [Google Scholar] [CrossRef] [Green Version]

- Jeong, E.G.; Jeon, Y.; Cho, S.H.; Choi, K.C. Textile-based washable polymer solar cells for optoelectronic modules: Toward self-powered smart clothing. Energy Environ. Sci. 2019, 12, 1878–1889. [Google Scholar] [CrossRef]

- Xu, J.; Li, M.; Wu, L.; Sun, Y.; Zhu, L.; Gu, S.; Liu, L.; Bai, Z.; Fang, D.; Xu, W. A flexible polypyrrole-coated fabric counter electrode for dye-sensitized solar cells. J. Power Sources 2014, 257, 230–236. [Google Scholar] [CrossRef]

- Xu, Q.; Li, M.; Yan, P.; Wei, C.; Fang, L.; Wei, W.; Bao, H.; Xu, J.; Xu, W. Polypyrrole-coated cotton fabrics prepared by electrochemical polymerization as textile counter electrode for dye-sensitized solar cells. Org. Electron. 2016, 29, 107–113. [Google Scholar] [CrossRef]

- Yun, M.J.; Cha, S.I.; Seo, S.H.; Kim, H.S.; Lee, D.Y. Float printing deposition to control the morphology of TiO 2 photoanodes on woven textile metal substrates for TCO-free flexible dye-sensitized solar cells. RSC Adv. 2016, 6, 67331–67339. [Google Scholar] [CrossRef]

- Opwis, K.; Gutmann, J.S.; Lagunas Alonso, A.R.; Rodriguez Henche, M.J.; Ezquer Mayo, M.; Breuil, F.; Leonardi, E.; Sorbello, L. Preparation of a textile-based dye-sensitized solar cell. Int. J. Photoenergy 2016, 2016, 3796074. [Google Scholar] [CrossRef] [Green Version]

- Yun, M.J.; Sim, Y.H.; Cha, S.I.; Seo, S.H.; Lee, D.Y. Three-dimensional textile platform for electrochemical devices and its application to dye-sensitized solar cells. Sci. Rep. 2019, 9, 2322. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, L.; Yin, X.; Xie, X.; Du, P.; Xiong, J.; Ko, F. Highly flexible TiO2/C nanofibrous film for flexible dye-sensitized solar cells as a platinum-and transparent conducting oxide-free flexible counter electrode. Electrochim. Acta 2017, 255, 256–265. [Google Scholar] [CrossRef]

- Song, L.; Wang, T.; Jing, W.; Xie, X.; Du, P.; Xiong, J. High flexibility and electrocatalytic activity MoS2/TiC/carbon nanofibrous film for flexible dye-sensitized solar cell based photovoltaic textile. Mater. Res. Bull. 2019, 118, 110522. [Google Scholar] [CrossRef]

- Knittel, D.; Köntges, M.; Heinemeyer, F.; Schollmeyer, E. Coatings on textiles for Cu(In,Ga)Se2 photovoltaic cell formation on textile carriers: Preparation of Cu(In,Ga)Se2 solar cells on glass−fiber textiles. J. Appl. Polym. Sci. 2009, 115, 2763–2766. [Google Scholar] [CrossRef]

- Plentz, J.; Andrä, G.; Pliewischkies, T.; Brückner, U.; Eisenhawer, B.; Falk, F. Amorphous silicon thin-film solar cells on glass fiber textiles. Mater. Sci. Eng. B 2016, 204, 34–37. [Google Scholar] [CrossRef]

- Ramier, J.; Plummer, C.; Leterrier, Y.; Månson, J.; Eckert, B.; Gaudiana, R. Mechanical integrity of dye-sensitized photovoltaic fibers. Renew. Energy 2008, 33, 314–319. [Google Scholar] [CrossRef]

- Lv, Z.; Fu, Y.; Hou, S.; Wang, D.; Wu, H.; Zhang, C.; Chu, Z.; Zou, D. Large size, high efficiency fiber-shaped dye-sensitized solar cells. Phys. Chem. Chem. Phys. 2011, 13, 10076–10083. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Sun, H.; Chen, T.; Qiu, L.; Luo, Y.; Peng, H. Photovoltaic wire derived from a graphene composite fiber achieving an 8.45% energy conversion efficiency. Angew. Chem. Int. Ed. 2013, 52, 7545–7548. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Zhang, G.; Sun, W.; Dong, P. High efficiency flexible fiber-type dye-sensitized solar cells with multi-working electrodes. Nano Energy 2015, 12, 501–509. [Google Scholar] [CrossRef]

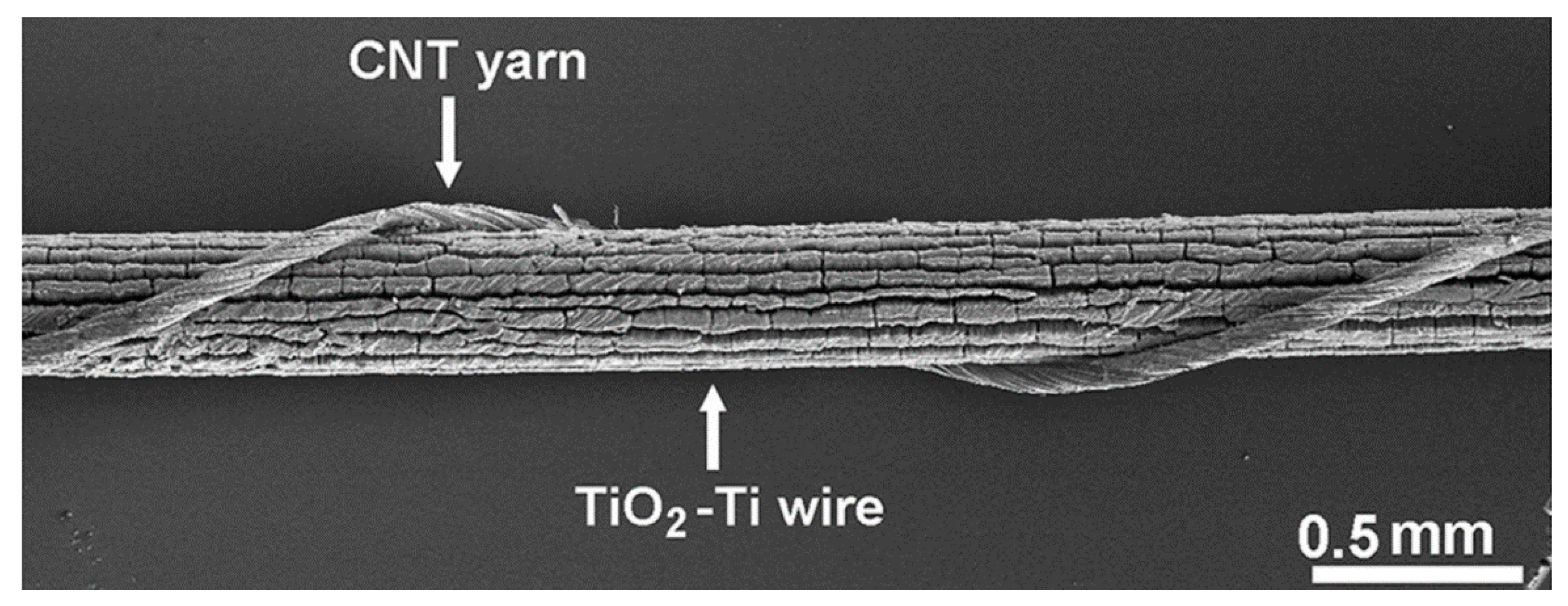

- Chen, T.; Qiu, L.; Cai, Z.; Gong, F.; Yang, Z.; Wang, Z.; Peng, H. Intertwined aligned carbon nanotube fiber based dye-sensitized solar cells. Nano Lett. 2012, 12, 2568–2572. [Google Scholar] [CrossRef] [PubMed]

- Velten, J.; Kuanyshbekova, Z.; Göktepe, Ö.; Göktepe, F.; Zakhidov, A. Weavable dye sensitized solar cells exploiting carbon nanotube yarns. Appl. Phys. Lett. 2013, 102, 203902. [Google Scholar] [CrossRef]

- Yan, J.; Uddin, M.J.; Dickens, T.J.; Daramola, D.E.; Okoli, O.I. 3D wire-shaped dye-sensitized solar cells in solid state using carbon nanotube yarns with hybrid photovoltaic structure. Adv. Mater. Interfaces 2014, 1, 1400075. [Google Scholar] [CrossRef]

- Chen, T.; Qiu, L.; Kia, H.G.; Yang, Z.; Peng, H. Designing aligned inorganic nanotubes at the electrode interface: Towards highly efficient photovoltaic wires. Adv. Mater. 2012, 24, 4623–4628. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Ji, C.; Bian, Z.; Yu, P.; Zhang, L.; Liu, D.; Shi, E.; Shang, Y.; Peng, H.; Cheng, Q. Porous, platinum nanoparticle-adsorbed carbon nanotube yarns for efficient fiber solar cells. ACS Nano 2012, 6, 7191–7198. [Google Scholar] [CrossRef] [PubMed]

- Uddin, M.J.; Davies, B.; Dickens, T.J.; Okoli, O.I. Self-aligned carbon nanotubes yarns (CNY) with efficient optoelectronic interface for microyarn shaped 3D photovoltaic cells. Sol. Energy Mater. Sol. Cells 2013, 115, 166–171. [Google Scholar] [CrossRef]

- Fu, X.; Sun, H.; Xie, S.; Zhang, J.; Pan, Z.; Liao, M.; Xu, L.; Li, Z.; Wang, B.; Sun, X. A fiber-shaped solar cell showing a record power conversion efficiency of 10%. J. Mater. Chem. A 2018, 6, 45–51. [Google Scholar] [CrossRef]

- Qiu, L.; Deng, J.; Lu, X.; Yang, Z.; Peng, H. Integrating perovskite solar cells into a flexible fiber. Angew. Chem. Int. Ed. 2014, 53, 10425–10428. [Google Scholar] [CrossRef]

- He, S.; Qiu, L.; Fang, X.; Guan, G.; Chen, P.; Zhang, Z.; Peng, H. Radically grown obelisk-like ZnO arrays for perovskite solar cell fibers and fabrics through a mild solution process. J. Mater. Chem. A 2015, 3, 9406–9410. [Google Scholar] [CrossRef]

- Hu, H.; Yan, K.; Peng, M.; Yu, X.; Chen, S.; Chen, B.; Dong, B.; Gao, X.; Zou, D. Fiber-shaped perovskite solar cells with 5.3% efficiency. J. Mater. Chem. A 2016, 4, 3901–3906. [Google Scholar] [CrossRef]

- Li, R.; Xiang, X.; Tong, X.; Zou, J.; Li, Q. Wearable double-twisted fibrous perovskite solar cell. Adv. Mater. 2015, 27, 3831–3835. [Google Scholar] [CrossRef] [PubMed]

- Chuangchote, S.; Sagawa, T.; Yoshikawa, S. Design of metal wires-based organic photovoltaic cells. Energy Procedia 2011, 9, 553–558. [Google Scholar] [CrossRef] [Green Version]

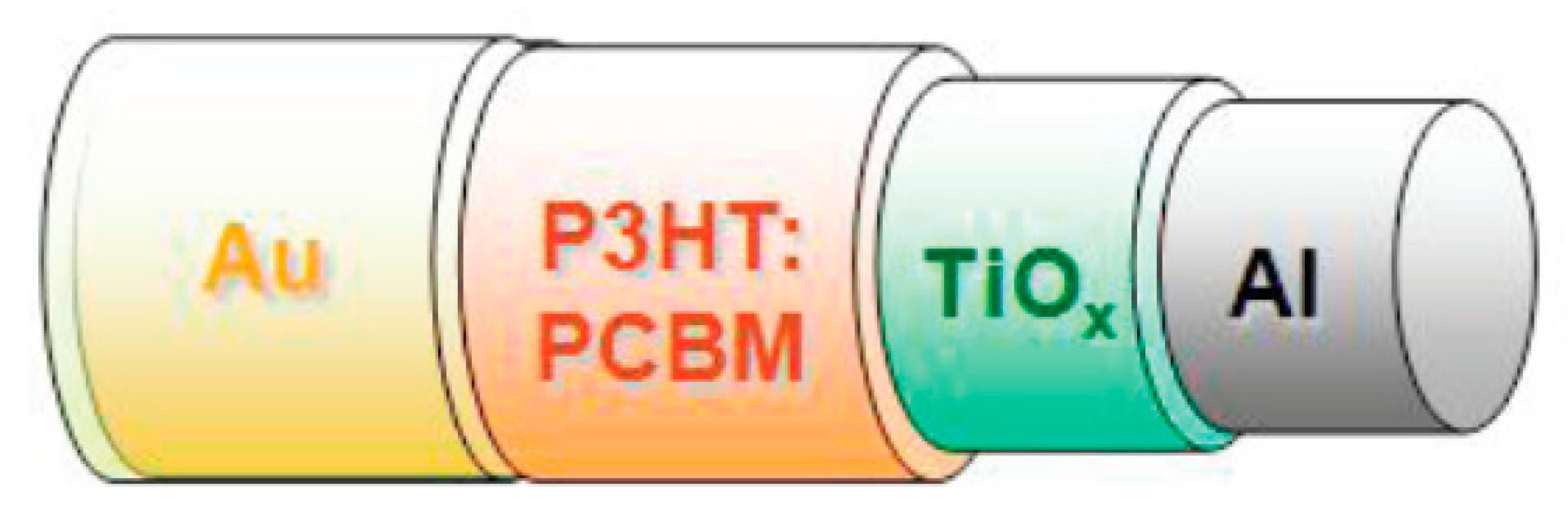

- Lee, M.R.; Eckert, R.D.; Forberich, K.; Dennler, G.; Brabec, C.J.; Gaudiana, R.A. Solar power wires based on organic photovoltaic materials. Science 2009, 324, 232–235. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Zhao, M.; Li, Y.; Bian, Z.; Zhang, L.; Shang, Y.; Xia, X.; Zhang, S.; Yun, D.; Liu, Z. Solid-state, polymer-based fiber solar cells with carbon nanotube electrodes. ACS Nano 2012, 6, 11027–11034. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, E.; Li, Z.; Li, P.; Jia, Y.; Ji, C.; Wei, J.; Wang, K.; Zhu, H.; Wu, D. Wire-supported CdSe nanowire array photoelectrochemical solar cells. Phys. Chem. Chem. Phys. 2012, 14, 3583–3588. [Google Scholar] [CrossRef]

- Zhang, L.; Song, L.; Tian, Q.; Kuang, X.; Hu, J.; Liu, J.; Yang, J.; Chen, Z. Flexible fiber-shaped CuInSe2 solar cells with single-wire-structure: Design, construction and performance. Nano Energy 2012, 1, 769–776. [Google Scholar] [CrossRef]

- O’Connor, B.; Pipe, K.P.; Shtein, M. Fiber based organic photovoltaic devices. Appl. Phys. Lett. 2008, 92, 172. [Google Scholar] [CrossRef]

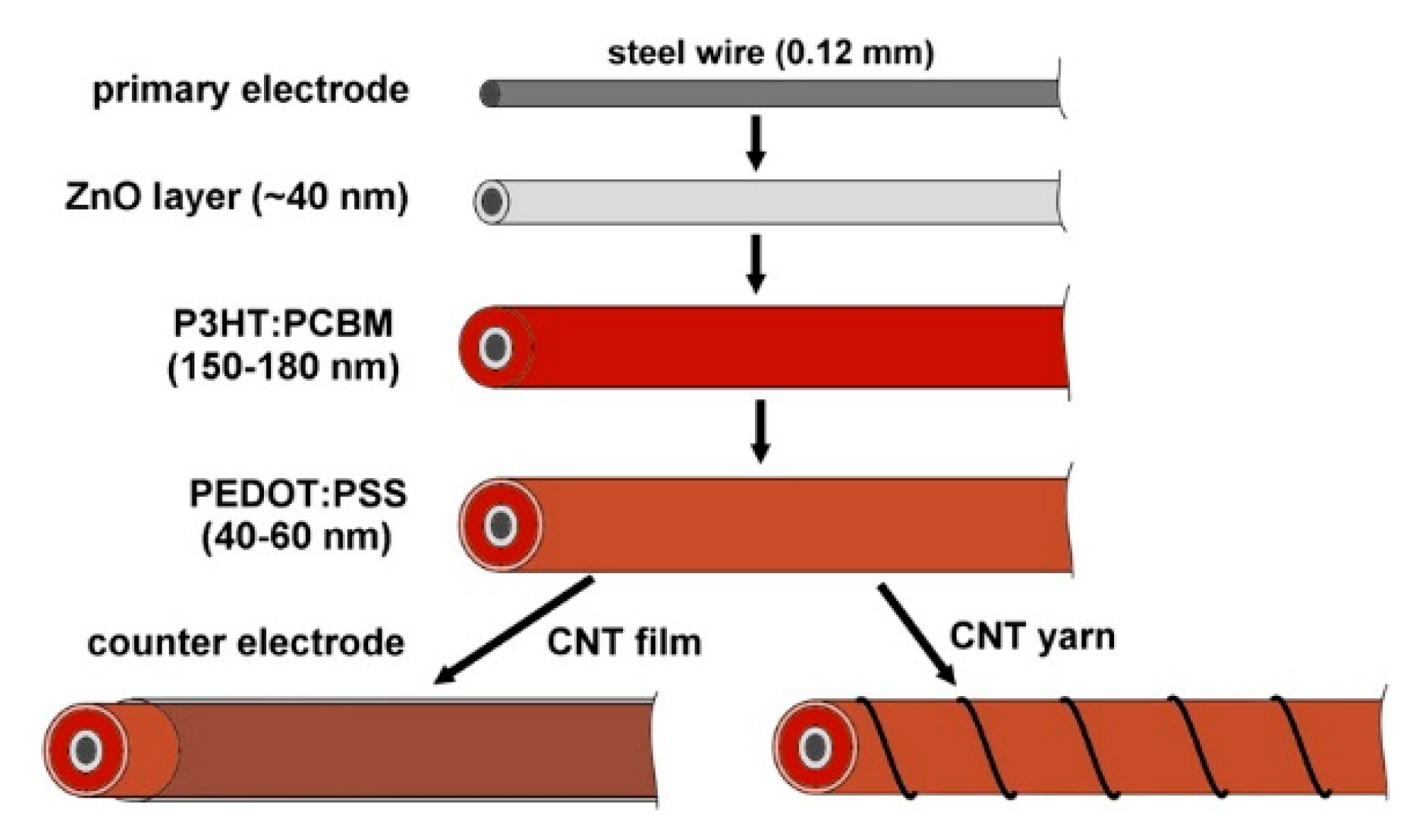

- Toivola, M.; Ferenets, M.; Lund, P.; Harlin, A. Photovoltaic fiber. Thin Solid Films 2009, 517, 2799–2802. [Google Scholar] [CrossRef]

- Bedeloglu, A.; Demir, A.; Bozkurt, Y.; Sariciftci, N.S. A photovoltaic fiber design for smart textiles. Text. Res. J. 2010, 80, 1065–1074. [Google Scholar] [CrossRef]

- Yang, Z.; Deng, J.; Sun, X.; Li, H.; Peng, H. Stretchable, wearable dye-sensitized solar cells. Adv. Mater. 2014, 26, 2643–2647. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, E.; Ji, C.; Li, Z.; Li, P.; Shang, Y.; Li, Y.; Wei, J.; Wang, K.; Zhu, H. Fiber and fabric solar cells by directly weaving carbon nanotube yarns with CdSe nanowire-based electrodes. Nanoscale 2012, 4, 4954–4959. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.; Yang, Z.; Chen, P.; Deng, J.; Li, H.; Peng, H. Wearable solar cells by stacking textile electrodes. Angew. Chem. Int. Ed. 2014, 53, 6110–6114. [Google Scholar] [CrossRef]

- Chai, Z.; Zhang, N.; Sun, P.; Huang, Y.; Zhao, C.; Fan, H.J.; Fan, X.; Mai, W. Tailorable and wearable textile devices for solar energy harvesting and simultaneous storage. ACS Nano 2016, 10, 9201–9207. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Chen, J.; Huang, Y.; Guo, W.; Yang, J.; Du, J.; Fan, X.; Tao, C. A wearable all-solid photovoltaic textile. Adv. Mater. 2016, 28, 263–269. [Google Scholar] [CrossRef]

- Liu, P.; Gao, Z.; Xu, L.; Shi, X.; Fu, X.; Li, K.; Zhang, B.; Sun, X.; Peng, H. Polymer solar cell textiles with interlaced cathode and anode fibers. J. Mater. Chem. A 2018, 6, 19947–19953. [Google Scholar] [CrossRef]

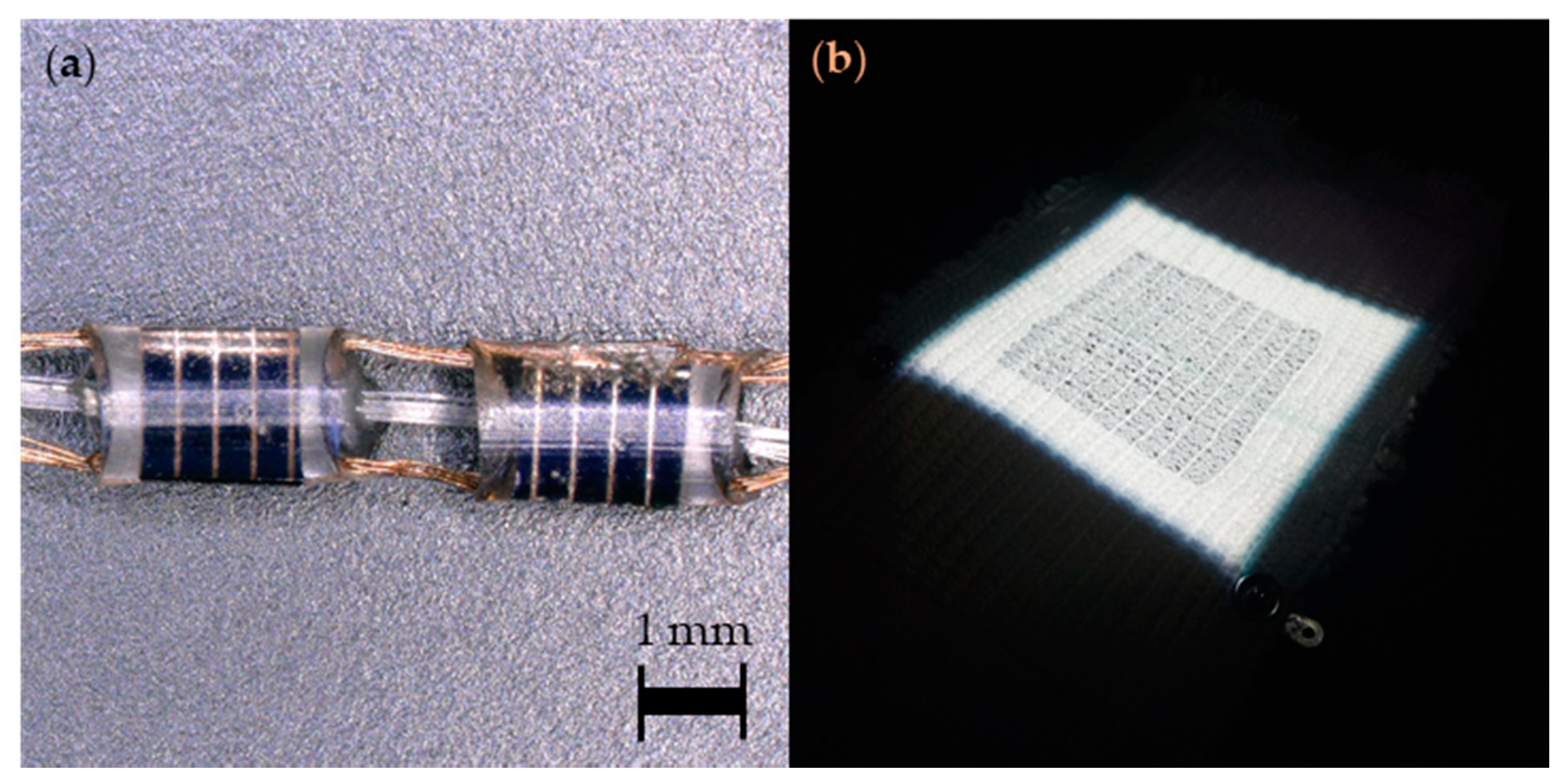

- Chen, J.; Huang, Y.; Zhang, N.; Zou, H.; Liu, R.; Tao, C.; Fan, X.; Wang, Z.L. Micro-cable structured textile for simultaneously harvesting solar and mechanical energy. Nat. Energy 2016, 1, 16138. [Google Scholar] [CrossRef]

- Krebs, F.C.; Hösel, M. The solar textile challenge: How it will not work and where it might. ChemSusChem 2015, 8, 966–969. [Google Scholar] [CrossRef]

- Yun, M.J.; Cha, S.I.; Seo, S.H.; Lee, D.Y. Insertion of dye-sensitized solar cells in textiles using a conventional weaving process. Sci. Rep. 2015, 5, 11022. [Google Scholar] [CrossRef] [Green Version]

- Kuhlmann, J.C.; de Moor, H.; Driesser, M.; Bottenberg, E.; Spee, C.; Brinks, G.J. Development of a Universal Solar Energy Harvesting System Suited for Textile Integration Including Flexible Energy Storage. J. Fash. Technol. Text. Eng. 2018. [Google Scholar] [CrossRef] [Green Version]

- Sundarrajan, S.; Murugan, R.; Nair, A.S.; Ramakrishna, S. Fabrication of P3HT/PCBM solar cloth by electrospinning technique. Mater. Lett. 2010, 64, 2369–2372. [Google Scholar] [CrossRef]

- Sun, K.C.; Sahito, I.A.; Noh, J.W.; Yeo, S.Y.; Im, J.N.; Yi, S.C.; Kim, Y.S.; Jeong, S.H. Highly efficient and durable dye-sensitized solar cells based on a wet-laid PET membrane electrolyte. J. Mater. Chem. A 2016, 4, 458–465. [Google Scholar] [CrossRef]

- Juhász Junger, I.; Wehlage, D.; Böttjer, R.; Grothe, T.; Juhász, L.; Grassmann, C.; Blachowicz, T.; Ehrmann, A. Dye-sensitized solar cells with electrospun nanofiber mat-based counter electrodes. Materials 2018, 11, 1604. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, J.; Park, N. Chemical Approaches for Stabilizing Perovskite Solar Cells. Adv. Energy Mater. 2020, 10, 1903249. [Google Scholar] [CrossRef]

- Kalantarian, H.; Alshurafa, N.; Pourhomayoun, M.; Sarrafzadeh, M. Power optimization for wearable devices. In Proceedings of the 2015 IEEE International Conference on Pervasive Computing and Communication Workshops (PerCom Workshops), St. Louis, MO, USA, 23–27 March 2015; pp. 568–573. [Google Scholar]

- Carroll, A.; Heiser, G. An Analysis of Power Consumption in a Smartphone. In Proceedings of the 2010 USENIX Conference on USENIX Annual Technical Conference, Boston, MA, USA, 22–25 June 2010; p. 21. [Google Scholar]

| Type of SC | PCE (%) | Mechanical Deformability | Mechanical Durability | Washability | Stability | Other | |

|---|---|---|---|---|---|---|---|

| Krebs et al. [103] | OPV | 0.0014 | Flexible | Substantial degradation after 2 h | |||

| Bedeloglu et al. [110] | OPV | 0.33 | Flexible | ||||

| Lipomi et al. [111] | OPV | 2 | Flexible, stretchable | ||||

| Kaltenbrunner et al. [112] | OPV | 4 | Flexible, stretchable, 3D deformation (drape) | Cyclic compression tested to 22 cycles. | |||

| Kylberg et al. [113] | OPV | 2.2 | Flexible | ||||

| Lee et al. [105] | OPV | 1.8 | Likely flexible | ||||

| Arumugam et al. [114] | OPV | 0.02 | Flexible | Bend and cyclic bend tests led to loss of functionality. | |||

| Jinno et al. [104] | OPV | 7.9 | Flexible, stretchable | Cyclic compression testing to 20 cycles. | Compatible with water, washable under mild conditions. | 46% decrease in PCE after 1000 h | |

| Jeong et al. [115] | OPV | 7.26 | Flexible | 1000 bend testing cycles | No notable degradation after 30 days. | ||

| Du et al. [102] | DSSC | 3.93 | Flexible | ||||

| Xu et al. [116] | DSSC | 3.3 | Flexible | ||||

| Xu et al. [117] | DSSC | 3.83 | Likely flexible | ||||

| Yun et al. [118] | DSSC | 4.16 | Flexible | Bend testing to 2000 cycles. | |||

| Opwis et al. [119] | DSSC | 1.1 | Flexible | Stable after seven week. | Performance at different operating temperatures reported. | ||

| Liu et al. [106] | DSSC | 2.78 | |||||

| Yun et al. [120] | DSSC | 1.7 | Flexible | Bend testing to 2000 cycles. | |||

| Song et al. [122] | DSSC | 5.08 | Flexible | ||||

| Knittel et al. [123] | CIGS | 8 | Flexible | ||||

| Plentz et al. [124] | a-Si | 1.41 | Likely flexible | ||||

| Lam et al. [108] | Perovskite | 15 | Likely flexible | Compatible with water | Maintained 70% initial PCE after 425 h | ||

| Jung et al. [109] | Perovskite | 5.7 | Flexible | Maintained 83% initial PCE after 300 h |

| Type of SC | PCE (%) | Mechanical Deformability | Mechanical Durability | Washability | Stability | Other | |

|---|---|---|---|---|---|---|---|

| Ramier et al. [125] | DSSC | Nominal | Strain and bending tested, however poor mechanical robustness reported. | ||||

| Lv et al. [126] | DSSC | 5.41 | Rigid | ||||

| Yang et al. [127] | DSSC | 8.45 | Flexible, high mechanical strength | Claimed to have good stability | |||

| Liang et al. [128] | DSSC | 9.1 | Flexible | Bend testing conducted with different bending angles | |||

| Chen et al. [129] | DSSC | 2.94 | Flexible | Claimed to have good stability | Shown woven into a textile | ||

| Chen et al. [132] | DSSC | 4.6 | Flexible | ||||

| Velten et al. [130] | DSSC | 3.4 | Likely flexible | ||||

| Yan et al. [131] | DSSC | 6.24 | Flexible | Stability shown in earlier work | Temperature stability shown | ||

| Zhang et al. [133] | DSSC | 4.85 | Flexible | 500 bending cycles | Limited lifetime | ||

| Uddin et al. [134] | DSSC | 2.57 | Flexible | Stable over 50 h | Temperature stability shown | ||

| Fu et al. [135] | DSSC | 10 | Flexible | 2000 bending cycles | Shown powering a pedometer | ||

| Qiu et al. [136] | Perovskite | 3.3 | Flexible | 50 bending cycles | Shown woven into a textile | ||

| He et al. [137] | Perovskite | 2.61 | Flexible, twistable, 3D deformable | 200 bending cycles, 100 twisting cycles | Shown woven into a textile | ||

| Hu et al. [138] | Perovskite | 5.3 | |||||

| Li et al. [139] | Perovskite | 3.03 | Flexible | 1000 bending cycles | 89% of initial performance after 96 h | ||

| Chuangchote et al. [140] | OPV | 0.11 | |||||

| Lee et al. [141] | OPV | 3.27 | Flexible | ||||

| Liu et al. [142] | OPV | 2.3 | Flexible | PCE of 1.7% after 14 days | |||

| Zhang et al. [143] | Flexible inorganic | 2 | Flexible | ||||

| Zhang et al. [144] | Flexible inorganic | 2.31 | Flexible | Stable when tested for 600 h | |||

| O’Conner et al. [145] | OPV | 0.5 | |||||

| Toivola et al. [146] | DSSC | <0.1 | |||||

| Bedeloglu et al. [147] | OPV | 0.021 | Flexible | ||||

| Yang et al. [148] | DSSC | 7.13 | Flexible, stretchable | 20 stretch cycles at 30% stretch | |||

| Zhang et al. [149] | Inorganic | 2.9 |

| Type of SC | PCE (%) | Mechanical Deformability | Mechanical Durability | Washability | Stability | Other | |

|---|---|---|---|---|---|---|---|

| Zhang et al. [149] | Inorganic | 1.24 | Flexible | Shown as a woven device | |||

| Pan et al. [150] | DSSC | 3.67 | Flexible, shear behavior | 100 bending cycles | Shown as a woven device, shown powering an LED | ||

| Pan et al. [150] | DSSC (solid electrolyte example) | 2.1 | Flexible | 100 bending cycles | Stable when tested for 300 h in air | Shown as a woven device | |

| Zhang et al. [152] | DSSC | 1.3 | Flexible | 500 bending cycles | Stable after 60 days | Shown as a woven device, normal textile appearance, shown powering a calculator | |

| Chai et al. [151] | DSSC | 1 | Flexible | 100 bending cycles | Stable after two months | Shown as a woven device | |

| Chen et al. [154] | DSSC | Flexible | Shown as a woven device, foldable, hybrid energy harvesting device | ||||

| Liu et al. [153] | OPV | 1.62 | Flexible, twistable | 1000 bending cycles, 1000 twisting cycles | Stable after 15 days (10% reduction in initial PCE) | Shown as a woven device, normal textile appearance | |

| Yun et al. [156] | DSSC | 2.63 | Flexible | Shown as a woven device | |||

| Krebs and Hösel [155] | OPV | 1 | Flexible | Shown as a woven device | |||

| Li et al. [26] | Perovskite | 10.41 | Flexible | 100 bending cycles | Stable after 10 days (10% reduction in initial PCE) | Shown as a woven device | |

| Kuhlmann et al. [157] | CIGS | Likely flexible | Shown as a woven device |

| Type of SC | PCE (%) | Mechanical Deformability | Mechanical Durability | Washability | Other | |

|---|---|---|---|---|---|---|

| Satharasinghe et al. [101] | c-Si array | 2.15 | Shear behavior, drapeable | Abrasion testing to 6000 abrasion cycles | Retained ~90% of their original power output after 15 machine wash cycles | Woven device, shown powering various devices |

| Lipomi et al. [111] | OPV film | 2 | Stretchable | |||

| Kaltenbrunner et al. [112] | OPV film | 4 | Stretchable, 3D deformation (drape) | Cyclic compression tested to 22 cycles. | ||

| Jinno et al. [104] | OPV film | 7.9 | Stretchable | Cyclic compression testing to 20 cycles. | Compatible with water, washable under mild conditions. | |

| Lam et al. [108] | Perovskite laminate | 15 | Compatible with water | |||

| He et al. [137] | Perovskite fiber | 2.61 | Twistable, 3D deformable | 100 twisting cycles | Shown woven into a textile | |

| Yang et al. [148] | DSSC fiber | 7.13 | Stretchable | 20 stretch cycles at 30% stretch | ||

| Pan et al. [150] | DSSC woven textile | 3.67 | Shear behavior | Shown as a woven device, shown powering an LED | ||

| Liu et al. [153] | OPV woven textile | 1.62 | Twistable | 1000 twisting cycles | Shown as a woven device, normal textile appearance |

| Maximum Reported PCE | Mechanical Deformability | Mechanical Durability | Washability | Maximum Stability Reported | Other | |

|---|---|---|---|---|---|---|

| Integrating flexible solar panels with textiles | Dependent on attached cell | Flexible | Likely durable to some wear and use | Not reported | The a-Si type of cells used are typically stable | |

| Solar cell arrays | 14.9 | Flexible, shear behavior, drapeable | Abrasion testing to 6000 abrasion cycles | Water compatible, can be machine washed | c-Si type cells are typically stable | Breathable |

| PV films and coating applied to textiles | 7.9 | Flexible, stretchable | Cyclic bend testing, cyclic compression testing | Water compatibility reported, can be washed under mild conditions | No degradation after 30 days reported | |

| Photovoltaic wires, fibers, and yarns | 10 | Flexible, twistable, stretchable, 3D deformable | Cyclic bend testing, cyclic stretching, cyclic twisting | Stable after 25 days reported | ||

| Textiles woven from photovoltatic fibers | 10.41 | Flexible, twistable, shear behavior | Cyclic bending, cyclic twisting | Stable after 2 months | Breathable | |

| Non-woven photovoltaic textiles | 10.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Satharasinghe, A.; Hughes-Riley, T.; Dias, T. A Review of Solar Energy Harvesting Electronic Textiles. Sensors 2020, 20, 5938. https://doi.org/10.3390/s20205938

Satharasinghe A, Hughes-Riley T, Dias T. A Review of Solar Energy Harvesting Electronic Textiles. Sensors. 2020; 20(20):5938. https://doi.org/10.3390/s20205938

Chicago/Turabian StyleSatharasinghe, Achala, Theodore Hughes-Riley, and Tilak Dias. 2020. "A Review of Solar Energy Harvesting Electronic Textiles" Sensors 20, no. 20: 5938. https://doi.org/10.3390/s20205938