Changes in Fabric Surface Pilling under Laser Ablation

Abstract

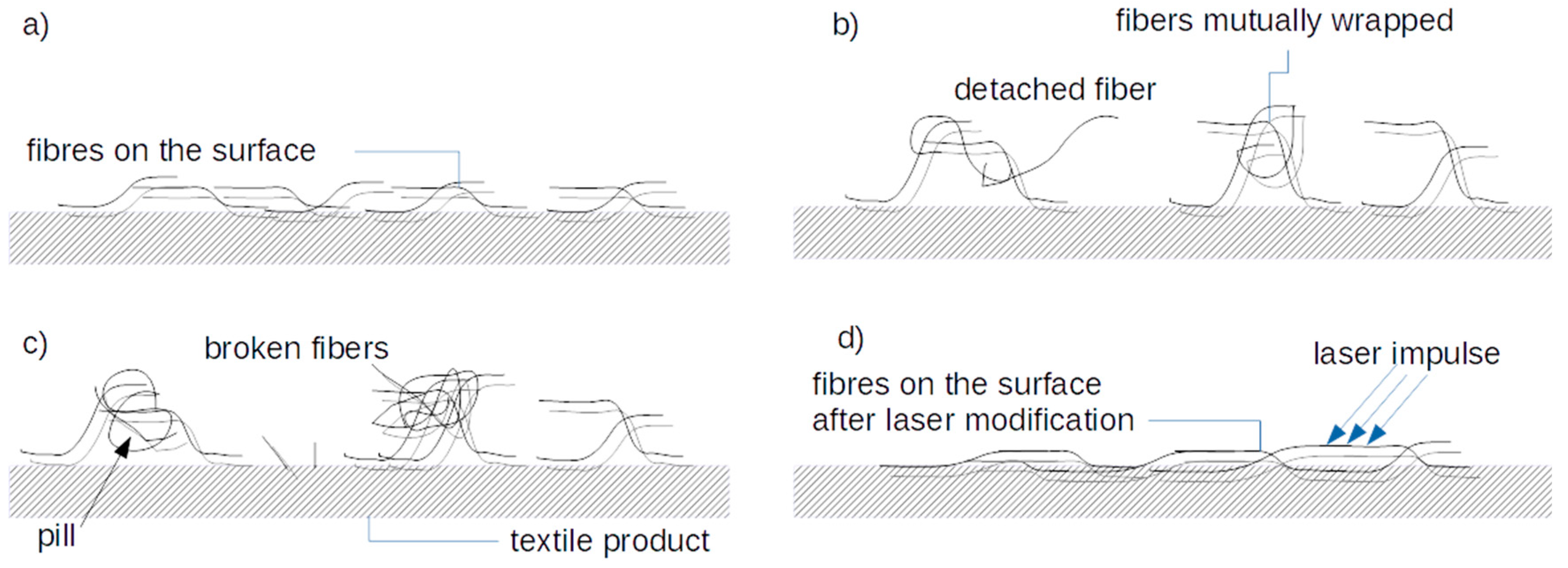

:1. Introduction

- extraction of loose threads from the yarn that makes up the fabric

- the generation of pills, also called combing the fibers

- pill growth

- shaping the structure of the pills

- changes inside the core and ligament of pills

- detachment of pills.

2. Materials and Methods

2.1. Textile Characteristic

2.2. Process of Laser Modification

2.3. Methods of Pilling Assessment

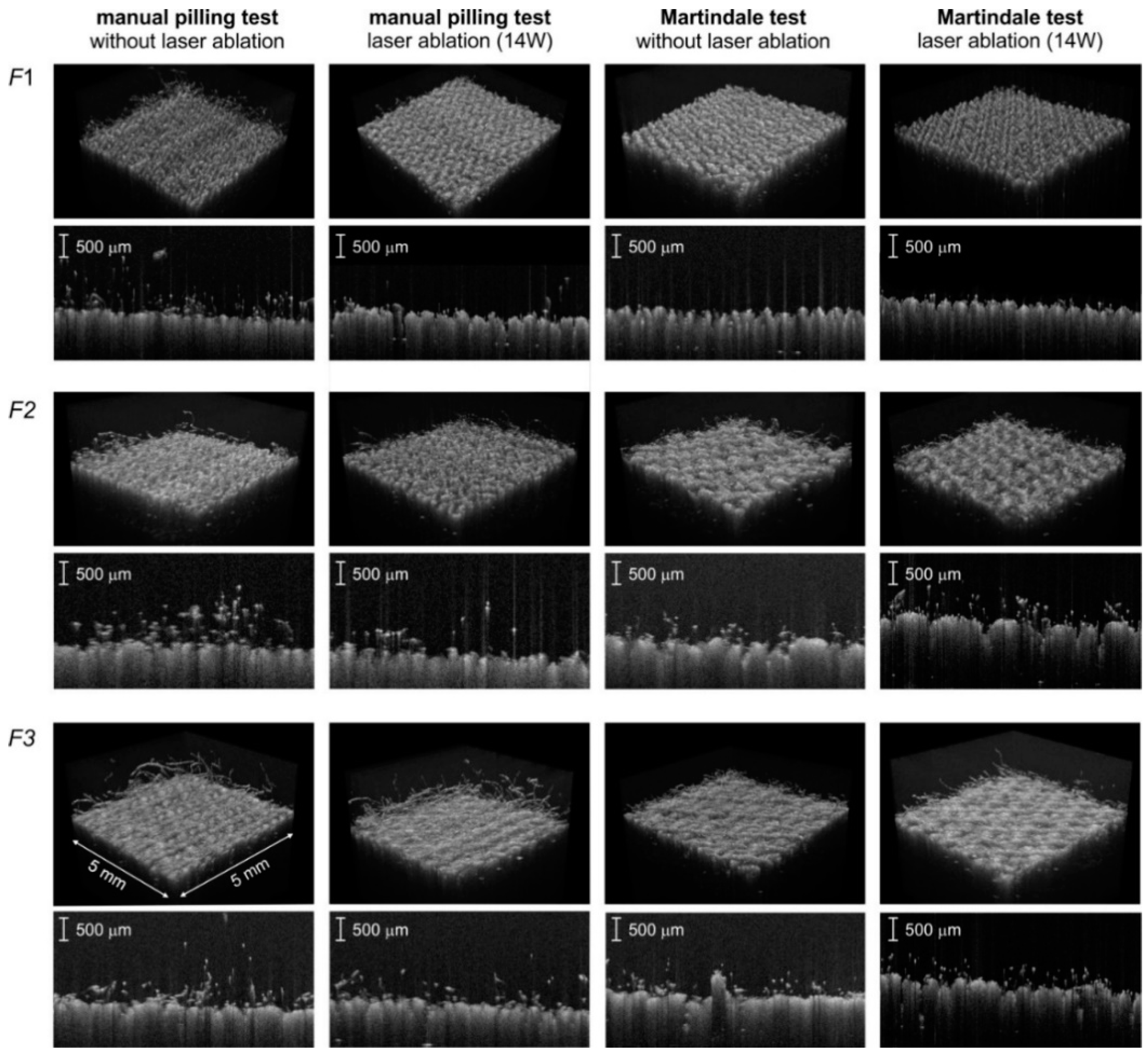

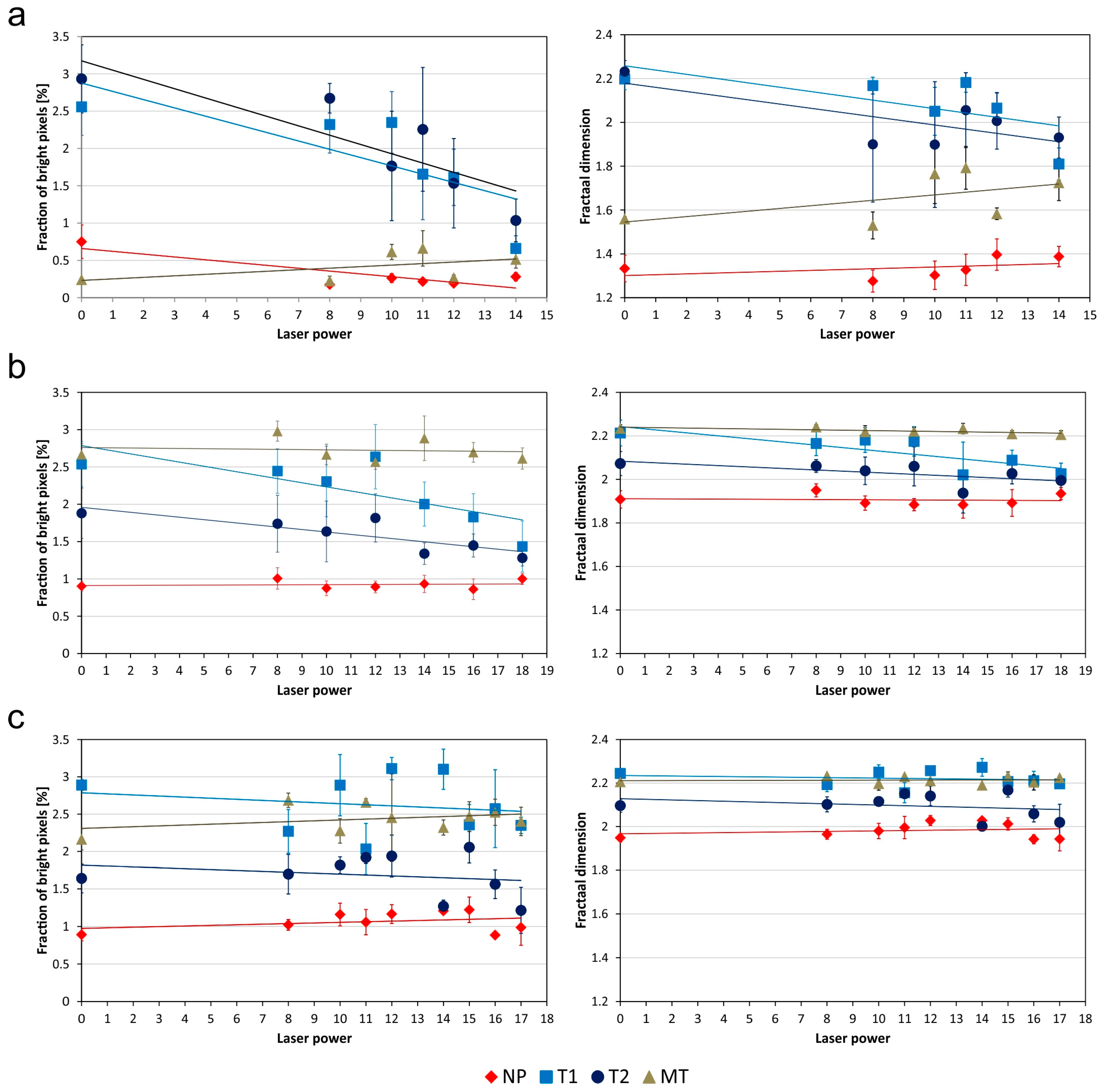

- Manual test T1, in which the knitted fabric was rubbed with the speed 23–25 cm/s for 15 s with a harsh hard fiber brush at a constant pressure of 2 N controlled by a strain gauge;

- Manual test T2, in which the knitted fabric was rubbed with the speed 23–25 cm/s for 15 s with an unglazed ceramic plate at a constant pressure of 1 N;

- Martindale’s test MT, carried out in accordance with the Polish Norm introducing the International Norm PN-EN ISO 12945-2: 2002 standard [18] for 5000 friction cycles, at a constant pressure of 100 N, diameter 20 cm.

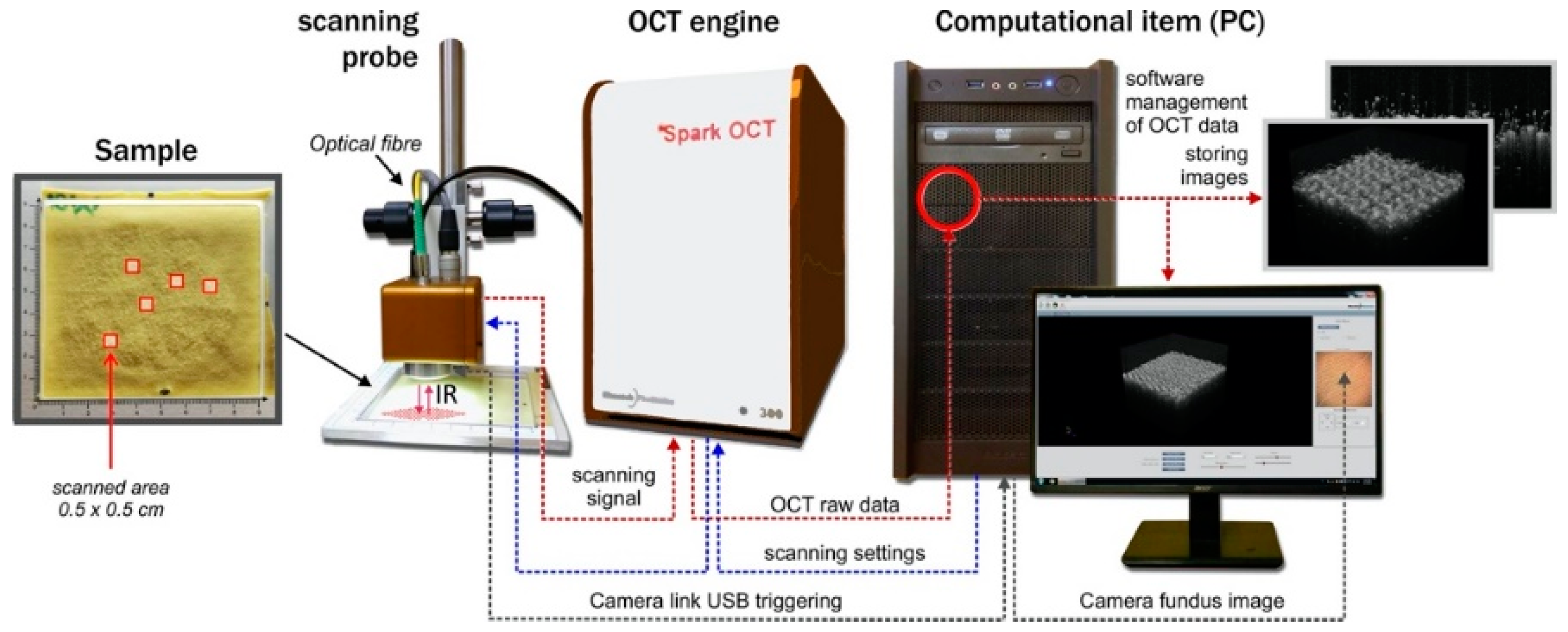

2.4. Textile Image Acquisition

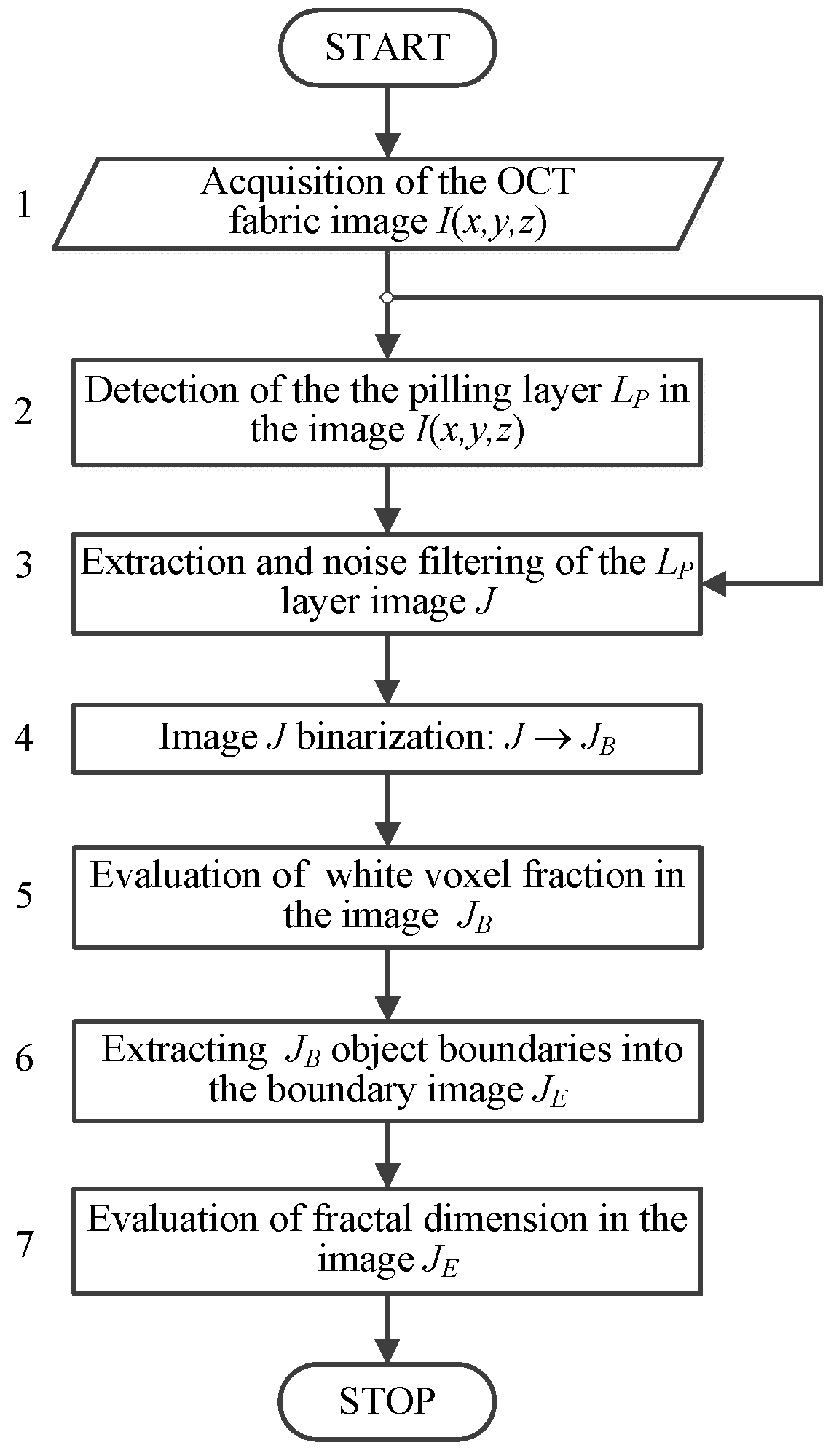

2.5. Assessment of Pilling Texture

2.6. Statistical Analysis

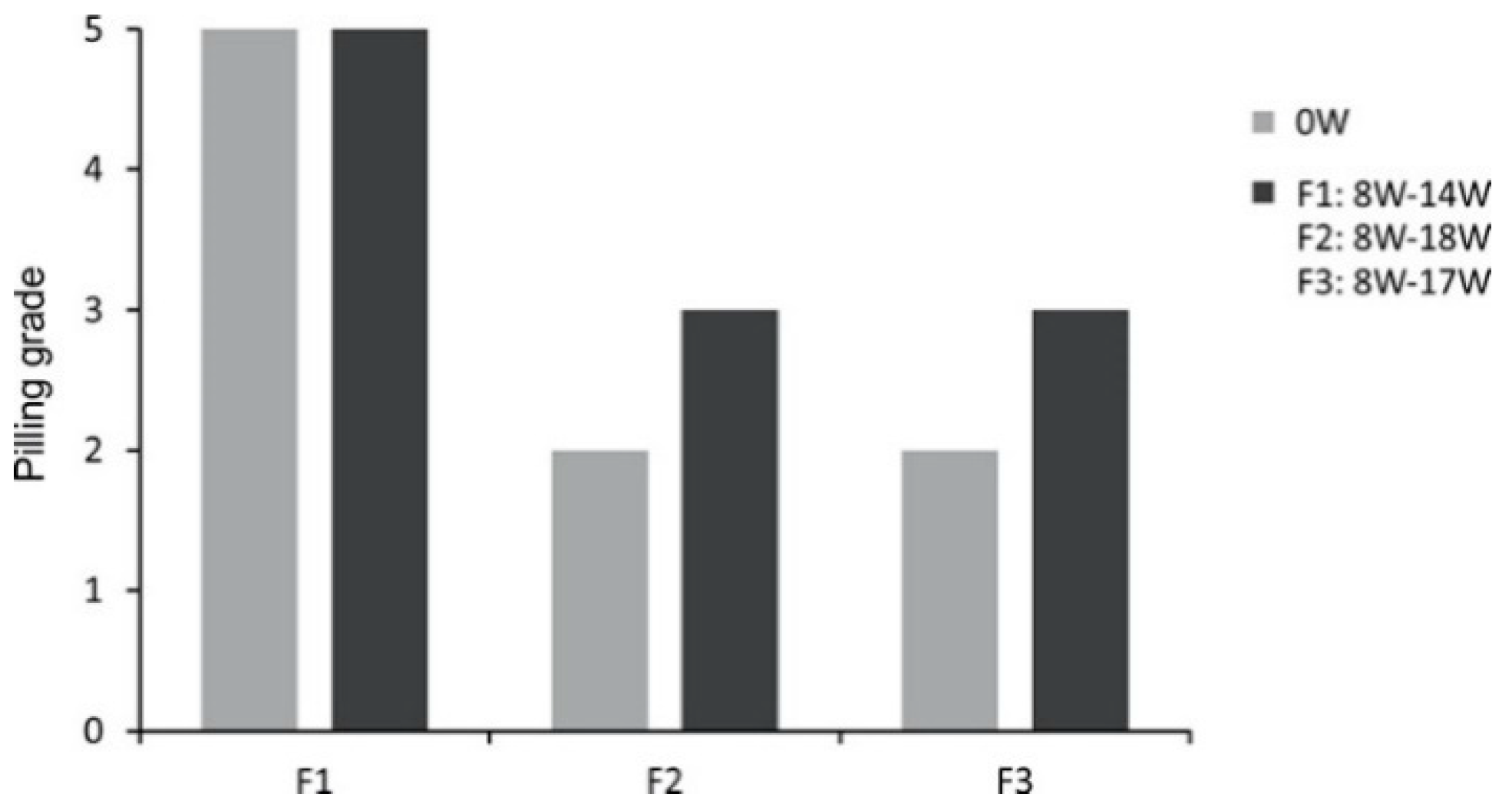

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, H.; Wang, H.; Wang, Y.; Su, X.; Wang, C.; Zhang, M.; Jian, M.; Xia, K.; Liang, X.; Lu, H.; et al. Laser Writing of Janus Graphene/Kevlar Textile for Intelligent Protective Clothing. ACS Nano 2020, 14, 3219–3226. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nayak, R.; Nadhye, R. The use of laser in garment manufacturing: An overview. Fash. Text. 2016, 3, 5. [Google Scholar] [CrossRef] [Green Version]

- Dudeja, J.P. Laser Application in Apparel Industry. Int. J. Adv. Sci. Technol. Eng. Manag. Sci. 2018, 4, 1–5. [Google Scholar]

- Micus, S.; Haupt, M.; Gresser, G.T. Soldering Electronics to Smart Textiles by Pulsed Nd:YAG Laser. Materials 2020, 13, 2429. [Google Scholar] [CrossRef] [PubMed]

- Pawlak, R.; Lebioda, M.; Tomczyk, M.; Rymaszewski, J.; Korzeniewska, E.; Walczak, M. Modelling and applications of conductive elements on textile materials . COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2018, 37, 1645–1656. [Google Scholar] [CrossRef]

- Bormashenko, E.; Chaniel, G.; Grynyov, R. Towards understanding hydrophobic recovery of plasma treated polymers: Storing in high polarity liquids suppresses hydrophobic recovery. Appl. Surf. Sci. 2013, 273, 549–553. [Google Scholar] [CrossRef]

- Hassan, M.; Carr, C. A review of the sustainable methods in imparting shrink resistance to wool fabrics. J. Adv. Res. 2019, 18, 39–60. [Google Scholar] [CrossRef]

- Gintis, D.; Mead, E. The mechanism of pilling. Text. Res. J. 1959, 15, 578–585. [Google Scholar]

- Thekkekara, L.V.; Gu, M. Large-scale waterproof and stretchable textile-integrated laser- printed graphene energy storages. Sci. Rep. 2019, 9, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Abdelrahman, M.S.; Fouda, M.G.; Ajarem, J.S.; Maodaa, S.M.; Allam, A.A.; Khattaba, T.A. Development of colorimetric cotton swab using molecular switching hydrazone probe in calcium alginate. J. Mol. Struct. 2020, 1216, 128301. [Google Scholar] [CrossRef]

- Lada-Tondyra, E.; Jakubas, A. Modern Applications of Textronic Systems. Prz. Elektrotechniczny 2018, 94, 198–201. [Google Scholar]

- Cooke, W.D. Pilling Attrition and Fatigue. Text. Res. J. 1985, 55, 409–414. [Google Scholar] [CrossRef]

- Ukponmwan, J.O.; Mukhopadhyay, A.; Chatterjee, K.N. Pilling. Text. Prog. 1998, 28, 1–57. [Google Scholar] [CrossRef]

- Breck, A. Filzfestausrustung in langer Flotte ohne Vergilbung. Melliand Text. 1989, 6, 452–454. [Google Scholar]

- Mori, M.; Inagaki, N. Relation between Anti-Felting Properties and Physicochemical Properties of Wool Treated with Low-Temperature Plasma. Res. J. Text. Appar. 2006, 10, 33–45. [Google Scholar] [CrossRef]

- Cardamone, M.; Yao, J. Wool Shrink Proofing by Chemical Enzymatic Methods. Textile Res. J. 2004, 74, 555–565. [Google Scholar] [CrossRef]

- Mori, M.; Fujiumoto, T.; Murakami, M. Influence of Fiber’s Surface Morphology Change on Anti-pilling Performance of Woolen Knitted Fabric. In Proceedings of the KEER2014: International Conference on Kansei Engineering and Emotion Research, Linköping, Sweden, 11–13 June 2014. [Google Scholar]

- Determining the tendency of the surface of a flat product to pilling and pilling. In Standard PN-EN ISO 12945-2: 2002 Textiles; Polish Committee for Standardization: Warsaw, Poland, 2002.

- Sekulska-Nalewajko, J.; Gocławski, J.; Korzeniewska, E. A Method for the Assessment of Textile Pilling Tendency Using Optical Coherence Tomography. Sensors 2020, 20, 3687. [Google Scholar] [CrossRef]

- Huang, D.; Swanson, E.A.; Lin, C.P.; Schuman, J.S.; Stinson, W.G.; Chang, W.; Hee, M.R.; Flotte, T.; Gregory, K.; Puliafito, C.A. Optical coherence tomography. Science 1991, 254, 1178–1181. [Google Scholar] [CrossRef] [Green Version]

- Fercher, A.F.; Drexler, W.; Hitzenberger, C.K.; Lasser, T. Optical coherence tomography–principles and applications. Rep. Prog. Phys. 2003, 66, 239–303. [Google Scholar] [CrossRef]

- Drexler, W.; Liu, M.; Kumar, A.; Kamali, T.; Unterhuber, A.; Leitgeb, R.A. Optical coherence tomography today: Speed, contrast, and multimodality. J. Biomed. Opt. 2014, 19, 071412. [Google Scholar] [CrossRef]

- Rymarczyk, T.; Bozek, P.; Oleszek, M.; Niderla, K.; Adamkiewicz, P. Construction of the SmartEIT tomograph based on electrical impedance tomography. Prz. Elektrotechniczny 2020, 96, 44–47. [Google Scholar] [CrossRef]

- Rymarczyk, T.; Golabek, M.; Cieplak, T.; Kania, K.; Adamkiewicz, P. Ultrasonic tomography for reflection and transmission wave analysis. Prz. Elektrotechniczny 2020, 96, 170–173. [Google Scholar] [CrossRef]

- Choma, M.; Sarunic, M.; Yang, C.; Izatt, J. Sensitivity advantage of swept source and Fourier domain optical coherence tomography. Opt. Express 2003, 11, 2183–2189. [Google Scholar] [CrossRef] [Green Version]

- Leitgeb, R.; Hitzenberger, C.; Fercher, A. Performance of Fourier domain vs. time domain optical coherence tomography. Opt. Express 2003, 11, 889–894. [Google Scholar] [CrossRef]

- Hee, M.R.; Puliafito, C.A.; Duker, J.S.; Reichel, E.; Coker, J.G.; Wilkins, J.R.; Schuman, J.S.; Swanson, E.A.; Fujimoto, J.G. Topography of diabetic macular edema with optical coherence tomography. Ophthalmology 1998, 105, 360–370. [Google Scholar] [CrossRef] [Green Version]

- Otis, L.L.; Everett, M.J.; Sathyam, U.S.; Colston, B.W. Optical coherence tomography: A new imaging technology for dentistry. J. Am. Dent. Assoc. 2000, 131, 511–514. [Google Scholar] [CrossRef]

- Yabushita, H.; Bouma, B.E.; Houser, S.L.; Aretz, H.T.; Jang, I.-K.; Schlendorf, K.H.; Kauffman, C.R.; Shishkov, M.; Kang, D.-H.; Halpern, E.F.; et al. Characterization of human atherosclerosis by optical coherence tomography. Circulation 2002, 106, 1640–1645. [Google Scholar] [CrossRef]

- Pierce, M.C.; Strasswimmer, J.; Park, B.H.; Cense, B.; de Boer, J.F. Advances in optical coherence tomography imaging for dermatology. J. Investig. Dermatol. 2004, 123, 458–463. [Google Scholar] [CrossRef] [Green Version]

- Hutiu, G.; Duma, V.F.; Demian, D.; Bradu, A.; Podoleanu, A. Assessment of Ductile, Brittle, and Fatigue Fractures of Metals Using Optical Coherence Tomography. Metals 2018, 8, 117. [Google Scholar] [CrossRef] [Green Version]

- Gliścińska, E.; Sankowski, D.; Krucińska, I.; Gocławski, J.; Michalak, M.; Rowińska, Z.; Sekulska-Nalewajko, J. Optical coherence tomography image analysis of polymer surface layers in sound-absorbing fibrous composite materials. Polym. Test. 2017, 63, 194–203. [Google Scholar] [CrossRef]

- Meglinski, I.V.; Buranachai, C.; Terry, L.A. Plant photonics: Application of optical coherence tomography to monitor defects and rots in onion. Laser Phys. Lett. 2010, 7, 307–310. [Google Scholar] [CrossRef]

- Czajkowski, J.; Prykäri, T.; Alarousu, E.; Palosaari, J.; Myllylä, R. Optical coherence tomography as a method of quality inspection for printed electronics products. Opt. Rev. 2010, 17, 257–262. [Google Scholar] [CrossRef]

- Thrane, L.; Jørgensen, T.M.; Jørgensen, M.; Krebs, F.C. Application of optical coherence tomography (OCT) as a 3-dimensional imaging technique for roll-to-roll coated polymer solar cells. Sol. Energy Mater. Sol. Cells 2012, 97, 181–185. [Google Scholar] [CrossRef]

- Meemon, P.; Yao, J.; Lee, K.-S.; Thompson, K.P.; Ponting, M.; Baer, E.; Rolland, J.P. Optical coherence tomography enabling non-destructive metrology of layered polymeric GRIN material. Sci. Rep. 2013, 3, 2045–2322. [Google Scholar] [CrossRef] [Green Version]

- Blanch-Perez-del-Notario, C.; Saeys, W.; Lambrechts, A. Hyperspectral imaging for textile sorting in the visible–near infrared range. J. Spectr. Imaging 2019, 8. [Google Scholar] [CrossRef]

- Zhang, Z.; Ikpatt, U.; Zheng, Y.; Lin, H.; Shen, Y. Sub-surface imaging of soiled cotton fabric using full-field optical coherence tomography. Opt. Expr. 2019, 27, 13951. [Google Scholar] [CrossRef] [PubMed]

- Pawlak, R.; Rosowski, A.; Tomczyk, M.; Walczak, M. Laser microscale technologies: Modeling assisted processes. In Proceedings of the SPIE Laser Technology 2012: Applications of Lasers, Szczecin, Poland, 24–28 September 2012. [Google Scholar]

- Siciński, M.; Korzeniewska, E.; Tomczyk, M.; Pawlak, R.; Bieliński, D.; Gozdek, T.; Kałuzińska, K.; Walczak, M. Laser-Textured Rubbers with Carbon Nanotube Fillers. Polymers 2018, 10, 1091. [Google Scholar] [CrossRef] [Green Version]

- Marczak, J.; Kusiński, J.; Major, R.; Rycyk, A.; Sarzyński, A.; Strzelec, M.; Czyż, K. Laser interference patterning of diamond-like carbon layers for directed migration and growth of smooth muscle cell depositions. Opt. Appl. 2014, 44, 575–586. [Google Scholar] [CrossRef]

- Wang, Z.B.; Hong, M.H.; Lu, Y.F.; Wu, D.J.; Lan, B.; Chong, T.C. Femtosecond laser ablation of polytetrafluoroethylene (Teflon) in ambient air. J. Appl. Phys. 2003, 93, 6375. [Google Scholar] [CrossRef]

- Furferi, R.; Governi, L.; Volpe, Y. Machine Vision-Based Pilling Assessment: A Review. J. Eng. Fibers Fabr. 2015, 10, 79–93. [Google Scholar] [CrossRef]

- Dey, S. Hands-On Image Processing with Python: Expert Techniques for Advanced Image Analysis and Effective Interpretation of Image Data; Packt: Birmingham, UK, 2018; p. 492. [Google Scholar]

- Lim, J.S. Two-Dimensional Signal and Image Processing; PrenticeHall: EnglewoodCliffs, NJ, USA, 1990; p. 694. [Google Scholar]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef] [Green Version]

- Kenneth, F. Fractal Geometry: Mathematical Foundations and Applications; John Wiley: Chichester, UK, 1990; pp. 38–47. ISBN 0-471-92287-0. [Google Scholar]

- Costa, A.F.; Humpire-Mamani, G.; Traina, A.J.M. An Efficient Algorithm for Fractal Analysis of Textures. In Proceedings of the 2012 25th SIBGRAPI Conference on Graphics, Patterns and Images, Ouro Preto, Brazil, 22–25 August 2012; pp. 39–46. [Google Scholar]

- Serra, J. Image Analysis and Mathematical Morphology; Academic Press: Cambridge, MA, USA, 1982; ISBN 0-12-637240-3. [Google Scholar]

- Gonzalez, R.C.; Woods, R.E. Digital Image Processing, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Wu, J.; Jin, X.; Mi, S.; Tang, J. An effective method to compute the box-counting dimension based on the mathematical definition and intervals. Results Eng. 2020, 6, 100106. [Google Scholar] [CrossRef]

- Danaila, I.; Joly, P.; Kaber, S.M.; Postel, M. (Eds.) An Introduction to Scientific Computing. Polynomial Approximation; Springer: New York, NY, USA, 2007. [Google Scholar]

- Numpy.Polyfit—NumPy v1.19 Manual. Available online: https://numpy.org/doc/stable/reference/generated/numpy.polyfit.html (accessed on 24 July 2020).

- Shapiro, S.S.; Wilk, M.B. An Analysis of Variance Test for Normality. Biometrika 1965, 52, 591–611. [Google Scholar] [CrossRef]

- Brown, M.B.; Forsythe, A.B. Robust tests for the equality of variances. J. Am. Stat. Assoc. 1974, 69, 364–367. [Google Scholar] [CrossRef]

- Skidmore, T.S.; Thompson, B. Bias and precision of some classical ANOVA effect sizes when assumptions are violated. Behav. Res. 2013, 45, 536–546. [Google Scholar] [CrossRef] [Green Version]

- Baguley, T. Serious Stats: A Guide to Advanced Statistics for the Behavioral Sciences; Macmillan International Higher Education Red Globe Press: London, UK, 2012. [Google Scholar]

| Name | Composition | Type | Surface Mass |

|---|---|---|---|

| (g/m2) | |||

| F1 | 100% polyester | single jersey, left–right weave | 240 |

| F2 | 65% polyester, 35% polyacrylonitrile | Lacoste blue | 240 |

| F3 | 68% cotton, 32% polyamide | smooth knit, left–right weave | 240 |

| Wavelength | Pulse Duration | Pulse Energy | Pulse Frequency | Hatching Distance | Scan Speed | Beam Diam. | |

|---|---|---|---|---|---|---|---|

| (nm) | (ns) | (µJ) | (µHz) | (µm) | (mm/s) | (µm) | |

| range | 1060 | 15–220 | 88–198 | 35–290 | 10–40 | 200–2000 | 26 |

| test | 1060 | 220 | 88–198 | 35 | 10 | 400 | 26 |

| Energy | (µJ) | 88 | 110 | 121 | 132 | 154 | 165 | 176 | 188 | 198 |

| Power | (W) | 8 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 |

| Textile | Test | ANOVA Results | Fisher LSD Test | |||

|---|---|---|---|---|---|---|

| F | P | ω² | F | p | ||

| F1 | T1 | 17.749 * | <0.000001 | 0.699 | 60.940 | <0.000001 |

| T2 | 4.670 * | 0.0094 | 0.372 | 9.887 | 0.0020 | |

| MT | 3.932 * | 0.0473 | 0.304 | 2.579 | 0.0653 | |

| F2 | T1 | 8.555 | <0.00001 | 0.452 | 46.904 | <0.000001 |

| T2 | 3.690 | 0.0040 | 0.218 | 10.280 | 0.0012 | |

| MT | 2.357 | 0.0871 | 0.279 | 0.973 | 0.1703 | |

| F3 | T1 | 5.004 | 0.0022 | 0.543 | 0.843 | 0.1853 |

| T2 | 6.005 | 0.0008 | 0.597 | 6.034 | 0.0122 | |

| MT | 1.758 | 0.2988 | 0.194 | n.s. | n.s. | |

| Textile | Test | ANOVA Results | Fisher LSD Test | |||

|---|---|---|---|---|---|---|

| F | P | ω² | F | p | ||

| F1 | T1 | 27.069 * | <0.000001 | 0.782 | 76.610 | <0.000001 |

| T2 | 2.655 * | 0.0698 | 0.222 | n.s. | n.s. | |

| MT | 6.926 * | 0.0052 | 0.518 | 5.387 | 0.0179 | |

| F2 | T1 | 8.475 * | <0.0001 | 0.415 | 26.452 | <0.00001 |

| T2 | 4.012 | 0.0024 | 0.244 | 7.869 | 0.0036 | |

| MT | 1.084 | 0.4241 | 0.026 | n.s. | n.s. | |

| F3 | T1 | 3.953 | 0.0074 | 0.467 | 0.529 | 0.2382 |

| T2 | 5.546 * | 0.0081 | 0.484 | 2.586 | 0.0614 | |

| MT | 0.989 * | 0.5298 | 0.018 | n.s. | n.s. | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korzeniewska, E.; Gocławski, J.; Sekulska-Nalewajko, J.; Walczak, M.; Wilbik-Hałgas, B. Changes in Fabric Surface Pilling under Laser Ablation. Sensors 2020, 20, 5832. https://doi.org/10.3390/s20205832

Korzeniewska E, Gocławski J, Sekulska-Nalewajko J, Walczak M, Wilbik-Hałgas B. Changes in Fabric Surface Pilling under Laser Ablation. Sensors. 2020; 20(20):5832. https://doi.org/10.3390/s20205832

Chicago/Turabian StyleKorzeniewska, Ewa, Jarosław Gocławski, Joanna Sekulska-Nalewajko, Maria Walczak, and Bożena Wilbik-Hałgas. 2020. "Changes in Fabric Surface Pilling under Laser Ablation" Sensors 20, no. 20: 5832. https://doi.org/10.3390/s20205832

APA StyleKorzeniewska, E., Gocławski, J., Sekulska-Nalewajko, J., Walczak, M., & Wilbik-Hałgas, B. (2020). Changes in Fabric Surface Pilling under Laser Ablation. Sensors, 20(20), 5832. https://doi.org/10.3390/s20205832