Evolutionary Algorithm-Based Complete Coverage Path Planning for Tetriamond Tiling Robots

Abstract

1. Introduction

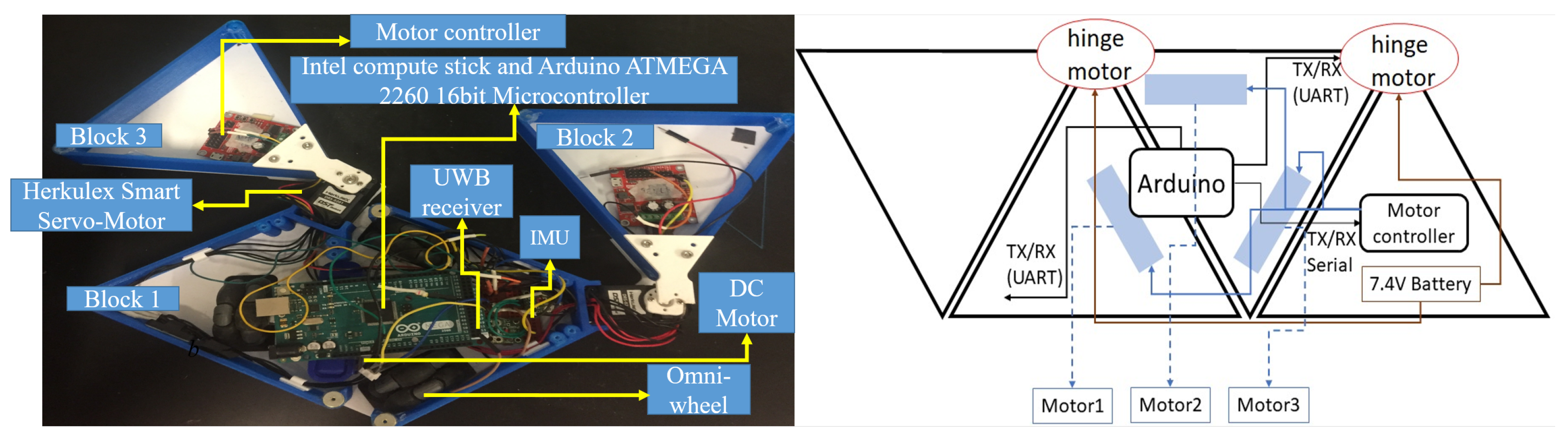

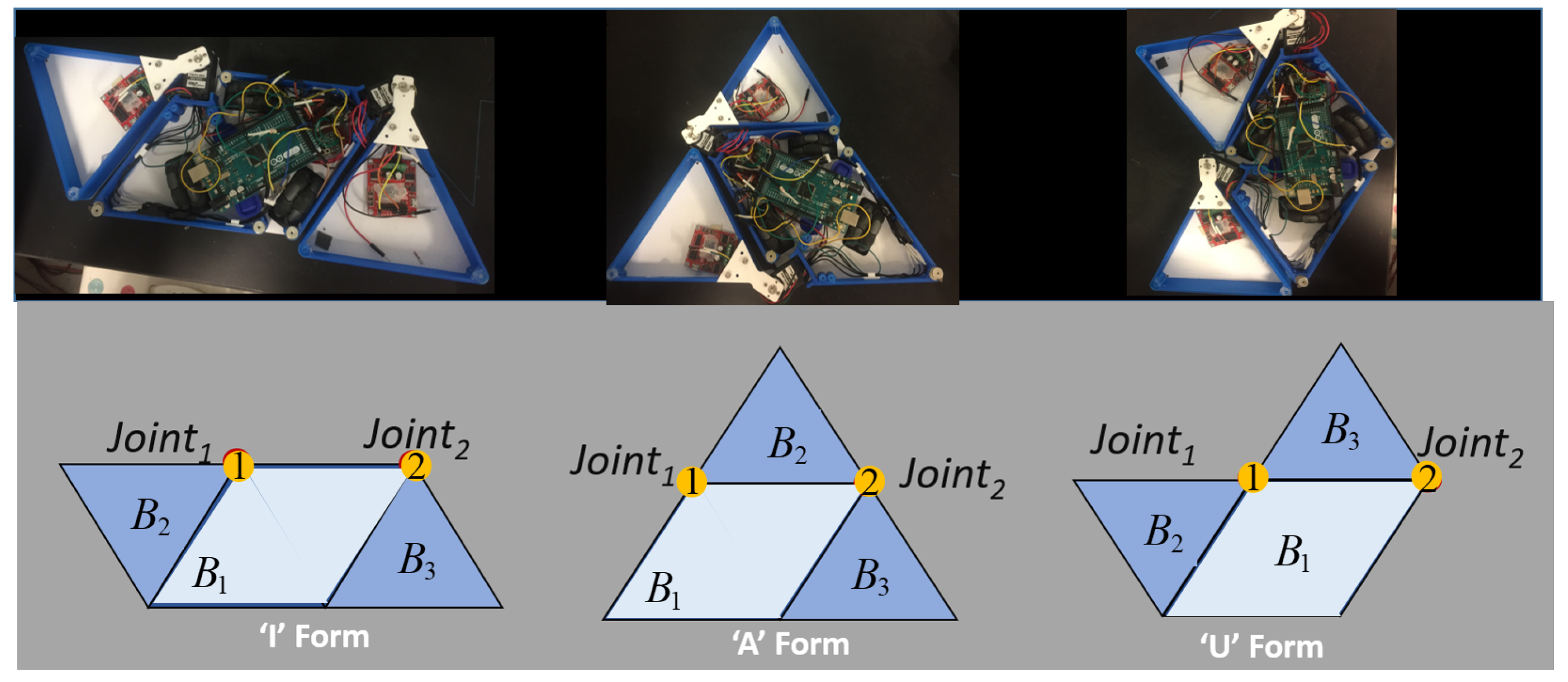

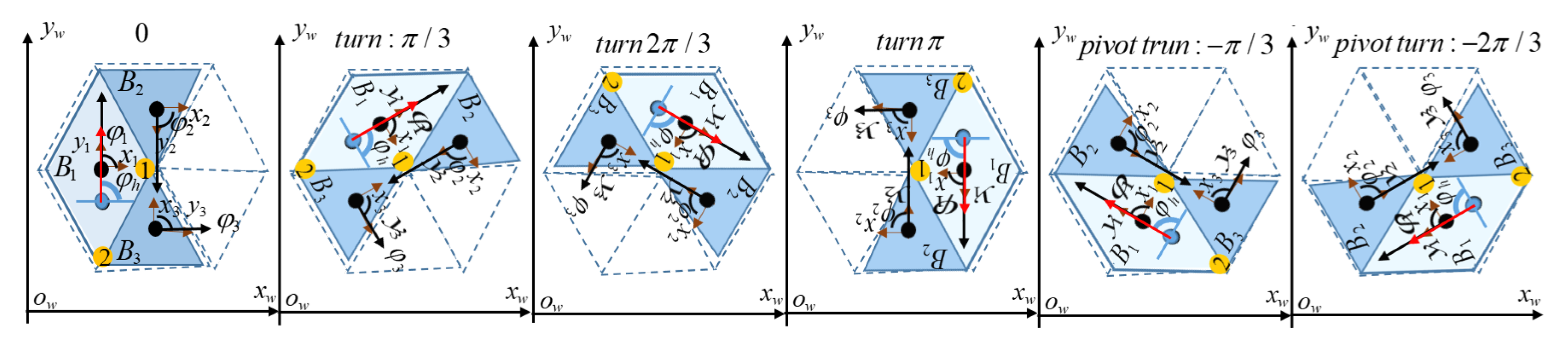

2. Architecture of the hTetrakis Robot

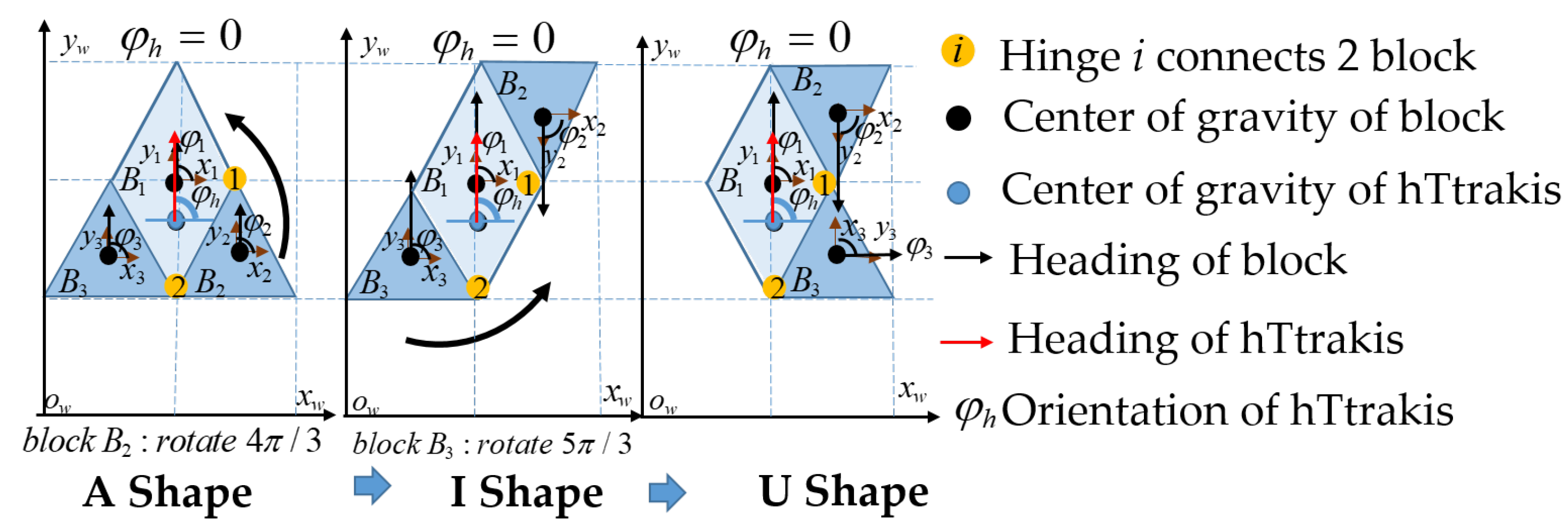

3. hTetrakis Energy Workspace

Representation of hTetrakis in a Workspace

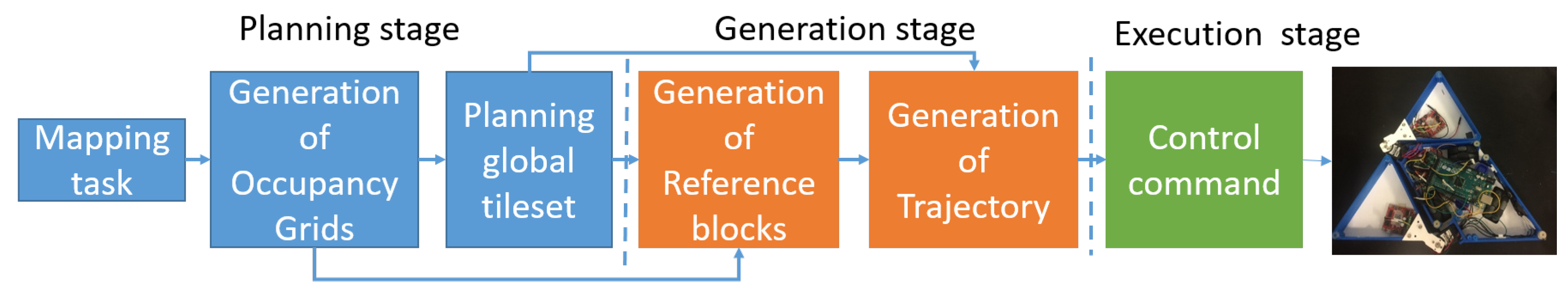

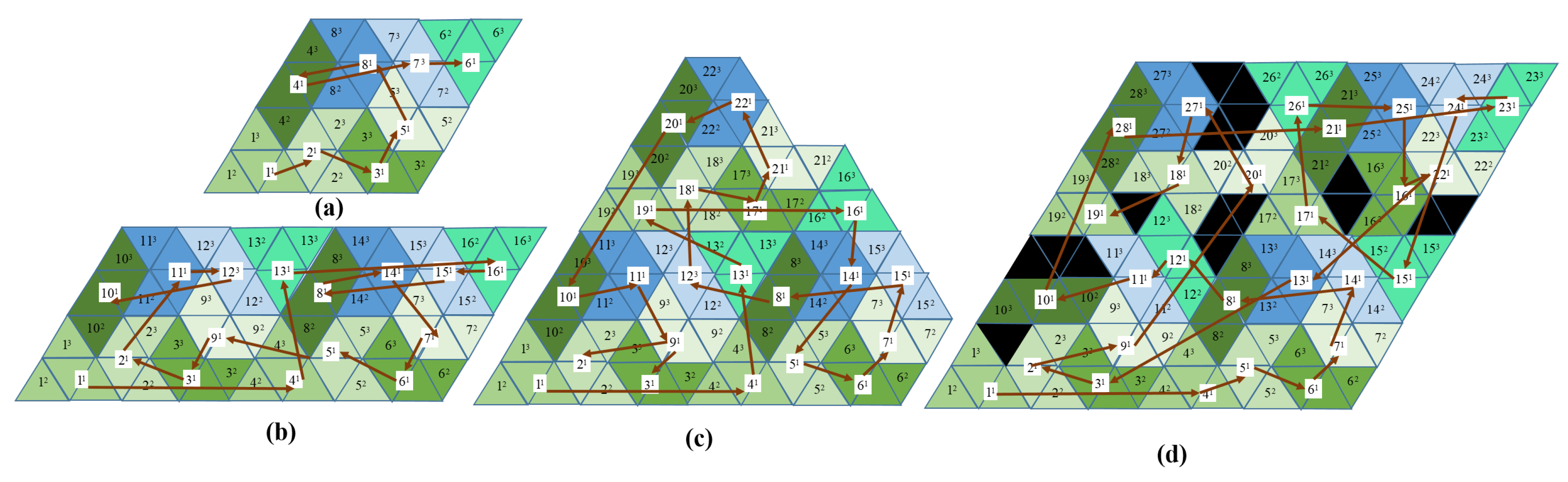

4. The Complete Coverage Path Planning (CCPP) Framework for hTetrakis by Tiling Theory

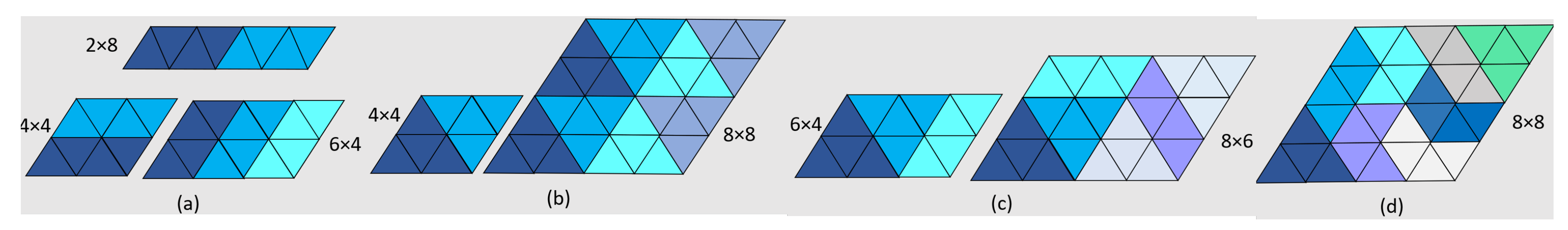

4.1. Tetriamond Tiling Theory for CCPP

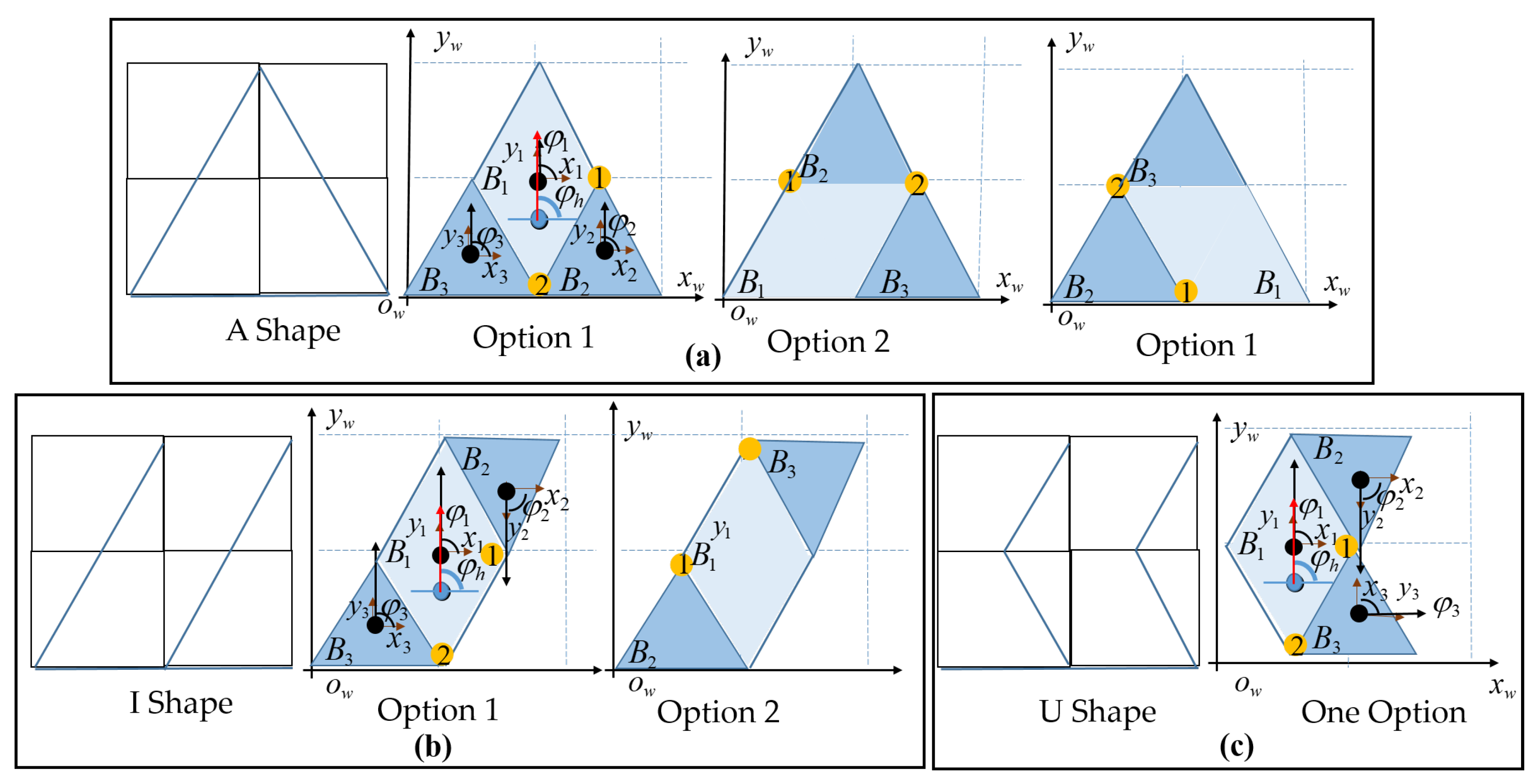

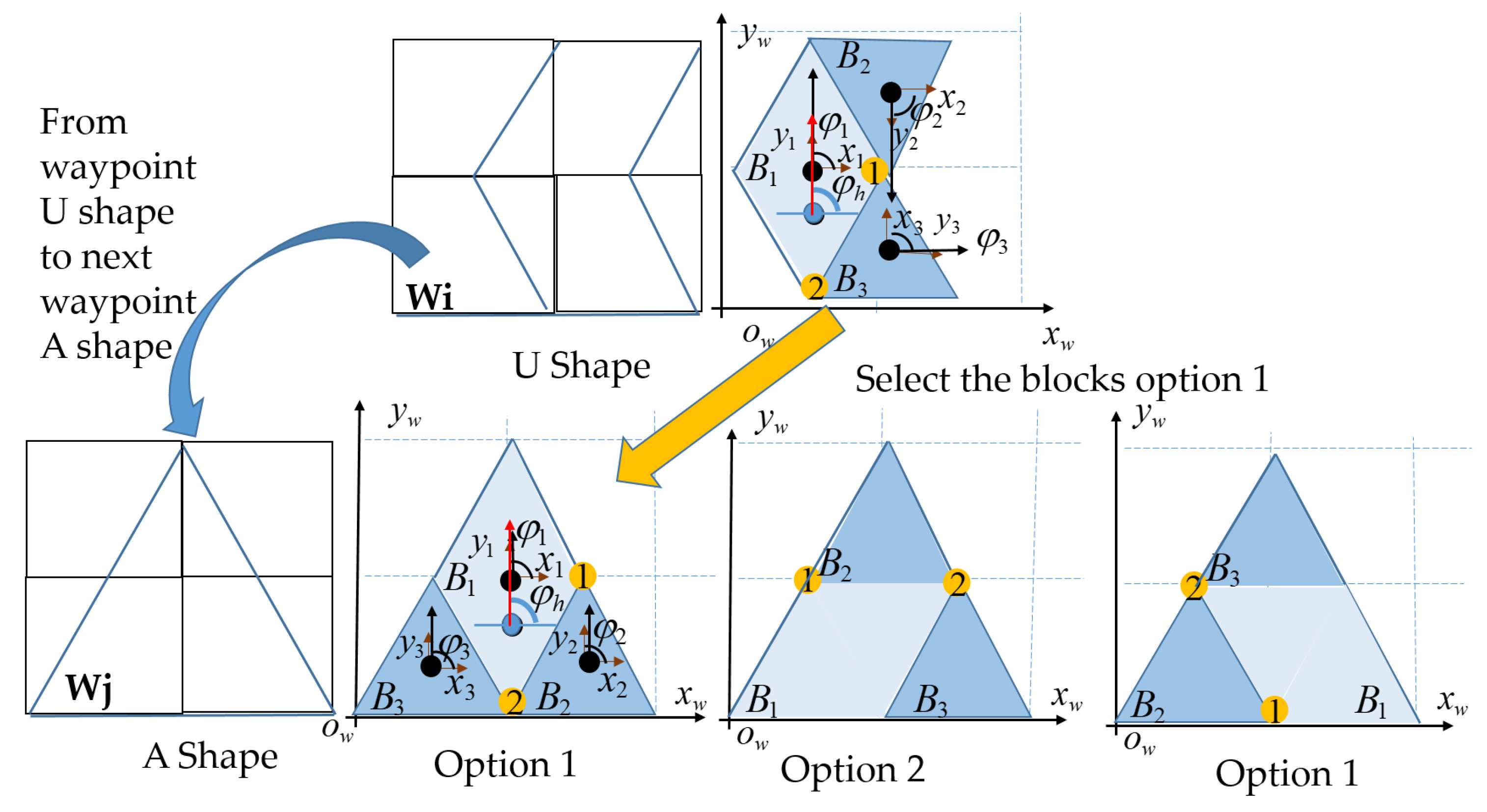

4.2. Assigning the hTetrakis Blocks Location

| Algorithm 1: block location setting |

| 1Function OPTIMAL BLOCKS{predefined workspace, selected tileset}: |

| 2 define {} |

| 3i ←1, j ←1, t ←1 |

| 4 for alli, i ←1, do |

| 5 for allj, j ←1, do |

| 6 location is COM of tile t: |

| 7 if tile t is asymmetrical tile: |

| 8 Locate: tile t blocks as Figure 8c |

| 9 else if tile t is symmetrical tile: |

| 10 Execute: shifting from to t |

| 11 Find: blocks of tile having the similar heading with the heading after transforming |

| 12 Locate: tile t blocks as Figure 8a,b |

| 13 end |

| 14 end |

| 15 end |

| End Function |

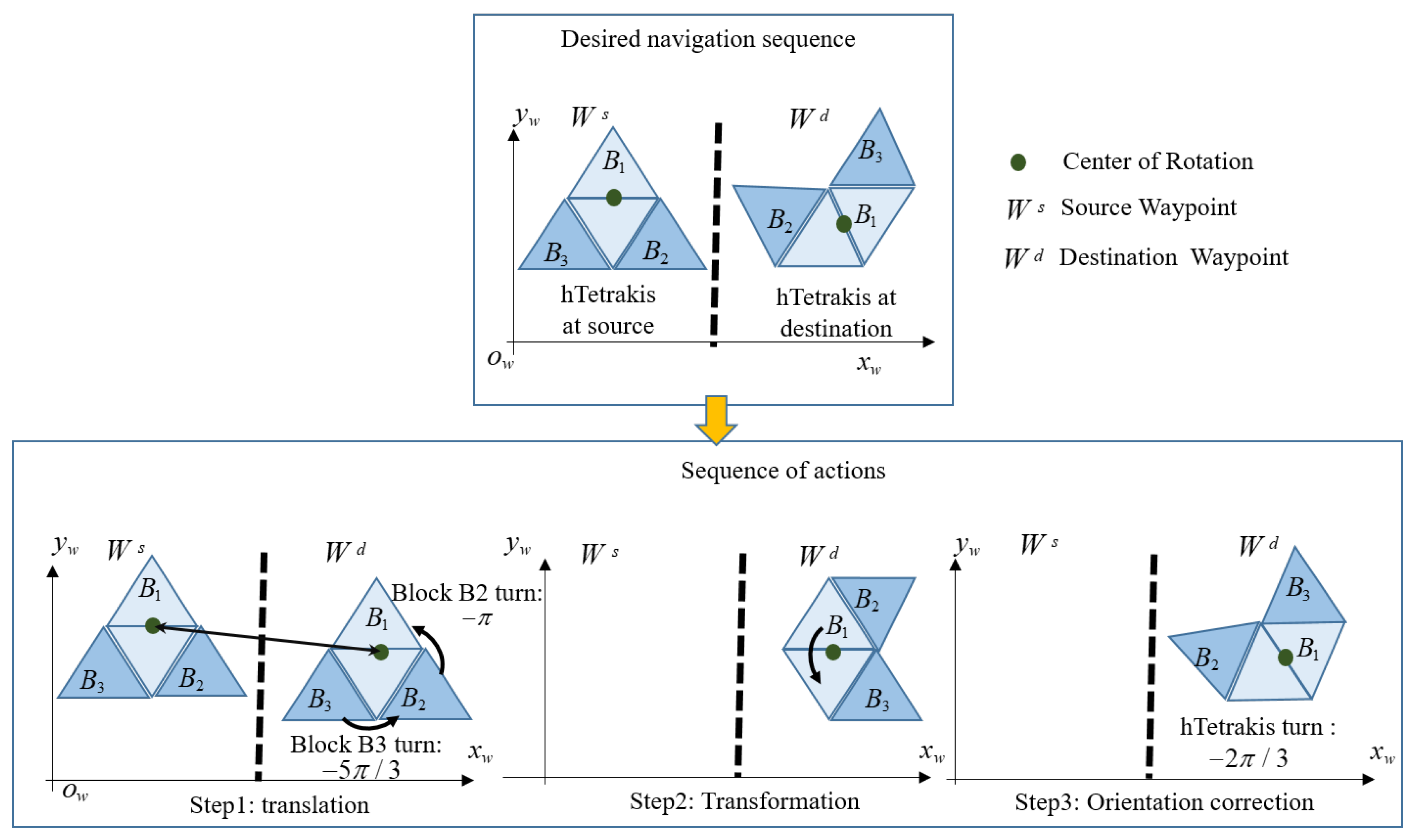

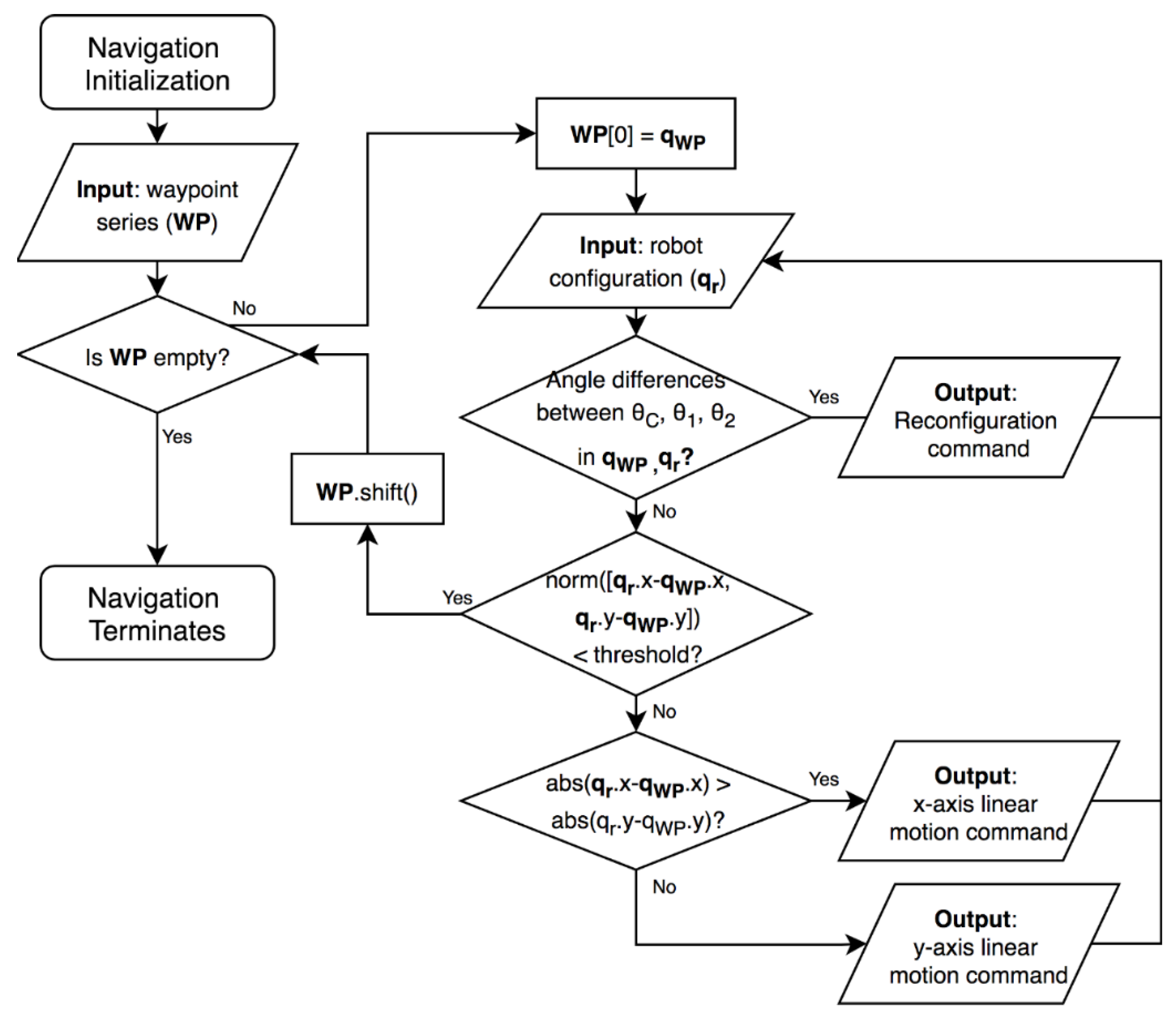

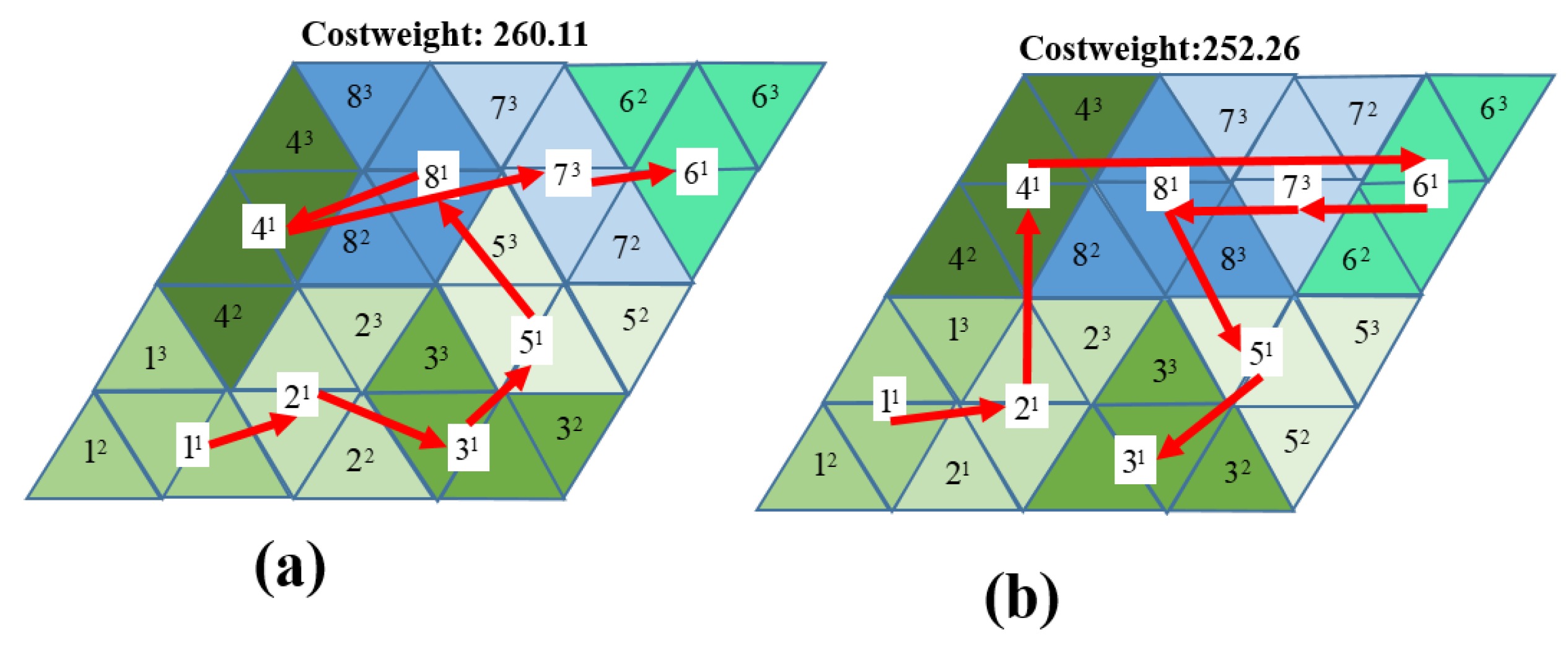

4.3. Optimal Navigation Sequence

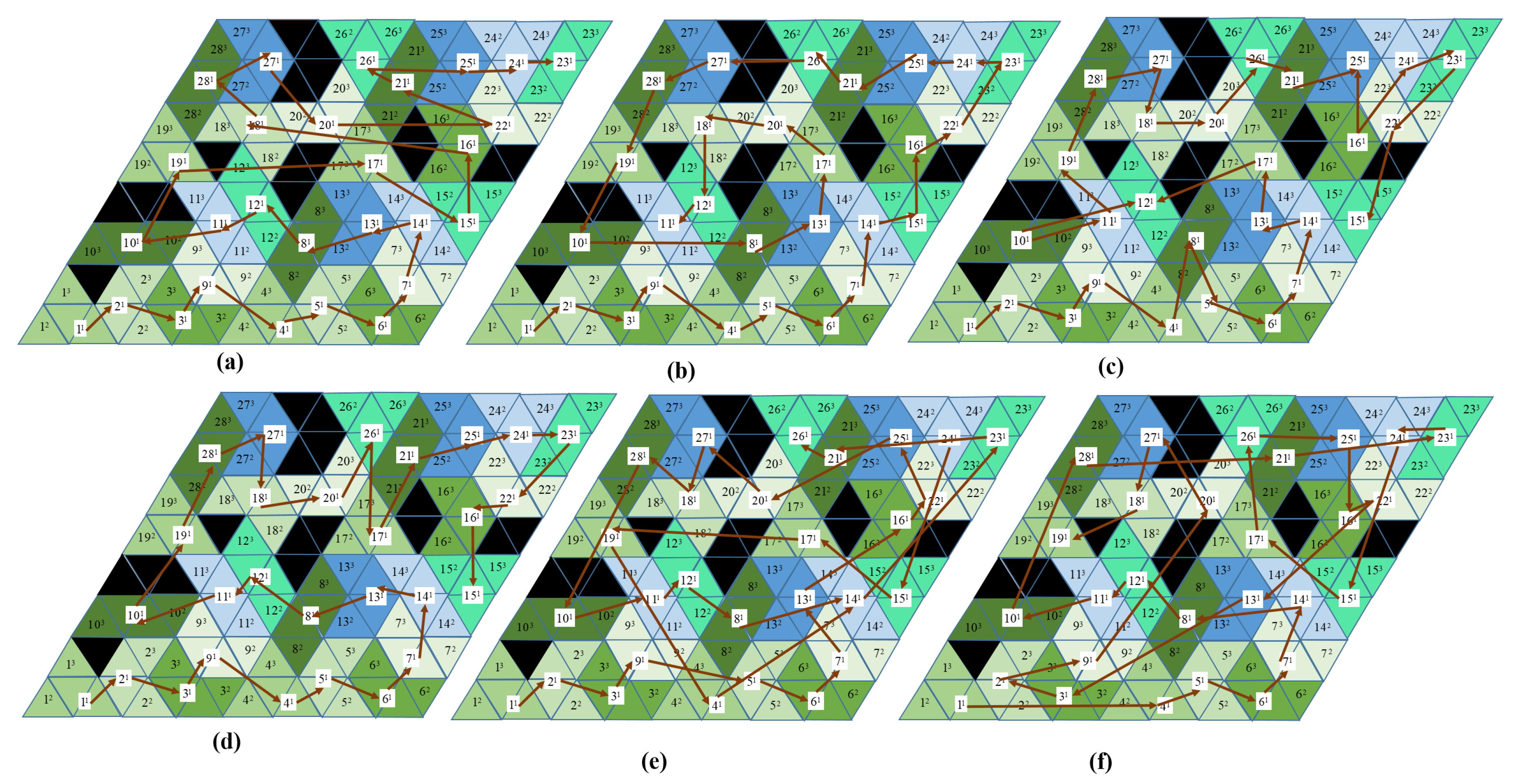

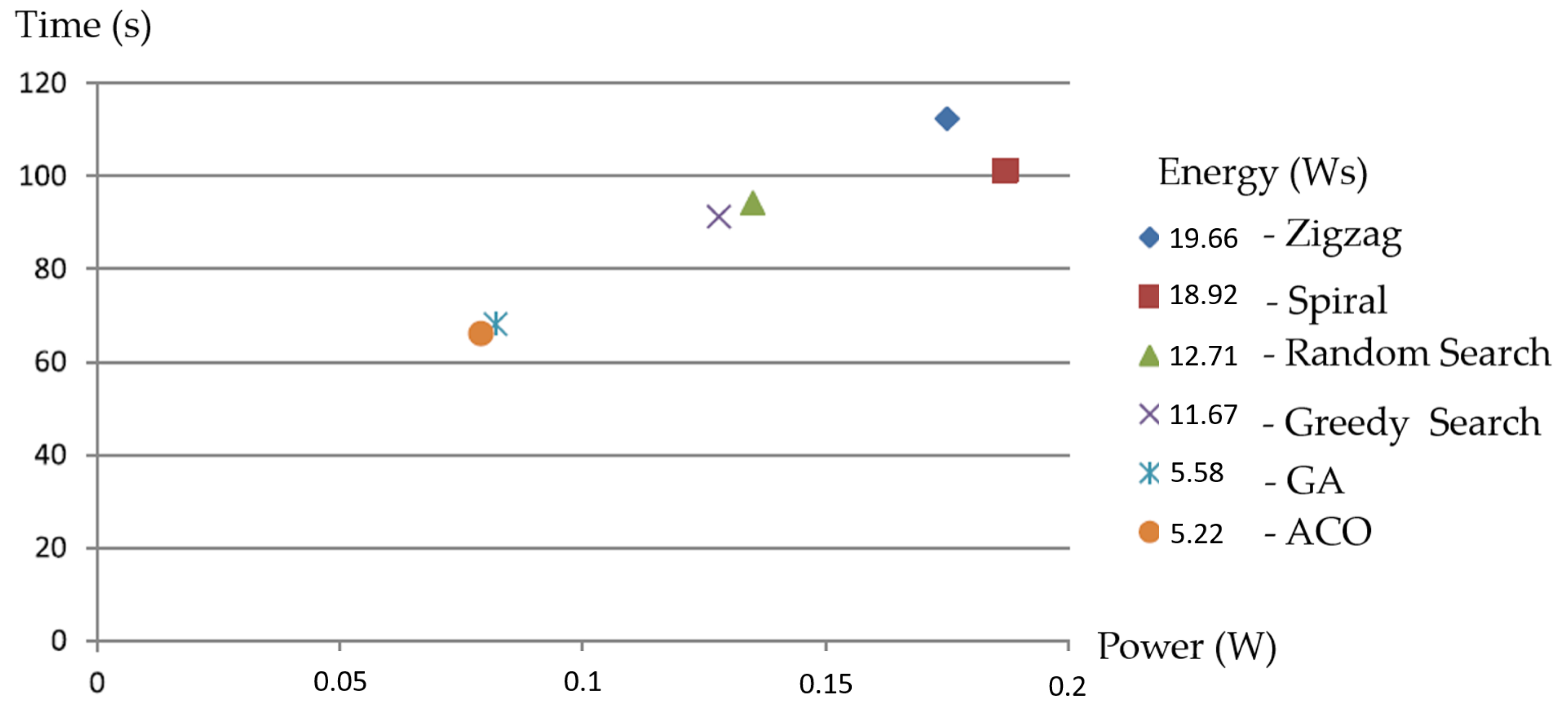

5. Experiment for the CCPP Framework

5.1. Simulation Environment

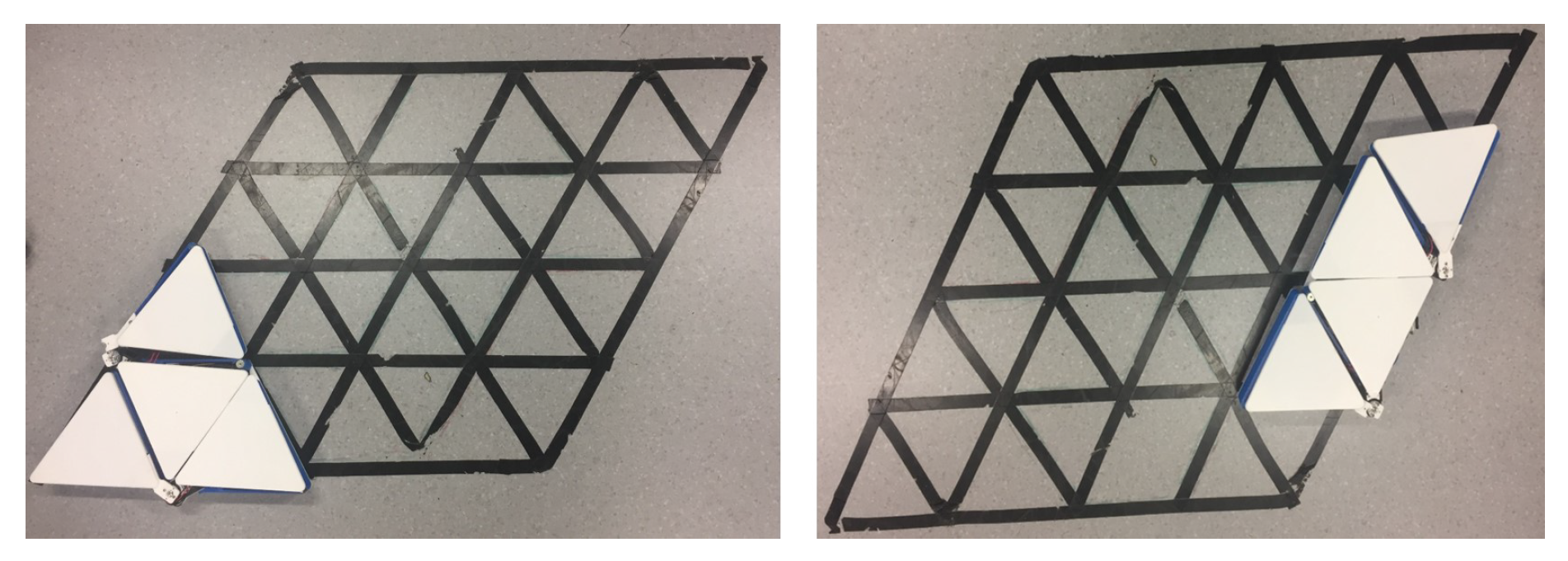

5.2. Real Environment Testbed

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Richter, F. Infographic: Let the Robot Do the Cleaning. 2017. Available online: https://www.statista.com/chart/9089/worldwide-personal-robot-sales-forecast (accessed on 20 December 2019).

- Cleaning Robot Market by Type, Product (Floor-Cleaning Robot, Lawn-Cleaning Robot, Pool-Cleaning Robot, Window-Cleaning Robot), Application (Residential, Commercial, Industrial, Healthcare), and Geography—Global Forecast to 2023. 2018. Available online: https://www.marketsandmarkets.com/Market-Reports/cleaning-robot-market-22726569.html (accessed on 20 December 2019).

- Jones, J.L.; Mack, N.E.; Nugent, D.M.; Sandin, P.E. Autonomous Floor Cleaning Robot. U.S. Patent No. 6,883,201, 11 November 2008. [Google Scholar]

- Yuan, X.; Zhao, C.X.; Tang, Z.M. Lidar Scan-Matching for Mobile Robot Localization. Inf. Technol. J. 2010, 9, 27–33. [Google Scholar] [CrossRef]

- Edwards, T.; Sörme, J. A Comparison of Path Planning Algorithms for Robotic Vacuum Cleaners. Bachelor’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, June 2018. [Google Scholar]

- Gao, X.; Li, K.; Wang, Y.; Men, G.; Zhou, D.; Kikuchi, K. A floor cleaning robot using Swedish wheels. In Proceedings of the 2007 IEEE International Conference on Robotics and Biomimetics (ROBIO), Sanya, China, 15–18 December 2007; pp. 2069–2073. [Google Scholar]

- Fink, J.; Bauwens, V.; Kaplan, F.; Dillenbourg, P. Living with a vacuum cleaning robot. Int. J. Soc. Robot. 2013, 5, 389–408. [Google Scholar] [CrossRef]

- Lumelsky, V.J.; Mukhopadhyay, S.; Sun, K. Dynamic path planning in sensor-based terrain acquisition. IEEE Trans. Robot. Autom. 1990, 6, 462–472. [Google Scholar] [CrossRef]

- Acar, E.U.; Choset, H.; Rizzi, A.A.; Atkar, P.N.; Hull, D. Morse Decompositions for Coverage Tasks. Int. J. Robot. Res. 2002, 21, 331–344. [Google Scholar] [CrossRef]

- Xu, L. Graph Planning for Environmental Coverage. Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, USA, 2011; p. 135. [Google Scholar]

- Wang, L.; Gao, H.; Cai, Z. Topological Mapping and Navigation for Mobile Robots with Landmark Evaluation. In Proceedings of the 2009 International Conference on Information Engineering and Computer Science, Wuhan, China, 19–20 December 2009. [Google Scholar] [CrossRef]

- Jin, J.; Tang, L. Coverage path planning on three-dimensional terrain for arable farming. J. Field Robot. 2011, 28, 424–440. [Google Scholar] [CrossRef]

- Cheng, P.; Keller, J.; Kumar, V. Time-optimal UAV trajectory planning for 3D urban structure coverage. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008; pp. 2750–2757. [Google Scholar]

- Choset, H. Coverage for robotics—A survey of recent results. Ann. Math. Artif. Intell. 2001, 31, 113–126. [Google Scholar] [CrossRef]

- Le, A.V.; Prabakaran, V.; Sivanantham, V.; Mohan, R. Modified a-star algorithm for efficient coverage path planning in tetris inspired self-reconfigurable robot with integrated laser sensor. Sensors 2018, 18, 2585. [Google Scholar] [CrossRef] [PubMed]

- Cheng, K.P.; Mohan, R.E.; Nhan, N.H.K.; Le, A.V. Graph theory-based approach to accomplish complete coverage path planning tasks for reconfigurable robots. IEEE Access 2019, 7, 94642–94657. [Google Scholar] [CrossRef]

- Luo, C.; Yang, S.X. A real-time cooperative sweeping strategy for multiple cleaning robots. In Proceedings of the IEEE Internatinal Symposium on Intelligent Control, Vancouver, BC, Canada, 30 October 2002; pp. 660–665. [Google Scholar]

- Zelinsky, A.; Jarvis, R.A.; Byrne, J.; Yuta, S. Planning paths of complete coverage of an unstructured environment by a mobile robot. In Proceedings of the International Conference on Advanced Robotics, Tokyo, Japan, 8–9 November 1993; Volume 13, pp. 533–538. [Google Scholar]

- Yang, S.X.; Luo, C. A neural network approach to complete coverage path planning. IEEE Trans. Syst. Man, Cybern. Part B (Cybern.) 2004, 34, 718–724. [Google Scholar] [CrossRef] [PubMed]

- Gabriely, Y.; Rimon, E. Spiral-stc: An on-line coverage algorithm of grid environments by a mobile robot. In Proceedings of the 2002 IEEE International Conference on Robotics and Automation, Washington, DC, USA, 11–15 May 2002; Volume 1, pp. 954–960. [Google Scholar]

- Veerajagadheswar, P.; Mohan, E.; Pathmakumar, T.; Nansai, S. hTetro: A tetris inspired shape shifting floor cleaning robot. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017. [Google Scholar] [CrossRef]

- Le, A.V.; Ku, P.C.; Than Tun, T.; Huu Khanh Nhan, N.; Shi, Y.; Mohan, R.E. Realization Energy Optimization of Complete Path Planning in Differential Drive Based Self-Reconfigurable Floor Cleaning Robot. Energies 2018, 12, 1136. [Google Scholar] [CrossRef]

- Le, A.V.; Arunmozhi, M.; Veerajagadheswar, P.; Ku, P.C.; Minh, T.H.; Sivanantham, V.; Mohan, R. Complete Path Planning for a Tetris-Inspired Self-Reconfigurable Robot by the Genetic Algorithm of the Traveling Salesman Problem. Electronics 2018, 7, 344. [Google Scholar] [CrossRef]

- Arkin, E.M.; Fekete, S.P.; Mitchell, J.S. Approximation algorithms for lawn mowing and milling. Comput. Geom. 2000, 17, 25–50. [Google Scholar] [CrossRef]

- Geng, X.; Chen, Z.; Yang, W.; Shi, D.; Zhao, K. Solving the traveling salesman problem based on an adaptive simulated annealing algorithm with greedy search. Appl. Soft Comput. 2011, 11, 3680–3689. [Google Scholar] [CrossRef]

- Larranaga, P.; Kuijpers, C.M.H.; Murga, R.H.; Inza, I.; Dizdarevic, S. Genetic algorithms for the travelling salesman problem: A review of representations and operators. Artif. Intell. Rev. 1999, 13, 129–170. [Google Scholar] [CrossRef]

- Dorigo, M.; Di Caro, G. Ant colony optimization: A new meta-heuristic. In Proceedings of the 1999 Congress on Evolutionary Computation-CEC99 (Cat. No. 99TH8406), Washington, DC, USA, 6–9 July 1999; Volume 2, pp. 1470–1477. [Google Scholar]

- Thomas, B. Evolutionary Algorithms in Theory and Practice: Evolution Strategies, Evolutionary Programming, Genetic Algorithms; Oxford Univ. Press: Oxford, UK, 1996. [Google Scholar]

- A Polyomino Tiling Algorithm. 2018. Available online: https://gfredericks.com/gfrlog/99 (accessed on 20 December 2019).

| A Shape | I Shape | U Shape | ||

|---|---|---|---|---|

| A Shape | 0 0 0 | 0 0 | 0 | |

| I Shape | 0 − 0 | 0 0 0 | 0 0 | |

| U shape | 0 − − | 0 0 − | 0 0 0 | |

| A Shape | I Shape | U Shape | ||

|---|---|---|---|---|

| A Shape | 0 0 0 | 0 0 | 0 | |

| I Shape | 0 0 | 0 0 0 | 0 0 | |

| U shape | 0 | 0 0 | 0 0 0 | |

| Method | Euclidean | Cost | Generation |

|---|---|---|---|

| Distance | Weight | Time | |

| Zigag | 982.12 | 933.29 | 0.01 |

| Sprial | 978.21 | 951.18 | 0.05 |

| Random search | 952.52 | 836.22 | 27.14 |

| Greedy search | 943.32 | 819.21 | 29.15 |

| Propsed method GA | 958.38 | 725.26 | 1.38 |

| Propsed method ACO | 993.39 | 715.59 | 1.19 |

| Method | Cost | Total | Translation | Transformation | Orientation |

|---|---|---|---|---|---|

| - | Weight | Energy (Ws) | Energy (Ws) | Energy (Ws) | Energy (Ws) |

| Zigzag | 321.15 | 19.66 | 10.39 | 6.35 | 2.92 |

| Spiral | 325.29 | 18.92 | 9.22 | 5.74 | 3.96 |

| Random search | 300.19 | 12.71 | 7.19 | 3.38 | 2.14 |

| Greedy search | 286.25 | 11.67 | 6.26 | 2.93 | 2.48 |

| GA | 267.12 | 5.58 | 3.01 | 1.61 | 0.96 |

| ACO | 260.11 | 5.22 | 2.91 | 1.39 | 0.92 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le, A.V.; Nhan, N.H.K.; Mohan, R.E. Evolutionary Algorithm-Based Complete Coverage Path Planning for Tetriamond Tiling Robots. Sensors 2020, 20, 445. https://doi.org/10.3390/s20020445

Le AV, Nhan NHK, Mohan RE. Evolutionary Algorithm-Based Complete Coverage Path Planning for Tetriamond Tiling Robots. Sensors. 2020; 20(2):445. https://doi.org/10.3390/s20020445

Chicago/Turabian StyleLe, Anh Vu, Nguyen Huu Khanh Nhan, and Rajesh Elara Mohan. 2020. "Evolutionary Algorithm-Based Complete Coverage Path Planning for Tetriamond Tiling Robots" Sensors 20, no. 2: 445. https://doi.org/10.3390/s20020445

APA StyleLe, A. V., Nhan, N. H. K., & Mohan, R. E. (2020). Evolutionary Algorithm-Based Complete Coverage Path Planning for Tetriamond Tiling Robots. Sensors, 20(2), 445. https://doi.org/10.3390/s20020445