A Hybrid Energy Harvesting Design for On-Body Internet-of-Things (IoT) Networks

Abstract

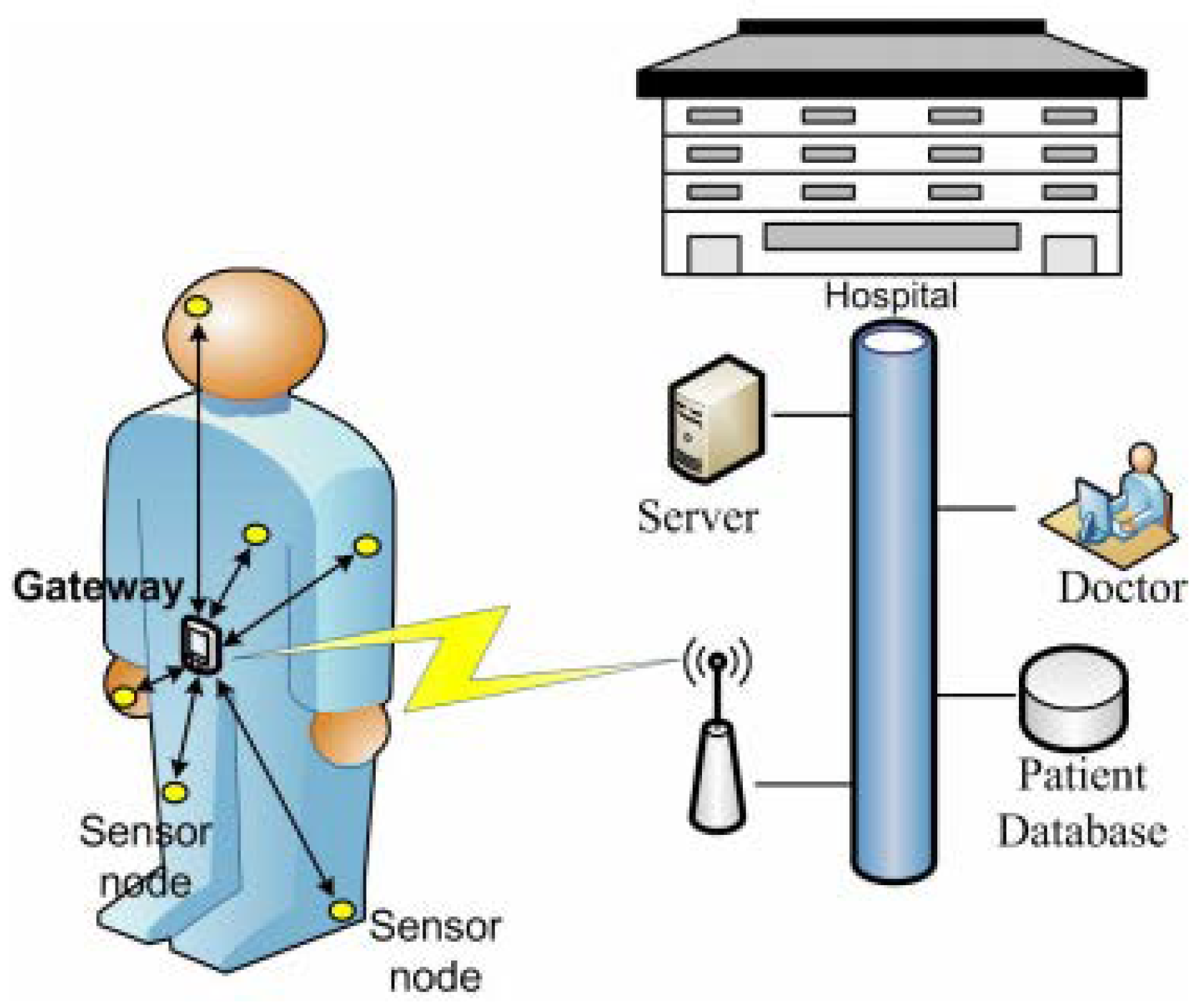

1. Introduction

1.1. Related Work

1.2. Motivation and Contribution

2. Energy Harvesting Techniques

2.1. Energy Harvesting

2.2. Energy Harvesting Sources

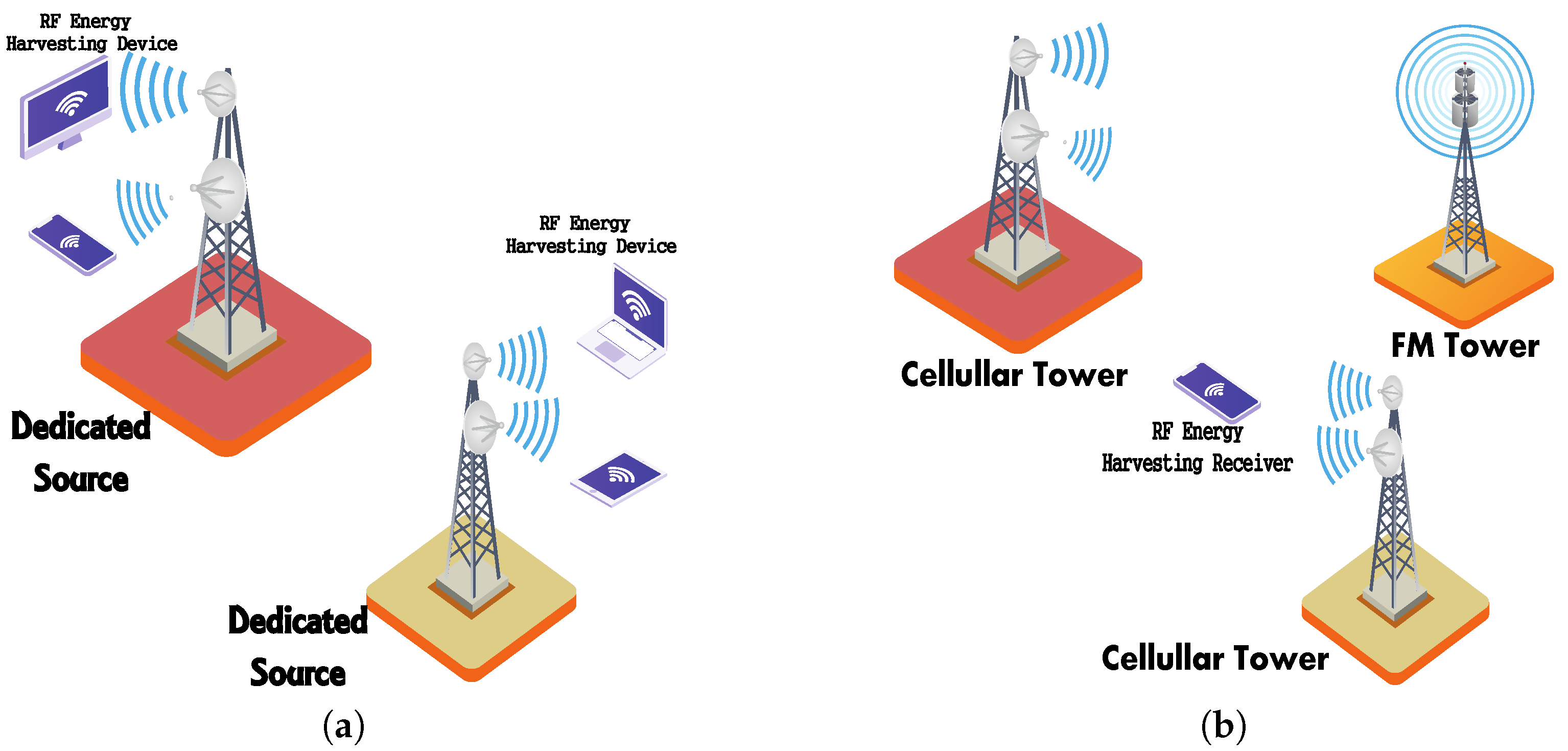

2.2.1. RF Energy Harvesting

2.2.2. Thermal Energy Harvesting

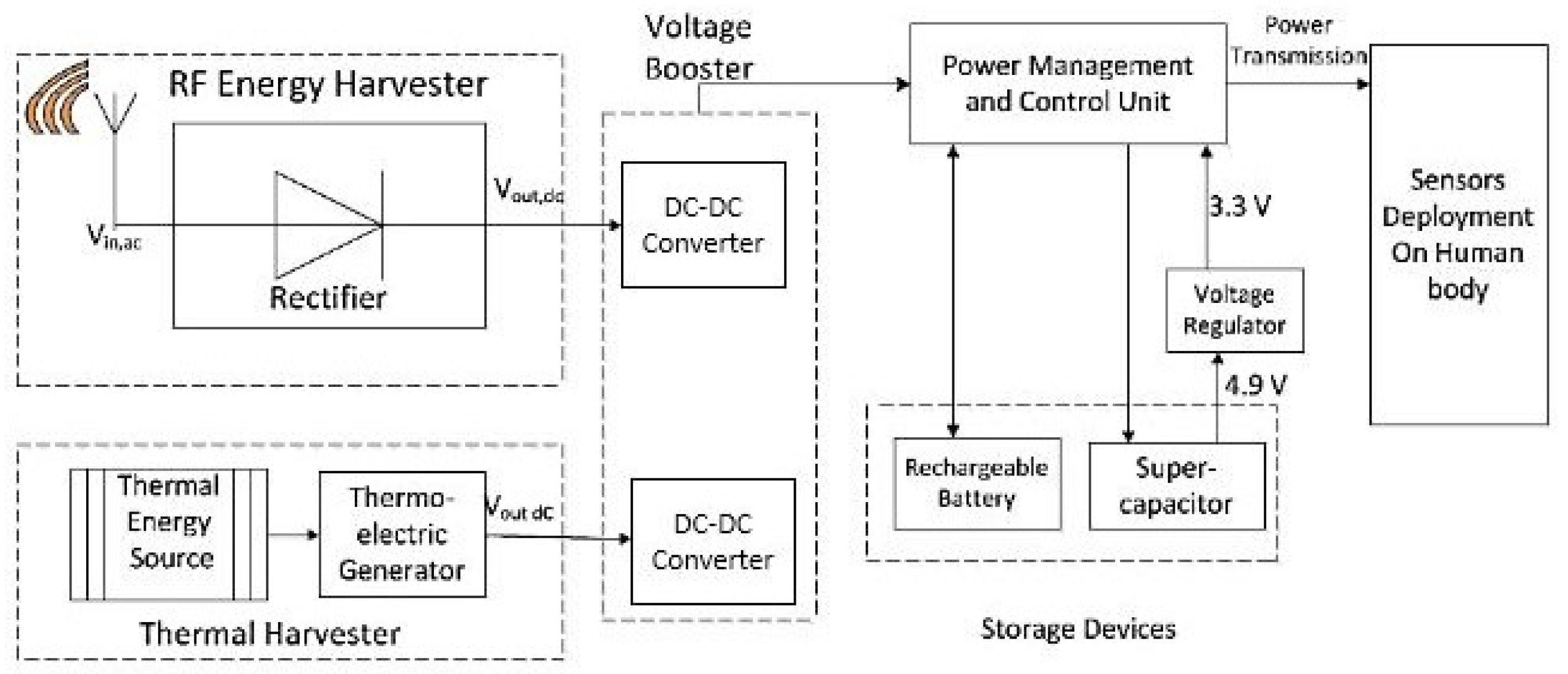

3. Proposed Energy Harvesting Design for On-Body Networks

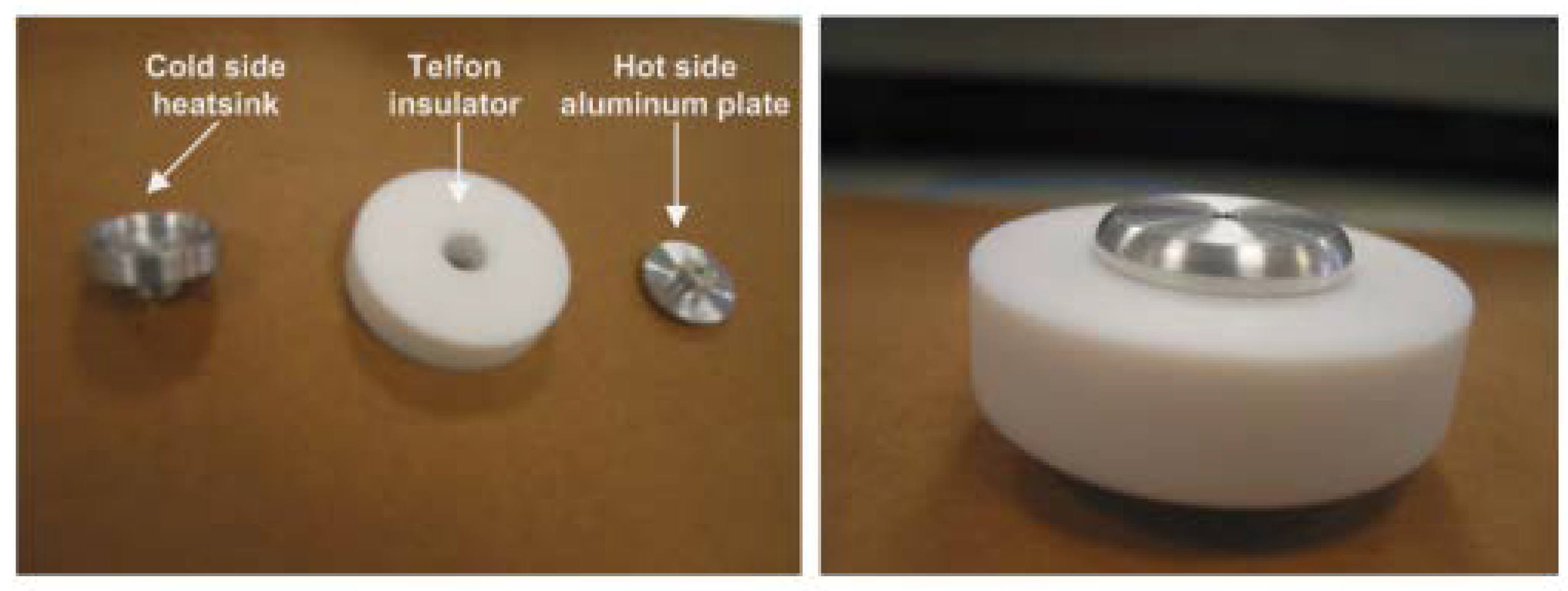

3.1. Design of Thermal Energy Harvesting

3.2. RF Energy Harvesting Structure With Rectenna

3.3. Power Management

3.4. Fall Detection

3.5. System Integration

3.6. Control Unit

4. Modules and Associated Components

4.1. Battery Module

4.2. RF Energy Harvesting Module

4.3. Thermal Energy Harvesting Module

4.4. Hybrid Energy Harvesting Module

4.5. Storage Unit Module

4.6. Load Unit Module

4.7. Communication Module

5. Simulation Platform

- Energy Harvester: This module models energy harvesting operation and handles the comparable device.

- Energy Storage: This module produces energy repository devices, such as supercapacitors and batteries, which are either disposable or rechargeable.

- Energy Manager: This module provides the control logic for repository application and charging.

5.1. Energy Harvester

5.2. Energy Storage

5.3. Energy Manager

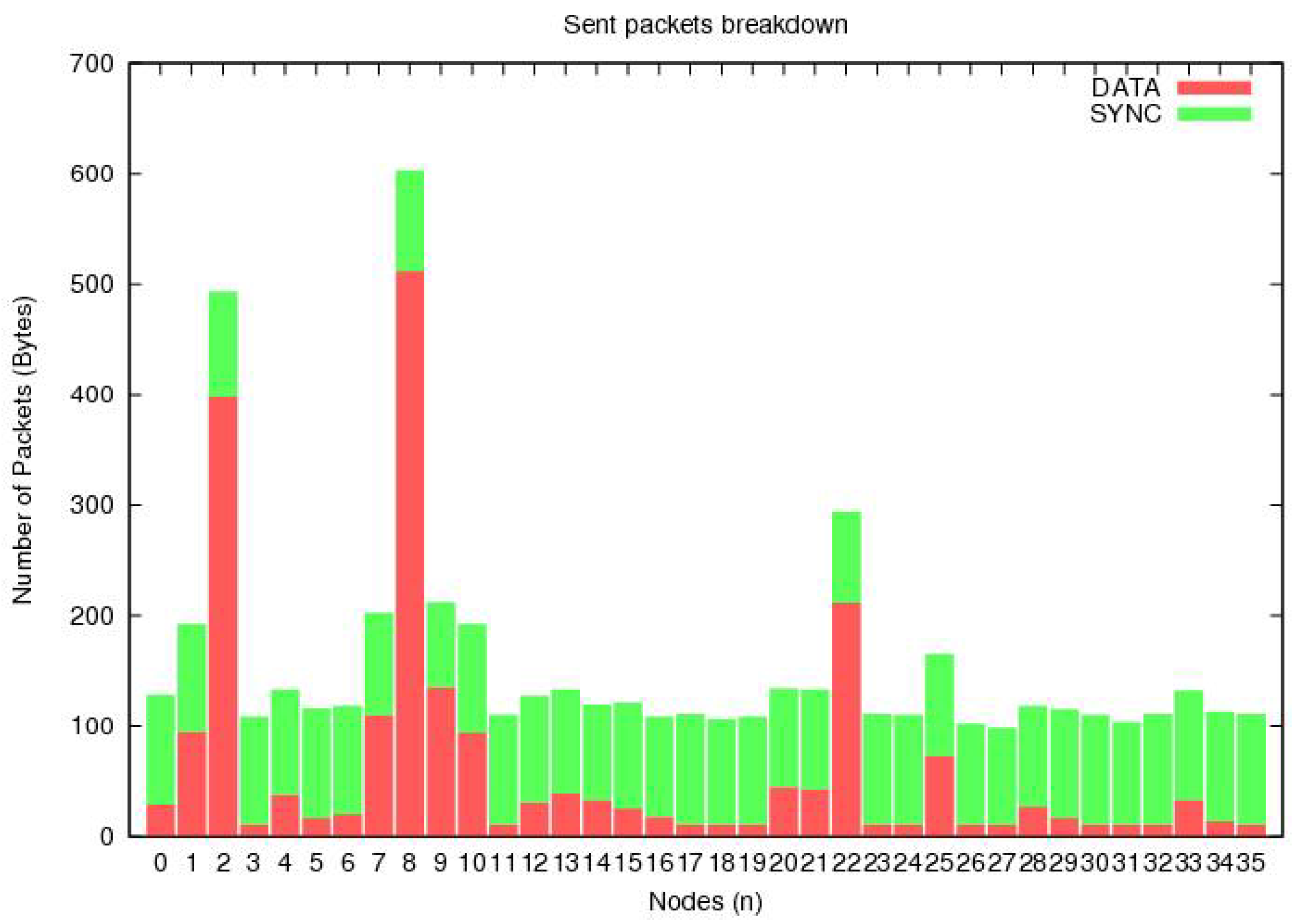

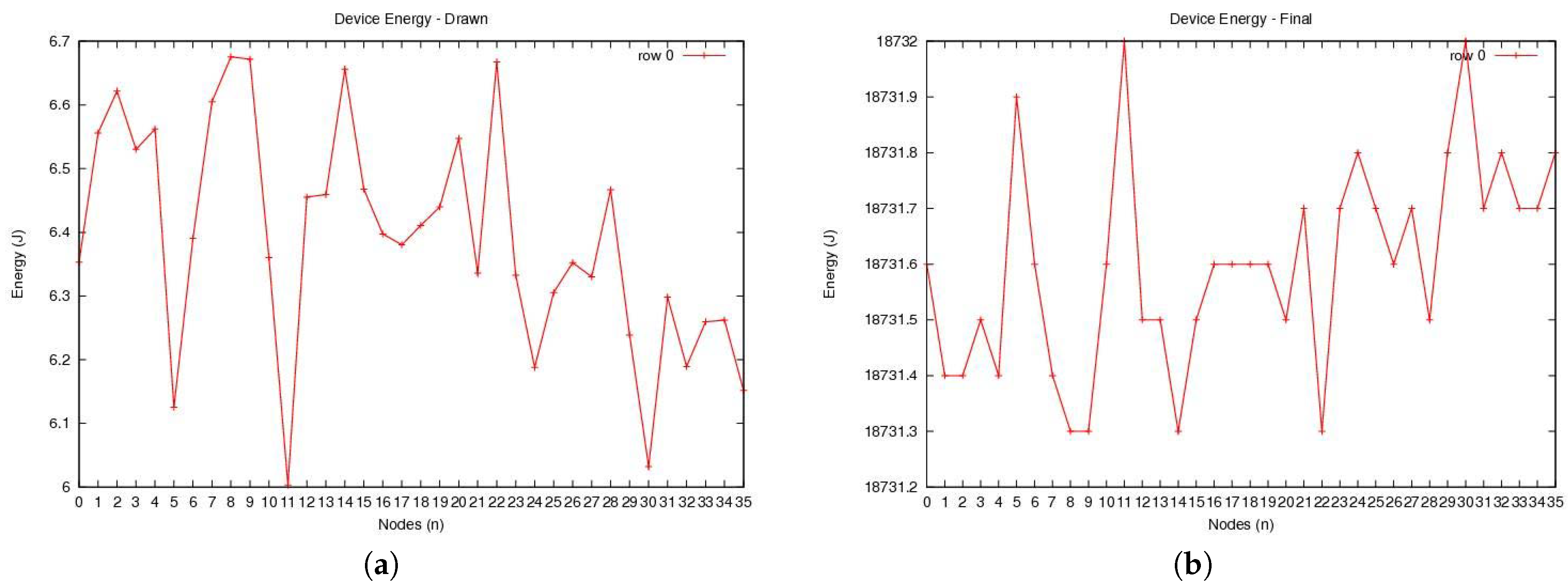

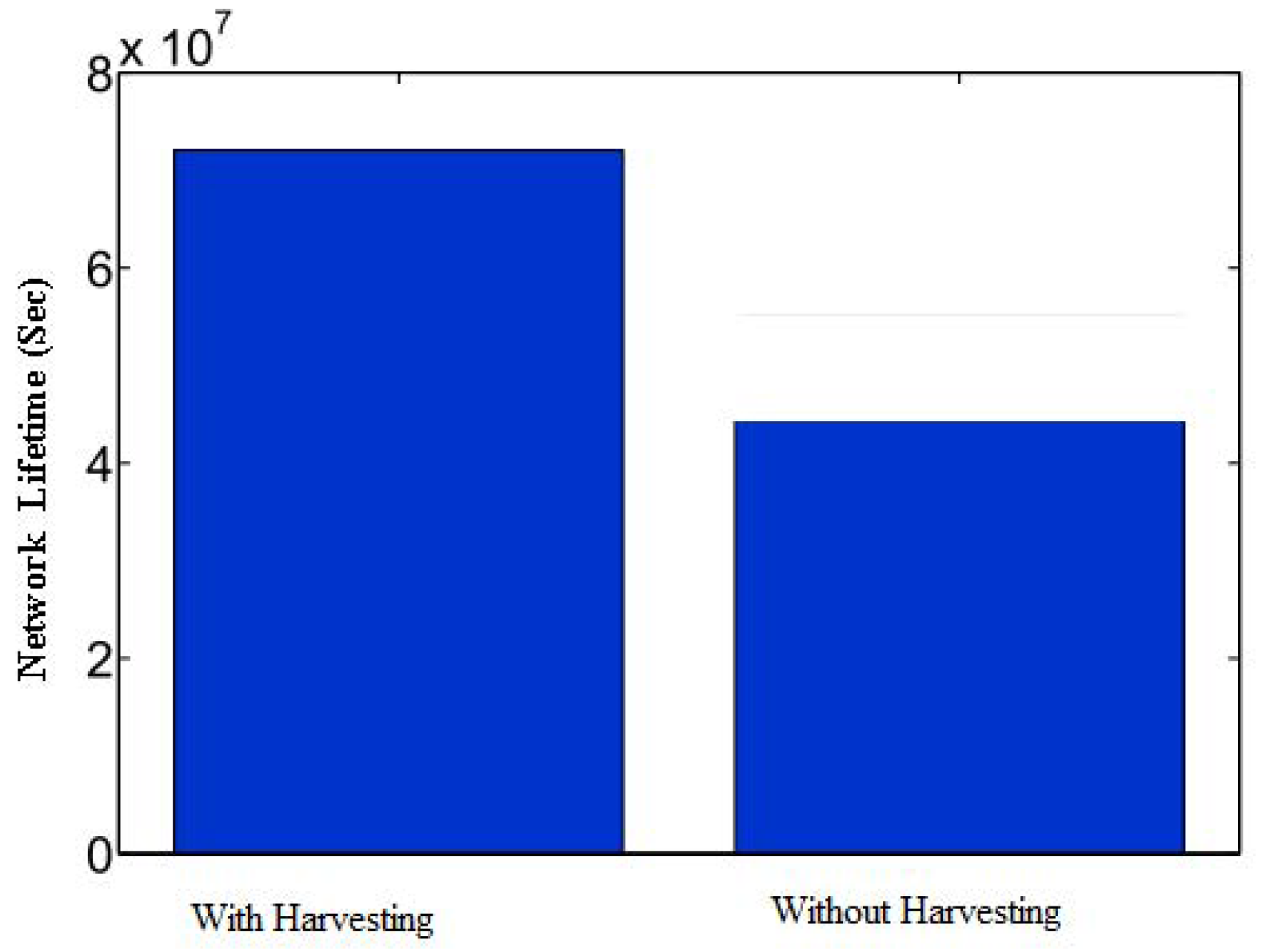

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jameel, F.; Ristaniemi, T.; Khan, I.; Lee, B.M. Simultaneous harvest-and-transmit ambient backscatter communications under Rayleigh fading. EURASIP J. Wirel. Commun. Netw. 2019, 2019, 166. [Google Scholar] [CrossRef]

- Ajith Kumar S., A.; Ovsthus, K.; Kristensen, L.M. An industrial perspective on wireless sensor networks— A survey of requirements, protocols, and challenges. IEEE Commun. Surv. Tutorials 2014, 16, 1391–1412. [Google Scholar] [CrossRef]

- Jameel, F.; Duan, R.; Chang, Z.; Liljemark, A.; Ristaniemi, T.; Jantti, R. Applications of Backscatter Communications for Healthcare Networks. arXiv 2019, arXiv:1906.09209. [Google Scholar] [CrossRef]

- Perera, T.D.P.; Jayakody, D.N.K.; Sharma, S.K.; Chatzinotas, S.; Li, J. Simultaneous wireless information and power transfer (SWIPT): Recent advances and future challenges. IEEE Commun. Surv. Tutorials 2017, 20, 264–302. [Google Scholar] [CrossRef]

- Elsersy, M.; Elfouly, T.M.; Ahmed, M.H. Joint optimal placement, routing, and flow assignment in wireless sensor networks for structural health monitoring. IEEE Sens. J. 2016, 16, 5095–5106. [Google Scholar] [CrossRef]

- Lu, Z.; Li, W.W.; Pan, M. Maximum lifetime scheduling for target coverage and data collection in wireless sensor networks. IEEE Trans. Veh. Technol. 2015, 64, 714–727. [Google Scholar] [CrossRef]

- Martinez, G.; Li, S.; Zhou, C. Multi-commodity online maximum lifetime utility routing for energy-harvesting wireless sensor networks. In Proceedings of the Global Communications Conference (GLOBECOM), Austin, TX, USA, 8–12 December 2014; pp. 106–111. [Google Scholar]

- Alippi, C.; Galperti, C. An adaptive system for optimal solar energy harvesting in wireless sensor network nodes. IEEE Trans. Circuits Syst. Regul. Pap. 2008, 55, 1742–1750. [Google Scholar] [CrossRef]

- Jameel, F.; Khan, W.U.; Chang, Z.; Ristaniemi, T.; Liu, J. Secrecy analysis and learning-based optimization of cooperative NOMA SWIPT systems. In Proceedings of the 2019 IEEE International Conference on Communications Workshops (ICC Workshops), Shanghai, China, 20–24 May 2019; pp. 1–6. [Google Scholar]

- Jameel, F.; Khan, F.; Haider, M.A.A.; Haq, A.U. On physical layer security of two way energy harvesting relays. In Proceedings of the 2017 International Conference on Frontiers of Information Technology (FIT), Islamabad, Pakistan, 18–20 December 2017; pp. 35–40. [Google Scholar]

- Yu, Y.; Yang, Z.; Wu, Y.; Hussein, J.A.; Jia, W.K.; Dong, Z. Outage Performance of NOMA in Cooperative Cognitive Radio Networks With SWIPT. IEEE Access 2019, 7, 117308–117317. [Google Scholar] [CrossRef]

- Mao, S.; Leng, S.; Hu, J.; Yang, K. Power minimization resource allocation for underlay MISO-NOMA SWIPT systems. IEEE Access 2019, 7, 17247–17255. [Google Scholar] [CrossRef]

- Tang, J.; Luo, J.; Liu, M.; So, D.K.; Alsusa, E.; Chen, G.; Wong, K.K.; Chambers, J.A. Energy Efficiency Optimization for NOMA with SWIPT. IEEE J. Sel. Top. Signal Process. 2019, 13, 452–466. [Google Scholar] [CrossRef]

- Liu, J.; Nishiyama, H.; Kato, N.; Guo, J. On the outage probability of device-to-device communication enabled multichannel cellular networks: An RSS-threshold-based perspective. IEEE J. Sel. Areas Commun. 2015, 34, 163–175. [Google Scholar] [CrossRef]

- Chen, Y.; Ai, B.; Niu, Y.; He, R.; Zhong, Z.; Han, Z. Resource Allocation for Device-to-Device Communications in Multi-Cell Multi-Band Heterogeneous Cellular Networks. IEEE Trans. Veh. Technol. 2019, 68, 4760–4773. [Google Scholar] [CrossRef]

- Jameel, F.; Butt, A.; Munir, U. Analysis of interference in body area networks over generalized fading. In Proceedings of the 2016 International Conference on Emerging Technologies (ICET), Islamabad, Pakistan, 18–19 October 2016; pp. 1–6. [Google Scholar]

- Wang, L.; Hu, F.; Ling, Z.; Wang, B. Wireless information and power transfer to maximize information throughput in WBAN. IEEE Internet Things J. 2017, 4, 1663–1670. [Google Scholar] [CrossRef]

- Ling, Z.; Hu, F.; Wang, L.; Yu, J.; Liu, X. Point-to-point wireless information and power transfer in WBAN with energy harvesting. IEEE Access 2017, 5, 8620–8628. [Google Scholar] [CrossRef]

- Rabby, M.K.M.; Alam, M.S.; Shawkat, S.A.; Hoque, M.A. A scheduling scheme for efficient wireless charging of sensor nodes in WBAN. In Proceedings of the Second IEEE/ACM International Conference on Connected Health: Applications, Systems and Engineering Technologies, Philadelphia, PA, USA, 17–19 July 2017; pp. 31–36. [Google Scholar]

- Pandey, B.; Jain, A. Self-sustaining WBAN implants for biomedical applications. In Proceedings of the 2016 2nd International Conference on Applied and Theoretical Computing and Communication Technology (iCATccT), Bangalore, India, 21–23 July 2016; pp. 494–503. [Google Scholar]

- Ferrari, M.; Ferrari, V.; Guizzetti, M.; Andò, B.; Baglio, S.; Trigona, C. Improved energy harvesting from wideband vibrations by nonlinear piezoelectric converters. Sens. Actuat. Phys. 2010, 162, 425–431. [Google Scholar] [CrossRef]

- Sui, D.; Hu, F.; Zhou, W.; Shao, M.; Chen, M. Relay selection for radio frequency energy-harvesting wireless body area network with buffer. IEEE Internet Things J. 2017, 5, 1100–1107. [Google Scholar] [CrossRef]

- Ul Huque, M.T.I.; Munasinghe, K.S.; Jamalipour, A. Body node coordinator placement algorithms for wireless body area networks. IEEE Internet Things J. 2014, 2, 94–102. [Google Scholar] [CrossRef]

- Zergoune, Z.; Kacem, N.; Bouhaddi, N. On the energy localization in weakly coupled oscillators for electromagnetic vibration energy harvesting. Smart Mater. Struct. 2019, 28, 07LT02. [Google Scholar] [CrossRef]

- Mateu, L.; Codrea, C.; Lucas, N.; Pollak, M.; Spies, P. Human body energy harvesting thermogenerator for sensing applications. In Proceedings of the International Conference on Sensor Technologies and Applications, Valencia, Spain, 14–20 October 2007; pp. 366–372. [Google Scholar]

- Jayakody, D.N.K.; Thompson, J.; Chatzinotas, S.; Durrani, S. Wireless Information and Power Transfer: A New Paradigm for Green Communications; Springer: Berlin, Germany, 2017. [Google Scholar]

- Mansourkiaie, F.; Ismail, L.S.; Elfouly, T.M.; Ahmed, M.H. Maximizing lifetime in wireless sensor network for structural health monitoring with and without energy harvesting. IEEE Access 2017, 5, 2383–2395. [Google Scholar] [CrossRef]

- Jameel, F.; Faisal; Haider, M.A.A.; Butt, A.A. A technical review of simultaneous wireless information and power transfer (SWIPT). In Proceedings of the 2017 International Symposium on Recent Advances in Electrical Engineering (RAEE), Islamabad, Pakistan, 24–26 October 2017; pp. 1–6. [Google Scholar]

- Raju, M. Energy Harvesting—ULP Meets Energy Harvesting: A Game-Changing Combination for Design Engineers (Texas Instruments, 2008). In Energy Harvesting from Human Power—A Roadmap to New Research Challenges; The Engineering and Physical Sciences Research Council (EPSRC): Swindon, UK, 2011; pp. 3672–3677. [Google Scholar]

- Vullers, R.; van Schaijk, R.; Doms, I.; Van Hoof, C.; Mertens, R. Micropower energy harvesting. Solid-State Electron. 2009, 53, 684–693. [Google Scholar] [CrossRef]

- Venkataraman, H.; Muntean, G.M. Green Mobile Devices and Networks: Energy Optimization and Scavenging Techniques; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Jameel, F.; Haider, M.A.A.; Butt, A.A. High SNR analysis of inter-body interference in Body Area Networks. In Proceedings of the 2017 International Conference on Communication, Computing and Digital Systems (C-CODE), Islamabad, Pakistan, 8–9 March 2017; pp. 117–121. [Google Scholar]

- Jameel, F.; Haider, M.A.A.; Butt, A.A. Robust localization in wireless sensor networks using RSSI. In Proceedings of the 2017 13th International Conference on Emerging Technologies (ICET), Islamabad, Pakistan, 27–28 December 2017; pp. 1–6. [Google Scholar]

- Zappi, P.; Lombriser, C.; Stiefmeier, T.; Farella, E.; Roggen, D.; Benini, L.; Troster, G. Activity recognition from on-body sensors: Accuracy-power trade-off by dynamic sensor selection. Lect. Notes Comput. Sci. 2008, 4913, 17. [Google Scholar]

- Uguz, S.; Ipek, O. The Management of Indoor Thermal Comfort with Wireless Sensor Networks. Meas. Control. 2017, 50, 206–213. [Google Scholar] [CrossRef]

- Ravindra, K.; Agarwal, N.; Kaur-Sidhu, M.; Mor, S. Appraisal of thermal comfort in rural household kitchens of Punjab, India and adaptation strategies for better health. Environ. Int. 2019, 124, 431–440. [Google Scholar] [CrossRef] [PubMed]

- Everredtronics. Available online: https://www.everredtronics.com/thermoelectric.generator.html (accessed on 31 December 2019).

- Lineykin, S.; Ben-Yaakov, S. Modeling and analysis of thermoelectric modules. IEEE Trans. Ind. Appl. 2007, 43, 505–512. [Google Scholar] [CrossRef]

- Huang, T.C.; Hsieh, C.Y.; Yang, Y.Y.; Lee, Y.H.; Kang, Y.C.; Chen, K.H.; Huang, C.C.; Lin, Y.H.; Lee, M.W. A Battery-Free 217 nW Static Control Power Buck Converter for Wireless RF Energy Harvesting with a-Calibrated Dynamic On/Off Time and Adaptive Phase Lead Control. IEEE J. Solid-State Circuits 2012, 47, 852–862. [Google Scholar] [CrossRef]

- De Roover, C.; Steyaert, M.S. Energy supply and ULP detection circuits for an RFID localization system in 130 nm CMOS. IEEE J. Solid-State Circuits 2010, 45, 1273–1285. [Google Scholar] [CrossRef]

- Hsieh, P.H.; Chou, C.H.; Chiang, T. An RF energy harvester with 44.1% PCE at input available power of-12 dBm. IEEE Trans. Circuits Syst. Regul. Pap. 2015, 62, 1528–1537. [Google Scholar] [CrossRef]

- Tan, Y.K. Energy Harvesting Autonomous Sensor Systems: Design, Analysis, and Practical Implementation; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Gudan, K.; Chemishkian, S.; Hull, J.J.; Thomas, S.J.; Ensworth, J.; Reynolds, M.S. A 2.4 GHz ambient RF energy harvesting system with- 20dbm minimum input power and NiMH battery storage. In Proceedings of the RFID Technology and Applications Conference (RFID-TA), Tampere, Finland, 8–9 September 2014; pp. 7–12. [Google Scholar]

- Ghribi, M.; Meddeb, A. Survey and taxonomy of MAC, routing and cross layer protocols using wake-up radio. J. Netw. Comput. Appl. 2019, 149, 102465. [Google Scholar] [CrossRef]

- Jameel, F.; Kumar, S.; Chang, Z.; Hamalainan, T.; Ristaniemi, T. Operator Revenue Analysis for Device-to-Device Communications Overlaying Cellular Network. In Proceedings of the 2018 IEEE Conference on Standards for Communications and Networking (CSCN), Paris, France, 29–31 October 2018; pp. 1–6. [Google Scholar]

- Arachchilage, D.N.K.J.; Jameel, F.; Qaraqe, M. Secure RF Energy Harvesting Scheme for Future Wireless Networks; HBKU Press: Doha, Quatar, 2018; Volume 2018, p. ICTPP179. [Google Scholar]

| Acronym | Definitions |

|---|---|

| RF | Radio Frequency |

| ine DC | Direct Current |

| ine GPS | Global Positioning System |

| ine TEG | Thermoelectric Generator |

| TEH | Thermoelectric Harvesting |

| EMR | Electronic Medical Record |

| ECG | Electrocardiogram |

| MOSFET | Metal–Oxide–Semiconductor Field-Effect Transistor |

| NiMH | Nickel-Metal Hydride |

| JFET | Junction Field-Effect Transistor |

| MAC | Medium Access Control |

| ine CSMA/CA | Carrier Sense Multiple Access Collision Avoidance |

| TDMA | Time Division Multiple Access |

| PCE | Power Conversion Efficiency |

| 5G | Fifth Generation |

| GSM | Global System for Mobile Communications |

| WiFi | Wireless Fidelity |

| FM | Frequency Modulation |

| MWCDCT | Minimum Weight Coverage and Data Collection Tree |

| MC-OMLU | Multi-Commodity Online Maximum Lifetime Utility |

| IoT | Internet-of-Things |

| OMNeT++ | Objective Modular Network Testbed in C++ |

| Energy Source | Harvested Power (W/cm) |

|---|---|

| Vibration/Motion | |

| Human | 4 |

| Industry | 100 |

| Temperature Difference | |

| Human | 25 |

| Industry | 1–10 |

| Light | |

| Indoor | 10 |

| Outdoor | 10,000 |

| Radio Frequency | |

| GSM | 0.1 |

| Wi-Fi | 1 |

| Type | Source of Availability | Energy Conversion Efficiency | Feasibility on Micro-scale Application |

|---|---|---|---|

| Wind | Depends on weather | Varies depending on source | Not suitable as wind speed is not consistent |

| Heat | Always available for on-body application | Low | Considerable with power management circuit under specific temperature range |

| Solar | Maximum 6 hours of peak irradiance daily | Maximum during the peak irradiance | Considerable with charge controller |

| Hydro | Available when there is a high-pressure water source | Depends on water pressure | Considerable only under specific flow rate of water |

| Kinetic | Available when there is movement and vibration | Depends on the motion | Very small energy and not suitable for many applications |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saraereh, O.A.; Alsaraira, A.; Khan, I.; Choi, B.J. A Hybrid Energy Harvesting Design for On-Body Internet-of-Things (IoT) Networks. Sensors 2020, 20, 407. https://doi.org/10.3390/s20020407

Saraereh OA, Alsaraira A, Khan I, Choi BJ. A Hybrid Energy Harvesting Design for On-Body Internet-of-Things (IoT) Networks. Sensors. 2020; 20(2):407. https://doi.org/10.3390/s20020407

Chicago/Turabian StyleSaraereh, Omar A., Amer Alsaraira, Imran Khan, and Bong Jun Choi. 2020. "A Hybrid Energy Harvesting Design for On-Body Internet-of-Things (IoT) Networks" Sensors 20, no. 2: 407. https://doi.org/10.3390/s20020407

APA StyleSaraereh, O. A., Alsaraira, A., Khan, I., & Choi, B. J. (2020). A Hybrid Energy Harvesting Design for On-Body Internet-of-Things (IoT) Networks. Sensors, 20(2), 407. https://doi.org/10.3390/s20020407